A kind of cleaning method and device of fouling membrane

A technology of forward osmosis membrane and drawing liquid, which is applied in the field of membrane separation to achieve the effect of reducing operating costs, high cleaning efficiency, and shortening cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

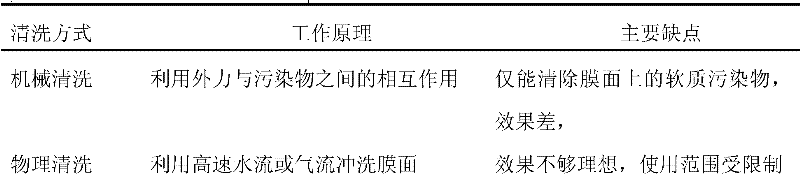

Problems solved by technology

Method used

Image

Examples

Embodiment 1

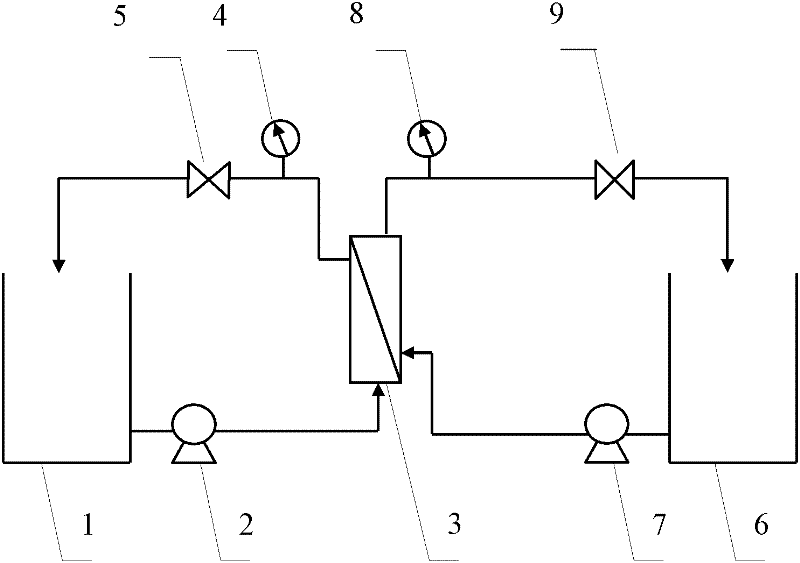

[0034] A 1M ammonium bicarbonate solution and a 3M ammonium hydroxide solution were mixed at a ratio of 1.2:1 to prepare a drawing solution, and distilled water was used as a raw material solution. The raw material liquid is on the cortex side of the polluted hollow fiber membrane (referred to as polluted membrane), and the draw solution is on the support layer side of the polluted membrane. The cross-flow rate of the feed solution and the draw solution was maintained at 2.0 L / min, and both were operated at room temperature. Put the polluted membrane to be cleaned into the forward osmosis membrane module 3, turn on the power, open the raw material liquid valve 5 and the draw liquid valve 9 respectively, and start the diaphragm pump 2 and the peristaltic pump 7 respectively, and adjust the pressure gauge so that the raw material liquid pressure The indications of Table 4 and the drawing hydraulic pressure gauge 8 are kept at 0.2MPa. The diaphragm pump 2 presses the distilled w...

Embodiment 2

[0036] The 5M fructose solution was used as the drawing solution, and distilled water was used as the raw material solution. The raw material solution was on the cortex side of the polluted membrane, and the drawing solution was on the support layer side of the polluted membrane. The cross flow rate of the two was 2.0L / min. The raw material solution and the drawing solution The temperature was heated to 50°C, and the rest was the same as that described in Example 1, and the power was turned off after 0.5h of operation. A completely cleaned membrane can be obtained.

Embodiment 3

[0038] Mix 5M sucrose solution and 1M sodium chloride solution at a ratio of 2:1 to prepare a drawing solution, use distilled water as the raw material solution, control the cross-flow rate of the raw material solution and the drawing solution at 100ml / min, and keep the experimental temperature at 25 ± At 2°C, the feed solution is on the skin side of the fouled membrane, and the draw solution is on the support layer side of the fouled membrane. The rest are the same as the method described in Example 1, run for 0.5h, and then turn off the power supply to obtain a completely cleaned membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com