Method for processing high-concentration refractory organic wastewater by using mixed rare earth-brass-iron-carbon catalytic oxidation method

A technology of mixing rare earth and organic wastewater, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of high price of single rare earth compound, addition effect, difficult separation of rare earth elements, etc., to improve treatment efficiency and reaction speed, and high production efficiency , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

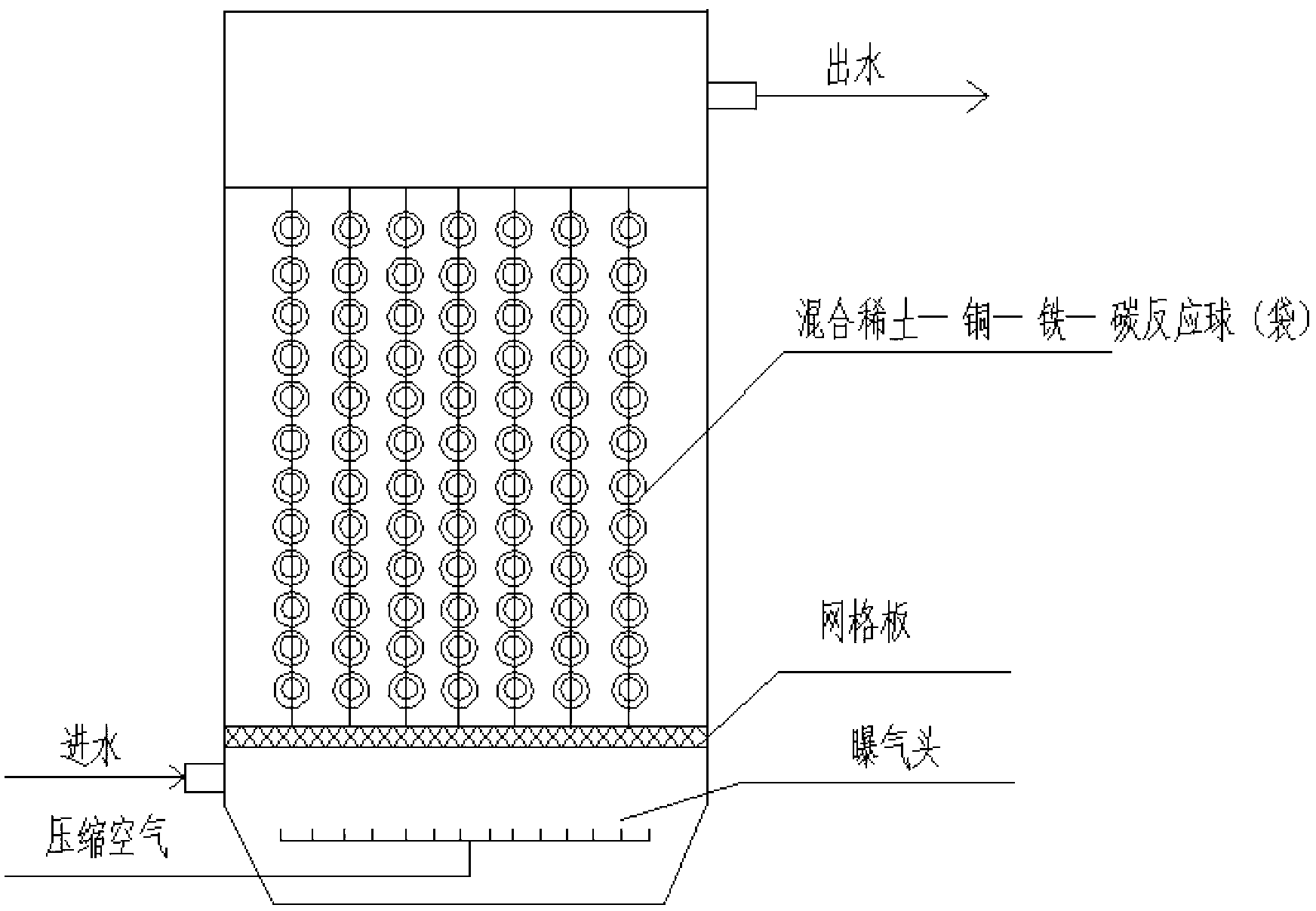

Image

Examples

Embodiment 1

[0029] Precipitate the rare earth ore without radioactive substances through carbonate and oxalic acid to obtain waste residue, mix 1 part of waste residue with 10% hydrochloric acid with a mass fraction of 1 part by weight, stir thoroughly and activate for 6 hours to obtain hydrochloric acid treated Waste residue, store for later use; waste residue contains mixed rare earth oxides 8%-25%;

[0030] Rare earth-copper-iron mixed catalyst configuration: mix pig iron scraps with a particle size of 2mm, brass scraps with a particle size of 5mm and waste residue after hydrochloric acid treatment and mix well, and activate them at 20°C for 1 hour to obtain rare earth -Copper-iron mixed catalyst, ready for use, ready for immediate use; the ratio of pig iron filings, brass filings and mixed rare earth oxides is 100 kg: 0.1-1 kg: 30 g.

[0031] Preparation of catalytic oxidation reaction balls: Stir and mix coke with a particle size of 1 cm and a rare earth-copper-iron mixed catalyst at...

Embodiment 2

[0035] Precipitate the rare earth ores without radioactive substances through carbonate and oxalic acid to obtain waste residues, mix 1 part of waste residues with 4 parts by weight of hydrochloric acid with a mass fraction of 40%, fully stir and activate for 12 hours to obtain hydrochloric acid treated Waste residue, store for later use; waste residue contains mixed rare earth oxides 8%-25%;

[0036] Rare earth-copper-iron mixed catalyst configuration: Mix pig iron chips with a particle size of 20 mm, brass chips with a particle size of 15 mm and waste residue after hydrochloric acid treatment and mix well, and activate at 100 ° C for 6 hours to obtain rare earth - Copper-iron mixed catalyst, ready for use, ready for immediate use; the ratio of pig iron scrap, brass scrap and mixed rare earth oxide is 100 kg: 0.1-1 kg: 30-150 g.

[0037] Catalytic oxidation reaction bag preparation: Stir and mix coke with a particle size of 10 cm and a rare earth-copper-iron mixed catalyst at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com