Desulfurized gypsum-high-calcium fly ash geopolymer cementing material and preparation method thereof

A technology of high-calcium fly ash and desulfurized gypsum, applied in the field of materials, can solve the problems of high carbon emission and high energy consumption, and achieve the effects of reducing the burden on the environment, reducing huge pressure and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

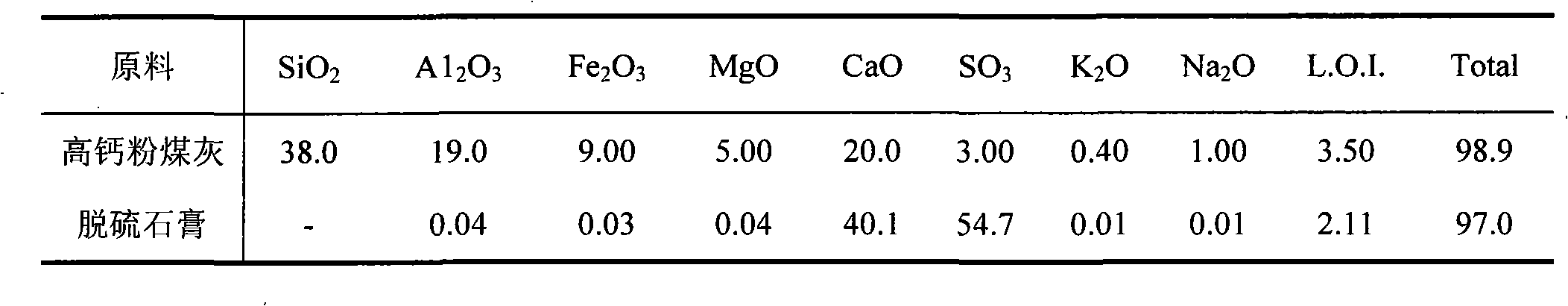

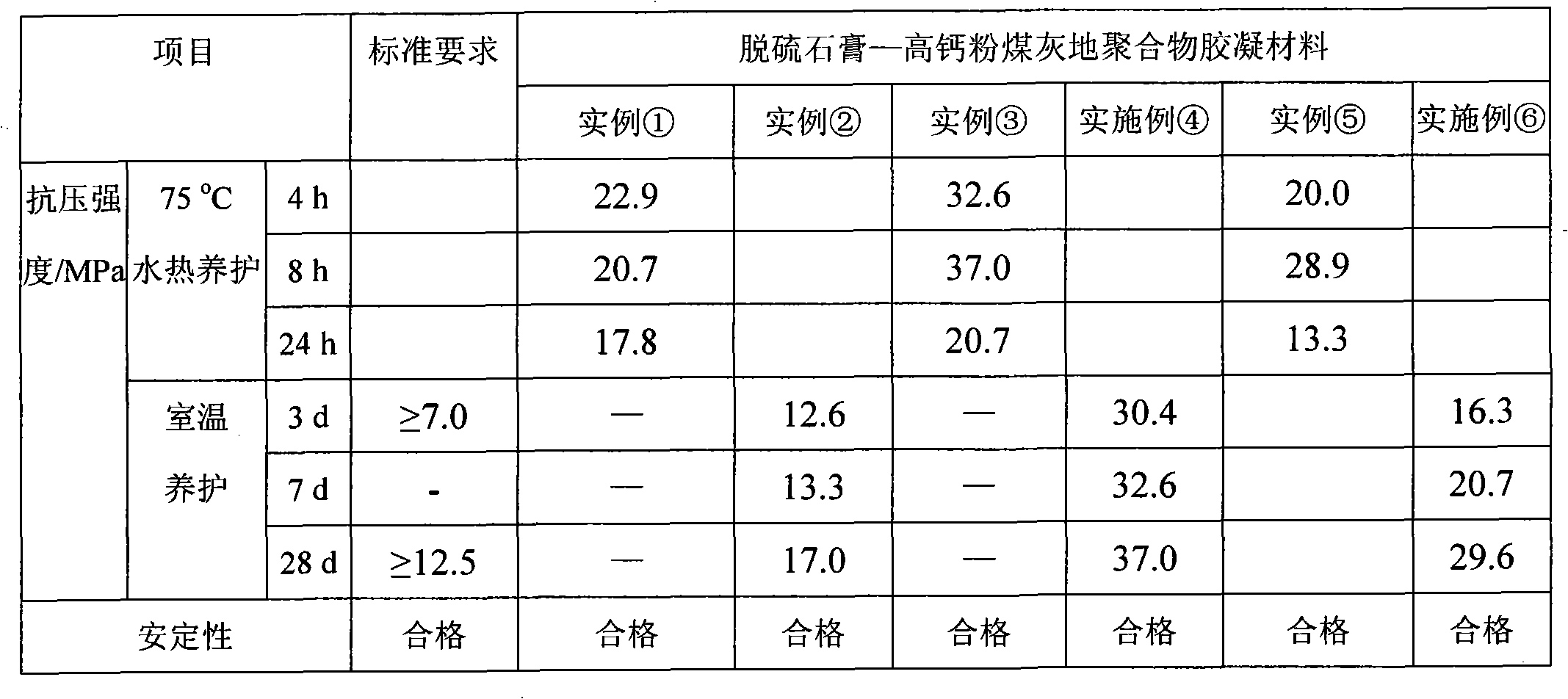

[0020] The main raw materials desulfurized gypsum and high-calcium fly ash in the six embodiments of the present invention are taken from a power plant, and their main components are shown in Table 1. Sodium hydroxide is a chemical reagent containing 99.2% NaOH; commercially available liquid sodium silicate has a solid content of 38.3% and contains 9.1% NaOH 2 O, 29.2% SiO 2 and 61.7% water.

[0021] Table 1 Main chemical components and contents of desulfurized gypsum and high calcium fly ash (wt.%)

[0022]

[0023] Example ①

[0024] a. Mix sodium hydroxide with liquid sodium water glass to control its modulus M (SiO 2 ) / n(Na 2 O) is 1.5, made into a compound chemical admixture, aged for 24h, and set aside.

[0025] b. Control the temperature rise rate to 10°C / min, raise the temperature of the desulfurized gypsum to 600°C, and calcinate for 1 hour to obtain heat-treated desulfurized gypsum, which is cooled for later use.

[0026] c. Mix high-calcium fly ash and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com