Electrochemical method of forming black trivalence chromic oxide coating and black trivalence chromic oxide coating

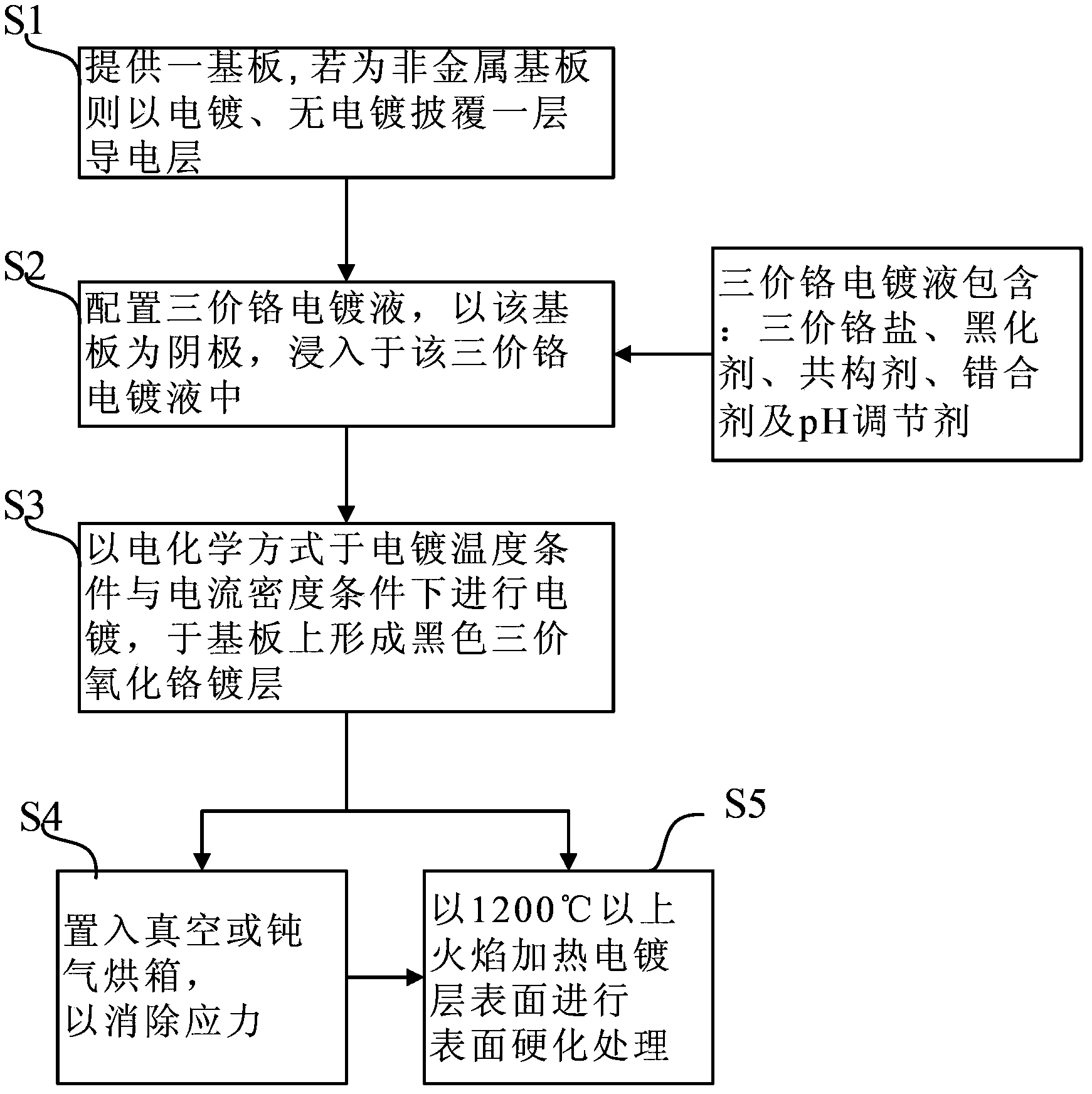

A chromium oxide and electrochemical technology, applied in the field of electrochemistry for forming black trivalent chromium oxide coating and its black trivalent chromium oxide coating, can solve the problems of inability to form blackening degree and low blackening degree, and reduce waste water Difficulty in handling, enhancement of mechanical properties, effect of stress relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

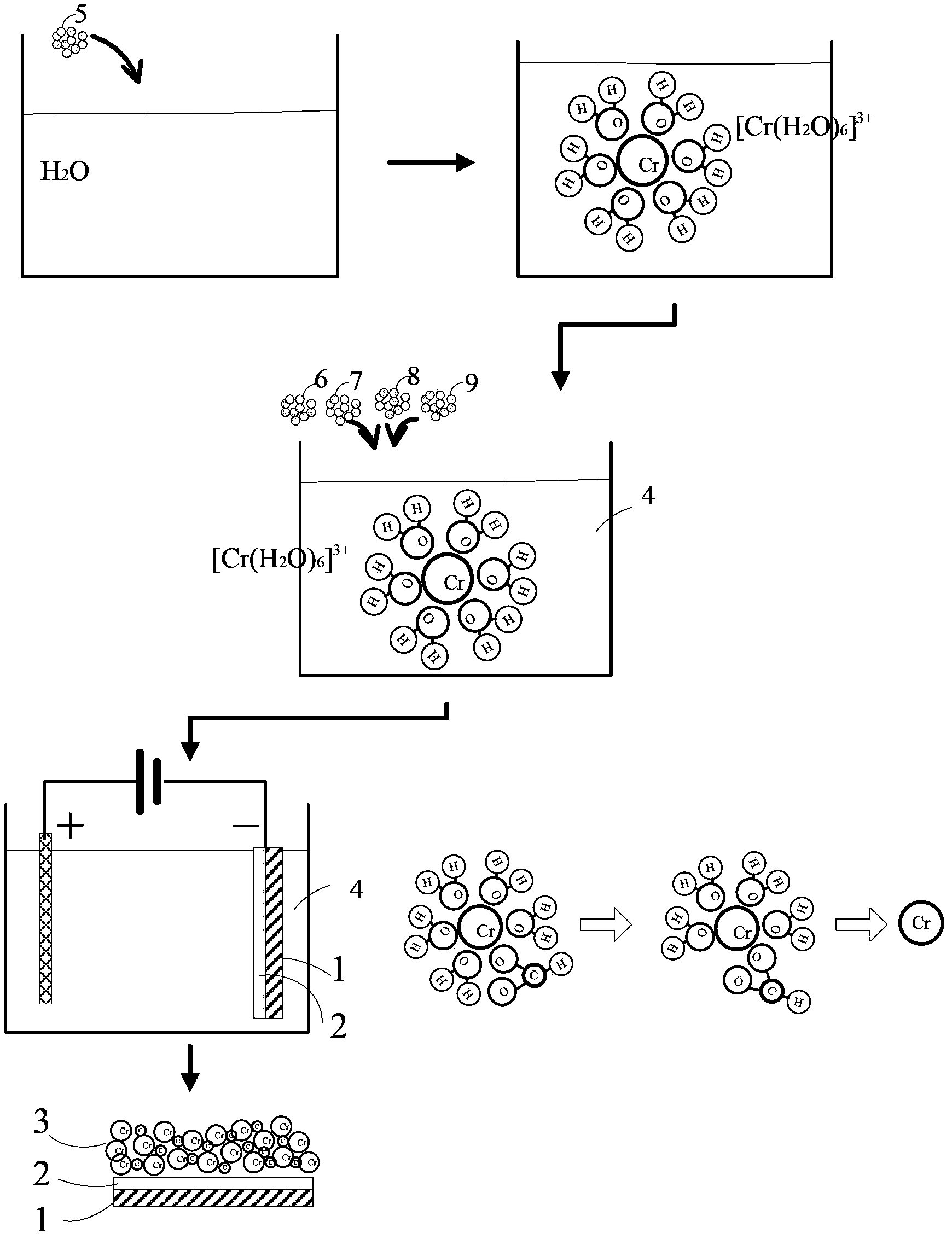

Method used

Image

Examples

Embodiment 1

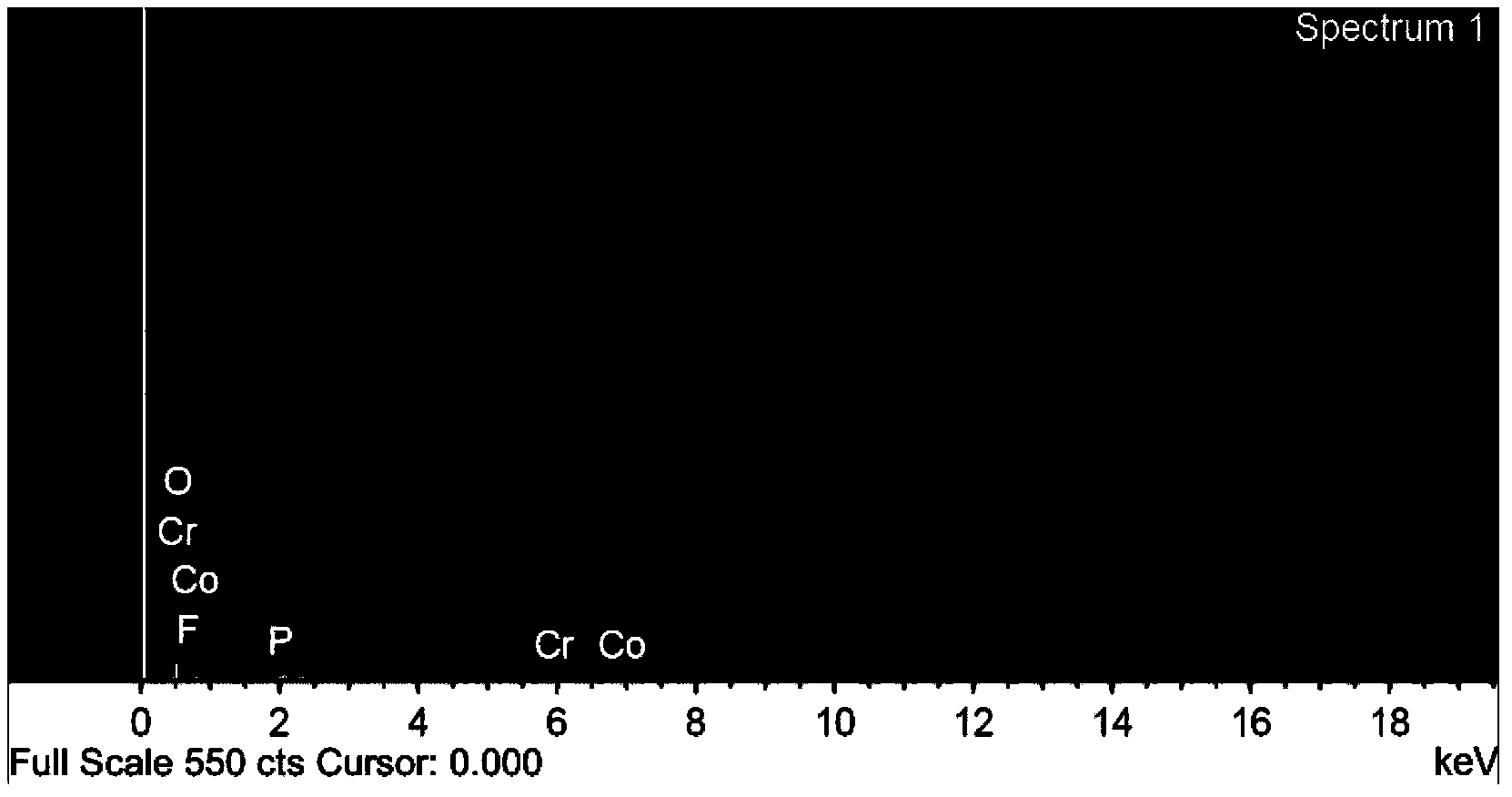

[0074] Please see Figure 4 , Which is the surface topography of the black trivalent chromium oxide plating layer 3 of this embodiment. The trivalent chromium electroplating solution 4 used in this embodiment is a sulfate electroplating bath, and its composition and operating conditions are shown in Table 2. The black trivalent chromium oxide plating layer 3 formed by electroplating using this trivalent chromium electroplating solution 4 and operating conditions is as follows Table three. The trivalent chromium electroplating bath 4 is a sulfate electroplating bath, the blackening agent 6 is fluorosilicic acid, the co-deposition agent 7 is cobalt sulfate, the complexing agent 9 is sodium hypophosphite, and the iron material is used as the substrate 1. Density 10A / dm 2 The operating temperature is 25° C., and the operating time is 1 minute; the resulting black trivalent chromium oxide coating 3 has a blackening degree of about 42.7% as measured by a Spectra Scan Colorimeter (Spe...

Embodiment 2

[0081] The trivalent chromium electroplating solution 4 used in this embodiment is a sulfate electroplating bath, and its composition and operating conditions are shown in Table 4. The black trivalent chromium oxide plating layer 3 formed by electroplating using this trivalent chromium electroplating solution 4 and operating conditions is as follows Table five. The trivalent chromium electroplating solution 4 is a sulfate electroplating bath, the blackening agent 6 is nitric acid, the co-deposition agent 7 is cobalt nitrate, the complexing agent 9 is sodium hypophosphite, and the copper alloy is used as the substrate 1, and the current density is used during electroplating. 30A / dm 2 The operating temperature is 10°C, and the operating time is 3 minutes; the resulting black trivalent chromium oxide coating 3 has a gray scale value of about 30.1%, roughness of about 0.8μm, and a coefficient of friction of about 0.4237. The electroplated layer of the embodiment is not subjected to...

Embodiment 3

[0088] The trivalent chromium electroplating solution 4 used in this embodiment is a sulfate electroplating bath, and its composition and operating conditions are shown in Table 6. The black trivalent chromium oxide plating layer 3 formed by electroplating using this trivalent chromium electroplating solution 4 and operating conditions is as follows Table seven. The trivalent chromium electroplating bath 4 is a sulfate electroplating bath, the blackening agent 6 is potassium nitrate, the co-deposition agent 7 is cobalt nitrate, the complexing agent 9 is sodium hypophosphite, the stainless steel is used as the substrate 1, and the current density is used during electroplating. 50A / dm 2 The operating temperature is 0℃, and the operating time is 5 minutes; the resulting black trivalent chromium oxide coating 3 has a gray scale value of about 27.3% and a roughness of about 0.5μm. The friction coefficient is about 0.3237, the electroplating layer of this embodiment is not subjected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com