Retrofitting a heating steam extraction facility in a fossil-fired power plant

a technology of heating steam extraction and fossil fuel power plant, which is applied in the direction of steam engine plants, machines/engines, mechanical equipment, etc., can solve the problems of reducing the efficiency of steam power plants, reducing the remaining steam volume, and no further contribution to the generation of steam, so as to reduce the efficiency of additional steam extraction, the effect of thermodynamic favorable, and simple and cost-effective manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

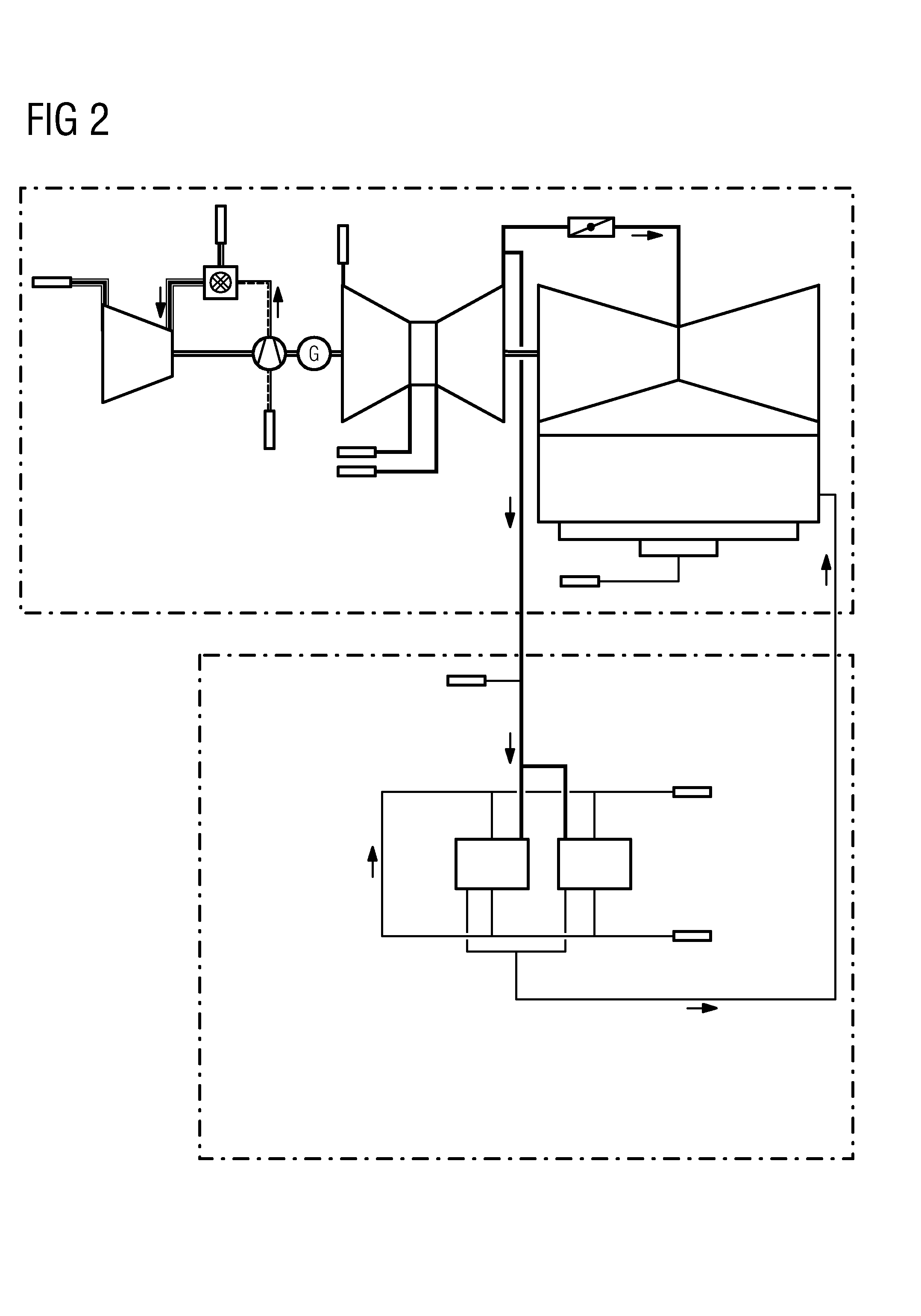

[0015]FIG. 2 shows a steam turbine arrangement having steam extraction from the overflow line according to the prior art. The steam extraction serves in this case to provide a district heating supply using two heating condensers HZ-K. The district heating system is connected to the gas and steam turbine power plant via the overflow line of the steam turbine. There, steam (NAA) is extracted and ducted by way of a steam line from the power house UMC to the district heating building UND. The actual district heating system in the form of 2×50% heating condensers is located in the district heating building UND. Depending on the required district heating capacity, provision of the district heating is effected using a single stage. The two district heating preheaters in combination can thermally transfer 265 MW at the maximum into the district heating system during normal operation.

[0016]Alternatively the district heating system can also be operated with steam from the cold reheat cycle (K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com