Seal water system

A technology for sealing water and mechanical seals, which is applied in the sealing of engines, cleaning hollow objects, engine components, etc., can solve the problems of wasting water, expensive, polluting the environment, etc., and achieve the effect of reducing the burden on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

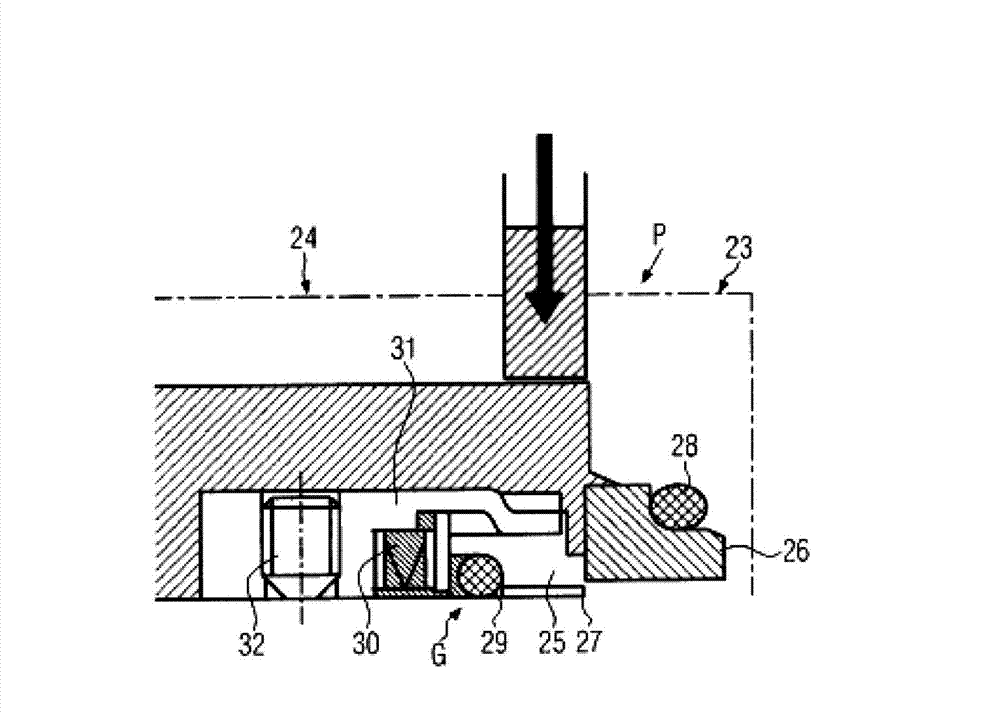

[0021] For example in image 3 Schematically shown in , since rotary mechanical seals G provide constant and good sealing performance, they are used, for example, in high-efficiency pumps. The rotary mechanical seal G will function best within a predetermined temperature range, as that maintains a certain sealing gap, however, this sealing gap will result in a certain leakage through the rotary mechanical seal. In pumps used, for example, in beverage transport technology or bottling technology, the transported food must not be subject to any contamination, for example due to leakage of rotary mechanical seals. On the one hand, also in order to adjust the specific operating temperature of the rotary mechanical seal, and on the other hand, in order to discharge contaminants or prevent contamination from mixing with the transported food, the sealing water is usually allowed to act on the rotary mechanical seal.

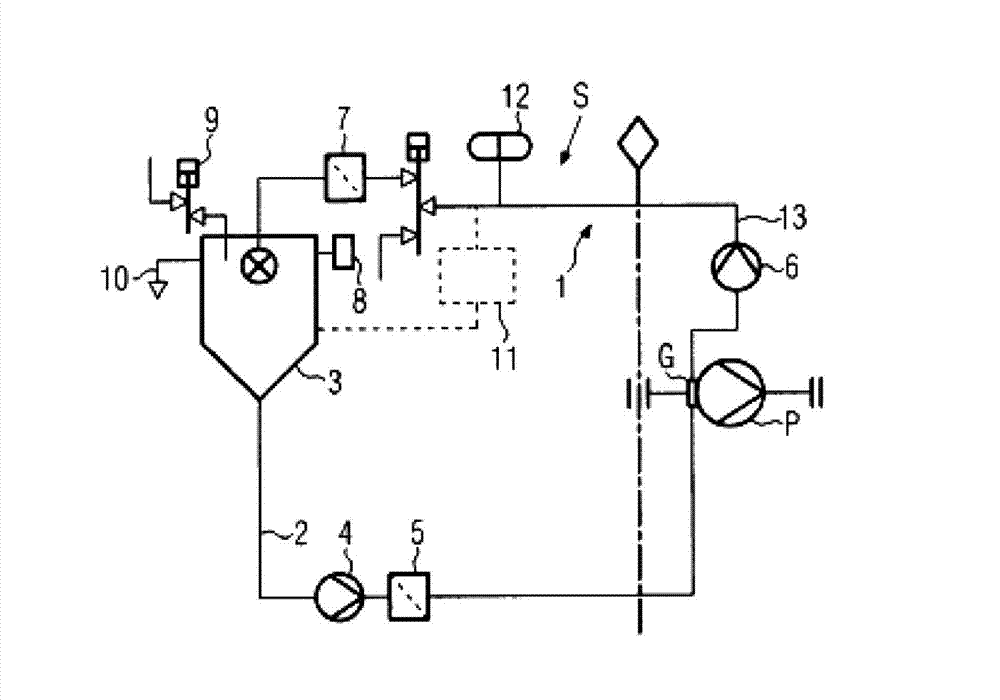

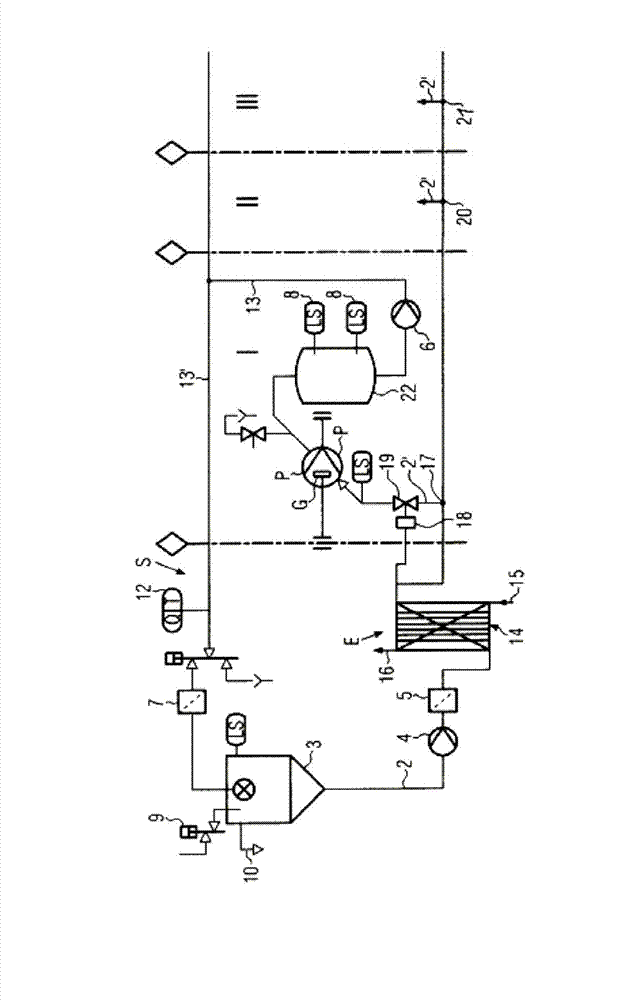

[0022] figure 1 Shown is a seal water system S for at least one r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com