Technological method of printing pattern on glass

A process method and technology on glass, applied in the directions of copying/marking methods, printing, printing devices, etc., can solve the problems of poor printing effect, poor coating adhesion, high application cost, and achieve simple and easy process methods. Appearance effect, good visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

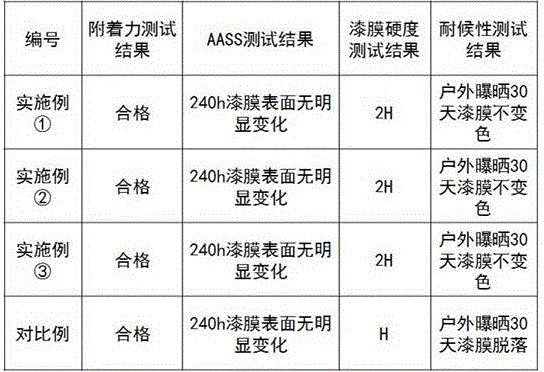

[0046] The content of the present invention is further described below by way of examples.

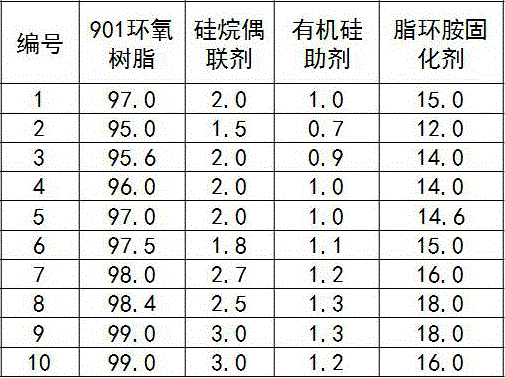

[0047] 1. Varnish formula and preparation method

[0048] According to the components and parts by mass in the following table, prepare the varnish according to the ratio.

[0049]

[0050] The preparation method of the varnish is as follows: put the raw materials of the varnish into the stirring device according to the ratio except the curing agent, stir at a speed of 4500-6000r / min until the raw materials are in a uniform liquid state, then add the curing agent, and continue to stir evenly. Pay attention to adjusting the rotation speed during the homogenization process to ensure that the temperature of the varnish raw material during the homogenization process does not exceed 200°C, so as not to affect the effectiveness of the varnish components.

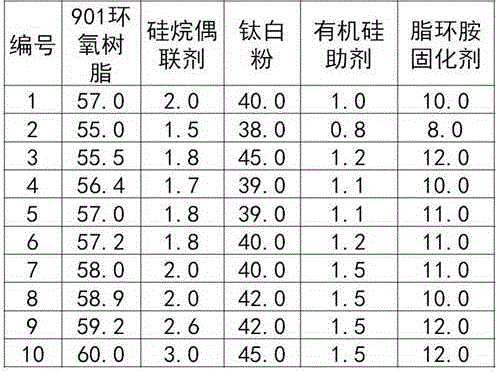

[0051] 2. Formula and preparation method of white base oil

[0052] Prepare the white base oil according to the composition and mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com