Patents

Literature

230results about How to "Suitably produced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cosmetic emulsions with long-term stability

ActiveUS20060204468A1Fine degree of dispersionExcellent long term stability and storage stabilityCosmetic preparationsTransportation and packagingUnsaturated fatty acidPharmaceutical formulation

Low-viscosity, finely divided oil-in-water emulsions with long-term stability, comprising an emulsifier combination of noncarbohydrate polyol partial esters of linear or branched, saturated or unsaturated fatty acids having 6 to 22 carbon atoms (emulsifier component A) and emulsifiers based on carbohydrate (emulsifier component B), one or more oils, and preservative are provided. Additionally, the present invention provides for the preparation of the emulsions from concentrates, the corresponding concentrates, and the use of the emulsions according to the invention for producing cosmetic, dermatological or pharmaceutical preparations, in particular for producing impregnation emulsions for wet wipes.

Owner:EVONIK DEGUSSA GMBH

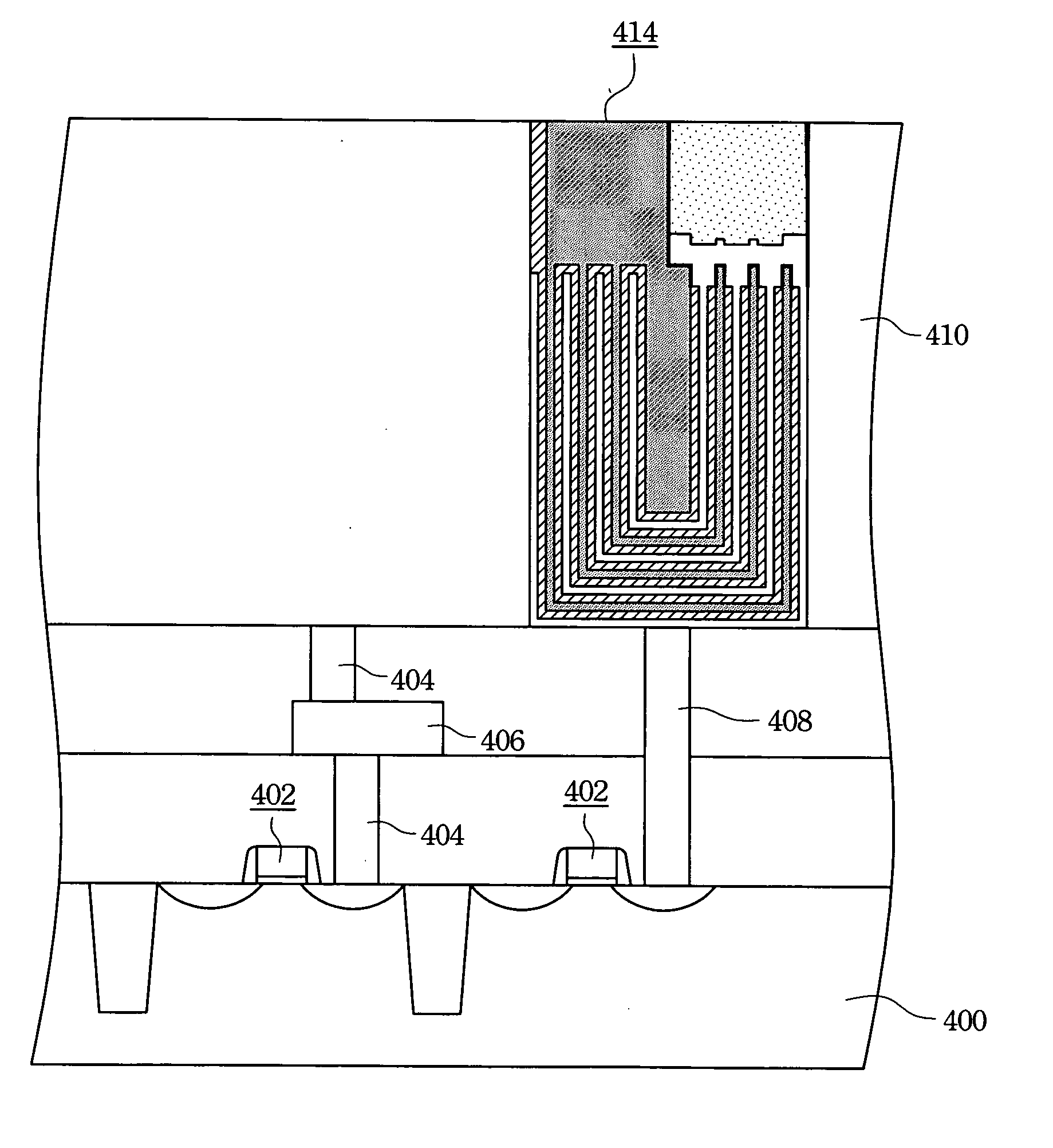

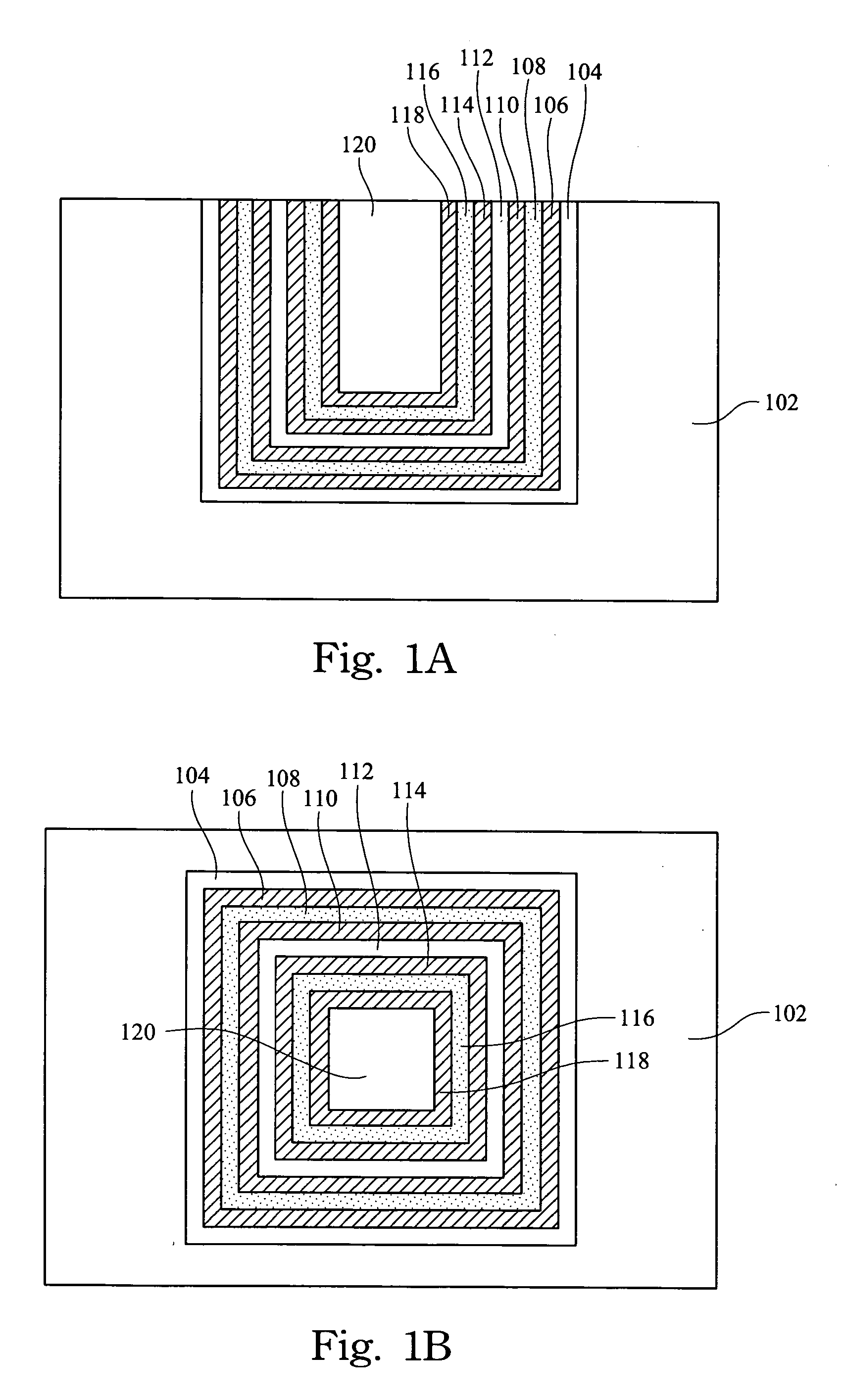

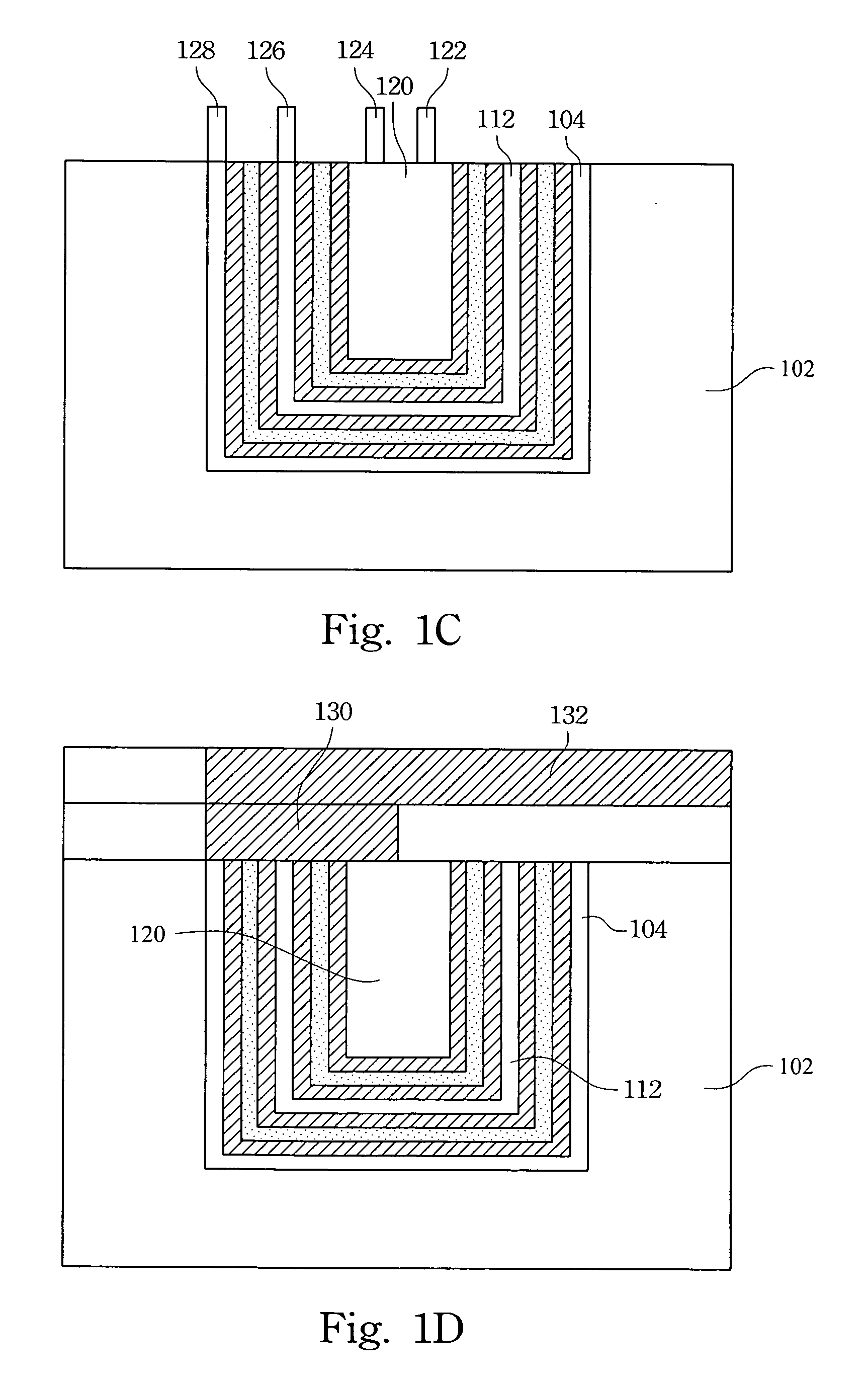

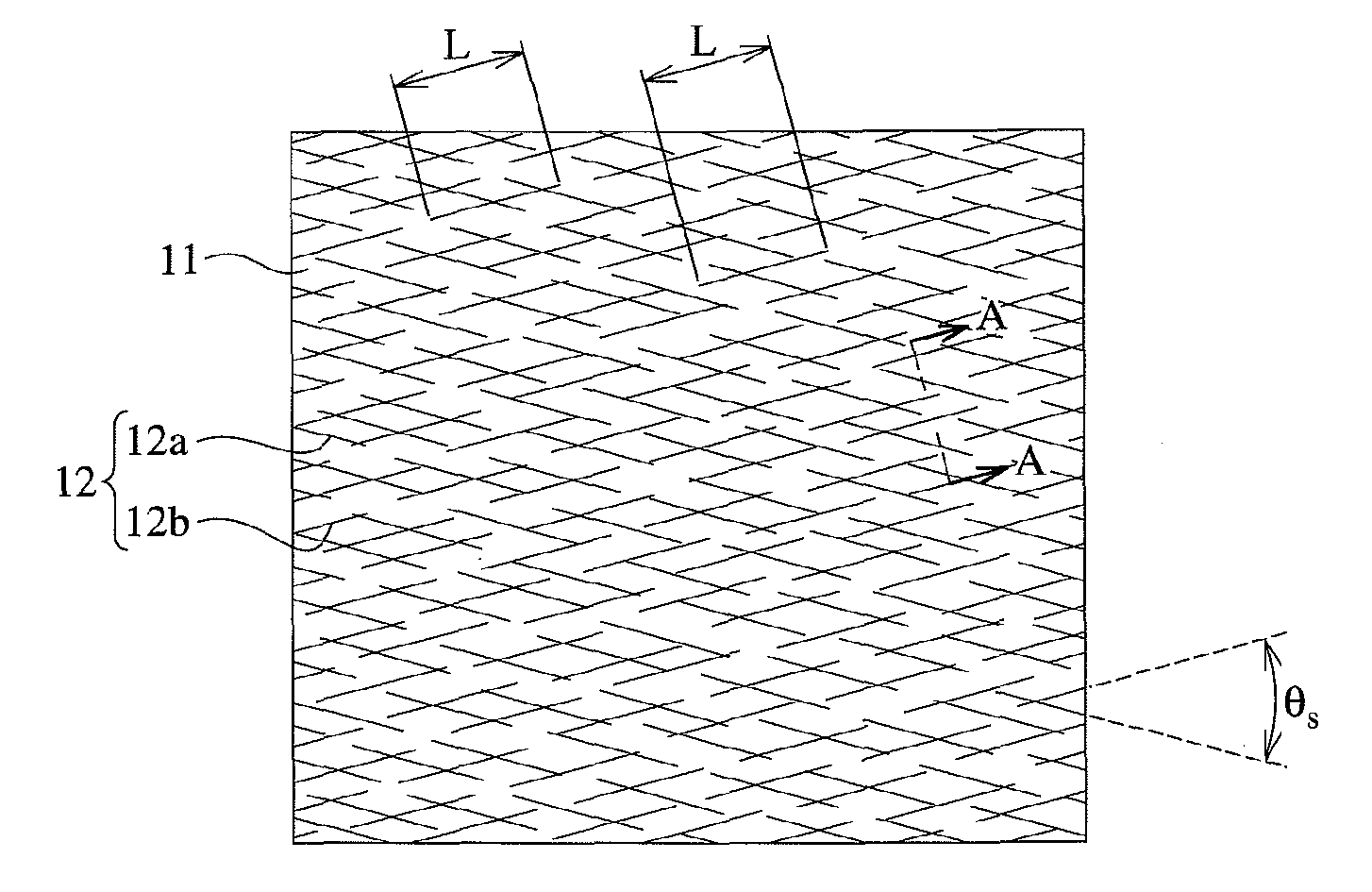

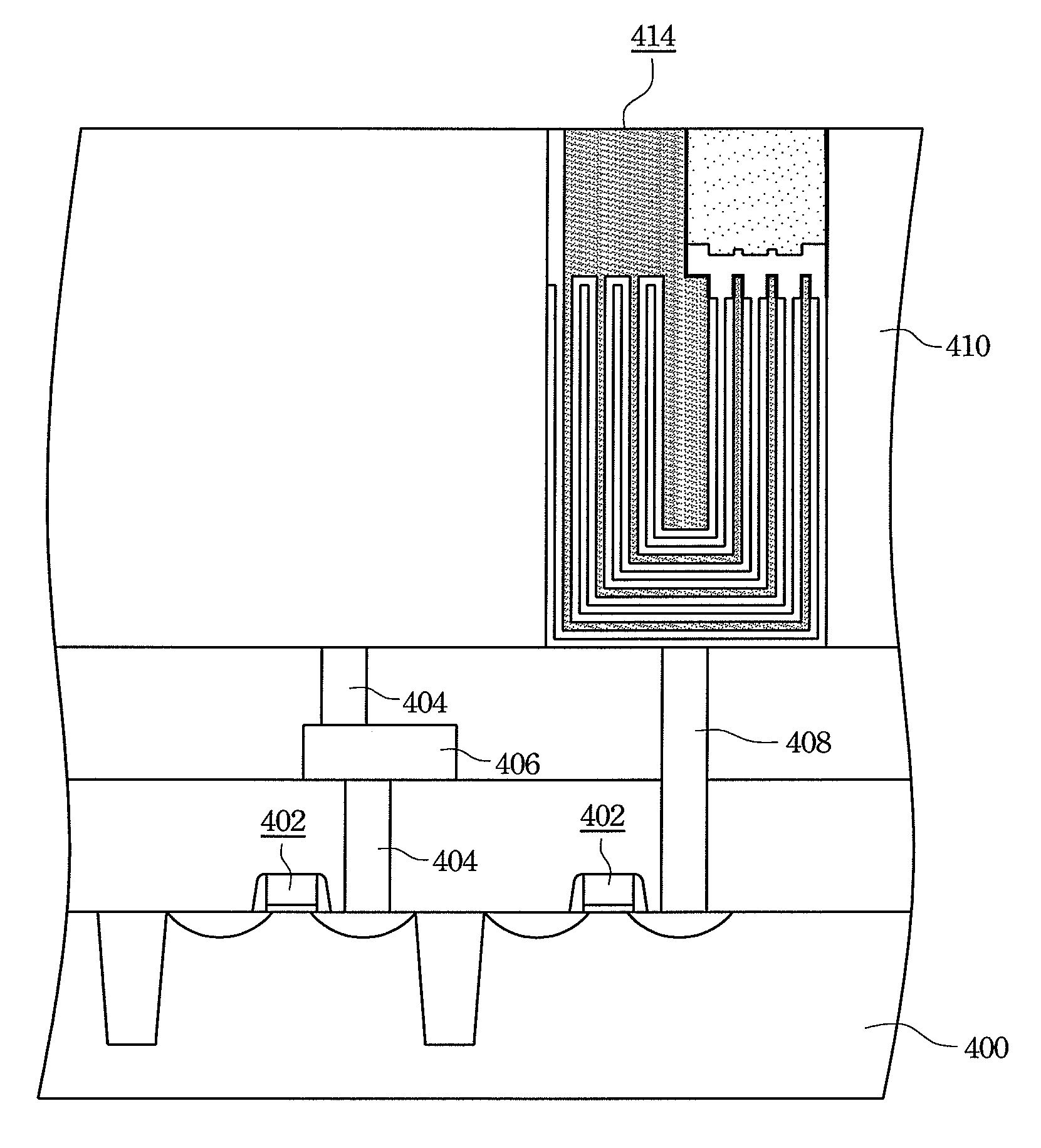

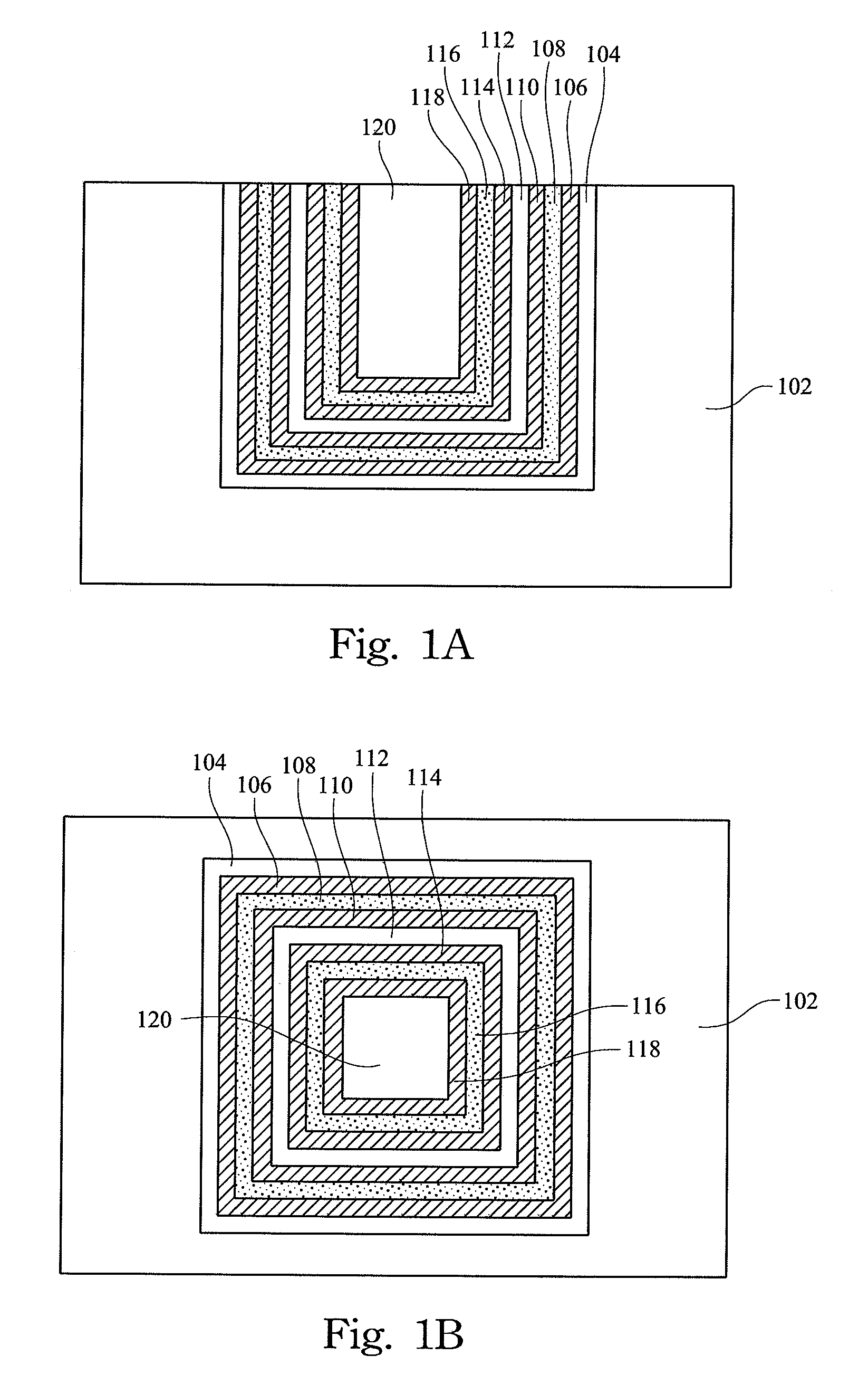

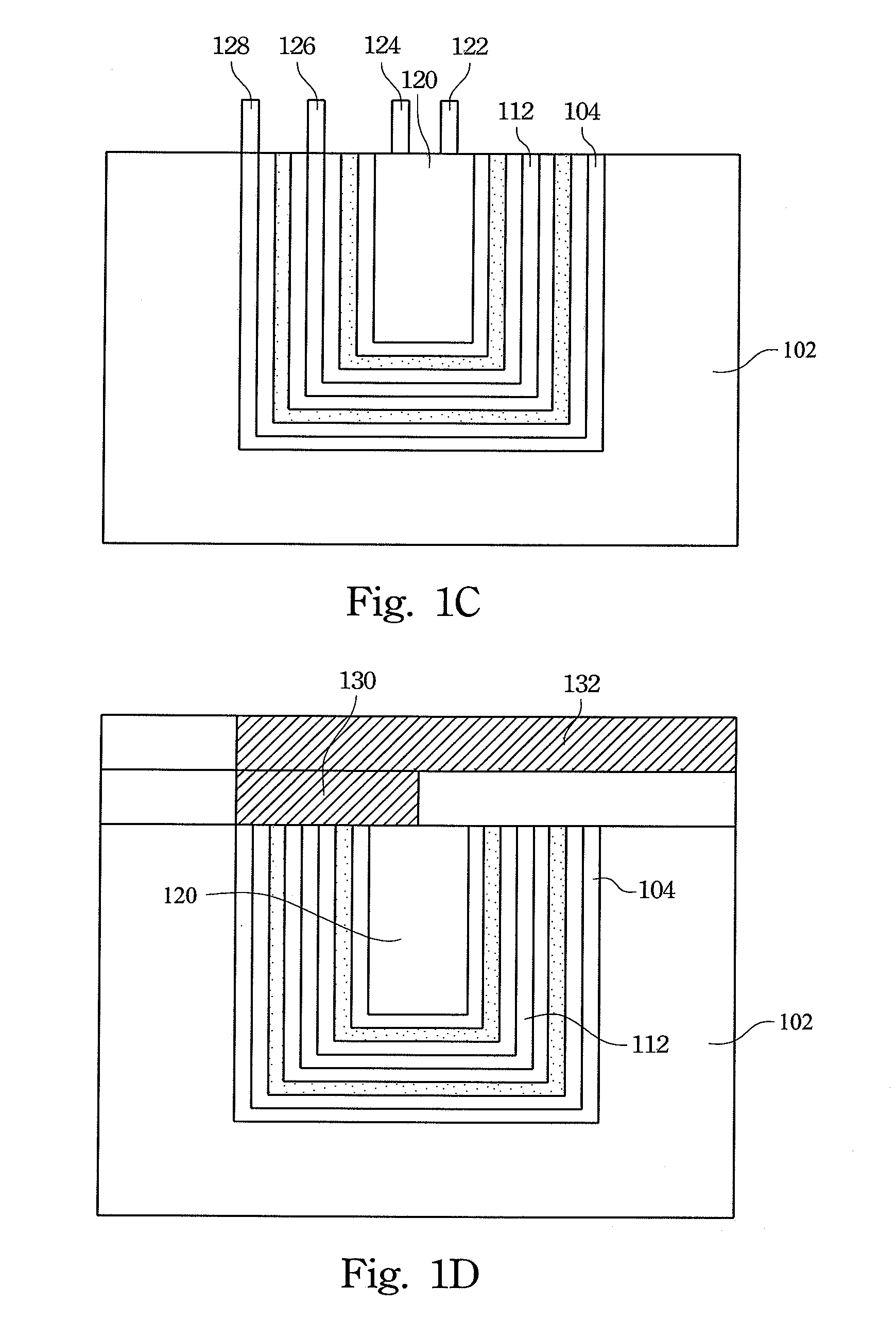

Method for forming multilayer electrode capacitor

InactiveUS20060115952A1Suitably producedSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsDielectric layer

A method of forming a multilayer electrode capacitor is described. A trench is formed in a substrate or in an insulator layer. Two sets of conductive layers are deposited on the inner surface of the trench. The first set of conductive layers is electrically connected to each other, and so is the second set of conductive layers. Each of the second set of conductive layers is inserted between two first conductive layers, and dielectric layers are interposed between two conductive layers to form a multilayer electrode capacitor.

Owner:PROMOS TECH INC

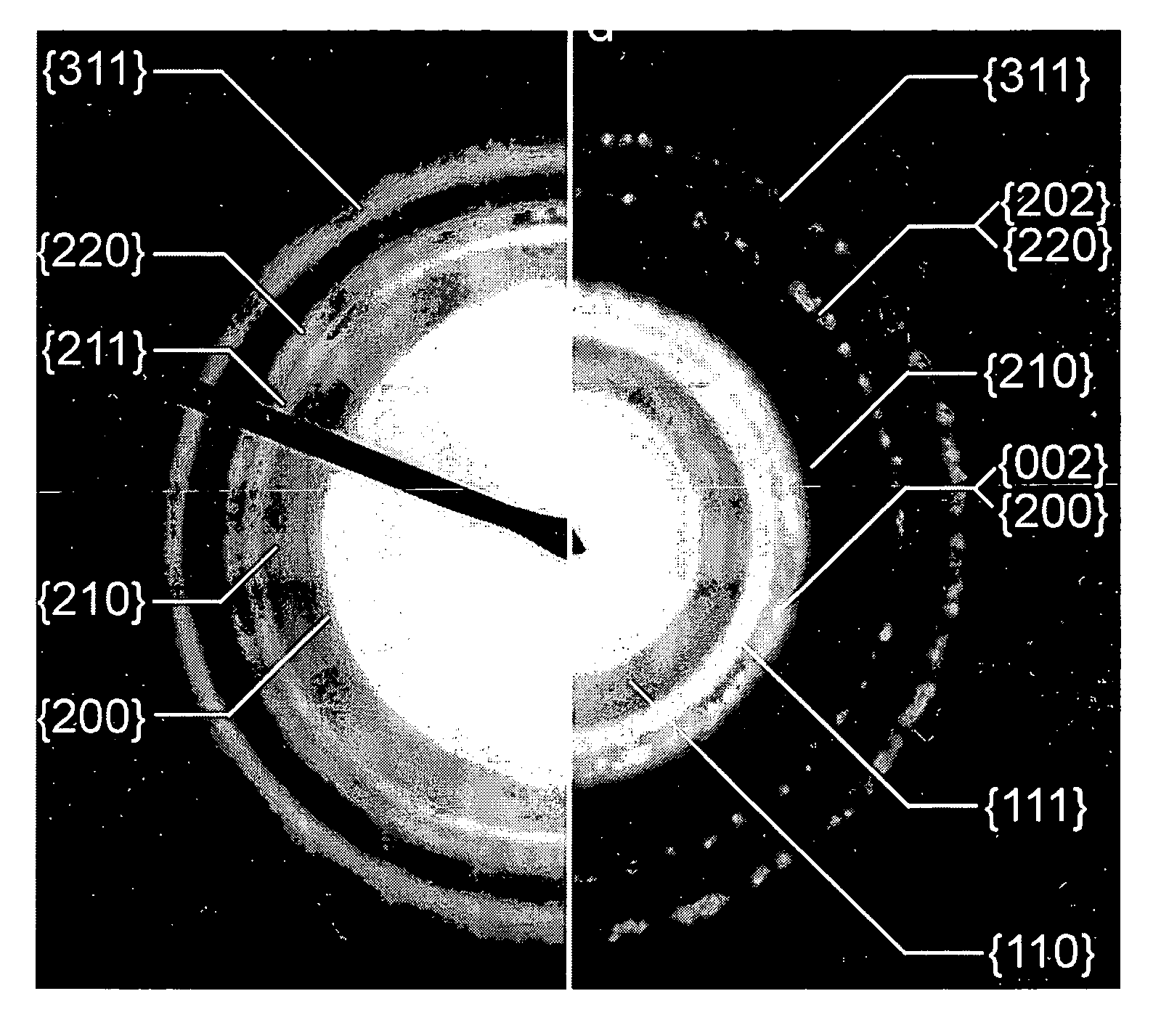

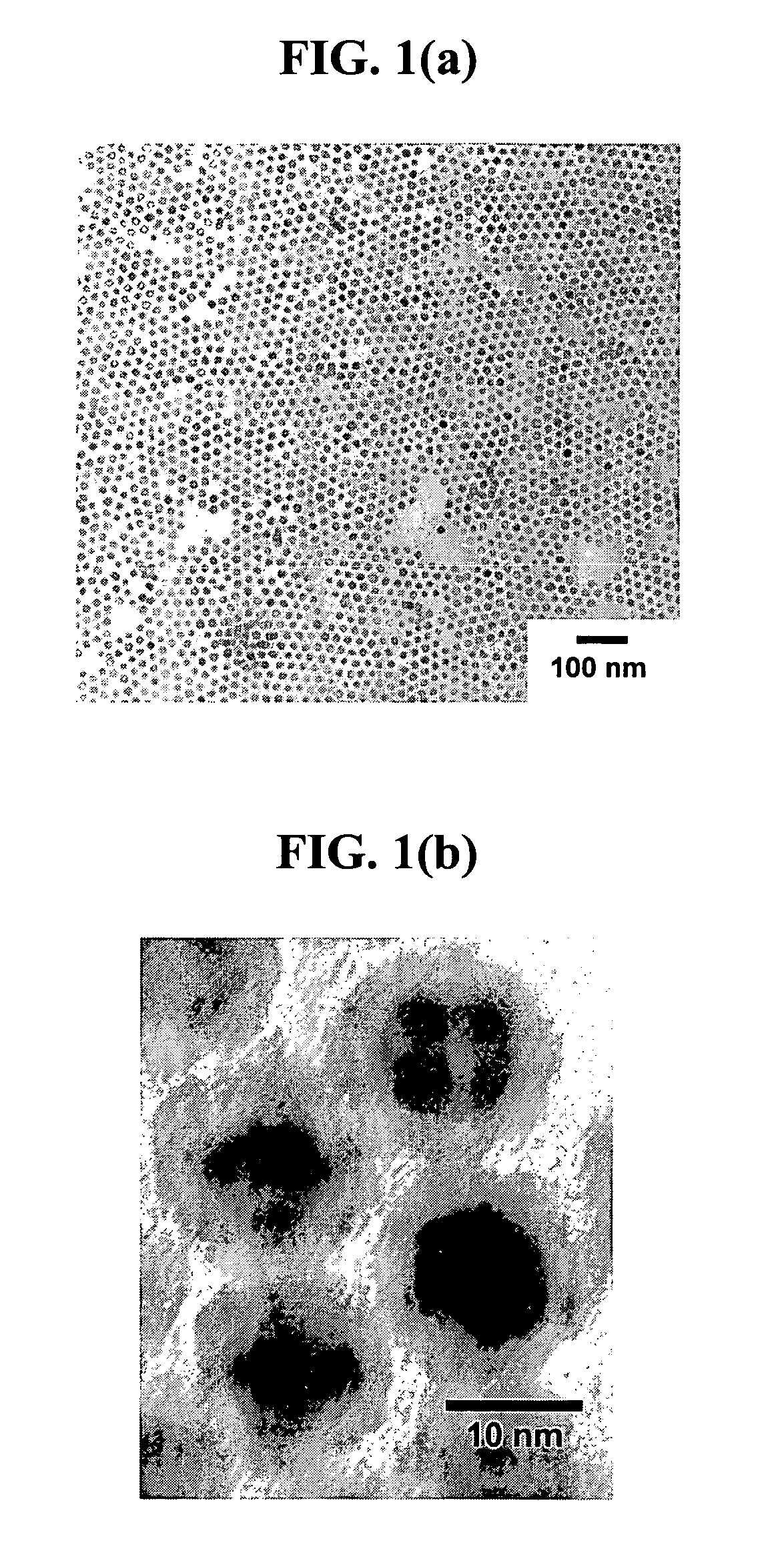

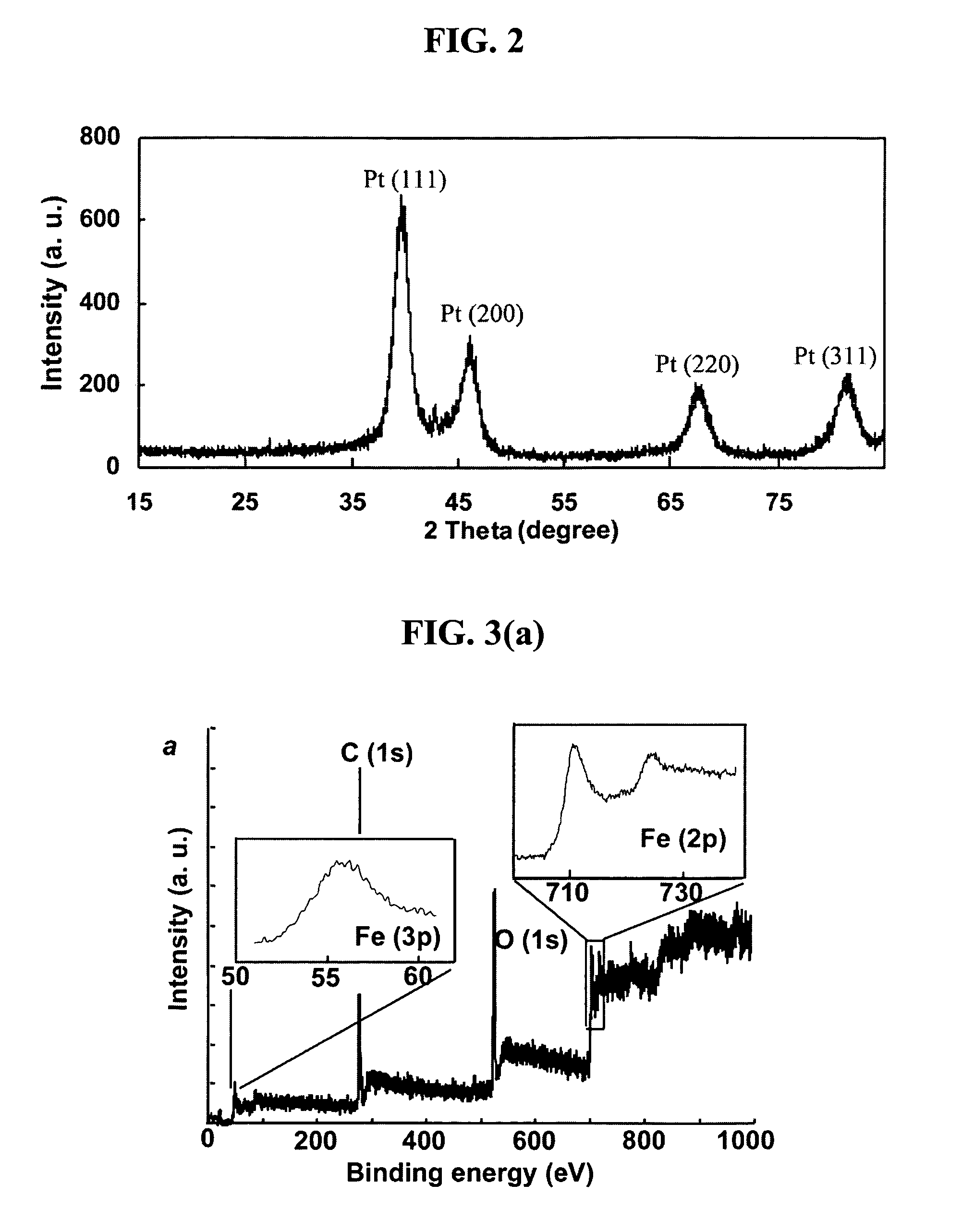

Core-shell magnetic nanoparticles and nanocomposite materials formed therefrom

InactiveUS7029514B1Eliminate needSuitably producedMaterial nanotechnologyNanomagnetismSynthesis methodsMagnetite Nanoparticles

Monodisperse core-shell types of metal, metal oxide, and alloy nanoparticles with variable core diameters and shell thicknesses, and controlled synthesis methods for producing such nanoparticles are provided. Nanocomposite materials fabricated from nanoparticles, and methods for producing such nanocomposite materials are also provided.

Owner:UNIVERSITY OF ROCHESTER

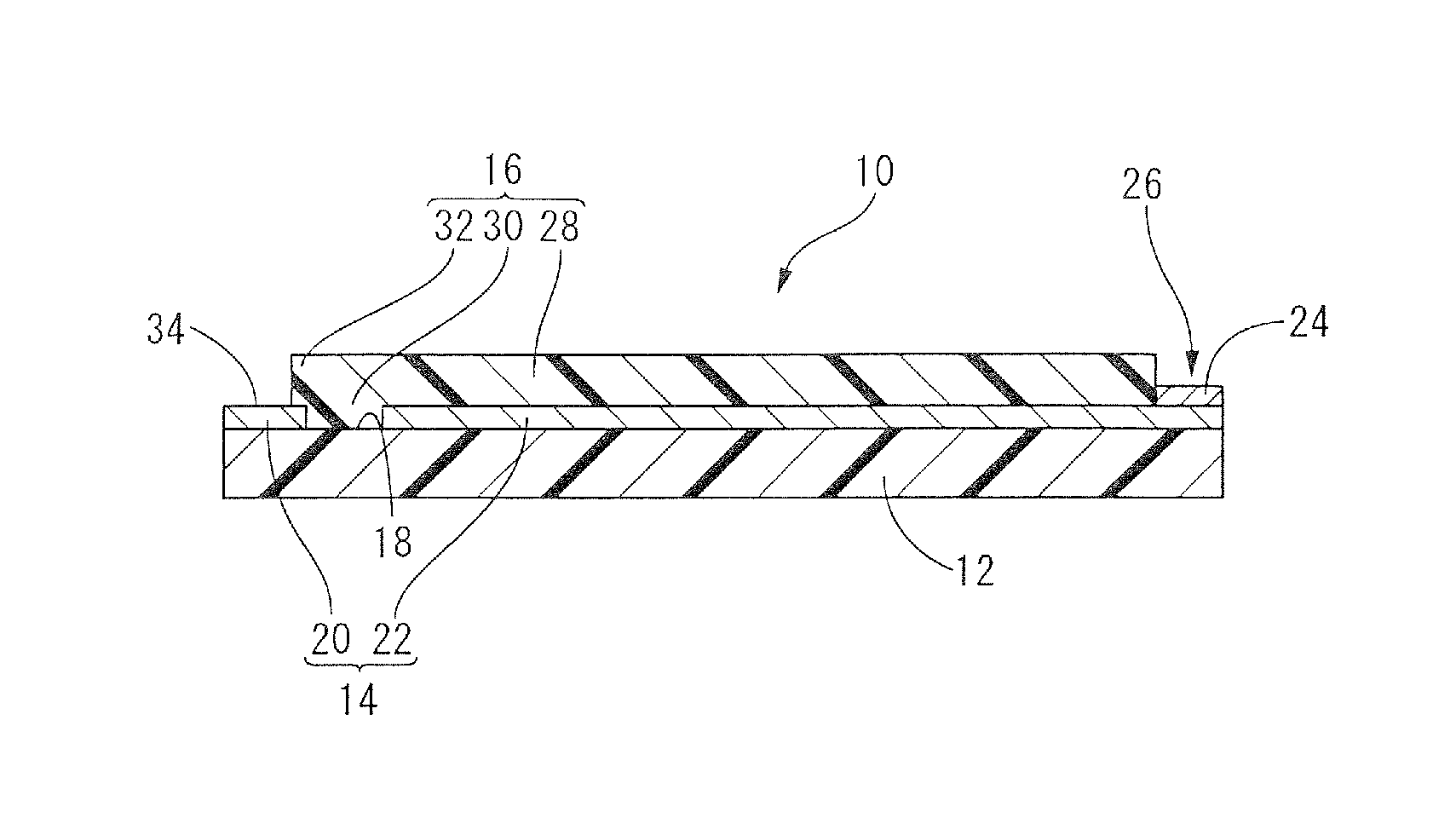

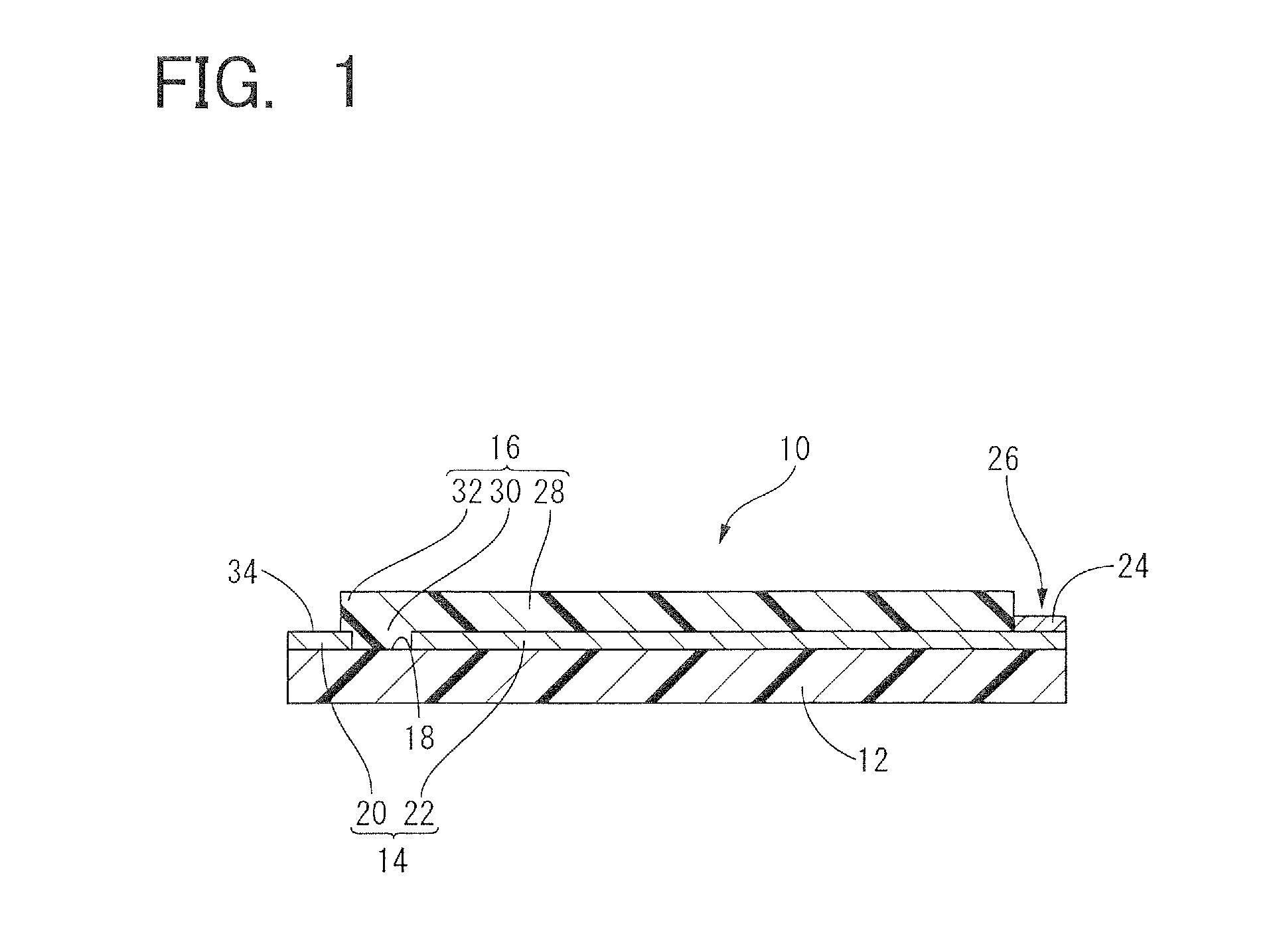

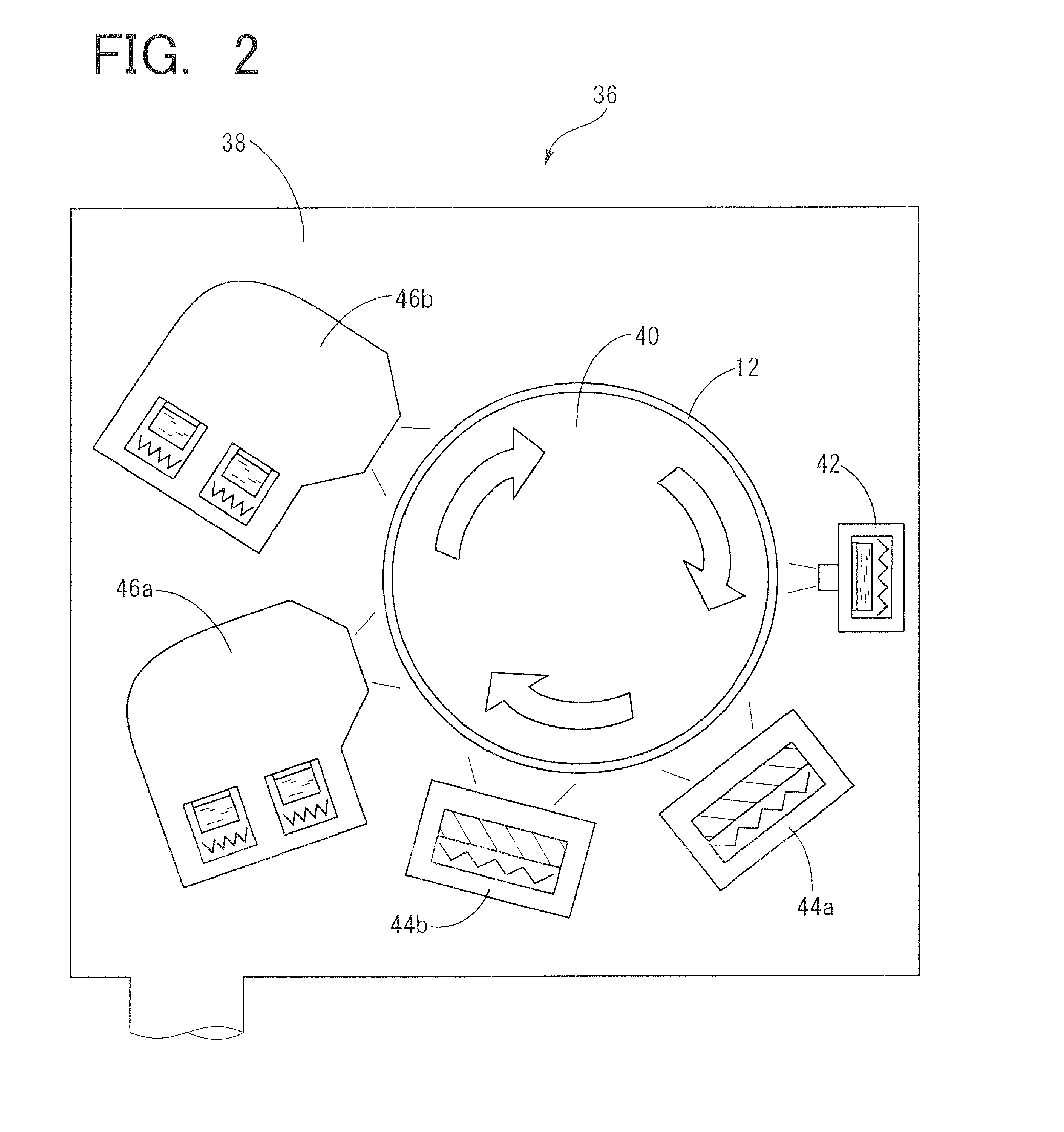

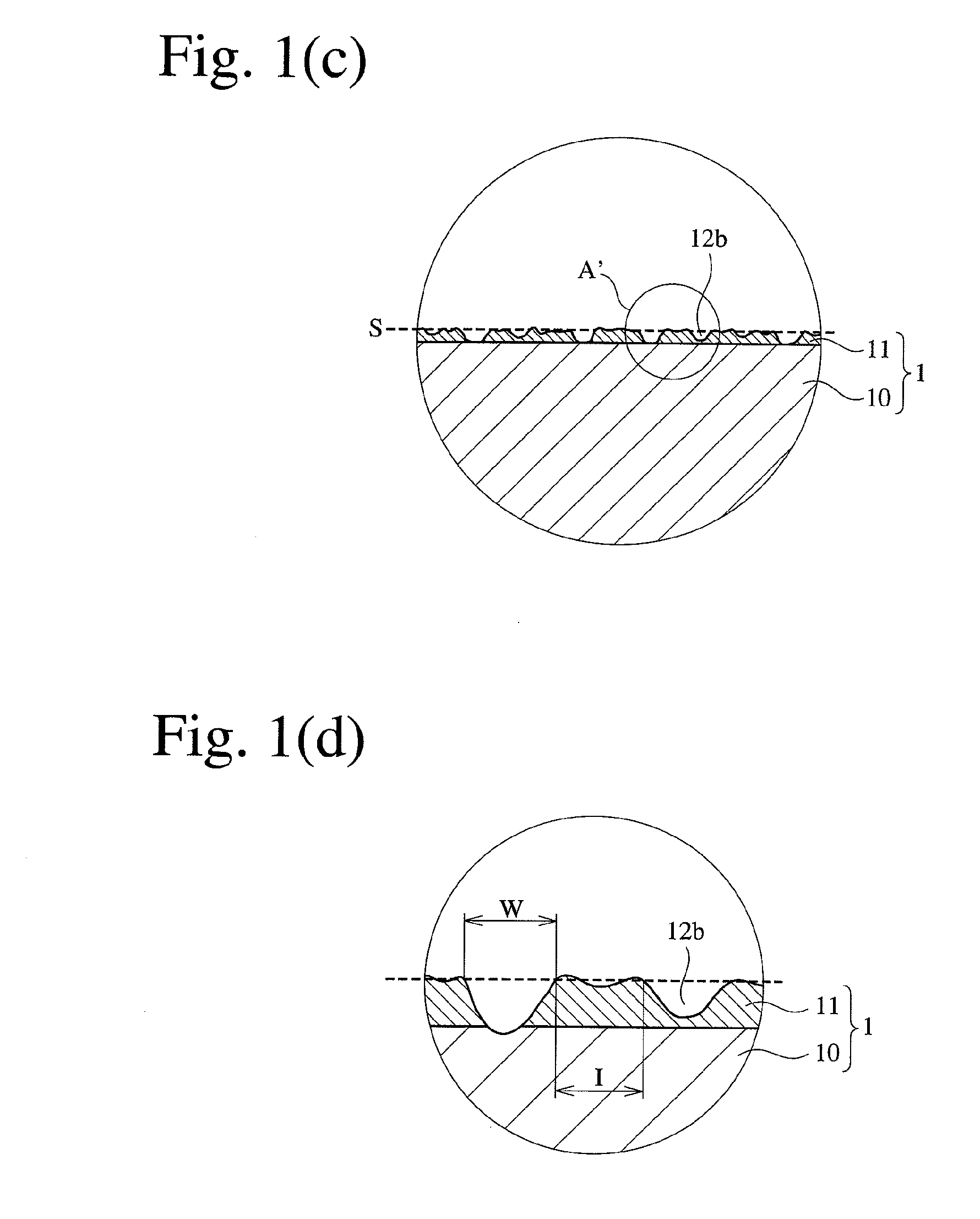

Film capacitor element, film capacitor, and method of producing the film capacitor element

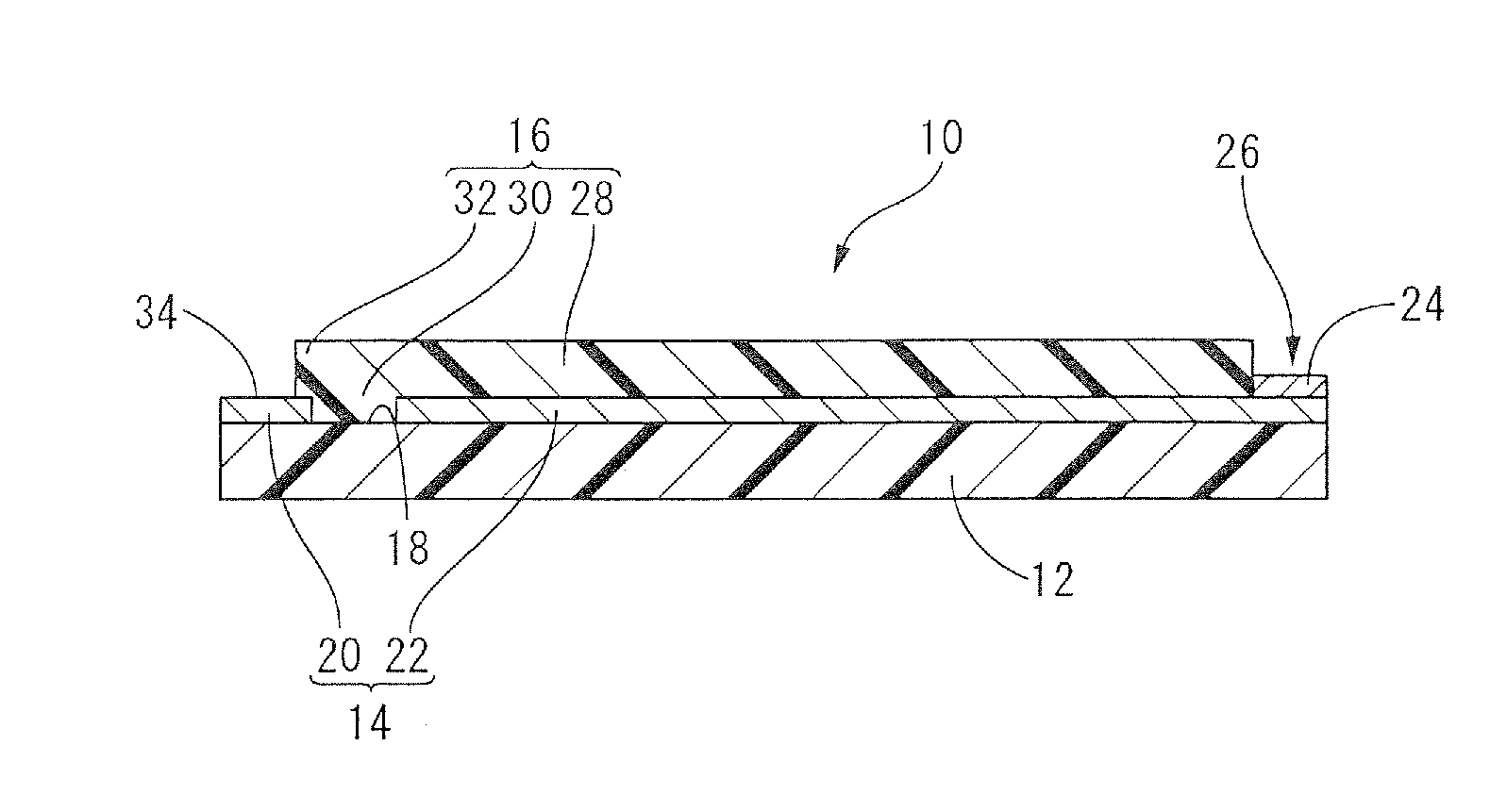

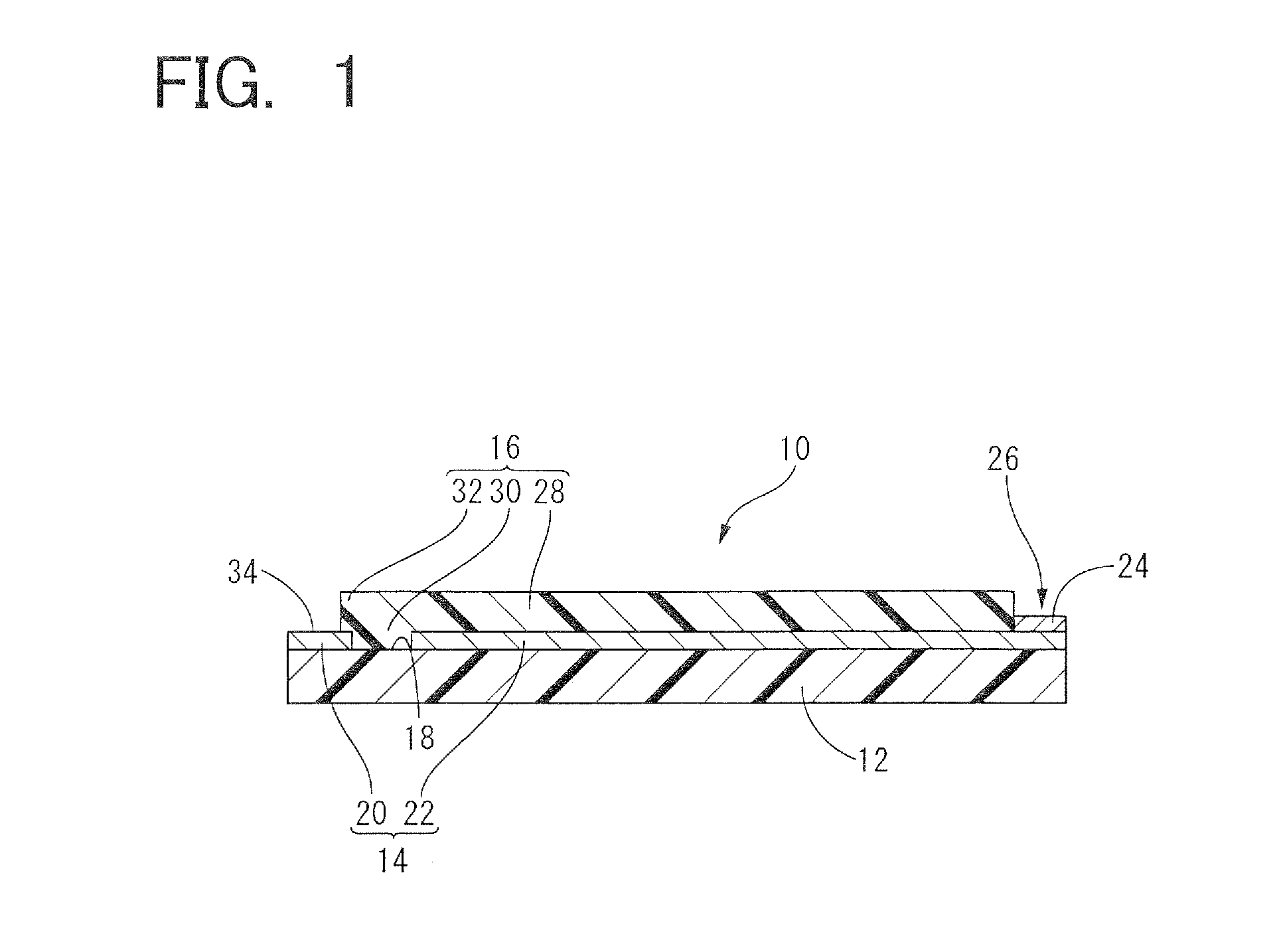

InactiveUS8861178B2Effectively increased degree of adhesivenessSuitably producedFixed capacitor electrodesThin/thick film capacitorDielectricVapor deposition polymerization

A film capacitor element including a base dielectric film layer 12, a vapor-deposition metal film layer 14 formed on the base dielectric film layer 12 and consisting of a first film portion 20 and a second film portion 22 that are spaced apart from each other by a margin portion 18, and a dielectric covering film layer 16 which is formed integrally on the second film portion 22 by vapor-deposition polymerization or coating and which has a covering portion 30 which fills the margin portion 18 and covers an entire area of an end face of the second film portion 22 on the side of the margin portion 18. The first film portion 20 including a non-covered portion 34 which is not covered by the dielectric covering film layer 16.

Owner:KOJIMA PRESS IND CO LTD

Polyurethane composition which contains an uretdione group

Polyurethane compositions which contain less than 5% by weight of free NCO groups and from 1 to 18% by weight of uretdione groups, can be cured at low temperature and can be used as coating compositions.

Owner:DEGUSSA AG

Method for producing a composite structure including a piezoelectric element

InactiveUS6162313AMaximize rangeSuitably producedPiezoelectric/electrostriction/magnetostriction machinesLaminationPre strainElectricity

A composite structure (3) includes a piezoelectric element (1) sandwiched between fiber composite panels (2). The composite structure can be used as an actuator element. In a method for producing the composite structure, the fiber composite panels are pre-stressed and pre-strained by applying respective pre-stressing forces (F1, F2) in opposite directions along two substantially perpendicular axes in the plane of the panel. The pre-stressed and pre-strained condition of the fiber composite panels (2) is maintained, while the panels are adhesively bonded (5) surfacially onto the piezoelectric element (1). After the bonding is completed, the pre-stressing forces are removed from the fiber composite panels. As a result, in the finished composite structure (3), the fiber composite panels (2) are under internal tension, while the piezoelectric element (1) is under internal compression. The pre-stressing forces (F1, F2) are particularly selected in magnitude and direction to achieve the required resultant balance of tension and compression within the composite structure (3). The pre-compression of the piezoelectric element (1) should be sufficient so that operating loads on the composite structure do not result in tension loading of the piezoceramic element, while substantially maintaining the useful active strain range of the overall composite structure.

Owner:AIRBUS HELICOPTERS DEUT GMBH

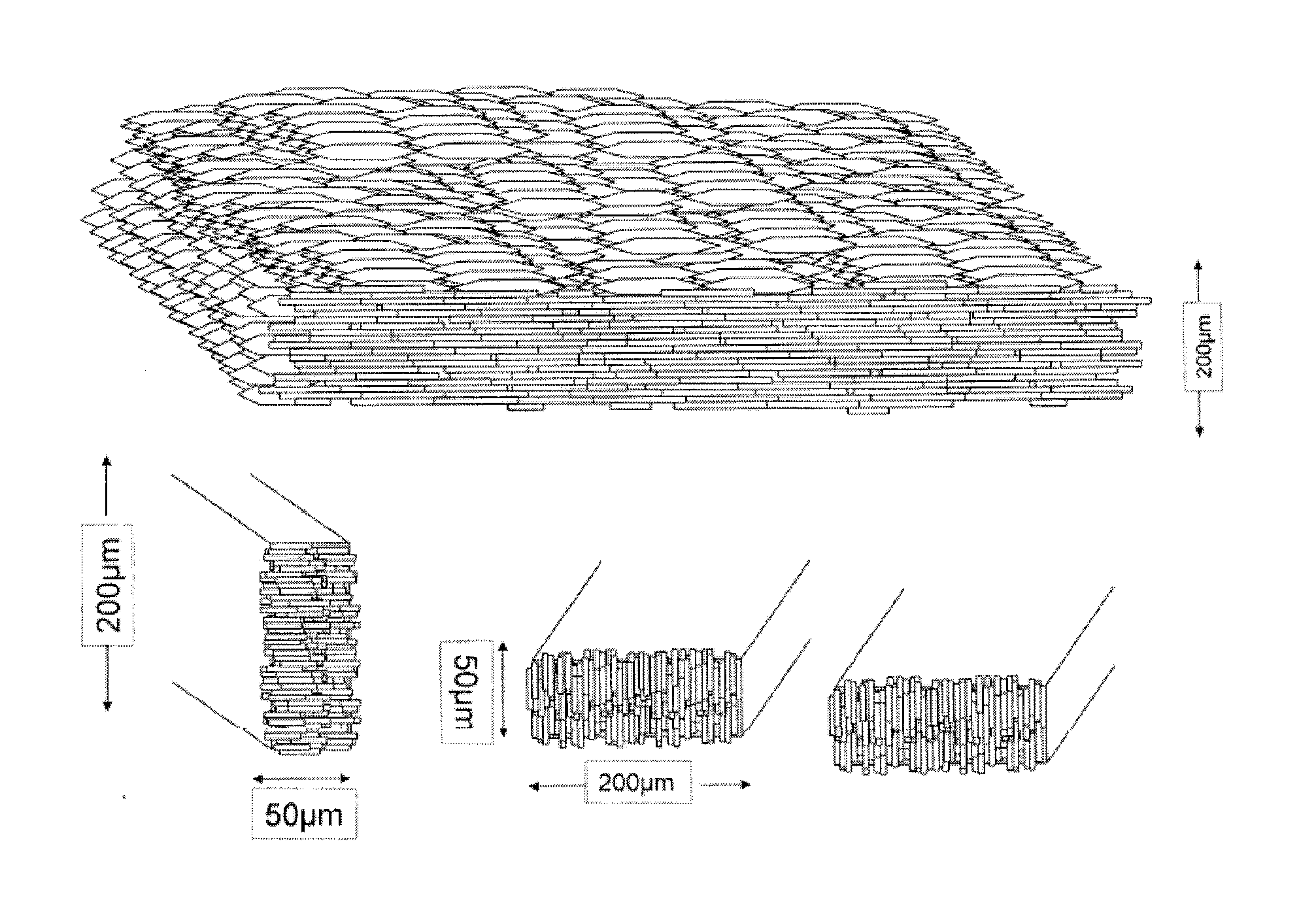

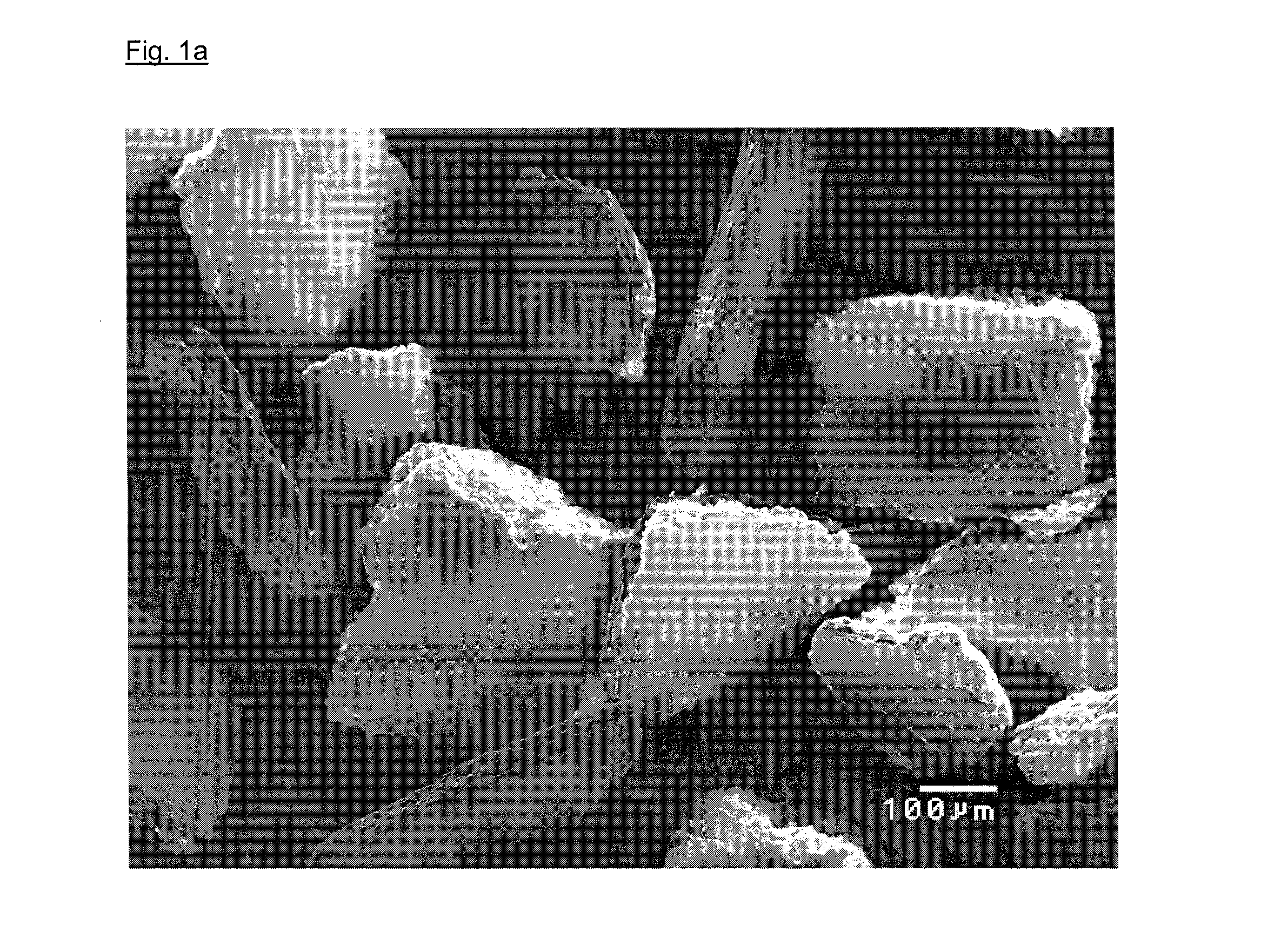

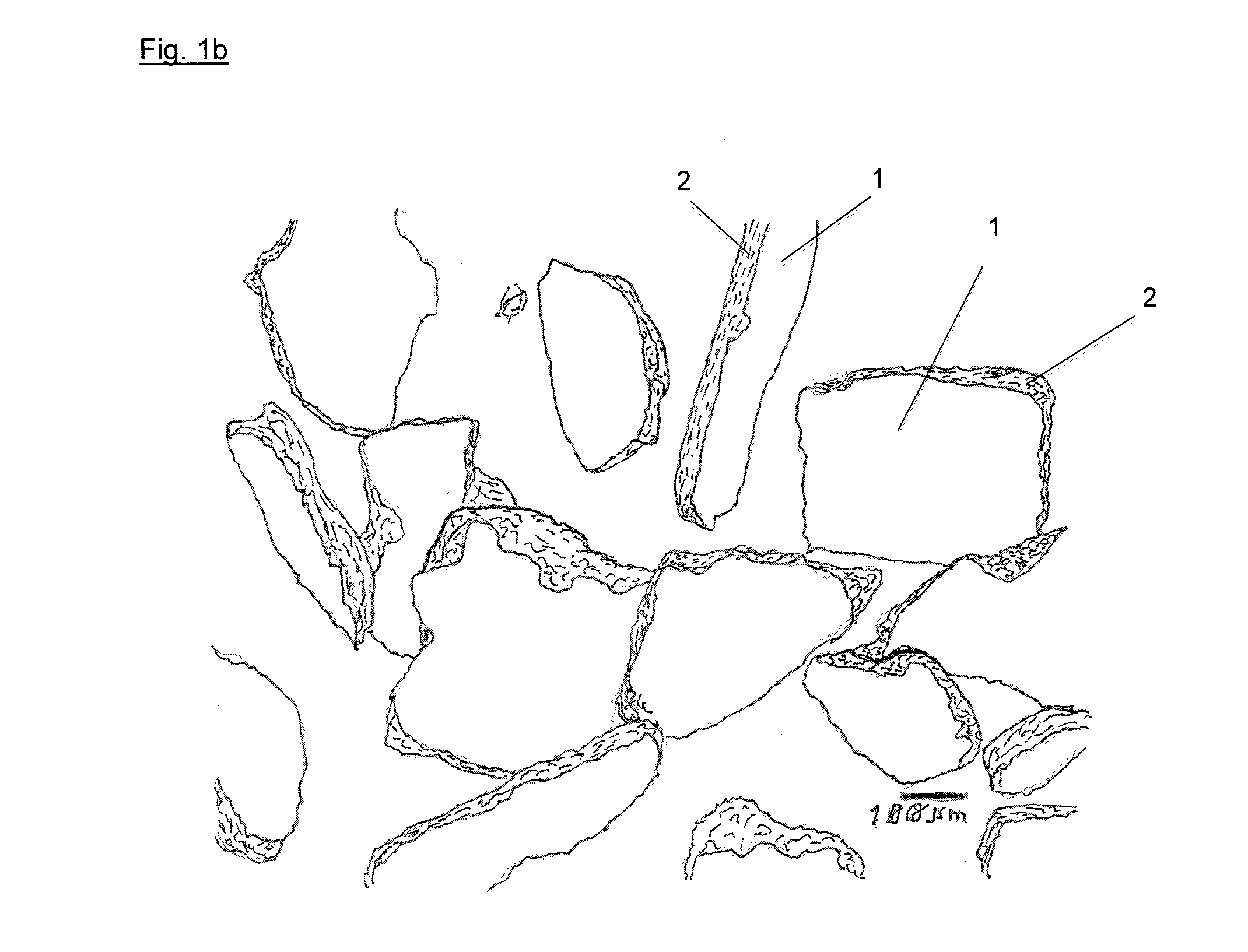

Boron nitride agglomerates, method of production thereof and use thereof

InactiveUS20120114905A1Increased through-plane thermal conductivityEasy to measureNitrogen compoundsSynthetic resin layered productsHexagonal boron nitrideBoron nitride

The invention relates to boron nitride agglomerates, comprising lamellar, hexagonal boron nitride primary particles, which are agglomerated with one another with a preferred orientation, the agglomerates formed being flake-shaped.The invention also relates to a method for producing said boron nitride agglomerates, characterized in that lamellar, hexagonal boron nitride primary particles are agglomerated in such a way that they line up with one another with a preferred orientation.The flake-shaped agglomerates according to the invention are suitable as filler for polymers for making polymer-boron nitride composites and for hot pressing of boron nitride sintered compacts.

Owner:3M INNOVATIVE PROPERTIES CO

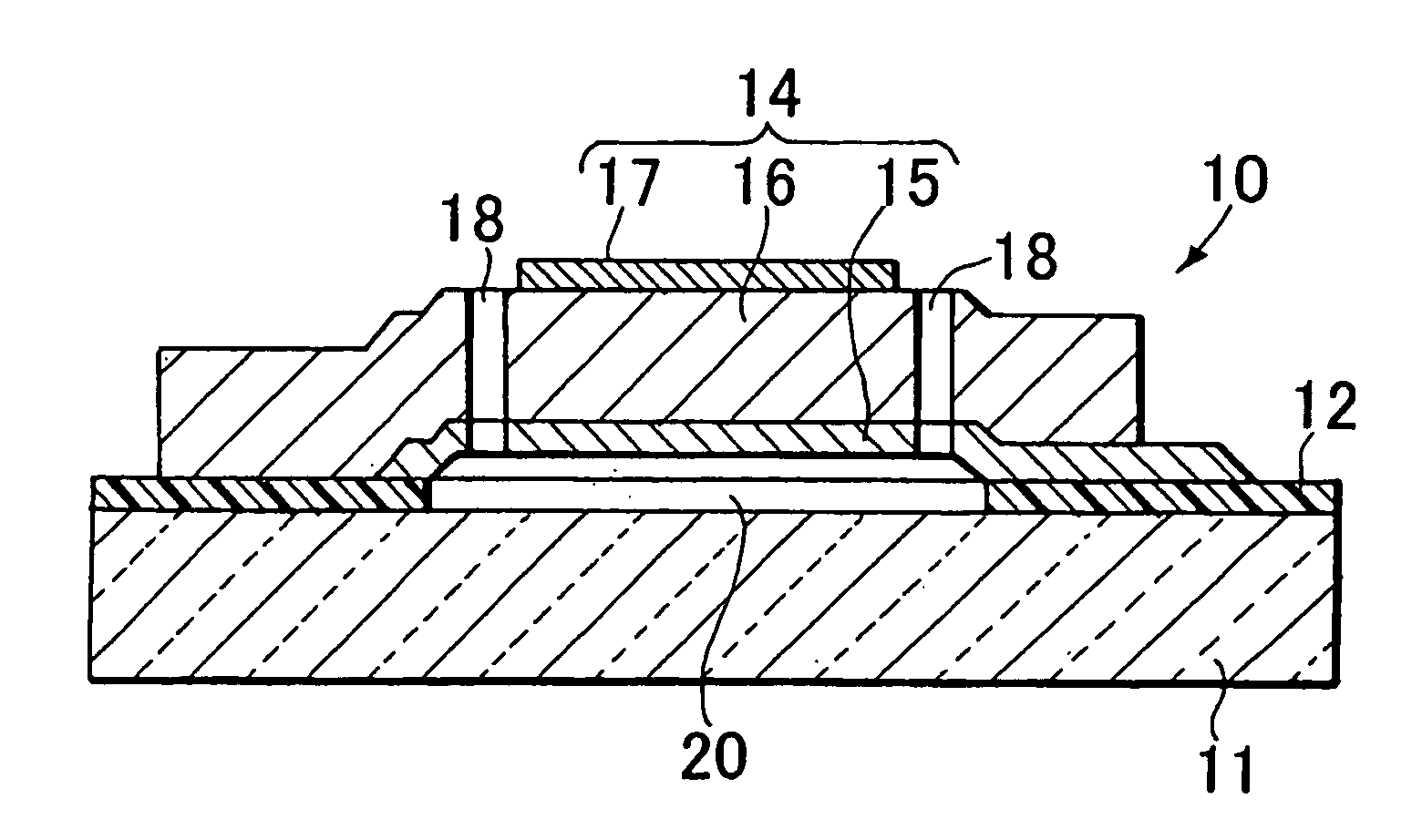

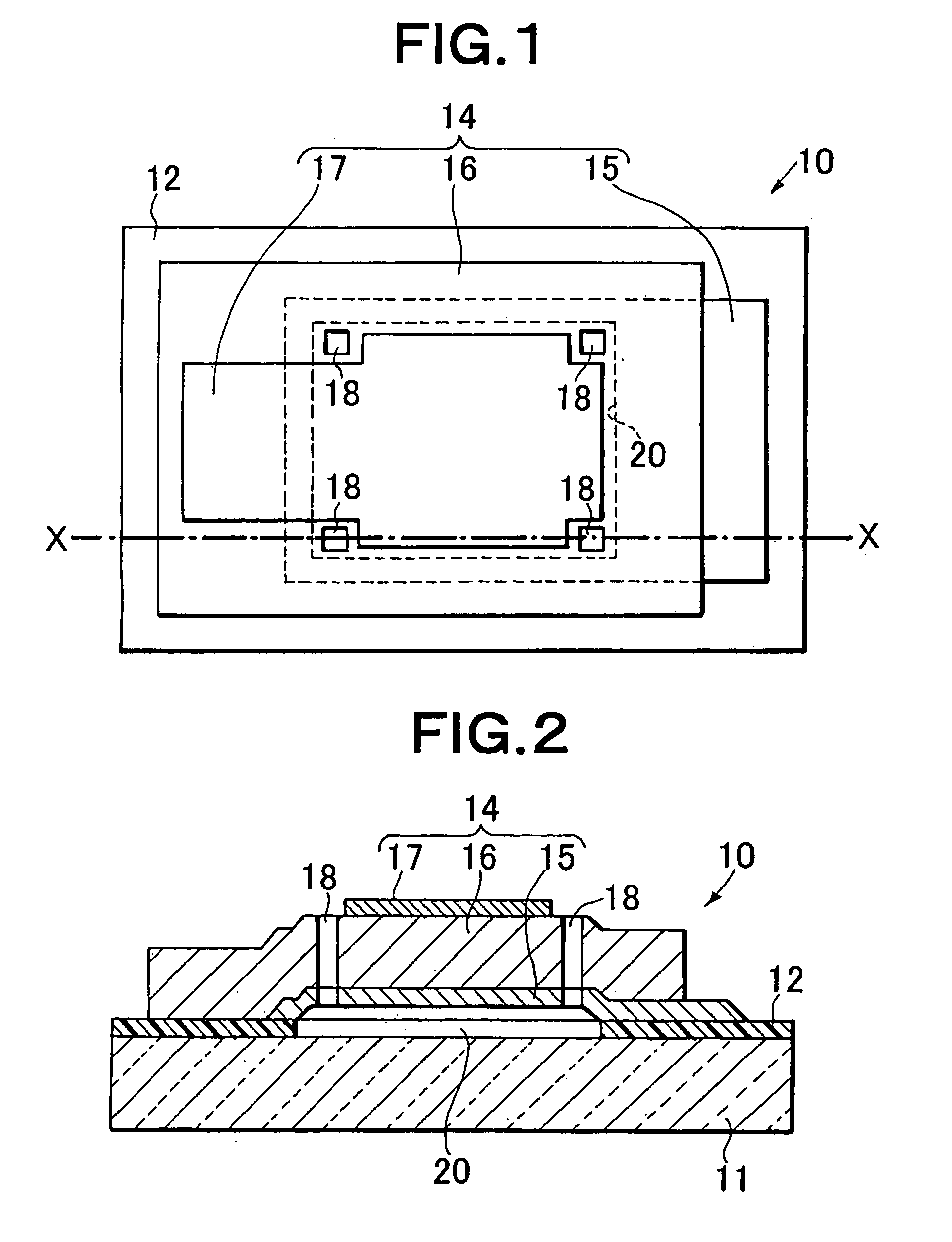

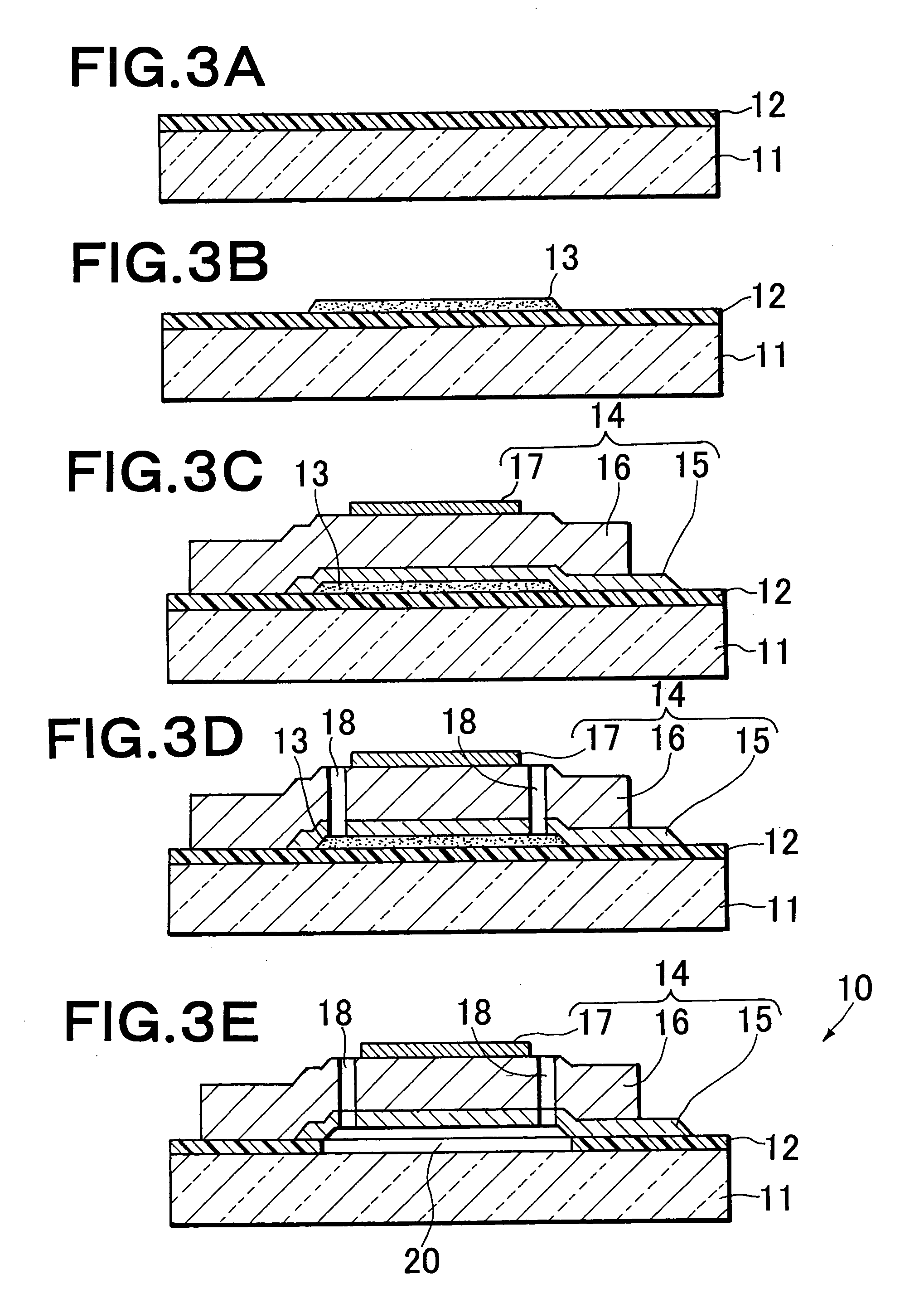

Method of manufacturing piezoelectric thin film device and piezoelectric thin film device

ActiveUS7212082B2Improve featuresImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesOptoelectronicsMaterials science

Method of producing a piezoelectric thin film device comprises a step of forming an insulating layer (12) capable of being etched by a specific chemical substance on the upper surface of a substrate (11); a step of forming a sacrificial layer (13) made of a substance having a higher etching rate by the specific chemical substance than the insulating layer on a partial region of the insulating layer; a step of forming a lower electrode (15) on a region including the sacrificial layer; a step of forming the piezoelectric thin film (16) on a region including a part of the lower electrode; a step of forming an upper electrode (17) on a region including a part of the piezoelectric thin film; a step of forming via hole (18), which penetrates the piezoelectric thin film and lower electrode, so as to expose a part of the sacrificial layer; and a step of forming a space (20) for oscillation by etching both the sacrificial layer and the insulating layer with the same specific chemical substance by introducing the specific chemical substance through the via hole.

Owner:MEMS SOLUTIONS INC

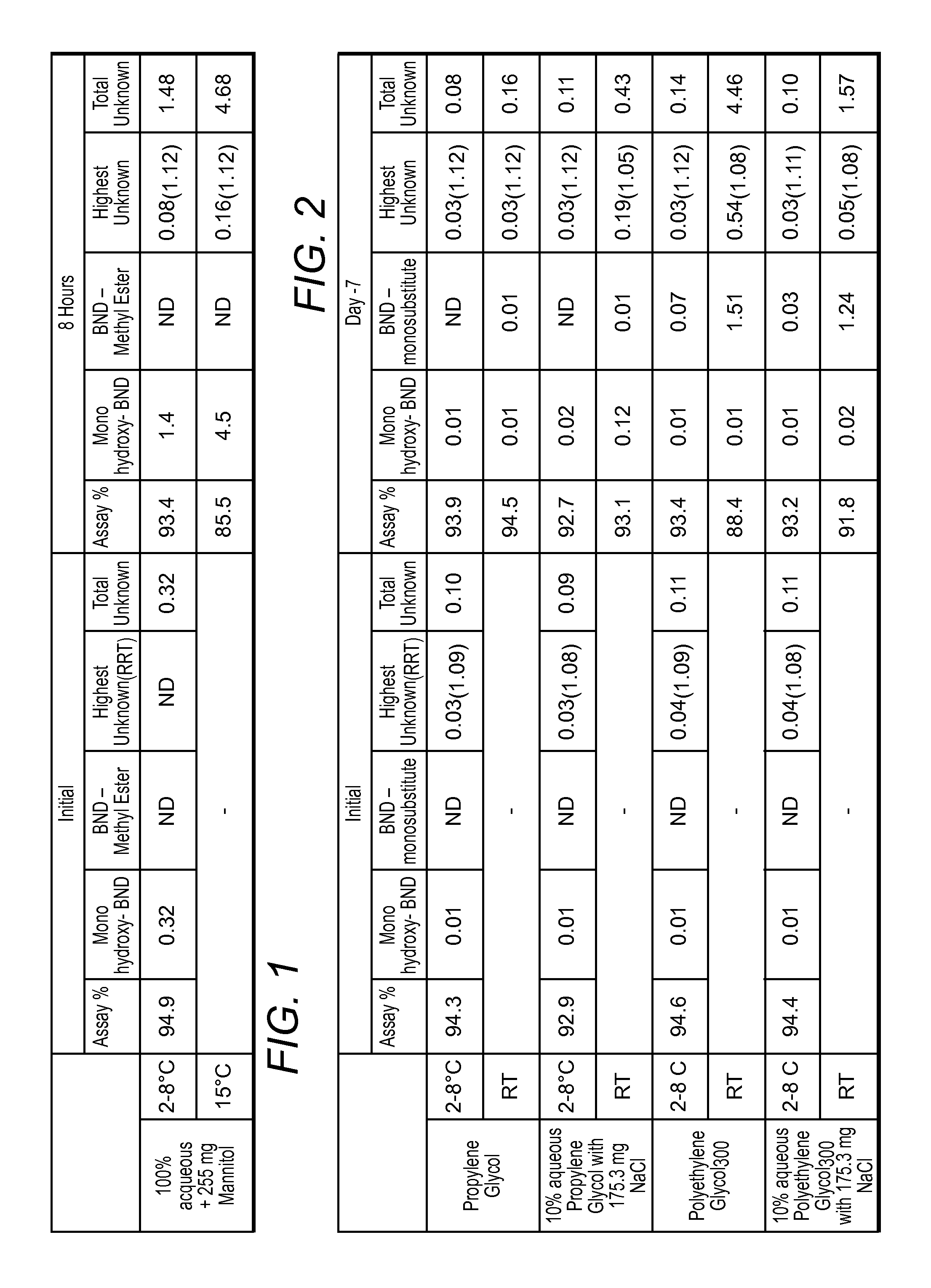

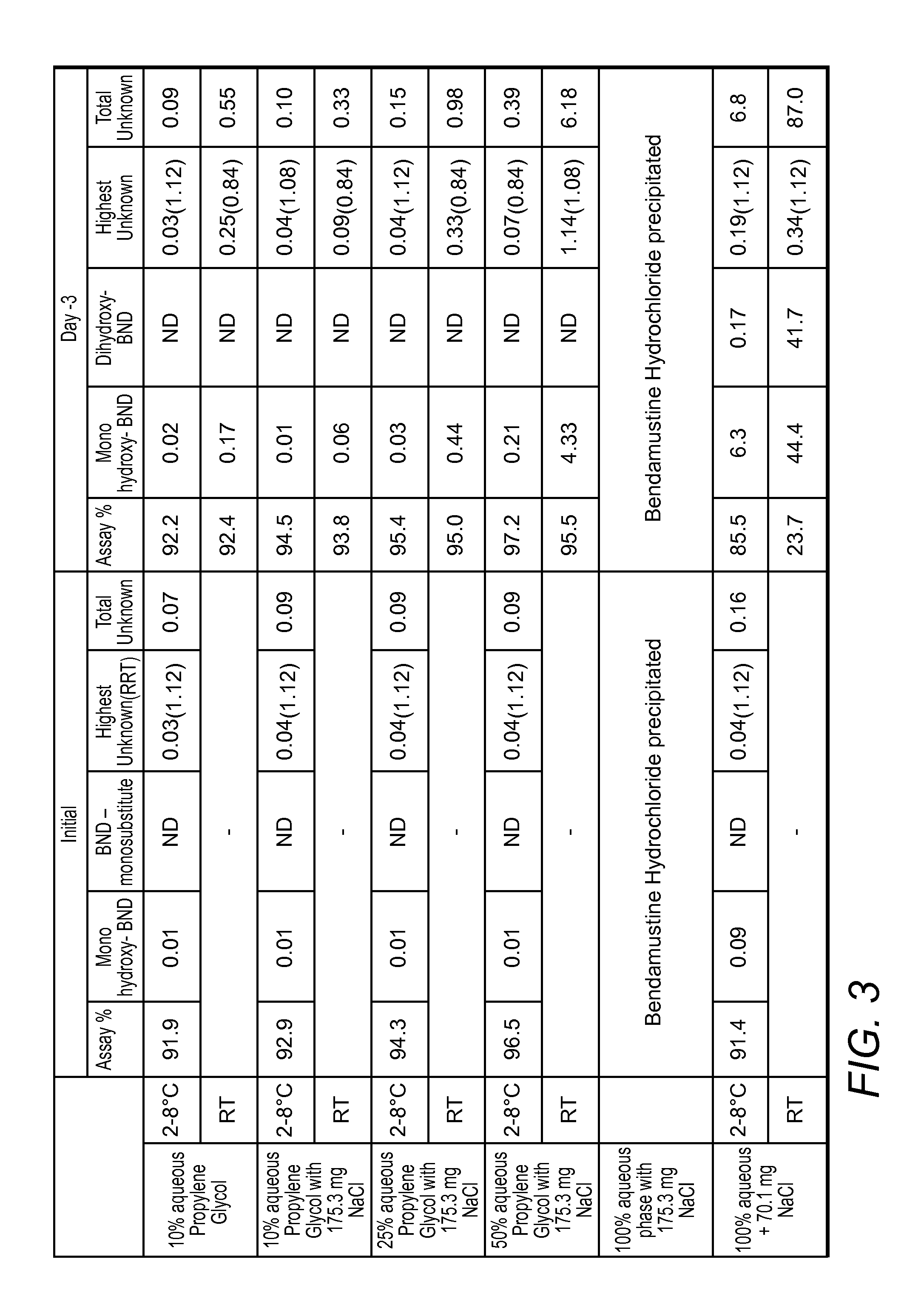

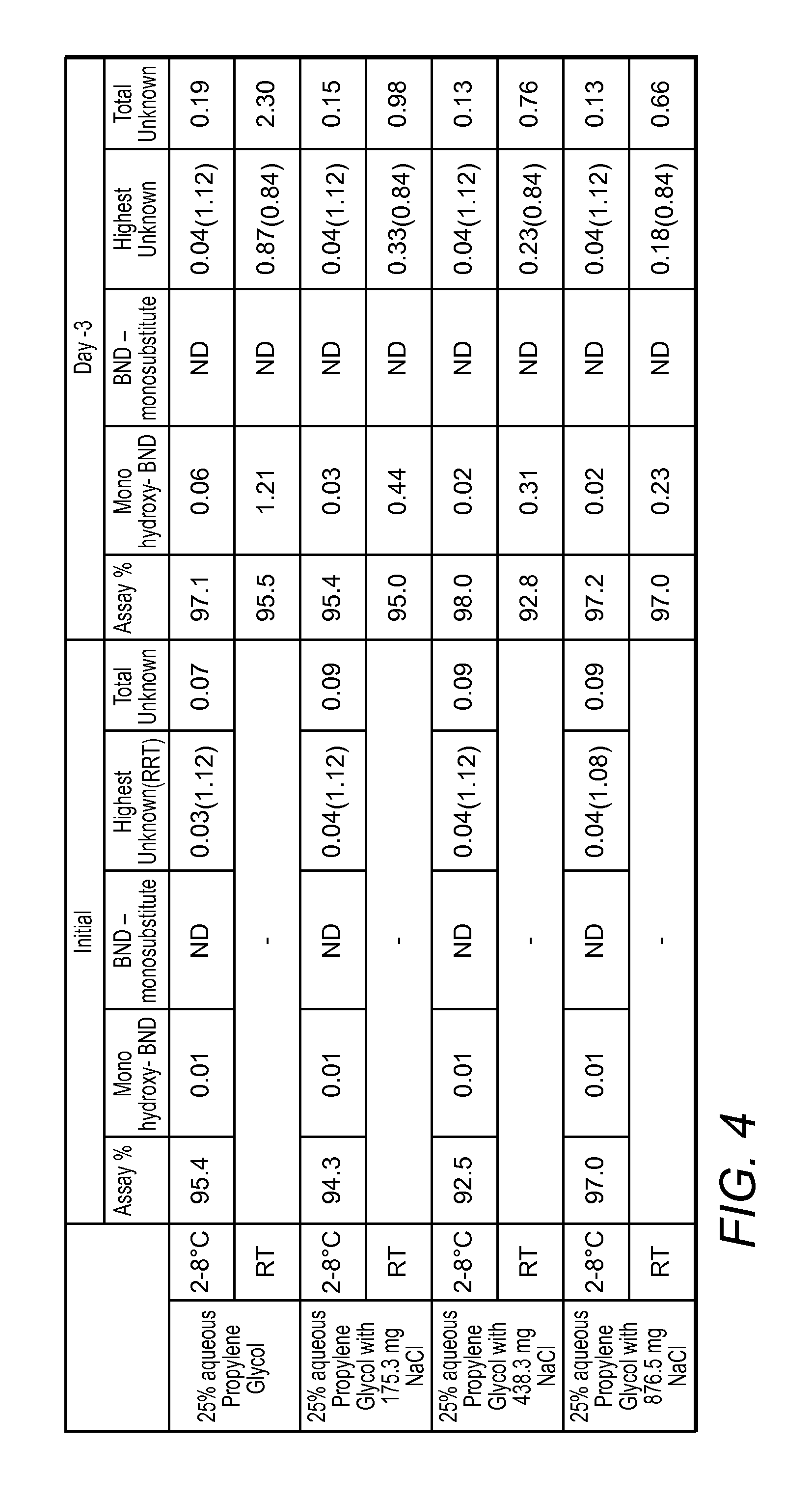

Bendamustine compositions and methods therefore

InactiveUS20130210878A1Improve stabilityPrevent precipitationBiocideOrganic active ingredientsChlorideReady to use

Aqueous Bendamustine formulations with improved stability are disclosed. Especially preferred formulations are low-dose ready-to-use liquid formulations in which Bendamustine is in a non-aqueous vehicle in combination with an aqueous phase that contains significant quantities of chloride.

Owner:INNOPHARMA

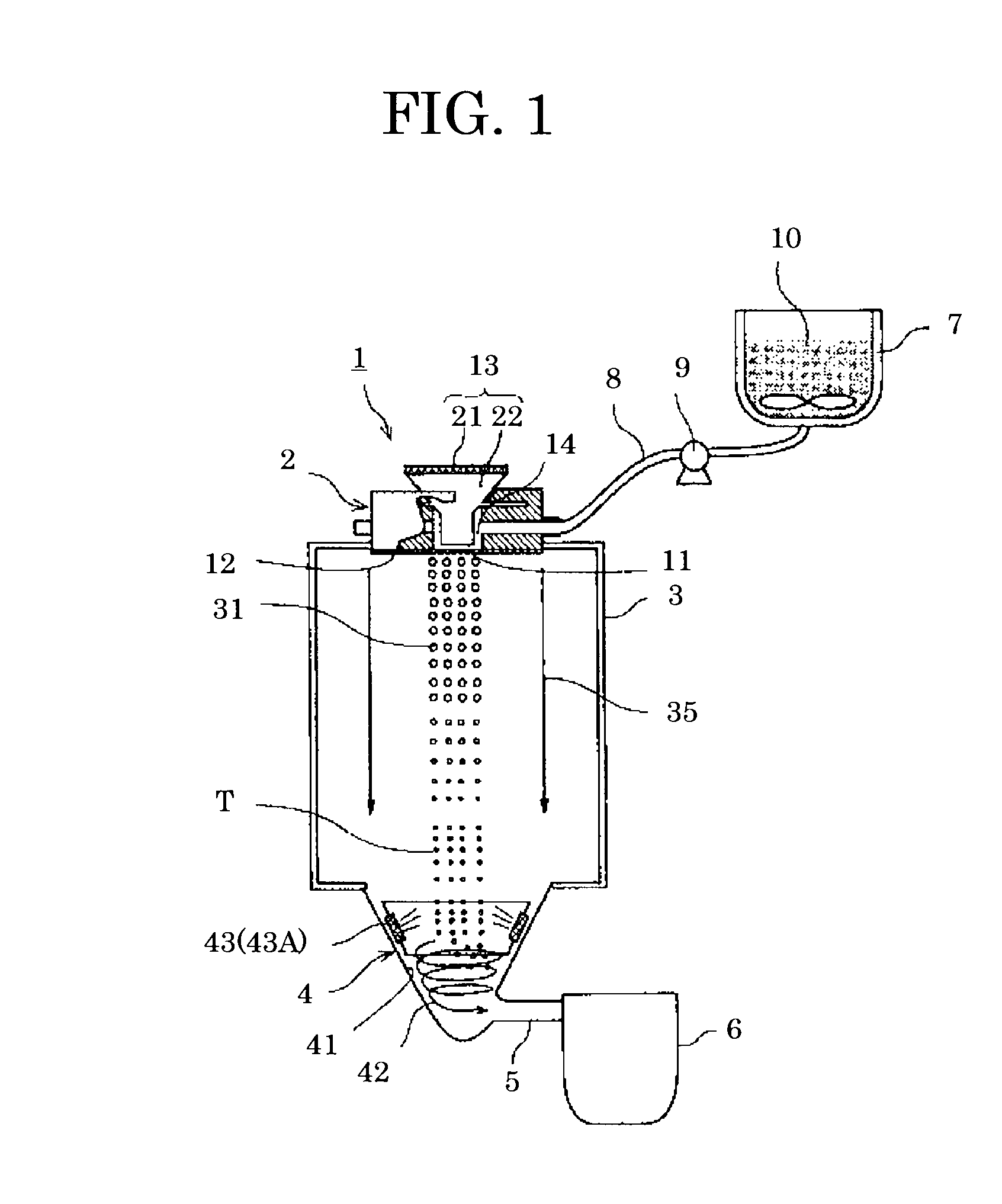

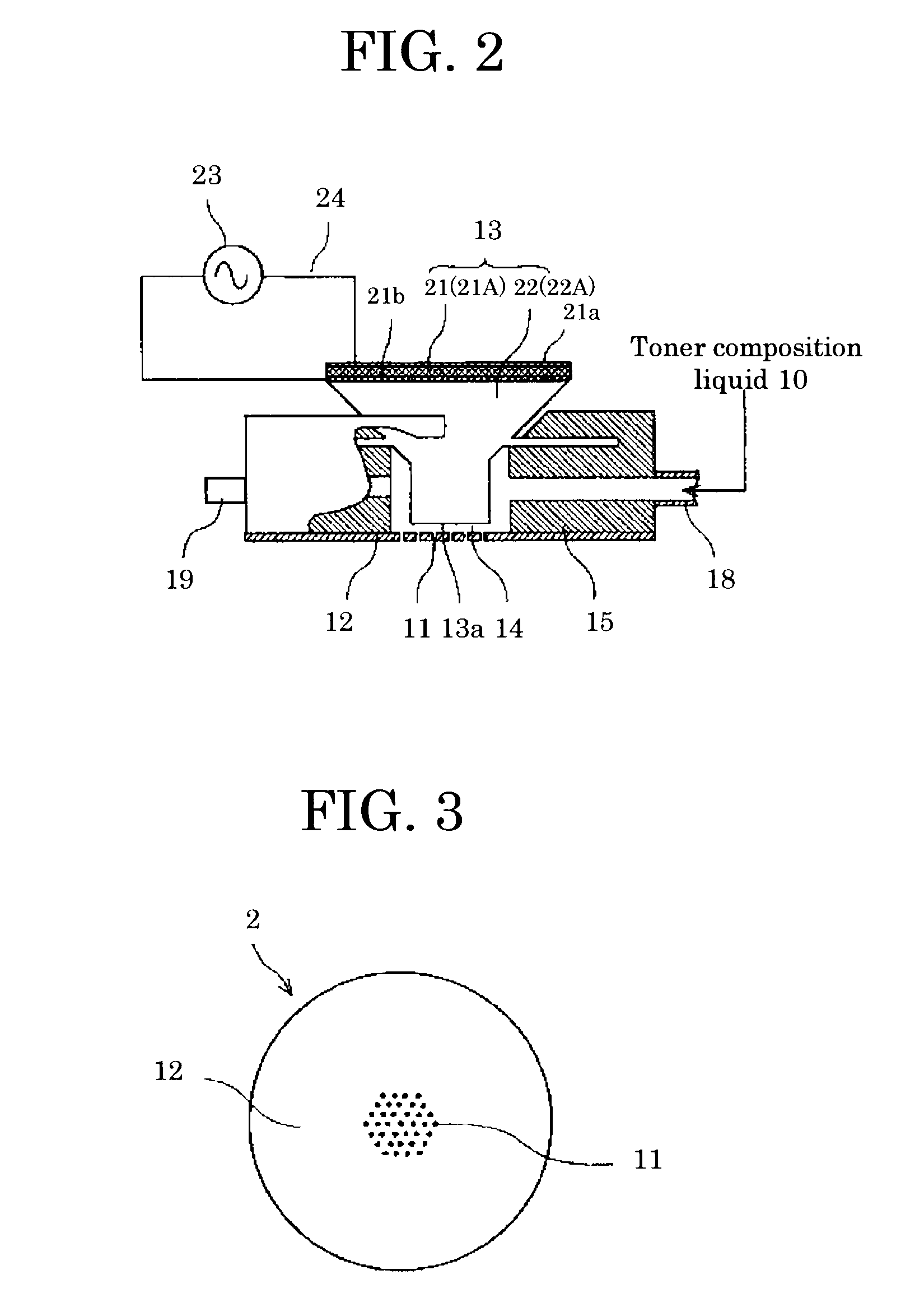

Method for producing toner, and toner

A method for producing a toner, the method including discharging a toner composition liquid from a plurality of nozzles to form liquid droplets thereof, the toner composition liquid being prepared by dissolving or dispersing in a solvent a toner composition containing at least a binder resin, a colorant, an acid-modified hydrocarbon wax and an unmodified hydrocarbon wax, the waxes serving as a releasing agent, and solidifying the liquid droplets so as to form solid particles.

Owner:RICOH KK

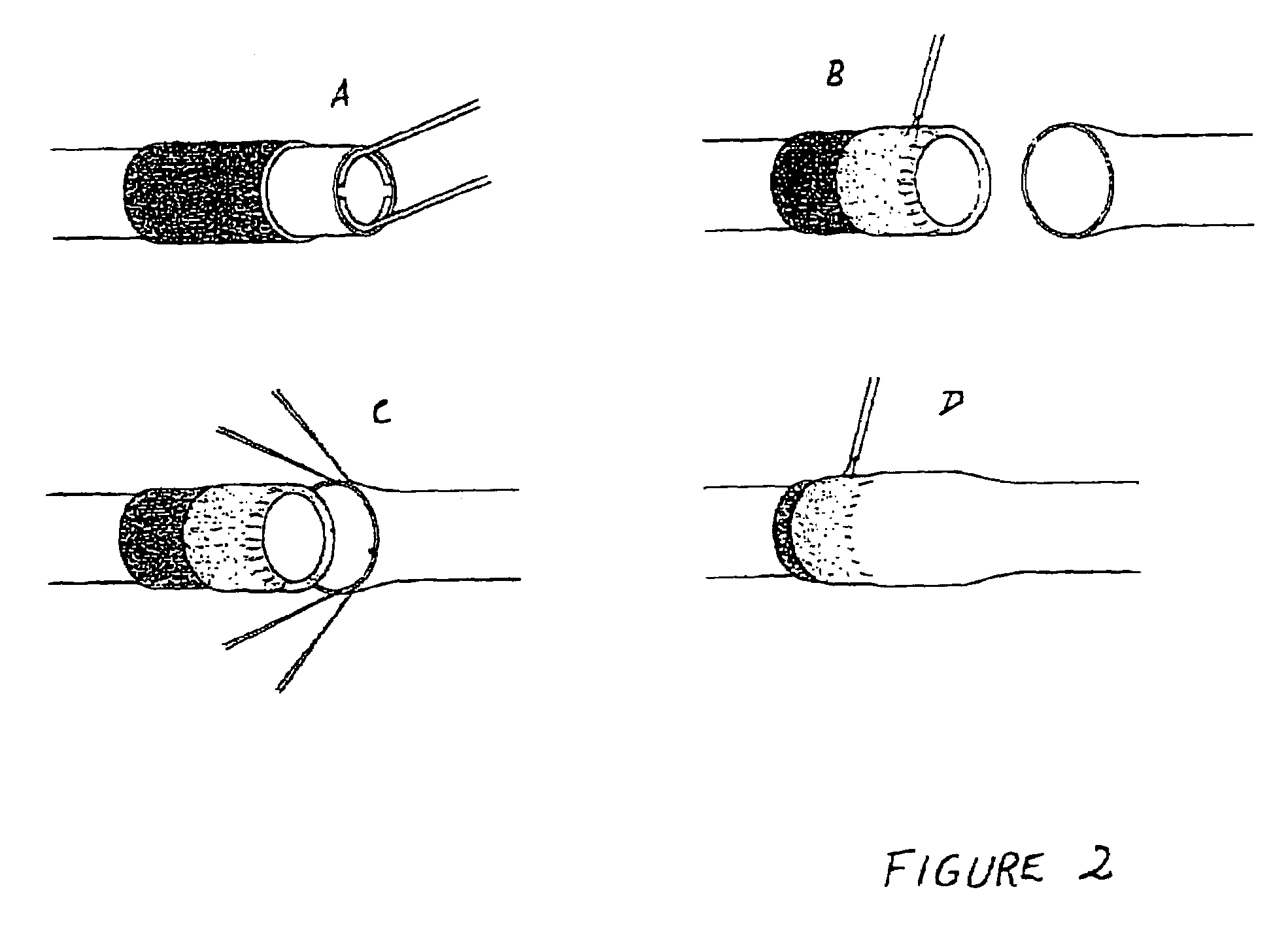

Method of tissue repair II

InactiveUS7078378B1Reduce solubilitySufficient longevityBiocideSurgical adhesivesTissue repairBiomedical engineering

A substantially solid biomolecular solder for joining tissue comprising a partially denatured biomolecule. The solder can be formed into shapes to suit the needs of a user. The invention also relates to methods for joining tissue and methods for preparing the solder.

Owner:MACQUARIE UNIV +1

Enhancement of industrial enzymes

InactiveUS6274178B1Improve usabilityImproved animal fodderAnimal feeding stuffAccessory food factorsIndustrial enzymesMicrowave irradiation

A method for enhancing or increasing the metabolisable dietary content of a plant-based animal feed, the method comprising reacting the feed with an enzyme capable of releasing a metabolisable dietary component from the feed under the influence of microwave irradiation such that the metabolisable dietary content of the feed is enhanced or increased.

Owner:CELLENCOR INC

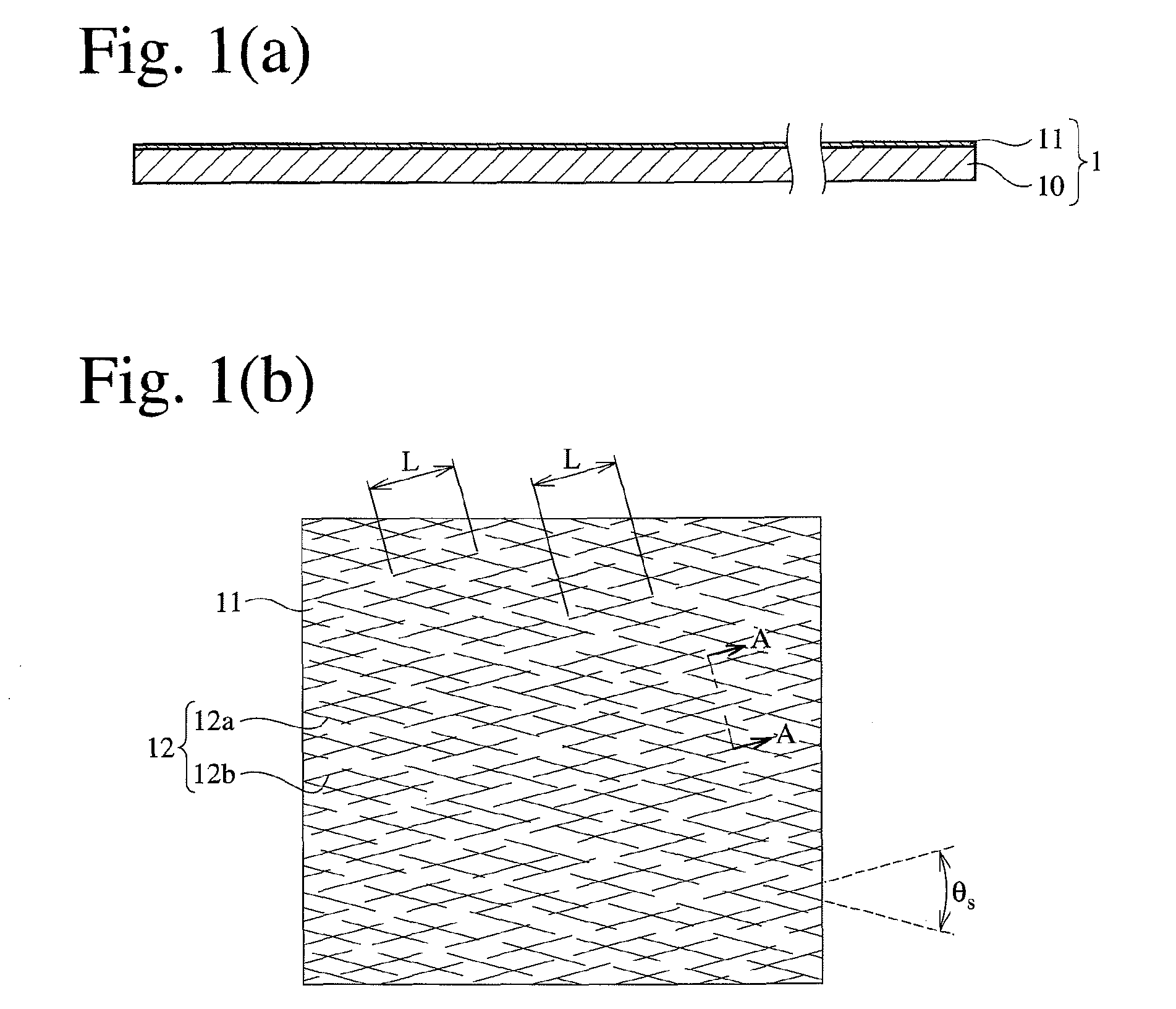

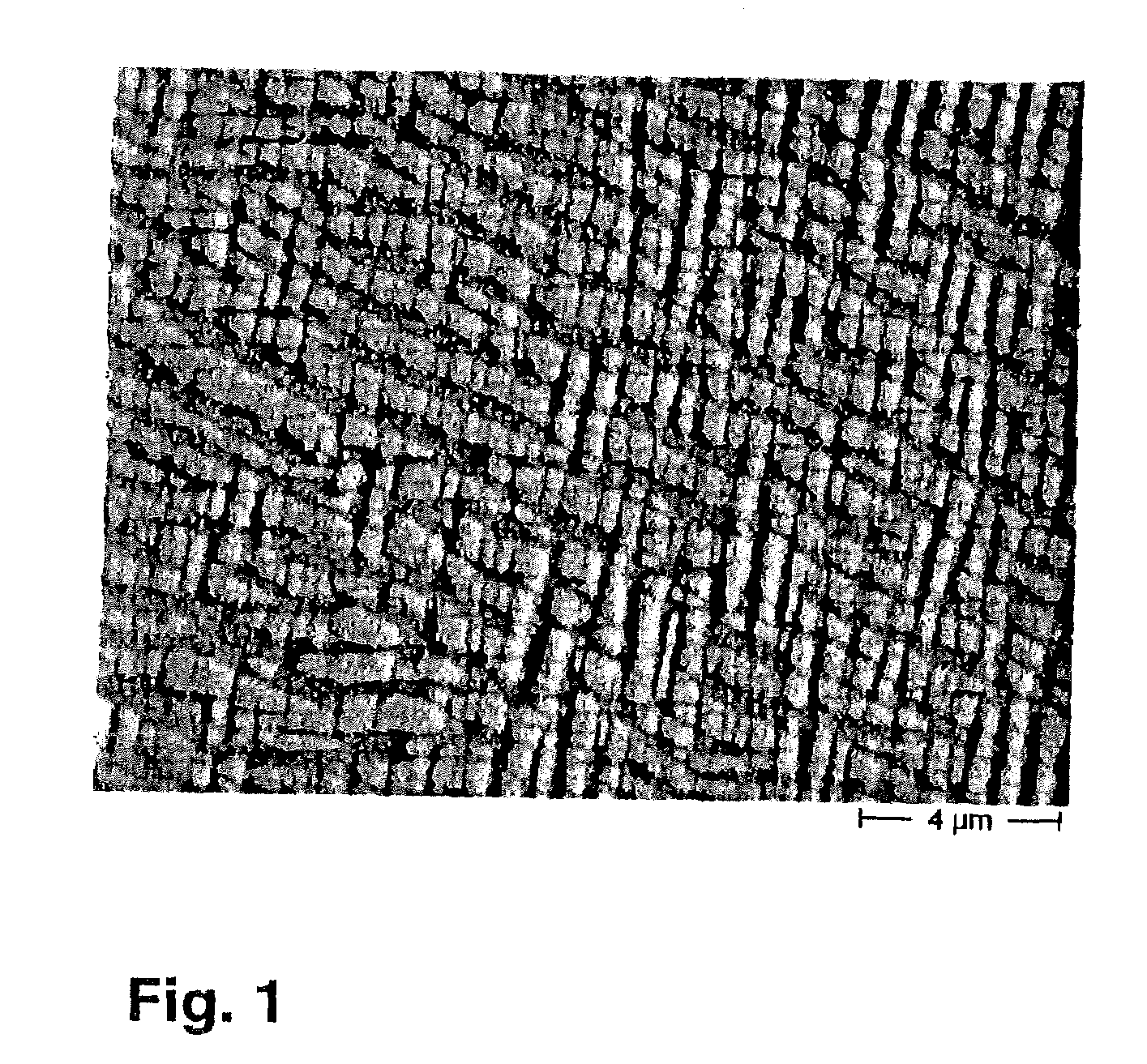

Composite film of linearly-scratched, thin metal film and plastic film, and its production apparatus

ActiveUS20110008580A1Promote absorptionReduce anisotropyMagnetic/electric field screeningSynthetic resin layered productsElectromagnetic wave absorberThin metal

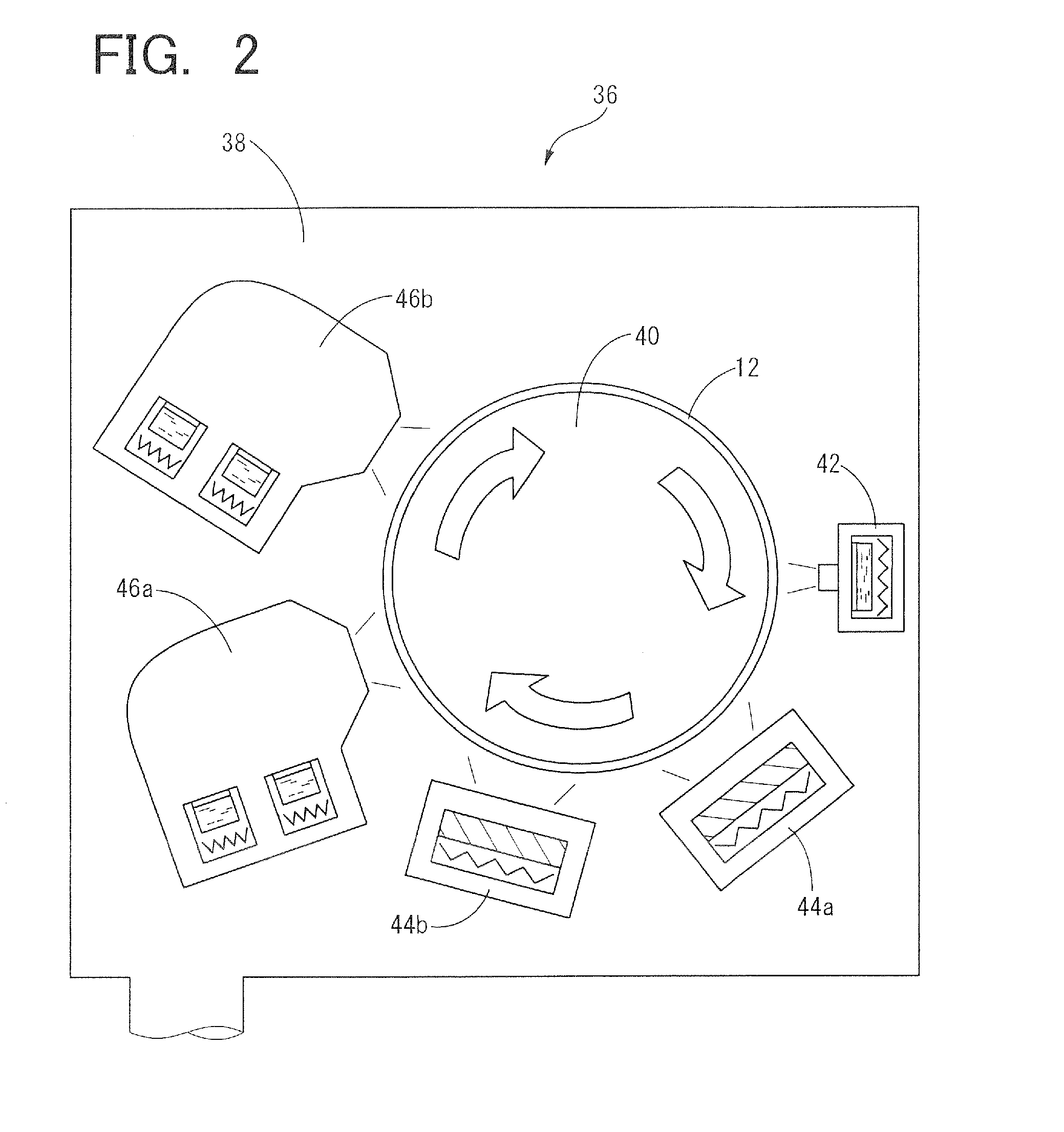

The present invention provides a composite film having a linearly-scratched, thin metal film and a plastic film, which has good absorbability to electromagnetic waves in various frequencies, as well as reduced anisotropy in electromagnetic wave absorbability, suitable for electromagnetic wave absorbers, and its production apparatus. The composite film having a linearly-scratched, thin metal film and a plastic film according to the present invention comprises a plastic film, and a single-or multi-layer, thin metal film formed on at least one surface of the plastic film, the thin metal film being provided with large numbers of substantially parallel, intermittent, linear scratches with irregular widths and intervals in plural directions. Its production apparatus comprises pluralities of pattern rolls each having large numbers of fine, high-hardness particles on the surface, which are arranged to form linear scratches on the thin metal film side of a thin metal film-plastic composite film, and means each pressing the pattern roll to the composite film, and pluralities of the pattern rolls being oriented in different directions in a plane in which they are in sliding contact with the thin metal film of the composite film.

Owner:KAGAWA SEIJI

Film capacitor element, film capacitor, and method of producing the film capacitor element

InactiveUS20130314839A1Improve adhesionWidth minimizedThin/thick film capacitorStacked capacitorsVapor deposition polymerizationThin membrane

A film capacitor element including a base dielectric film layer 12, a vapor-deposition metal film layer 14 formed on the base dielectric film layer 12 and consisting of a first film portion 20 and a second film portion 22 that are spaced apart from each other by a margin portion 18, and a dielectric covering film layer 16 which is formed integrally on the second film portion 22 by vapor-deposition polymerization or coating and which has a covering portion 30 which fills the margin portion 18 and covers an entire area of an end face of the second film portion 22 on the side of the margin portion 18. The first film portion 20 including a non-covered portion 34 which is not covered by the dielectric covering film layer 16.

Owner:KOJIMA PRESS IND CO LTD

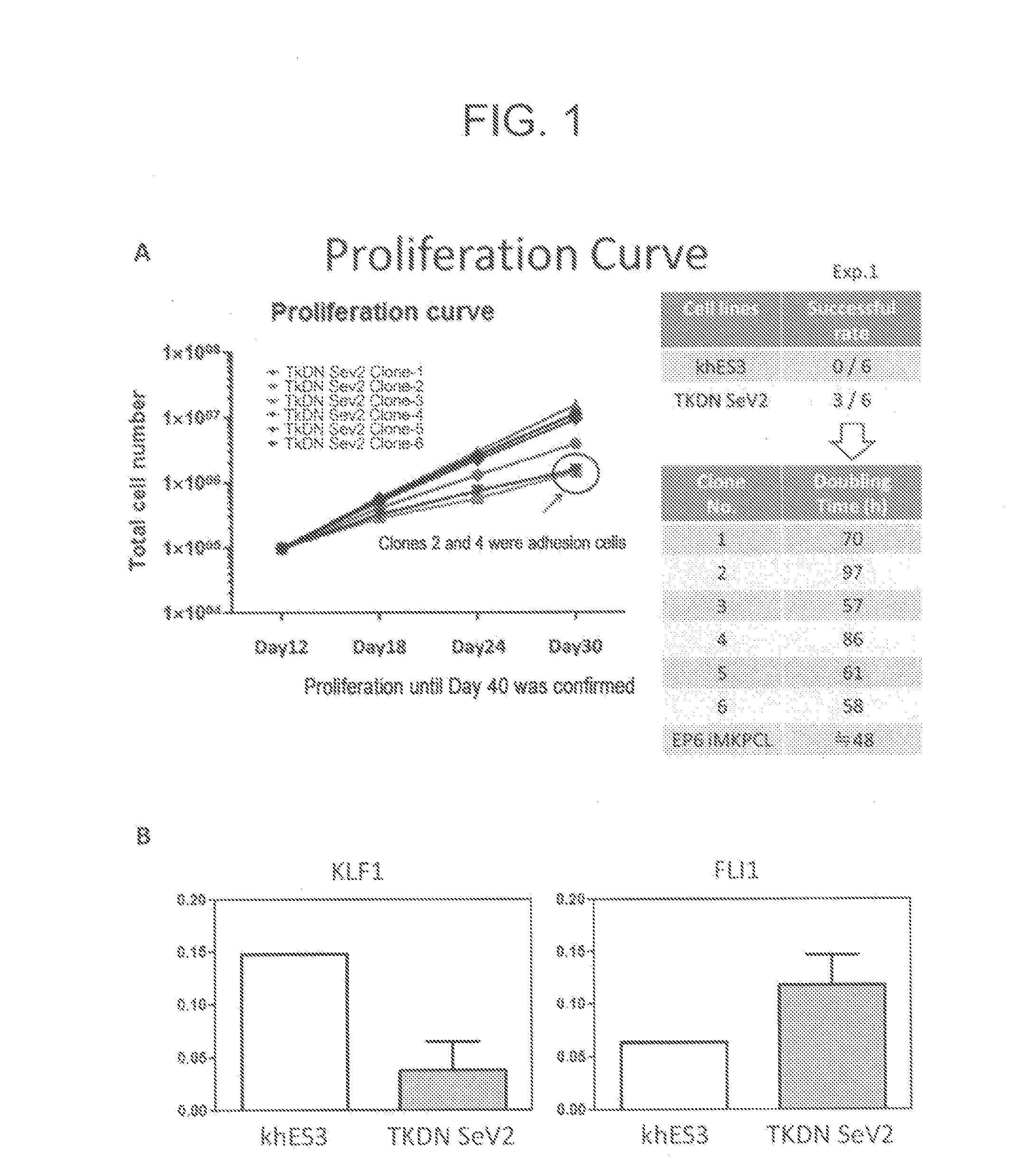

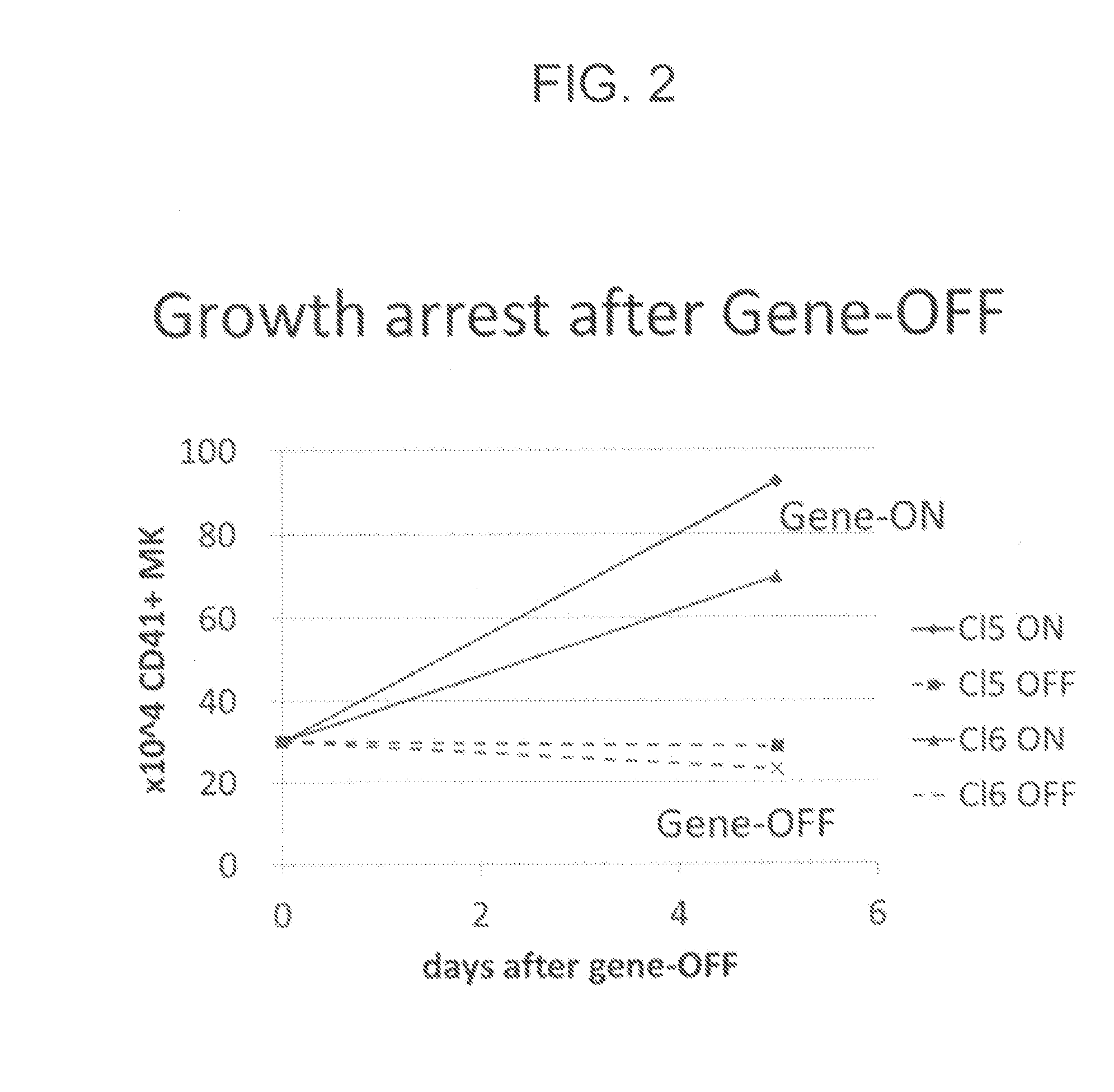

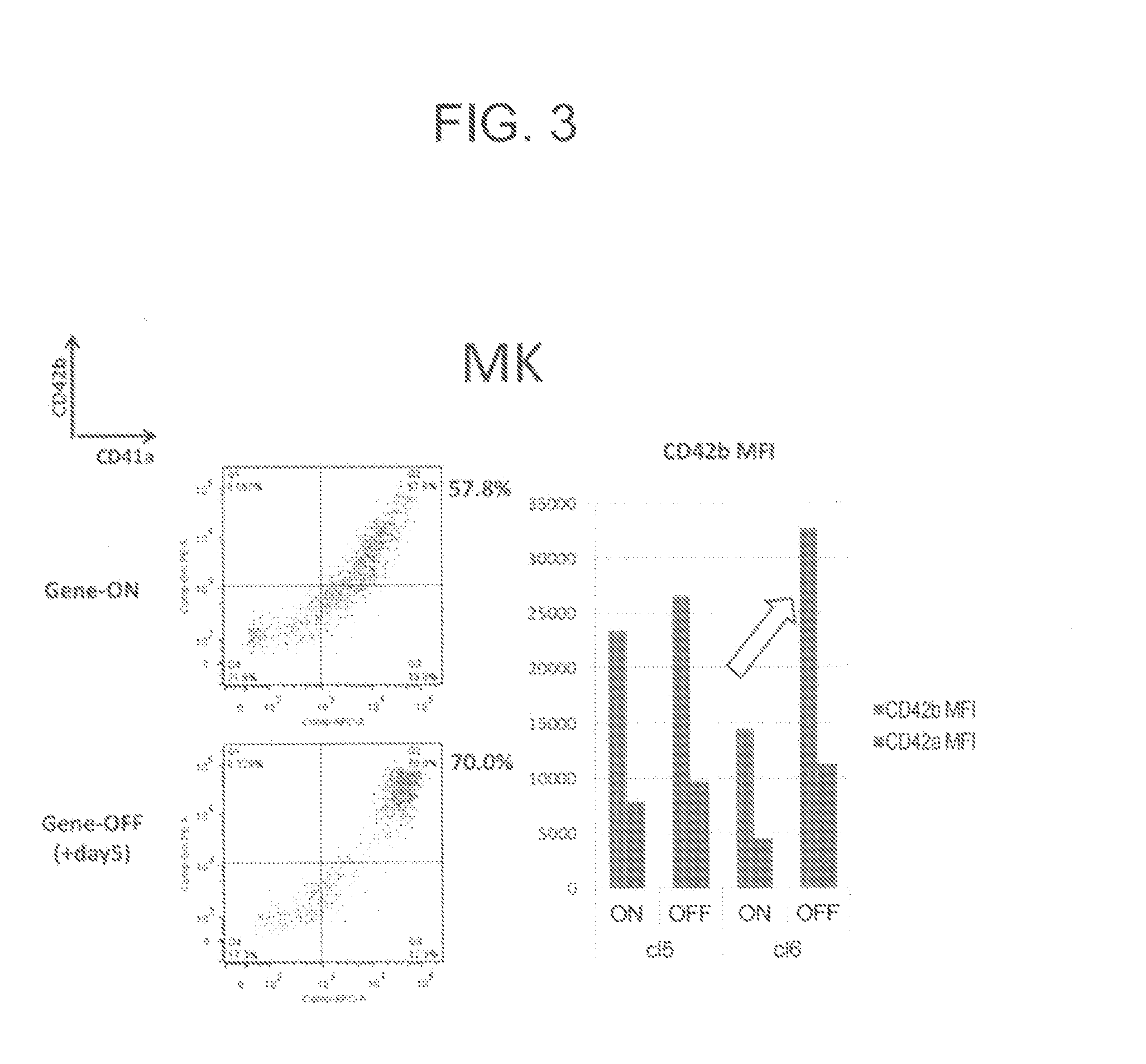

Production methods for megakaryocytes and platelets

InactiveUS20160002599A1Suitably producedMammal material medical ingredientsSkeletal/connective tissue cellsApoptosisPlatelet

An object of the present invention is to provide a method of efficiently producing a maturated megakaryocytic cell line from hematopoietic progenitor cells. The present invention provides a method for producing megakaryocytes from hematopoietic progenitor cells, comprising(i) forcibly expressing an apoptosis suppression gene and an oncogene in hematopoietic progenitor cells and culturing the cells, and(ii) arresting forced expression of the apoptosis suppression gene and the oncogene and culturing the hematopoietic progenitor cells.

Owner:KYOTO UNIV

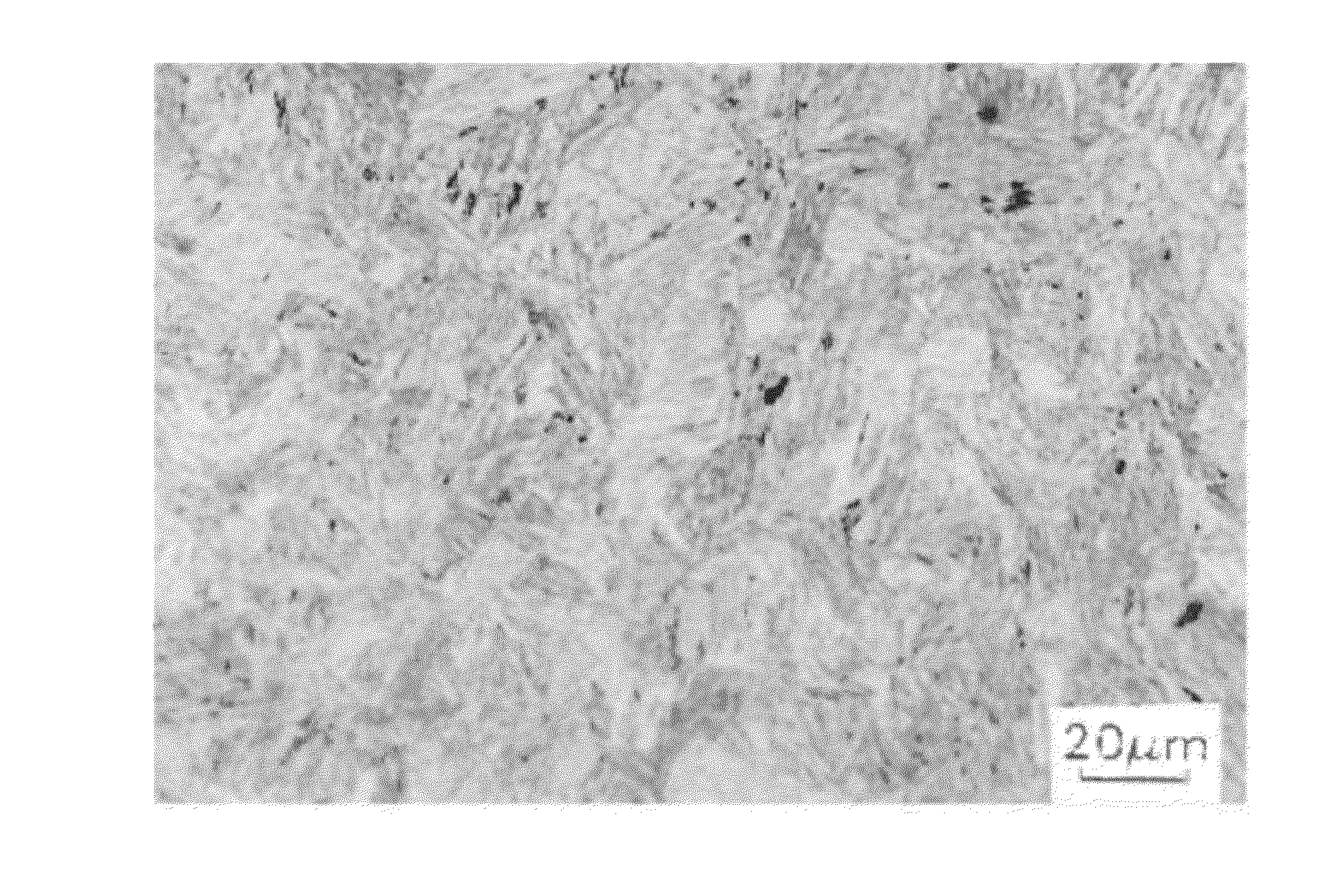

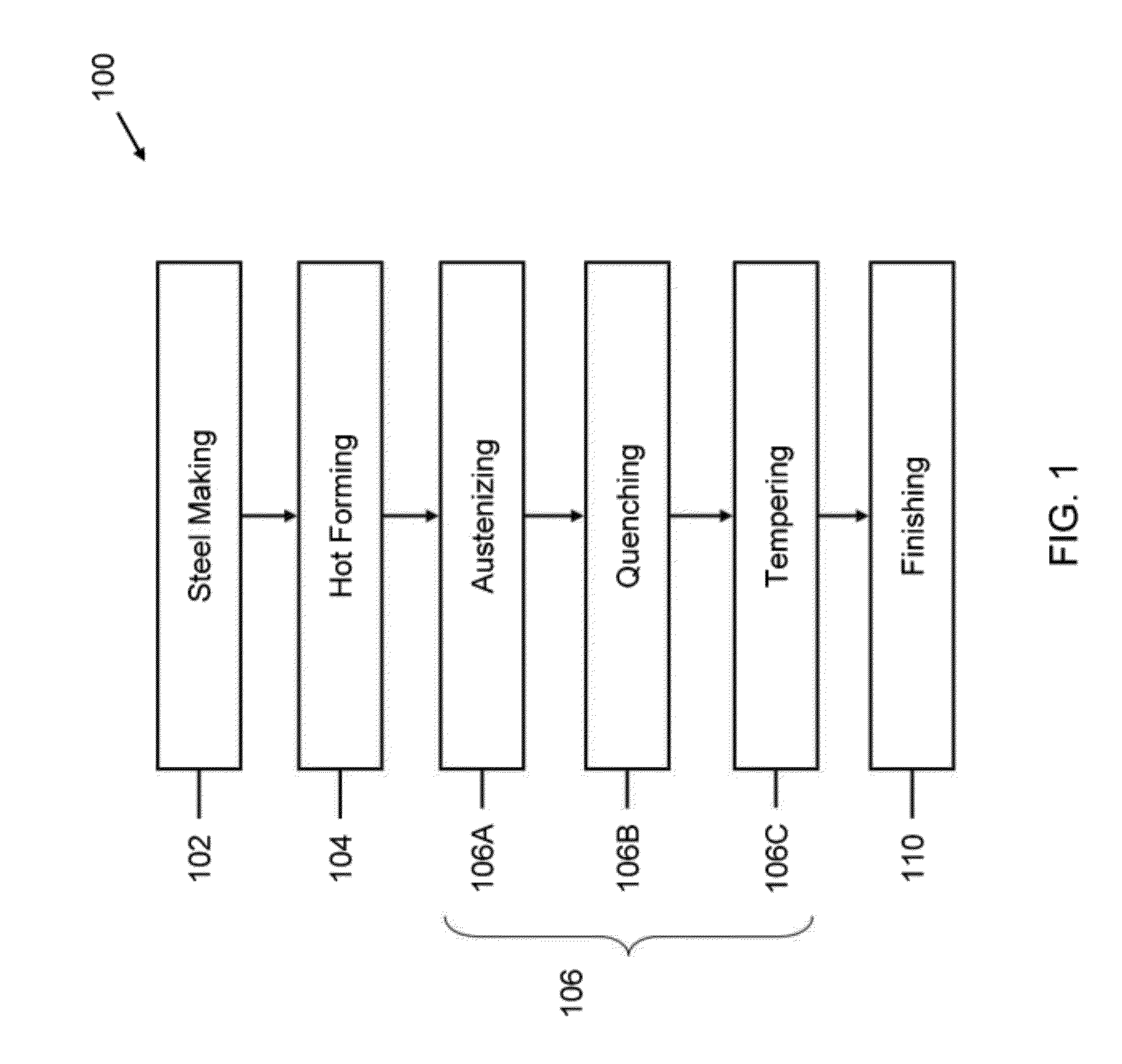

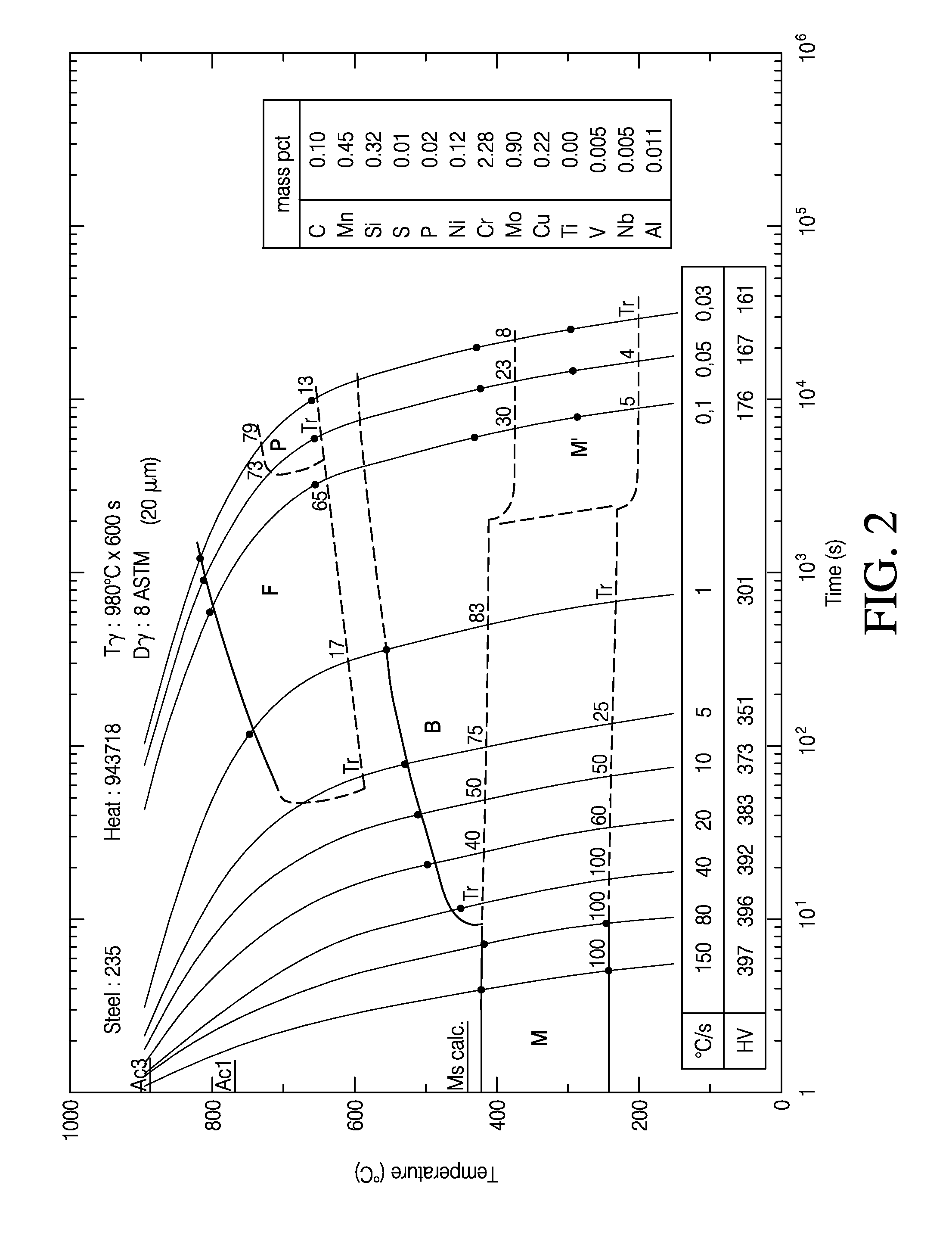

High strength steel pipes with excellent toughness at low temperature and sulfide stress corrosion cracking resistance

ActiveUS20120199255A1Improve low temperature toughnessImprove corrosion resistanceFurnace typesHeat treatment furnacesAustenite grainStress corrosion cracking

Low-alloy steels and methods of manufacturing pipes having a wall thickness greater than or equal to about 8 mm and less than or equal to about 35 mm therefrom are provided. In one embodiment, a steel composition is processed that yields an average prior austenite grain size greater than about 15 or 20 μm and smaller than about 100 μm. A quenching sequence has been determined that yields a microstructure of greater than or equal to about 60% martensite by volume, and less than or equal to about 40% by volume lower bainite, without substantial formation of ferrite, upper bainite, or granular bainite. The yield strength of the quenched and tempered pipes may be greater than about 70 ksi, 80 ksi, or 90 ksi. The quenched and tempered pipes are suitable for 70 ksi, 80 ksi, and 90 ksi grades and resistant to sulfide stress corrosion cracking.

Owner:DALMINE SPA

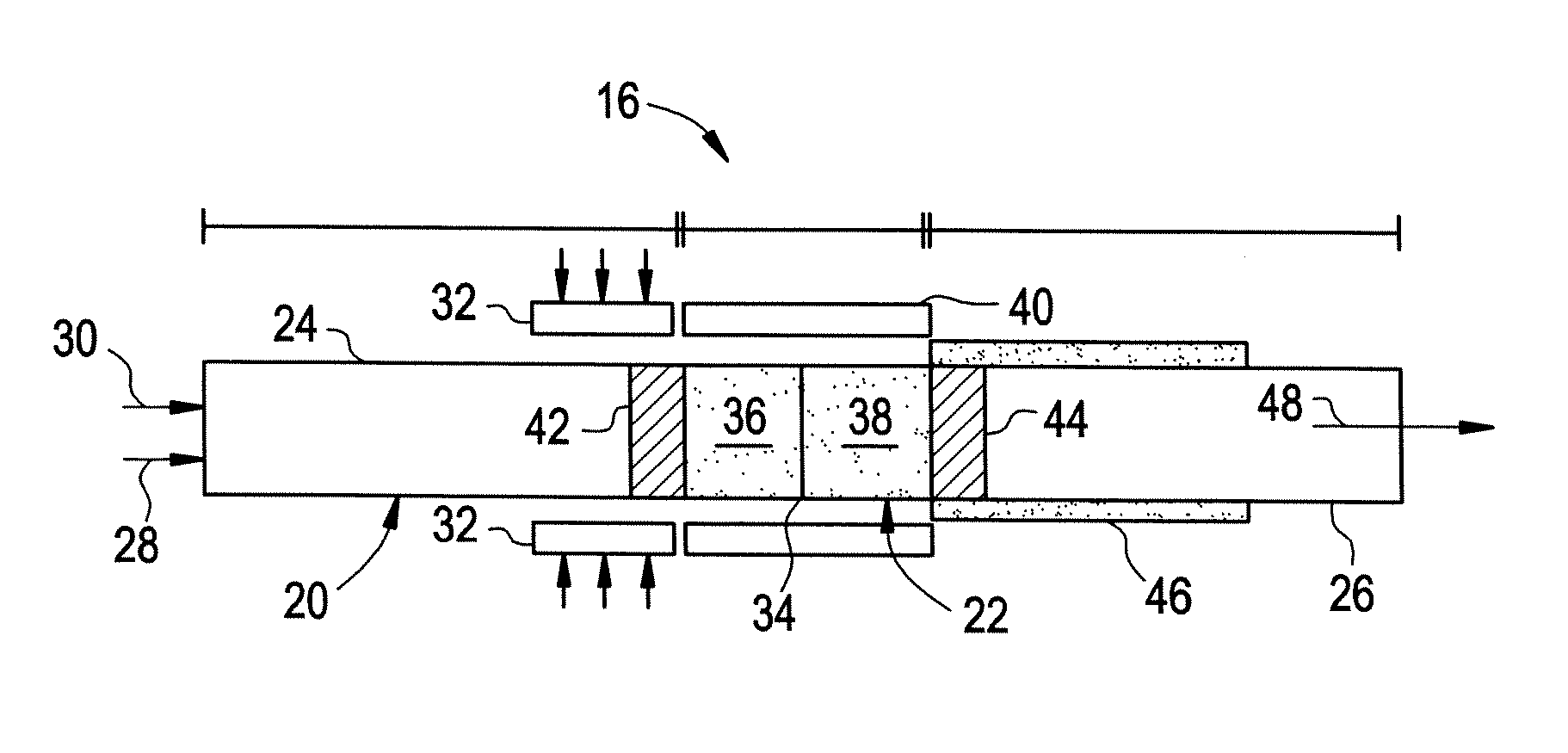

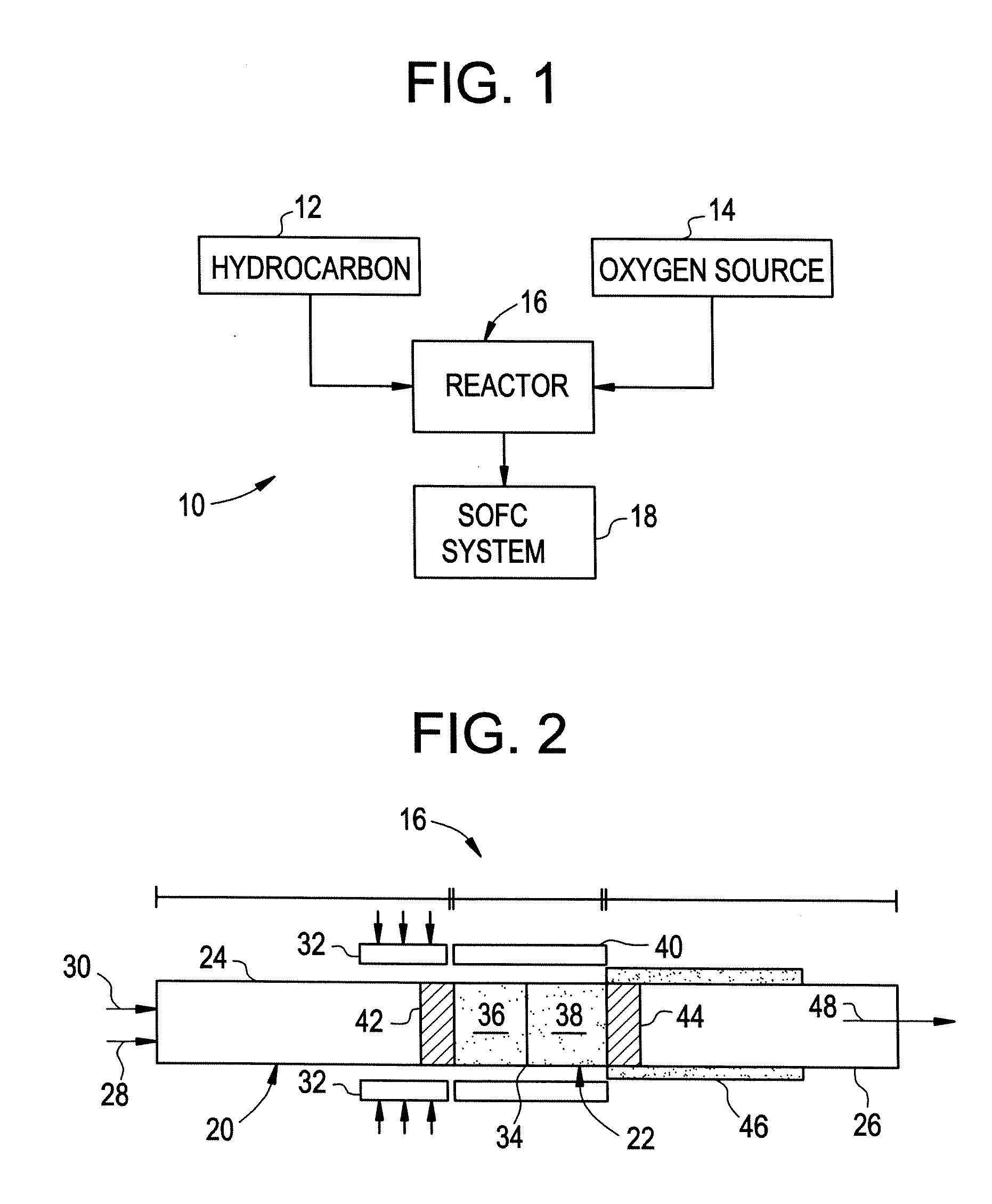

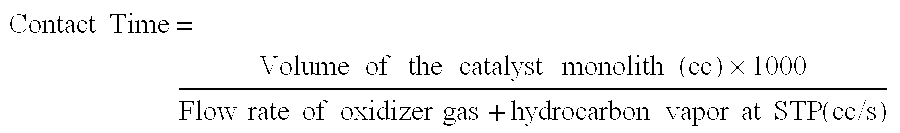

Thermally Managed Catalytic Partial Oxidation Of Hydrocarbon Fuels To Form Syngas For Use In Fuel Cells

InactiveUS20050089465A1Improve throughputHigh yieldCatalytic gas-gas reactionHydrogen productionSyngasPartial oxidation

Method and equipment for converting hydrocarbon fuel to a mixture of hydrogen and carbon monoxide through catalytic partial oxidation. Thermal management of the process in the pre-reaction and post reaction zones of the reactor enhance yields and reduces carbon deposition.

Owner:GENERAL ELECTRIC CO

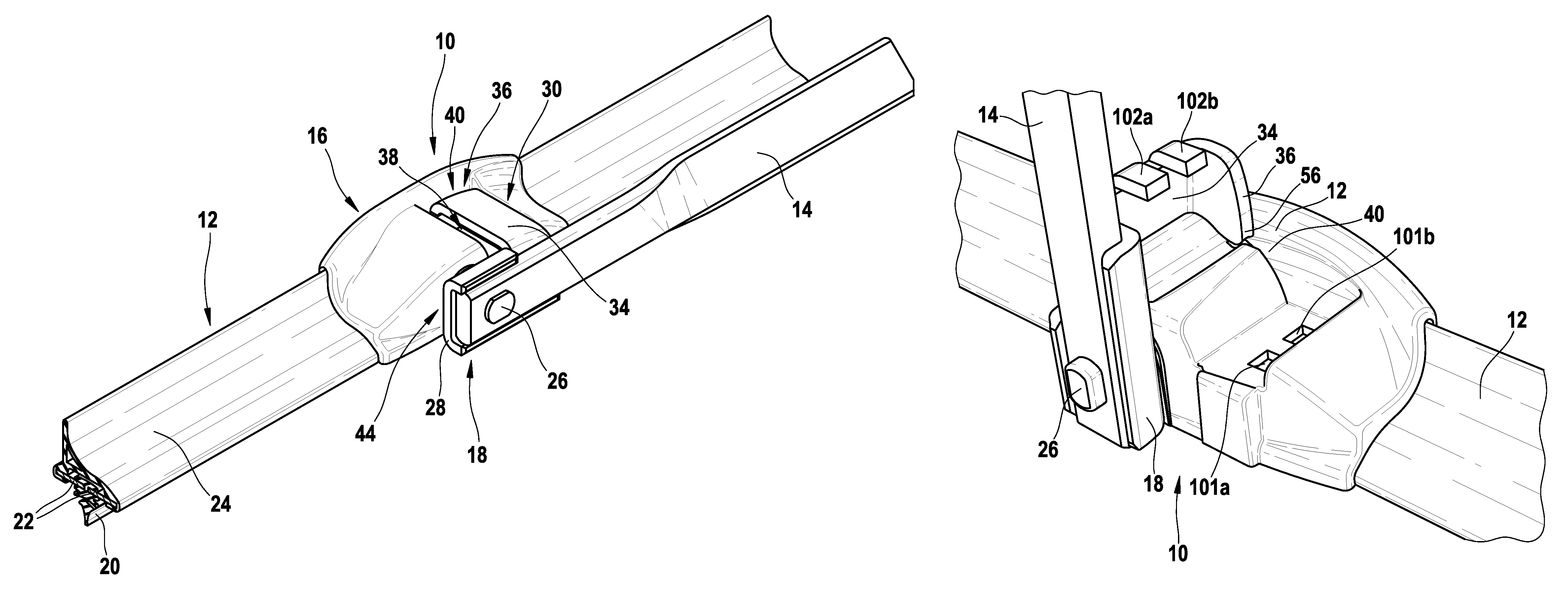

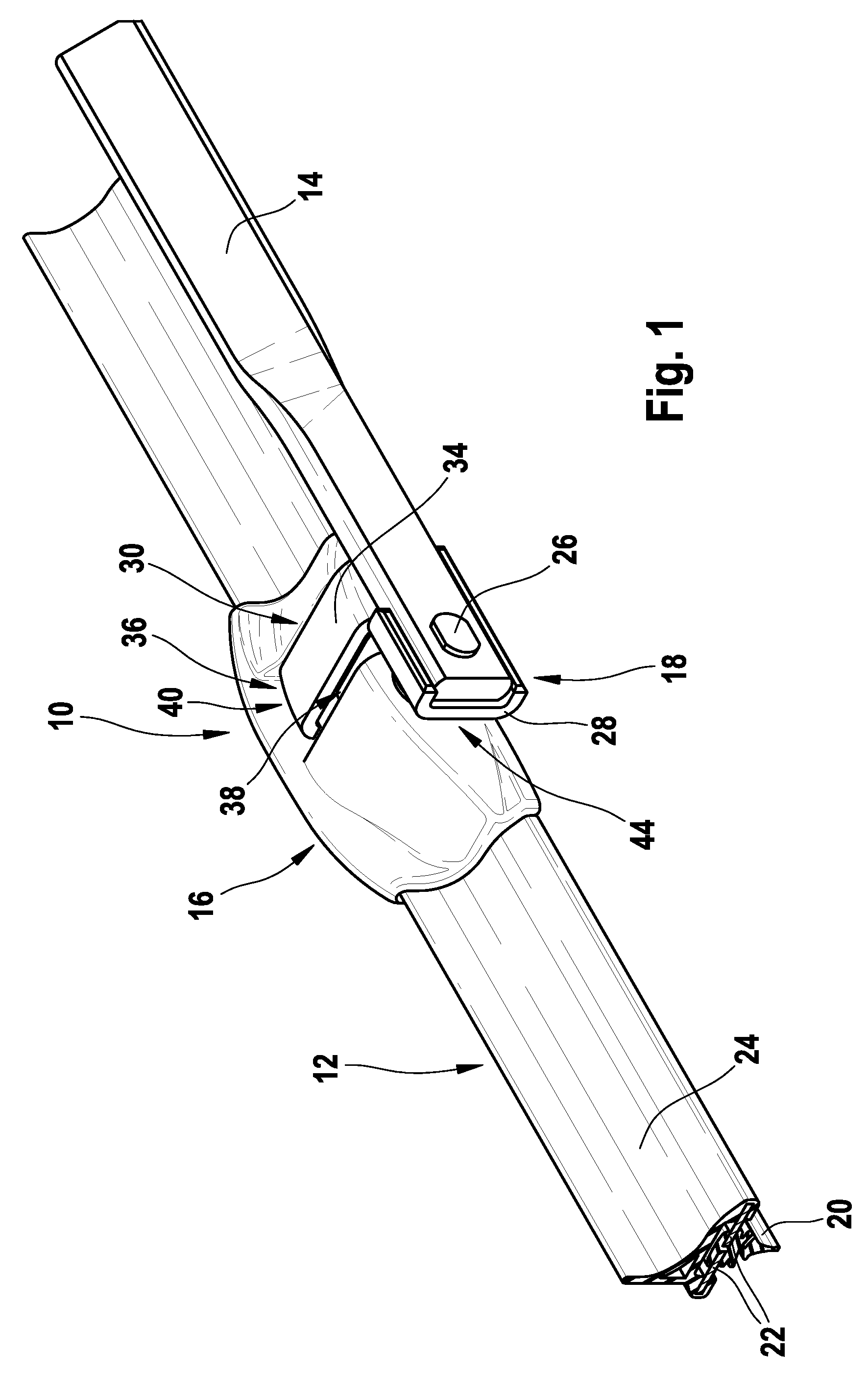

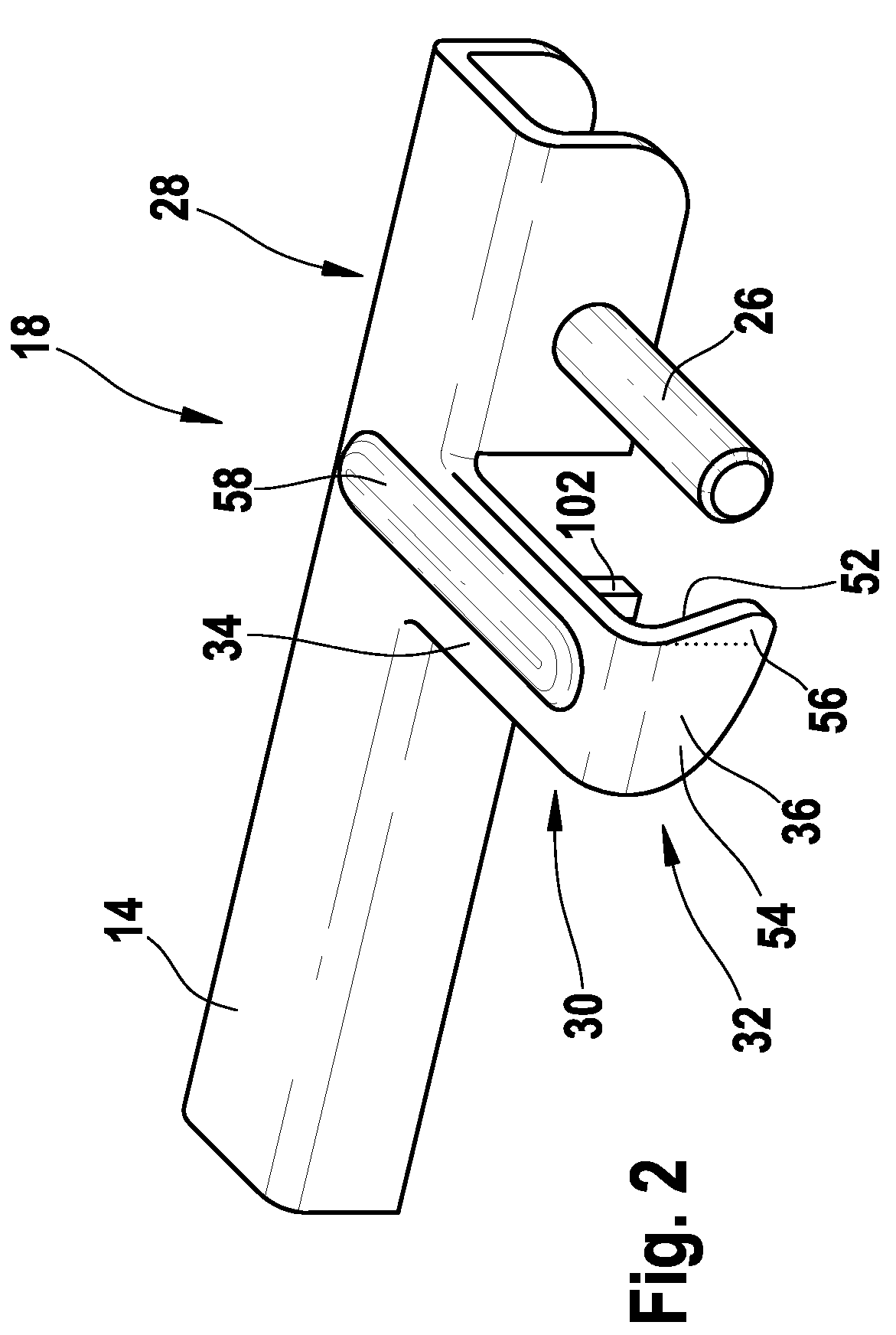

Connection apparatus for a wiping arm

InactiveUS8196255B2Secure retentionEasy to operateWindow cleanersVehicle cleaningEngineeringIdentification device

The invention relates to a connection apparatus (10) for a wiper arm (14) and a wiper blade (12). The connection apparatus comprises a first and a second connection part. According to the invention, provision is made for the first connection part to have a first identification means and for the second connection part to have a second identification means which corresponds to the first identification means. The invention also comprises a system with two flat-bar wiper blades, with at least one first identification means being provided on at least one flat-bar wiper blade in order to distinguish between the two wiper blades.

Owner:ROBERT BOSCH GMBH

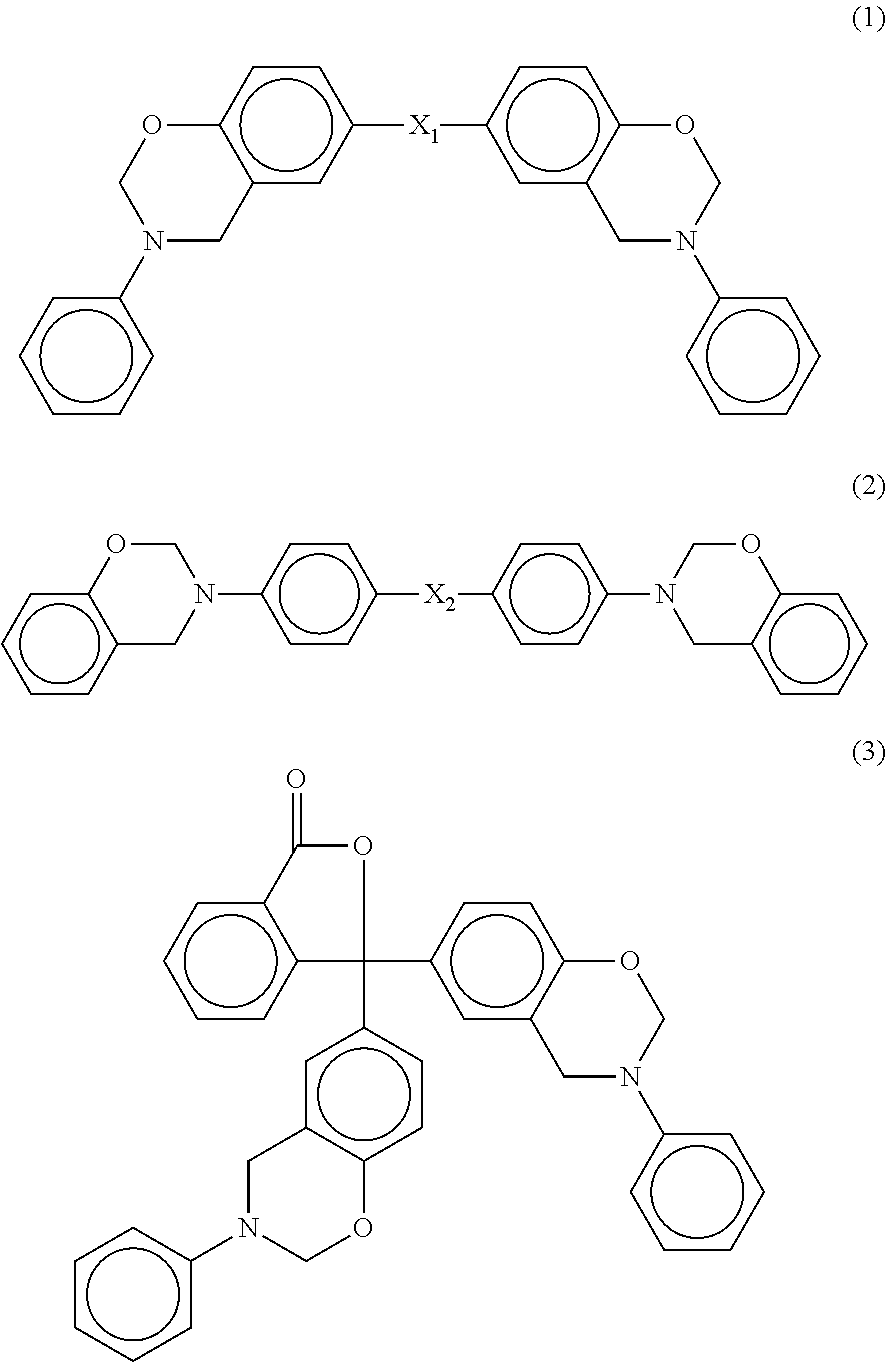

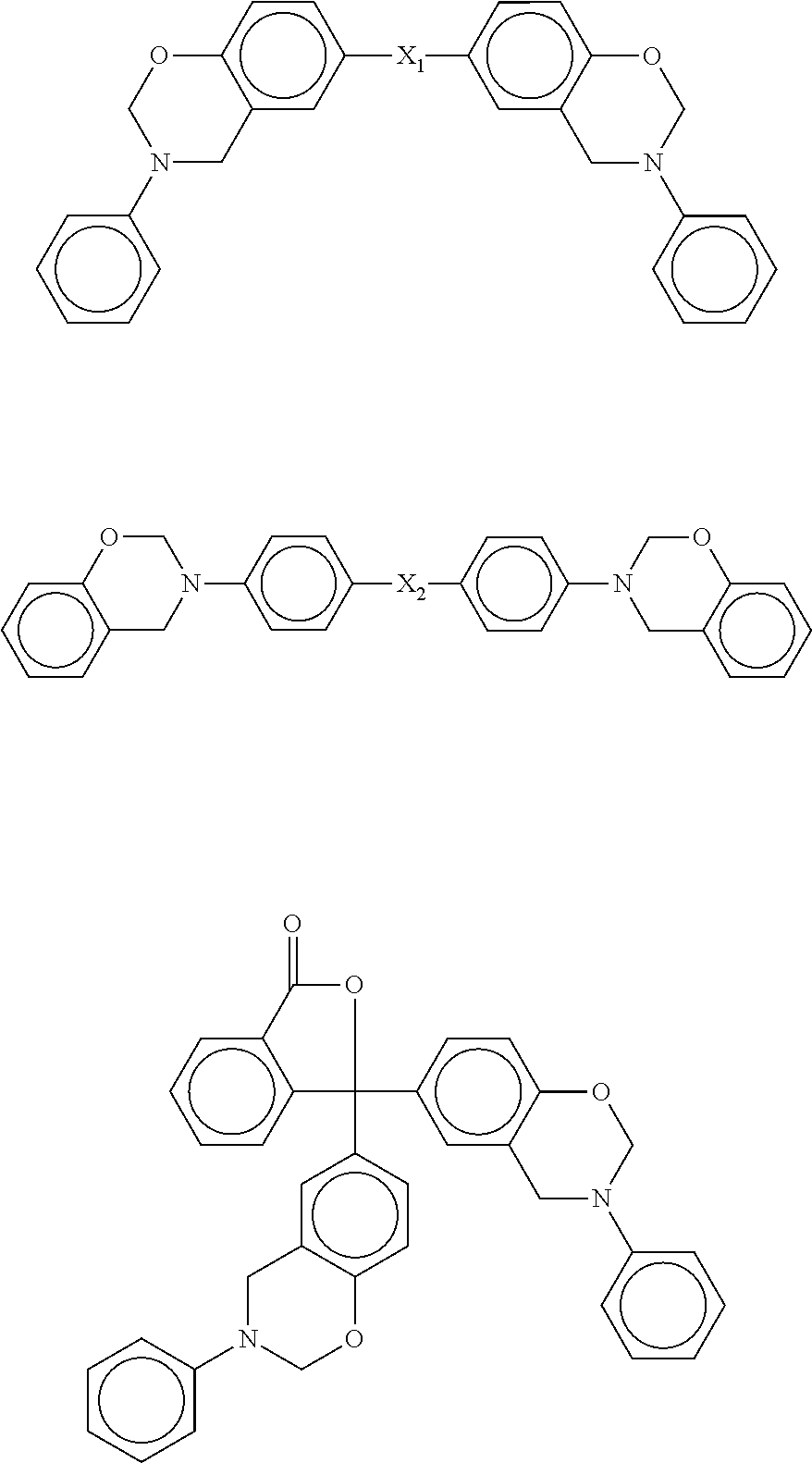

Halogen-free resin composition, copper clad laminate using the same, and printed circuit board using the same

ActiveUS20140023839A1Low dielectric constantImprove flame retardant performanceGroup 5/15 element organic compoundsSynthetic resin layered productsEpoxyLow dissipation

A halogen-free resin composition includes (A) 100 parts by weight of epoxy resin; (B) 10 to 100 parts by weight of benzoxazine resin; (C) 5 to 50 parts by weight of diallylbisphenol A resin; and (D) 0.05 to 20 parts by weight of an amine curing agent. The halogen-free resin composition includes specific ingredients and proportions thereof to attain low dielectric constant (Dk), low dissipation factor (Df), high heat resistance, and high flame retardation. The halogen-free resin composition is suitable for producing a prepreg or a resin film and thus applicable to copper clad laminates and printed circuit boards.

Owner:ELITE ELECTRONICS MATERIAL KUNSHAN

Biaxially oriented polyester film having more than one layer; its use; and process for its production

InactiveUS6376042B1Improve applicabilitySuitable for industrial useRecord information storageCeramic layered productsPolyesterOxygen barrier

The invention relates to a biaxially oriented polyester film having at least two layers and which, together with good processing performance, after it has been metalized or has been coated with oxidic materials, is a very good gas or oxygen barrier, and which has been built up from at least one base layer and at least one outer layer applied to this base layer, where the film has a planar orientation DELTAp of greater than 0.165.

Owner:MITSUBISHI POLYESTER FILM

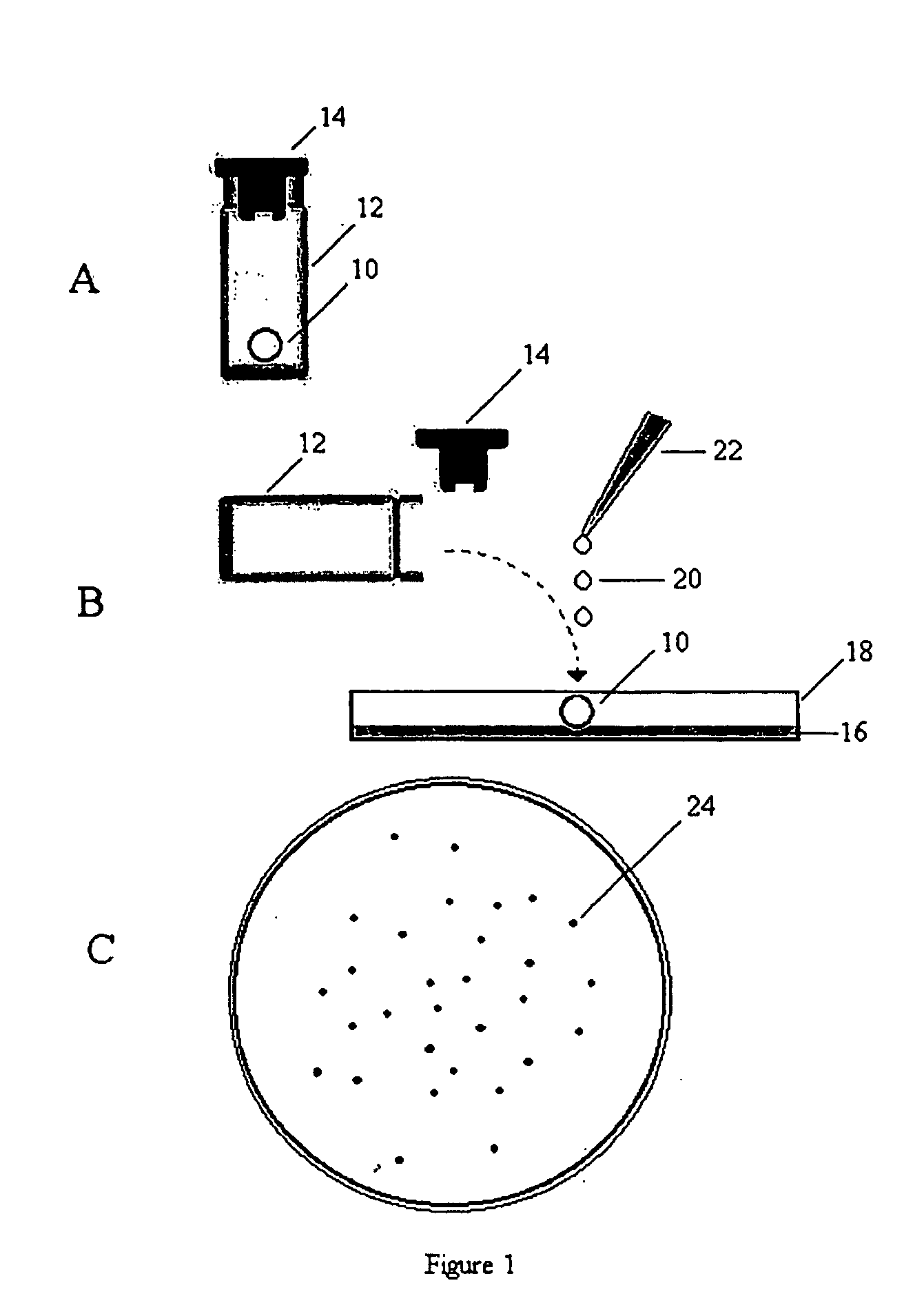

Products containing quantum of bioparticles and method for production thereof

InactiveUS20050032192A1Allocation is accurateSuitably producedBacteriaUnicellular algaeQuantumFood science

A method for forming a substantially solid product containing a desired quantum of bioparticle, the method comprising (a) providing a sample of bioparticle in liquid form; (b) selecting a desired quantum of the bioparticle; and (c) forming a substantially solid product containing the desired quantum of the bioparticle, wherein the product is capable of being transferred between containers in its solid form without loss of bioparticle, and wherein the product is capable of releasing the bioparticle in a liquid.

Owner:BTF

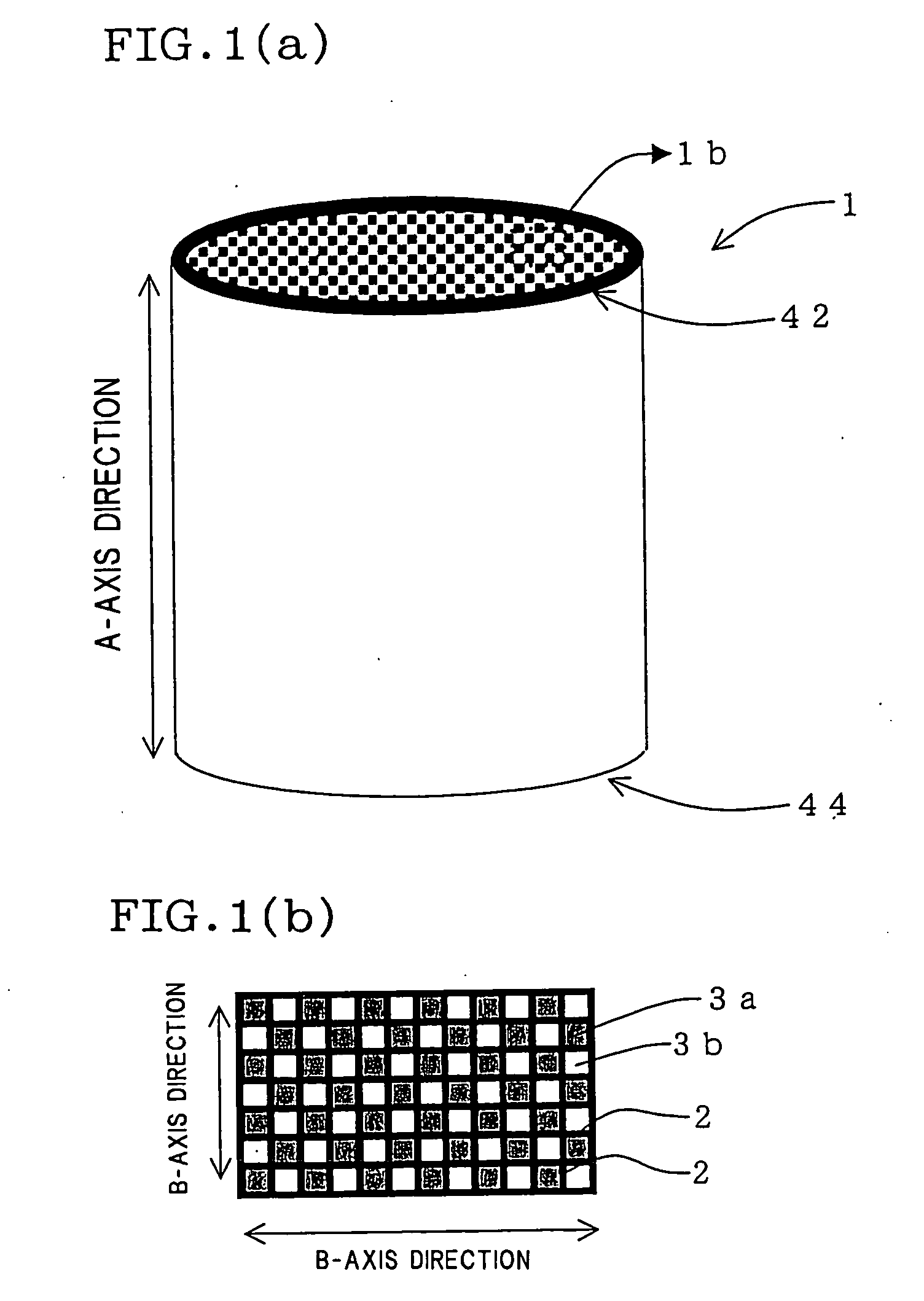

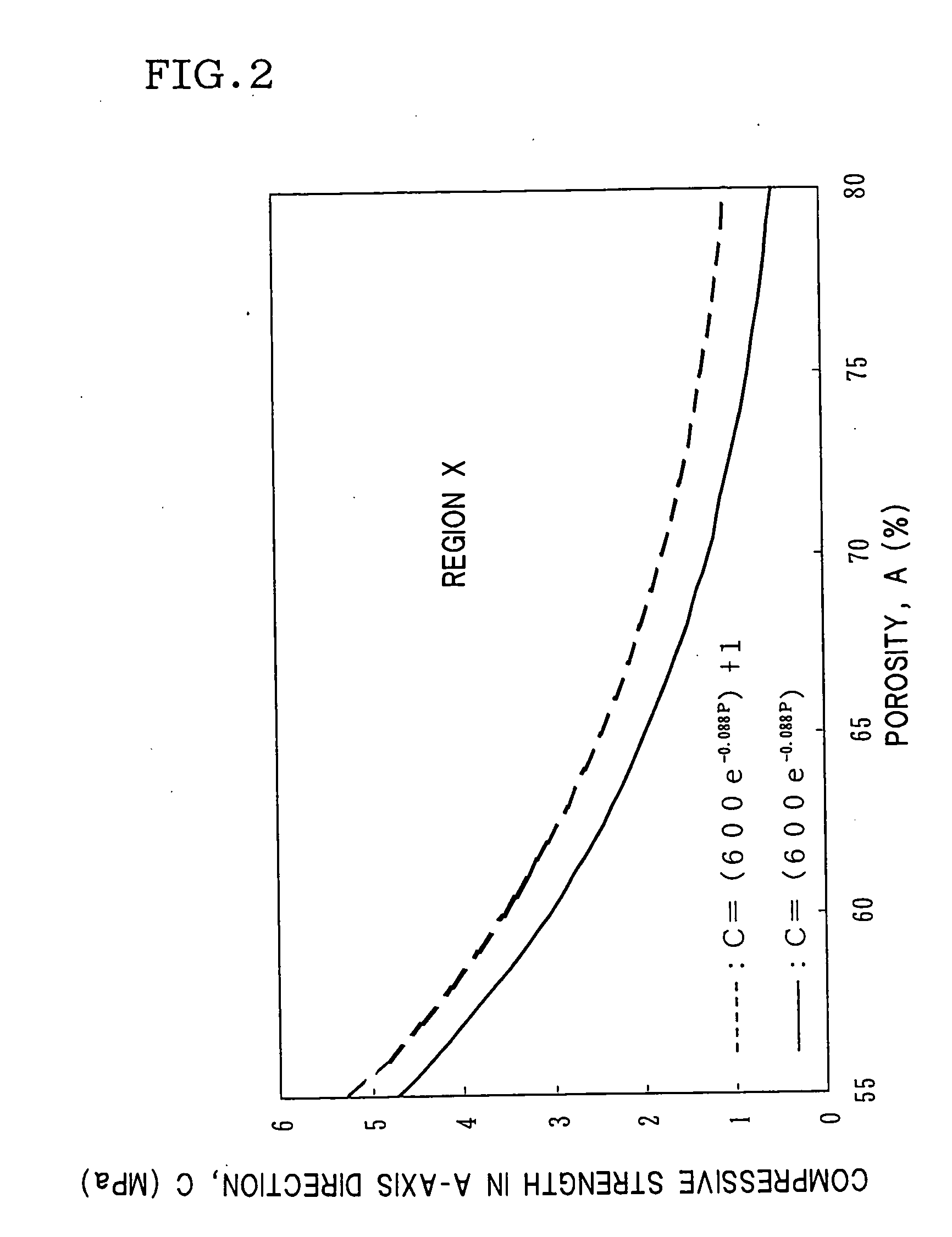

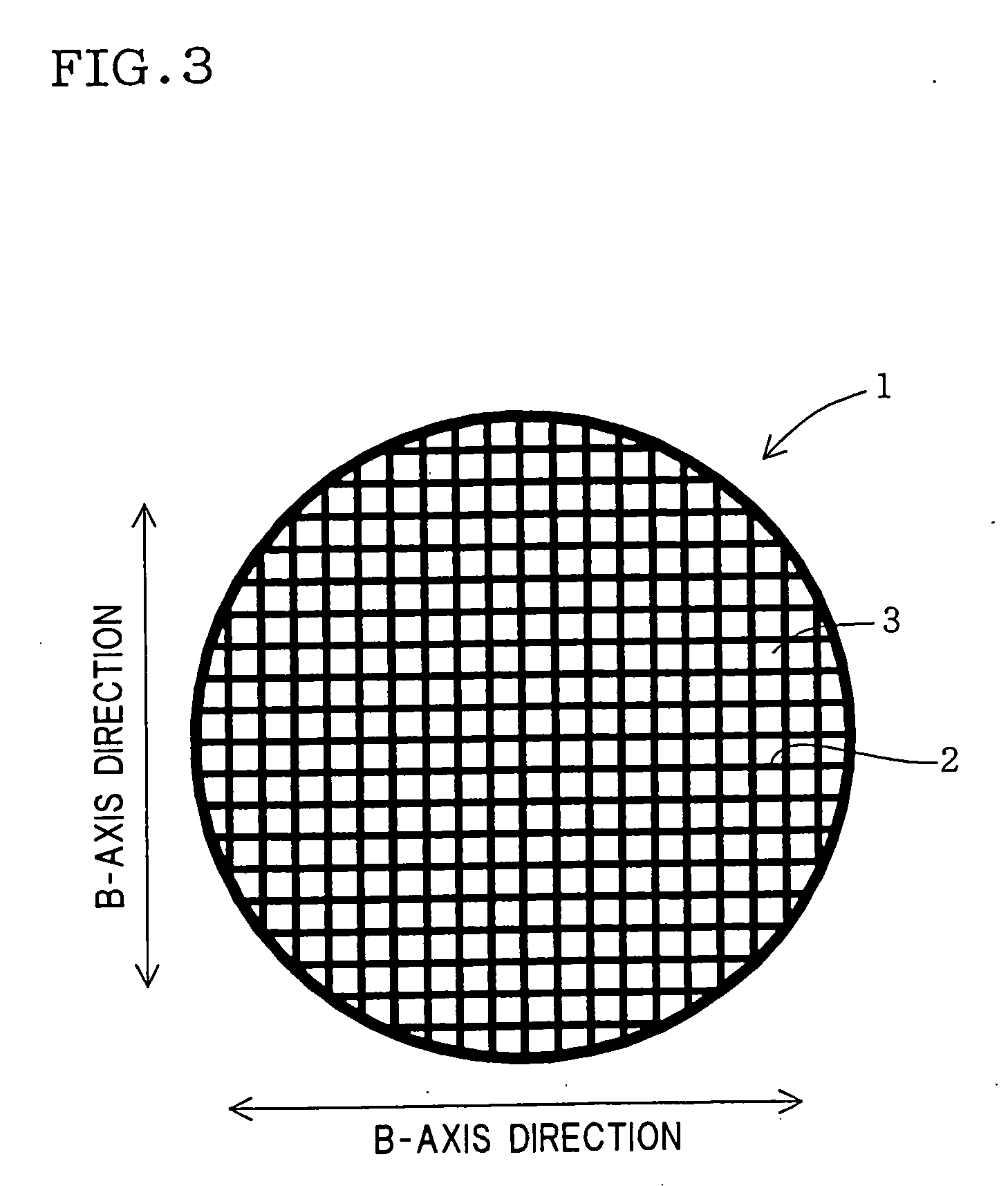

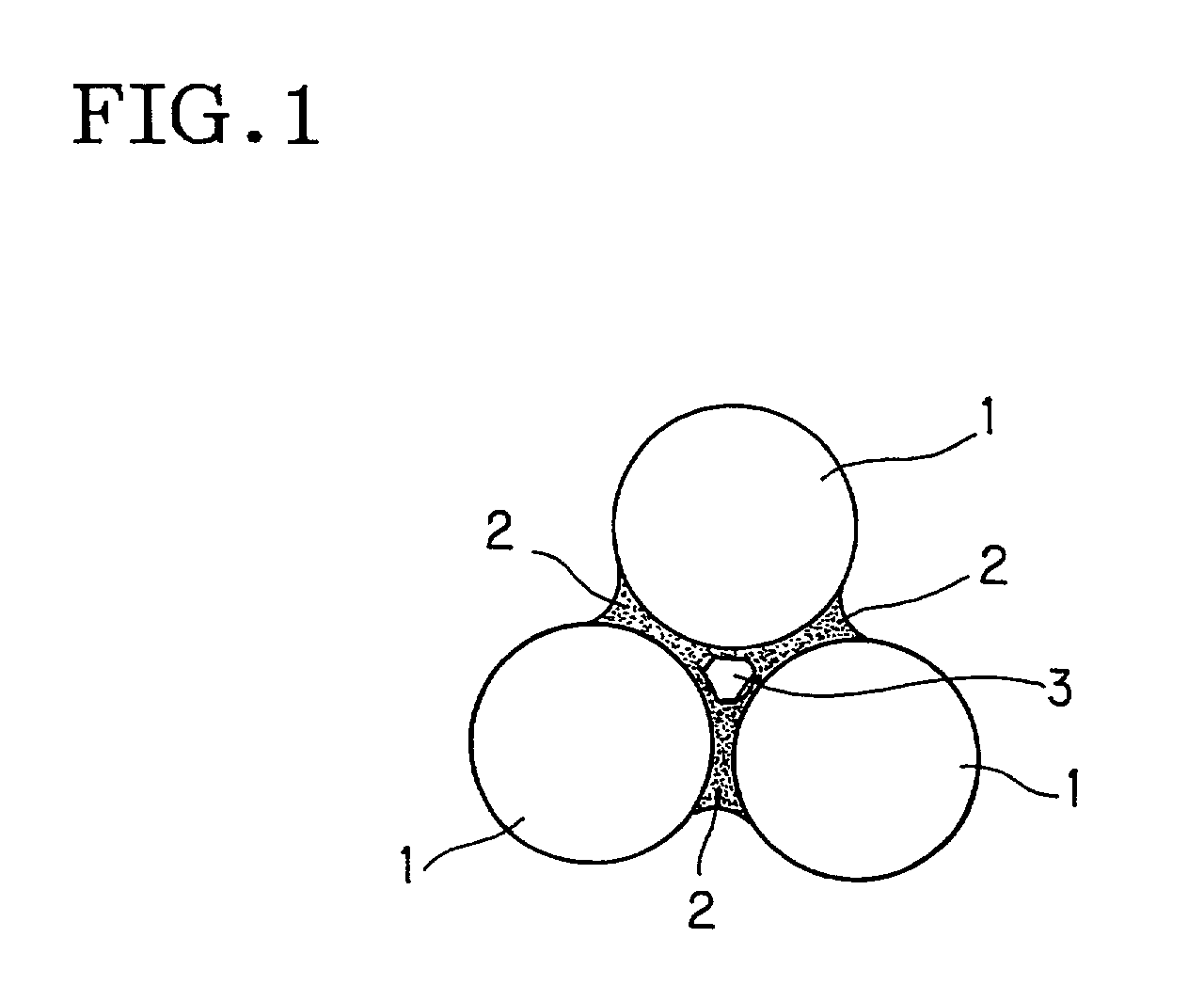

Honeycomb structure

ActiveUS20060193756A1Suitably producedCombination devicesAuxillary pretreatmentPorosityCompressive strength

There is provided a honeycomb structure 1 including porous partition walls 2 disposed so as to form a plurality of through holes 3a, 3b extending from one end portion to the other end portion in A-axis direction, and containing cordierite as a main component. When porosity is P (%), compressive strength in the A-axis direction is C(MPa), and open frontal area is A (%); a relation of C≧(600e−0.0014AP)+0.5 is satisfied. The honeycomb structure has small pressure loss, is hardly damaged, and has excellent trapping efficiency.

Owner:NGK INSULATORS LTD

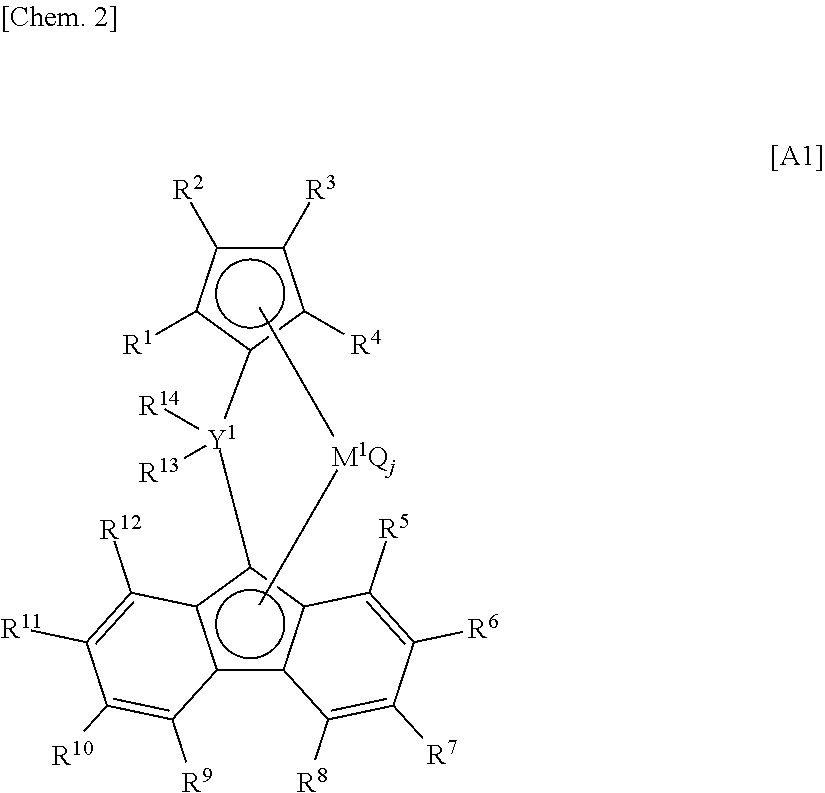

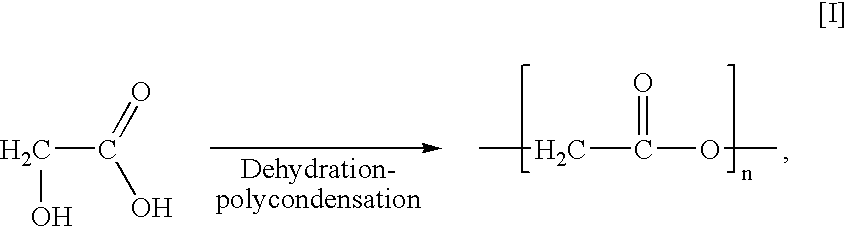

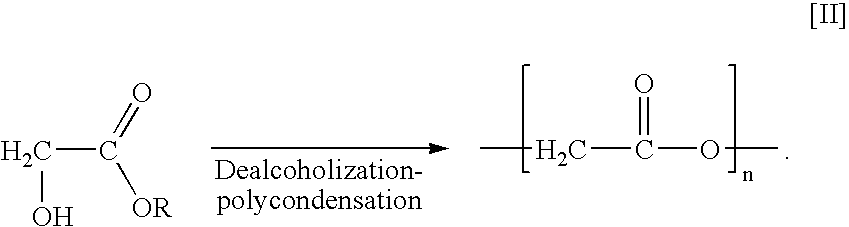

Ethylene/alpha-olefin/non-conjugated polyene copolymer, and production process and use thereof

ActiveUS20160355622A1Small long-chain branch contentExcellent curing propertyPlastic/resin/waxes insulatorsSpecial tyresChemistryStructural unit

A novel ethylene / α-olefin / non-conjugated polyene copolymer comprising structural units derived from ethylene (A), an α-olefin (B) of 3 to 20 carbon atoms, and a non-conjugated polyene (C) containing intramolecularly two or more partial structures in total selected from the group consisting of structures of Formulae (I) and (II), and having a small number of long-chain branches,The novel ethylene / α-olefin / non-conjugated polyene copolymer contains a non-conjugated polyene such as VNB as a copolymerization component and a small long-chain branch content and is excellent in curing properties in the case of crosslinking using peroxide; and a process for producing the ethylene / α-olefin / non-conjugated polyene copolymer, and a use thereof are provided.

Owner:MITSUI CHEM INC

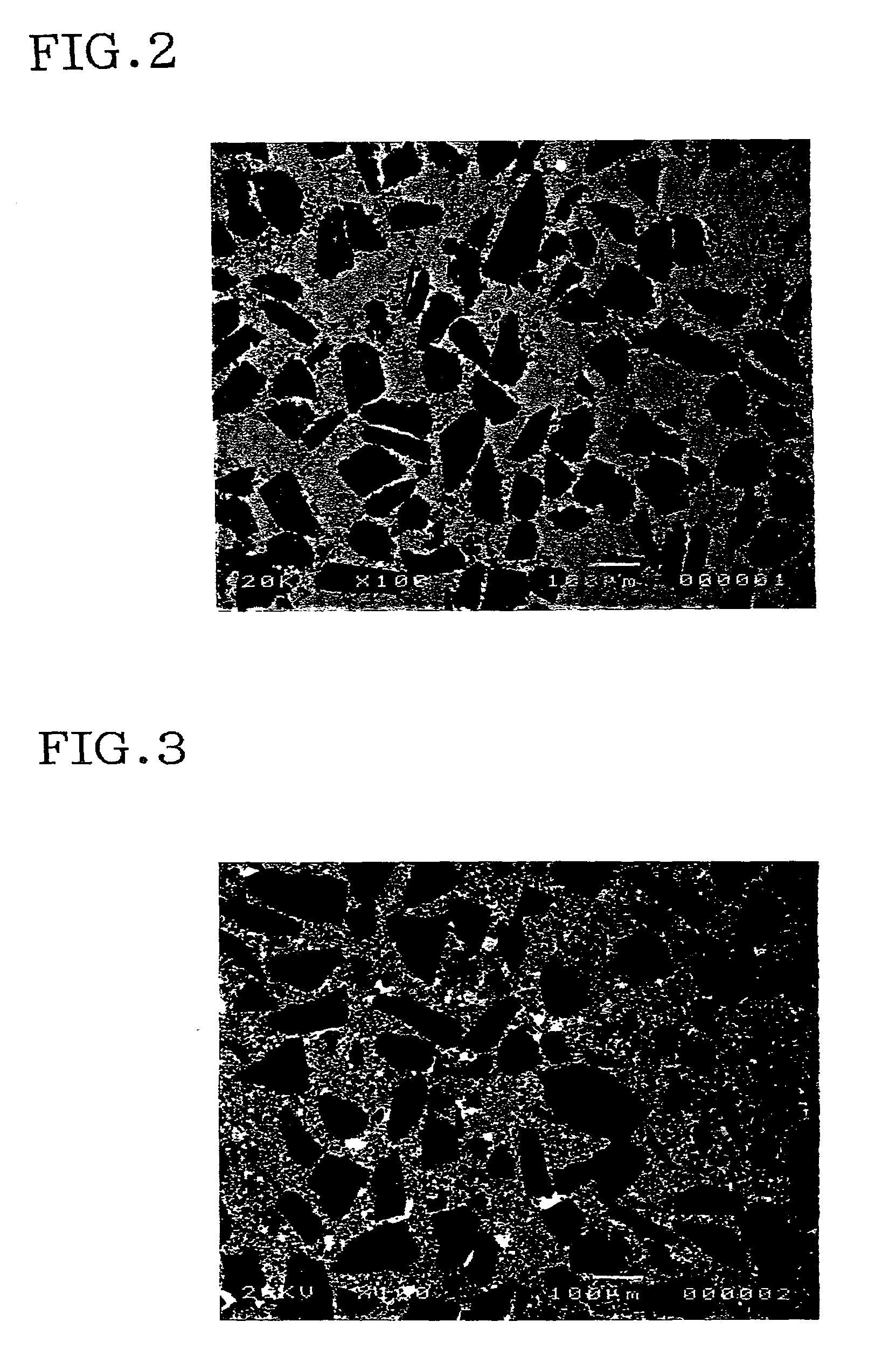

Method of producing metal/ceramic composite, and method of producing porous ceramic body

InactiveUS20010033038A1Easy to crackDifficulty in debindingCeramic shaping apparatusCeramicwareCeramic compositeSlurry

There is provided a method of producing a metal / ceramic composite, comprising the steps of adding starch to a ceramic slurry; casting the slurry into a water-nonabsorptive mold; heating the slurry to harden it to obtain a hardened body; demolding the hardened body out of the mold; and drying the hardened body to obtain a molded body; and then impregnating pores of the molded body or pores of a porous ceramic body produced by firing the molded body with a metal. The method can produce a metal / ceramic composite having a narrow metal distribution at a low cost, while freely controlling metal content as designed for complex shapes, or products with varying thickness or highly thick products, to say nothing of simple shapes.

Owner:NGK INSULATORS LTD

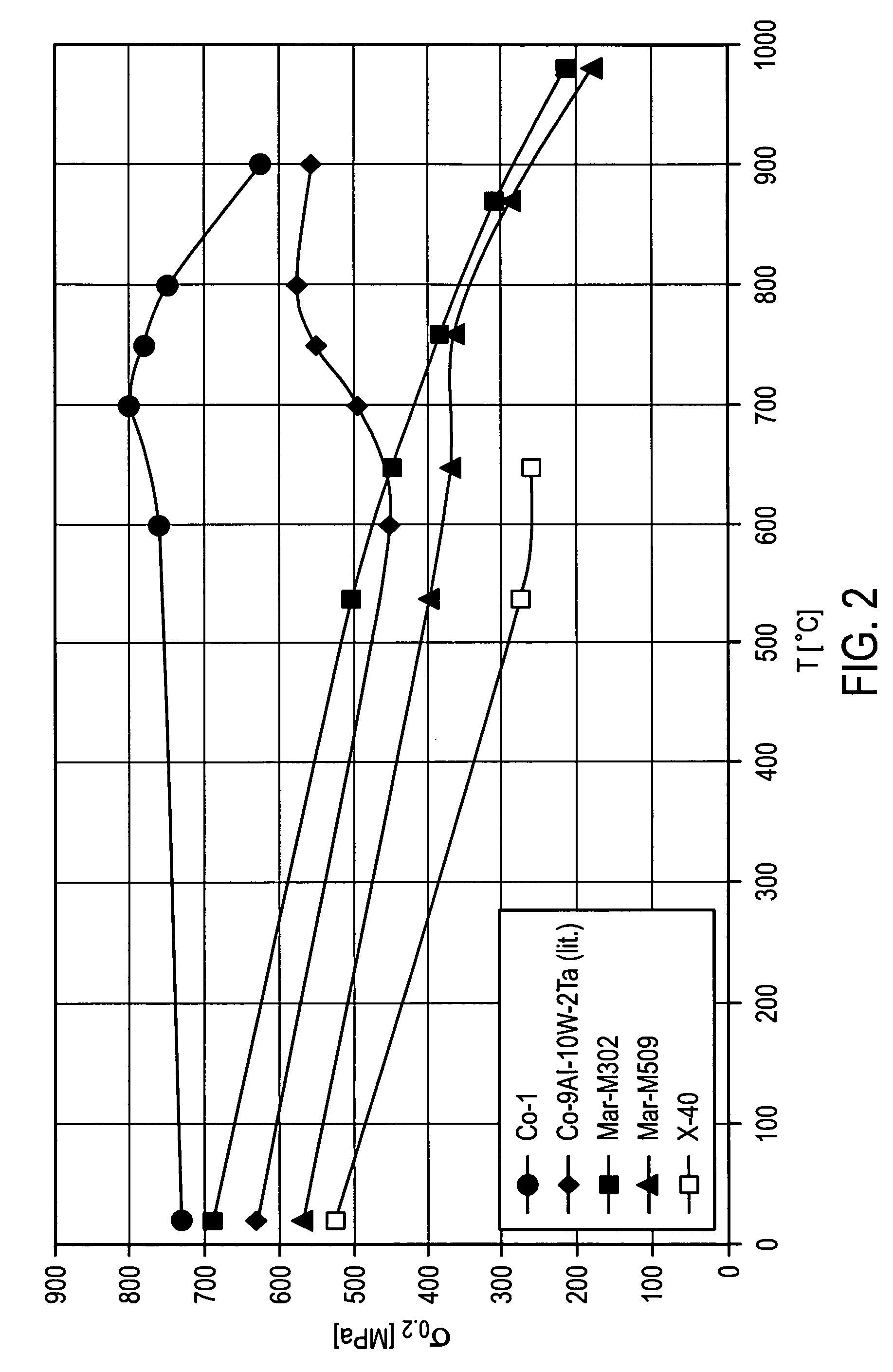

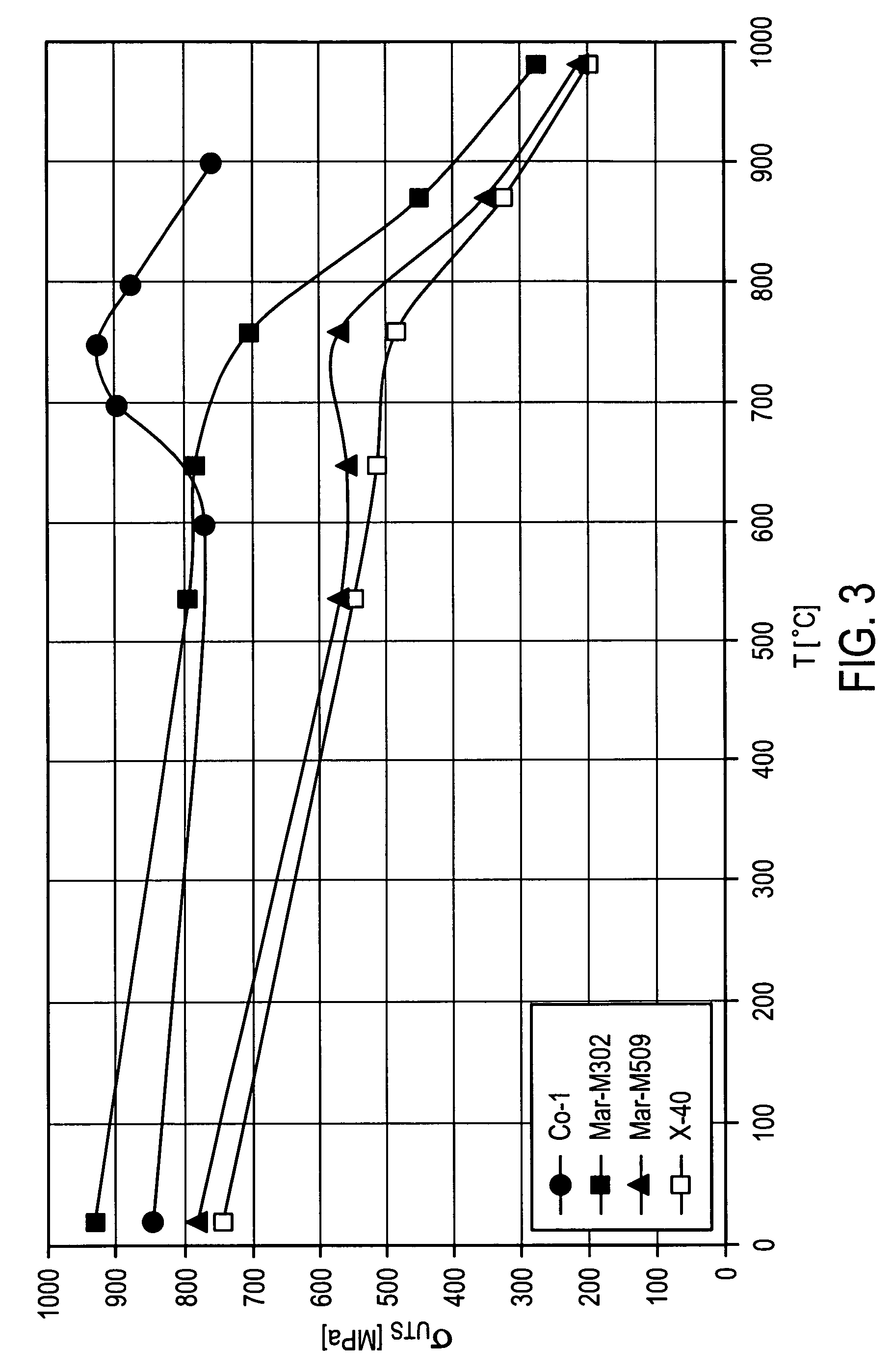

High-temperature-resistant cobalt-base superalloy

ActiveUS20100061883A1Improve mechanical propertiesImprove the immunityChemical compositionSuperalloy

A cobalt-base superalloy chemical composition is disclosed which includes, in % by weight: 25-28 W; 3-8 Al; 0.5-6 Ta; 0-3 Mo; 0.01-0.2 C; 0.01-0.1 Hf; 0.001-0.05 B; 0.01-0.1 Si; and remainder Co and unavoidable impurities. This superalloy can be strengthened by γ′ dispersions and further dispersion mechanisms. Exemplary compositions can provide good oxidation properties and improved strength values at high temperatures.

Owner:ANSALDO ENERGIA IP UK LTD

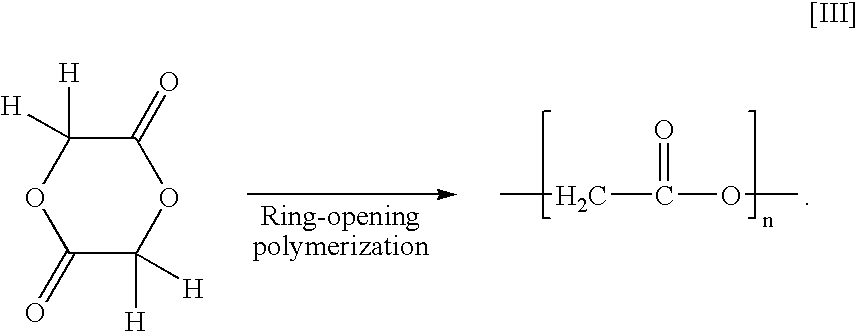

Polyester production process and reactor apparatus

InactiveUS6852827B2Promote recoverySimple meansChemical/physical/physico-chemical stationary reactorsPolyesterBulk polymerization

The invention provides a polyester production process by bulk polymerization in a reactor, wherein the volume of the resulting polyester is shrunk for a release from the inner surface of the reactor, so that the polyester can be recovered in the form of a bulky mass. The invention also provides a reactor for bulk polymerization for polyester, which comprises an inner surface that enabling the resulting polyester to be released therefrom upon its volume shrinkage.

Owner:KUREHA KAGAKU KOGYO KK

Halogen-free resin composition

ActiveUS20130316155A1Low dielectric constantImprove heat resistanceSynthetic resin layered productsPrinted circuit aspectsEpoxyDielectric loss factor

A halogen-free resin composition includes 100 parts by weight of epoxy resin; 10 to 100 parts by weight of benzoxazine resin; 10 to 100 parts by weight of styrene-maleic anhydride copolymer; and 10 to 90 parts by weight of dicyclopentadiene phenol novolac resin. The halogen-free resin composition features specific ingredients and proportions thereof to attain low dielectric constant (Dk), low dielectric dissipation factor, high heat resistance and high non-flammability and produce prepregs or resin film, and is thus applicable to copper clad laminates and printed circuit boards.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

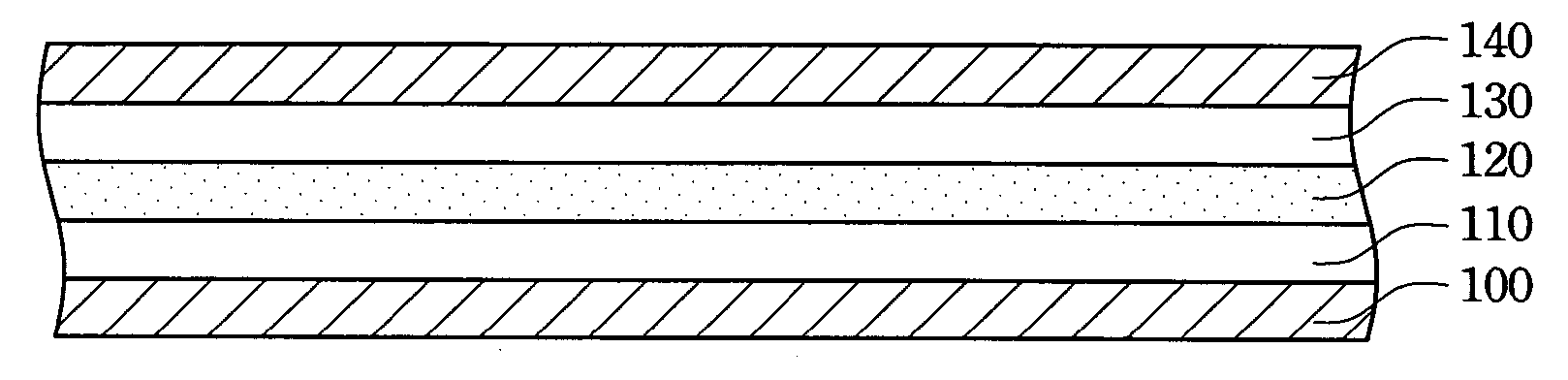

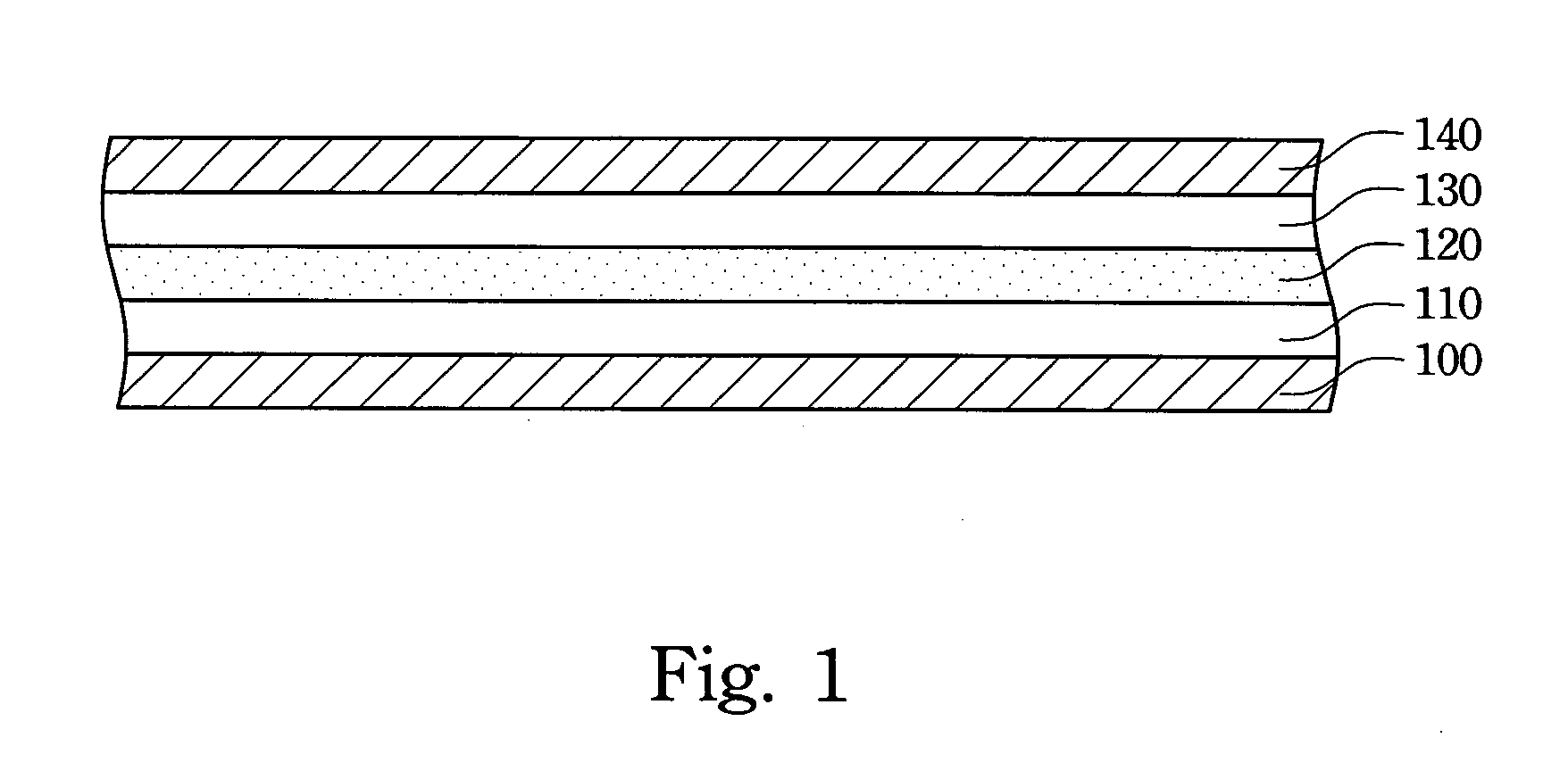

Polyimide based flexible copper clad laminates and method of producing the same

InactiveUS20070044910A1Low production costEasy to controlAdhesive processes with surface pretreatmentMovable spraying apparatusCopper foilFlexible electronics

The present invention relates to a polyimide based flexible copper clad laminate for manufacturing a flexible printed circuit board. The polyimide based flexible copper clad laminate comprises, in order, a copper foil, a thermoset polyimide layer, a thermoplastic polyimide layer, a thermoset polyimide layer, and a copper foil. The present invention also relates to a method for producing the polyimide copper foil laminate. First, a structure of copper foil coated with thermoset polyimide is formed. Then, the thermoset polyimide layers of two of the structures are adhered to each other by thermoplastic polyimide. Finally, after compressing and curing, the polyimide based flexible copper clad laminate according to the present invention is produced.

Owner:THINFLEX CORP

Method for forming multilayer electrode capacitor

A method of forming a multilayer electrode capacitor is described. A trench is formed in a substrate or in an insulator layer. Two sets of conductive layers are deposited on the inner surface of the trench. The first set of conductive layers is electrically connected to each other, and so is the second set of conductive layers. Each of the second set of conductive layers is inserted between two first conductive layers, and dielectric layers are interposed between two conductive layers to form a multilayer electrode capacitor.

Owner:PROMOS TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com