Cleaning method of optical substrate for laser thin-film element

A laser thin film and optical technology, applied in the field of optics, can solve the problems of increased surface roughness, difficult to remove sub-micron particles, and no connection, etc., and achieve the effect of increasing the damage threshold, increasing the damage threshold, and improving the cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

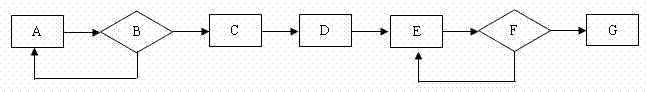

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The whole process process cleaning of K9 optical substrate:

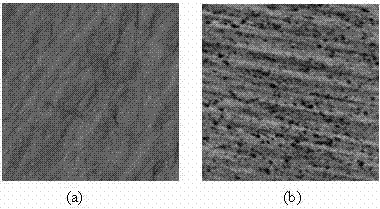

[0023] Use a cotton swab dipped in acetone to gently wipe the optical substrate in the order of side, back, and surface, and use an 80W incandescent lamp to observe until there are no particles, fingerprints, oil stains and other pollutants visible to the naked eye on the surface of the substrate under the incandescent lamp; Add alkaline solution into the first cleaning tank, the temperature of the solution is 45°C, and the ratio of alkaline solution is NH 4 OH:H 2 o 2 :H 2 O=1:10:50, put the wiped crystal substrate in the first cleaning tank, and use the frequency of 20KHz, 80KHz, and 120KHz to clean the substrate successively for 2 to 4 minutes. The substrate is pulled out of the solution at a high speed; then the substrate is placed in the second cleaning tank and sprayed with 45°C deionized water for 2 minutes; then the substrate is placed in the third cleaning tank of 45°C deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com