Acoustic packaging material with convex hull form and preparation method of acoustic packaging material

A technology of packaging materials and convex hulls, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of acoustic performance research and vacancies of non-smooth surface acoustic packaging materials, and achieve good wear resistance, improved sound absorption performance, and controllable thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A method for preparing an acoustic packaging material with a convex hull shape, specifically comprising the following steps:

[0042] (1) Weigh polyol 330N, polyol 3630, catalyst A33, triethanolamine, catalyst A1, silicone oil, MDI and deionized water according to the material ratio;

[0043] (2) Place the polyol 330N, polyol 3630, catalyst A33, triethanolamine, catalyst A1, silicone oil, and deionized water weighed in the above step (1) in a paper cup, and use a material mixer at a stirring speed of 2000r / min Stir for 90s;

[0044] (3) Pour the MDI weighed in the above step (1) into a paper cup, use a mixer to stir at 500r / min, and stir until the paper cup heats up;

[0045] (4) Pour the mixed material stirred in the above step (3) into the mold of the acoustic packaging material having a convex hull shape rapidly, and seal the mold;

[0046] (5) Put the mold into a drying oven, set the temperature of the drying oven to 50° C., store it in the incubator for 2 hours, ...

Embodiment 1

[0048] Design and manufacture the acoustic packaging material with a convex hull shape with a convex hull unit spacing of 4 mm.

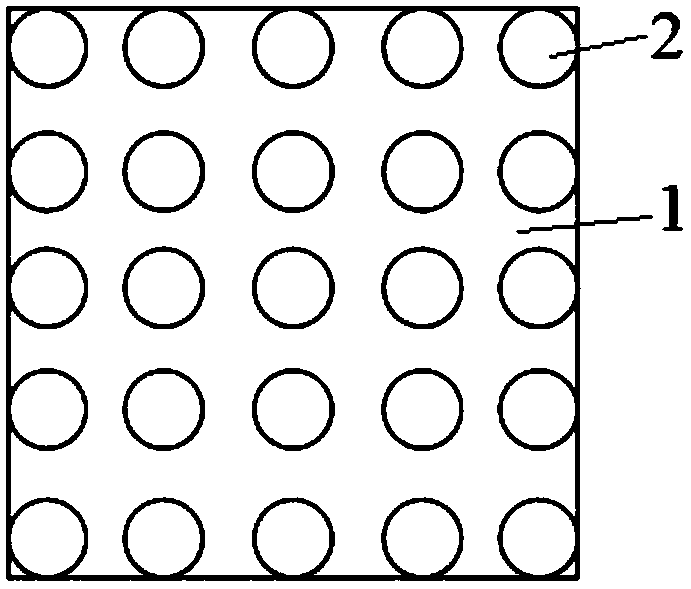

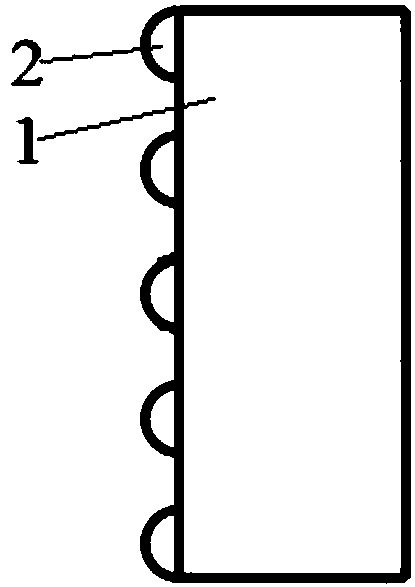

[0049] Please refer to the attached figure 2 and image 3 , the non-smooth surface shape of the acoustic package is that the convex hull units are evenly distributed on the surface of the substrate. The convex hull units are hemispheres with a diameter of 3mm, and the distance between two adjacent convex hull units is 4mm. The acoustic packaging matrix is made of polyurethane material, and the thickness of the matrix composed of the substrate and the convex hull unit is 30mm. Compared with the smooth surface polyurethane foam of the same matrix, the designed and manufactured polyurethane foam on the convex hull surface with a distance of 4mm between the convex hull units has better performance in medium frequency and The high-frequency sound absorption performance is significantly improved, and the mass is reduced by 5%.

Embodiment 2

[0051] Design and manufacture the acoustic packaging material with a convex hull shape with a convex hull unit spacing of 5 mm.

[0052] Please refer to the attached figure 2 and image 3 , the non-smooth surface shape of the acoustic package is that the convex hull units are evenly distributed on the surface of the substrate. The convex hull units are hemispheres with a diameter of 3mm, and the distance between two adjacent convex hull units is 5mm. The acoustic packaging matrix is made of polyurethane material, and the thickness of the matrix composed of the substrate and the convex hull unit is 30mm. Compared with the smooth surface polyurethane foam of the same matrix, the designed and manufactured polyurethane foam on the convex hull surface with a distance of 4mm between the convex hull units has better performance in medium frequency and The high-frequency sound absorption performance is significantly improved, and the mass is reduced by 6.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com