Method for treating waste salt dregs containing cyanogen

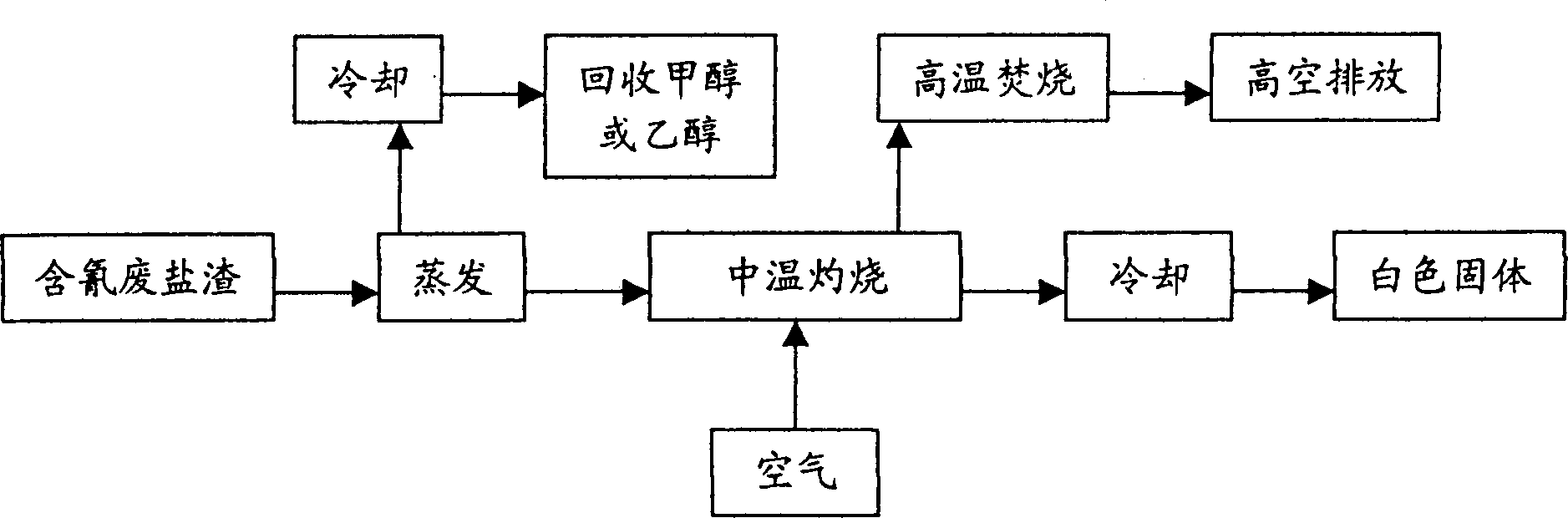

A treatment method and technology for waste salt slag, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of large equipment requirements and investment, low cyanide removal rate, large amount of exhaust gas for treatment, etc., and achieve investment and treatment costs. Low, overcoming the effect of low cyanide removal efficiency and high cyanide removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The continuous production device treats the cyanide-containing waste salt slag produced by the production of methyl cyanoacetate, and feeds at 250kg / h. The cyanide-containing waste salt slag contains 12% methanol, the cyanide content is 3.6g / Kg slag, and the organic matter content is 0.2 %. At 70-90°C, use a hollow paddle dryer to recover methanol. After removing methanol, use a continuous reverberatory furnace to burn aerobically at 550°C for 1.0 hour, the air excess coefficient is 1.0, and the cyanide content is reduced to 0.012g / Kg slag, the organic content is not detected, but the discharged salt slag contains 0.03% inorganic carbon, which is light gray.

Embodiment 2

[0021] The feed amount and ingredients are the same as those in Example 1. Methanol is recovered with a hollow paddle dryer at 70-90°C, and the waste residue after methanol removal is burned with oxygen in a continuous reverberatory furnace at 600°C for 1.0 hour. 1.5, the discharged salt slag is white, the cyanide content drops to 0.002g / Kg slag, and the organic matter content is not detected.

Embodiment 3

[0023] The continuous production device treats the cyanide-containing waste salt slag produced by the production of ethyl cyanoacetate, and the feed is 250kg / h. The cyanide-containing waste salt slag contains 12% ethanol, the cyanide content is 3.6g / Kg slag, and the organic matter content is 0.2 %. At 70-90°C, the hollow paddle dryer is used to recover ethanol, and the waste residue after ethanol removal is burned aerobically in a continuous reverberatory furnace at 650°C for 1.0 hour, with an air excess coefficient of 1.5, and the discharged salt residue is white, cyanide and organic content were not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com