Patents

Literature

189results about How to "Suitable for industrial use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

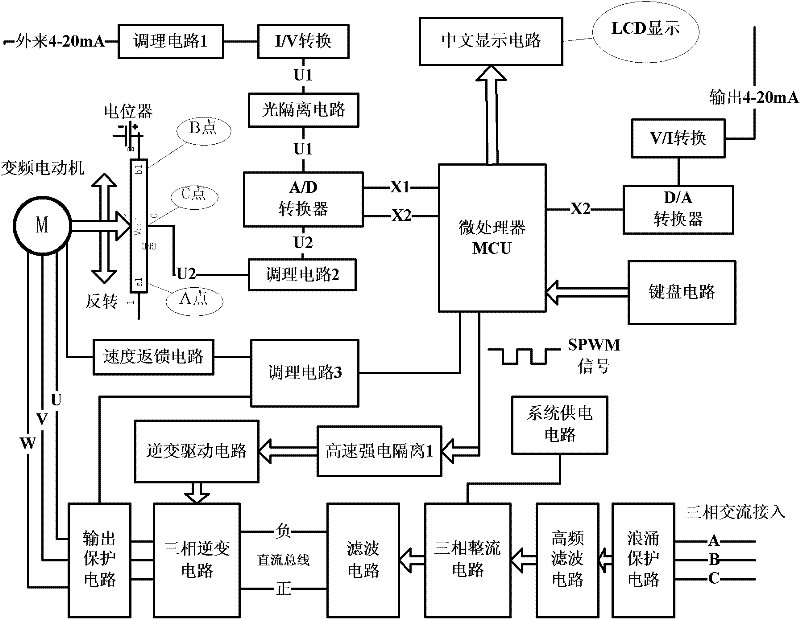

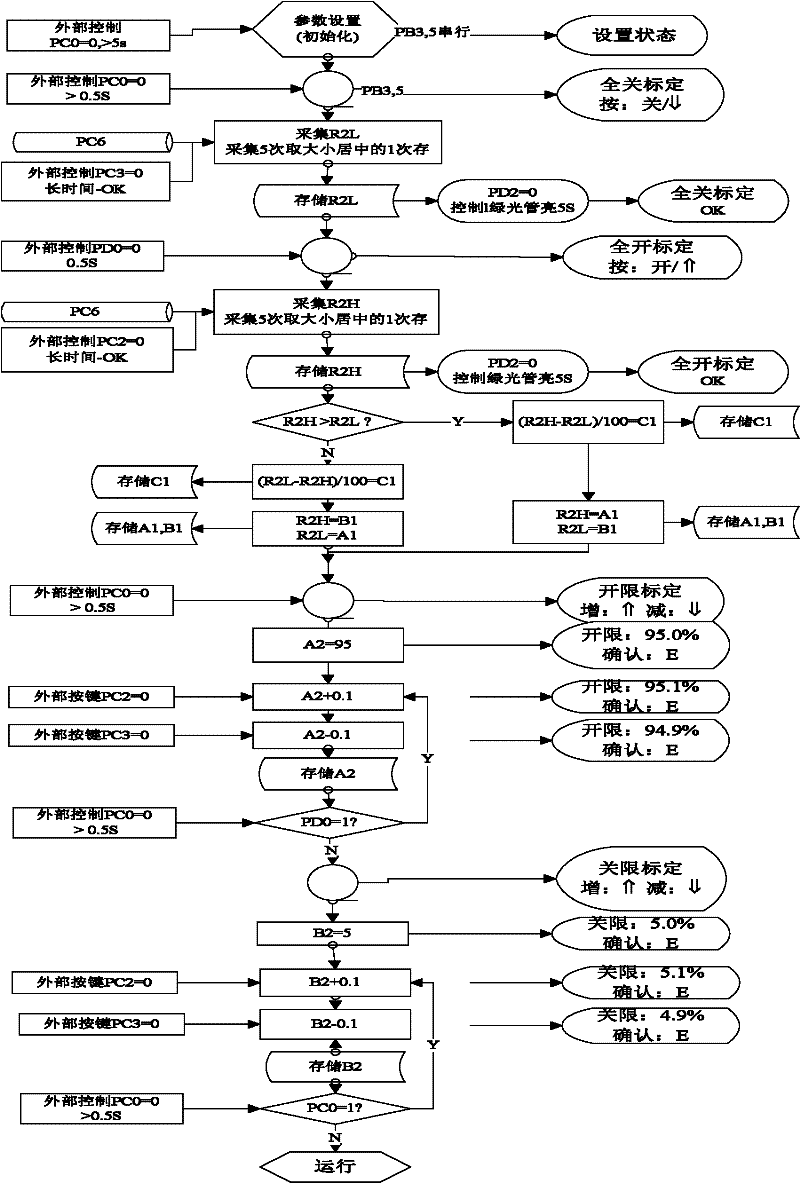

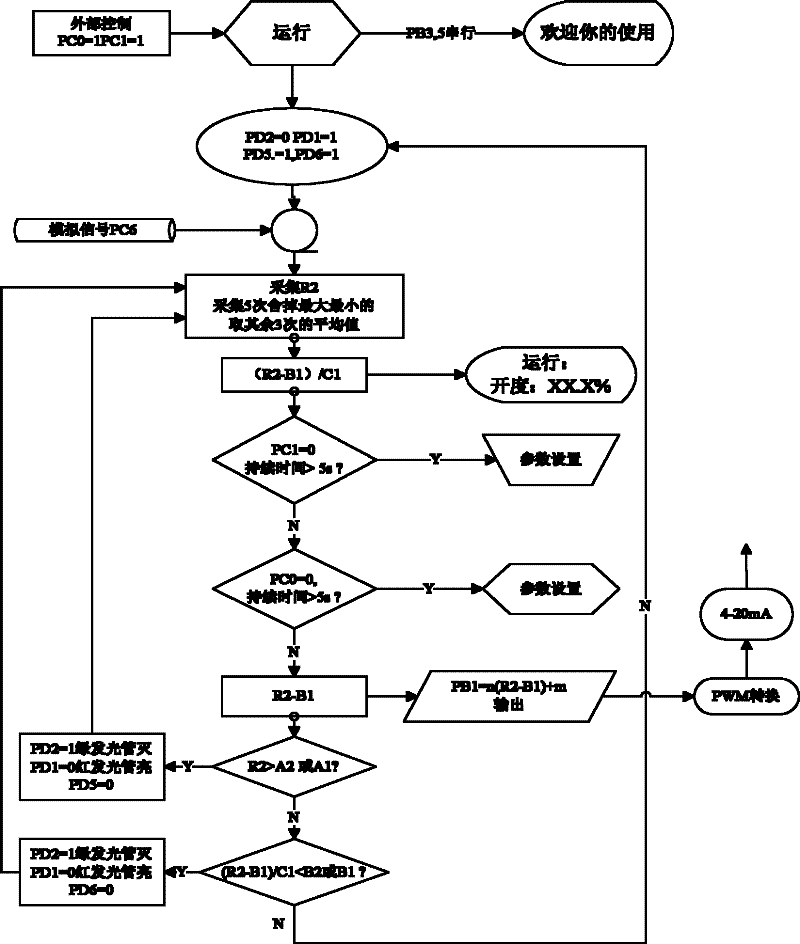

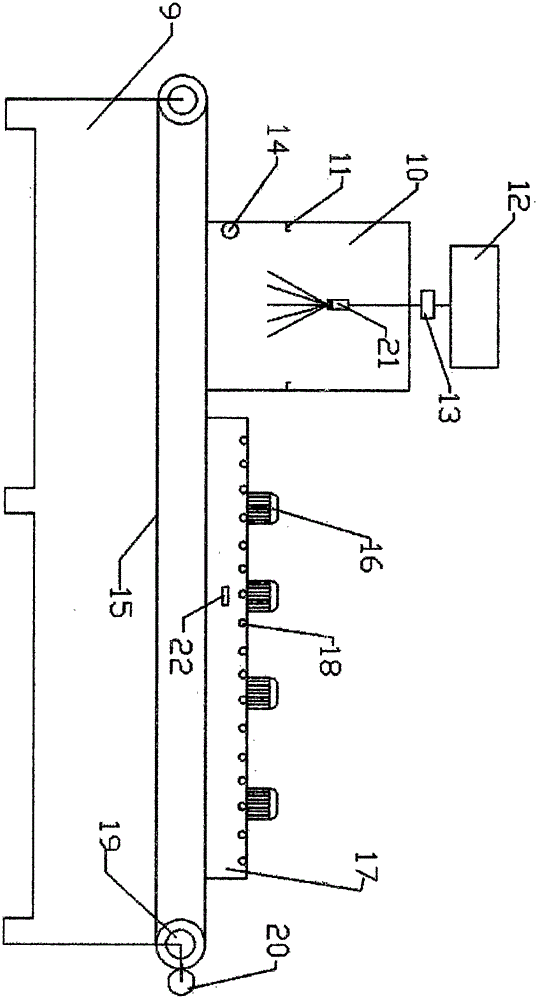

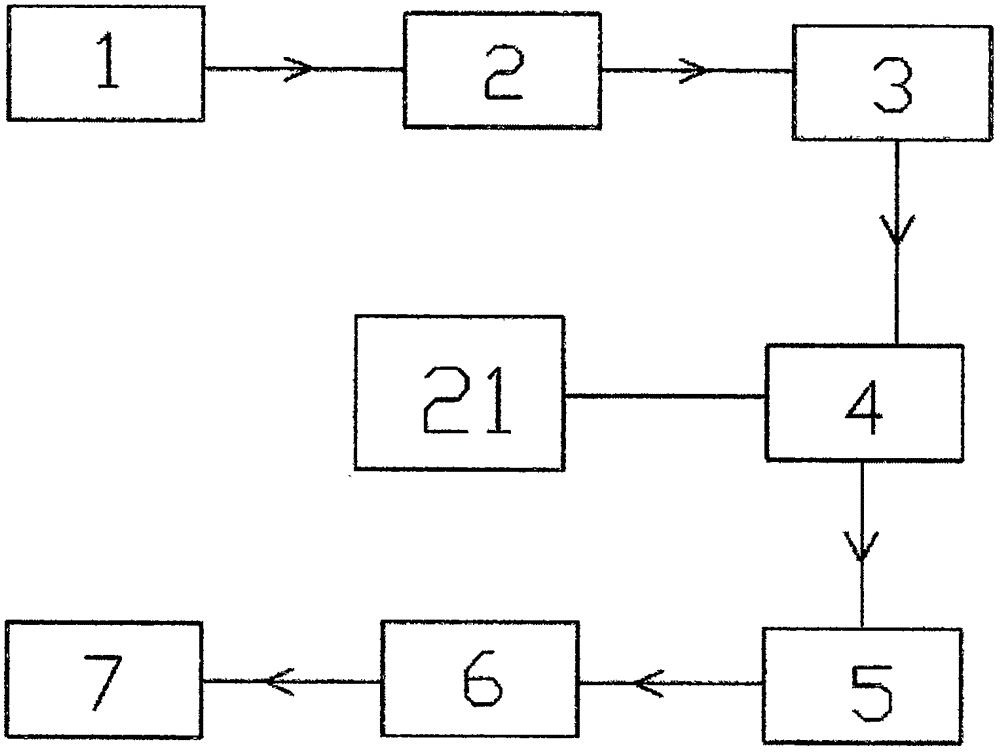

Intelligent alternating current frequency conversion control system of electric actuator

InactiveCN102368677AProcessing speedAdjustable running speedMotor/generator/converter stoppersOperating means/releasing devices for valvesHuman–machine interfaceEngineering

The invention discloses an intelligent alternating current frequency conversion control system of an electric actuator, which comprises a hardware part and a software part and is characterized in that the hardware part adopts a modular design and comprises a microprocessor, A / D (Analog-to-Digital) and D / A (Digital-to-Analog) converters, a Chinese display circuit, an optical isolation circuit, a rectified three-phase circuit, a three-phase inverting circuit, an inversion driving circuit, a high-speed strong-current isolation circuit, a surge protection circuit, a high-frequency filter circuit, a filter circuit and an output protection circuit; all the component units take the microprocessor as the core and are connected with the microprocessor in a star-type way; the A / D and D / A converters are embedded in the microprocessor; the microprocessor is connected with the Chinese display circuit through a communication port; the microprocessor is connected with the three-phase inverting circuit sequentially through the high-speed strong-current isolation circuit and the inversion driving circuit; and the software part comprises a main program, a human-computer interface processing program, an automatic debugging program, a fault processing program, a digital-to-analog conversion and data processing program and a manual operation fault processing program.

Owner:TIANJIN HIGHWAYTECH TECH

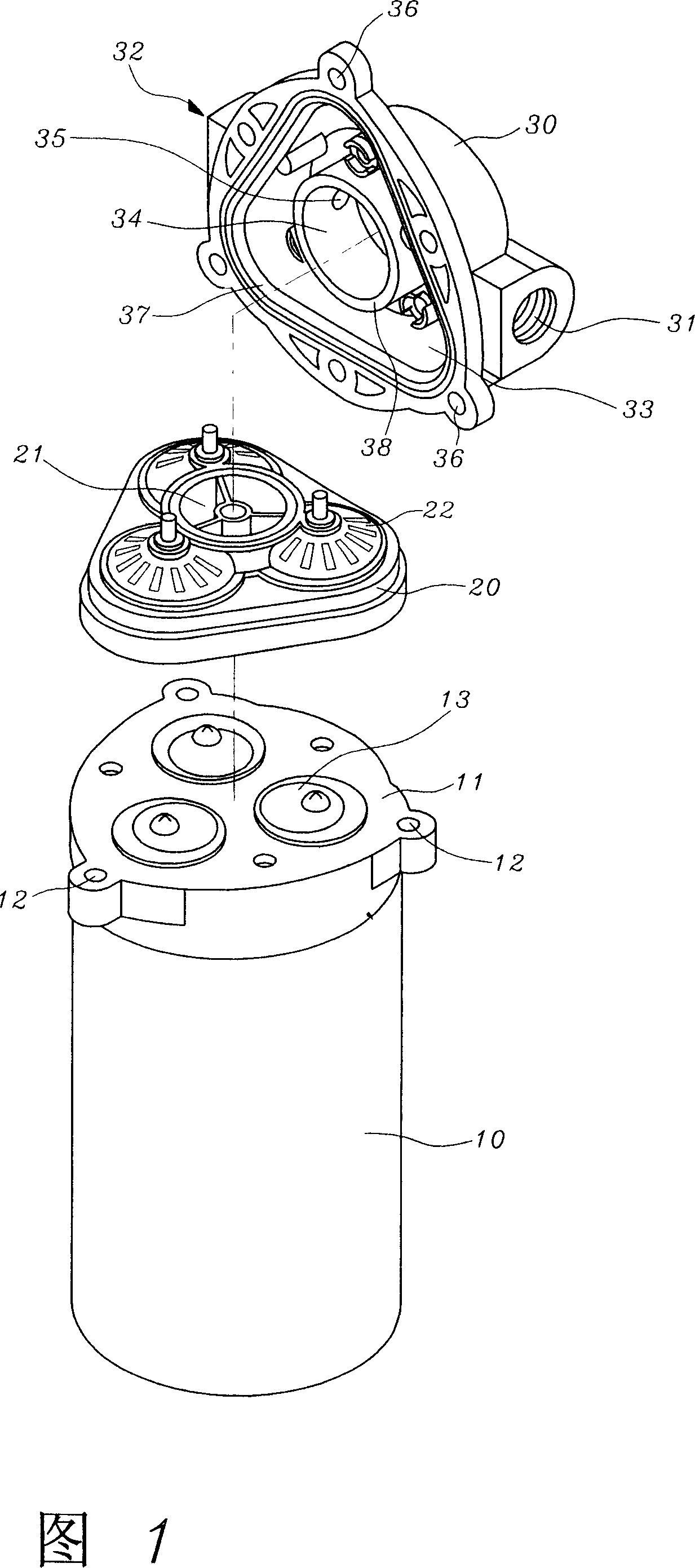

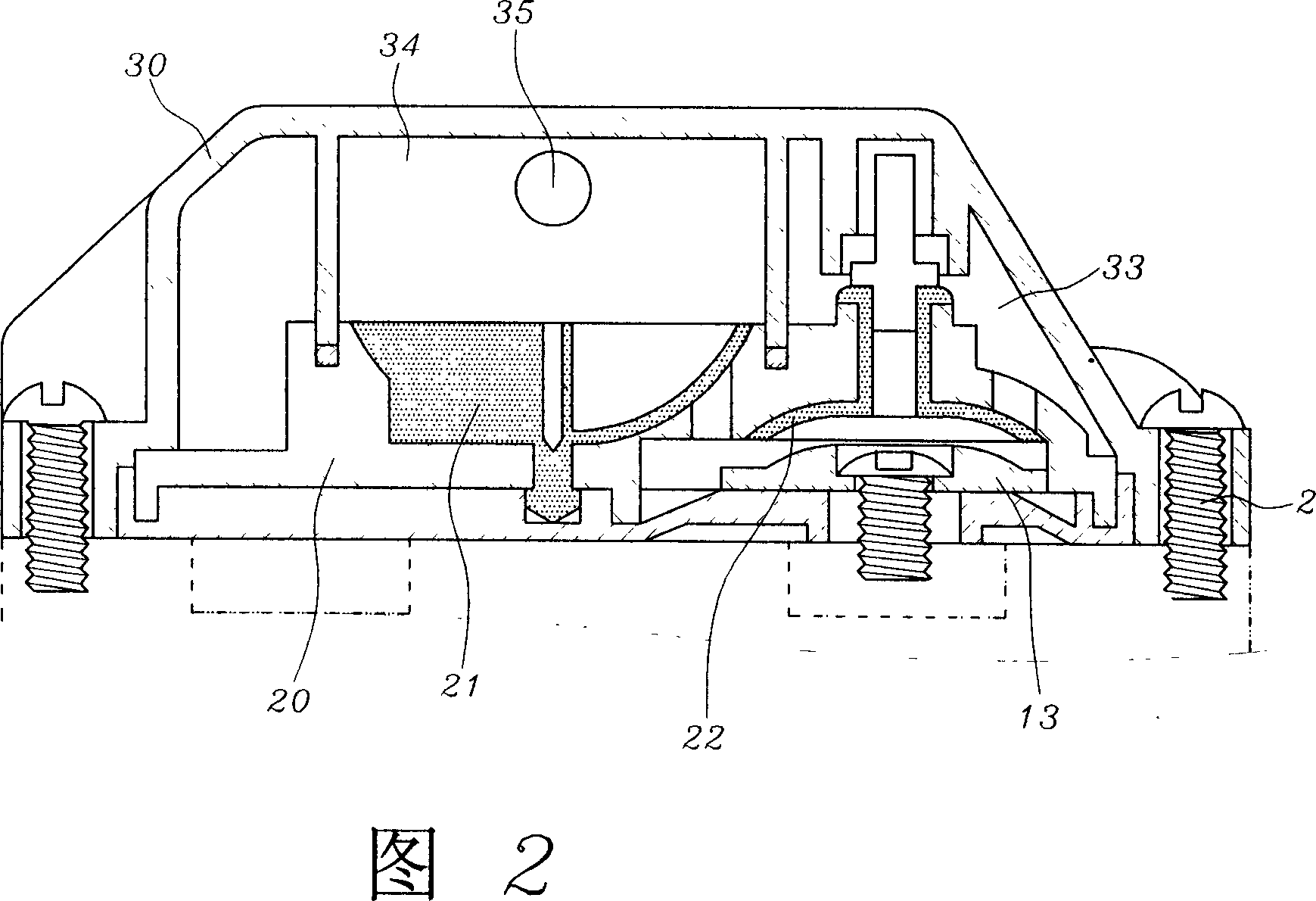

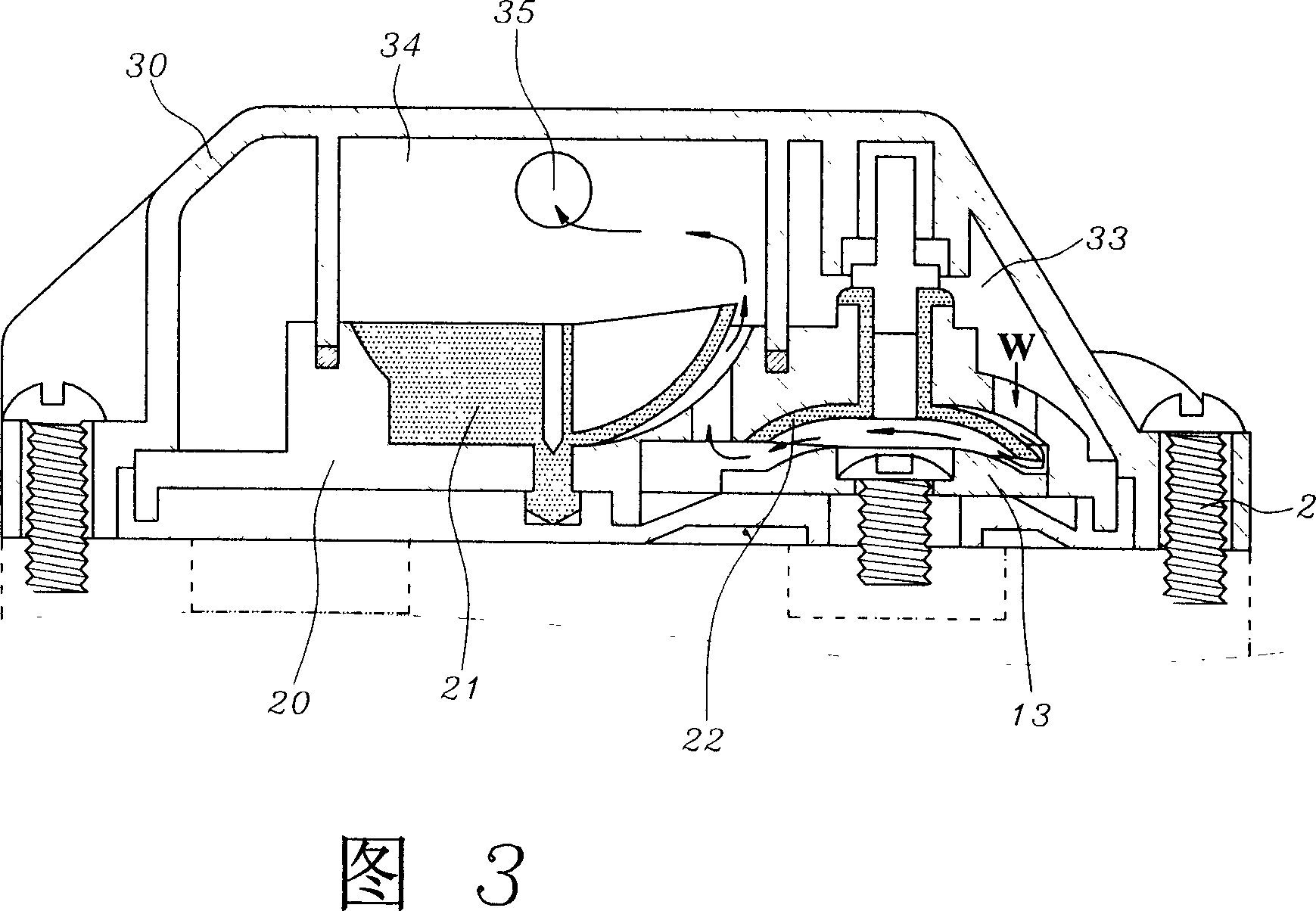

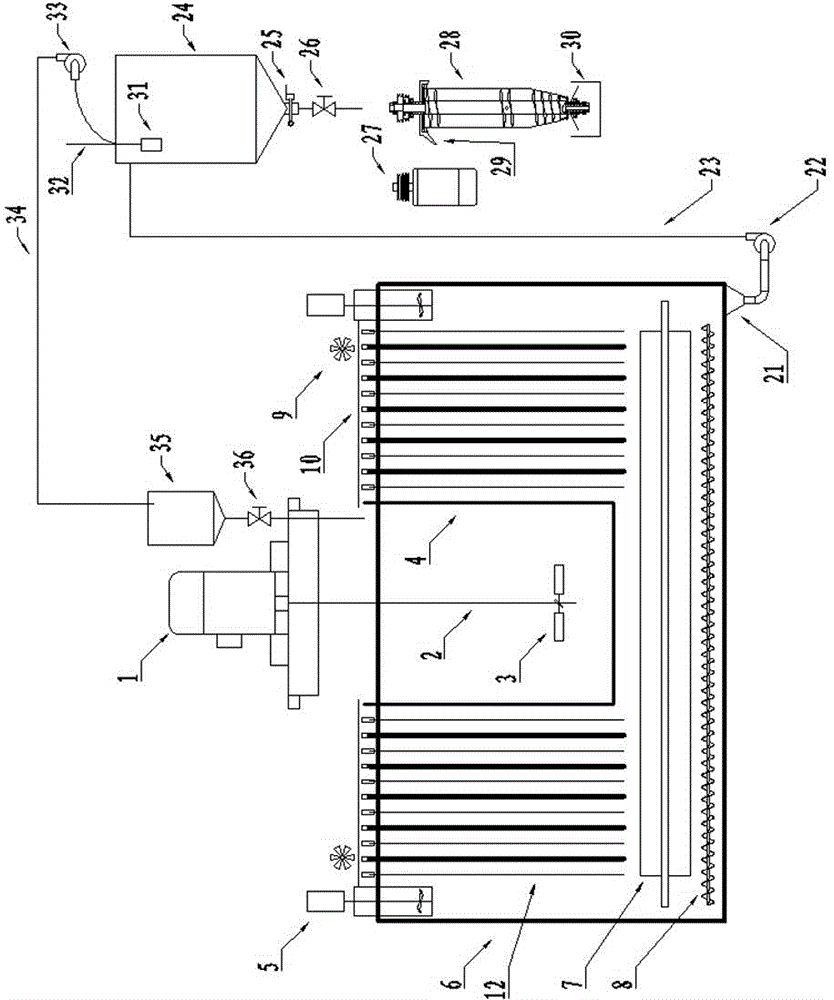

Diaphragm pump of constant pressure type

InactiveCN101050763ASuitable for industrial useReduce power consumptionFlexible member pumpsPump controlDiaphragm pumpPore water pressure

The present invention provides a diaphragm pump of constant pressure type, mainly wherein a passage tube links between said pressure discharge port and said inlet port of said pump cover body; Thereby, the extra water pressure coming from said compressed chamber can be orderly discharged through said pressure discharge port, next guided through said passage tube to reach said inlet port, then directly flowed into said low pressure chamber; Therefore, a close water circulation loop of discharge pressure is built by means of connecting said compressed chamber, said pressure discharge port, said passage tube, said inlet port and said low pressure chamber; Thus, the present invention not only provides the function of keeping constant pressure, but also completely recycles the drained water by extra water pressure without any waste in water resource; Moreover, the present invention not only has the energy-saving effect in power consumption, but also has the environment-protecting effect in reducing operation noise; Thus, it is really an innovative invention with multiple practical effect.

Owner:FOSHAN CITY SANJIAOZHOU ELECTRICAL TECH CO LTD

Biaxially oriented polyester film having more than one layer; its use; and process for its production

InactiveUS6376042B1Improve applicabilitySuitable for industrial useRecord information storageCeramic layered productsPolyesterOxygen barrier

The invention relates to a biaxially oriented polyester film having at least two layers and which, together with good processing performance, after it has been metalized or has been coated with oxidic materials, is a very good gas or oxygen barrier, and which has been built up from at least one base layer and at least one outer layer applied to this base layer, where the film has a planar orientation DELTAp of greater than 0.165.

Owner:MITSUBISHI POLYESTER FILM

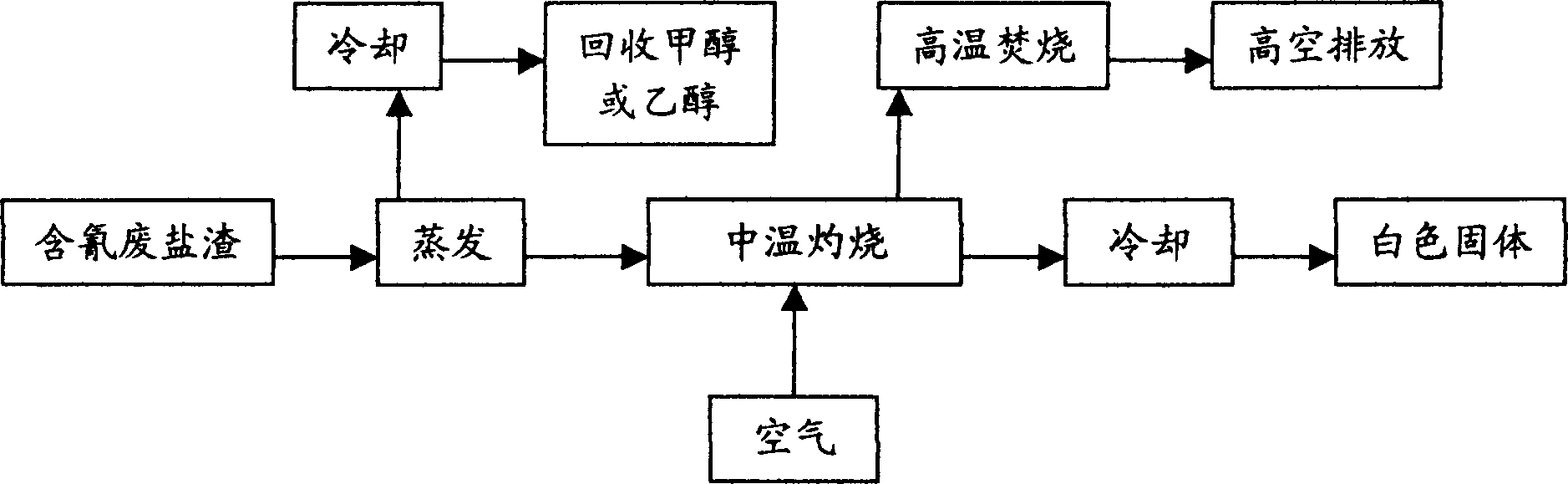

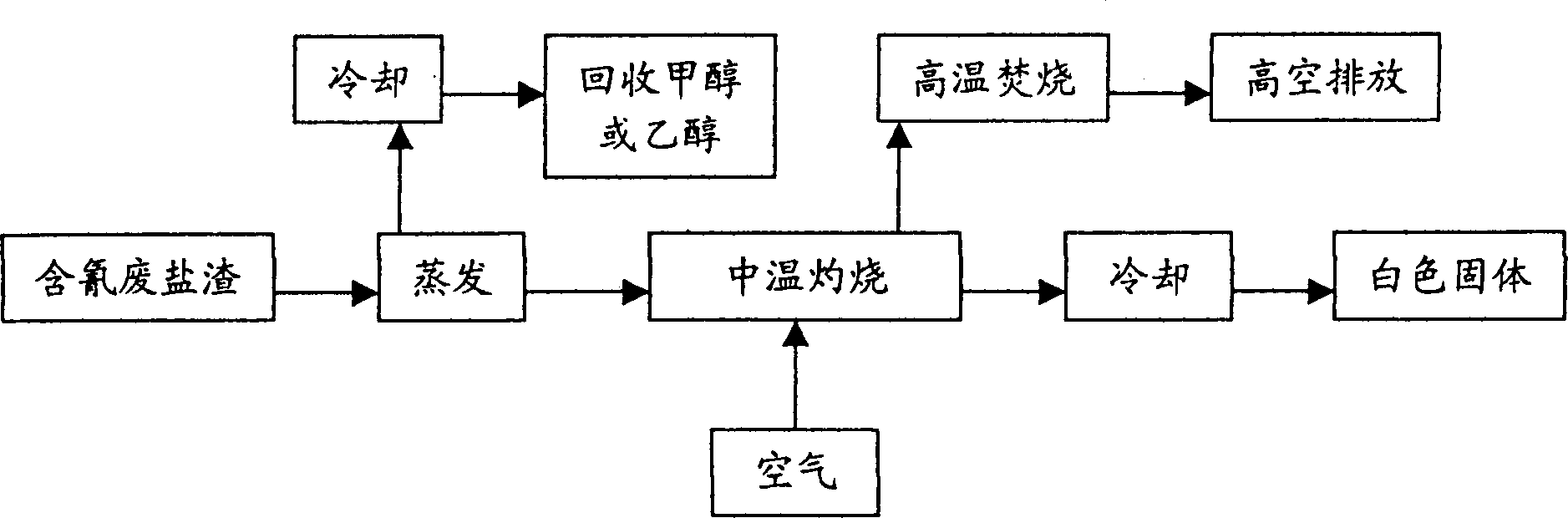

Method for treating waste salt dregs containing cyanogen

The invention relates to a processing method for cyanogens contained waste salt dredge, the process steps are: the cyanogens contained waste salt dredge is put into the drier to be heated; the heating temperature is controlled with 60-120deg.C, the carbinol and the alcohol volatilize from the dredge, the carbinol and the alcohol are reclaimed with high purity after beings cooled in the condenser; the cyanogens contained waste salt dredge without carbinol and alcohol is baked in oxygen condition, the oxide in the dredge is fully oxidized, the organic is oxidized or volatilized off, thus eliminates the cyanogens and organic in the salt dredge; the gas generated in the baking process is transmitted to the burning furnace, the temperature is not lower than 1100deg.C, thus the tail gas may accord the discharging standard.

Owner:邱滔 +1

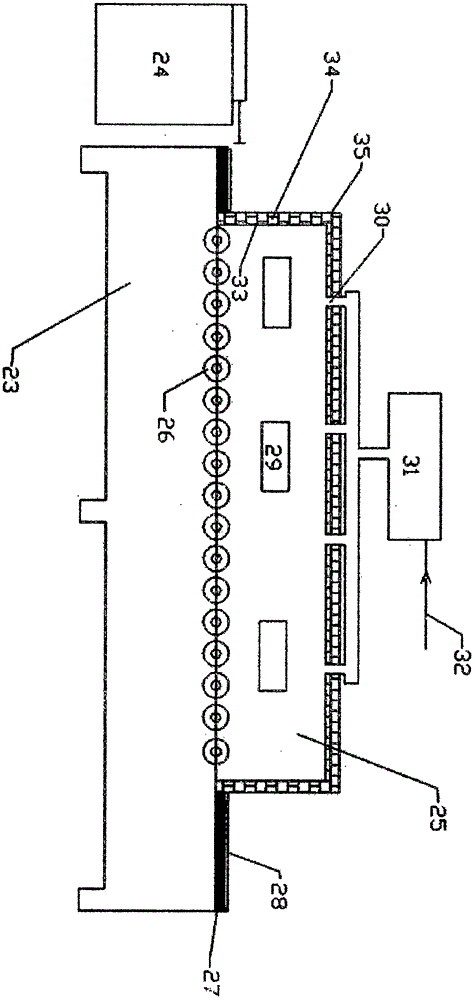

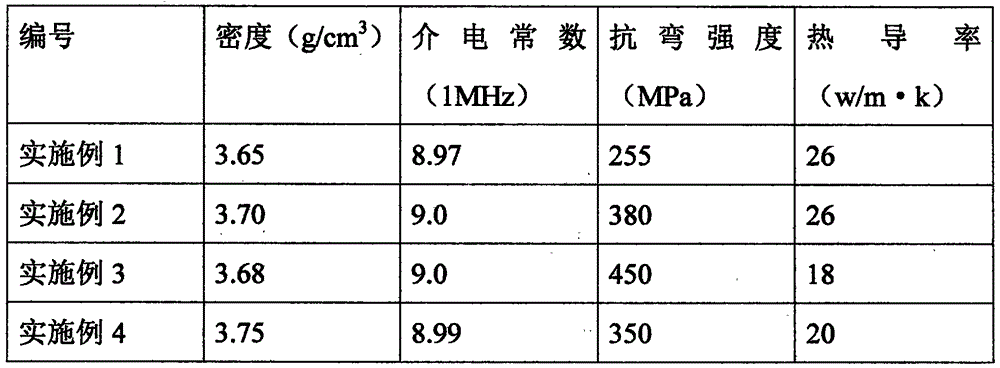

High-strength ceramic substrate and preparation method and production line thereof

InactiveCN105881700AHigh strengthHigh mechanical strengthCeramic shaping plantsProduction linePlasticizer

The invention discloses a high-strength ceramic substrate. The high-strength ceramic substrate is composed of ceramic powder, binders, dispersing agents, plasticizers and solvents, wherein the weight ratio of the ceramic powder to the binders to the dispersing agents to the plasticizers and to the solvents is 1 to 0.08-0.15 to 0.01-0.03 to 0.03-0.06 to 0.5-0.8; the ceramic powder is composed of alumina powder and zirconium oxide powder, and the content of the zirconium oxide powder accounts for 3-30% in the ceramic powder by weight. The invention further discloses a preparation method and a production line of the ceramic substrate. The ceramic substrate is excellent in mechanical strength, high in bending strength, good in heat conduction characteristic, high in stability at high temperature and capable of being machined into various complex shapes. The preparation method is simple, the number of processes is small, and the obtained substrate is uniform and compact in structure, high in bending strength, smooth in surface and low in cost. The production line is simple, small in occupied space and suitable for industrial application.

Owner:SINOCERAM TECH (ZHENGZHOU) CO LTD

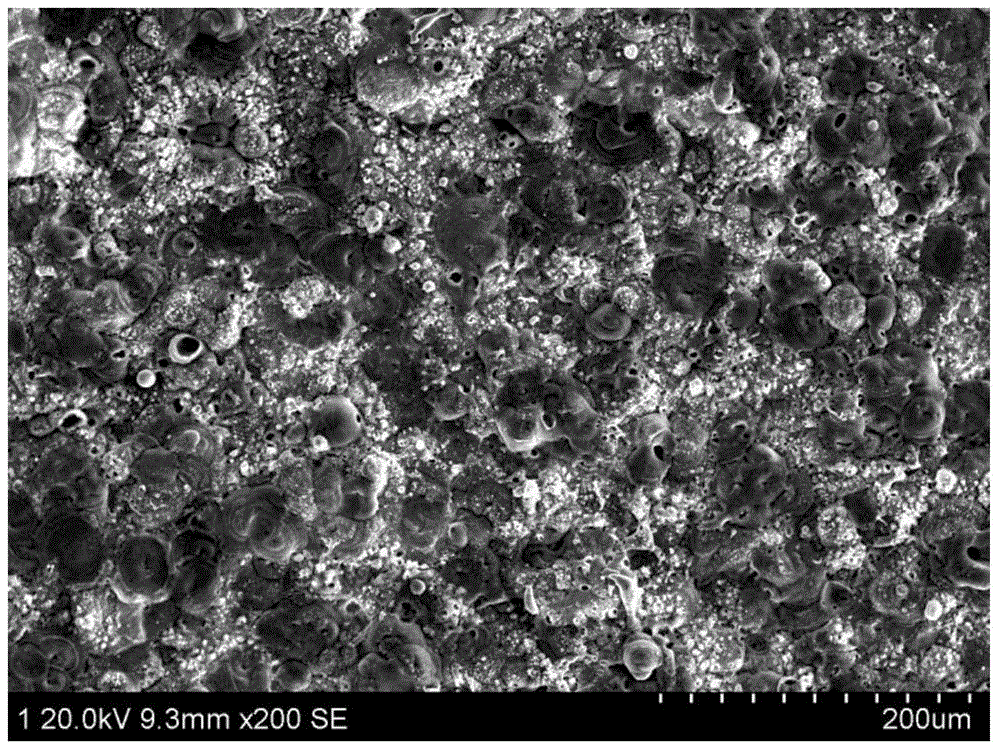

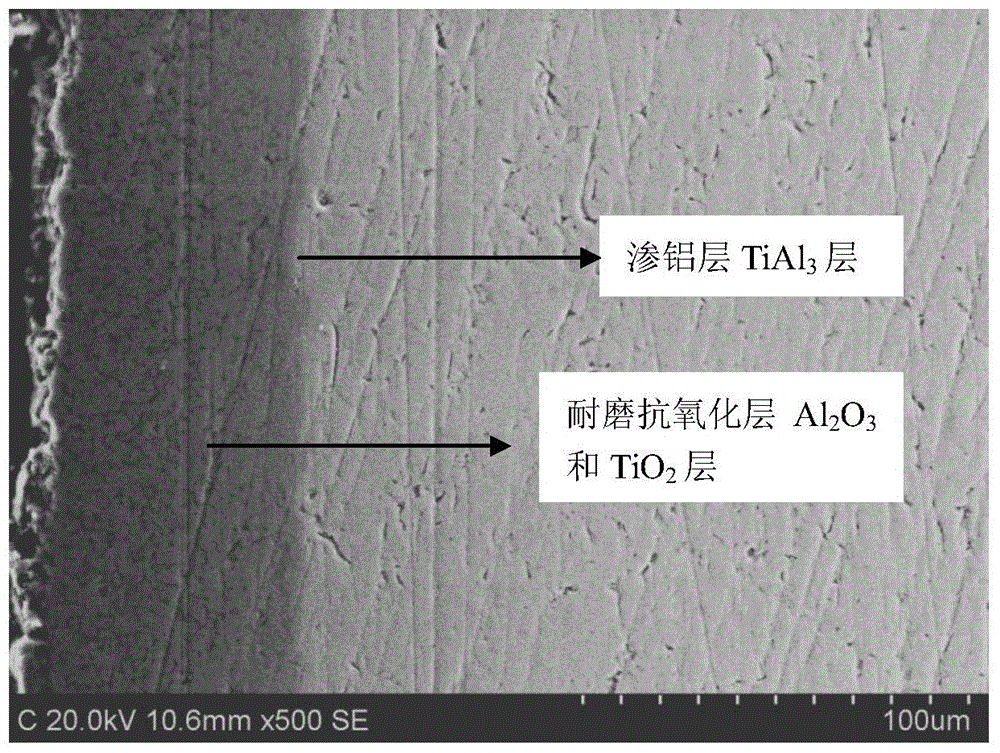

Titanium and titanium alloy surface antioxidant wear-resistant composite coating and manufacturing method thereof

ActiveCN104947107AImprove bindingImprove antioxidant capacityAnodisationSolid state diffusion coatingMicro arc oxidationPlasma electrolytic oxidation

The invention provides a titanium and titanium alloy surface antioxidant wear-resistant composite coating and a manufacturing method thereof and belongs to the technical field of surface treatment. The titanium and titanium alloy surface antioxidant wear-resistant composite coating and the manufacturing method thereof are used for solving the problems of a protective layer used for achieving high-temperature oxidation resistance of the surface of titanium alloy and improving the abrasion resistance of the surface of the titanium alloy in the prior art. The composite coating is composed of an inner oxygen isolating layer and an outer abrasion-resistant anti-oxidation layer. The oxygen isolating layer is an aluminized coating rich in aluminum, and the main component of the oxygen isolating layer is Til3. The abrasion-resistant anti-oxidation layer is made of high-hardness ceramic containing Al2O3 and TiO2. The manufacturing method comprises the steps that 1, pretreatment of the surface of titanium or titanium alloy; 2, aluminizing treatment of the surface of the titanium or titanium alloy; 3, micro-arc oxidation treatment of the surface of the titanium or titanium alloy. The method is simple and suitable for industrial use. The composite coating is better in high-temperature oxidation resistance compared with an existing protective coating, the problems that through cracks are caused and the bonding force of a painting layer is poor during ordinary aluminizing are solved, the problems that the titanium alloy subjected to ordinary micro-arc oxidation is insufficient in hardness, and nitrided modified coating is thin are also solved, and the requirements of most titanium alloy parts for abrasion resistance are met.

Owner:SHENYANG LIGONG UNIV

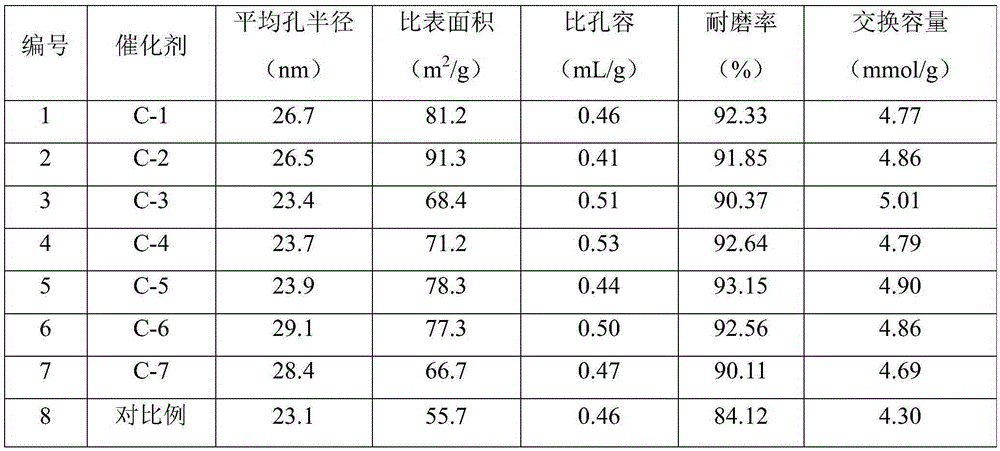

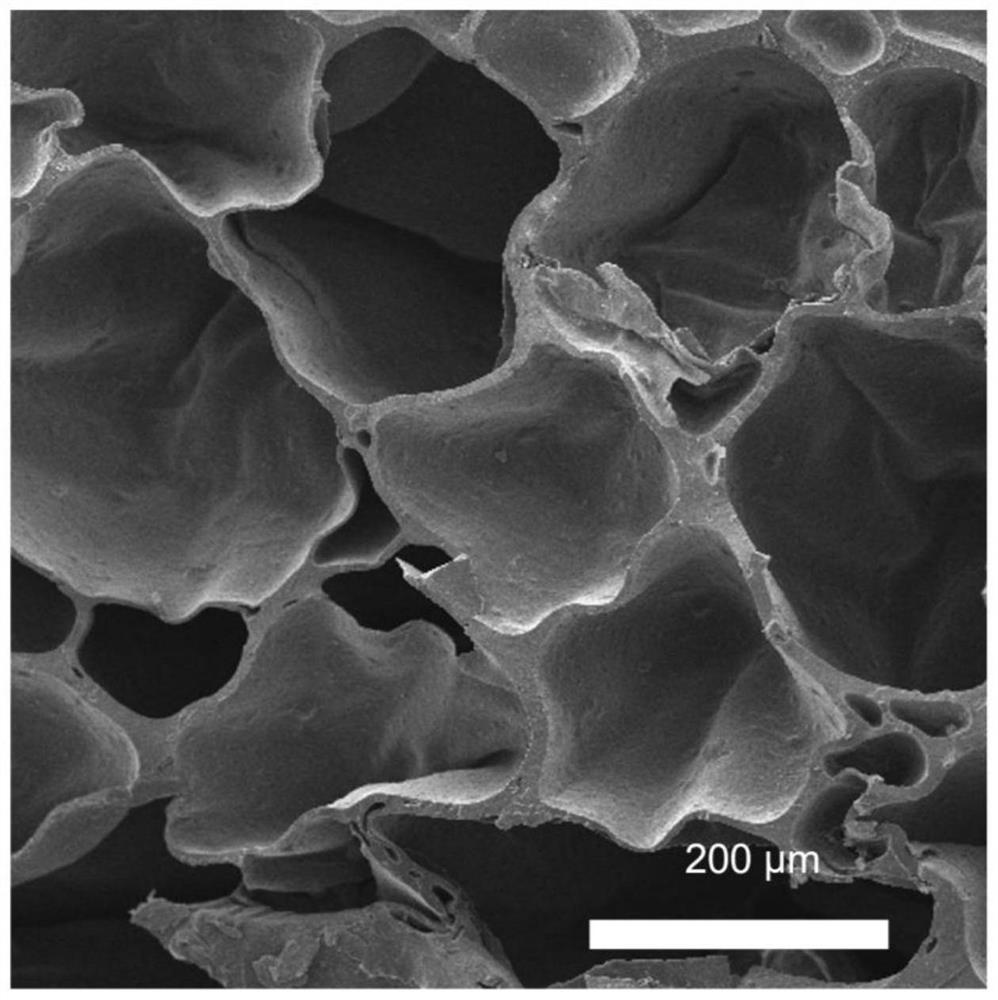

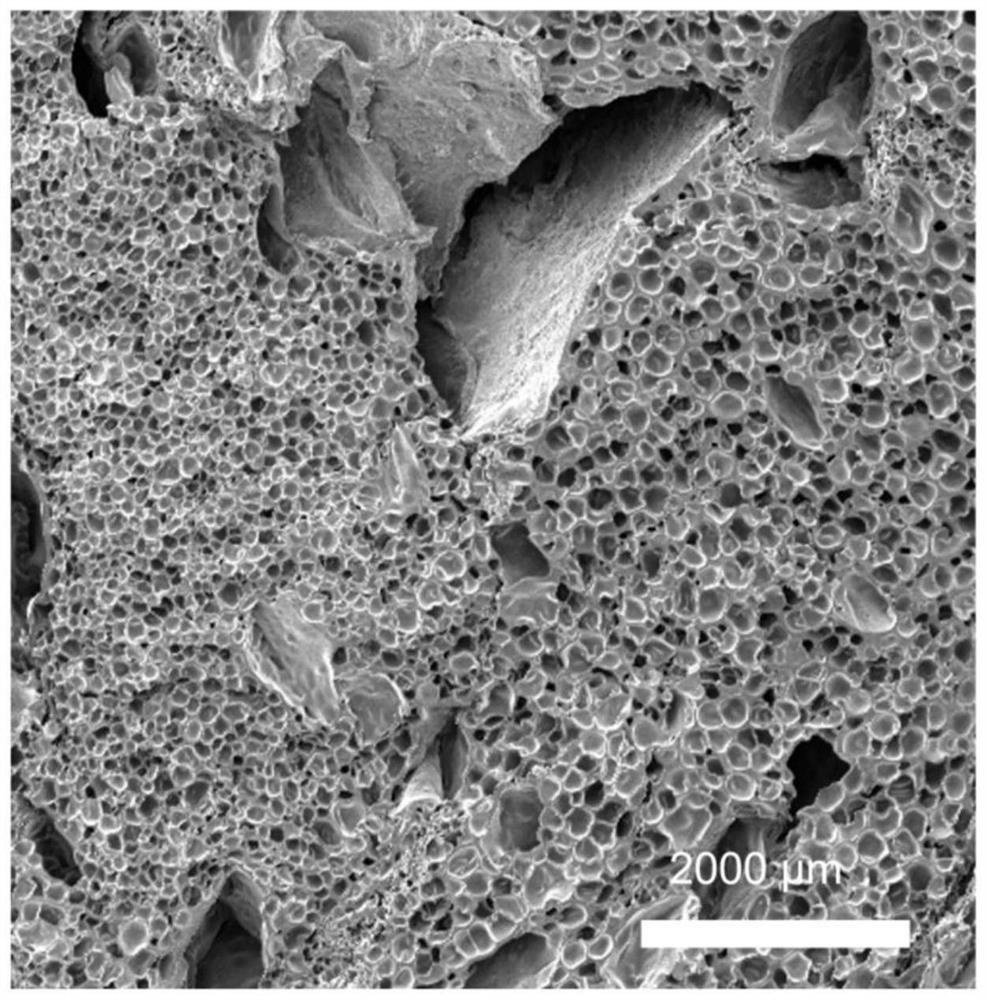

Large particle resin catalyst, and preparation method and applications thereof

ActiveCN106552669AHigh pore volumeIncrease the areaOrganic-compounds/hydrides/coordination-complexes catalystsEther preparationEtherHydrolysis

The invention relates to the field of resin catalyst preparation, and specifically relates to a large particle resin catalyst, and a preparation method and applications thereof. The preparation method comprises the following steps: (1) polymerization: taking styrene and polyvinyl monomers as the raw materials, and carrying out suspension copolymerization in the presence of a dispersant, a water phase polymerization inhibitor, a pore forming agent, and an initiator; (2) purifying the pore structure; and (3) carrying out sulfonation. The prepared large particle resin catalyst has the advantages of high strength and proper specific area, specific pore volume, stability, and activity, and can be applied to hydration of olefins, hydrolysis of ethers, esterification, etherification, and condensation reactions.

Owner:CHINA PETROLEUM & CHEM CORP

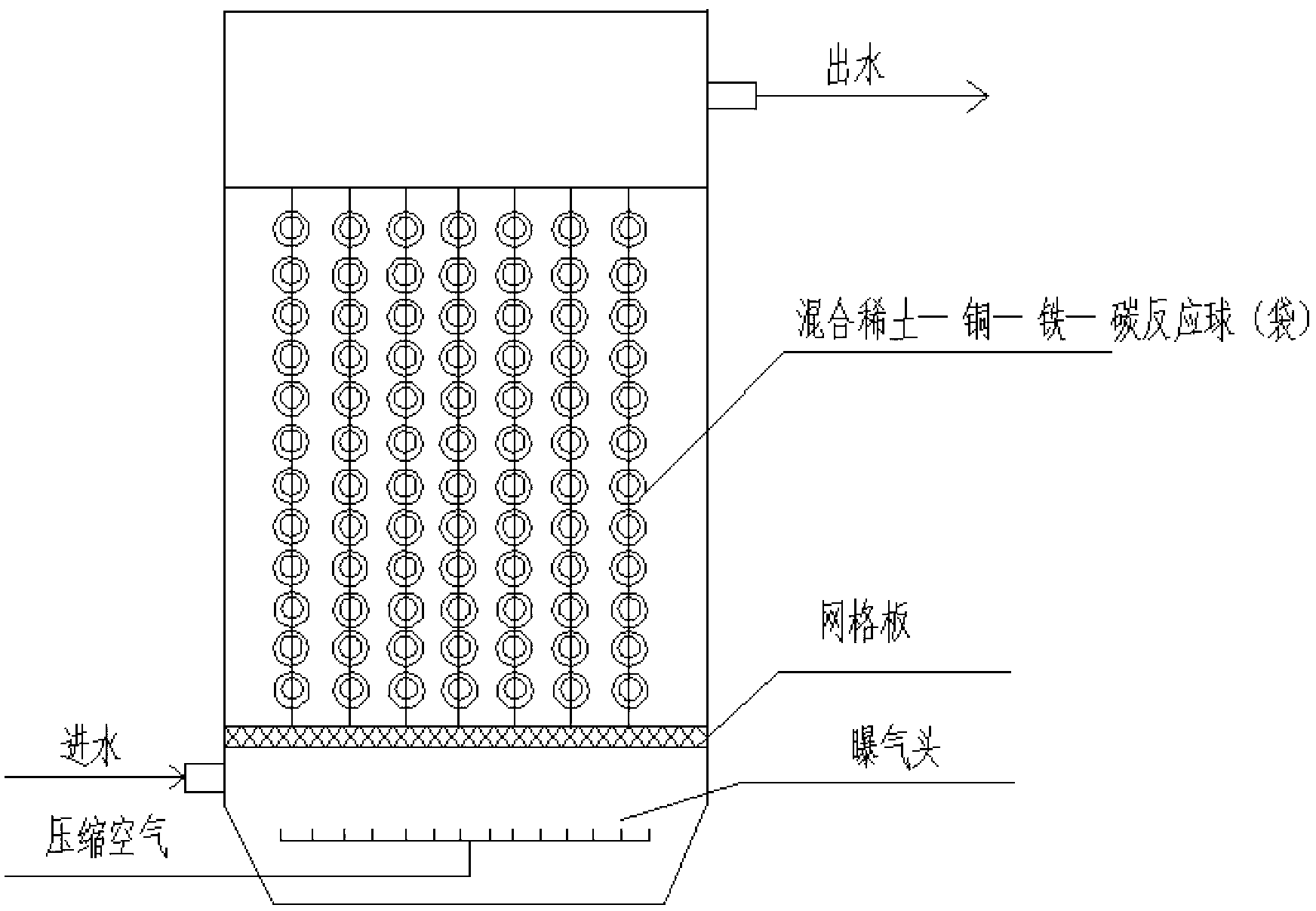

Method for processing high-concentration refractory organic wastewater by using mixed rare earth-brass-iron-carbon catalytic oxidation method

InactiveCN103058347AGood removal effectEasy to handleWater/sewage treatment by oxidationHigh concentrationSlag

The invention relates to a method for processing high-concentration refractory organic wastewater by using a mixed rare earth-brass-iron-carbon catalytic oxidation method. The method comprises the steps that: rare earth ores are precipitated by using carbonate and oxalic acid, such that waste slag is obtained; the waste slag is activated for 6-12h by using hydrochloric acid, and is mixed with raw iron chips and brass chips; activation is carried out for 1-6h under a temperature of 20-100 DEG C; the product is mixed with coke, and the mixture is packaged into a reaction ball or bag, such that a mixed rare earth-brass-iron-carbon catalytic oxidant is obtained; wastewater is directly delivered into the reaction ball or bag, and is subjected to an aeration reaction for 0.5-2.5h; after the reaction is finished, polymeric alumina PAC is added for coagulation sedimentation. The method provided by the invention is suitable to be used in processing of high-concentration refractory organic wastewater with a pH value of 3-13. With the method, acid or alkali regulations are not needed, a reaction speed is high, and processing effect is good. The method provided by the invention is simple, and has the advantages of low cost, high production efficiency, environment friendliness, and suitability for industrialized application.

Owner:DONGHUA UNIV

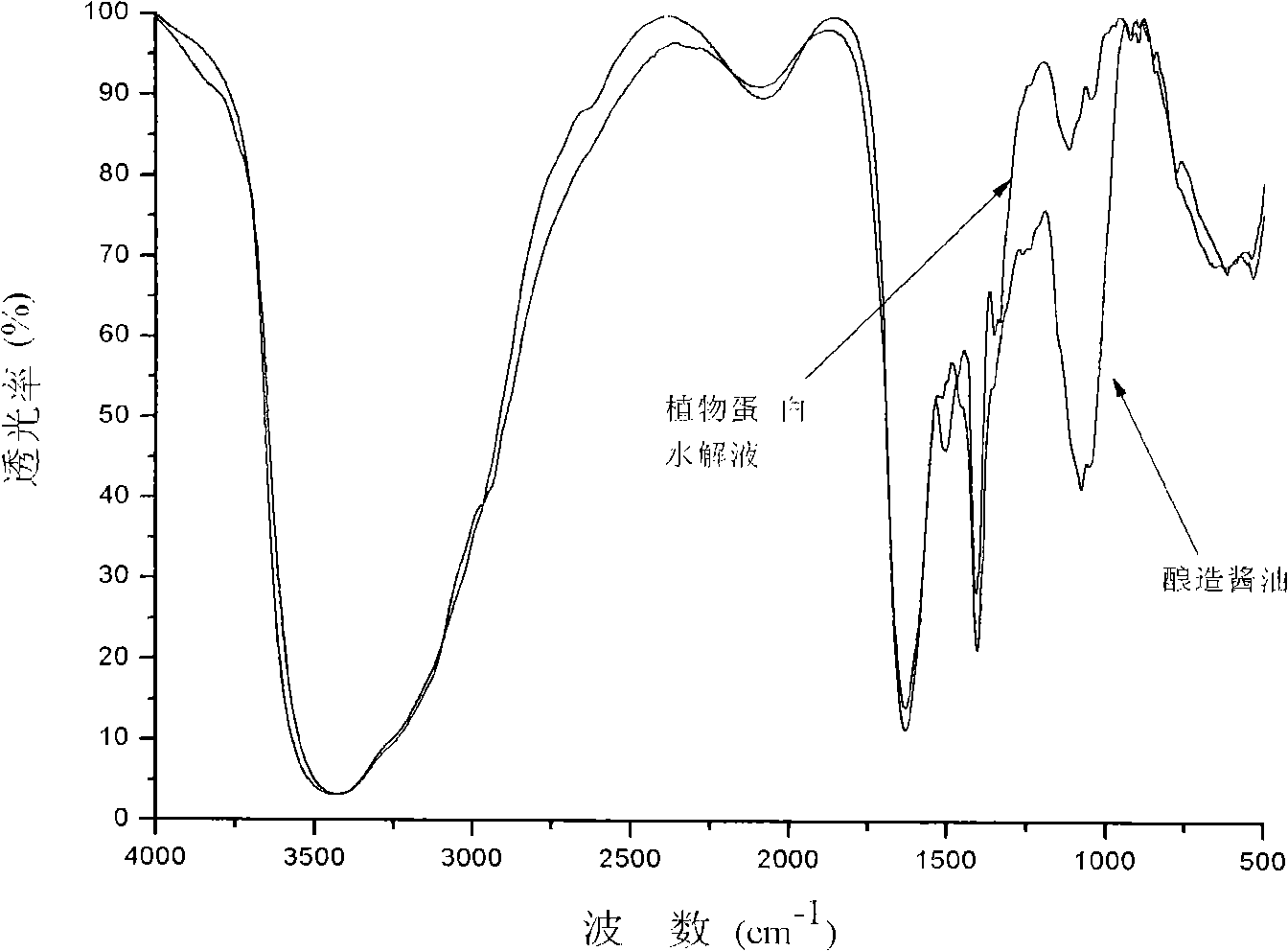

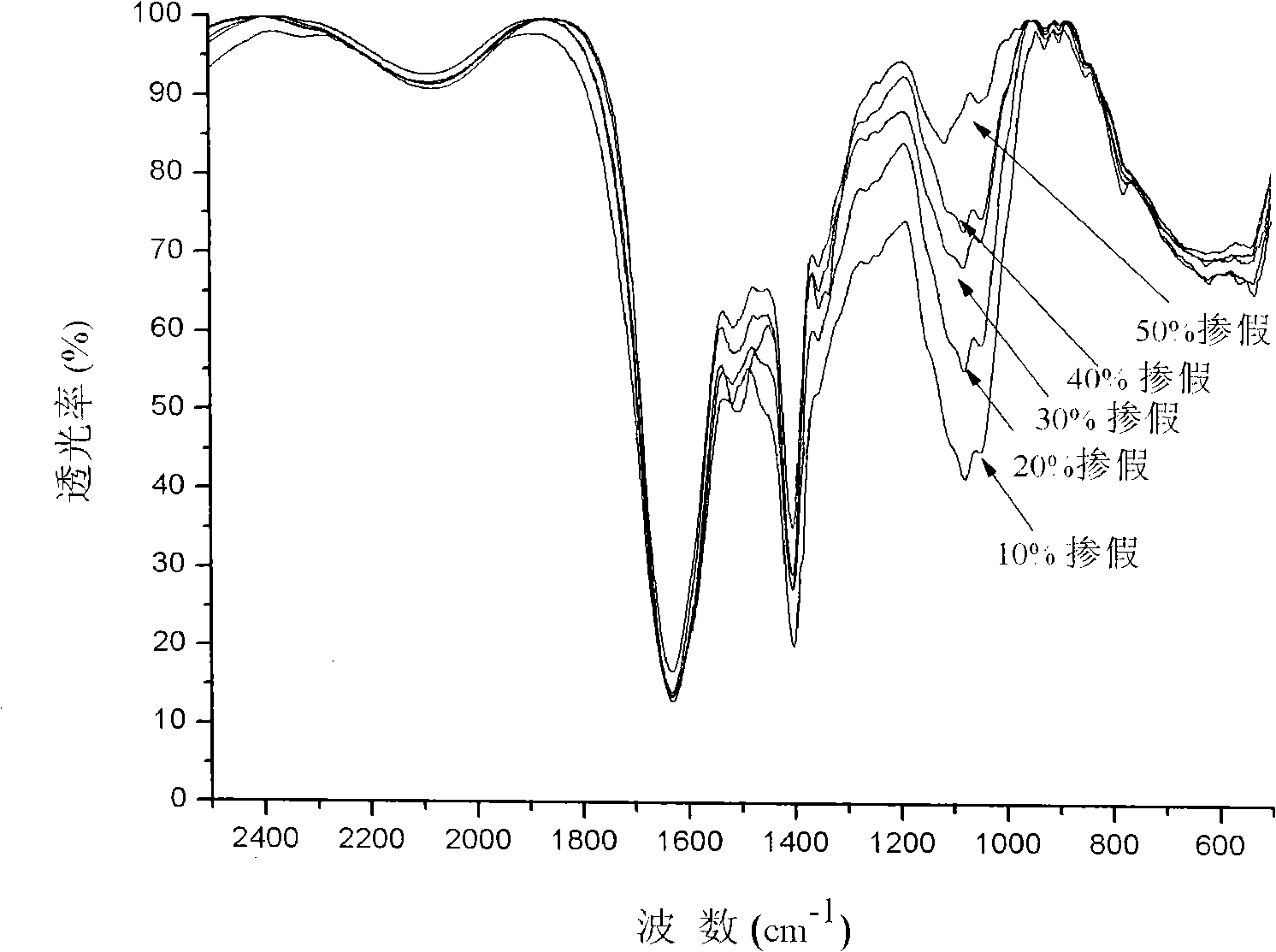

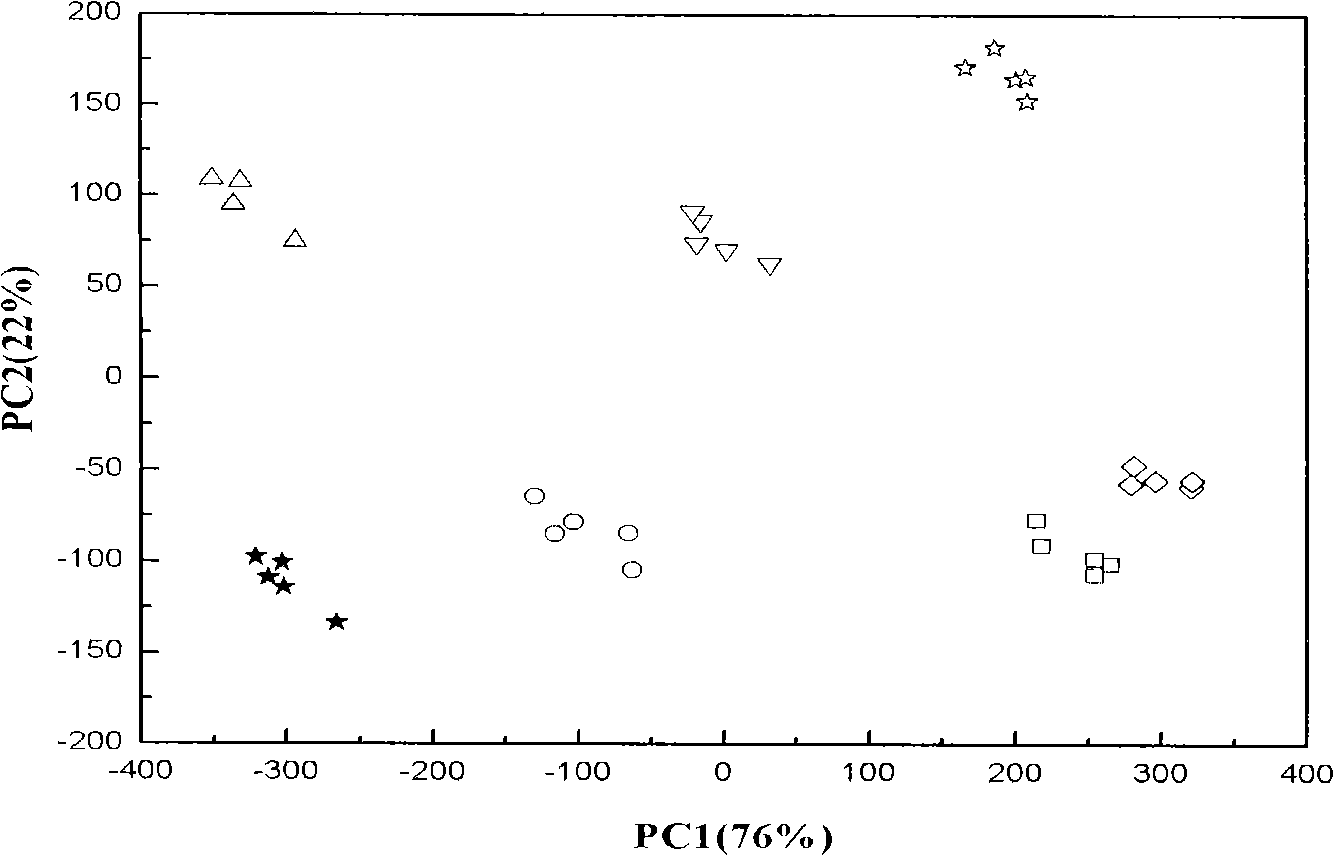

Method for identifying brewed sauce and prepared sauce based on partial least squares (PLS) method

InactiveCN102053072AEasy to operateImprove accuracyColor/spectral properties measurementsLeast squaresChemistry

The invention relates to a method for identifying brewed sauce and prepared sauce based on a partial least squares (PLS) method. The method comprises the following specific steps: acquiring a standard infrared atlas, establishing a PLS identification model, and judging. in the method, an infrared spectrum in Fourier transform is combined with the PLS, and class analysis is carried out on the brewed sauce, hydrolyzed vegetable protein (HVP) and the prepared sauce obtained by adding HVPs at different weight ratios (10-50%). The method is easy to operate, has high accuracy, can effectively detect the additive amount of HVP in the prepared sauce, and has the maximum deviation which is less than 3.5% and is suitable for industrial application.

Owner:SOUTHWEST UNIVERSITY

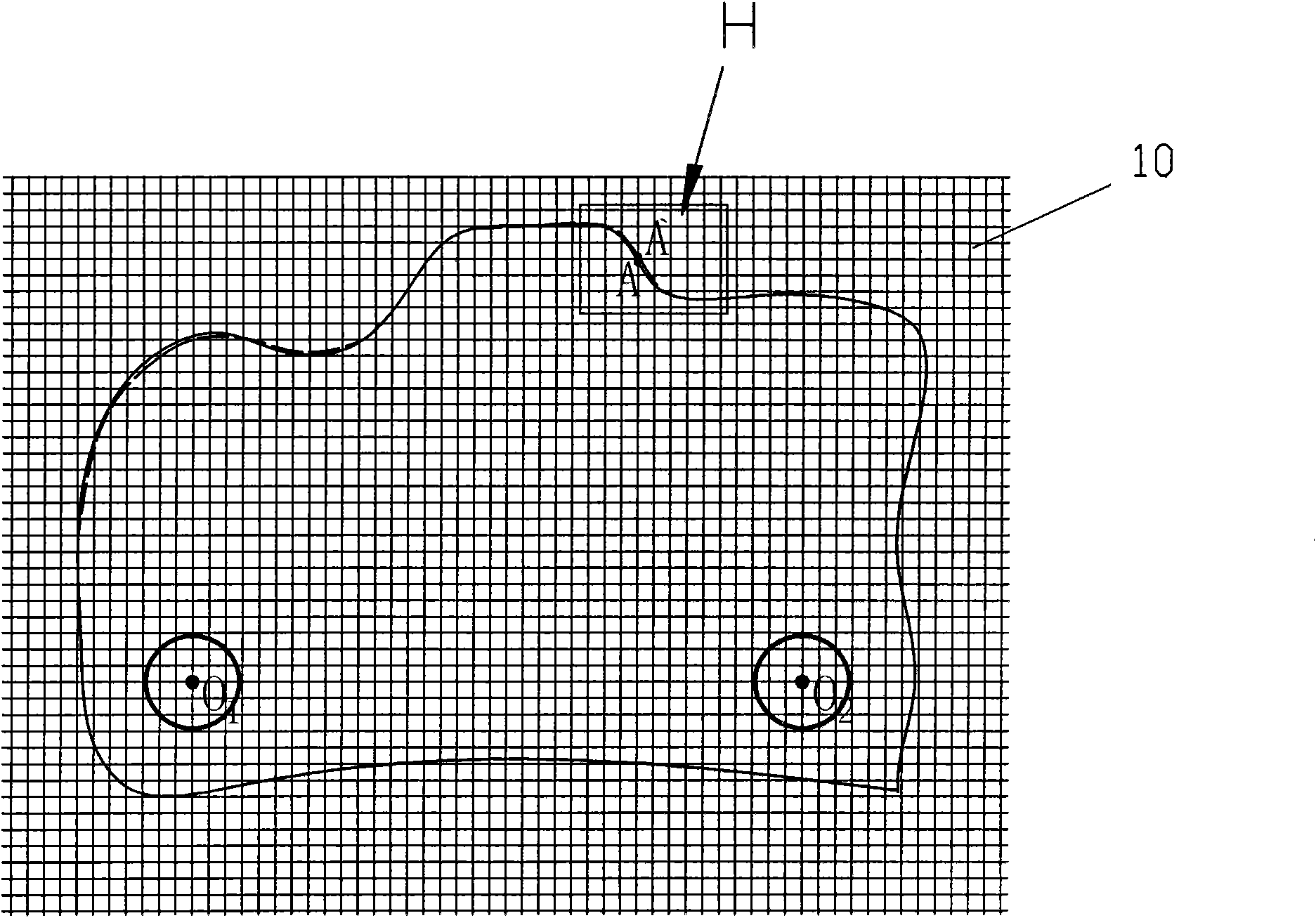

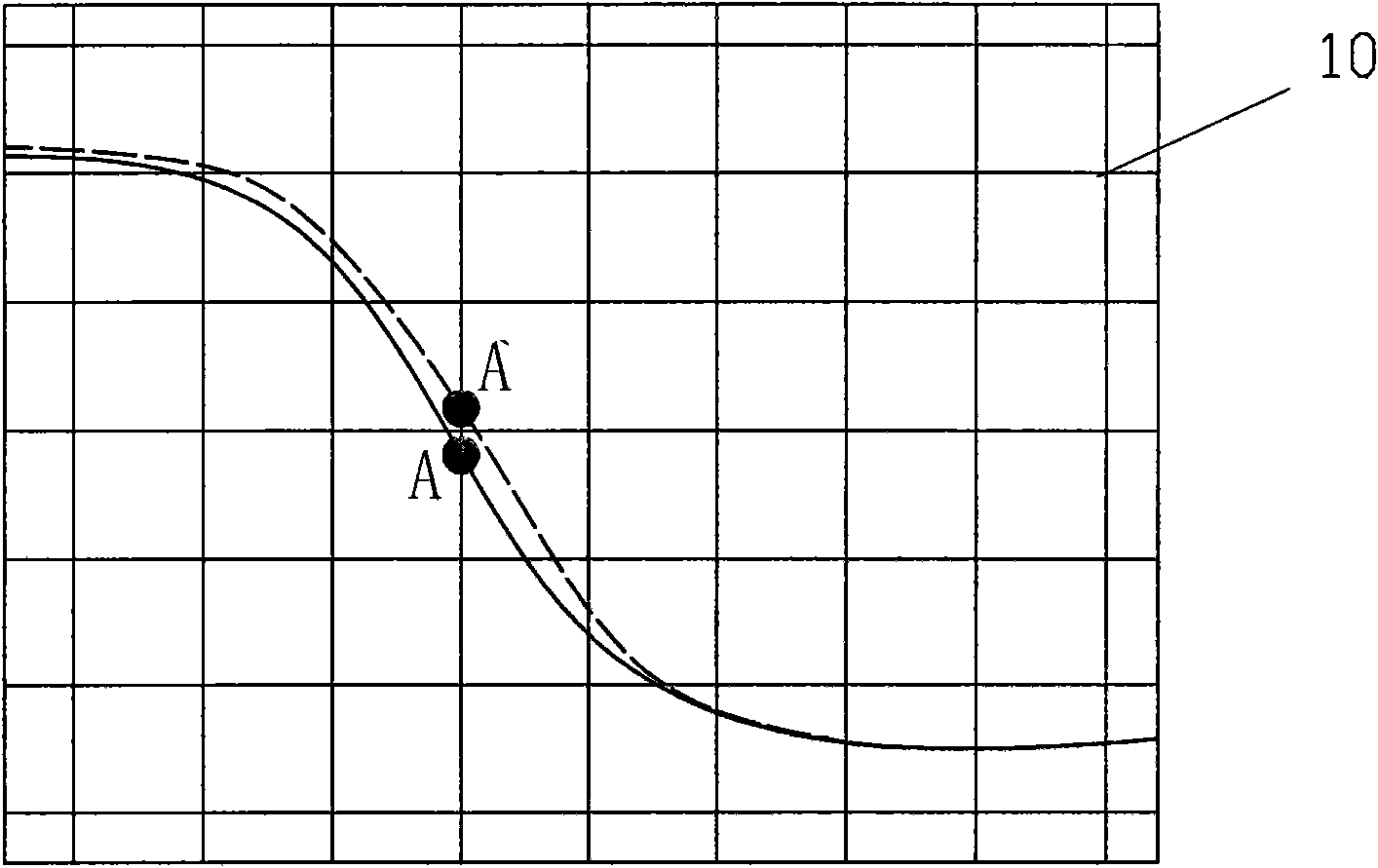

Contour line quality detection method

InactiveCN101614527AImprove accuracyReduce false positivesUsing optical meansGraphicsMeasuring instrument

The invention relates to the measurement technical field, in particular to a detection method for measuring product contour line combining a photoelectric instrument. The method includes the following steps: inputting a standard graph into a computer, reading corresponding point or line of the standard graph in the world coordinate system of the computer as the basis standard, and then constructing a virtual network in the computer and recording the coordinate of the intersecting point of the contour line of the standard graph and the virtual network; inputting the image of a product to be detected into the computer by a measurement instrument, leading the image to fall into a virtual grid and reading the coordinate of the intersecting point of the contour line of the image and the virtual grid; and comparing the coordinate value of the intersecting point of the contour line of the standard graph and the virtual grid with that of the intersecting point of the corresponding part of the contour line of the image and the virtual grid and judging the product contour line quality by coordinate deviation value. The invention has high detection precision and easy operation and accords with industrial utilization.

Owner:HEXAGON METROLOGY SPA

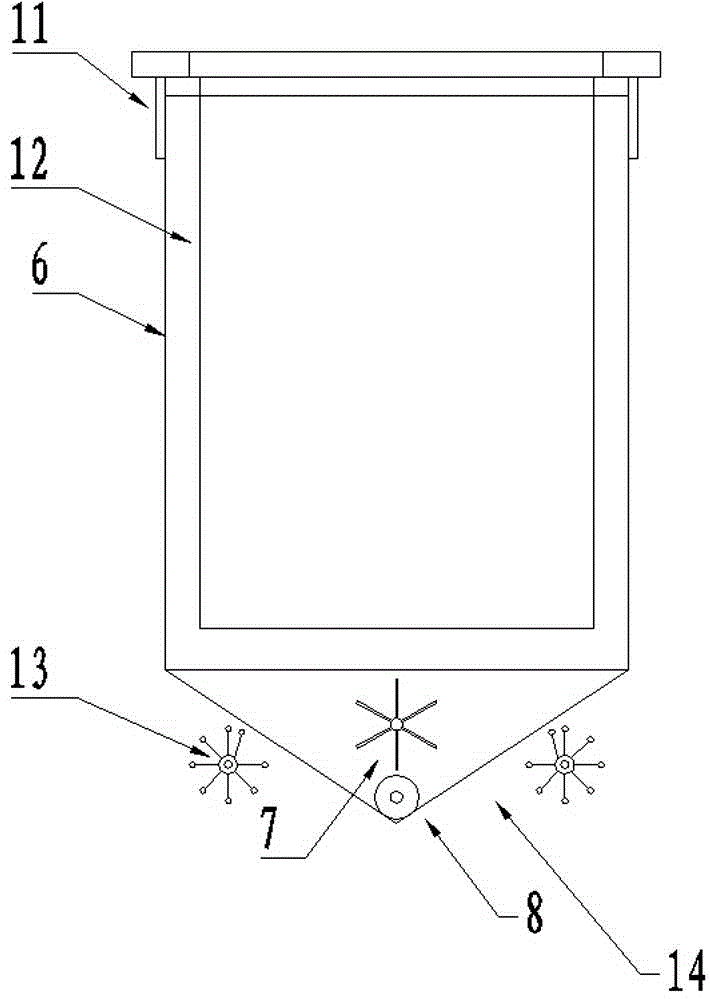

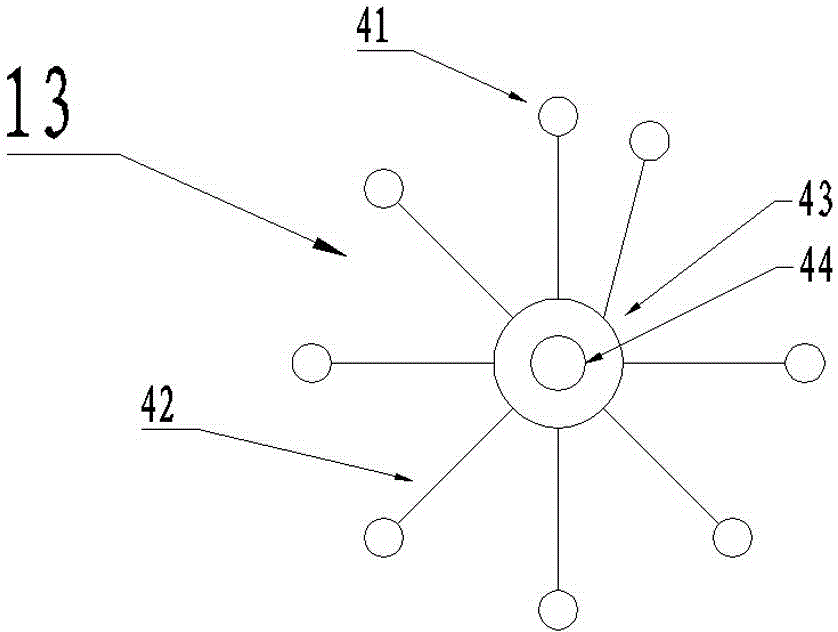

Wet-process discharge type ore pulp electrolytic lead device

ActiveCN104532302ASimple and reasonable structureEasy to implementPhotography auxillary processesAxial-flow pumpElectrolysis

The invention discloses a wet-process discharge type ore pulp electrolytic lead device. An electrolytic membrane for containing ore pulp is arranged in an electrolytic tank body, and a stirring device is arranged in an electrolytic membrane cavity; the electrolytic membrane cavity is connected with the electrolytic tank body through an axial flow pump and a pipe; the electrolytic tank body is of a conic bottom structure, the conic bottom is provided with an axial stirring paddle and a spiral conveyor, and a knocking device is arranged outside the conic bottom; the conic bottom is connected with a temporary storage barrel through a collecting hopper, a discharging pump and a conveying pipe, a bib and a valve are arranged at the bottom of the temporary storage barrel, a filter net is arranged in the temporary storage barrel to be connected with a circulation pump, and an outlet of a pipe of the circulation pump is connected with the electrolytic membrane cavity. By means of the wet-process discharge type ore pulp electrolytic lead device, low-speed long-paddle large-area sweeping is adopted, so that coincident temperature density is achieved with low energy consumption; the knocking device and the spiral conveyor conduct synchronous and reasonable interruption starting, so that continuous tank bottom cleaning and sedimentation sponge lead discharging are achieved with low energy consumption; liquid circulation homogenization electrolysis is achieved through the axial flow pump and the pump, and the wet-process discharge type ore pulp electrolytic lead device is suitable for industrialization use and wide in prospect.

Owner:中科创新发展(北京)科技有限公司

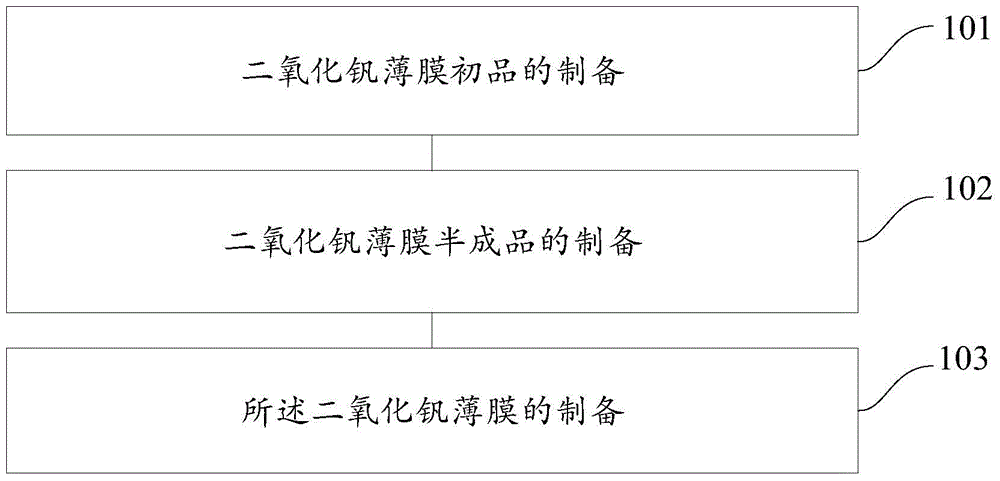

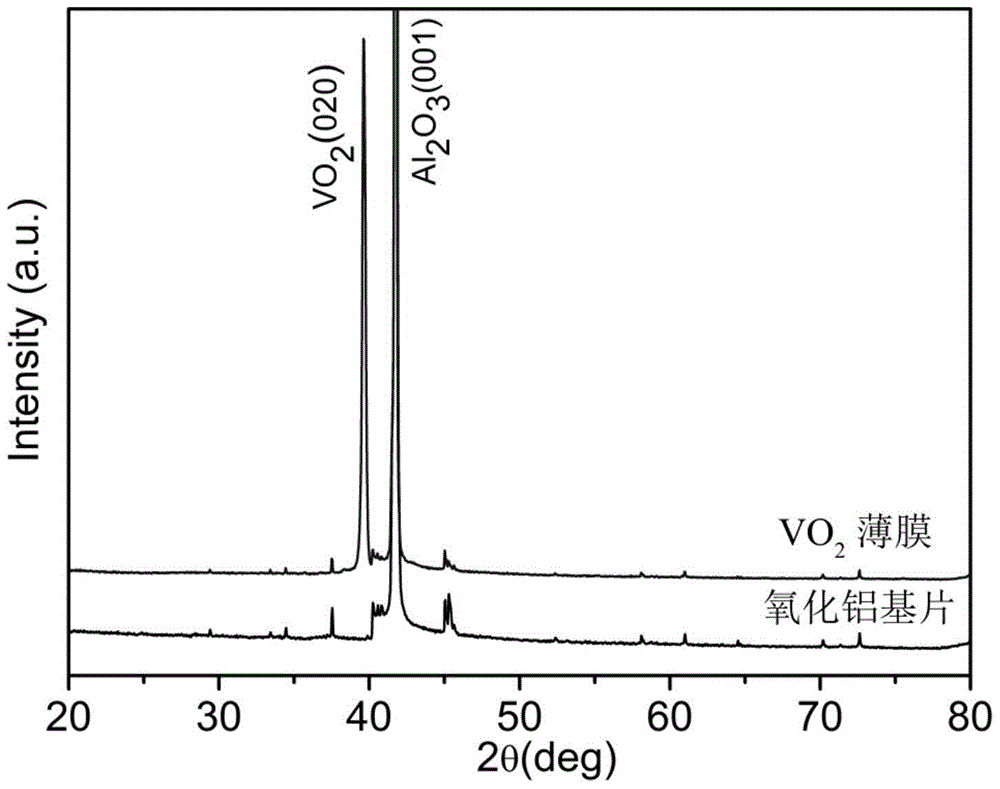

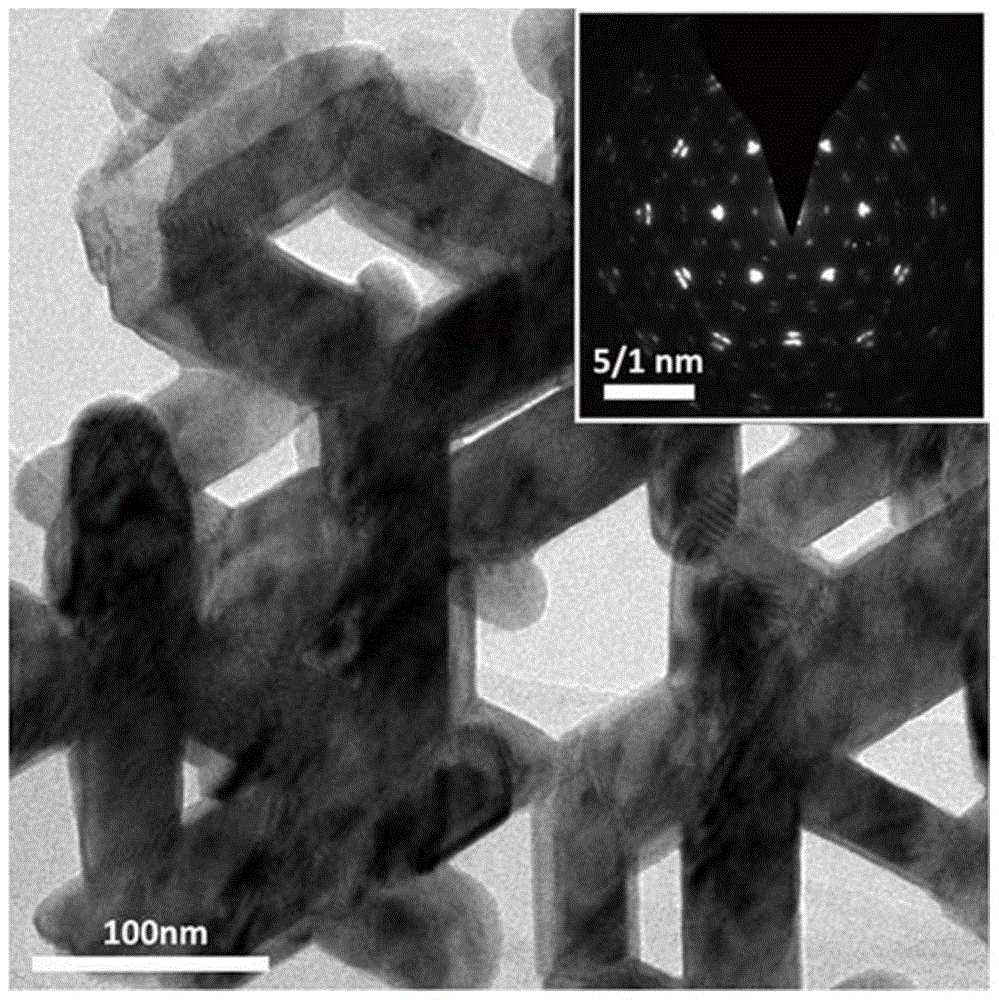

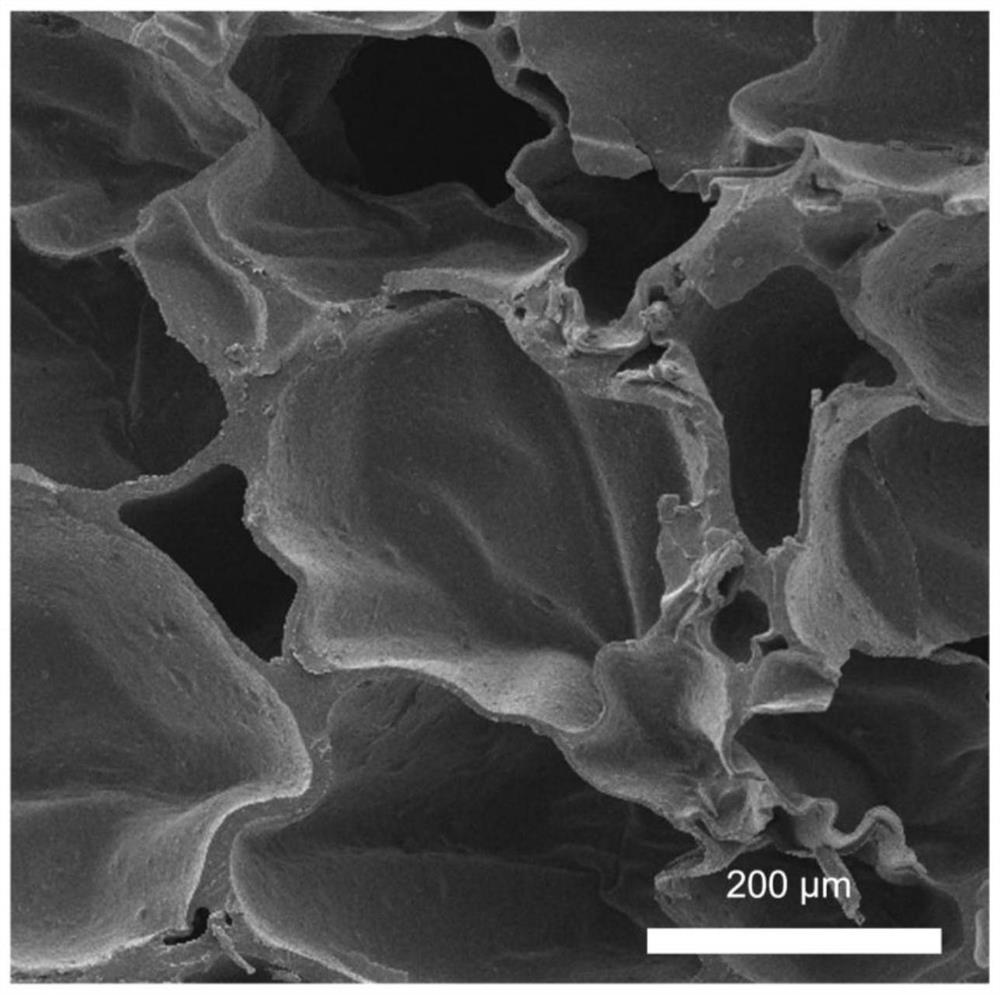

Vanadium dioxide thin film having regular truss network structure and preparation method thereof

InactiveCN105669248AUniform filmExcellent thermally induced phase change performanceChemistryTransmittance

The invention provides a vanadium dioxide thin film having a regular truss network structure and a preparation method thereof. The vanadium oxide thin film is an M phase and has the regular truss network structure formed by uniformly connecting nanorods, wherein the nanorods are each of a monocrystal structure, the length of crystal grains is 200-500 nm and the width of the crystal grains is 30-60 nm. The method includes the steps: step (1), preparation of an initial product of the vanadium dioxide thin film; step (2), preparation of a semi-finished product of the vanadium dioxide thin film, and step (3), preparation of the vanadium oxide thin film. The vanadium dioxide thin film prepared by the method provided by the embodiment of the invention has excellent thermal induced phase transition performance and excellent heat induced resistance modulation capability, and also has relatively high visible light transmittance rate and relatively strong thermal radiation modulation performance. At the same time, the thin film morphology, size and density are effectively controlled through controlling reaction conditions, and the preparation method has the advantages of simple process, large-area production, easily obtained raw materials, low cost and the like and is suitable for use in industrialization.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

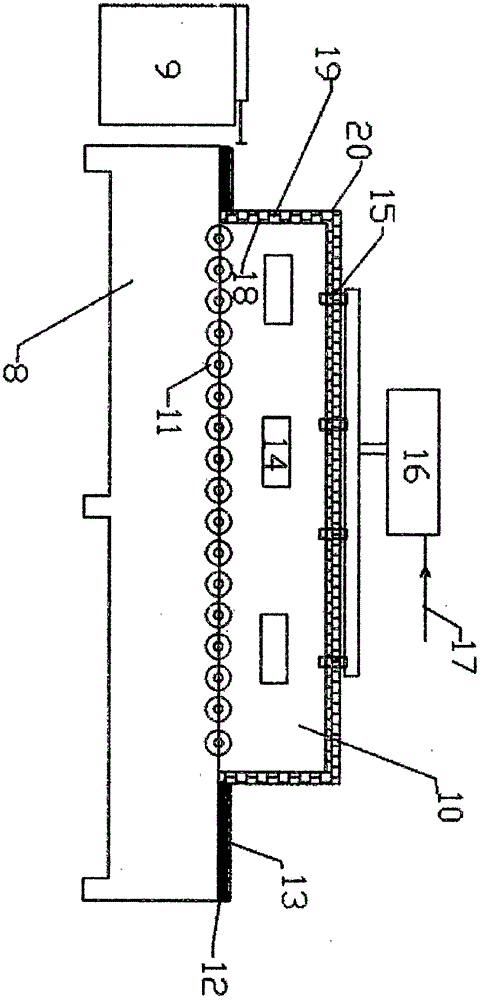

Large-size ceramic substrate, and preparation method and production line thereof

InactiveCN105906331AHigh mechanical strengthGood thermal conductivityCeramic shaping plantsAdhesiveSolvent

The invention discloses a large-size ceramic substrate which is prepared from the following components in parts by weight: 1 part of ceramic powder, 0.04-0.14 part of adhesive, 0.005-0.018 part of dispersing agent, 0.02-0.06 part of plasticizer and 0.3-0.9 part of solvent. The ceramic powder is prepared from the following raw materials in percentage by weight: 93-96% of aluminum oxide, 0.5-3% of silicon dioxide, 0.3-2% of magnesium oxide, 0.2-1% of calcium oxide, 0.1-2% of yttrium oxide, 0.1-2.5% of barium carbonate, 0.05-1% of zirconium oxide and 0.1-2% of bismuth oxide. The invention also discloses a production method of the ceramic substrate and a production line required by the production method. The ceramic substrate has the characteristics of excellent mechanical strength and favorable heat conductivity. The preparation method is simple and is low in cost. The production line is simple, does not occupy the space, and effectively improves the quality of products.

Owner:SINOCERAM TECH (ZHENGZHOU) CO LTD

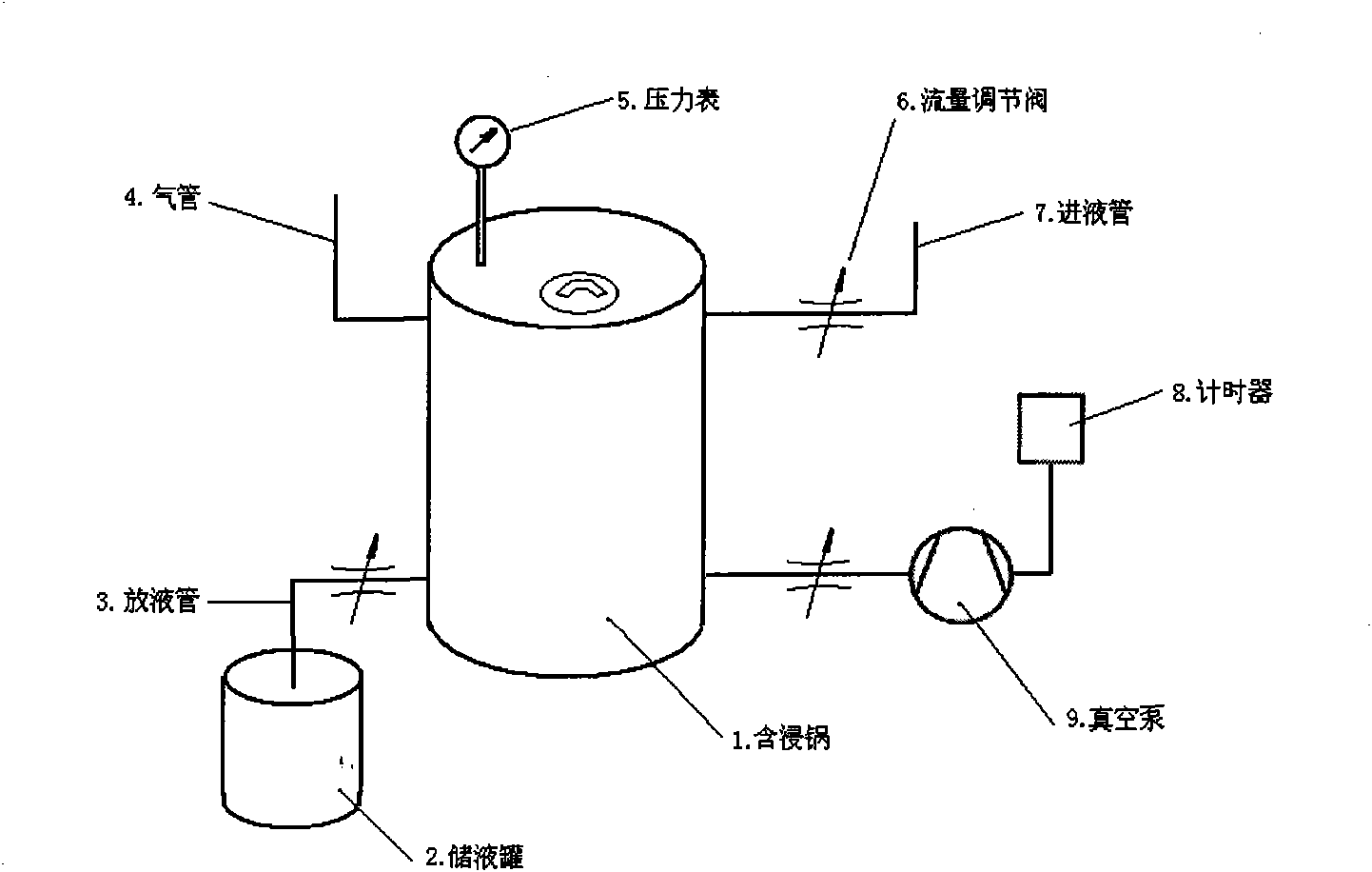

Method for impregnating low-viscosity electrolyte used for electrolytic capacitor

The invention relates to a method for impregnating low-viscosity electrolyte used for an electrolytic capacitor. The method comprises the following steps of: (1) discharging a cartridge to obtain a cartridge sieve; (2) then superposing the cartridge sieve in an impregnation container and sealing and vacuumizing the impregnation container; (3) sucking the low-viscosity electrolyte from a liquid storage barrel, keeping the impregnation container in a vacuum state and then restoring the impregnation container back to a normal-pressure state; (4) applying positive pressure to the impregnation container and vacuumizing the impregnation container again after the electrolyte is completely discharged; and (5) taking the cartridge sieve out. The method of the invention has the advantages of simplicity, low cost, suitability for industrial use and capability of effectively controlling the impregnation time, impregnation rate and impregnation effect of the capacitor cartridge during and after impregnation by rationally utilizing equipment, so that the low-temperature performance of the manufactured capacitor is met; and damage to the capacitor cartridge is avoided without performing a centrifugal fluid exhaustion process, so that the stability of the capacitor is improved and the service life is prolonged.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

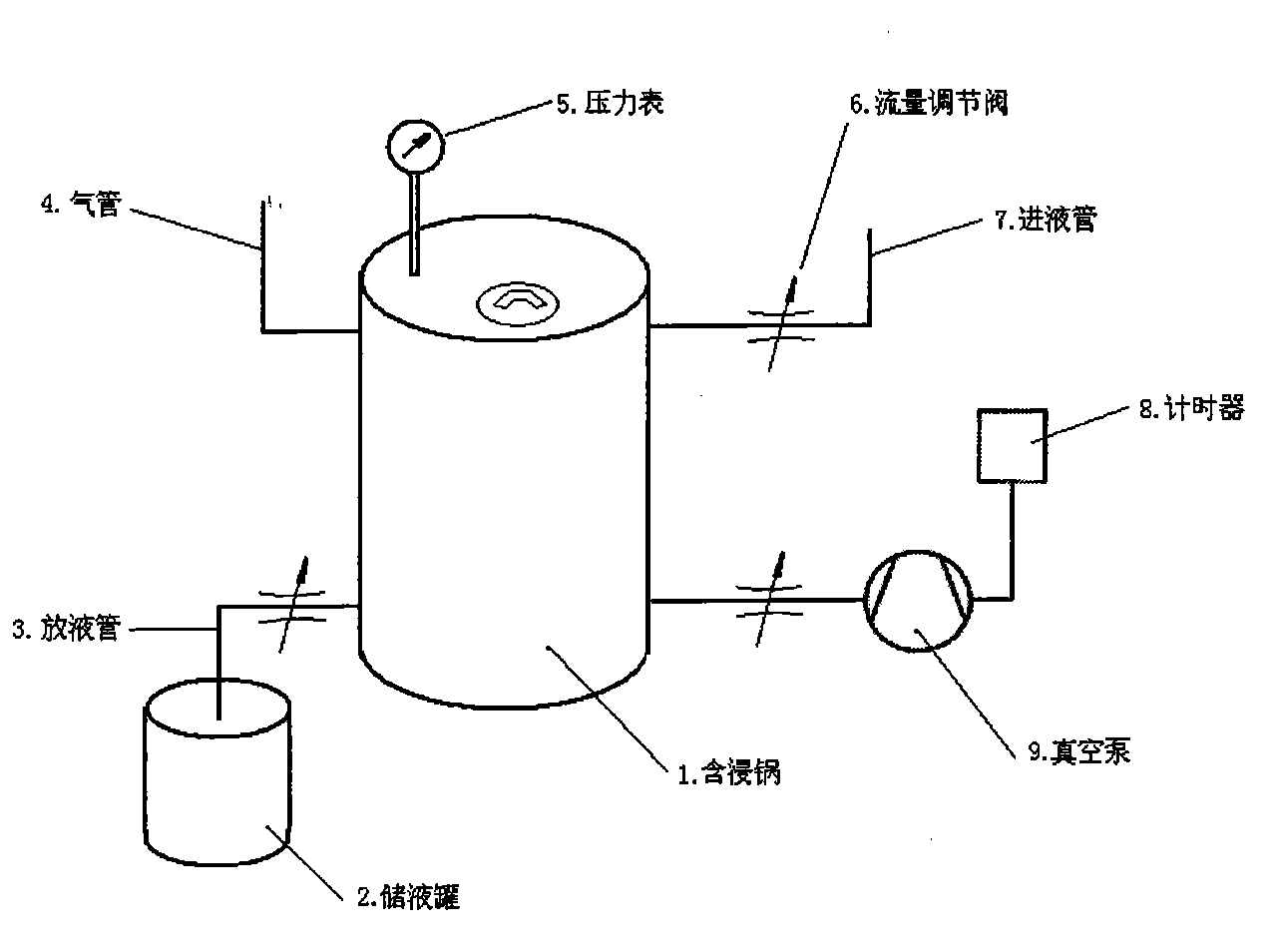

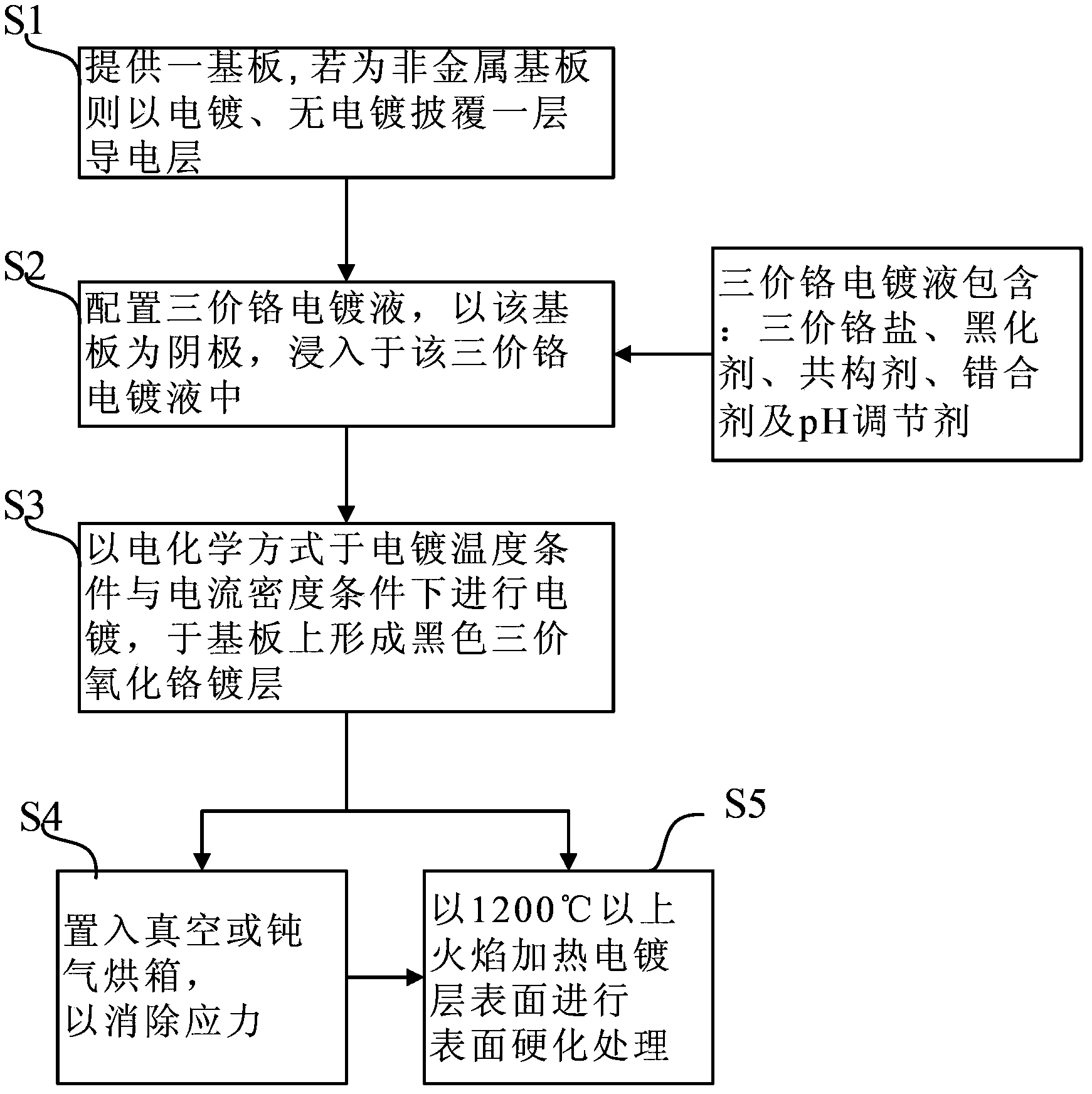

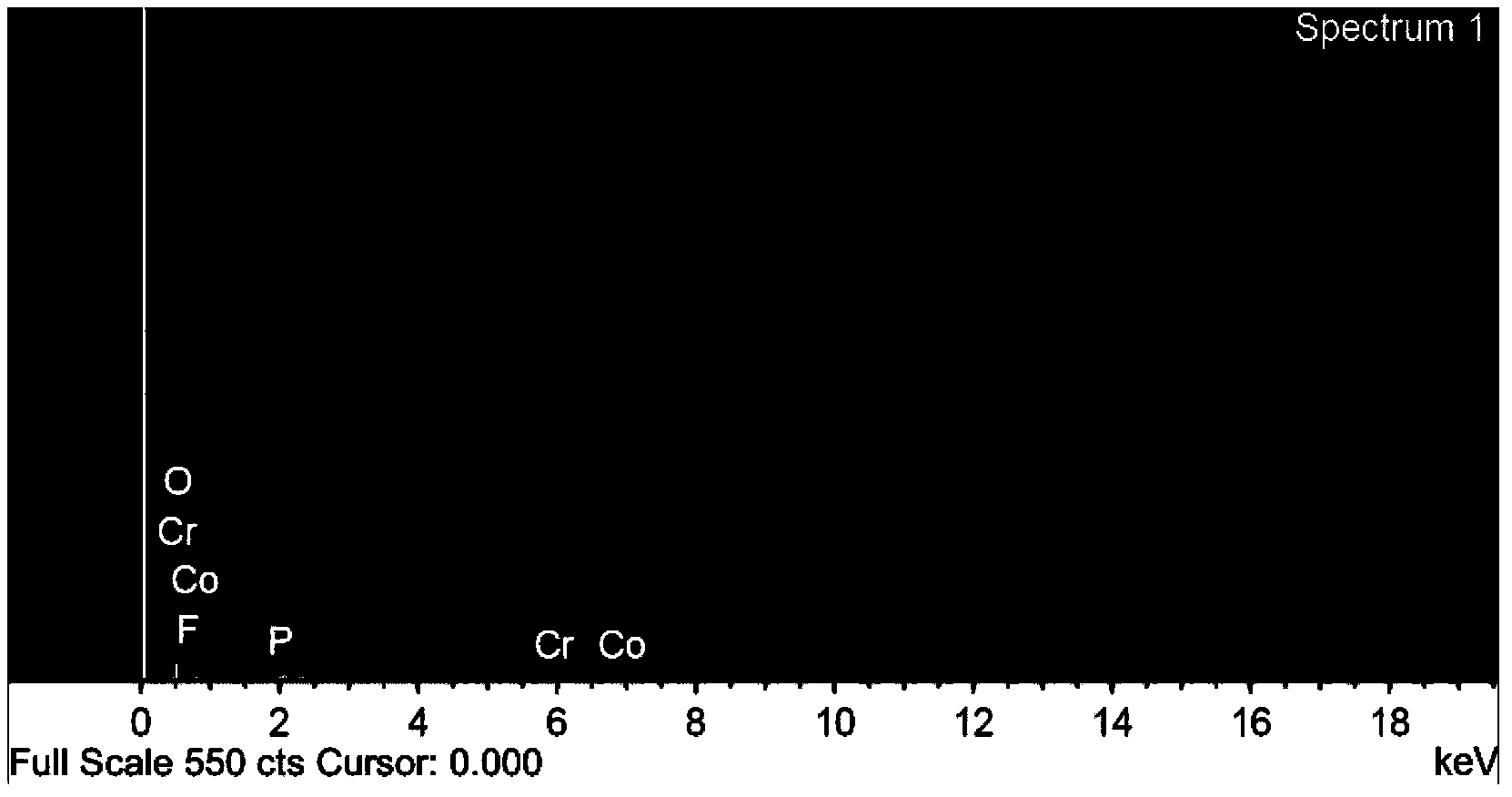

Electrochemical method of forming black trivalence chromic oxide coating and black trivalence chromic oxide coating

ActiveCN103510131AReduce the burden on the environmentReduce the difficulty of wastewater treatmentCorrosionInorganic salts

The invention discloses an electrochemical method of forming black trivalence chromic oxide coating and the black trivalence chromic oxide coating; a black trivalence chromic oxide electroplating layer is formed on the surface of the substrate through the electroplating method; black trivalence chromic oxide electroplating liquid comprises chromic salt, darkening agent containing nitrate, co-deposition agent containing cobalt salt, complexing agent of inorganic salt, and water solution formed by PH modifier of inorganic acid salt. The thickness of the black trivalence chromic oxide electroplating layer formed under the set electroplating operation condition is between 0.5-15 micrometers, the gray-scale value of the darkening degree is below 45%, and the requirements of corrosion resistance, high surface hardness and good wear resistance are satisfied so as to be applied on tools needing high precision, high hardness and wear resistant property, such as a slide rail and a screw rod.

Owner:DEXNANO CHEM TECH

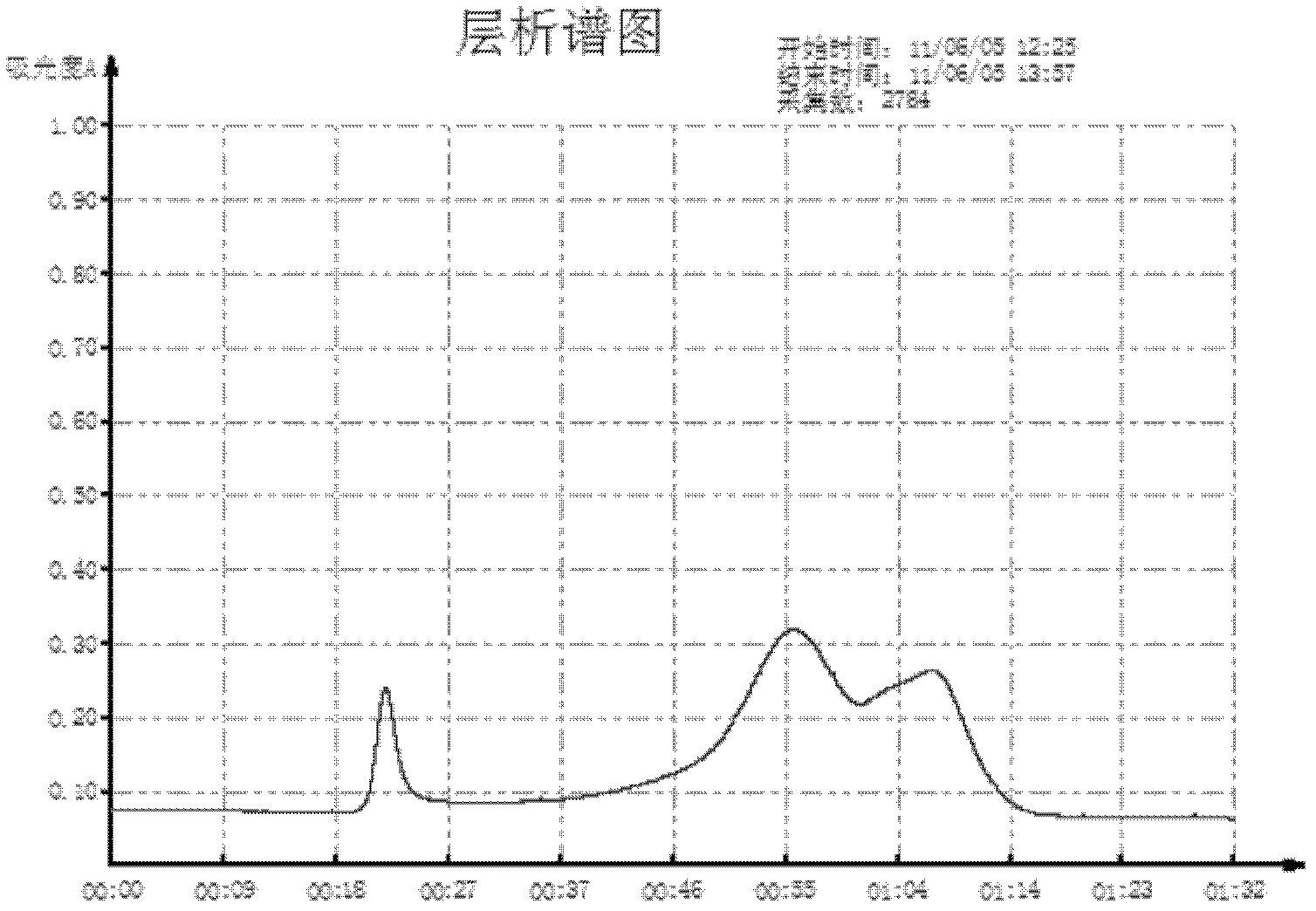

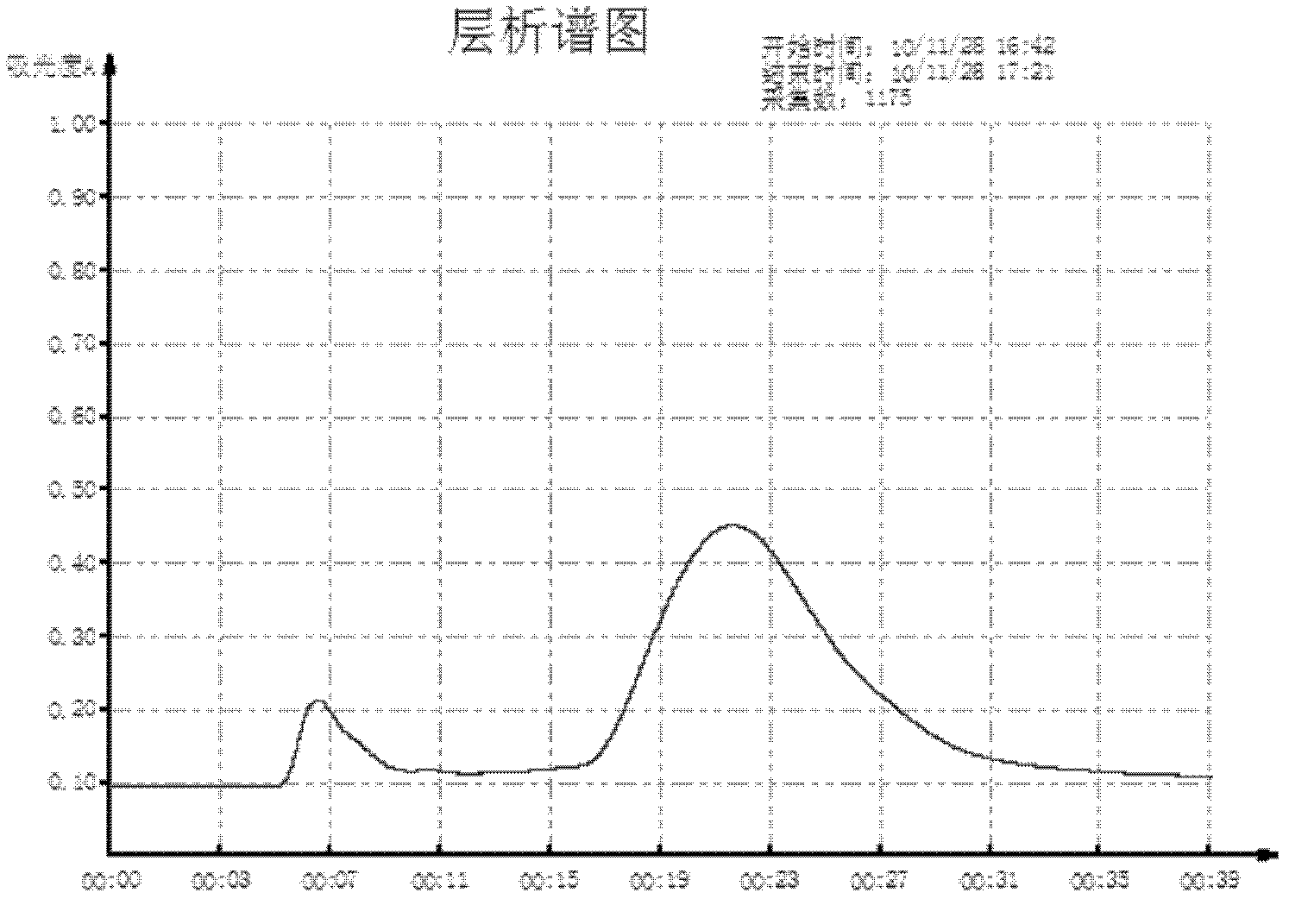

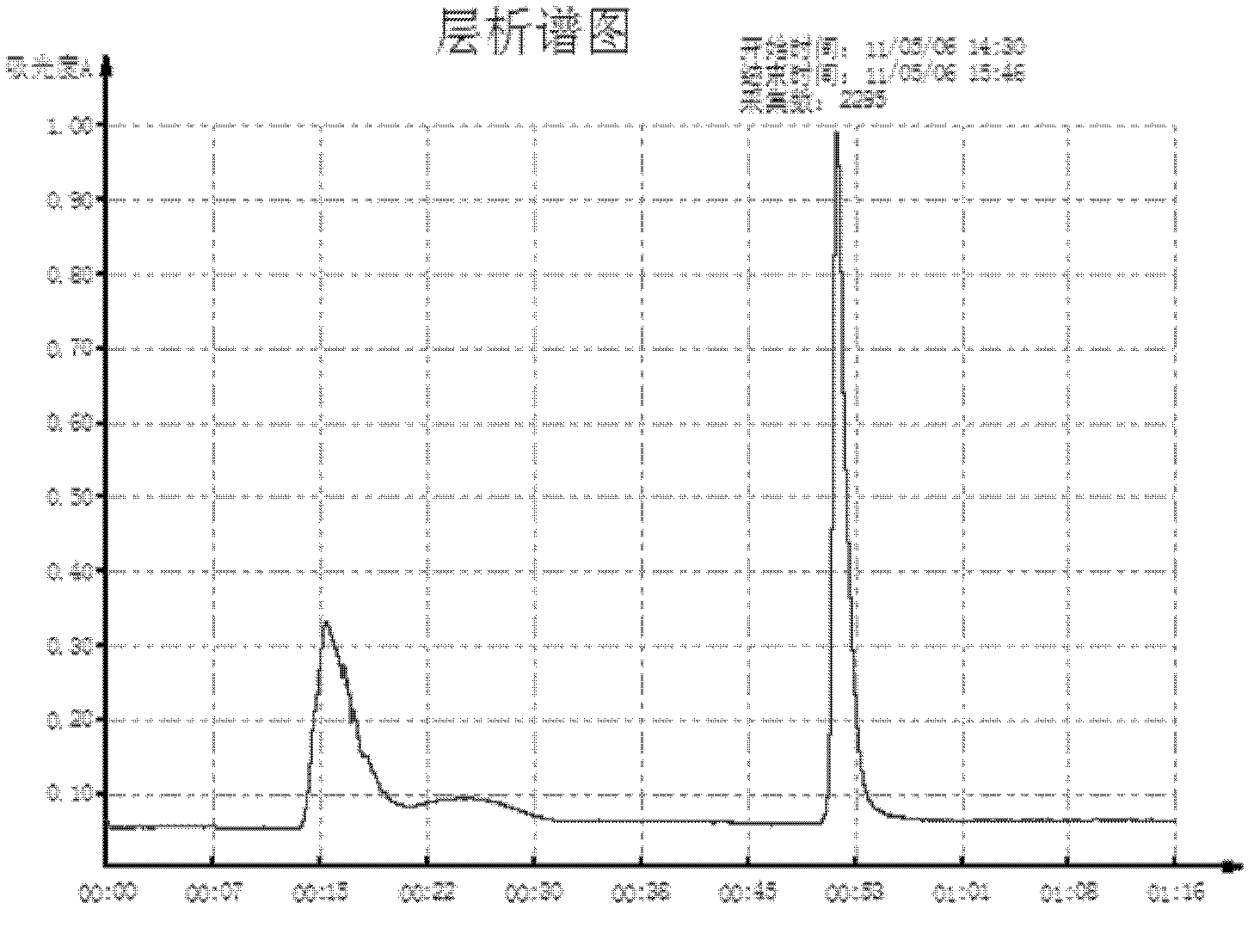

Foot-and-mouth disease purification vaccine, preparation method and applications thereof

ActiveCN102988970AGood immune effectStable in natureAntiviralsRecovery/purificationAdjuvantFiltration

The present invention discloses a foot-and-mouth disease purification vaccine, a preparation method and applications thereof. The preparation method comprises: adopting protamine sulfate precipitation to remove most of hybridproteins and nucleic acids of host cells; condensing a virus liquid through a concentration system to be adopted as a chromatography sample; and selecting a polyacrylamide dextran gel as a chromatography medium to carry out purification elution, collecting a first elution peak, carrying out filtration sterilization inactivation, adding an adjuvant to carry out emulsification, and carrying out sub-packaging to obtain the foot-and-mouth disease purification vaccine. The preparation method has characteristics of economy, efficiency, low cost, simple and reasonable process, and effective removal of impurities in the host cells and the culture medium, wherein virus recovery rate is more than 85%, protein and nucleic acid removal rate is more than 90%, and the foot-and-mouth disease purification vaccine prepared by the preparation method has characteristics of safety, good immunity and stable property.

Owner:内蒙古必威安泰生物科技有限公司

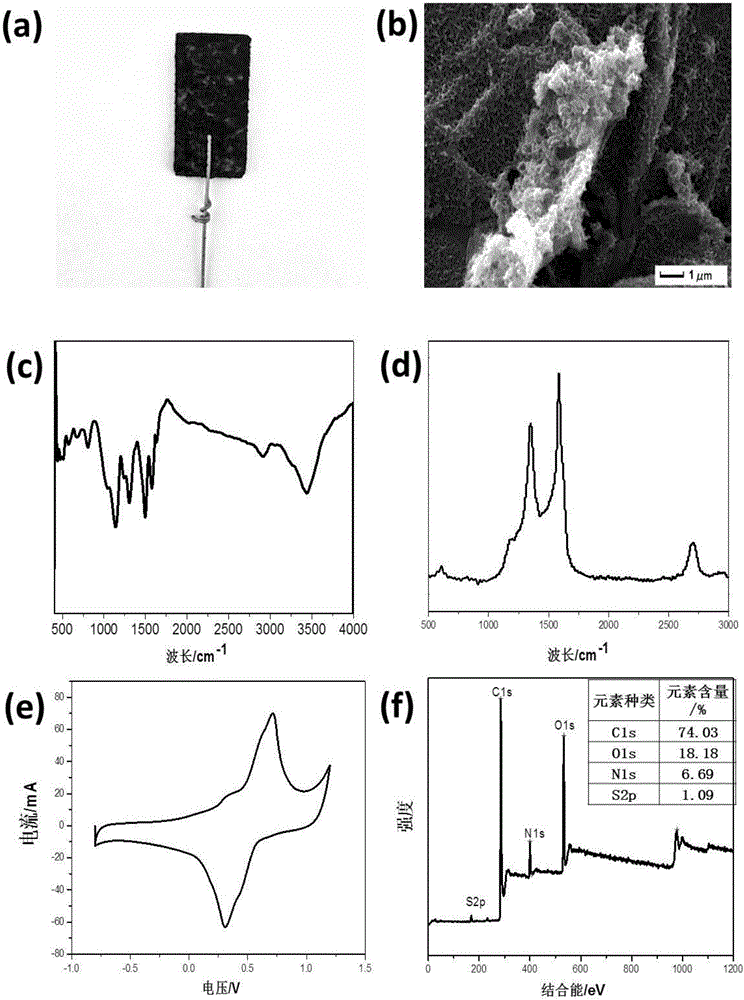

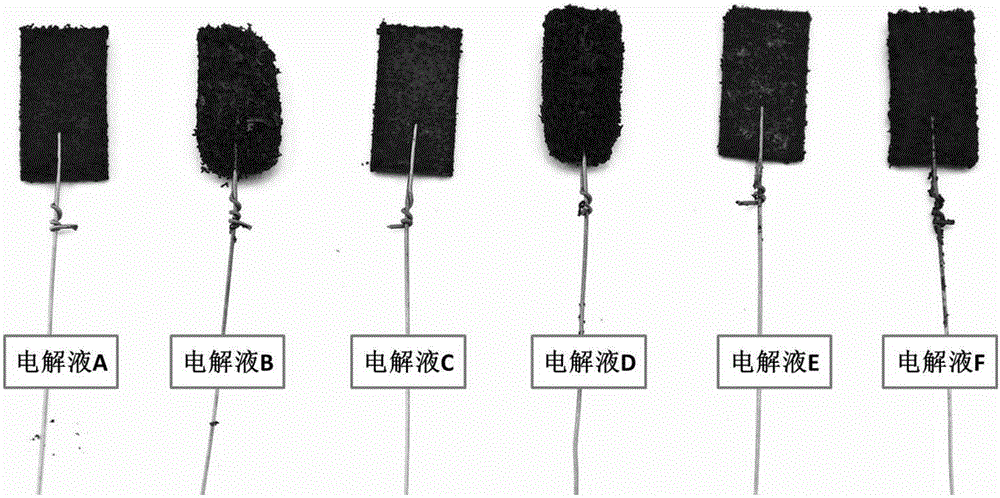

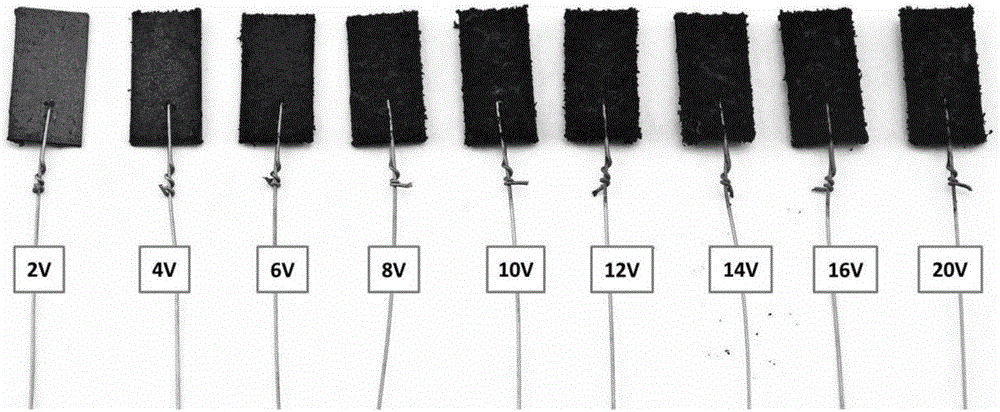

One-step in-situ preparation method of graphene/polyaniline composite electrode

InactiveCN106058278AEasy to adjust sizeEasy to adjust shapeCell electrodesBiochemical fuel cellsComposite electrodeSynthesis methods

The invention provides a one-step in-situ preparation method of a graphene / polyaniline composite electrode. The in-situ synthesis of graphene and polyaniline in the composite electrode is simultaneously performed. The method comprises the following steps that the composite electrode is processed and prepared under the effect of direct current voltage by using a traditional graphite paper electrode as a carrier electrode and protonic acid / aniline electrolyte as a working medium and using a work electrode-counter electrode double electrode system; and the composite electrode is cleaned in deionized water and is naturally dried in the air. Compared with exogenous graphene modification means such as deposition, doping and smearing, and in-situ graphene stripping and synchronous polyaniline synthesis methods, the one-step in-situ preparation method has the advantages that the operation is simple; the processing is fast; and the bioelectrochemistry compatibility is high, and the like. Compared with a traditional electrode, the composite electrode is more suitable for a bioelectrochemistry system.

Owner:JIANGSU UNIV

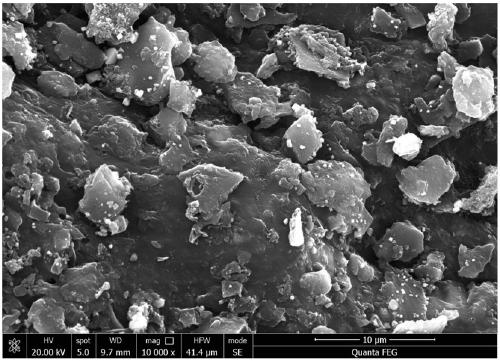

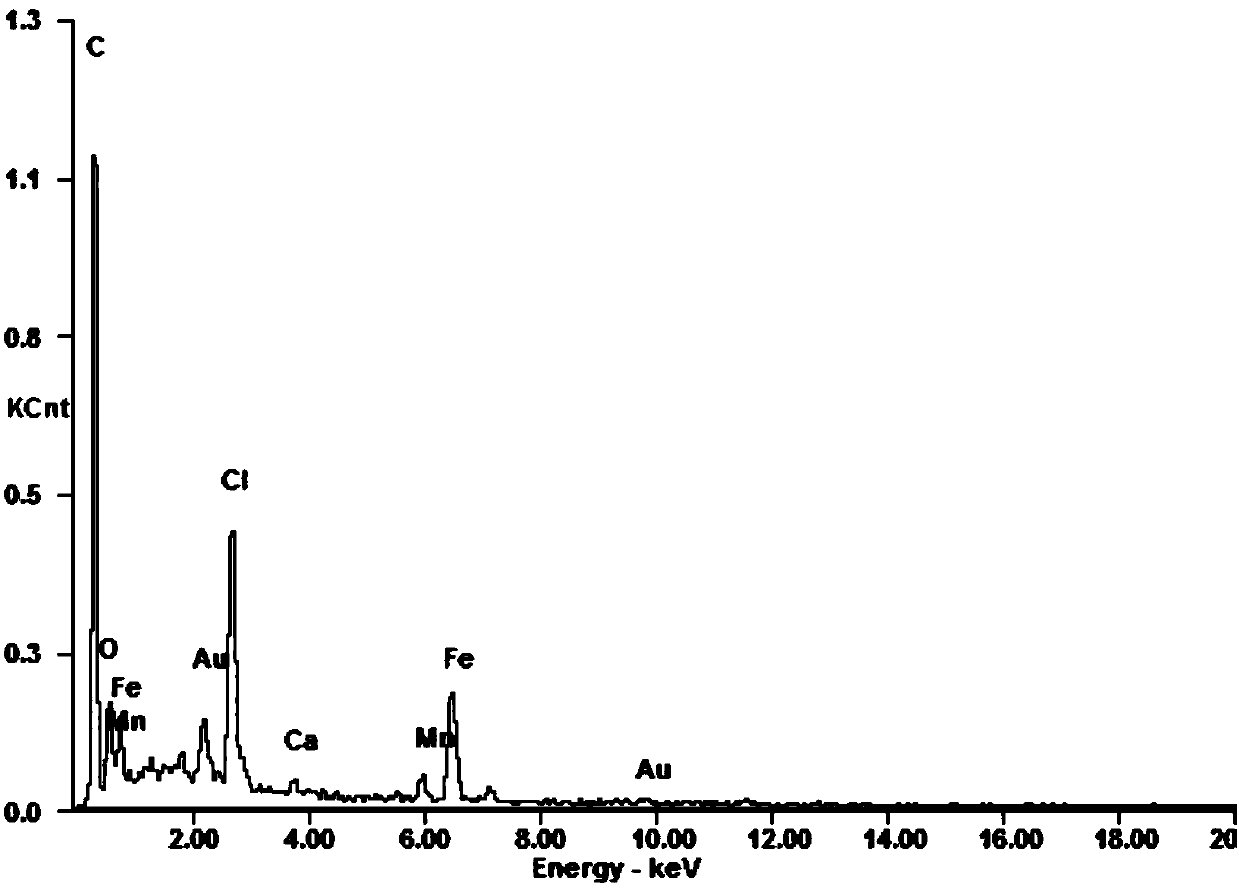

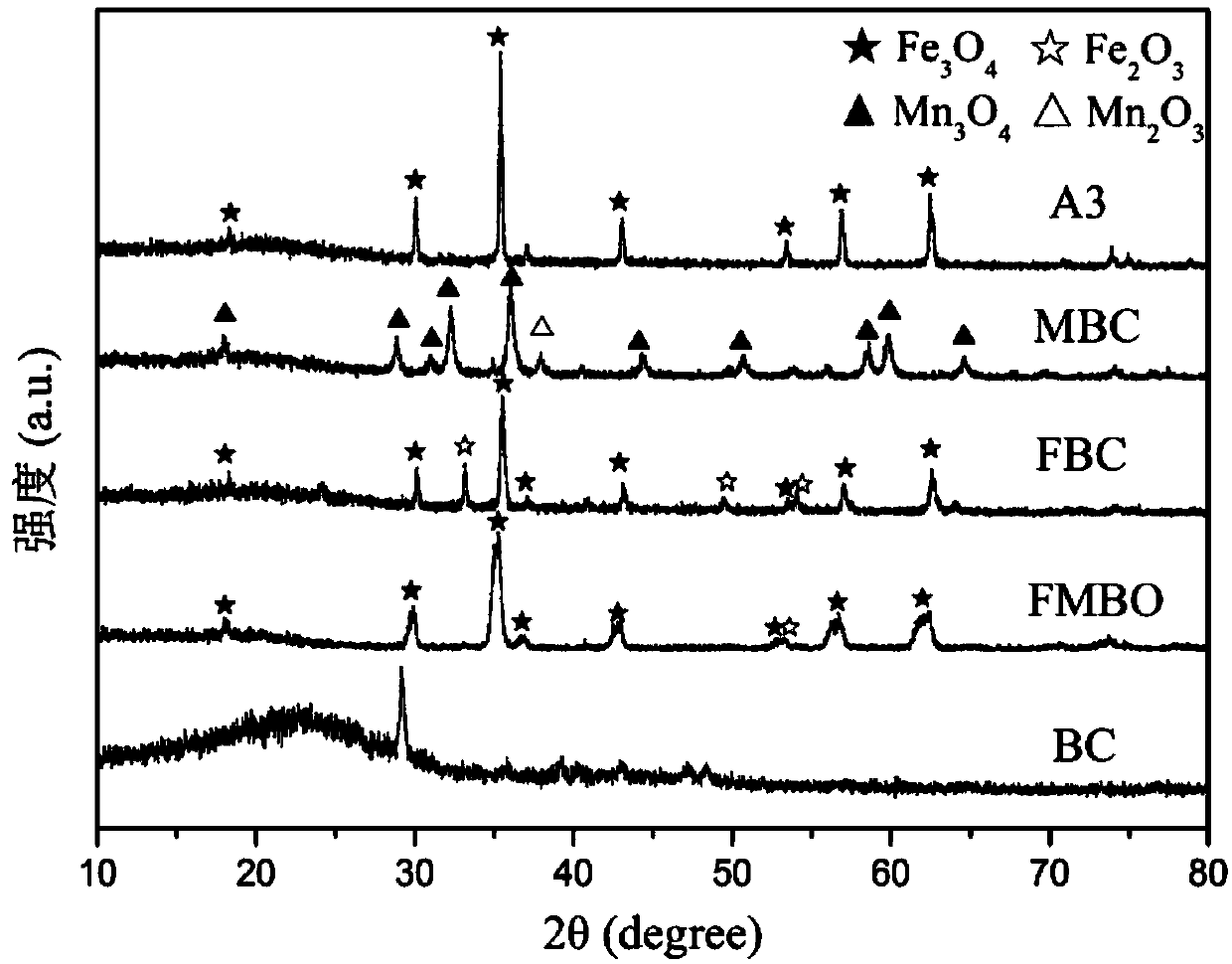

Ferro-manganese double metal oxide modified bio-carbon photo-Fenton composite material and preparation method thereof

ActiveCN109675581AImprove catalytic performanceStrong hydrogen peroxide decomposition abilityWater treatment compoundsCatalyst activation/preparationPolycyclic aromatic hydrocarbonManganese oxide

The invention discloses a ferro-manganese double metal oxide modified bio-carbon photo-Fenton composite material and a preparation method thereof. The composite material comprises bio-carbon and ferro-manganese double metal oxide attached to the bio-carbon, wherein the ferro-manganese double metal oxide is a mixture of iron oxide and manganese oxide; the iron oxide comprises Fe3O4 and Fe2O3; and the manganese oxide comprises Mn3O4 and Mn2O3. The preparation method comprises the steps of preparing a ferro-manganese double metal oxide modified bio-carbon precursor and calcining the ferro-manganese double metal oxide modified bio-carbon precursor. The composite material takes the bio-carbon as a main body material and the ferro-manganese double metal oxide as a modification material, combinesthe advantages of the bio-carbon and the ferro-manganese double metal oxide, has the advantages of excellent catalytic performance, high stability, high recoverability, low cost, environmental friendliness and the like, and has a good degradation effect on polycyclic aromatic hydrocarbon in water. The preparation method has the advantages of mild reaction condition, simple operation flow, environmental friendliness and the like, and can be applied to large-scale production and preparation.

Owner:HUNAN UNIV

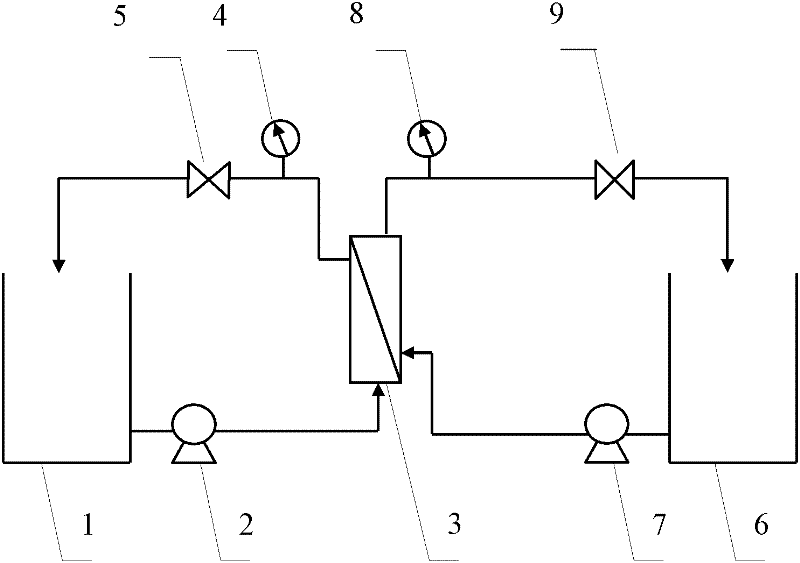

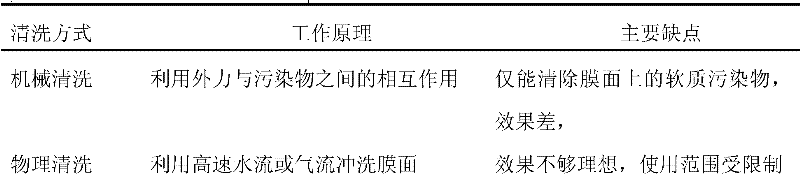

A kind of cleaning method and device of fouling membrane

InactiveCN102284249AShorten cleaning timeImprove cleaning efficiencySemi-permeable membranesDistilled waterRoom temperature

The invention discloses a method and a device for cleaning a polluted membrane. The cleaning method adopts two circulation systems of raw material liquid and drawing liquid. The raw material liquid with low osmotic pressure is "absorbed" by the high osmotic drawing liquid, and the membrane cavity will be polluted when the raw material liquid enters the drawing liquid. The impurities on the surface of the cortex and the impurities adsorbed in the porous support layer are taken away to realize the thorough cleaning of the polluted membrane; the raw material liquid circulation system and the draw liquid circulation system are prepared in cross-flow at the forward osmosis membrane module, and the cleaning cycle rate is 2.0-3.0L / min, the cleaning pressure is 0.2MPa, the cleaning temperature is room temperature, and the cleaning time is 20-30min; the raw material liquid is distilled water; the drawing liquid includes inorganic salt solution, sugar solution or a mixture of inorganic salt and sugar solution. The cleaning device is suitable for the cleaning method of the present invention, and includes two circulation systems of raw material liquid and drawing liquid, and the two circulation systems are prepared in cross-flow at the forward osmosis membrane module.

Owner:TIANJIN POLYTECHNIC UNIV

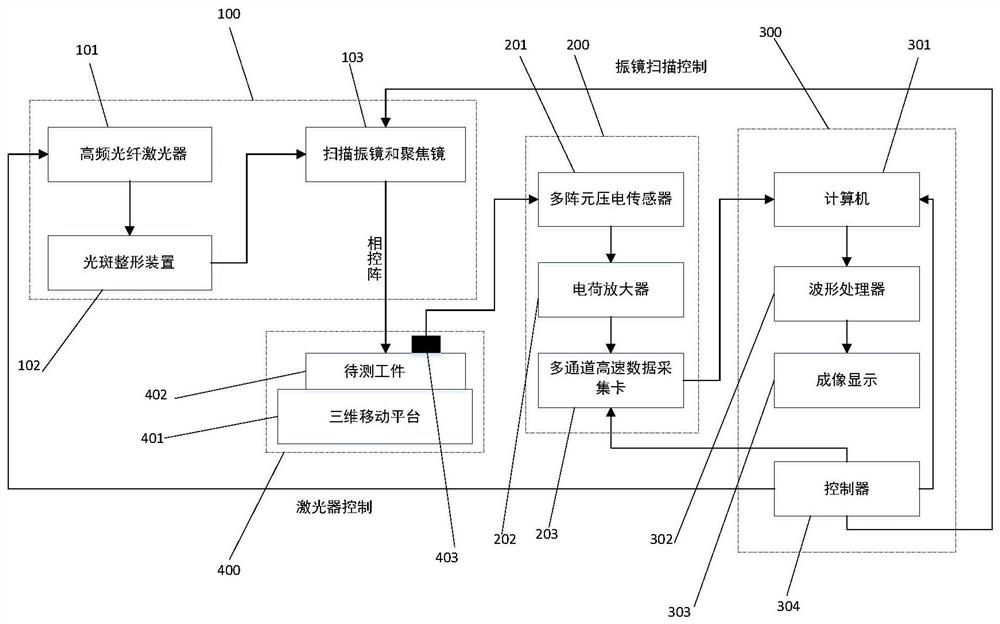

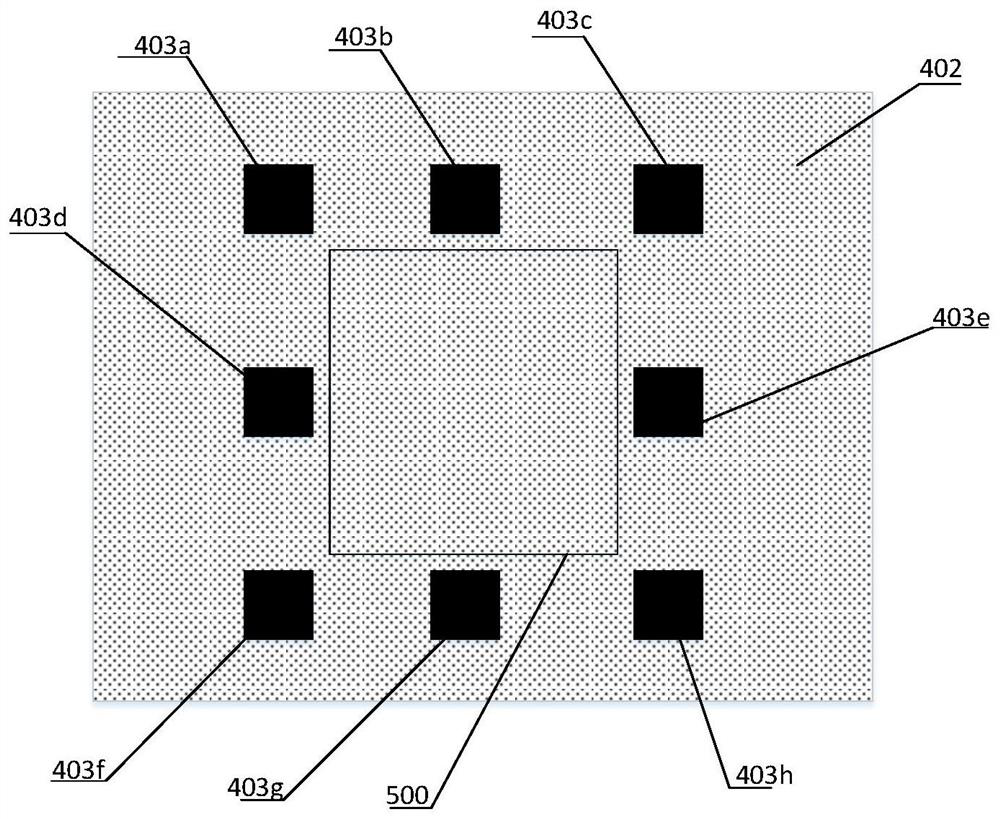

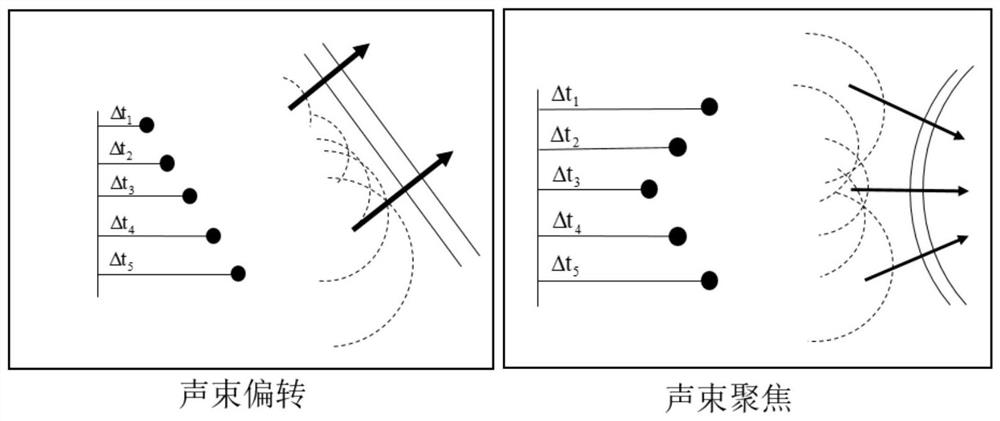

Ultrasonic nondestructive testing system

PendingCN111830134AHigh precisionImprove work efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalLight spotData acquisition

The invention discloses an ultrasonic nondestructive testing system. The ultrasonic nondestructive testing system comprises a laser ultrasonic transmitting system, an ultrasonic receiving system, a control and analysis imaging system and a three-axis platform system; the laser ultrasonic transmitting system comprises a high-frequency fiber laser, a light spot shaping device, a scanning galvanometer and a focusing mirror; the ultrasonic receiving system comprises a multi-array-element piezoelectric sensor, a charge amplifier and a multi-channel high-speed data acquisition card; the control andanalysis imaging system comprises a computer, a waveform processor and an imaging display and controller; the three-axis platform system comprises a three-dimensional mobile platform, a to-be-detectedworkpiece and an ultrasonic probe. According to the system of the invention, omnibearing 360-degree detection of surface and internal defects can be realized, the working efficiency is higher, the signal receiving sensitivity is higher, the price is low, the signal envelope extraction precision is higher, and the system is more suitable for industrial use.

Owner:SHANGHAI UNIV OF ENG SCI

Method for treating waste salt dregs containing cyanogen

The invention relates to a processing method for cyanogens contained waste salt dredge, the process steps are: the cyanogens contained waste salt dredge is put into the drier to be heated; the heating temperature is controlled with 60-120deg.C, the carbinol and the alcohol volatilize from the dredge, the carbinol and the alcohol are reclaimed with high purity after beings cooled in the condenser; the cyanogens contained waste salt dredge without carbinol and alcohol is baked in oxygen condition, the oxide in the dredge is fully oxidized, the organic is oxidized or volatilized off, thus eliminates the cyanogens and organic in the salt dredge; the gas generated in the baking process is transmitted to the burning furnace, the temperature is not lower than 1100deg.C, thus the tail gas may accord the discharging standard.

Owner:邱滔 +1

Technological method of printing pattern on glass

InactiveCN106183500AImprove adhesionGood lookingDuplicating/marking methodsOther printing apparatusEngineeringBase oil

The invention discloses a process method for printing patterns on glass. Firstly, a varnish layer is printed on the glass, and after the varnish layer is cured and dried, a white bottom oil layer is printed. After the white bottom oil layer is cured and dried, a thermal transfer printing The pattern is printed on the white primer layer. Use varnish as a primer to increase the adhesion between the ink layer and the glass surface, and then print a white primer layer to provide a thermal transfer adhesion layer, which can not only print refined pattern effects on the glass surface through thermal transfer, but also improve the quality of glass products. Appearance effect, and the overall process method is simple and easy, suitable for industrial use.

Owner:FOSHAN CITY GREEND CHEM

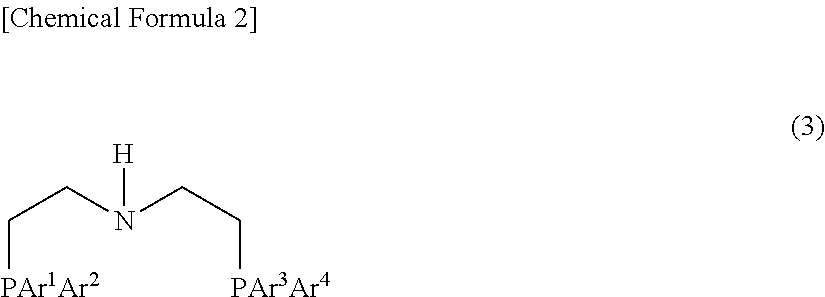

Method for alkylation of amines

ActiveUS20160009632A1Easy to prepareImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAmine alkylationAlcohol

The present invention provides a simple, efficient, and industrially advantageous method for the alkylation of amines. The present invention relates to a production method for N-alkylamines whereby an amine is reacted with an alcohol in the presence of a ruthenium complex represented by general formula (1): RuXY(CO)(L) (wherein X and Y can be the same or different and represent a monovalent anionic ligand, and L represents a tridentate aminodiphosphine ligand).

Owner:TAKASAGO INTERNATIONAL CORPORATION

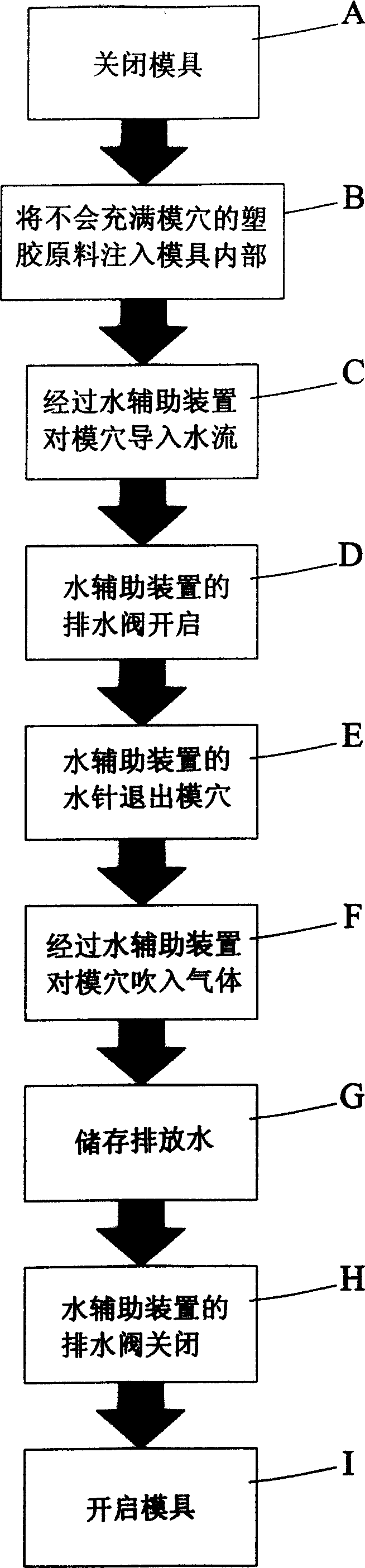

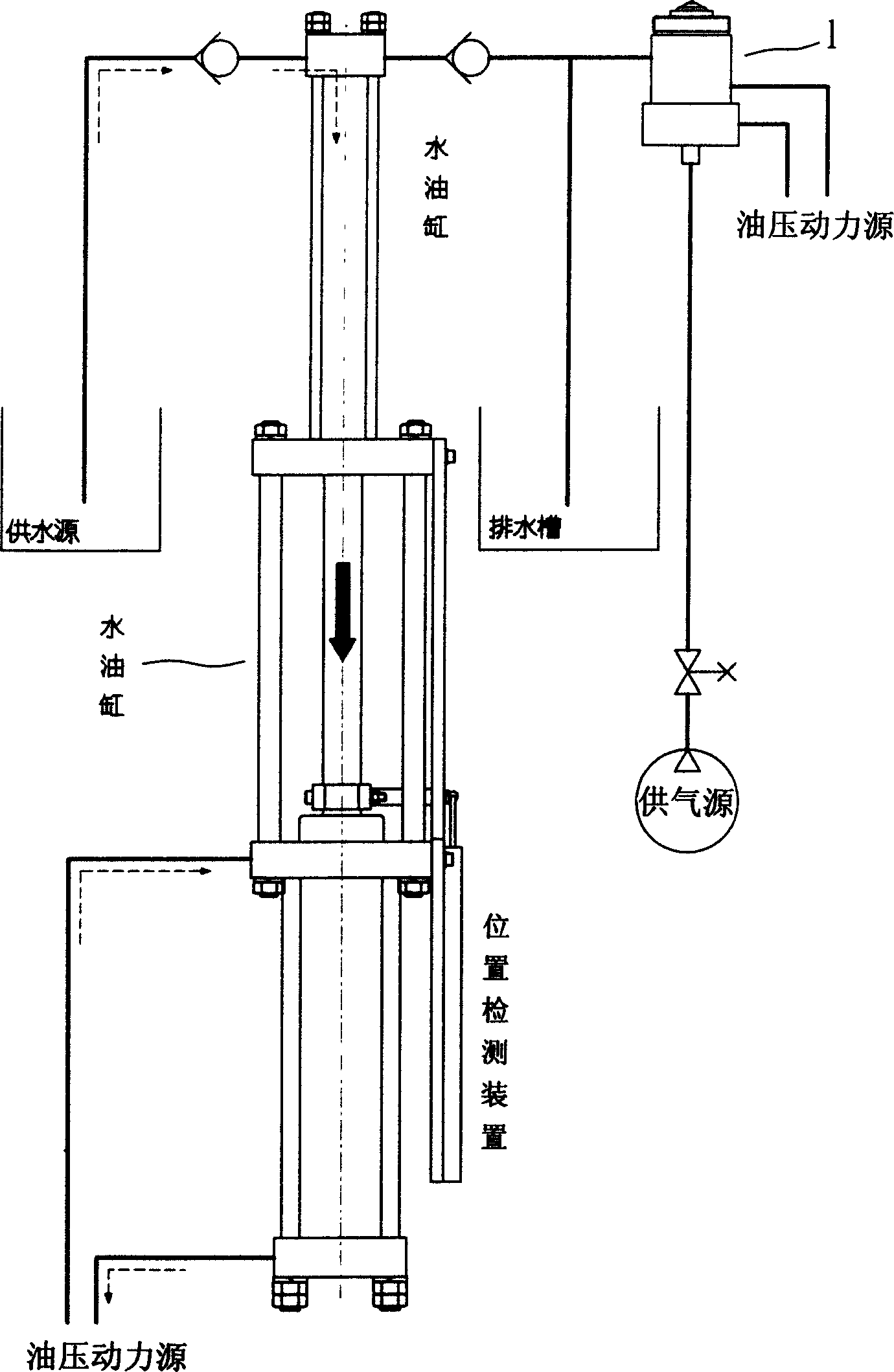

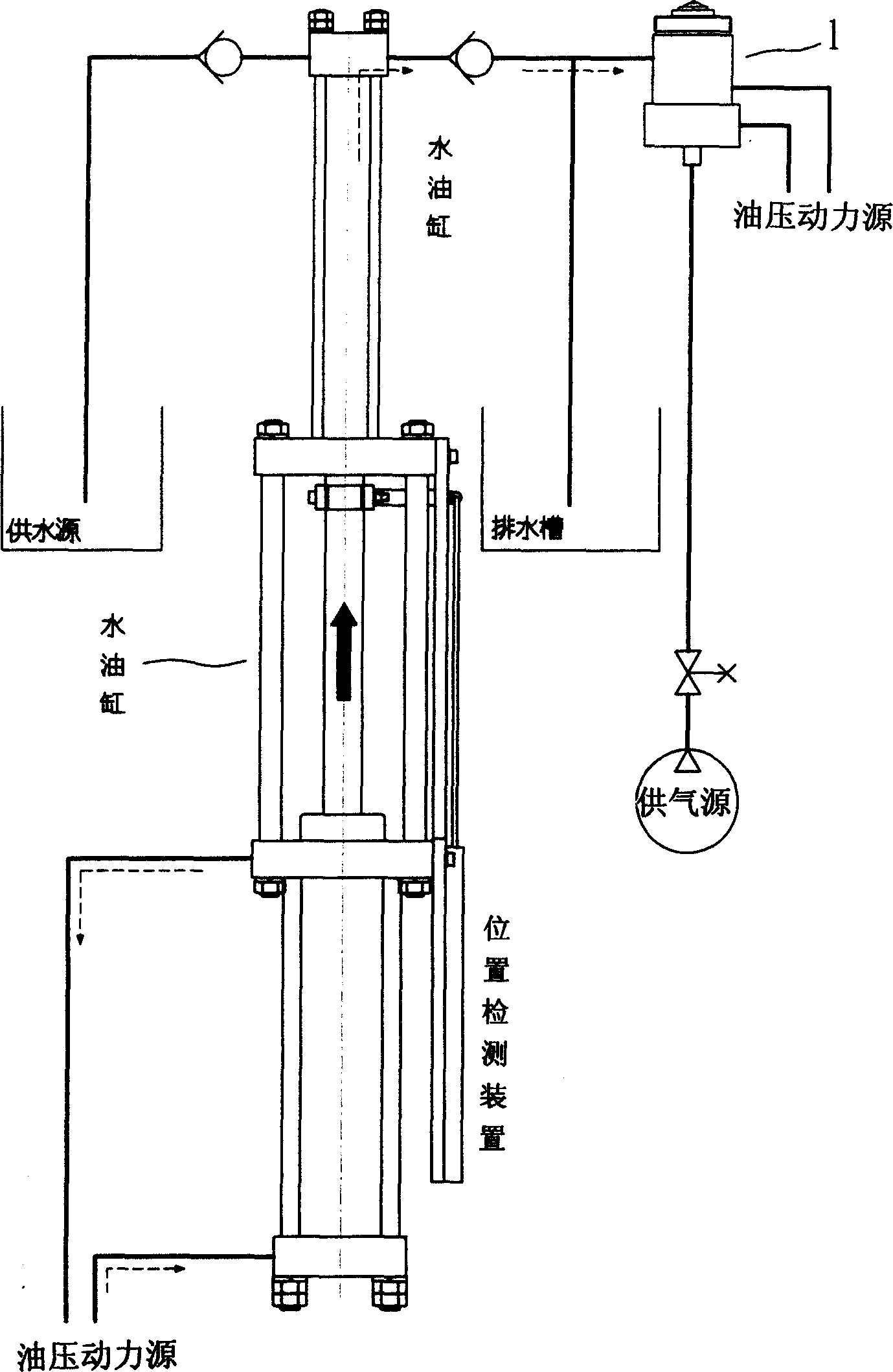

Water assistant jetting and forming method

InactiveCN1565825AReduce the disadvantages of high manufacturing costsReduce the absence of uneven thicknessWater assistedWater flow

The invention relates to a water-assisted injection molding method which includes the following steps: A. closing the mold, B. injecting plastic raw material into the mold, C. guiding water into the mold cavity by water-assisted device, D. opening the drainage valve of water-assisted device, E. the water needle of water-assisted device exiting from mold cavity, F. blowing gas into the mold cavity by water-assisted device, G. storing drainage water, H. closing the drainage valve of water-assisted device, I. opening the mold. By the sequent steps of inside jetting water, blowing, pushing liquid and draining, the plastic product with hollow part can be obtained.

Owner:CHUAN LIH FA MACHINERY WORKS CO LTD

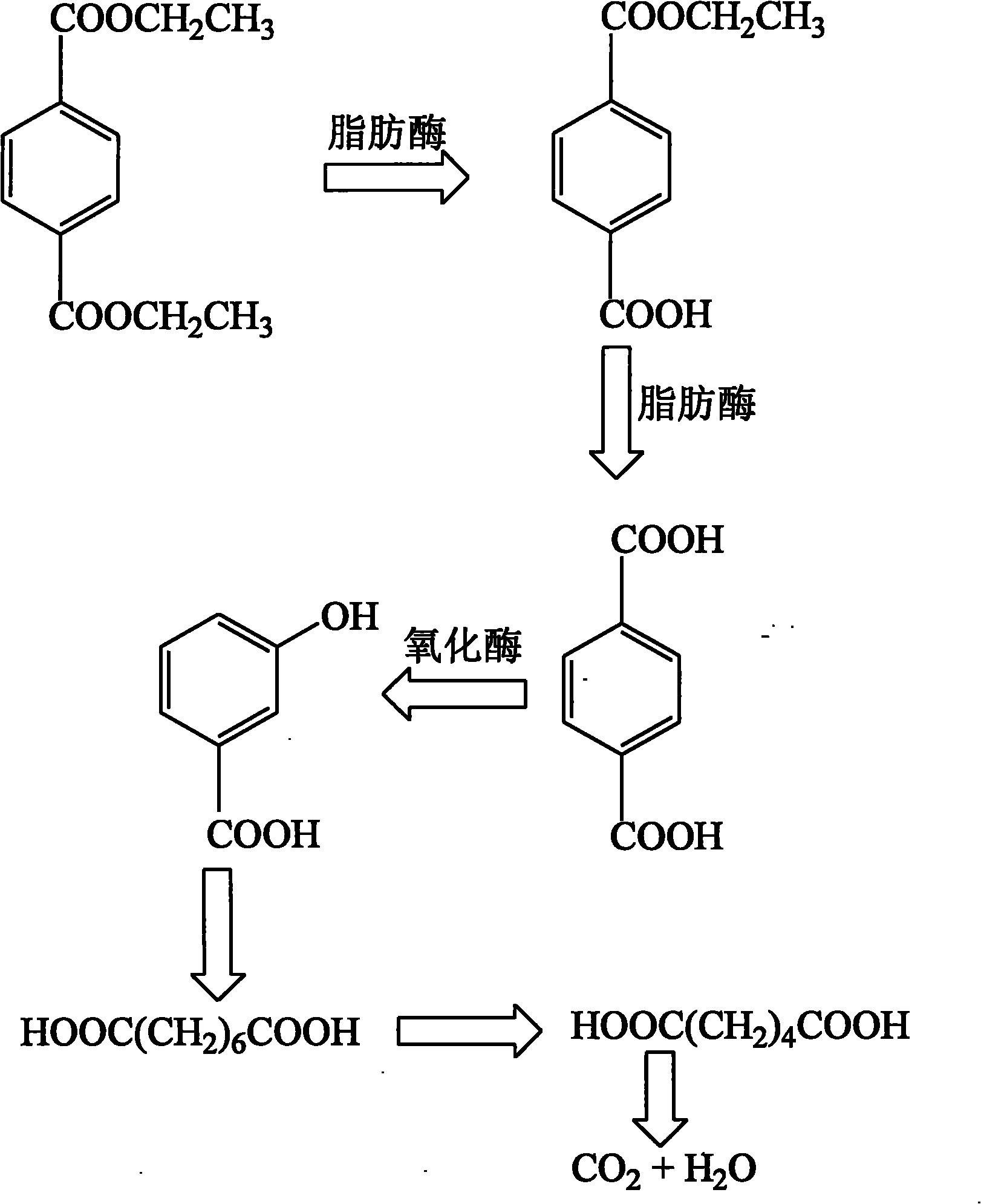

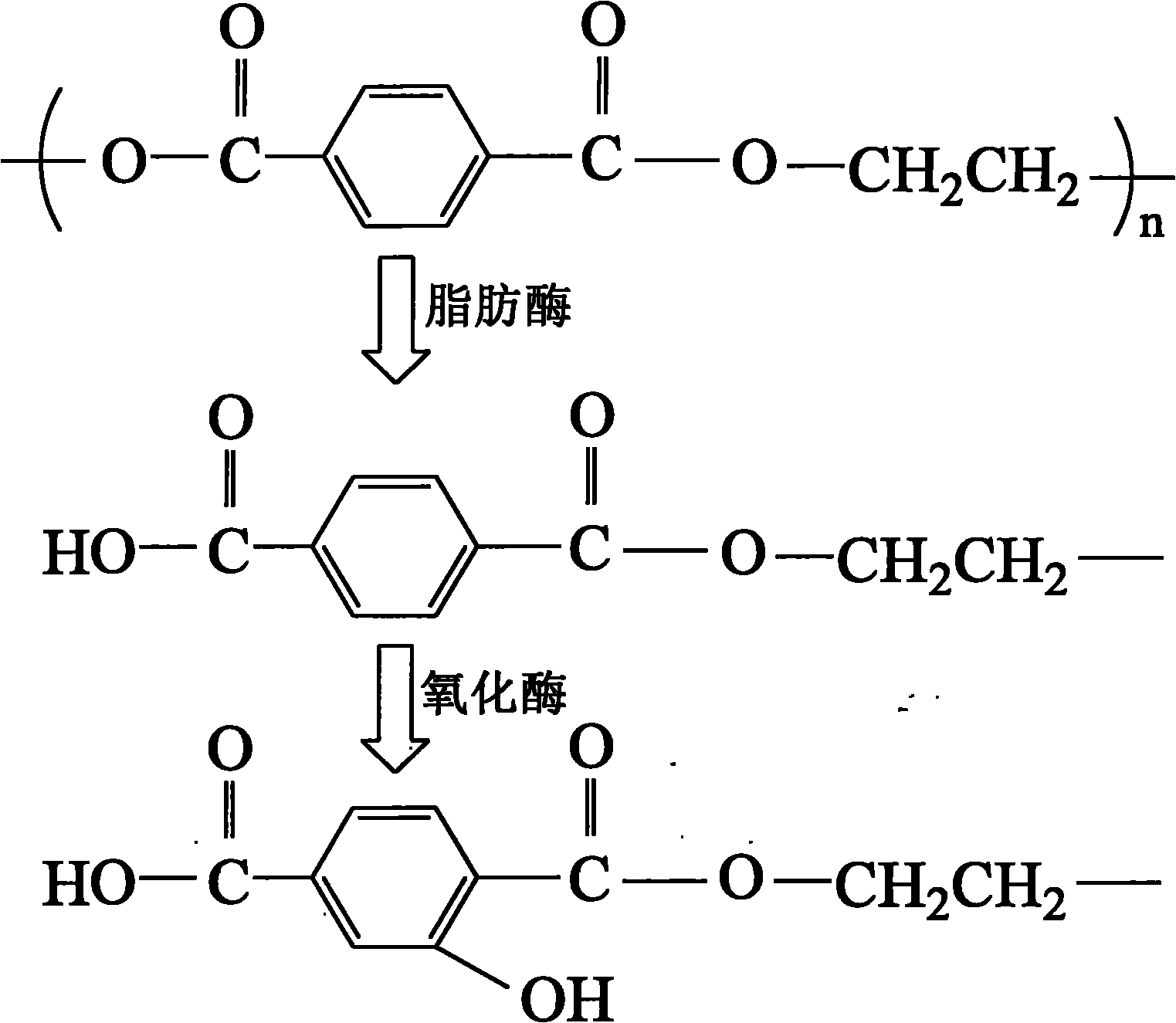

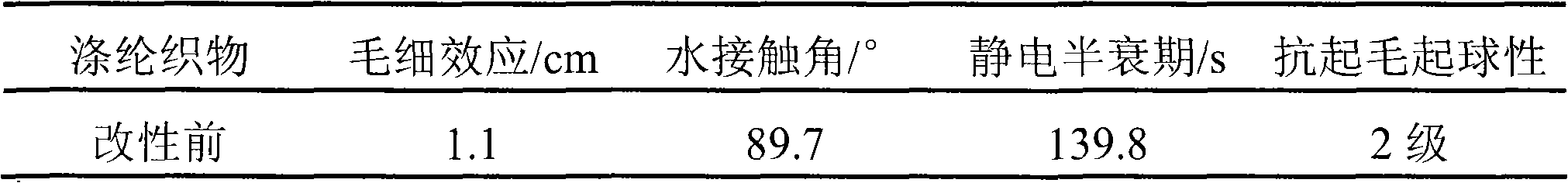

Method for modifying polyester fabric biologically

InactiveCN101942764AImprove comfortImprove aestheticsBacteriaBiochemical fibre treatmentTO-18Polyester

The invention discloses a method for modifying a polyester fabric biologically. In the method, DTP is taken as an inducing substrate, comonas testosteroni is induced to produce lipase and oxidase, and the polyester fabric is modified by a complex enzyme. The method mainly comprises the following steps of: 1, culturing strains, namely culturing the comonas testosterone in a slope solid medium at the temperature of between 30 and 37 DEG C for 12 to 18 hours; 2, preparing bacterial suspension, namely preparing a liquid medium of which the substrate concentration is 1 to 3g / L, binding the liquid medium and sterilizing at the temperature of 121 DEG C for 25 minutes, after the liquid medium is cooled, transferring seeds in the slope solid medium to the liquid medium, and performing shaking culture at the temperature of between 30 and 37 DEG C for 12 to 36 hours under the condition that the rotating speed of a shaking incubator is 200r / min to obtain the bacterial suspension; 3, modifying the polyester fabric, namely after the polyester fabric is sterilized, adding the polyester fabric into the bacterial suspension, and performing shaking culture to produce the corresponding lipase and oxidase, and then modifying the polyester fabric by catalyzing; and 4, cleaning the polyester fabric to obtain the modified polyester fabric.

Owner:江苏东方阳光科技有限公司

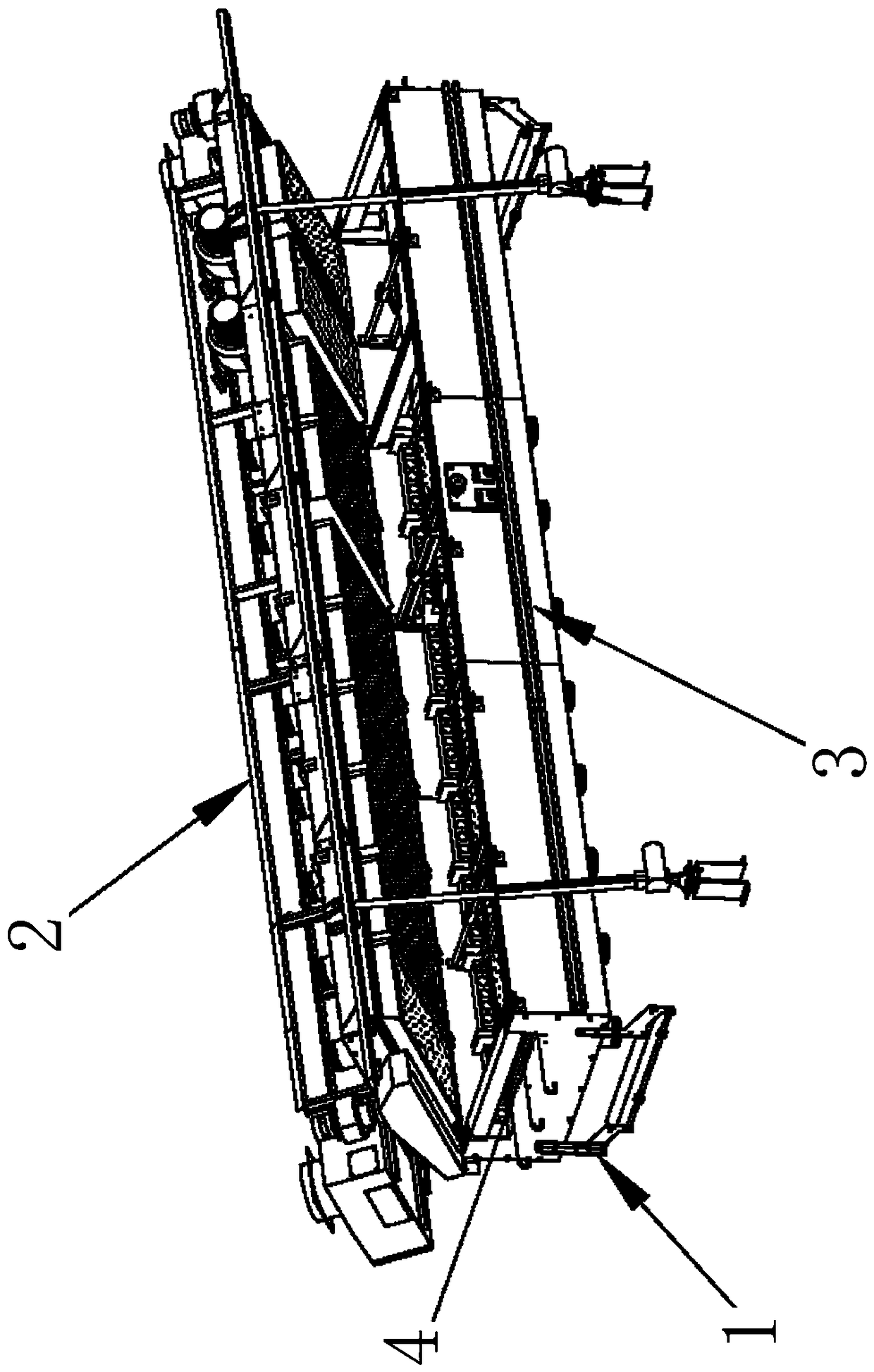

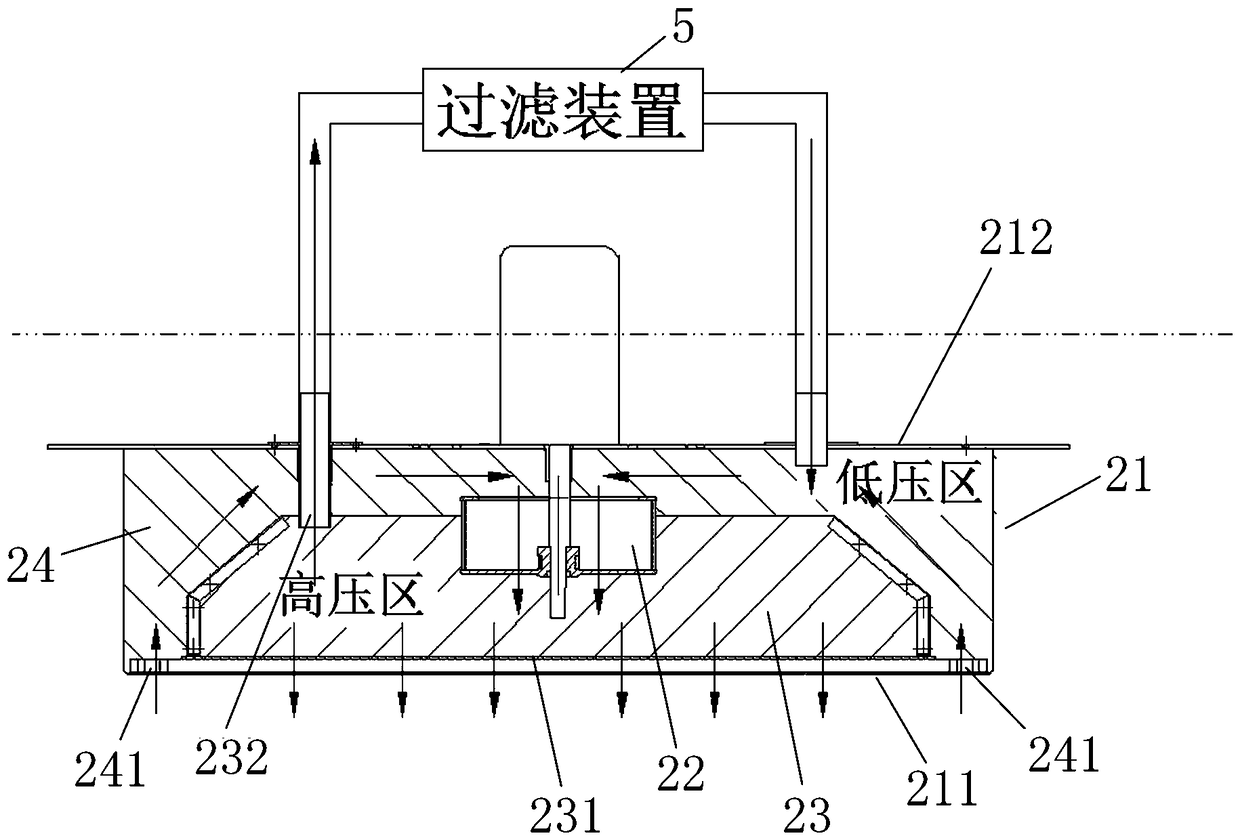

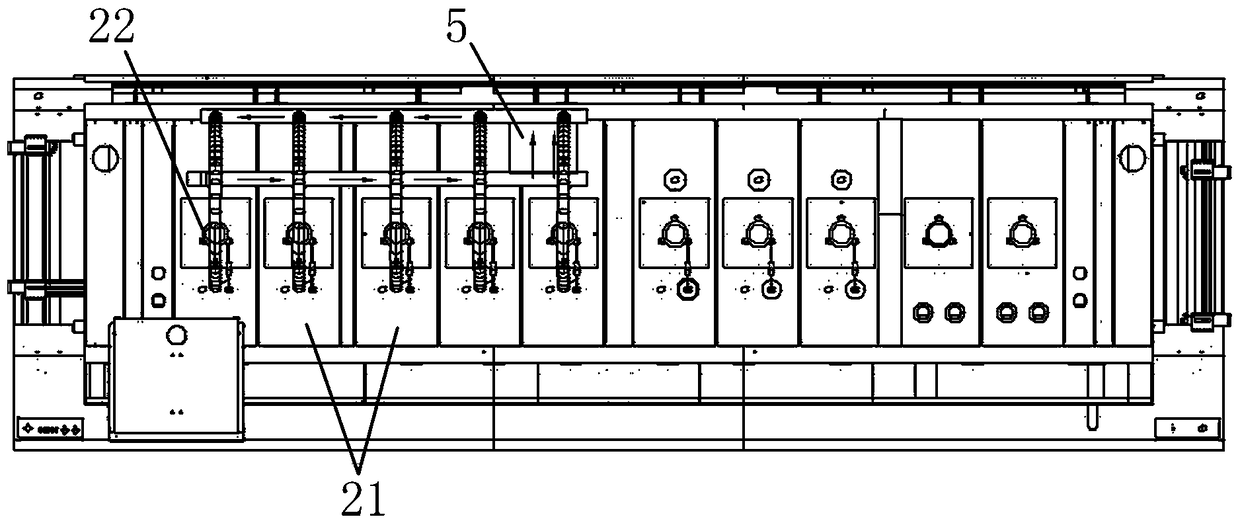

Hot air reflow furnace

PendingCN108200732AReduce churnSave energyPrinted circuit assemblingMetal working apparatusTransport systemEngineering

The invention relates to a hot air reflow furnace. The hot air reflow furnace comprises a furnace frame, an upper hearth, a lower hearth and a transport system, wherein the upper hearth, the lower hearth and the transportation system are installed on the furnace frame. The upper hearth is provided with a hearth body and a fan, the hearth body is provided with an inner container and an outer container, a high pressure zone is formed in the inner container, and a low pressure zone is formed in the outer container; the inner container is provided with a recycling vent, the recycling vent is connected to a filtering device outside a furnace body, the filtering device is connected to the outer container through an air returning duct, and the outer container is further provided with air suctionports in a first side face; transport chains of the transport system are erected on the upper sides of transport net chains through chain guide rails, the distance between the pair of chain guide rails is adjusted through a turbine worm mechanism to achieve more effective synchronous adjustment, and the accuracy of adjusting the distance between the chain guide rails is improved. Through the structures of the inner and outer containers, circulation work is achieved. In addition, the inner container is provided with the recycling vent which is connected with the filtering device outside the furnace body to dispose exhaust gas, and meanwhile the gas of the filtering device is returned to the furnace body for reuse at relatively high temperature. The energy is effectively saved, and heat lossis reduced.

Owner:东莞市创威自动化科技有限公司

Degradable foam material and preparation method thereof

The invention discloses a degradable foam material and a preparation method thereof, and relates to the technical field of foam materials. The degradable foam material comprises the following components by mass: 40-80 parts of poly(butylene adipate-co-terephthalate); 20-40 parts of polylactic acid; 1-5 parts of a photosensitizer; and 3-20 parts of a foaming agent. The PBAT and the PLA are adopted as matrixes, the prepared foam material is degradable, environmentally friendly and high in ductility and comprehensive mechanical property, meanwhile, the processing temperature is reduced, advanced decomposition of a chemical foaming agent is inhibited, and the cell uniformity and foaming stability of the foaming material are improved. Meanwhile, the photosensitizer is added, after irradiation, the overall melt strength of the material can be improved, then the foaming ratio and the foam structure stability in the foaming process are increased, and the temperature resistance and the mechanical property of the foaming material can be further improved.

Owner:ZHEJIANG UNIV OF TECH

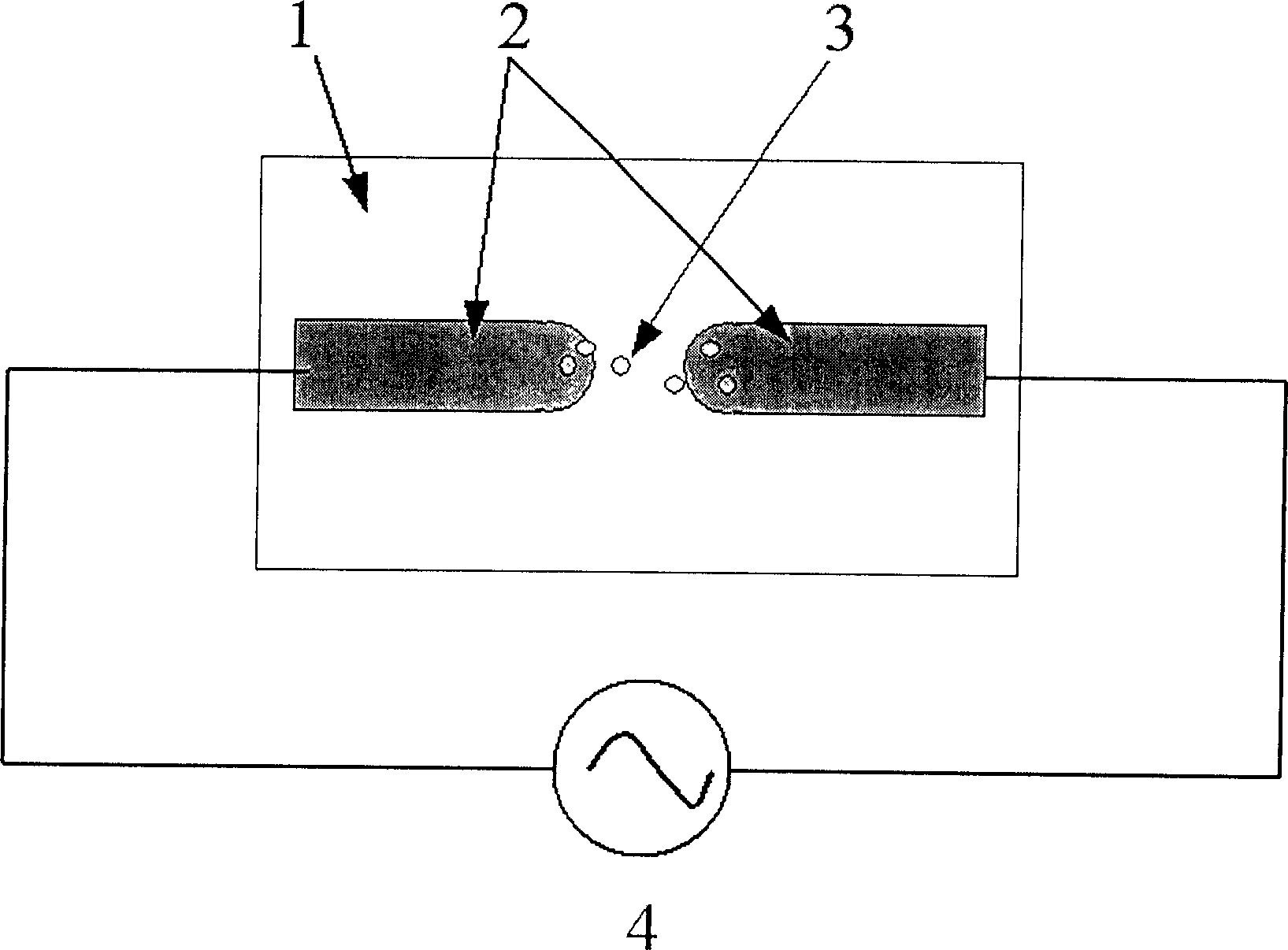

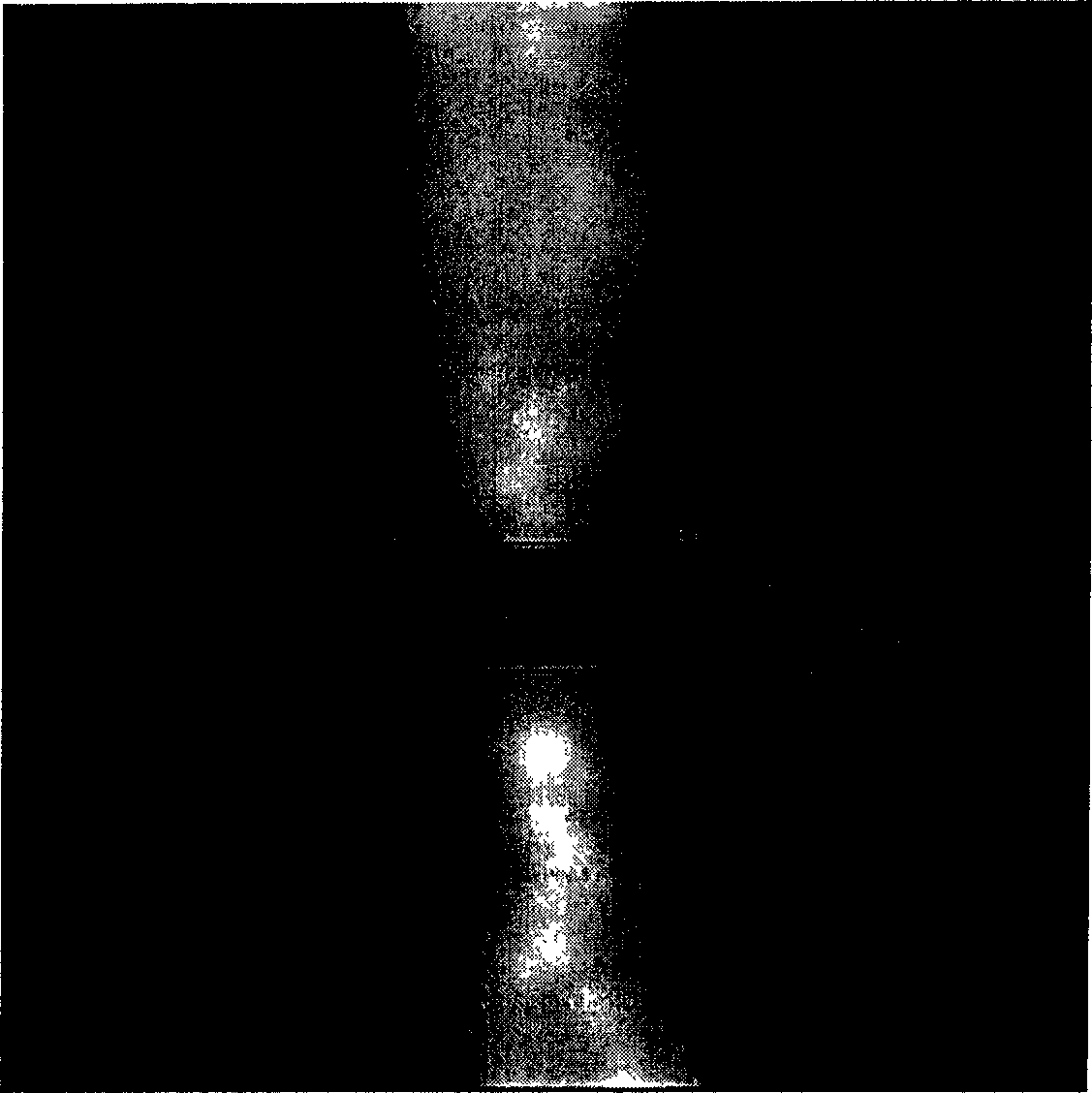

10 nano-level gap electrode preparing method

InactiveCN1529346AReduce concentrationFlat surfaceNanostructure manufactureSemiconductor/solid-state device manufacturingDrop SuspensionPhysical chemistry

The preparing method includes steps: (1) preparing metal electrode by using method of electronbeam exposure, removing organic matter from prepared metal electrode, interval of electrodes is as 50-300 Nano; (2) preparing suspension liquid of gold granule in size 5-50 Nano; (3) diluting suspension liquid prepared by using water till particle concentration is 1012-1014 pieces / cubic centimeter, dropping suspension liquid diluted onto surface of metal electrode prepared at step (1); applying AC voltage to two ends of electrode, then blowing drying surface by using inactive gas; (4) carrying out low temperature annealing treatment for electrode obtained from step (3). Advantages of the method are: simple technique, easy of controlling parameters. Nano electrode prepared by using the method is very stable, shape of the electrode is not easy to change, the product is suitable to use in industrial.

Owner:UNIV OF SCI & TECH OF CHINA

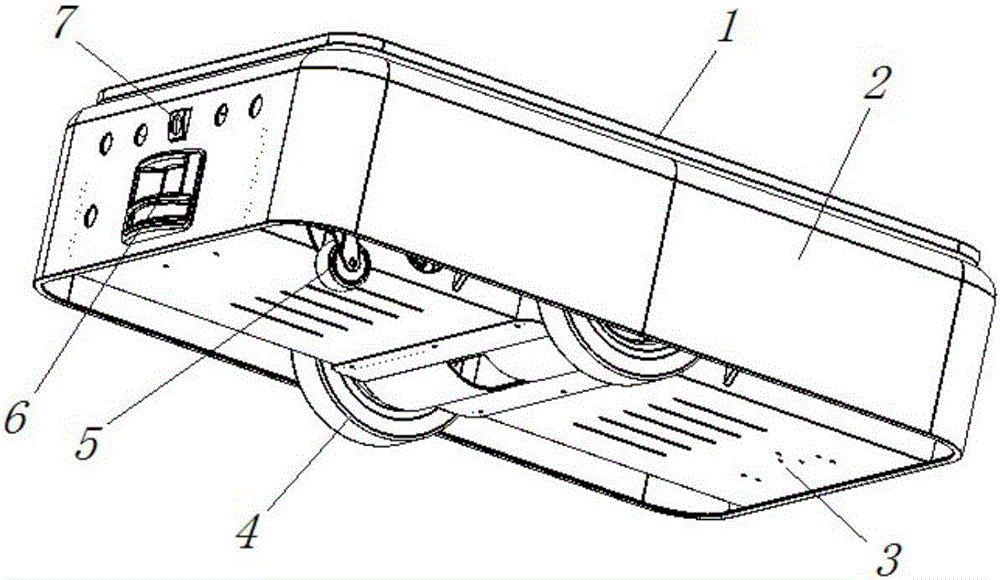

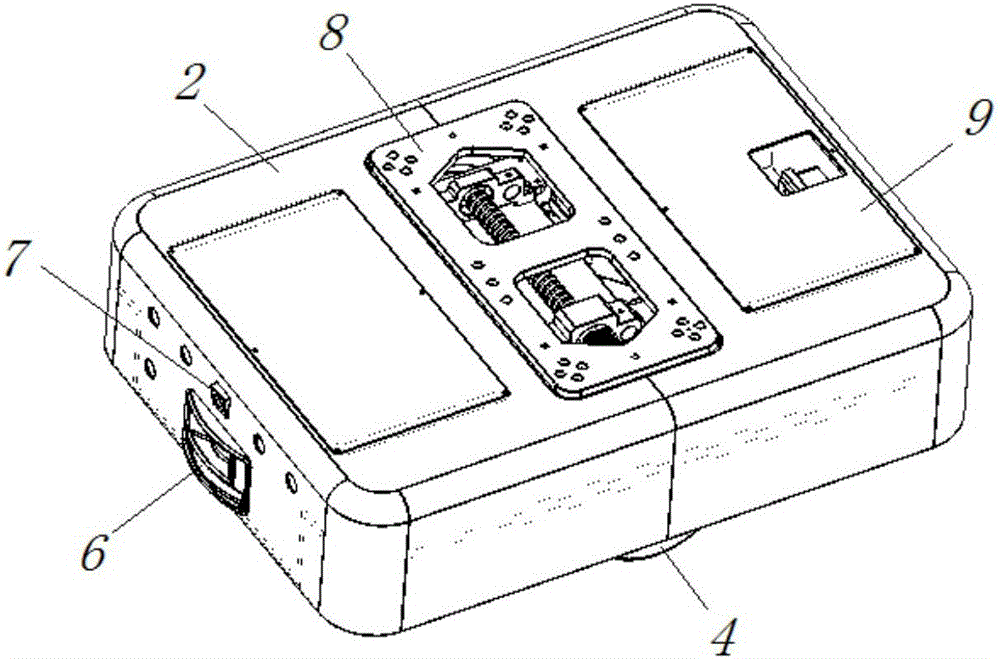

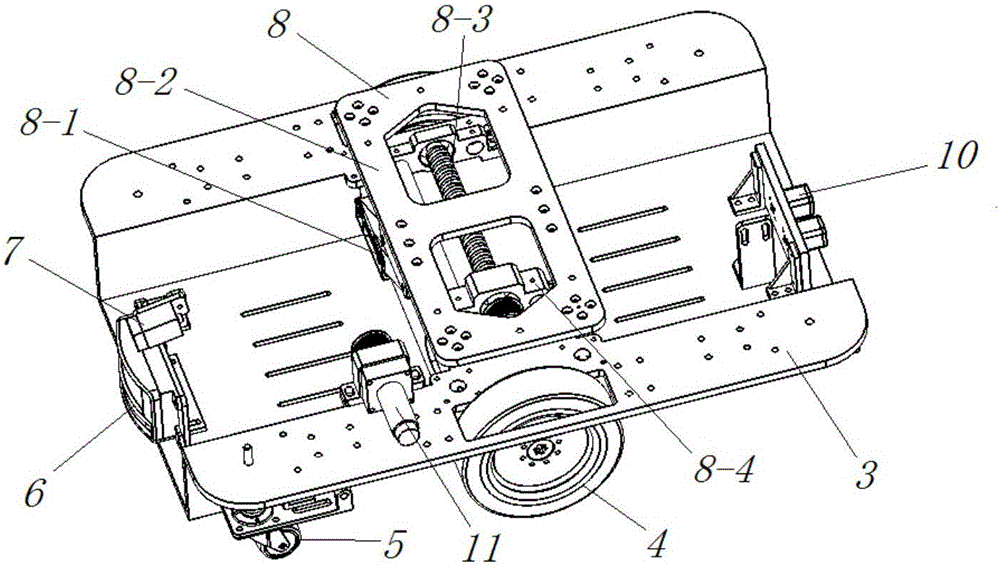

Embedded automated guided vehicle

ActiveCN105966818ACompact designCompact layoutPackagingStorage devicesAutomated guided vehicleEngineering

The invention relates to an embedded automated guided vehicle which comprises a movable chassis device, wherein a lifting mechanism is mounted at the middle of the movable chassis device; and a shell is mounted on the movable chassis device in a buckled manner; the lifting mechanism is exposed from a window formed in the middle of the shell; a top plate positioned right over the shell is mounted at the top of the lifting mechanism; the movable chassis device comprises a chassis; a lug boss is arranged at the middle of the chassis; driving mechanisms are respectively mounted on two sides of the middle of the chassis; the lifting mechanism is fixedly mounted on the lug boss; shock-absorbing universal wheels are mounted at four corners of the chassis; the lifting mechanism comprises a lead screw, and further comprises two four-link bars and a driver; the lead screw is fixedly mounted on the lug boss through bearing seats at the two ends and equipped with a nut; connecting blocks are fixedly connected with two sides of the nut; bottom bar bodies of the two four-link bars are fixedly connected with the two connecting blocks respectively; a lifting plate is fixedly mounted between top bar bodies of the two four-link bars; the driver is used for driving the lead screw; a code scanner is mounted at the front of the chassis; and a charging assembly is mounted at the rear of the chassis.

Owner:天津市山石机器人有限责任公司

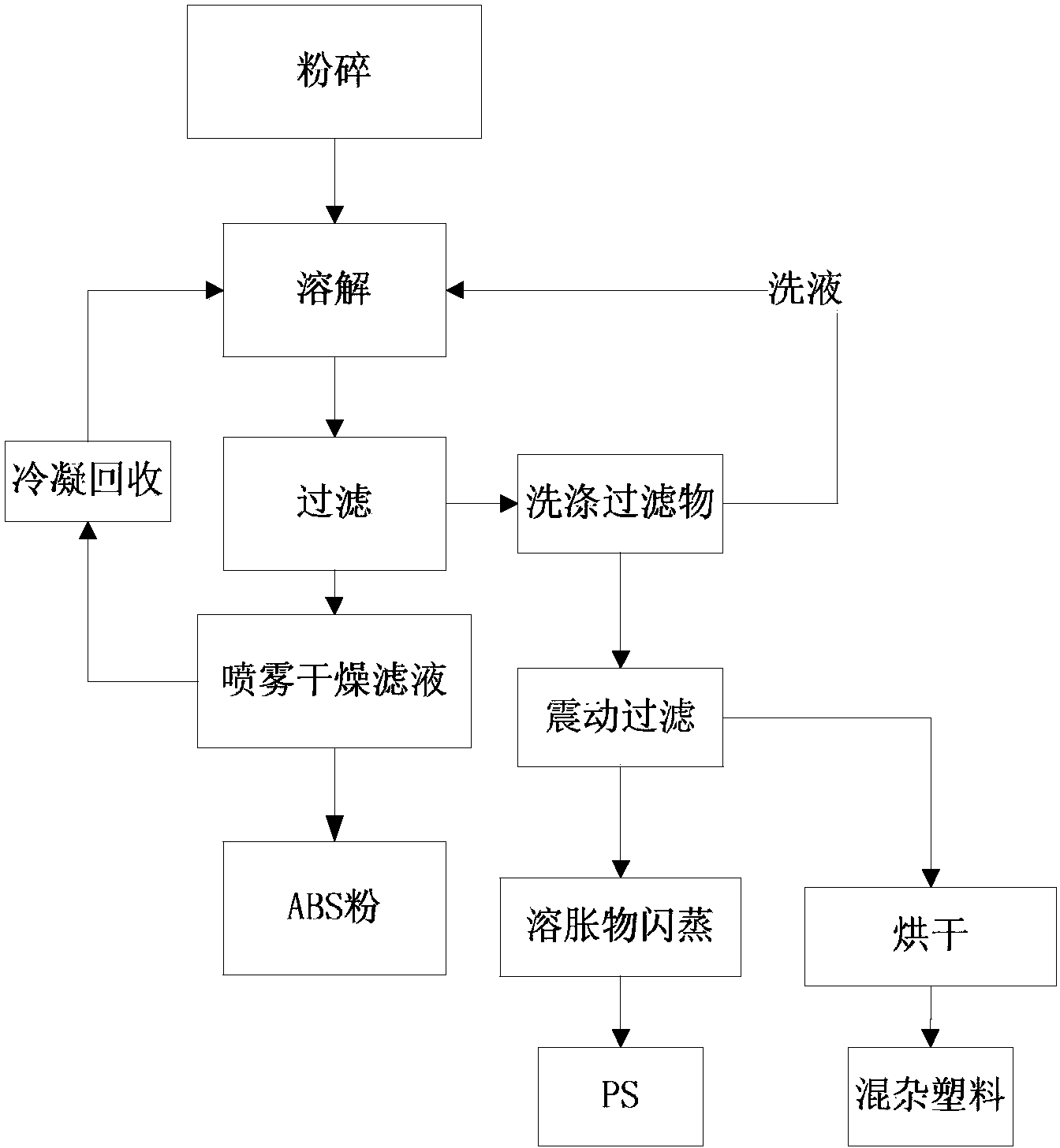

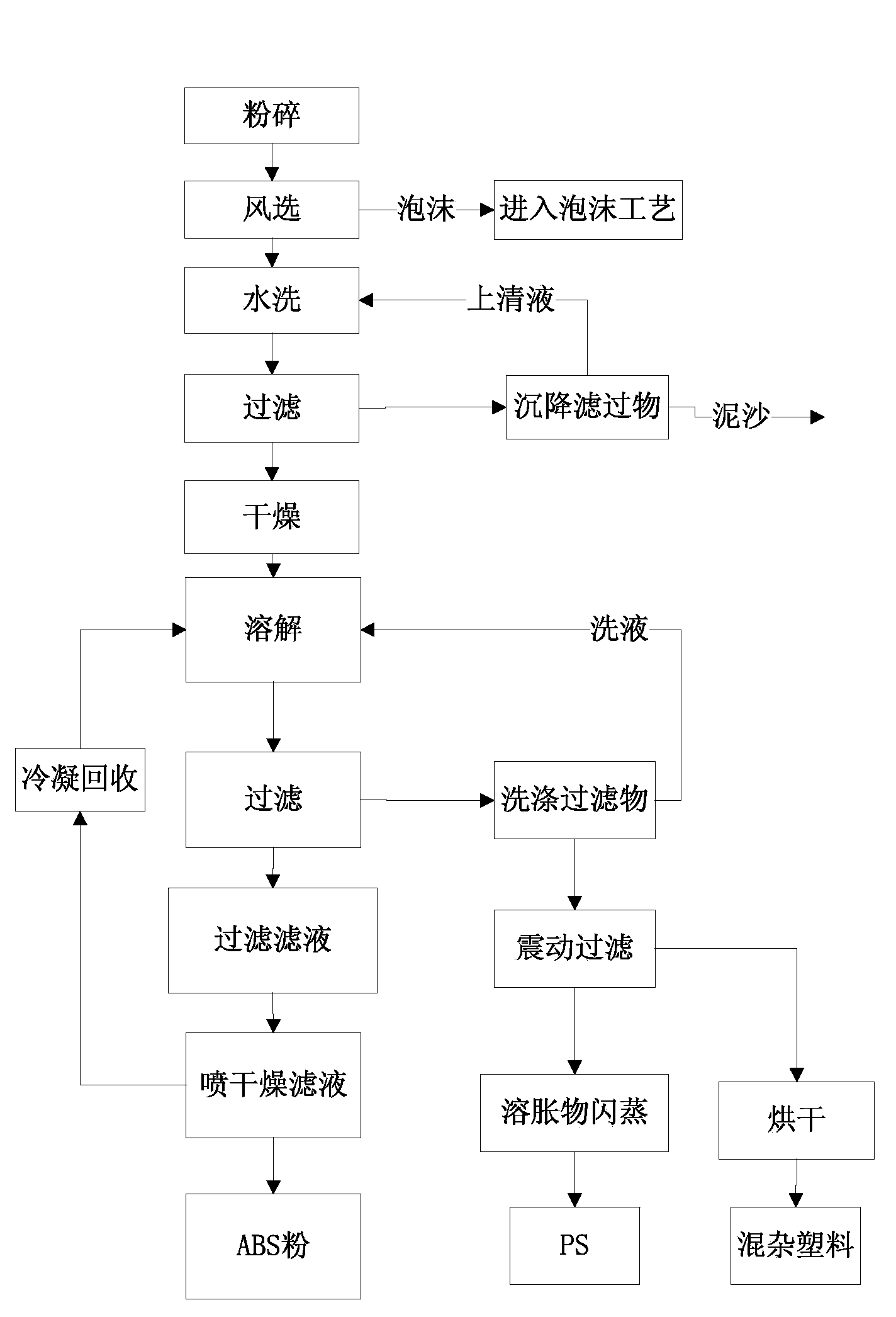

Method for separating ABS (Acrylonitrile Butadiene Styrene) and PS (Poly Styrene) from waste mixed plastic and application of method

ActiveCN103709436AShorten the production cycleReduce energy consumptionPlastic recyclingPolyvinyl chlorideSolvent

The invention provides a method for separating ABS (Acrylonitrile Butadiene Styrene) and PS (Poly Styrene) from waste mixed plastic and application of the method. The method comprises the following steps of dissolving the waste mixed plastic into a solvent to obtain a plastic solution; and filtering the plastic solution to obtain filtrate and filtered articles, wherein the solvent consists of 85 to 95% by mass of acetone and 5 to 15% by mass of n-hexane. According to the method, the ABS / PS is separated from PP (Polypropylene), PE (Polyethylene Tube), PVC (Polyvinyl Chloride) and the like in the waste mixed plastic, and then the ABS and PS are further separated and purified; the ABS purity reaches more than 99%; the waste plastic can only be dissolved for 30 to 40 minutes under a temperature of 30 to 40 DEG C with the solvent above; the method is short in production cycle, low in energy consumption, and applicable to industrial application.

Owner:HUNAN VARY TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com