Absorber

A technology of absorption tubes and reaction vessels, applied in the field of absorbers, can solve problems such as expensive materials, and achieve the effects of increasing absorption efficiency, increasing volume flow, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

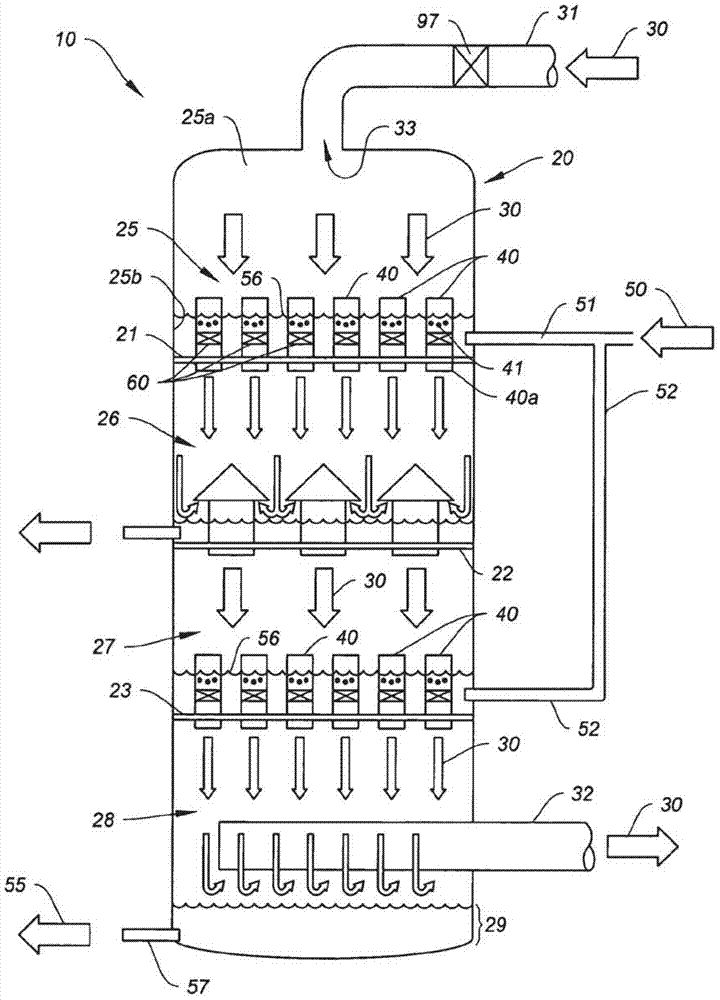

[0053] figure 1 A first embodiment of the invention is shown, referred to herein as a "Flood Tube Gas Absorber" (FTGA). It includes a reaction or absorber vessel 20, which as shown is a cylindrical, vertically extending vessel which in some applications may exceed 15 meters in diameter. The reaction or absorber vessel 20 may be of virtually any shape and have a circular, oval, rectangular, polyhedral, or other shaped cross-section.

[0054] An input flow stream 30 such as flue gas from a fossil fuel power plant flows into an inlet pipe 31 connected to an inlet 33 at the top or upper end of the vessel 20 . Gas stream 30 contains selected components to be absorbed, such as CO 2 , for example in the case of flue gas flow. The input flow gas stream 30 flows downwardly through the reaction or absorber vessel 20 and exits through the outlet pipe 32 after undergoing the absorption process described herein.

[0055] The reaction vessel 20 has a first chamber 25 and a second chambe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com