Porous chemical mechanical polishing pads

a technology of chemical mechanical and polishing pads, which is applied in the direction of grinding devices, wrenches, manufacturing tools, etc., can solve the problems of reducing the removal rate of pads made of hard materials, forming numerous scratches, and exhibiting low removal rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

process examples

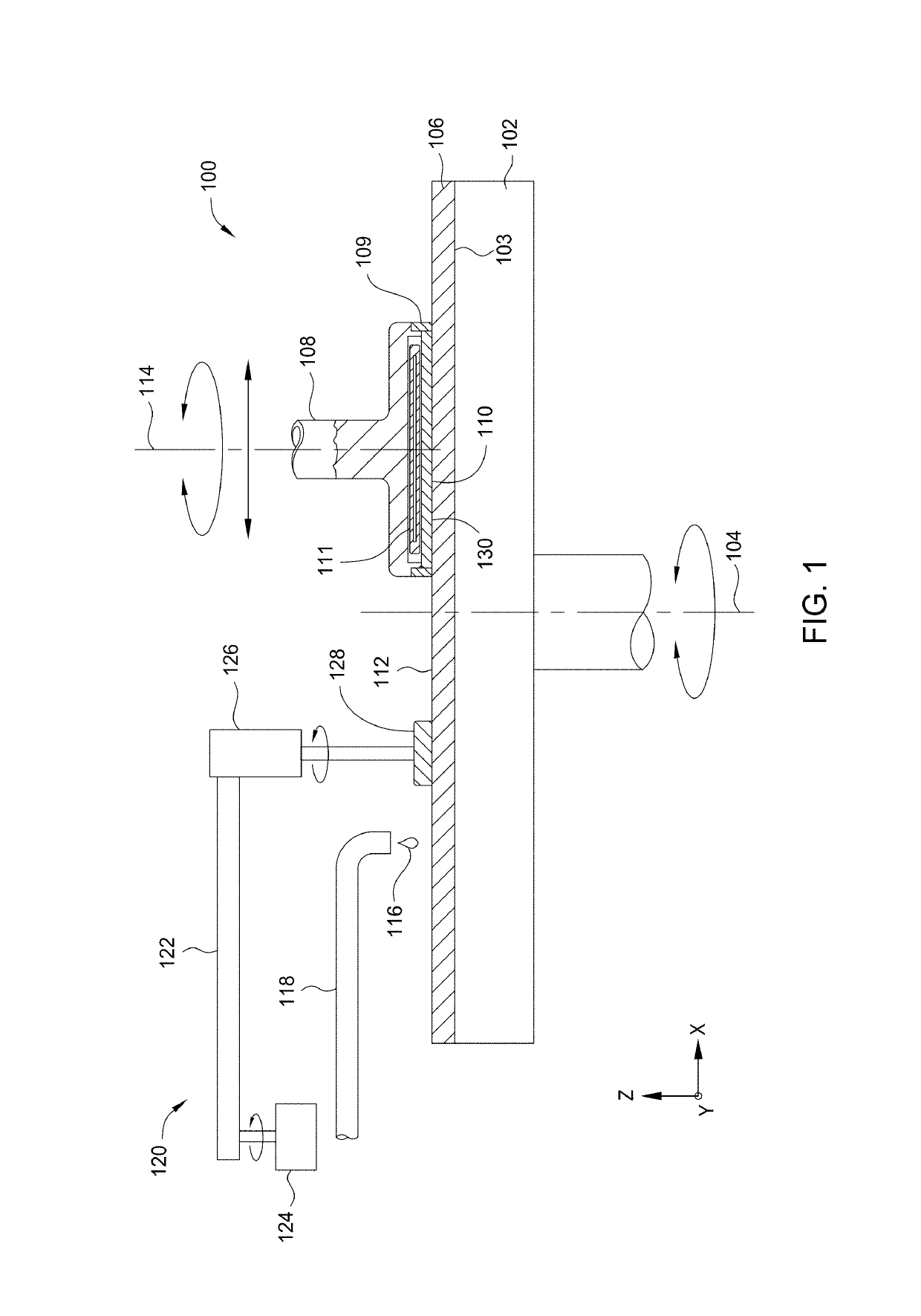

Additive Manufacturing Apparatus and Process Examples

[0158]FIG. 3A is a schematic sectional view of an additive manufacturing system 350 that can be used to form a porous polishing pad using an additive manufacturing process according to one or more implementations of the present disclosure. An additive manufacturing process may include, but is not limited to a process, such as a polyjet deposition process, inkjet printing process, fused deposition modeling process, binder jetting process, powder bed fusion process, selective laser sintering process, stereolithographic process, vat photopolymerization process, digital light processing, sheet lamination process, directed energy deposition process, or other similar 3D deposition process.

[0159]The additive manufacturing system 350 generally includes a precursor delivery section 353, a precursor formulation section 354 and a deposition section 355. The precursor formulation section 354 includes a section of the additive manufacturing sy...

process example

Advance Polishing Pad Formation Process Example

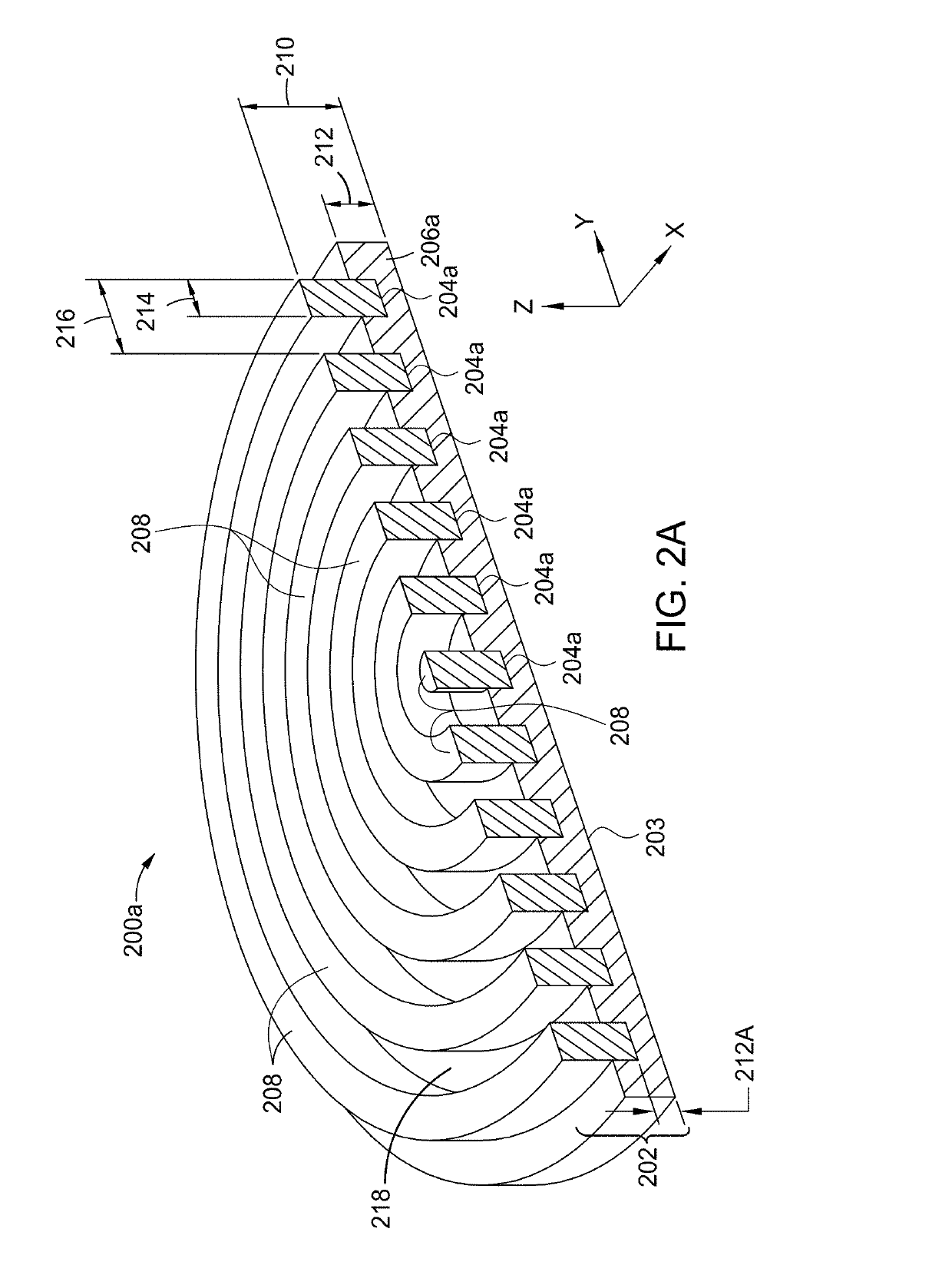

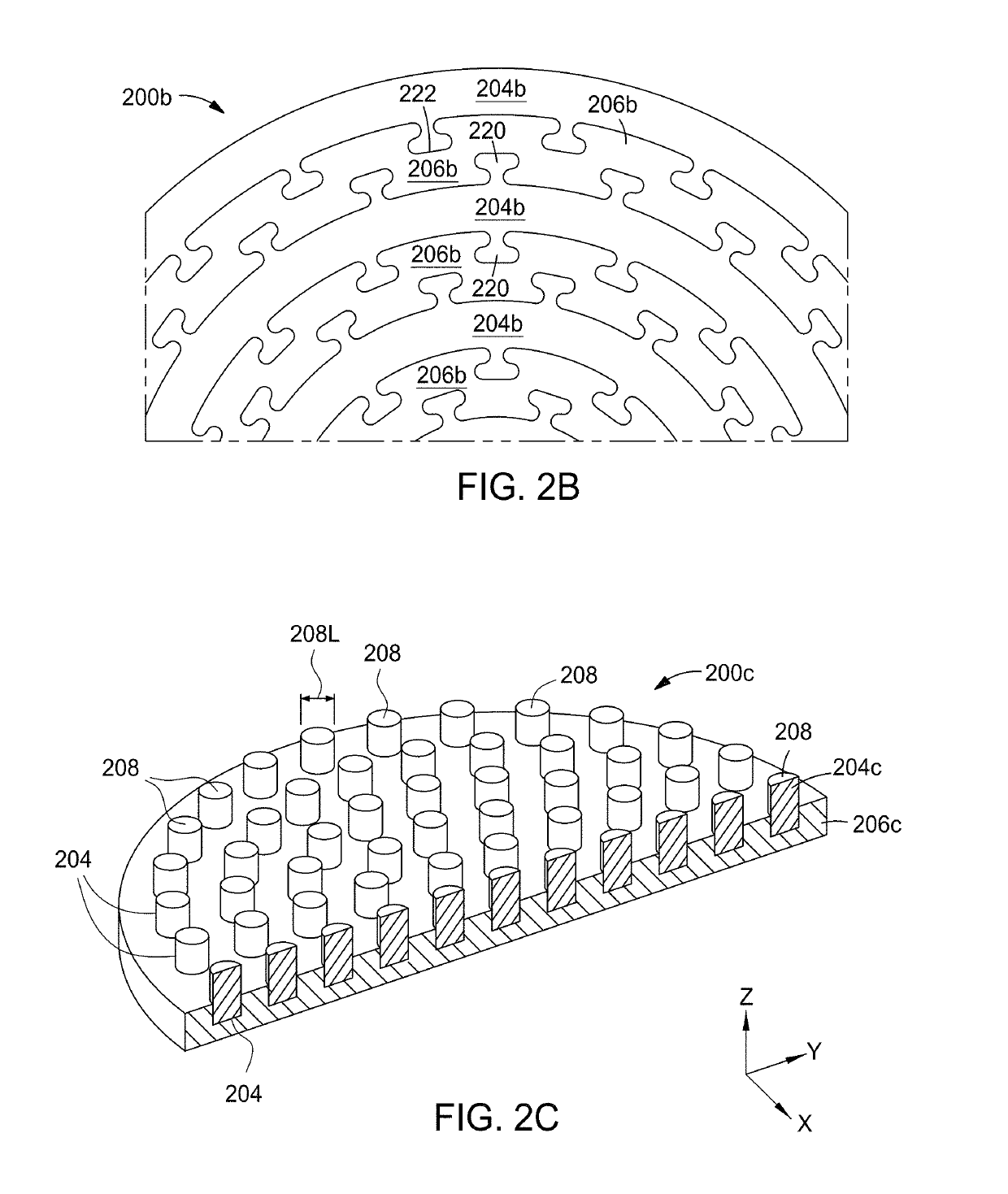

[0210]In some implementations, as discussed above, the construction of the porous polishing pad 200 by an additive manufacturing process begins by creating a CAD model of the porous polishing pad design. This can be done using existing CAD design software, such as Unigraphics or other similar software. An output file, which is generated by the modelling software, is then loaded to an analysis program to ensure that the porous polishing pad design meets the design requirements (e.g., water tight, mass density). The output file is then rendered, and the 3D model is then “sliced” into a series of 2D data bitmaps, or pixel charts. As noted above, the 2D bitmaps, or pixel charts, are used to define the locations across an X and Y plane where the layers in the porous polishing pad will be built. In one implementation, the 2D bitmaps of the polishing article are represented in a data structure readable by a computer rendering device or a compu...

example 1 (

Control)

[0223]As noted in Item 1 in Table 2, a formulation that contains multifunctional oligomers with 01:03:04:M1 was mixed in the ratio of 30:33:15:33. Then photoinitiators and additives (P1:P2:A1 in the ratio of 67:8.25:24.75) in about 3% by weight of the formulation were added for curing. This mixture (8 g) was placed in an aluminum cup and exposed to UV radiation to cure the acrylate monomers. This did not result in measureable pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| void volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com