Patents

Literature

50results about How to "Adjustable running speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

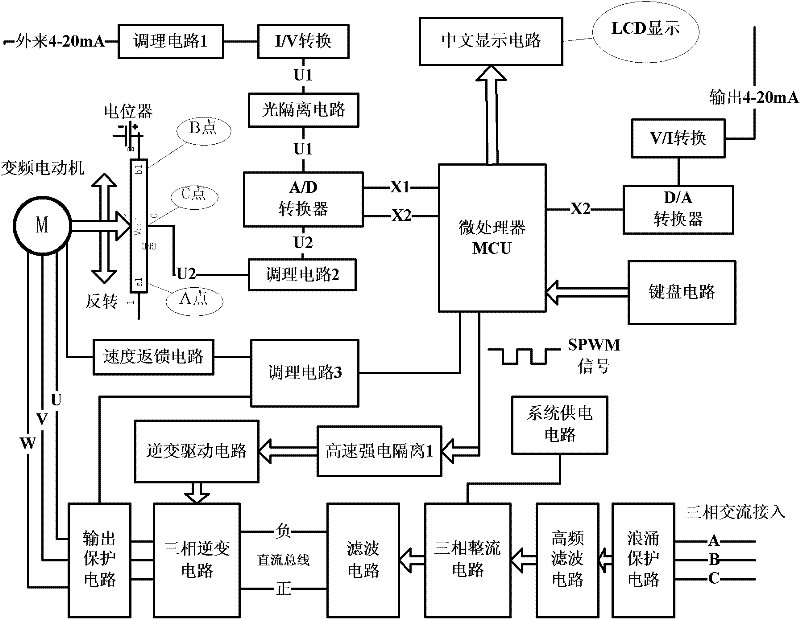

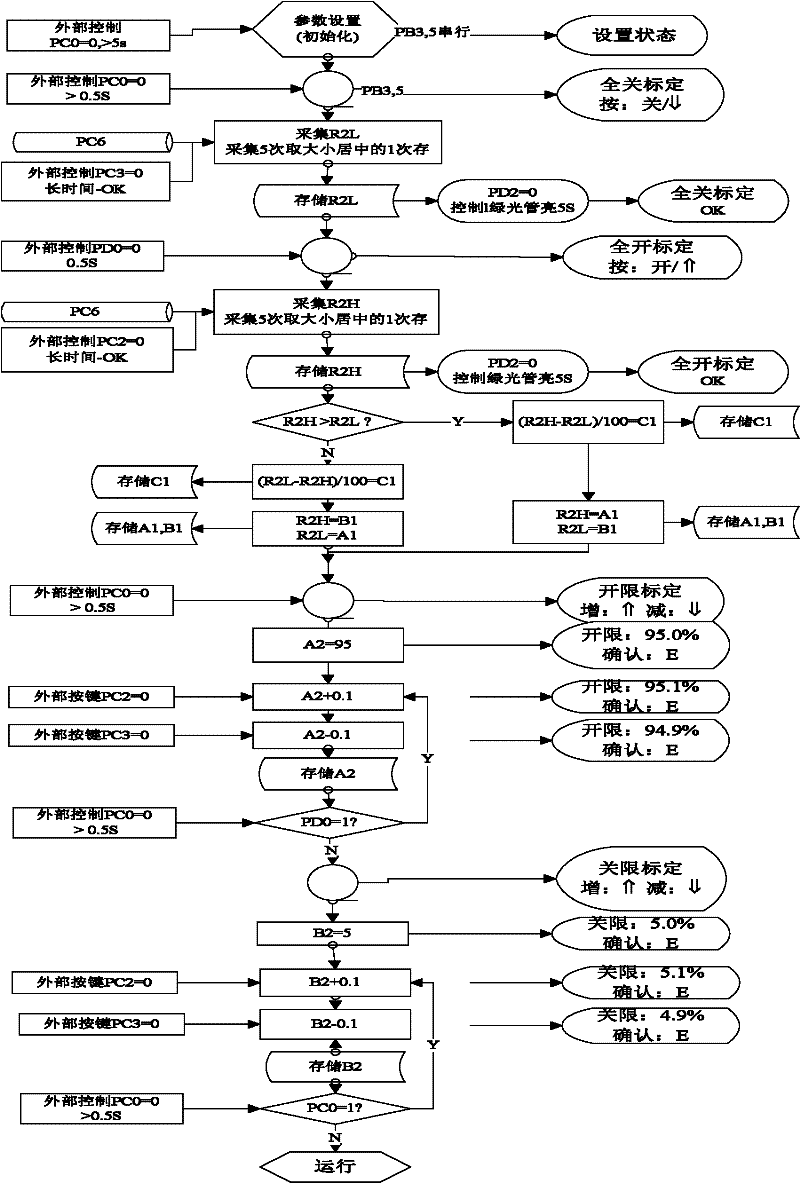

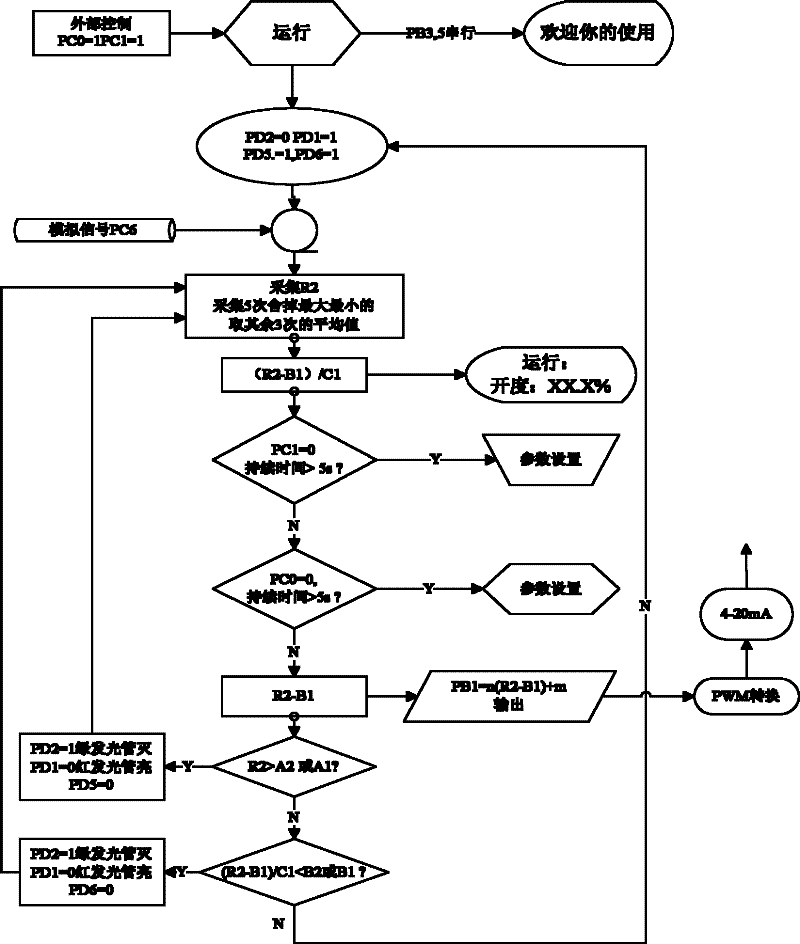

Intelligent alternating current frequency conversion control system of electric actuator

InactiveCN102368677AProcessing speedAdjustable running speedMotor/generator/converter stoppersOperating means/releasing devices for valvesHuman–machine interfaceEngineering

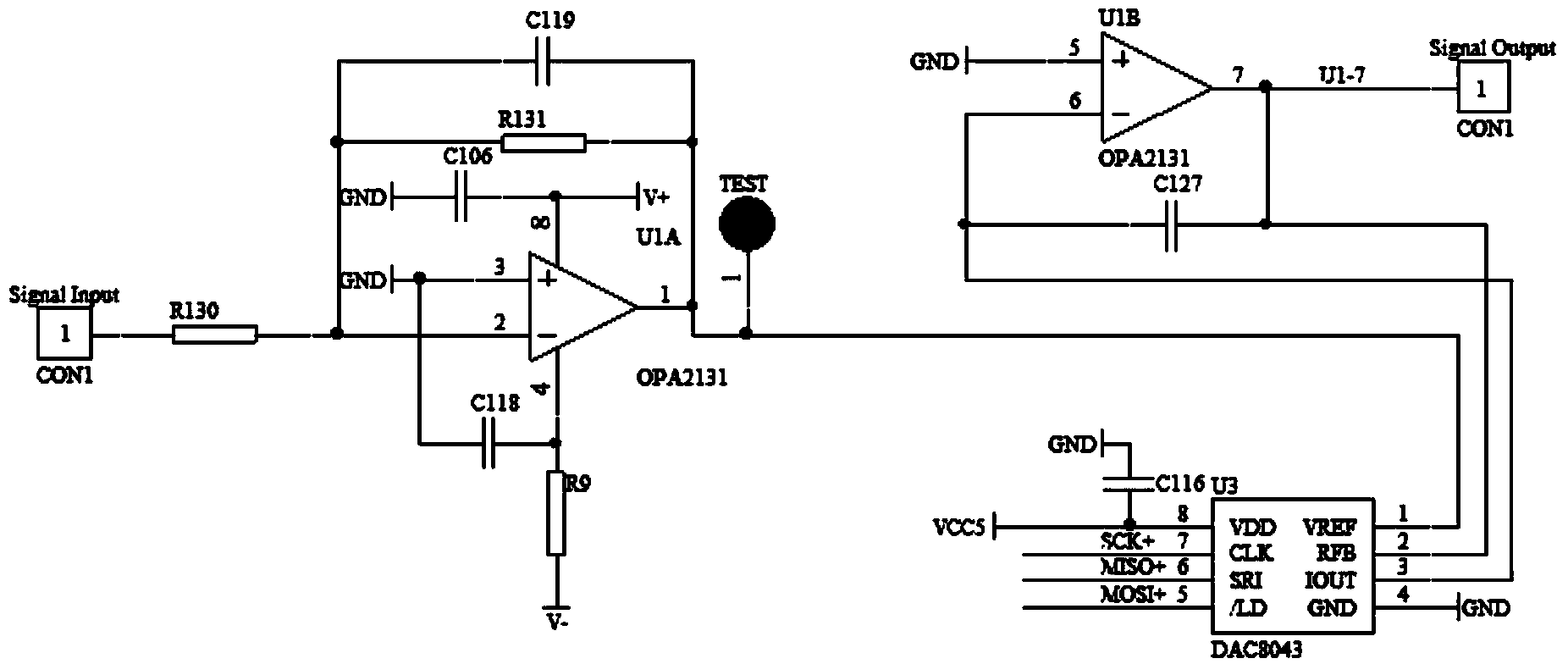

The invention discloses an intelligent alternating current frequency conversion control system of an electric actuator, which comprises a hardware part and a software part and is characterized in that the hardware part adopts a modular design and comprises a microprocessor, A / D (Analog-to-Digital) and D / A (Digital-to-Analog) converters, a Chinese display circuit, an optical isolation circuit, a rectified three-phase circuit, a three-phase inverting circuit, an inversion driving circuit, a high-speed strong-current isolation circuit, a surge protection circuit, a high-frequency filter circuit, a filter circuit and an output protection circuit; all the component units take the microprocessor as the core and are connected with the microprocessor in a star-type way; the A / D and D / A converters are embedded in the microprocessor; the microprocessor is connected with the Chinese display circuit through a communication port; the microprocessor is connected with the three-phase inverting circuit sequentially through the high-speed strong-current isolation circuit and the inversion driving circuit; and the software part comprises a main program, a human-computer interface processing program, an automatic debugging program, a fault processing program, a digital-to-analog conversion and data processing program and a manual operation fault processing program.

Owner:TIANJIN HIGHWAYTECH TECH

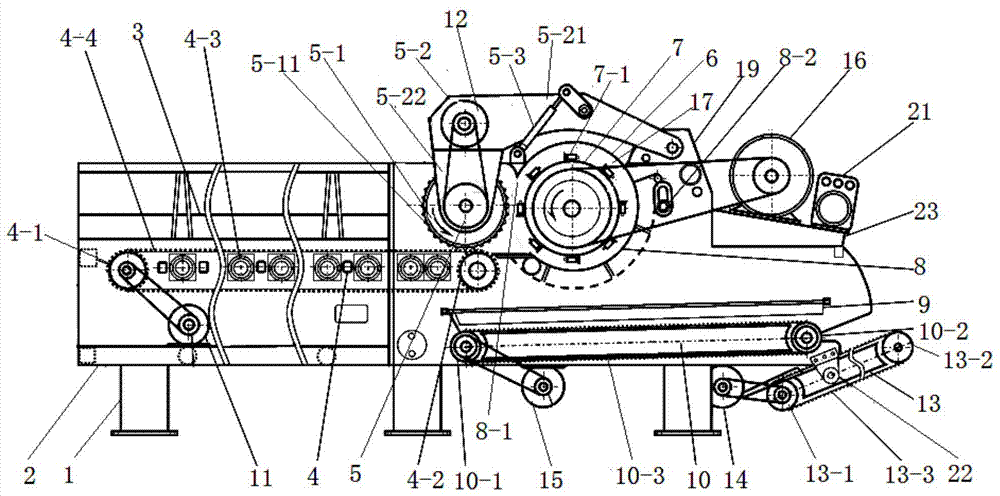

Biomass fuel crusher

The invention discloses a biomass fuel crusher. The biomass fuel crusher comprises a supporting base, wherein a rack is arranged on the supporting base, a feeding bin is arranged at the front part of the rack, a crawler-type feeding conveyer is horizontally distributed in the feeding bin, a forced feeding roll is arranged at the top part of the rear end of the crawler-type feeding conveyer, a crushing compartment is arranged on the rack at the rear part of the forced feeding roll, a crushing roll is arranged in the crushing compartment, a crushing cutter bit is arranged on the surface of the crushing roll, a crushing separating screen is coaxially sheathed at the periphery of the crushing roll, a crushing feeding hole matched with the forced feeding roll is formed at the front part of the crushing separating screen, a discharging compartment communicated with the crushing compartment is arranged at the bottom of the crushing compartment, a discharging hole is formed at the bottom of the discharging compartment, and a discharging conveyer is arranged under the discharging hole. According to the biomass fuel crusher, the universality of the crusher is improved, various biomass fuels in wastes in the fields of agriculture, forest industry, industry, construction industry and the like can be subjected to crushing processing, the operating efficiency and the crushing quality of the crusher are improved, the service life of the crusher is prolonged, the power consumption is reduced, and the using cost and the operating expense are reduced.

Owner:格薪源生物质燃料有限公司

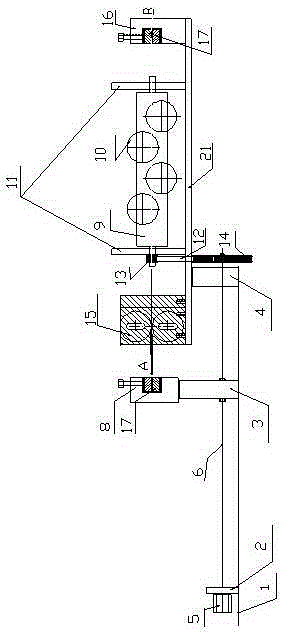

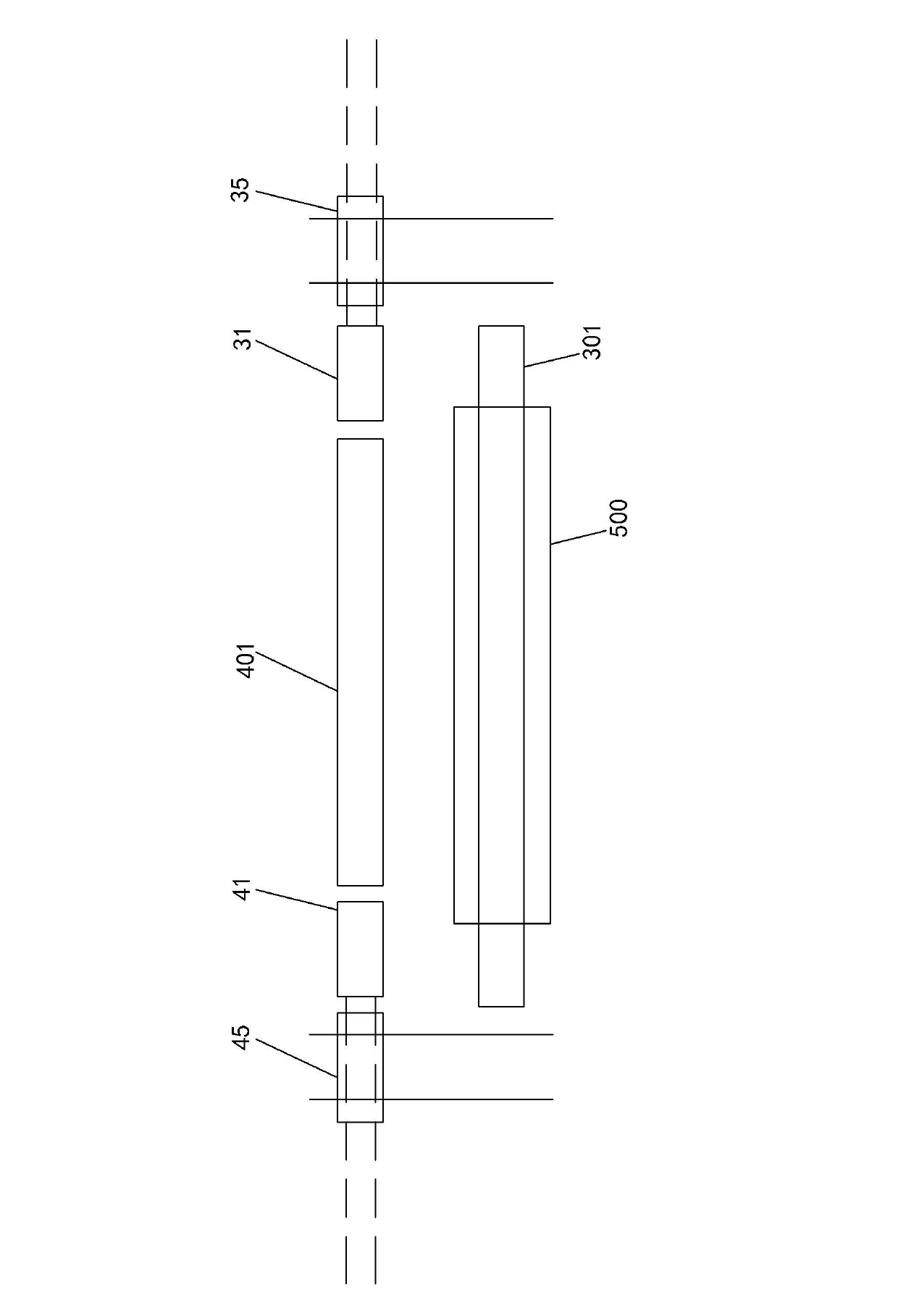

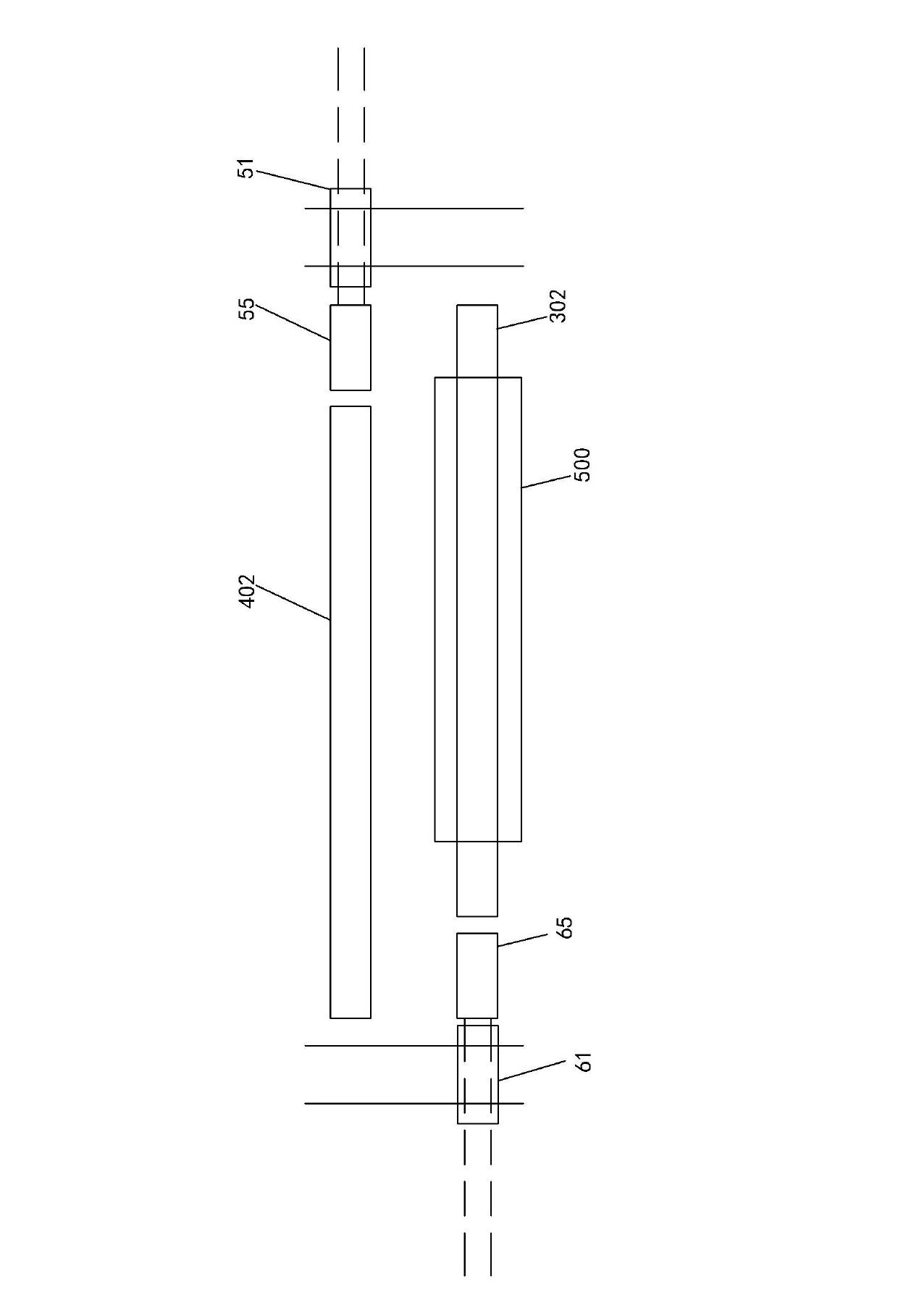

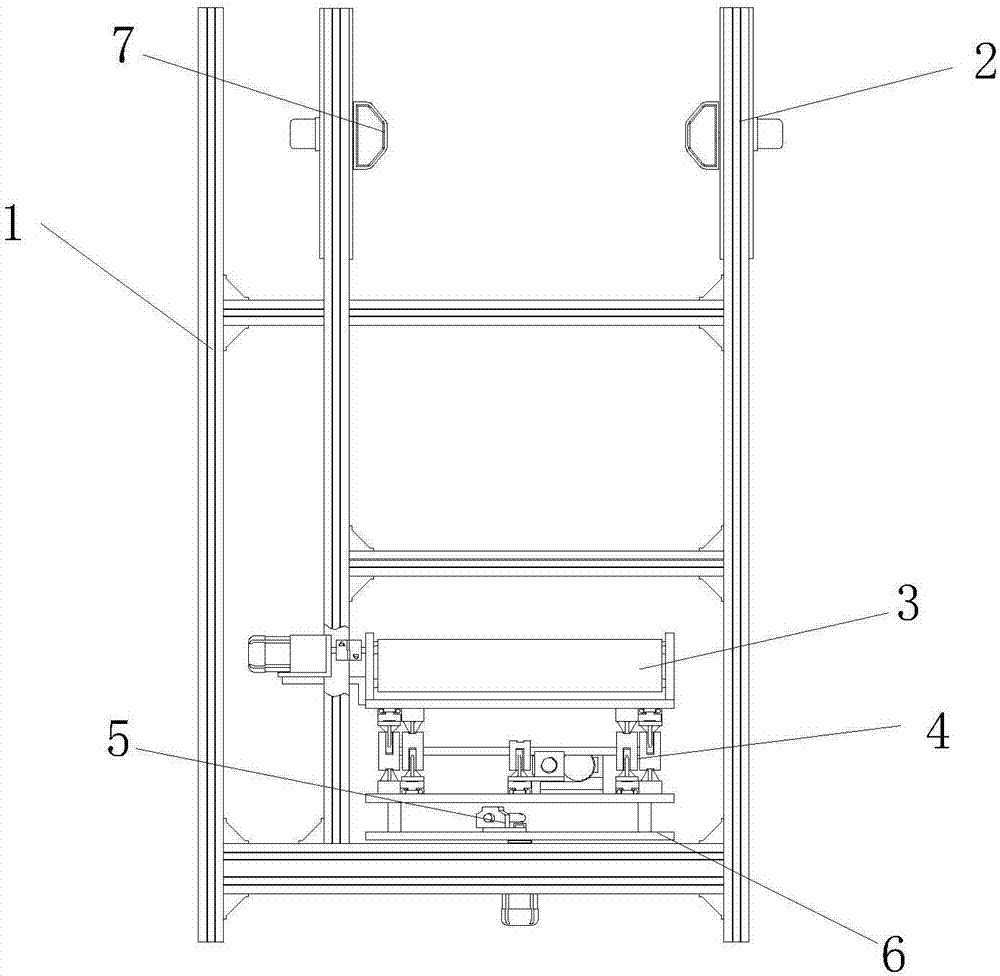

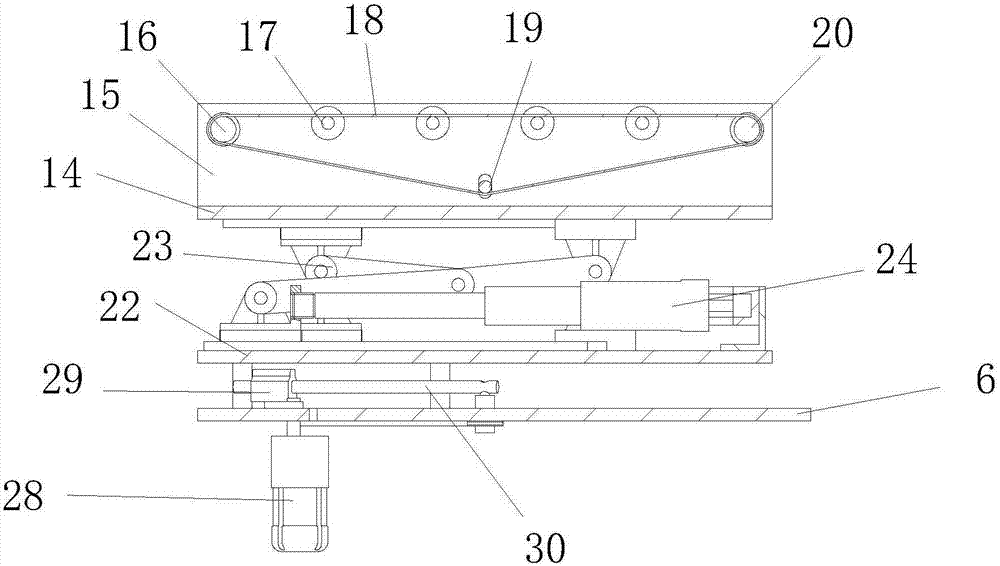

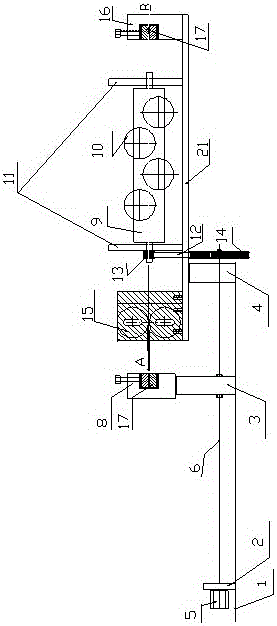

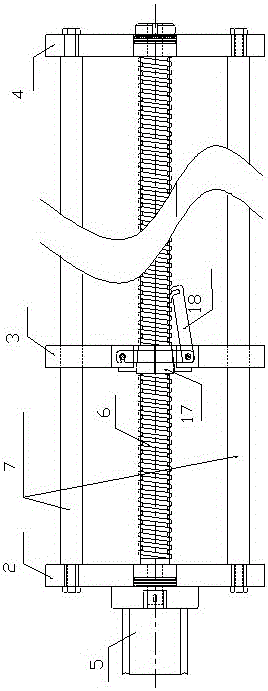

Device for straightening steel wire split from steel wire rope

ActiveCN105290267ADoes not destroy performanceImprove performancePreparing sample for investigationBall screwEngineering

The invention discloses a device for straightening a steel wire split from a steel wire rope. A base disc, three supports, a stepping motor, a ball screw, two guide rails, a clamping mechanism, a straightening wheel frame, four straightening wheels, a supporting frame, a synchronous belt, two synchronous belt wheels, a feeding assembly and a pre-tightening mechanism are installed inside an enclosure. The steel wire to be straightened penetrates from a point B to a point A, sequentially passes through the pre-tightening mechanism, the feeding assembly and the four straightening wheels, and is clamped by the clamping mechanism. The stepping motor is started to drive the ball screw to rotate, and then the two synchronous belt wheels and the straightening wheel frame are further driven to rotate simultaneously, so that the steel wire can be straightened in an omnibearing mode. The ball screw rotationally drives the clamping mechanism to move leftwards. The steel wire is pulled out from the point B to the point A, and straightening of the steel wire is achieved. An experiment with the device shows that the split steel wire with the diameter below 3 mm can be straightened, and the requirements of tensioning, twisting and repeatedly bending the steel wire subsequently are met. In addition, the surface of the steel wire is basically not damaged, the performance of the steel wire is not damaged, equipment is easy to operate, and the operation speed is adjustable.

Owner:CHEM MINERALS & METALLIC MATERIALS INSPECTION CENT OF TIANJIN ENTRY EXIT INSPECTION & QUARANTINE BUREAU

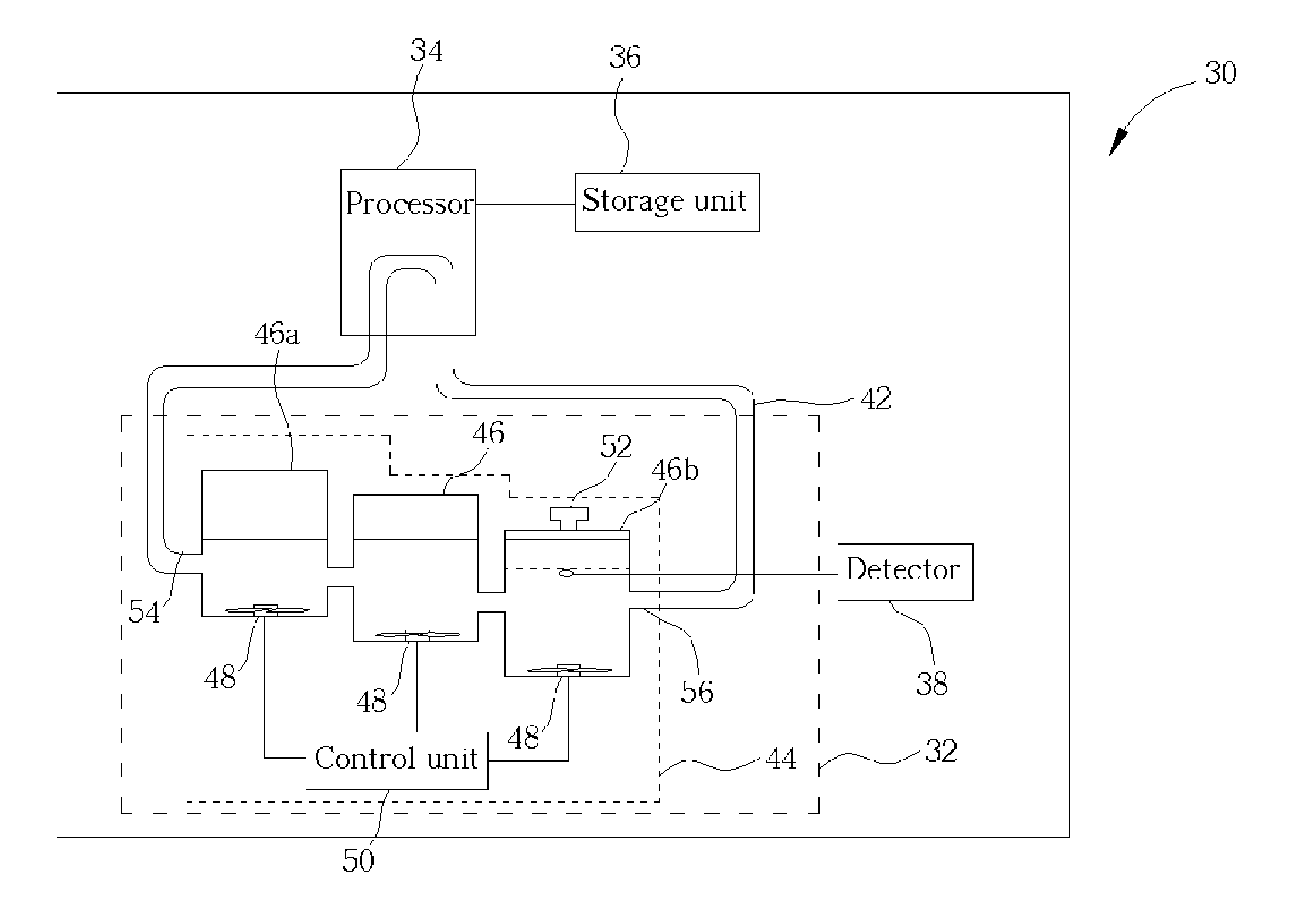

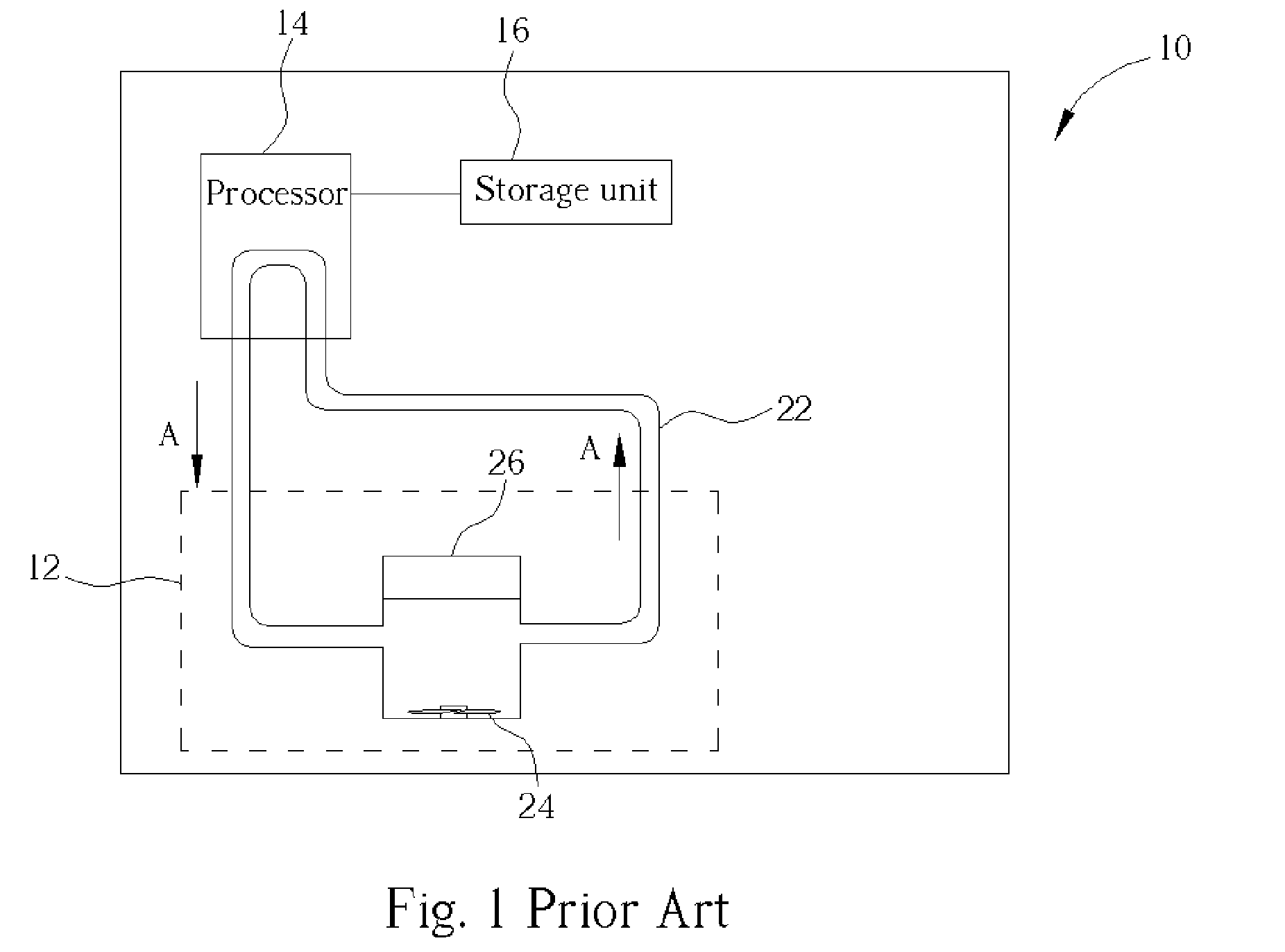

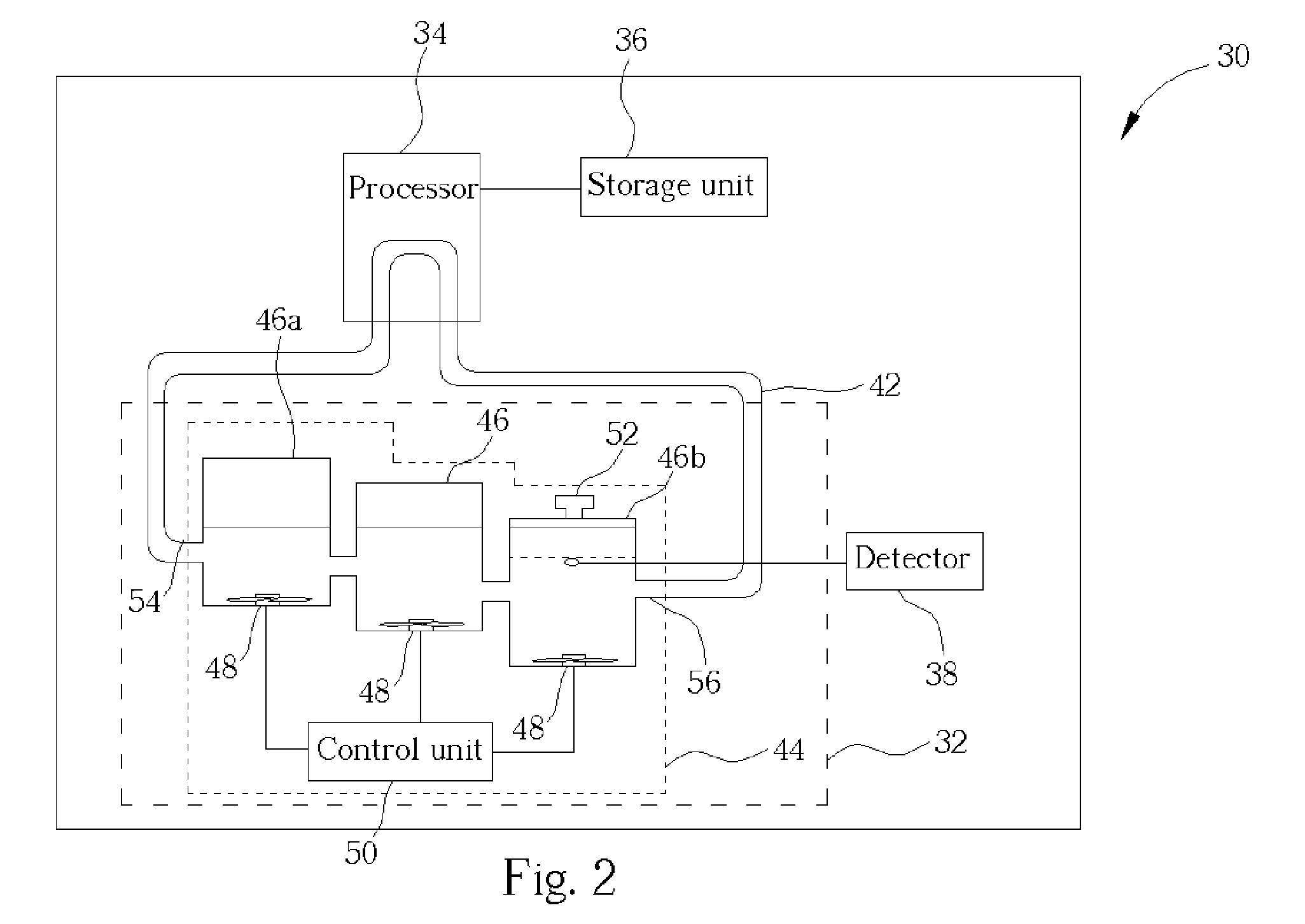

Computer system with a liquid-cooling thermal module having a plurality of pumps

ActiveUS7057894B2Adjustable running speedDigital data processing detailsSemiconductor/solid-state device detailsStorage cellEngineering

A computer system includes a processor for processing data, a storage unit for storing data, and a liquid cooling thermal module for dissipating heat generated by the processor. The thermal module has a liquid coolant carrying pipe adjacent to the processor for conducting heat, and a cooling device. The cooling device has a plurality of tanks, which are connected with each other.

Owner:MICRO-STAR INTERNATIONAL

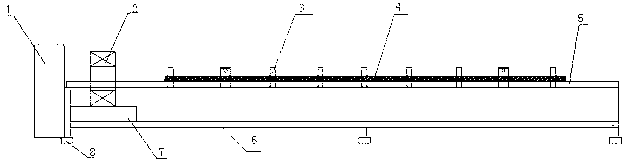

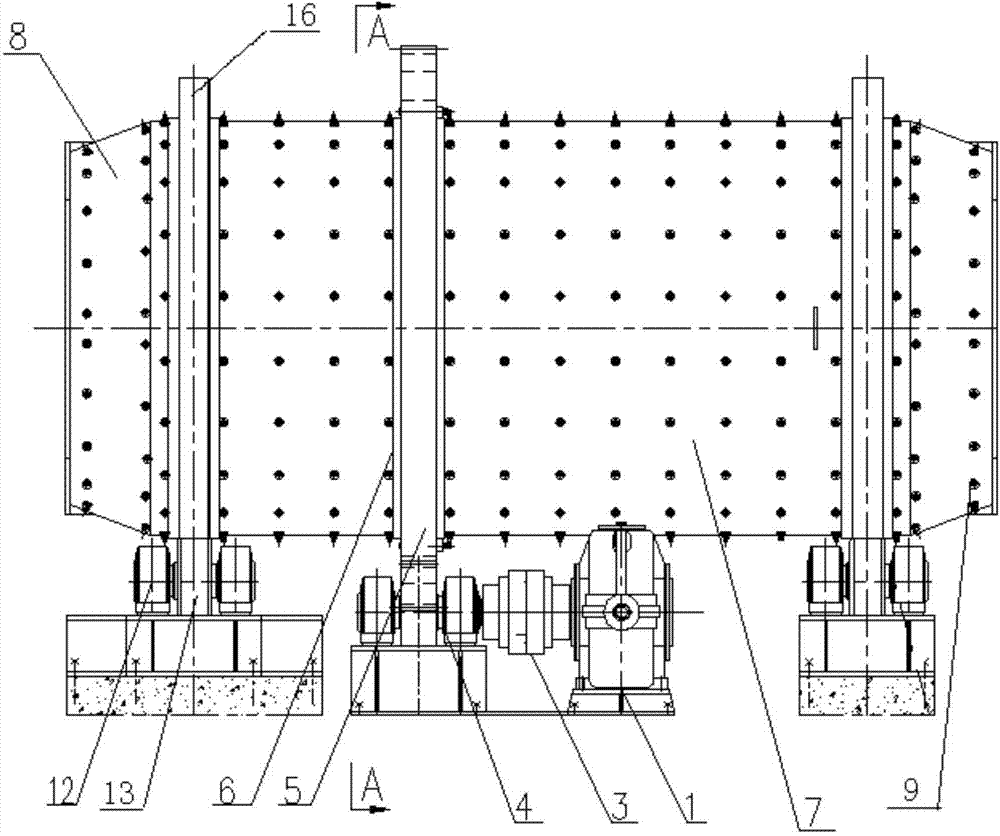

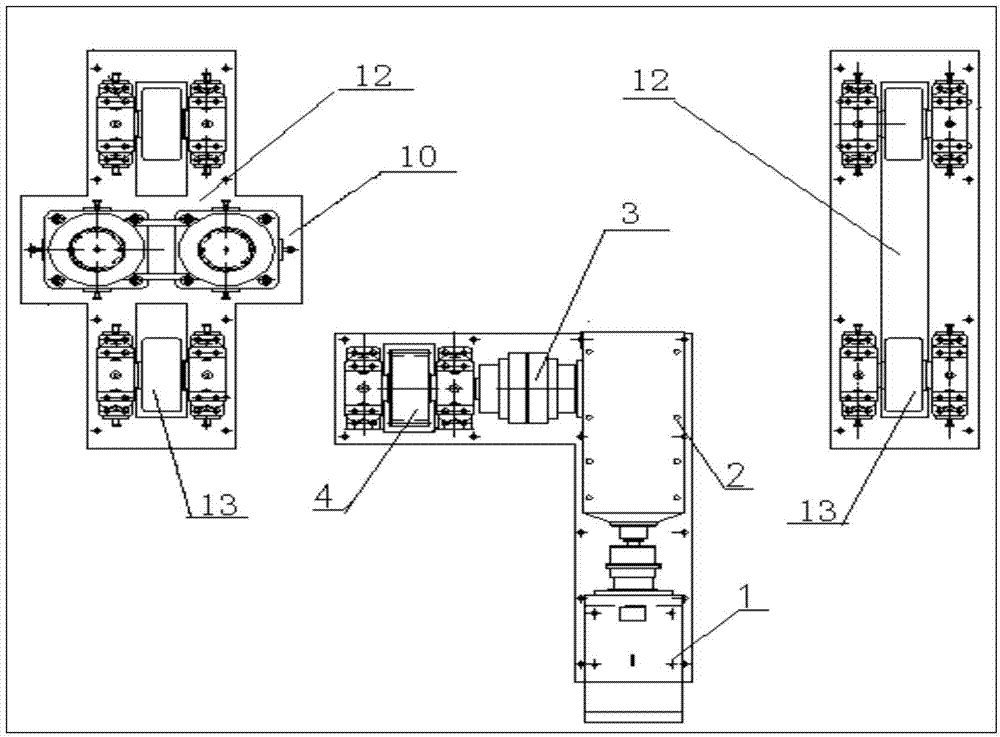

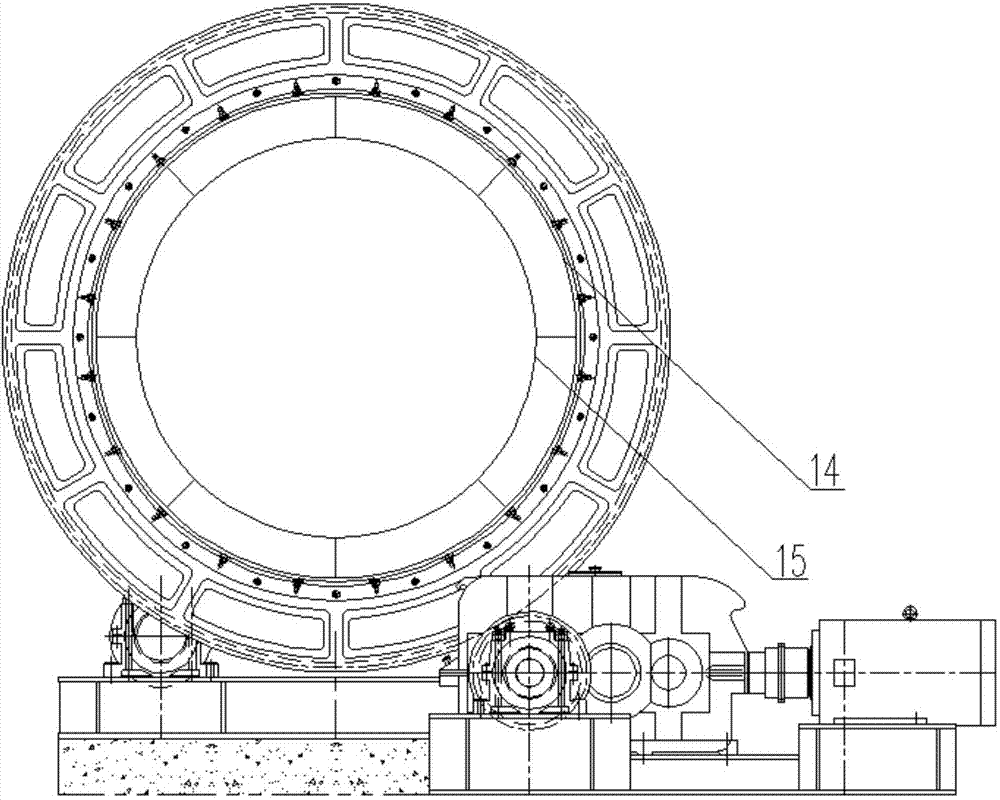

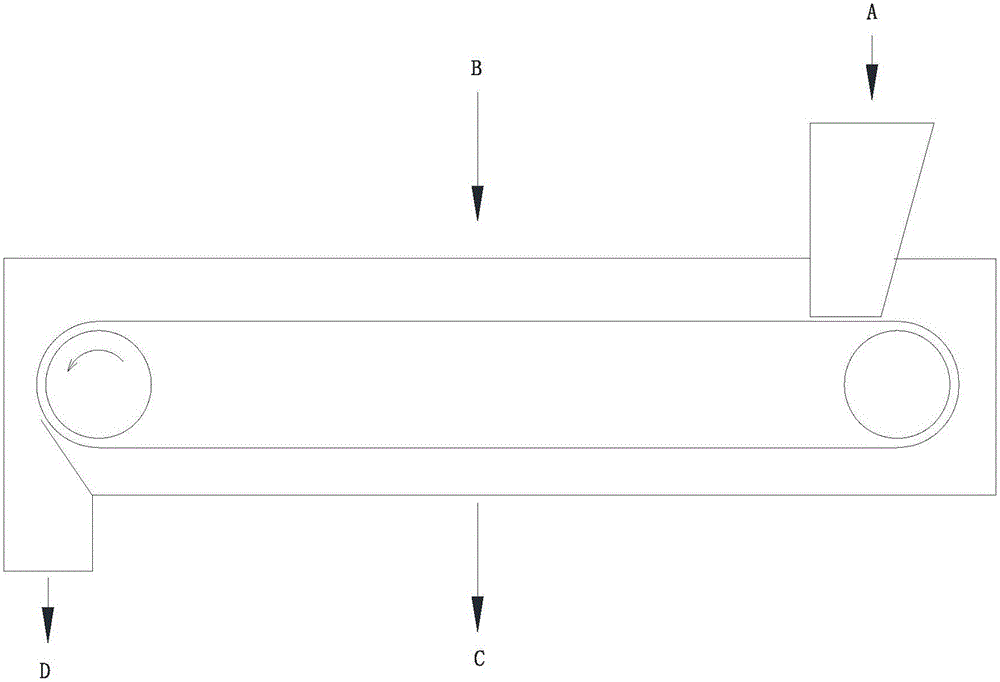

Air reverse skid conveying system

InactiveCN102502171ASolve the problem of oil pollutionSolve noise pollutionConveyorsEngineeringDelivery system

The invention discloses an air reverse skid conveying system, which comprises multiple air reverse skids, an inlet switching device and an outlet switching device for circularly conveying the air reverse skids at the inlet and outlet positions of the system, and two air reverse skids, which extend in parallel along a straight line, are opposite in conveying directions, and are connected between the two switching devices. The reverse skid conveying system disclosed by the invention completely adopts belt type or roller bed conveying, is frequency-variable and adjustable in operating speed frequency, meets the requirements of high-tempo conveying of the existing automobile plants, and solves the chain oil pollution and noise pollution problems at the same time. The spare parts of the air reverse skid conveying system are universal for absolutely most of the existing ground skids.

Owner:ZHONGQI CHANGXING LUOYANG ELECTROMECHANICAL EQUIP ENG +1

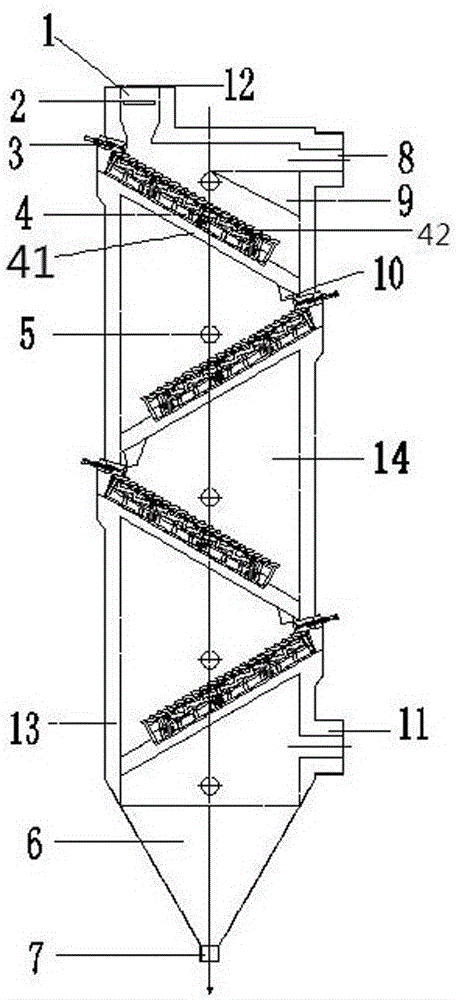

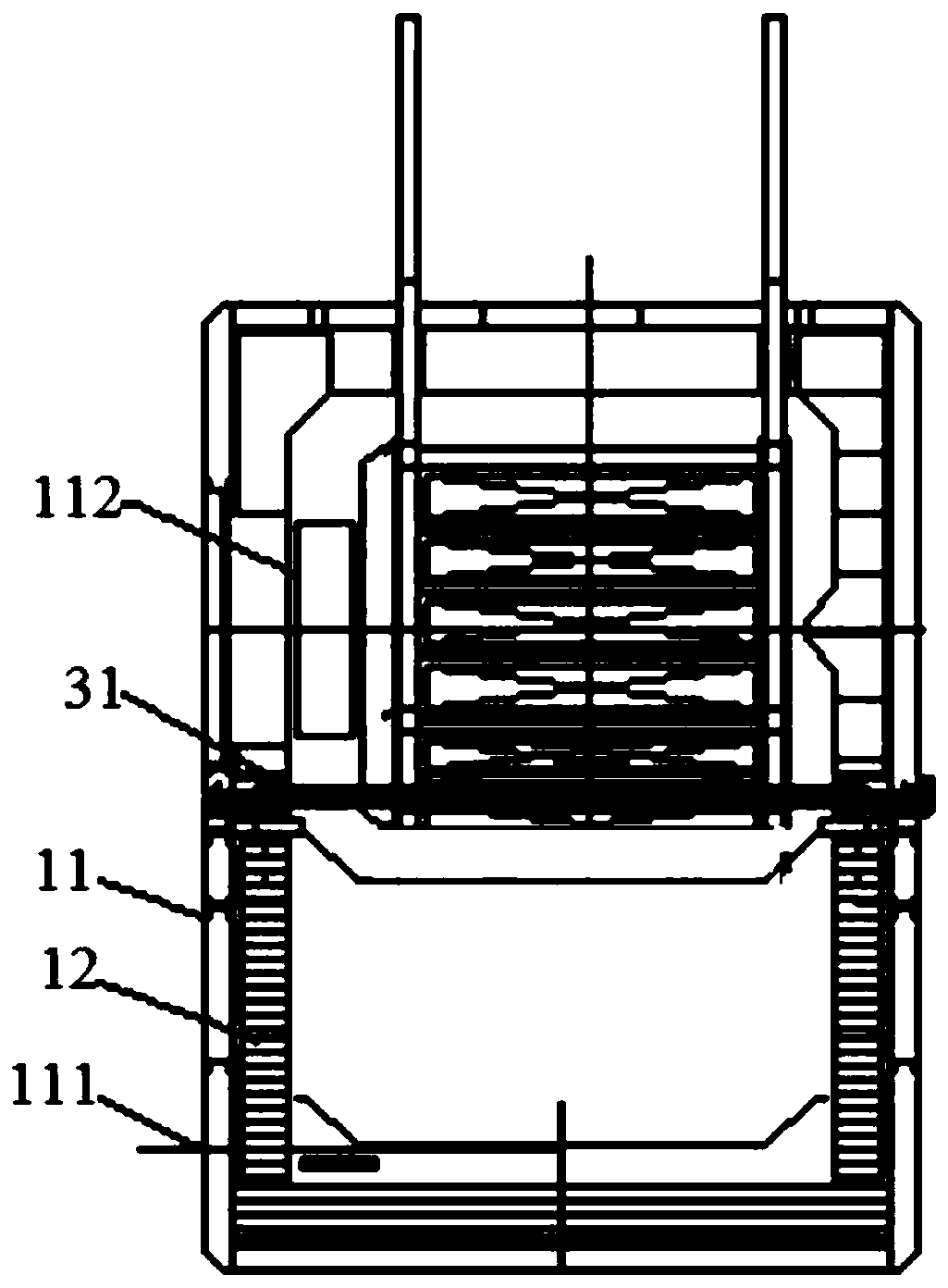

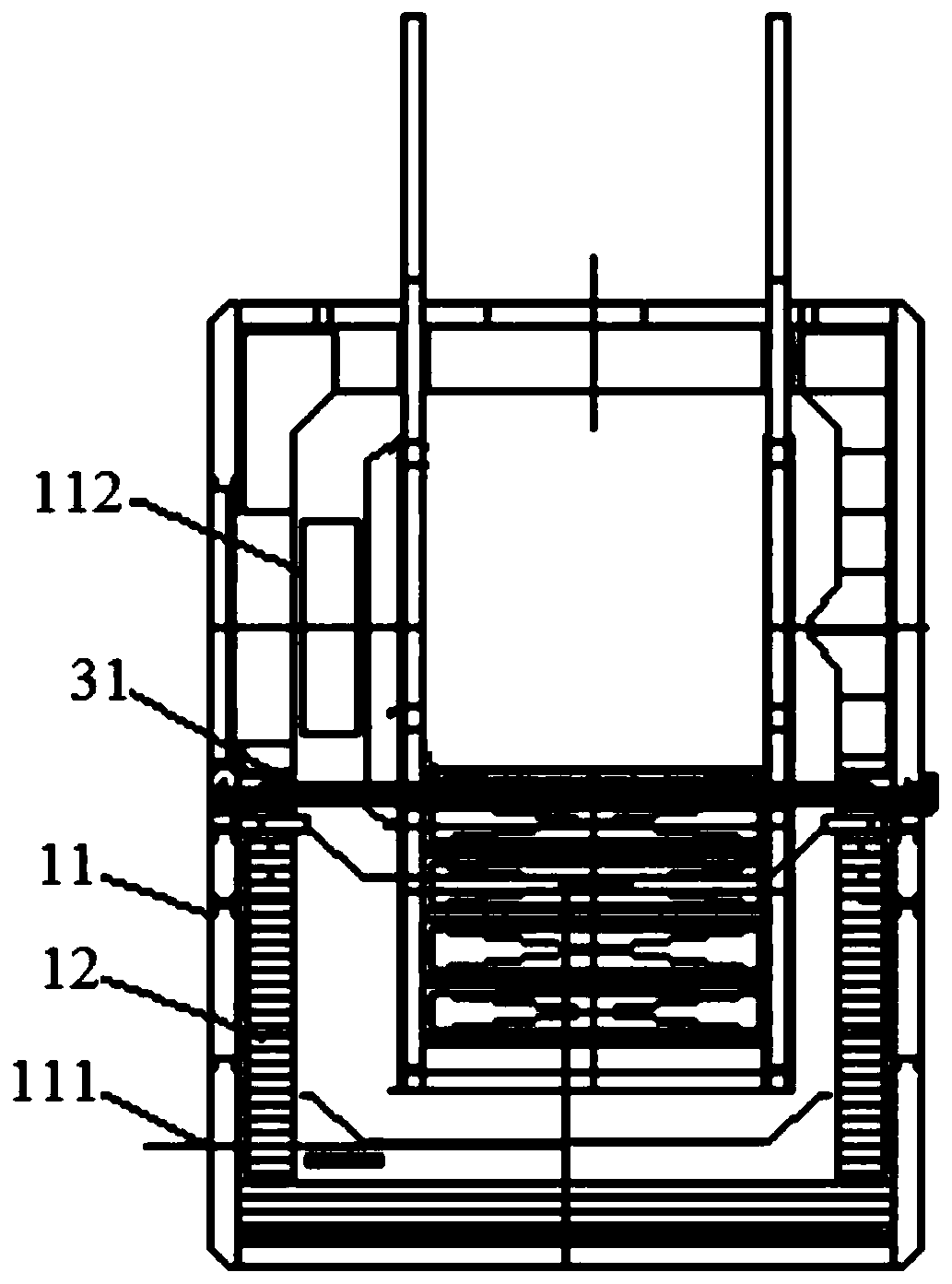

Closed-loop steel sintered red ore cooling device and process method thereof

ActiveCN106123609AIncrease productionGood qualityHandling discharged materialCooling methodsCold air

The invention discloses a closed-loop steel sintered red ore cooling device. The device comprises a device body, a heat exchange cavity arranged in the device body, a feeding inlet formed in the upper end of the device body, a uniform distributor arranged at the lower end of the feeding inlet, a discharging outlet formed in the lower end of the body, a uniform temperature device and at least one fire grate. The uniform temperature device is arranged on the device body and communicates with a cold air outlet. The at least one fire grate is movably installed in the heat exchange cavity. Each fire grate and the heat exchange cavity form an obliquely-downward angle, and the fire grates are parallel to each other. A pushing device is arranged at the front end of each fire grate. A hopper is arranged at the tail end of each fire grate. The device replaces a cooling section of an original sintering machine or a ring cooling machine. Compared with an original cooling mode, the device is high in yield, good in quality and low in energy consumption. Compared with the original cooling mode, the yield of a marching type sintering machine can be increased by 30%-40%, zone firing is increased by 5%-10%, and energy consumption only accounts for about 50% of the original cooling mode.

Owner:BEIJING RUIDA HONGXIN TECH CO LTD

Limb rehabilitation machine

InactiveCN107050751APromote recoveryAdjustable running speedChiropractic devicesMovement coordination devicesEngineeringOrbit

A limb rehabilitation machine comprises a support, arm rehabilitation assemblies, a treadmill, a lifting assembly and a left and right shaking assembly. The cross section of the support is in a U shape, the arm rehabilitation assemblies are arranged at the upper ends of the two sides of the U-shaped support, and a base, the left and right shaking assembly, the lifting assembly and the treadmill are sequentially arranged at the bottom of the U-shaped support from bottom to top; each arm rehabilitation assembly comprises a baffle, a handle and an elliptical instrument mechanism, wherein the baffle is provided with an elliptical orbit with a semi-notch, the handle penetrates through the elliptical orbit, is embedded in the elliptical orbit and slides in the elliptical orbit, the elliptical instrument mechanism is arranged on the baffle on the inner side of the elliptical orbit, and one end of a crank in a cross groove of each elliptical instrument mechanism is pivoted with the handle; the lifting assembly controls the height of the treadmill; the left and right shaking assembly controls the lifting assembly and the treadmill to shake left and right.

Owner:温州市从煜科技有限公司

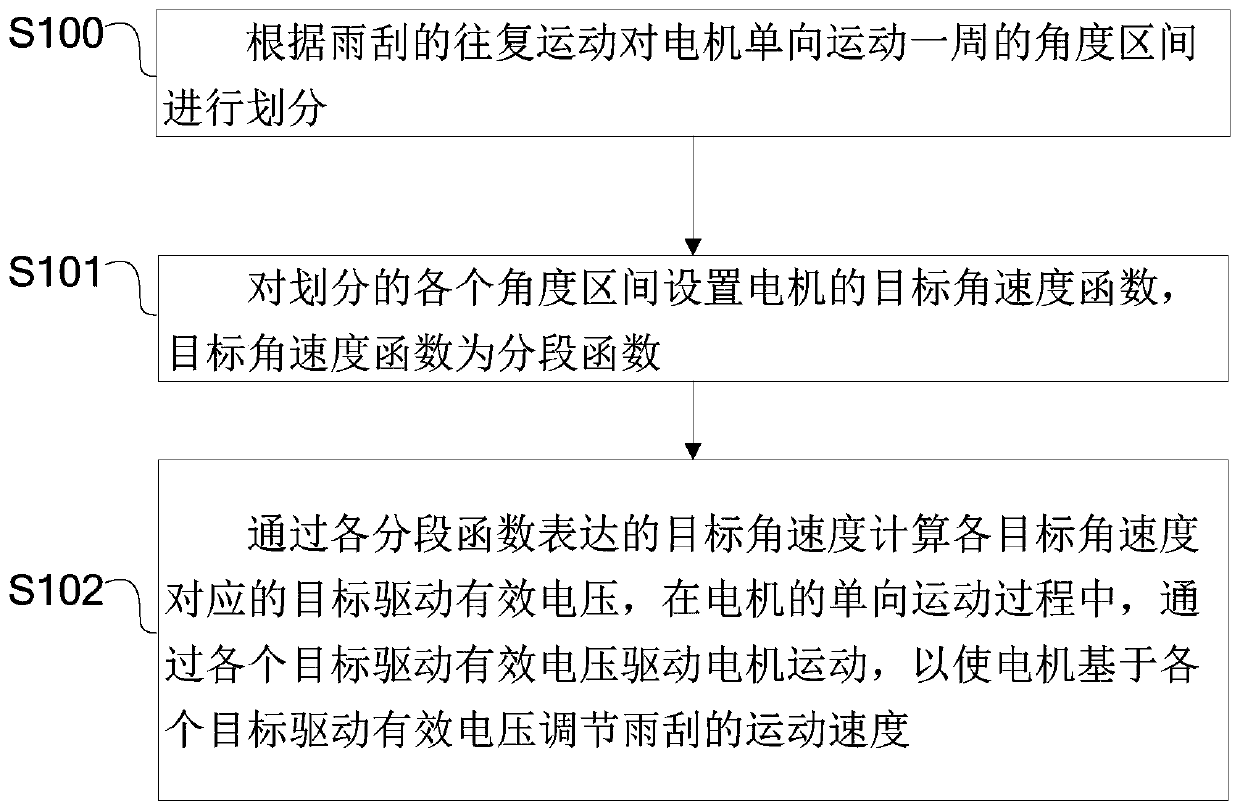

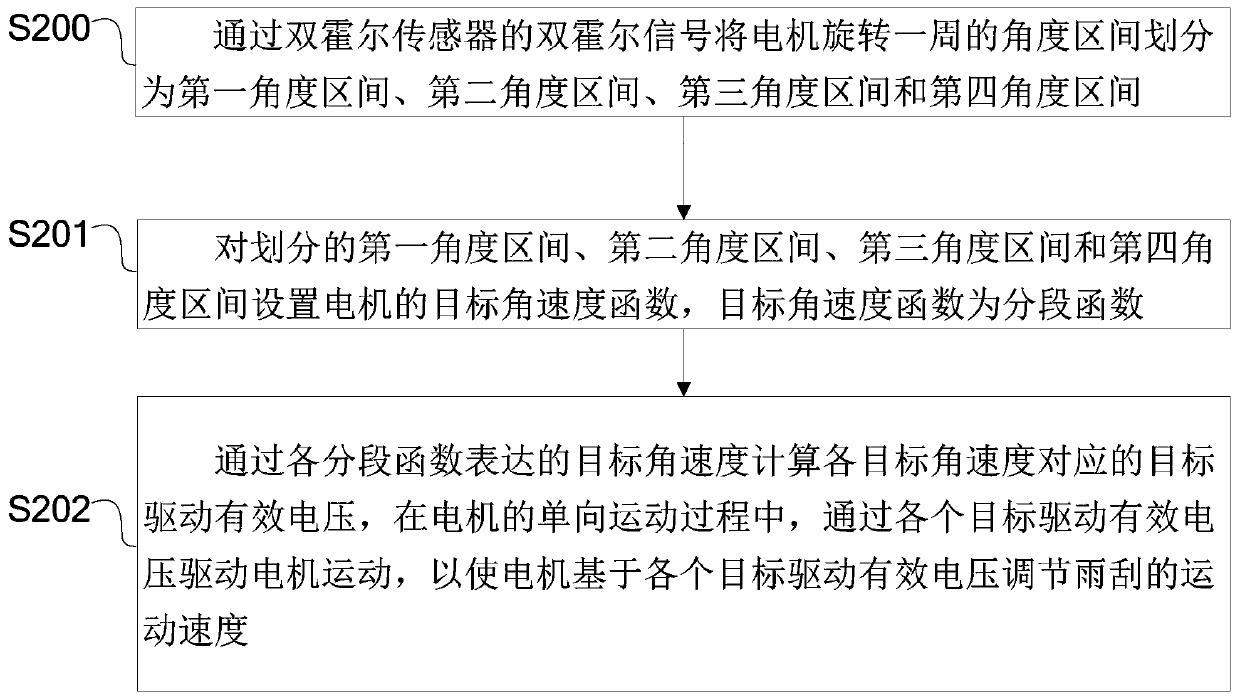

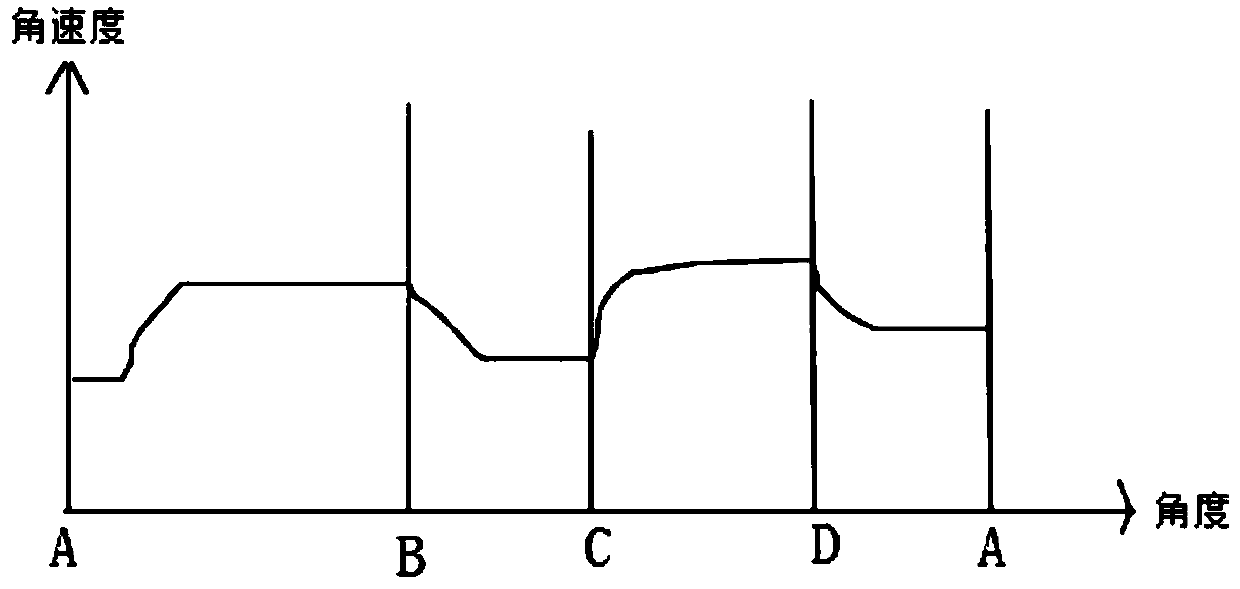

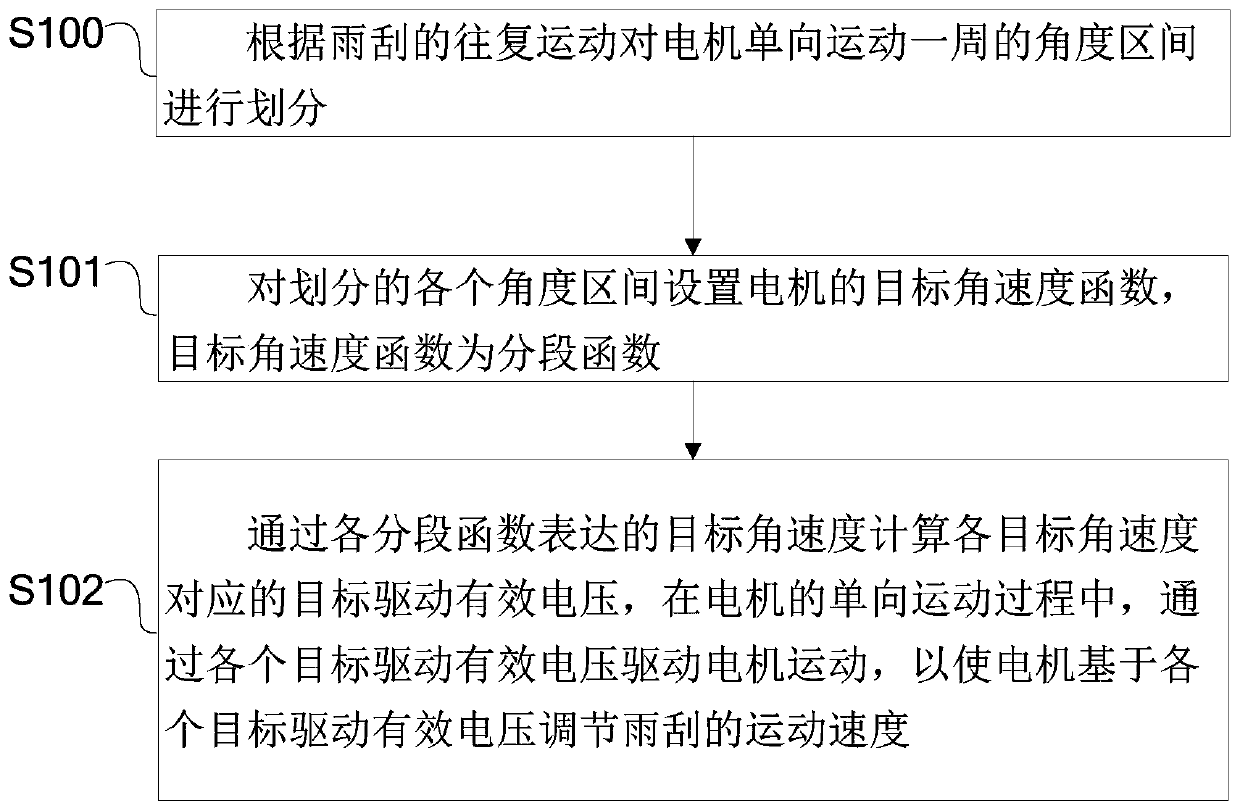

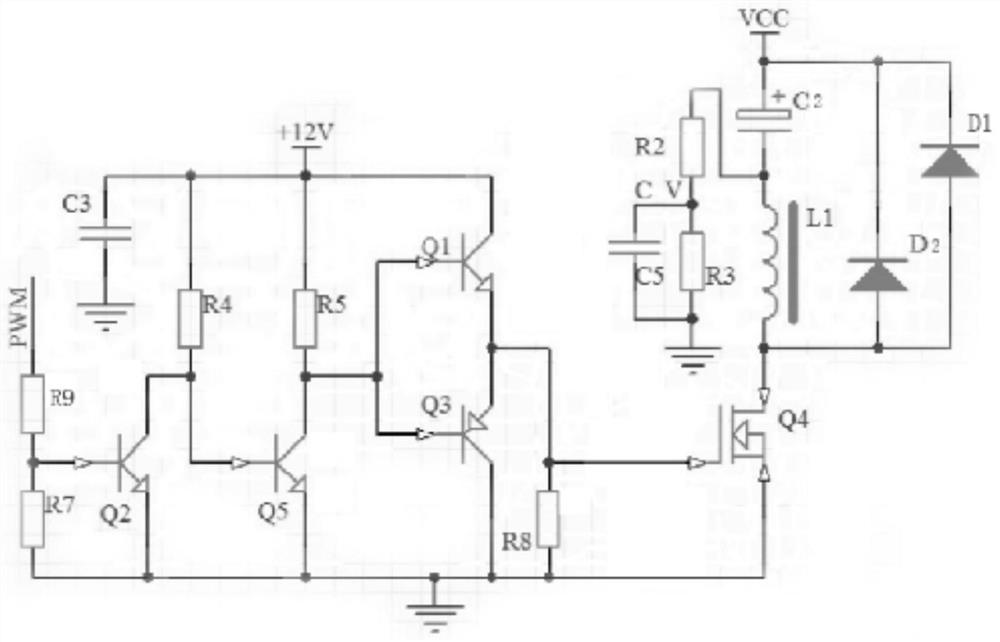

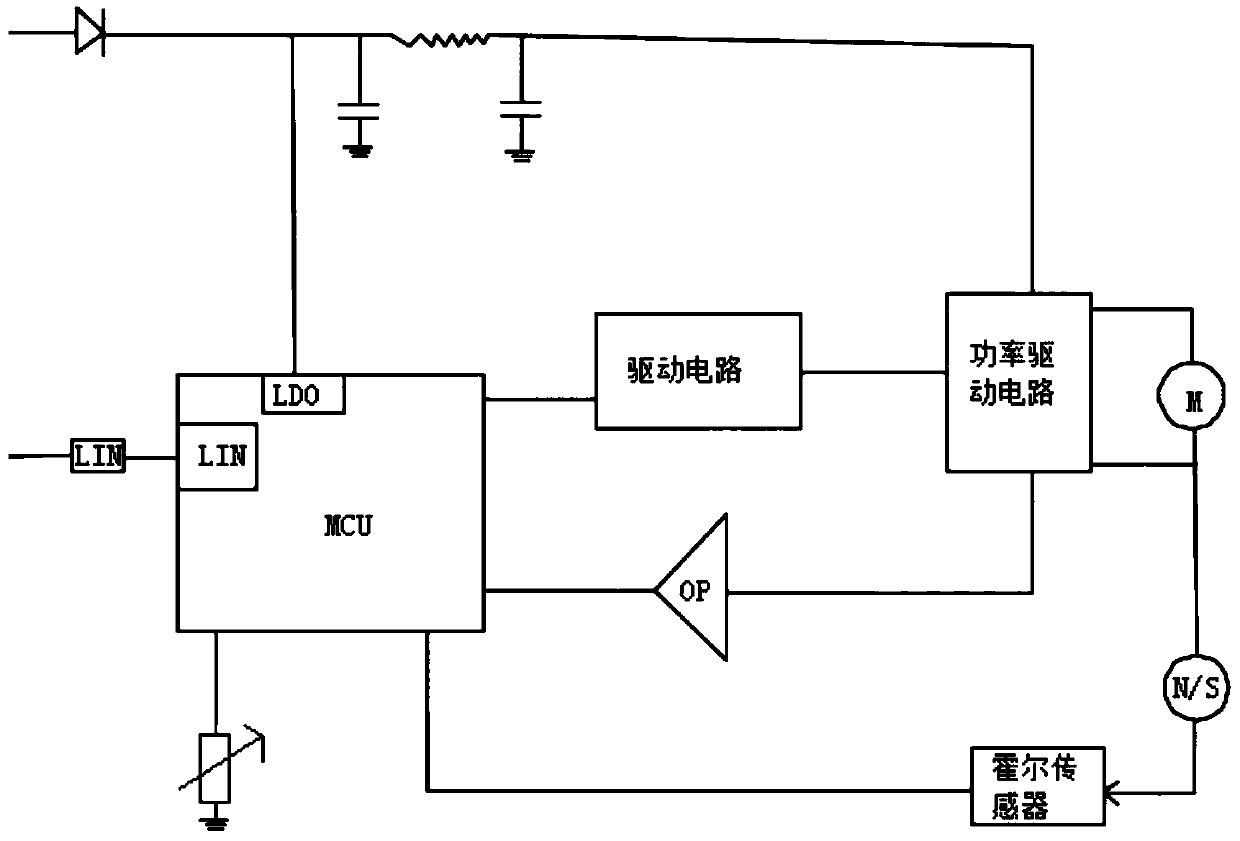

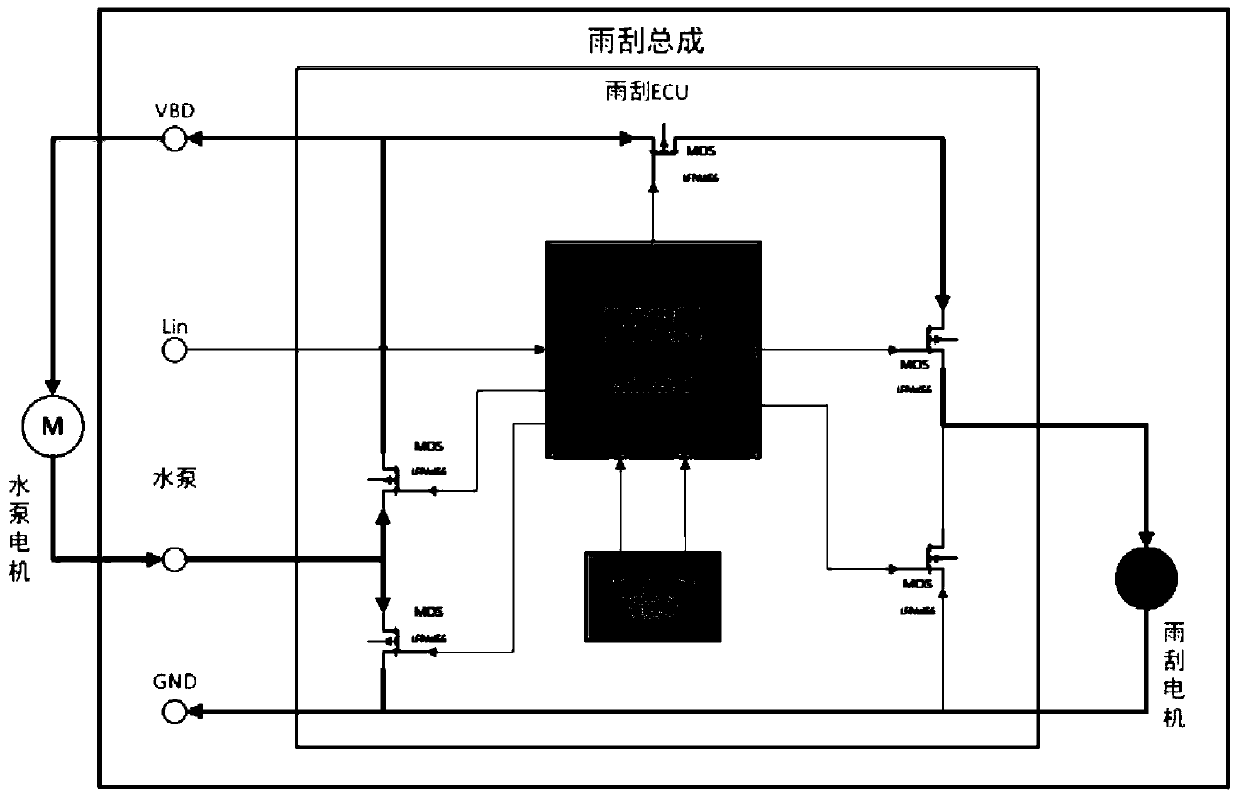

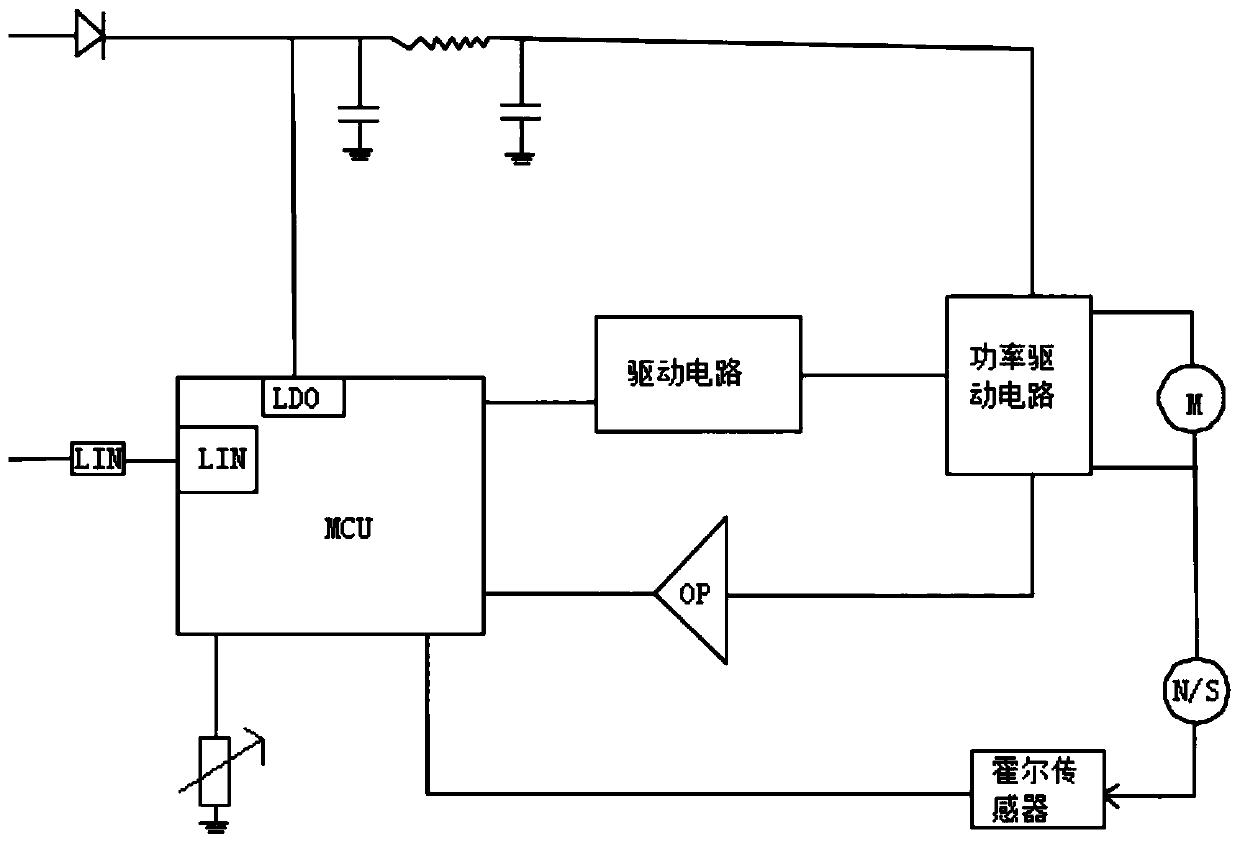

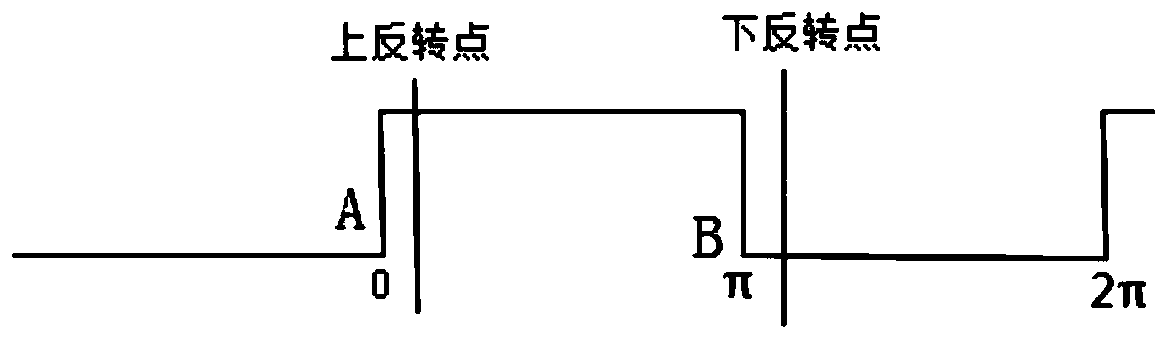

Wiper speed regulating control method, system and controller

PendingCN110015267AAdjustable running speedReduce reverse noiseSingle motor speed/torque controlVehicle cleaningControl systemVoltage regulation

The invention discloses a wiper speed regulating control method. The wiper speed regulating control method comprises the steps that a rotation angle interval of a motor is divided into four angle intervals through a double hall signal of a double hall sensor; target angular velocity functions of the motor are set for each divided angle interval, wherein the target angular velocity functions are piecewise functions; and target driving effective voltage corresponding to each target angular velocity is calculated through the target angular velocity expressed by each piecewise function, in the process of one-way movement of the motor, and the motor is driven to move by each target driving effective voltage to make the motor adjust the motion speed of a wiper based on each target driving effective voltage. By controlling the driving effective voltage of the motor to control variable motion of the wiper, for instance, the wiper can slow down near a reversal point, the wiper is controlled toaccelerate in a certain way in the middle of the reversal point, the wiper speed is increased, thus the adjustable speed of the wiper throughout the wiper cycle is ensured, elastic deformation of a blade during the high-speed wiper is reduced, and at the same inversion noise of the wiper is reduced.

Owner:SHANGHAI YUDIAN ELECTRONICS TECH CO LTD

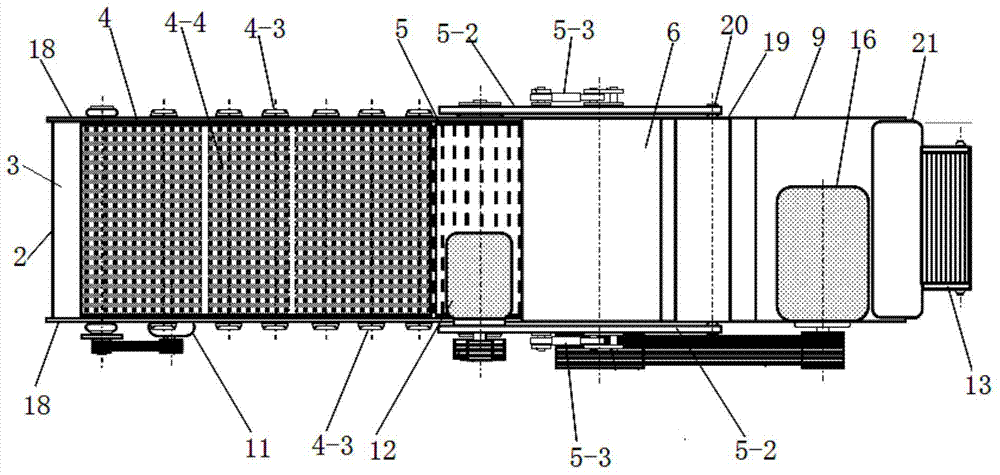

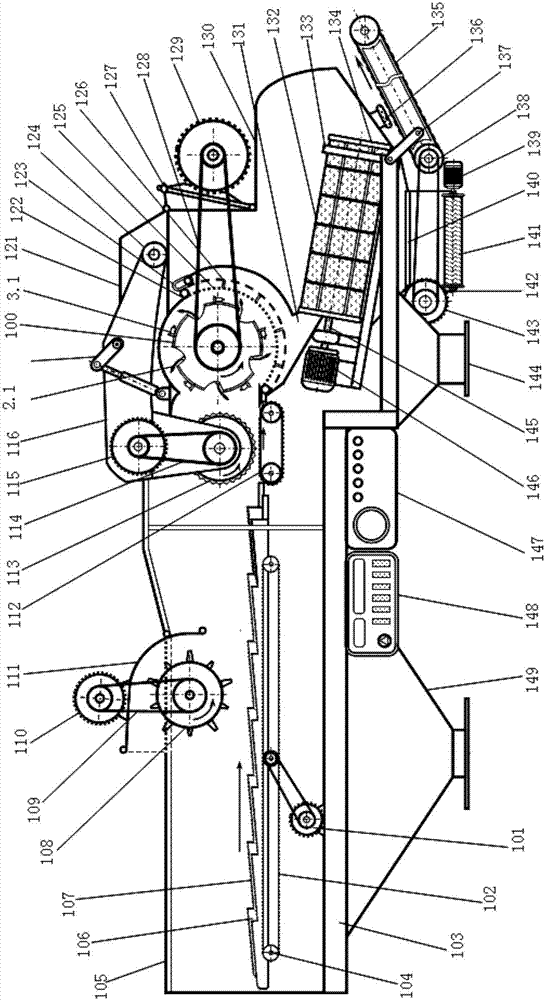

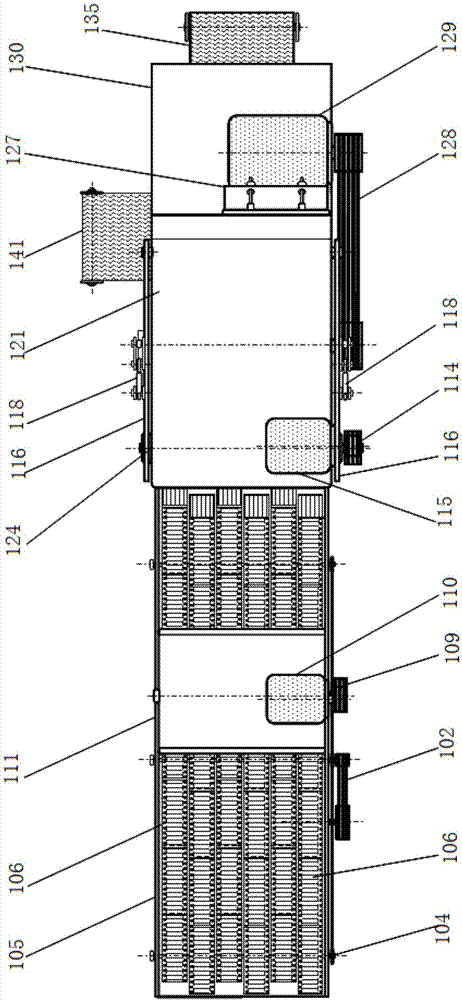

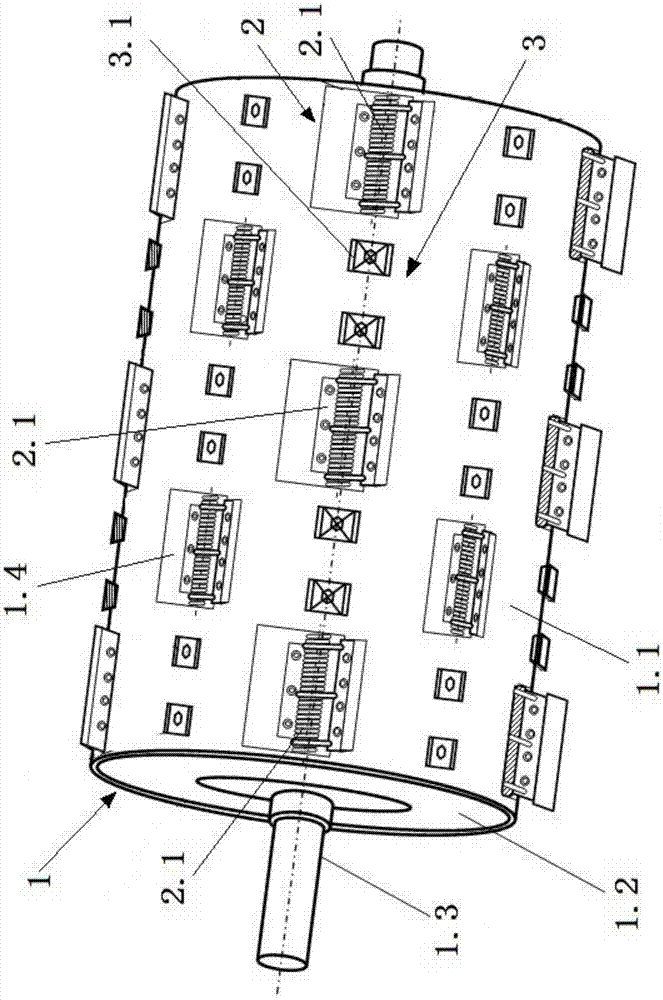

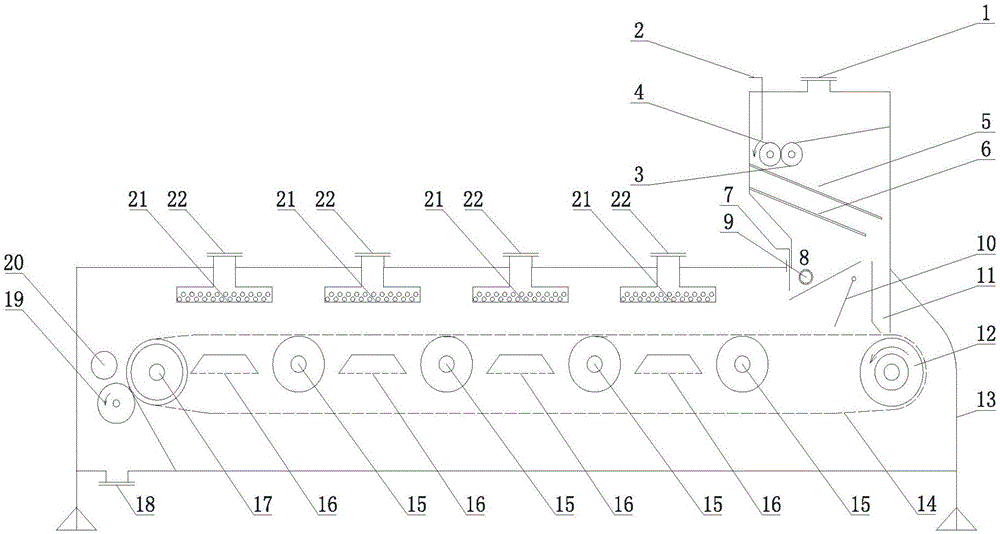

Axial-flow type cutter claw combined type biomass fuel comprehensive crusher

The invention discloses an axial-flow type cutter claw combined type biomass fuel comprehensive crusher. The biomass fuel comprehensive crusher comprises a feeding bin, a straw shaker type horizontal feeding conveyor, a crushing processing bin and a screening separating and discharging bin, and feeding operation of bulk material and bundling material is completed in the feeding bin; the crushing processing bin is provided with a forced feeding machine, an axial-flow type cutter claw combined crushing roller and a combined crushing separating screen, and the combined operation of crushing, screening and separating different materials can be completed; and the screening separating and discharging bin is provided with a roller type fuel screening separating machine and a discharging conveying machine, and the operations such as screening, lifting and conveying of crushed materials can be completed. The crusher can be used for crushing and processing a plurality of biomass fuels, the operation efficiency and the crushing quality are improved, the power consumption, the use cost and the operation cost are reduced, the requirements of processing and production mechanization of the biomass fuels in China are met, the development of comprehensive utilization of the biomass fuels in China is promoted, and the crusher has important practical significance and good application prospect.

Owner:格薪源生物质燃料有限公司

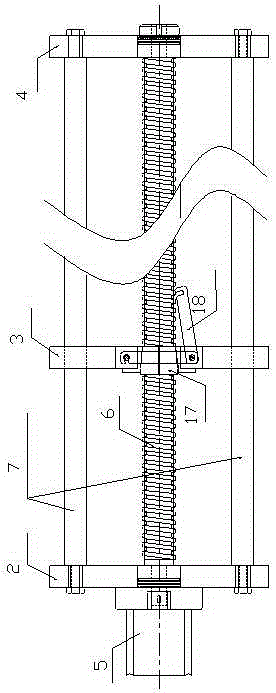

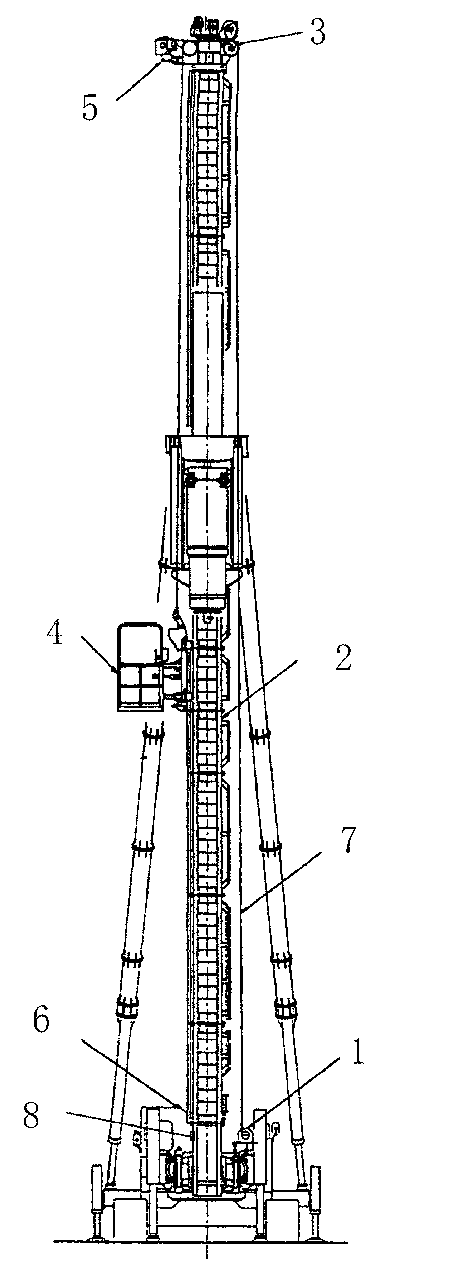

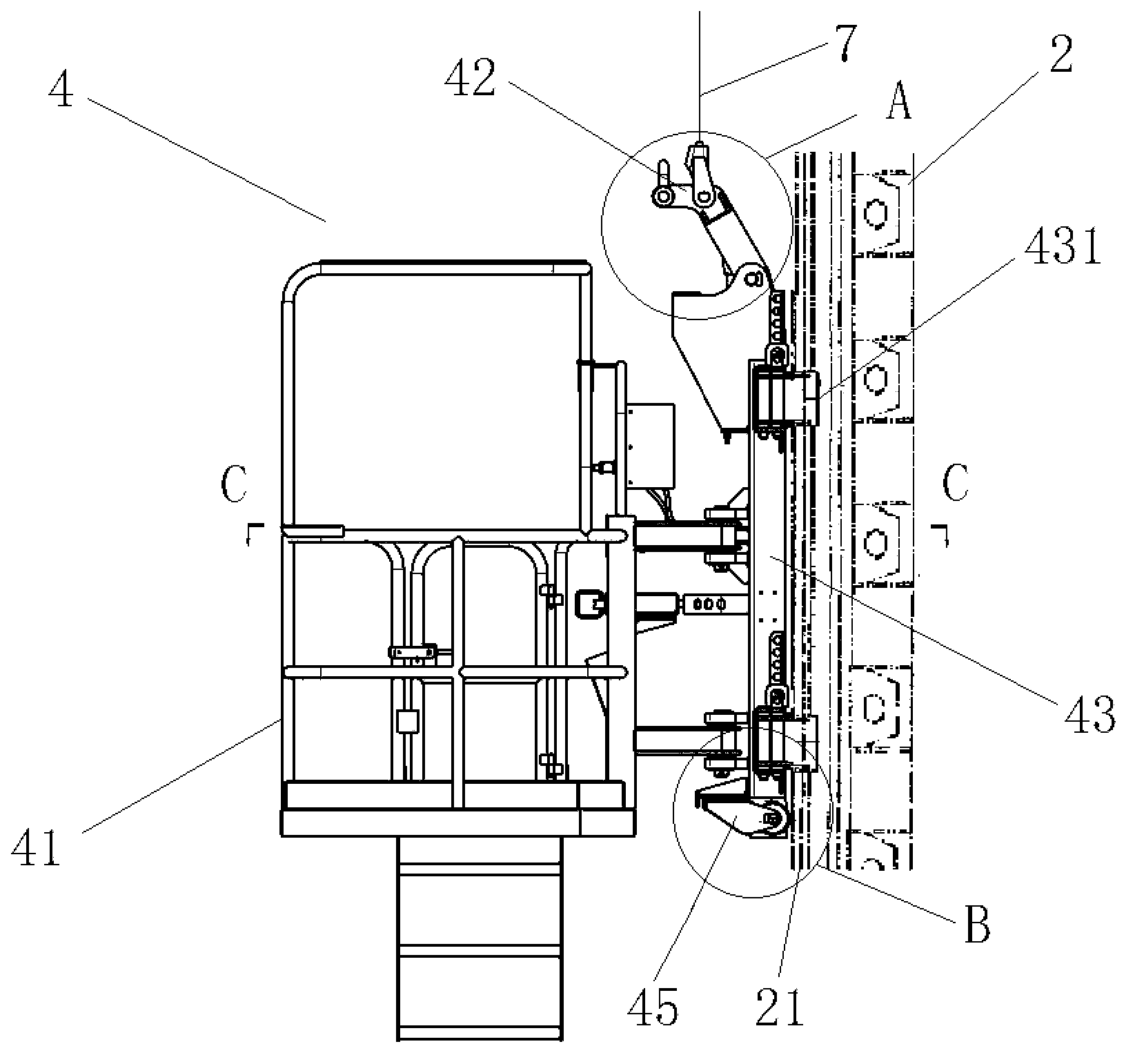

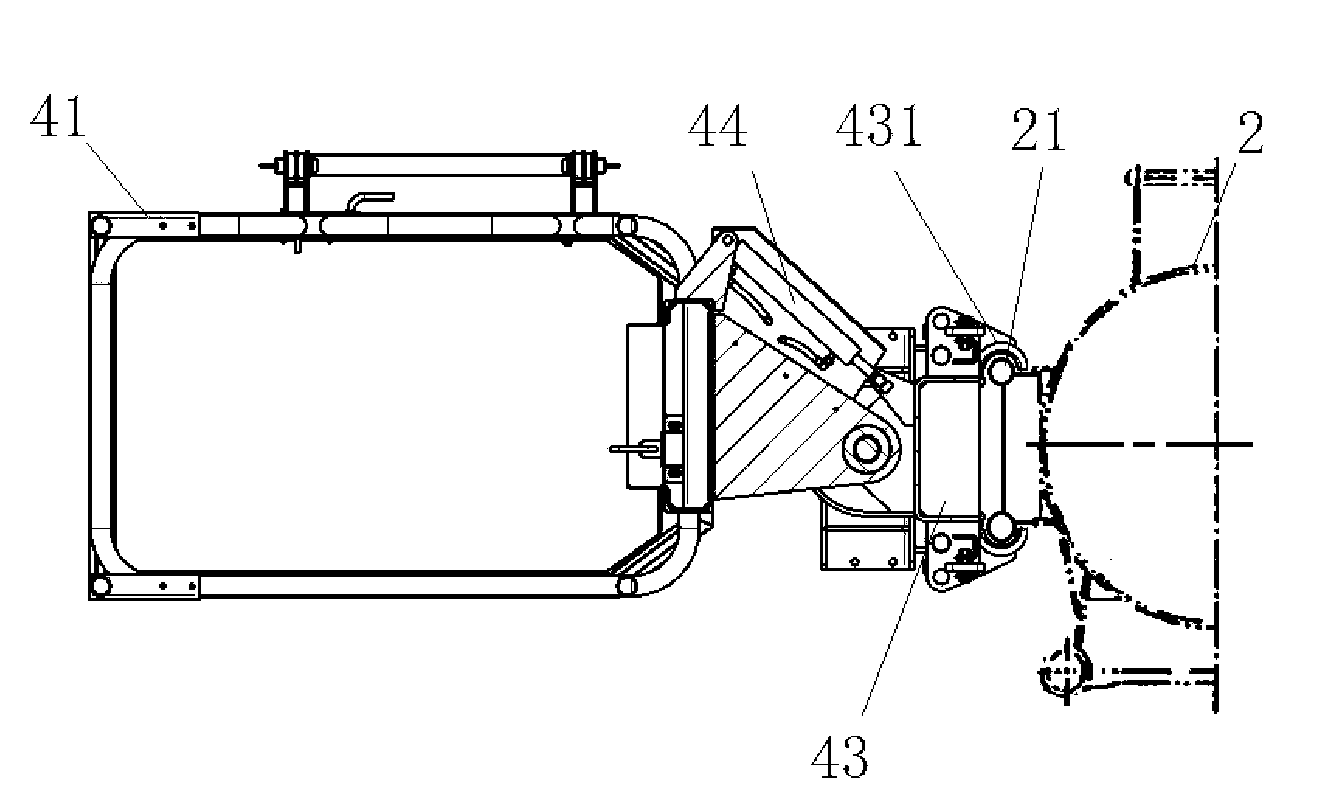

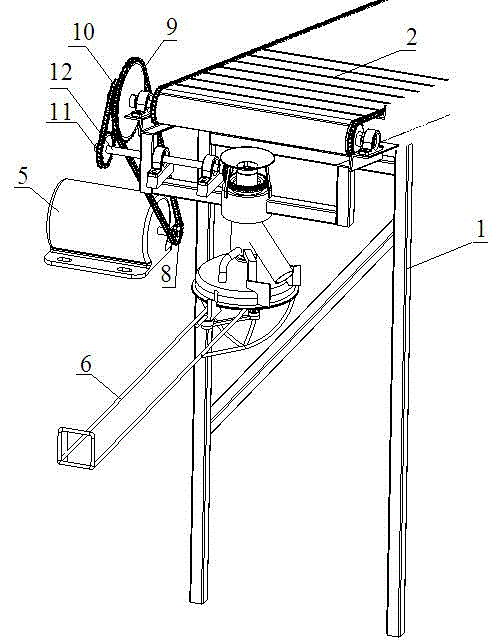

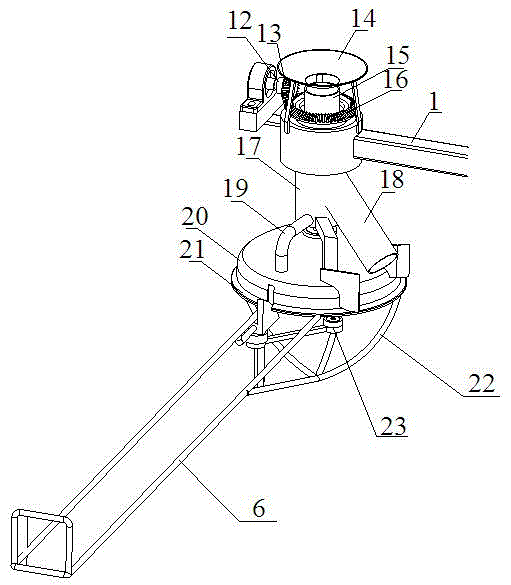

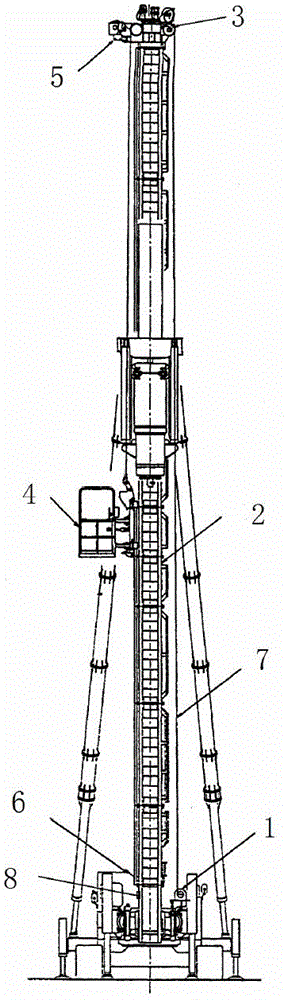

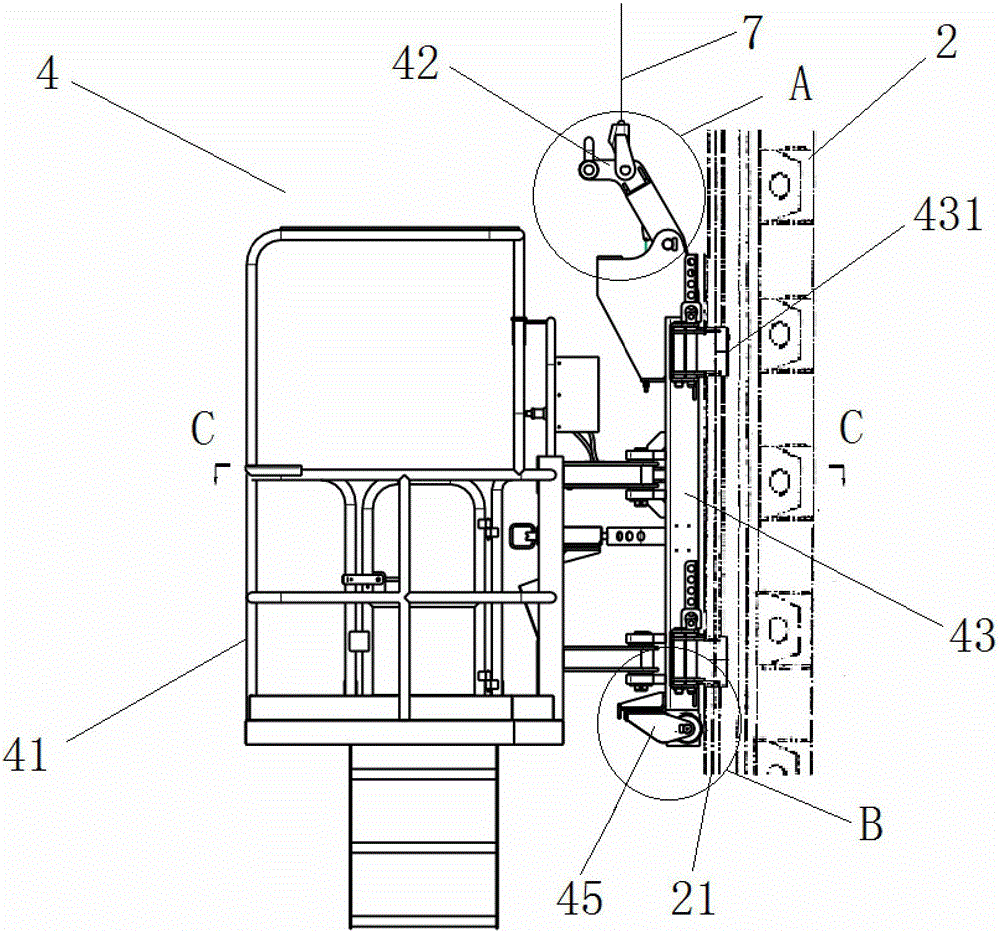

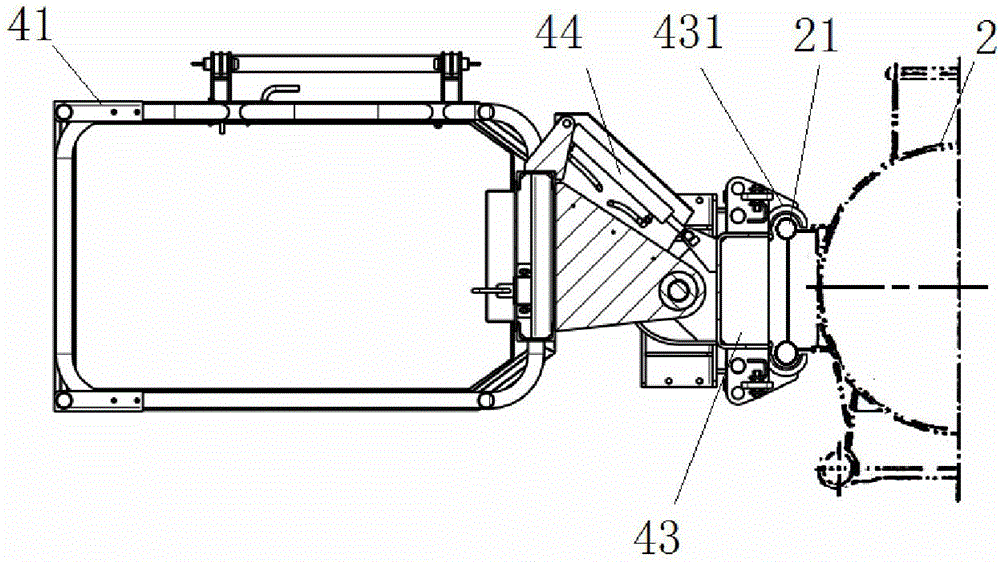

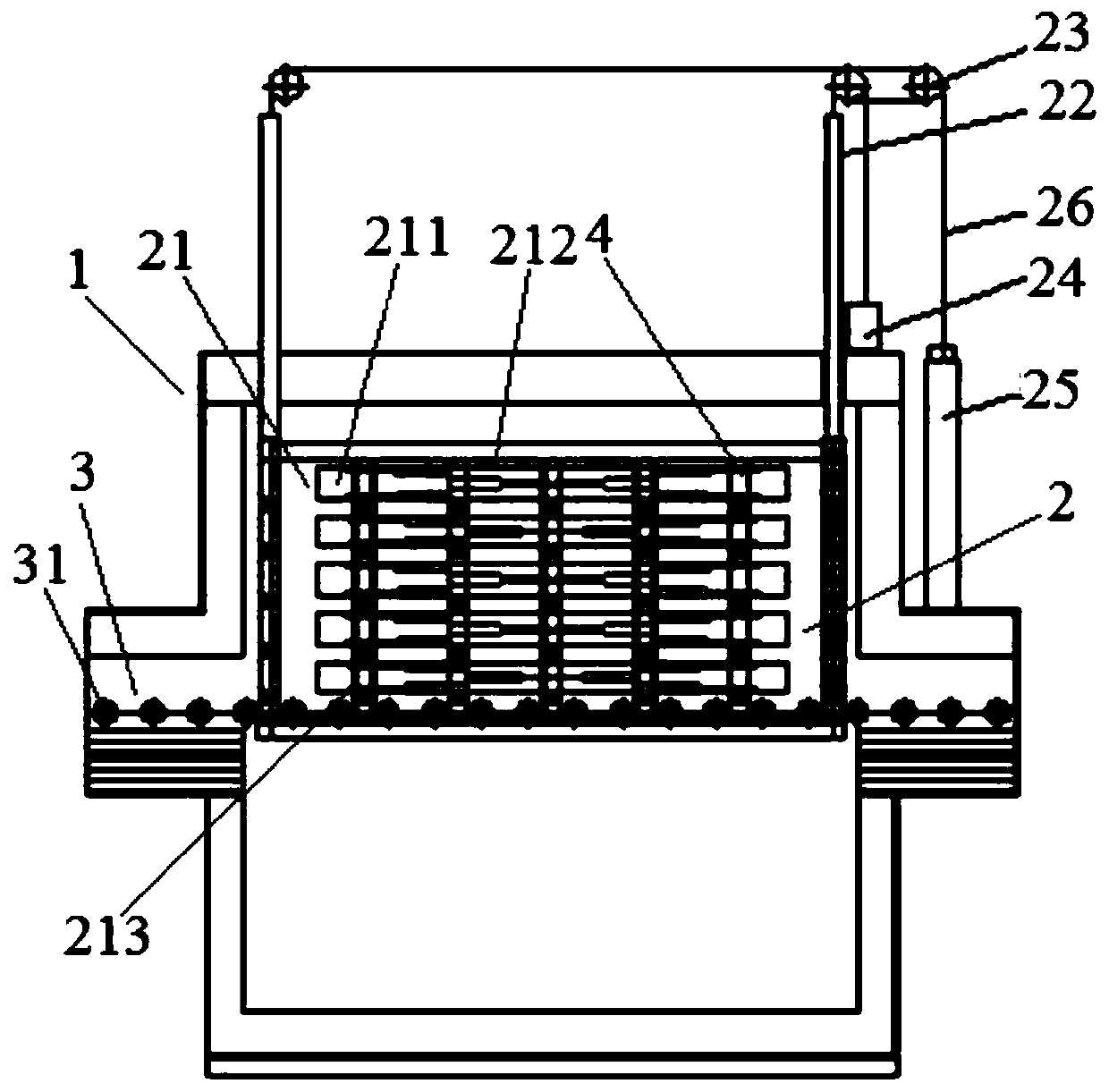

Pile frame lifting operation mechanism

ActiveCN102795579AEasy to operateExpand the scope of workLifting devicesSpeed control systemEngineering

The invention discloses a pile frame lifting operation mechanism which comprises a hoisting machine group, a vertical column, a top pulley yoke, an operating suspension cage, a hoisting machine over-hoisting limiter, a hoisting machine over-releasing limiter, a wire rope, stop dogs and a speed control system. The vertical column is provided with a pair of side guide rails and rib plates distributed at equal intervals; the operating suspension cage is arranged on the side guide rails; a suspension cage body is hinged with a frame; an angling cylinder is respectively connected with the suspension cage body and the frame; the hoisting machine over-hoisting limiter and the hoisting machine over-releasing limiter are respectively installed in proper positions of lower parts of the top pulley yoke and the vertical column; the wire rope is connected with a hoisting frame; the hoisting frame adopts a rod piece, is installed at the upper part of the frame through a hinge pin and can rotate around the hinge pin; a spring connected with the frame is arranged at the lower end part of the hoisting frame; a throttle valve is arranged in the speed control system; and the stop dogs are symmetrically distributed in proper positions at lower parts of the side guide rails. The pile frame lifting operation mechanism ensures that the operating suspension cage is lifted and rotates along the side guide rails of the vertical column, is convenient to operate, stable and reliable, is convenient to mount and dismount, and guarantees the safety of operating personnel.

Owner:上海工程机械厂有限公司

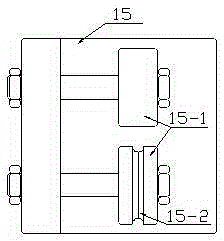

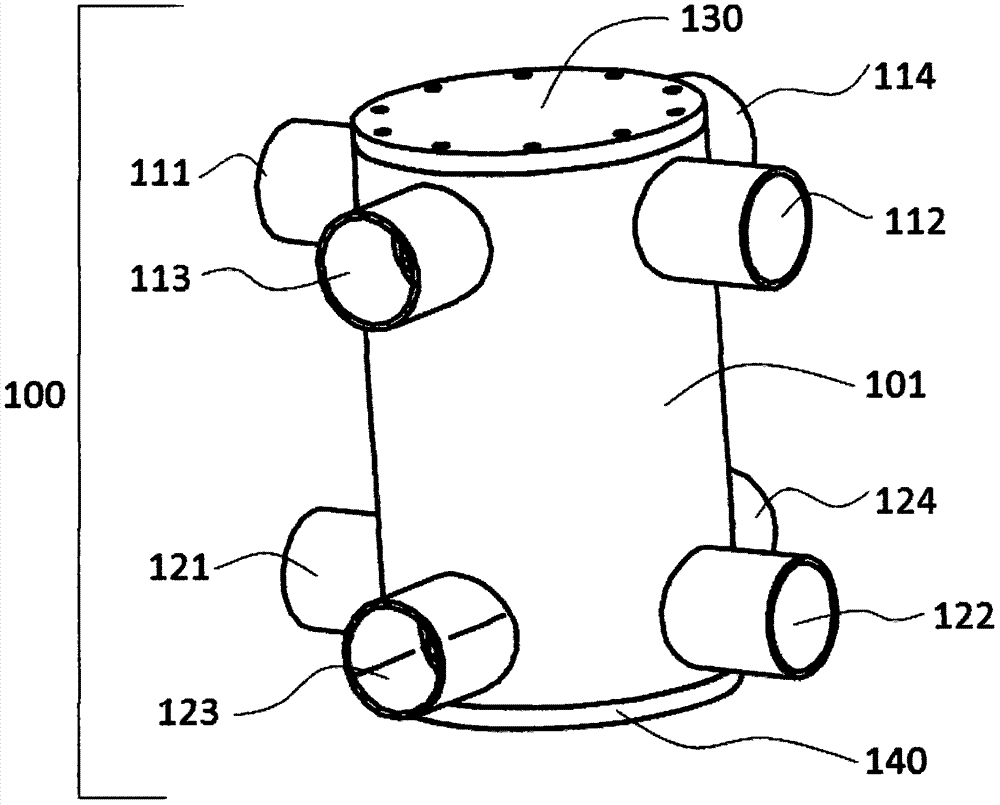

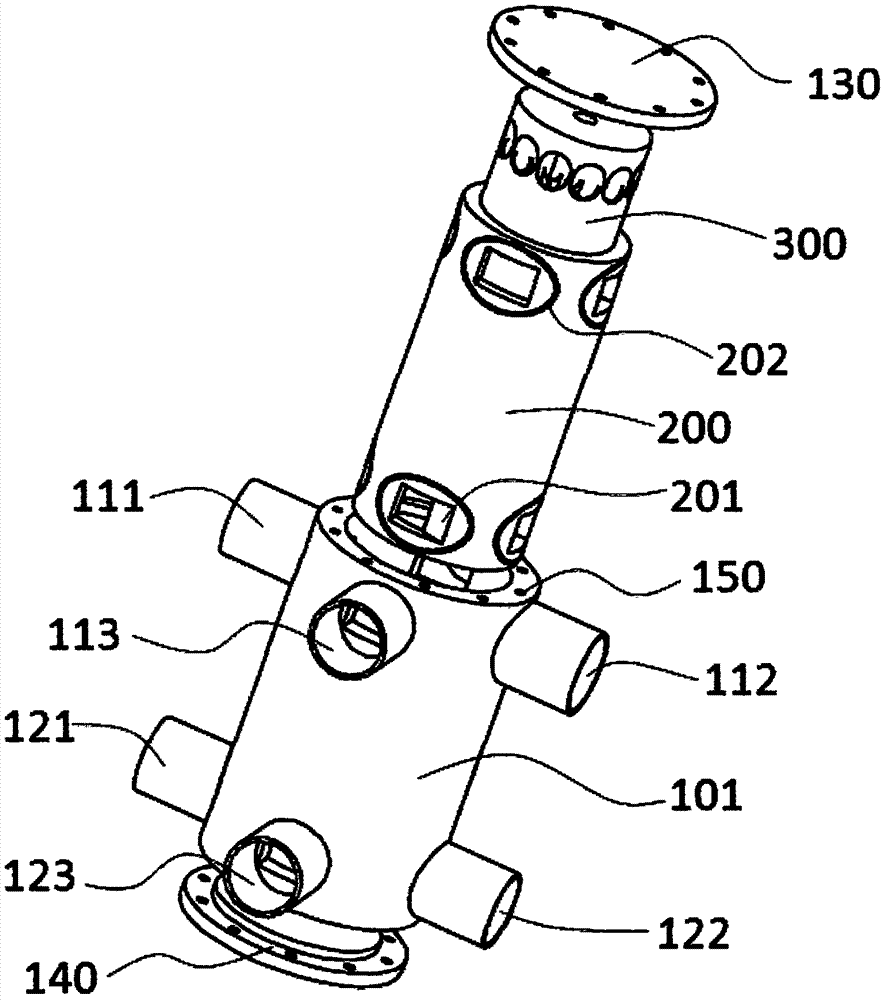

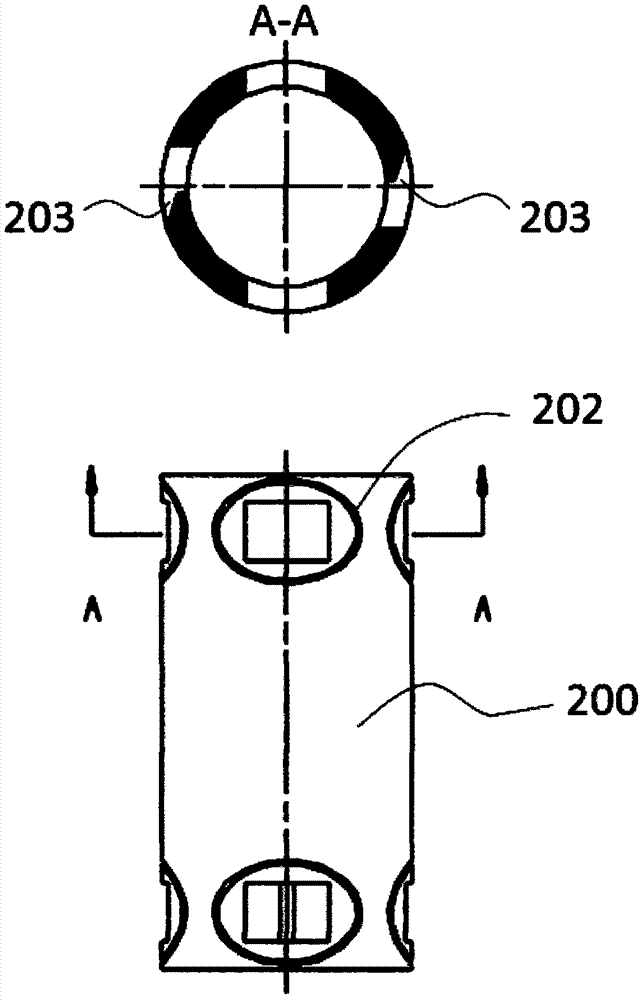

Multiple-in and multiple-out type pressure exchanger

InactiveCN107542705AReduce processing difficultyIncrease exchange frequencySeawater treatmentReverse osmosisEngineeringFluid pressure

A multiple-in-multiple-out pressure exchanger, the pressure exchanger is used for transferring pressure energy from a high-pressure first fluid to a low-pressure second fluid to provide a pressurized second fluid, the pressure exchanger is characterized by comprising: a body , a sleeve disposed within the body and a rotor rotating within the sleeve; the rotor having a plurality of passages extending generally axially through the rotor, the passages having a first opening at one end of the rotor , having a second opening at the other end of the rotor, the openings being spaced apart from each other along the length of the rotor; the sleeve having four or more internally distorted inlet passages and four or more a discharge passage, the sleeve passage is arranged such that when the end opening of the first passage of the rotor is aligned with the inlet passage on one of the sleeves, the other end opening of the passage is also aligned with the discharge passage on the sleeve allow.

Owner:宁波淡海智能科技有限公司

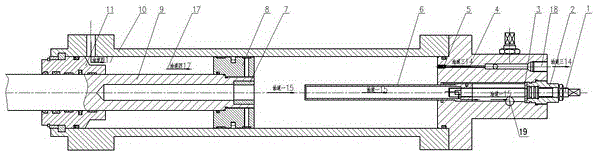

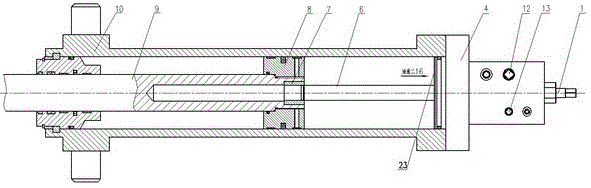

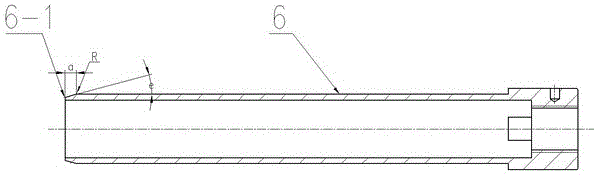

Hydraulic cylinder capable of adjusting throttling and cushioning stroke in two stages

The invention discloses a hydraulic cylinder capable of adjusting throttling and cushioning stroke in two stages. The hydraulic cylinder comprises a cylinder body, a piston rod and a piston, and further comprises a valve block, wherein a stroke adjusting device and an oil duct III are arranged on the valve block; the stroke adjusting device comprises a stroke adjusting rod, a control rod and an adjusting seat; the control rod is connected with the stroke adjusting rod through the adjusting seat; an oil duct I is arranged on the stroke adjusting rod; a primary cushioning oil duct used for cushioning the piston rod before the end surface of the piston rod is in contact with the stroke adjusting rod, and a secondary cushioning oil duct II used for cushioning the piston rod after the end surface of the piston rod is in contact with the stroke adjusting rod are arranged on the valve block as well; the oil duct I is communicated with the oil duct III through the primary cushioning oil duct and a large throttle valve core mounted in the primary cushioning oil duct; and the secondary cushioning oil duct II is communicated with the oil duct III through a small throttle valve core. The hydraulic cylinder has the characteristics that the structure is simple, the one-time delivery-check qualified rate of the product is high, and the unqualified product is repairable; and when the pressure oil pushes the piston rod to retract, the movement time of the piston rod can be controlled in two stages, and the operating speed during the whole process is adjustable.

Owner:HUBEI JIANGSHAN HEAVY IND

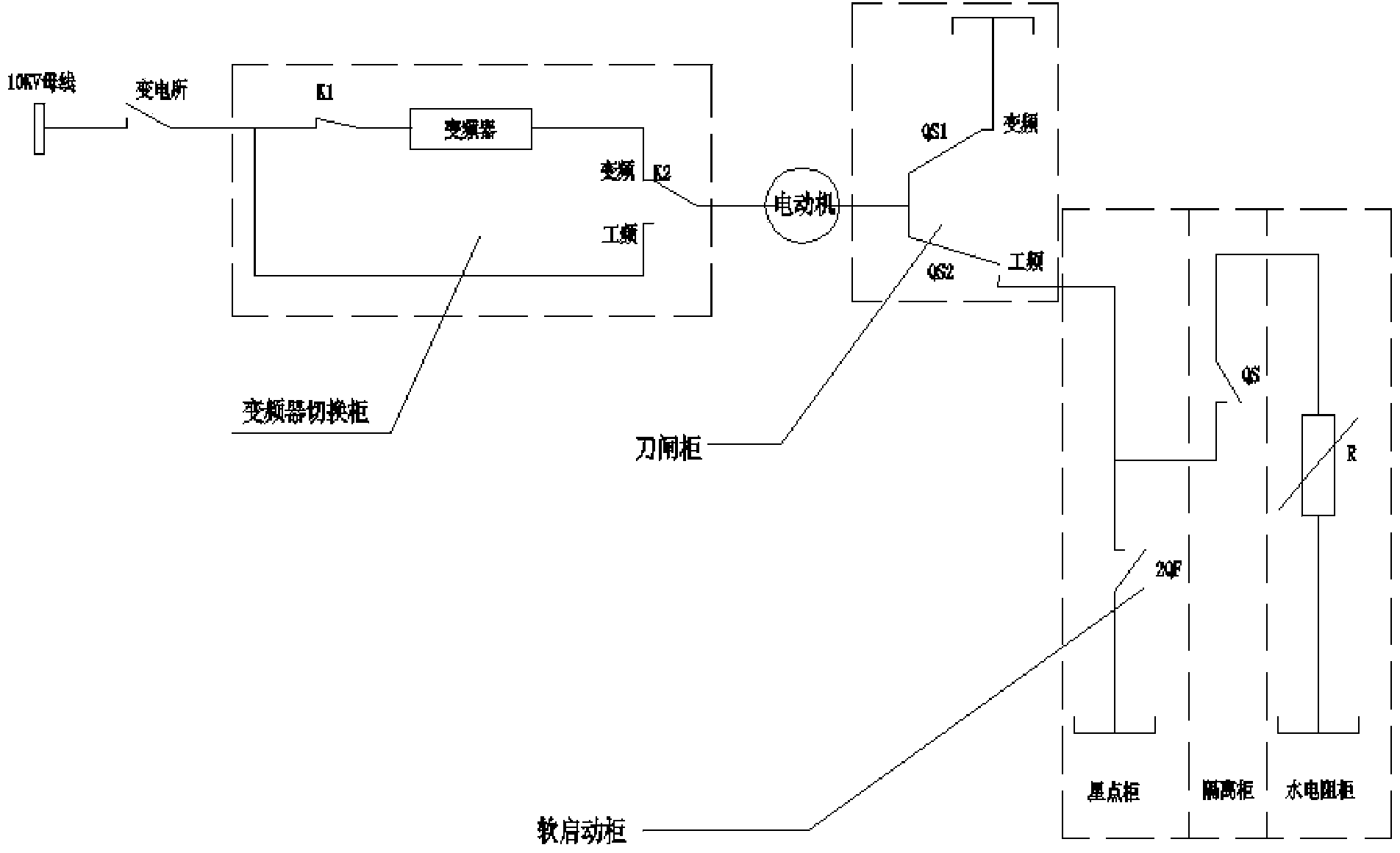

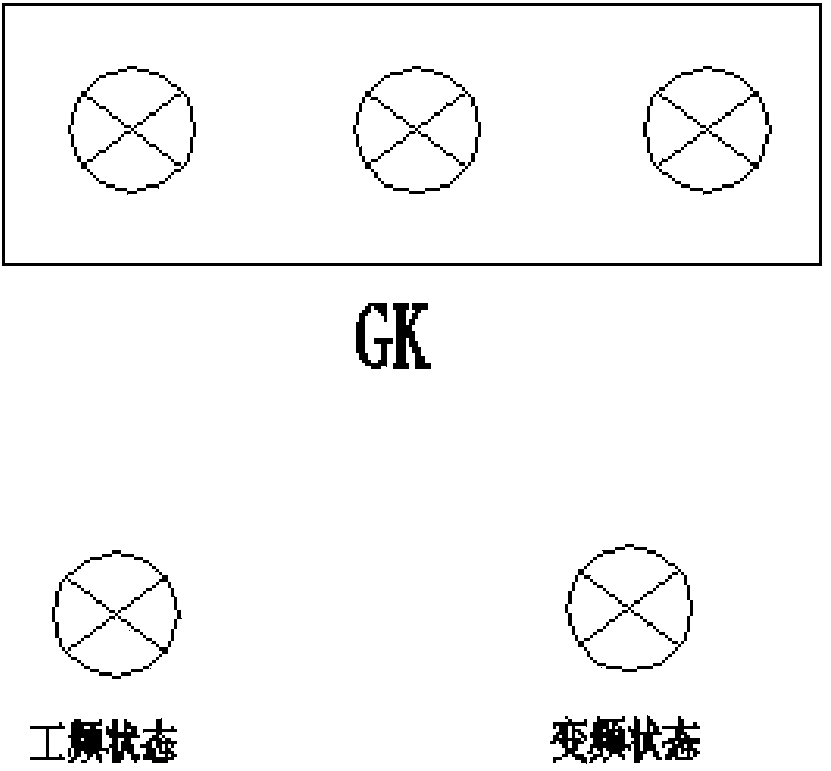

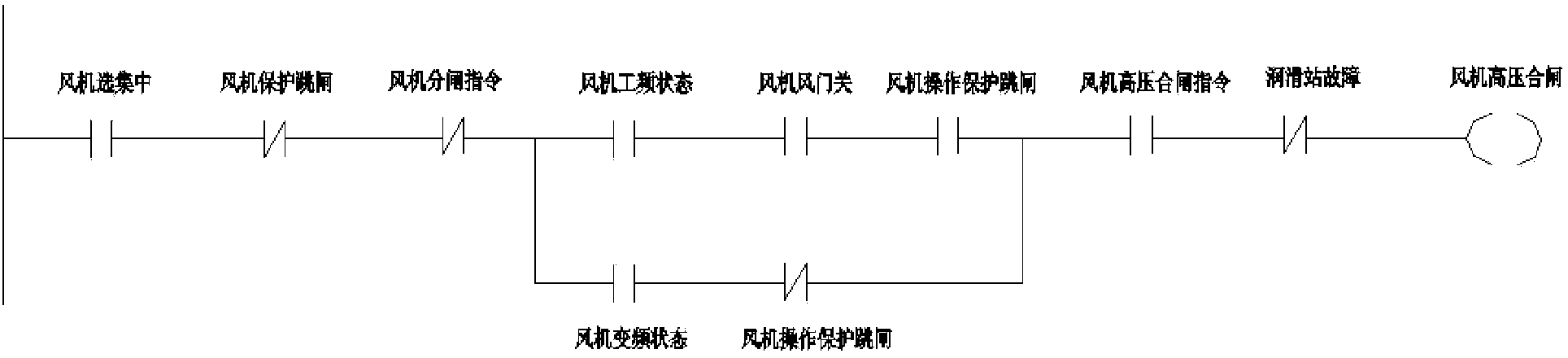

Drive control method and device of final dusting high-voltage motor of steel mill

InactiveCN104320039AAdjustable running speedGuaranteed uptimeAC motor controlFrequency changerSteel mill

The invention discloses a drive control method and device of a final dusting high-voltage motor of a steel mill. When a frequency converter serves as main drive, an outgoing line of the frequency converter is connected with an inlet line of the motor, and a secondary line of the motor is in short connection in the working process. When the motor breaks down, the outgoing line of the frequency converter and the inlet line of the motor are disconnected, the power frequency is connected to the inlet line of the motor, the secondary line of the motor is connected with a water resistance cabinet, the resistance value of the water resistance is reduced through a pole plate of the water resistance cabinet, the running speed of the motor is increased, and when the running speed of the motor reaches the full gear, the secondary line of the motor is separated from the water resistance cabinet, and the secondary line of the motor is in short connection. The frequency converter is used for driving the final dusting high-voltage motor, the running speed of the final dusting high-voltage motor can be adjusted, the purpose of saving electric energy is achieved, and when the frequency converter serves as the main drive, the water resistance standby drive is added, and it is guaranteed that when the main drive breaks down, the high-voltage motor can normally run.

Owner:武钢集团有限公司

Ultra-silent terminal

InactiveCN103208721AAdjustable running speedNo noise pollutionLine/current collector detailsElectric machineryEngineering

The invention belongs to the field of terminals and discloses an ultra-silent terminal. The ultra-silent terminal comprises a rack, the rack portion of the terminal is made of imported high-quality steel plates through splicing, the rack is provided with a terminal stamping device and an automatic feeding device, and the terminal stamping device is further provided with a variable frequency controller which is connected with a counter. According to the ultra-silent terminal, the variable frequency controller is adopted, and a motor rotates when stepped, so that electricity is saved, and noise pollution is avoided; the sound is small during terminal stamping, mold adjustment is convenient, the running speed of the terminal can be adjusted, and the amount of stamped terminals can be known clearly due to a counting function; and the continuous terminal stamping function is provided, the amount of terminals to be stamped is set, terminals can be stamped continuously at intervals, automatic feeding is achieved, and the use is safe and convenient.

Owner:王庆云

Tunnel scanning pass-type demagnetizer

InactiveCN103187140AEliminate residual magnetismImprove qualityMagnetic bodiesEngineeringDemagnetizer

The invention relates to workpiece demagnetizing equipment, in particular to a tunnel scanning pass-type demagnetizer. The tunnel scanning pass-type demagnetizer comprises a bed body and a control cabinet; the bed body comprises a base and a material loading bridge frame, wherein the material loading bridge frame is positioned above the base and is connected with the base end to end; a sports car is arranged on the base; the base is movably connected with the sports car; the upper part of the sports car is connected with an executive coil by adopting a supporting screw; and the sports car is also provided with a variable frequency motor. By the adoption of the tunnel scanning pass-type demagnetizer, the labor intensity of workers is lightened; the running speed of the sports car, the demagnetizing intensity and the waveform can all be adjusted; safe and efficient demagnetization can be realized; the quality of a workpiece is improved; and therefore, the service life of the workpiece is prolonged.

Owner:杭州飞宇磁电器材有限公司

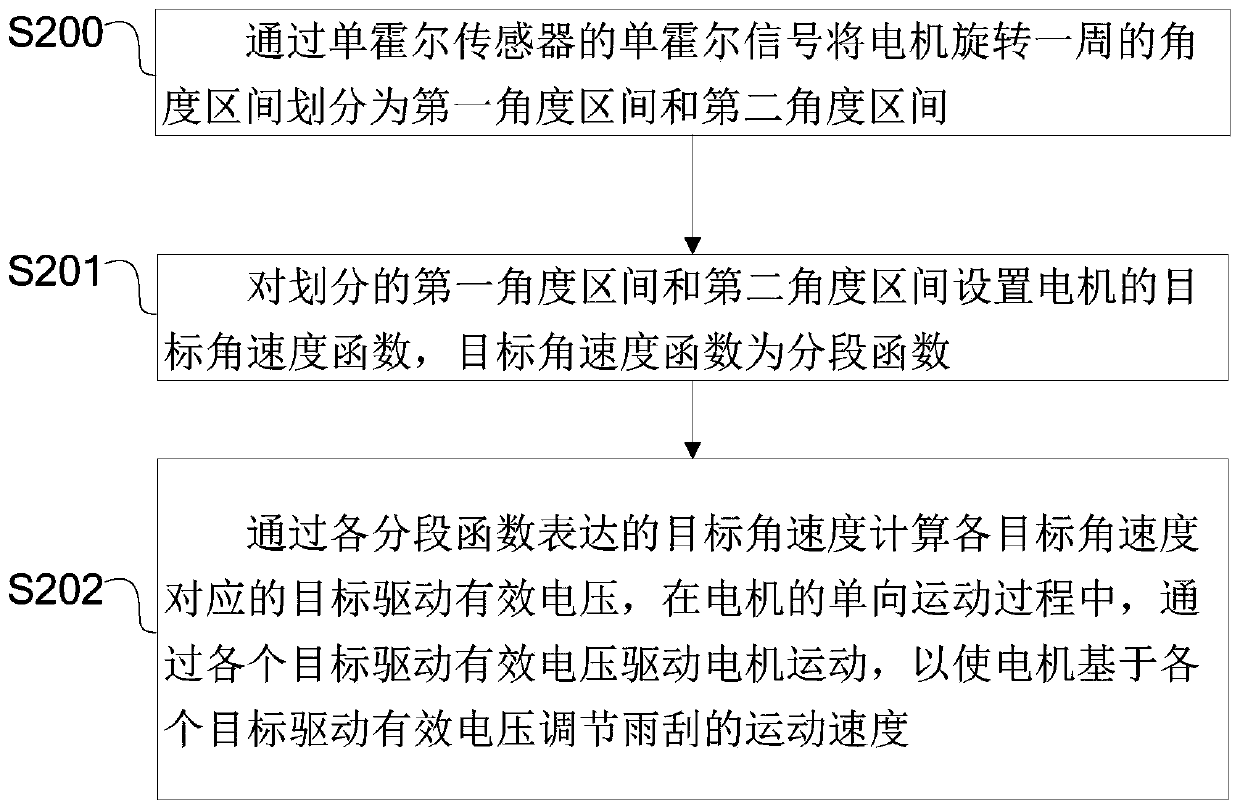

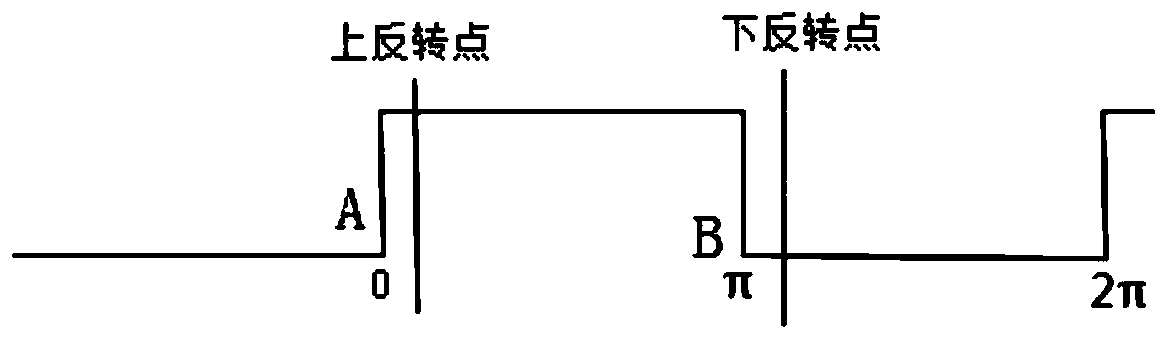

Wiper speed regulation control method and system and speed regulation controller

InactiveCN110112961AAdjustable running speedReduce reverse noiseSingle motor speed/torque controlVehicle cleaningControl systemAngular velocity

The invention relates to a wiper speed regulation control method. The method comprises steps that an angular interval in which a motor rotates one circle is divided by one single Hall signal of a single Hall sensor into a first angular interval and a second angular interval; target angular velocity functions of the motor are set for the divided angular intervals, and the target angular velocity functions are piecewise functions; target driving effective voltages corresponding to the target angular velocities are calculated through the target angular velocities expressed by the piecewise functions, during one-way movement of the motor, and the motor is driven by the target driving effective voltages to make the motor adjust the movement speed of a wiper based on the target driving effectivevoltages. Through controlling the driving effective voltages of the motor, the variable motion of the wiper is controlled, the wiper is made to slow down near a reversal point, in the middle area, the wiper is controlled for acceleration in a certain way, the speed of the wiper is improved, that the wiper can be adjusted in speed throughout the wiper cycle is guaranteed, elastic deformation of ablade during high-speed scraping is reduced, and the wiper reversal noise is further reduced.

Owner:SHANGHAI YUDIAN ELECTRONICS TECH CO LTD

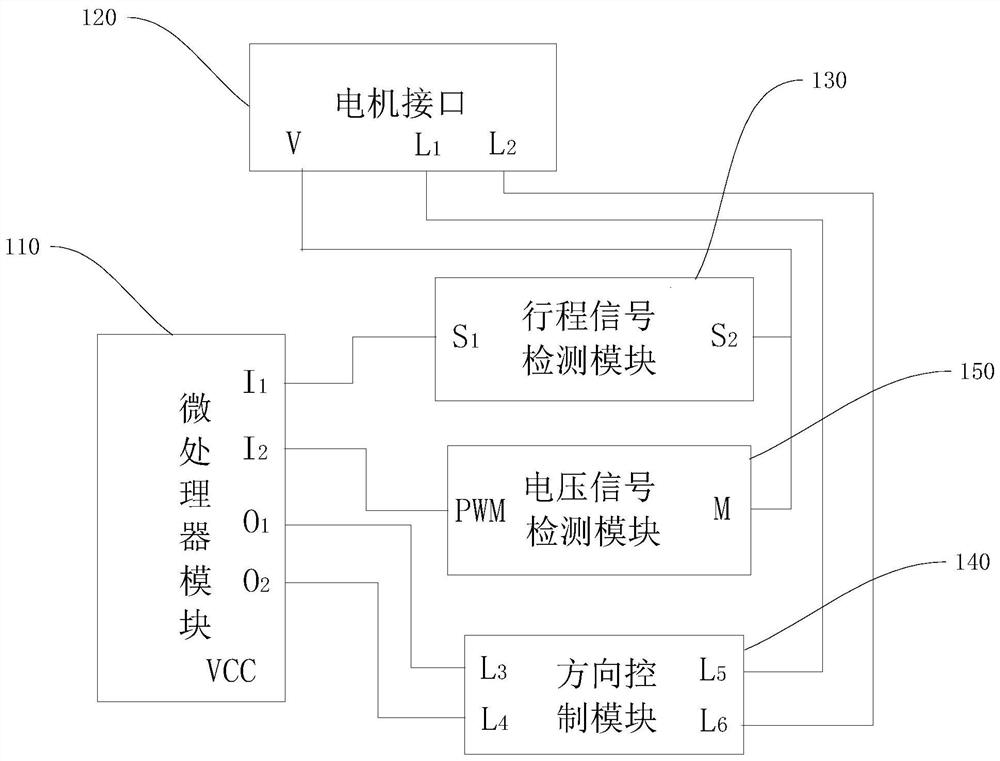

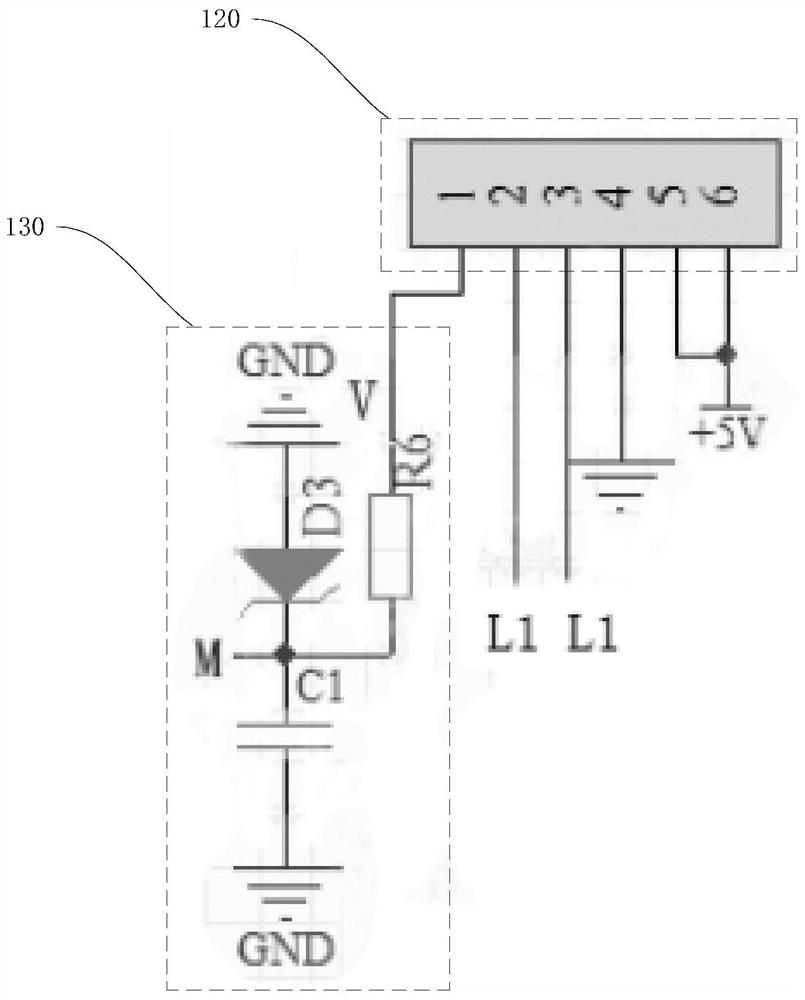

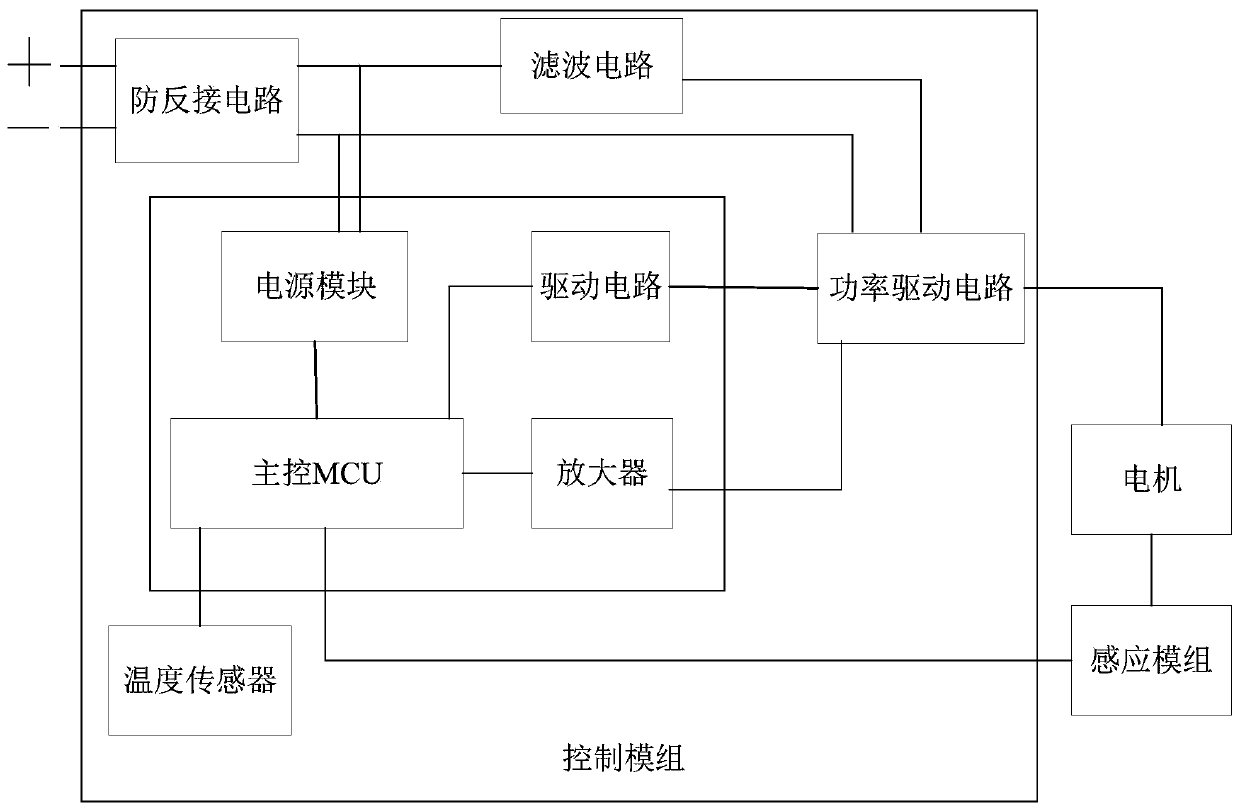

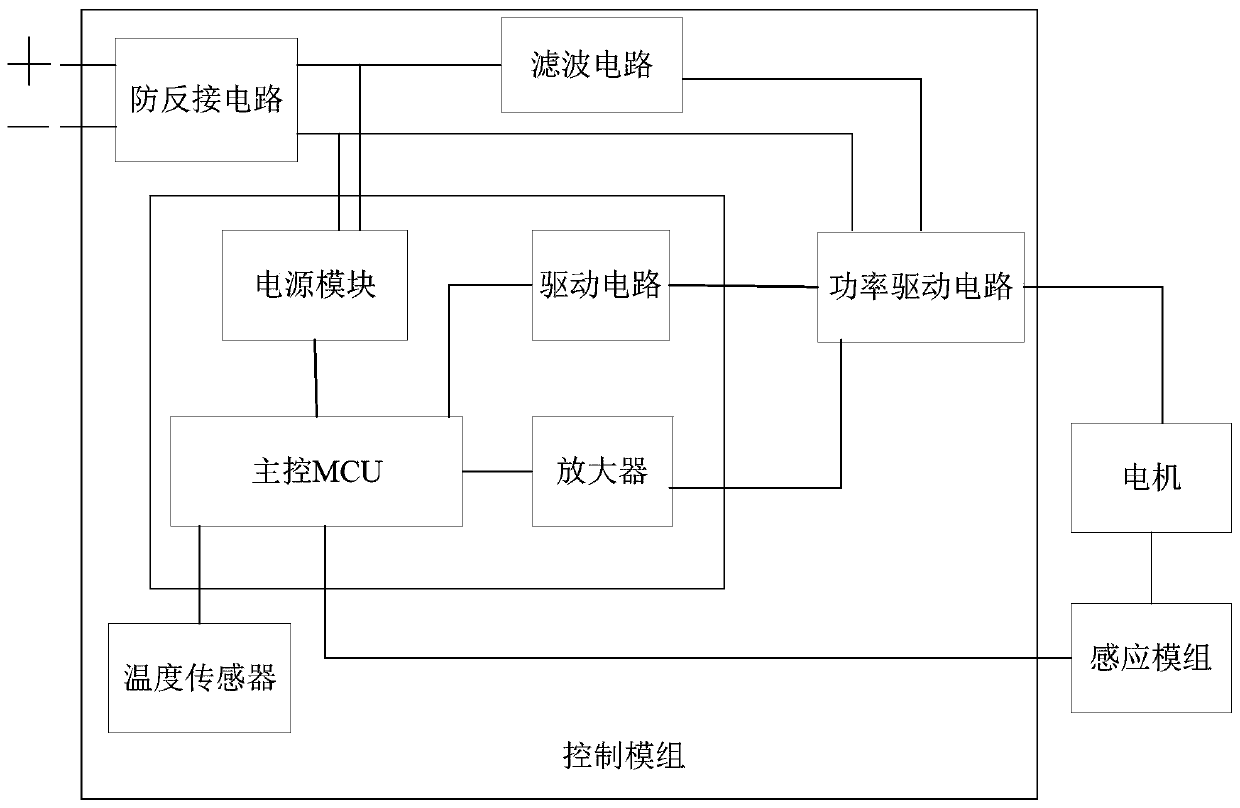

Control circuit, electric chair and control method thereof

PendingCN112506084AAdjustable running speedResolve frustrationElectric motor controlOperating chairsControl engineeringElectric machinery

The invention discloses a control circuit, an electric chair and a control method thereof. The electric chair comprises a power supply module, a microprocessor module, a motor interface, a stroke signal detection module, a direction control module and a voltage signal detection module. The microprocessor module records a motor stroke signal, the real-time position of a motor is obtained in combination with a motor motion direction signal, total travel and implementation position information are stored in an EEPROM of a chip, and meanwhile, a microprocessor module controls driving signal information of a motor in real time by processing a voltage feedback signal received from a voltage signal detection module, so that the running speed of the motor at each position is adjustable; and starting, stopping and speed adjustment at different positions of the motor are realized, so that the problems of jerking and unsafety during movement of the chair are solved, and the user experience is improved.

Owner:SILVERFOX CORP LTD

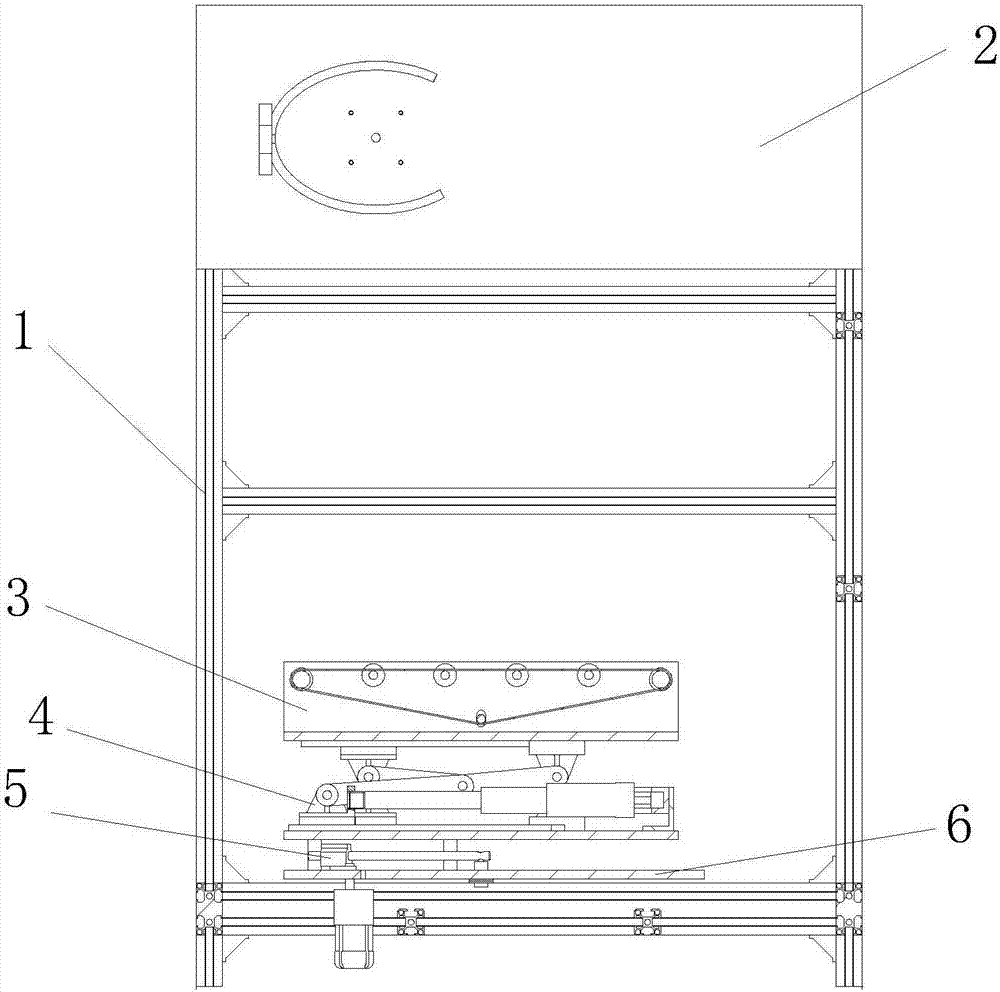

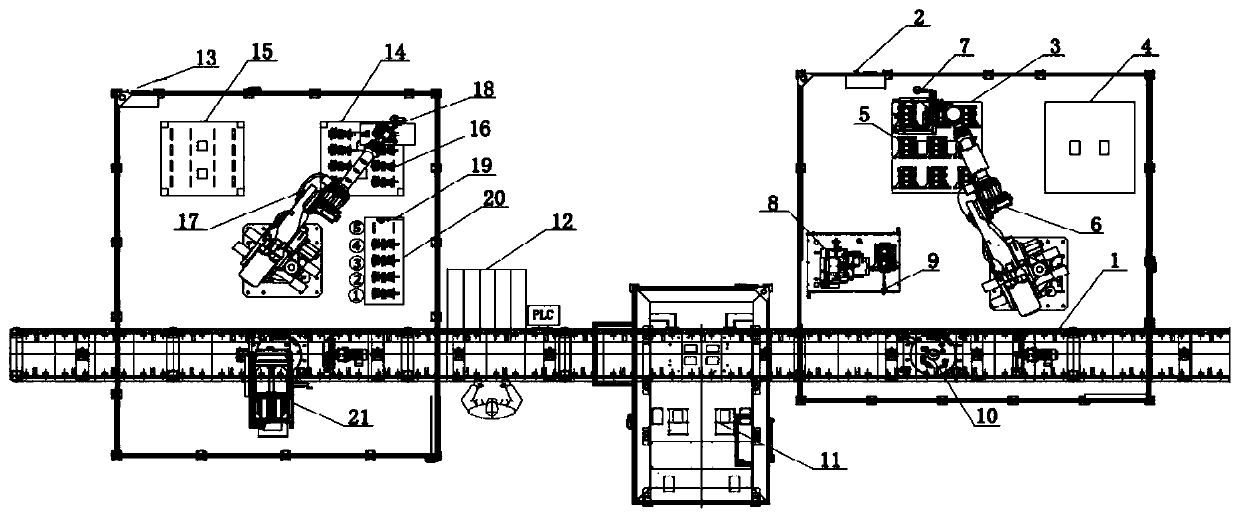

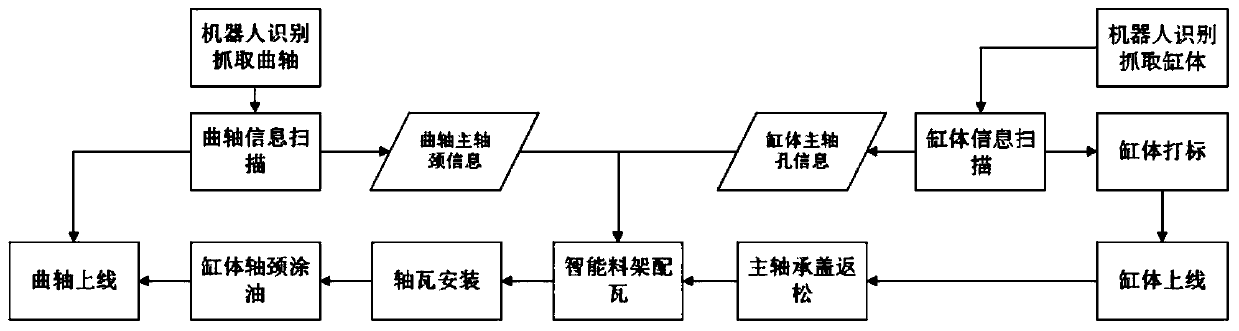

Automatic feeding assembly system for engine crankshaft and process method

ActiveCN111571200AImprove operational efficiencyReduce areaAssembly machinesAutomotive engineeringMain bearing

The invention discloses an automatic feeding assembly system for an engine crankshaft and a process method. The automatic feeding assembly system for the engine crankshaft comprises an engine assemblyline body and an engine tray arranged on the engine assembly line body. A cylinder body feeding workstation used for feeding an engine cylinder body, a main bearing loosening workstation used for loosening main bearing support bolts, a main bearing bush installation workstation used for main bearing bush installation and a crankshaft feeding workstation used for feeding an engine crankshaft are sequentially arranged in the conveying direction of the engine assembly line body. Two sets of feeding robots and visual systems are used for achieving automatic assembly of the crankshaft and the cylinder body, the manual carrying operation is omitted, the operation efficiency is obviously improved, the operation speed is adjustable, and the automatic assembling machine can adapt to rapid tightening.

Owner:DONGFENG MOTOR CORP HUBEI

Speed regulation control system of windscreen wiper

PendingCN110228448AAdjustable running speedReduce reverse noiseVehicle cleaningReciprocating motionControl system

A speed regulation control system of a windscreen wiper comprises a motor, a connecting rod structure, a control module and an induction module; the connecting rod structure converts one-way motion ofthe motor into reciprocating motions of the windscreen wiper on a glass surface, and the induction module is used for inducting discrete signals or continuous signals according to one circle of one-way motions of the motor; the control module is in electric signal connection with the motor and the induction module. And the control module provides a target driving effective voltage corresponding to a signal to the motor for controlling the motor according to the signal fed back by the induction module, so that the motor is driven by the target driving effective voltage corresponding to each group of signals in one-way motions of the motor, and the movement speed of the windscreen wiper is further adjusted. By controlling the driving effective voltage of the motor, the variable-speed motions of the windscreen wiper is controlled, so the windscreen wiper is decelerated near a reverse rotation point, and the windscreen wiper is controlled to run in a certain mode in the middle area, thusincreasing the water wiping speed; it is guaranteed that the operating speed of the windscreen wiper in a whole water wiping period is adjustable, elastic deformation of a wiper blade during high-speed water wiping is reduced, and windscreen wiper reverse rotation noises are reduced.

Owner:SHANGHAI YUDIAN ELECTRONICS TECH CO LTD

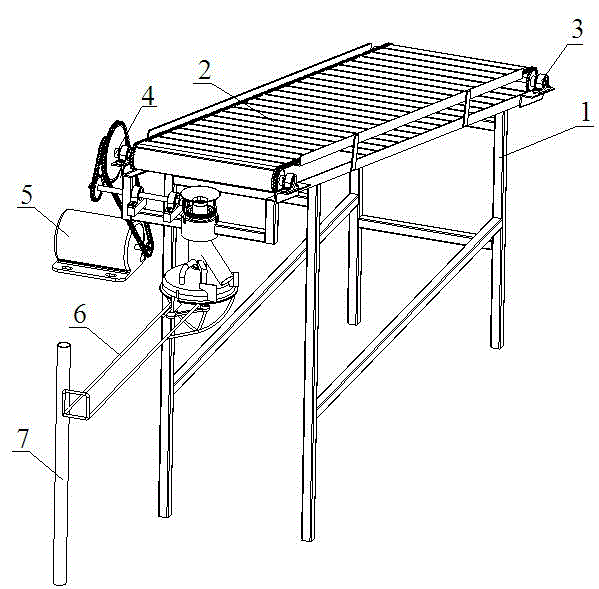

Wet-process efficient beater for cake-shaped products of high-pressure grinding roller

The invention discloses a wet-process efficient beater for cake-shaped products of a high-pressure grinding roller and belongs to the field of mine machinery equipment. The wet-process efficient beater comprises a barrel body, a power device and a transmission device, wherein the power device is fixed on the ground and comprises a motor, a speed reducer and a shaft coupler, which are in continuous transmission connection; the barrel body comprises a feeding end and a discharging end and is arranged in an inclined way with the feeding end being higher than the discharging end; a tooth ring cover is arranged on the outer wall of the barrel body and a rubber lining is arranged on the inner wall of the barrel body; a material guide plate is fixed along the peripheral line of the inner ring of the rubber lining; the suitable height and distance of the material guide plate are selected according to material sizes; the transmission device comprises a large gear assembly and a small gear assembly which is engaged with the large gear assembly; and the speed reducer is in transmission connection with the small gear assembly and the large gear assembly through the shaft coupler. The wet-process efficient beater for the cake-shaped products of the high-pressure grinding roller can be used for beating cake-shaped materials and can conveniently achieve a subsequent working wet-process sieving aim, and is wet-process beating equipment with a great treatment capability.

Owner:ANHUI MASTEEL ENG & TECH GRP

Vertical and horizontal combined type vermicelli machine conveying mechanism

InactiveCN104859997AGuaranteed not to overlapGuaranteed not to tangleConveyorsFood preparationAfter treatmentSprocket

The invention discloses a vertical and horizontal combined type vermicelli machine conveying mechanism, and belongs to the field of mechanical equipment. The vermicelli machine conveying mechanism involves a horizontal conveying stage and a vertical conveying stage when conveying vermicelli. At the vertical conveying stage, water and materials are separated, and the vermicelli is conveyed to a bracket through a length compensation mechanism and a semi-crankshaft drive mechanism. It can be guaranteed that the vermicelli is not overlapped or wound through conveyance of a vertical water and material separation barrel and the semi-crankshaft drive mechanism, after-treatment is convenient, 1 / 3 of labor force can be saved, and working efficiency is improved. The vermicelli is arranged on the bracket in order through the arrangement of the length compensation mechanism, and then the vermicelli which is uniform in length and attractive can be easily obtained. The equipment operating speed can be adjusted through the arrangement of speed change chain wheels, and then the vermicelli of different lengths can be produced through a vermicelli machine.

Owner:权恩存

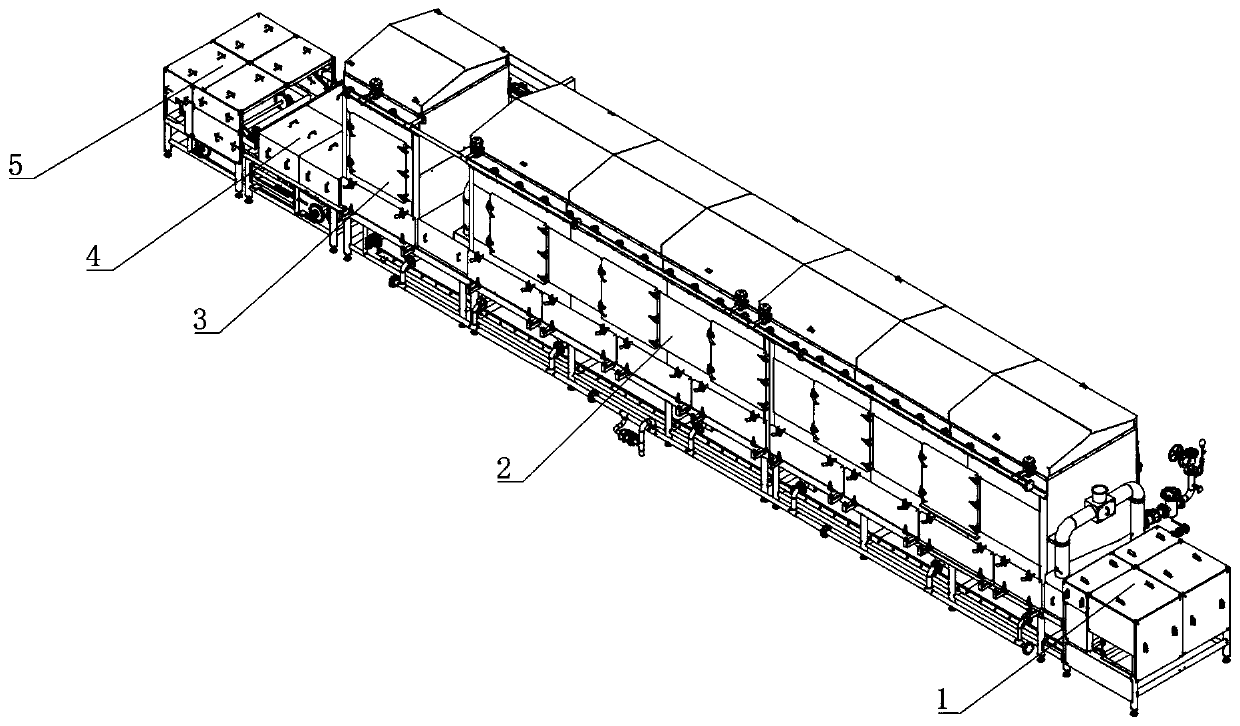

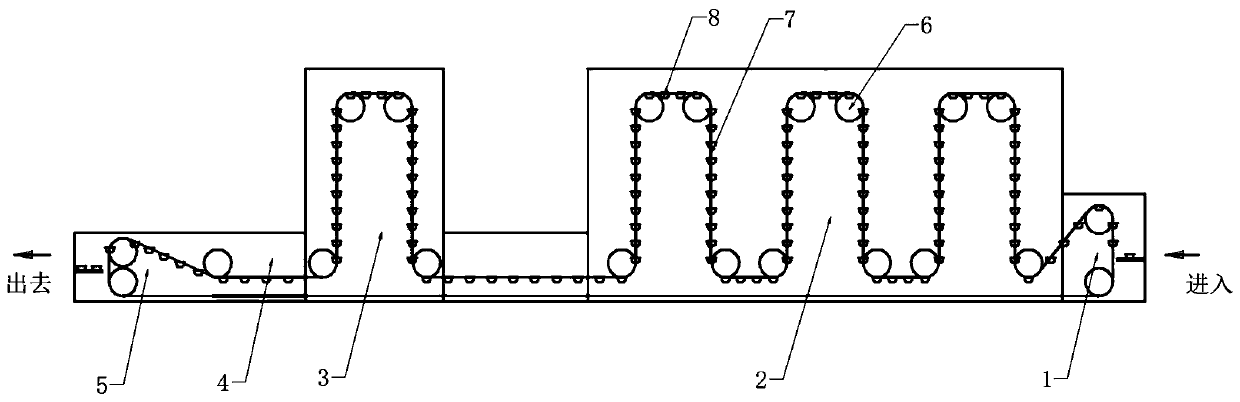

Rice linear cooking system

PendingCN111296721AIncrease productivitySave floor space and human resourcesConveyor partsMechanical conveyorsProcess engineeringRice dishes

The invention discloses a rice linear cooking system. The rice linear cooking system is characterized by comprising an input device, a cooking device, a slow cooling device, a sterilizing device and an output device, wherein the devices are connected in a ring-closing way through a chain provided with rice trays. The rice linear cooking system has the advantages that the trays are automatically and circularly operated among the devices by utilizing the chain, the operation speed is adjustable, and production without stopping is realized, so that production efficiency of equipment is greatly improved, and the space and human resources occupied by the equipment are saved.

Owner:南京乐鹰科技股份有限公司

Horizontal type moving bed particle layer filtration high-temperature oil gas dedusting technology and device

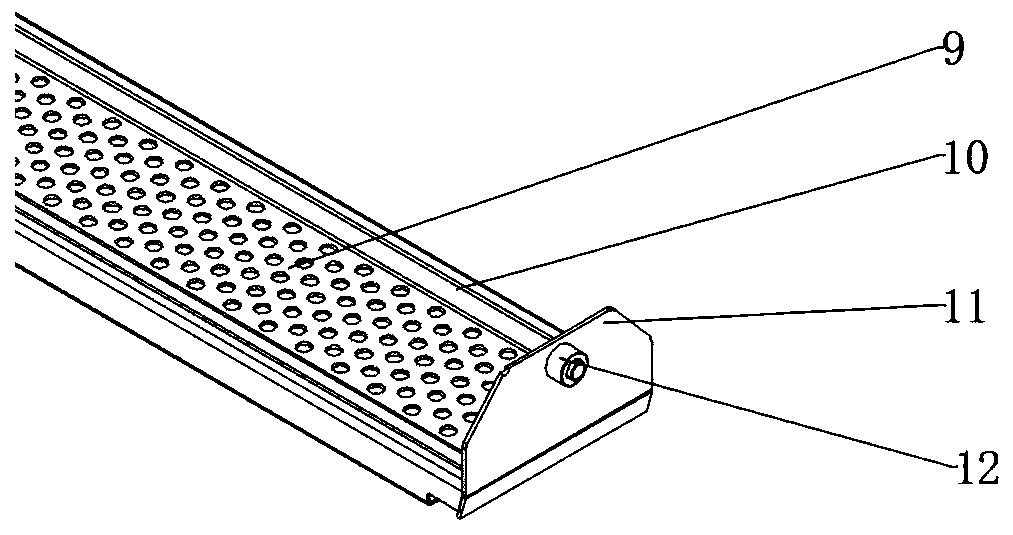

InactiveCN105032078ANo secondary dustEasy to operateDispersed particle filtrationRotational axisDrive wheel

The invention discloses a horizontal type moving bed particle layer filtration high-temperature oil gas dedusting technology and device. The device comprises a shell, a material filtering bin and a plurality of gas inlet pipes are arranged on the upper portion of the shell, and distributing pipes are arranged in the gas inlet pipes. A hot semicoke inlet is formed in the upper end of the material filtering bin. Feeding rollers are arranged in the material filtering bin, and a feeding gate plate is vertically mounted at the front end tangent line position in the rotating direction of the feeding rollers. A bar grating type screener is obliquely mounted below the feeding rollers. A tooth rake device with the top being provided with a rotating shaft is mounted below the bar grating type screener. A driving wheel and a driven wheel are arranged in the shell, a conveying belt is arranged between the driving wheel and the driven wheel, and cold purification high-temperature oil gas outlets are formed below the conveying belt. A material stopping tube and a sealing roller which is tangent to the material stopping tube are arranged beside the driving wheel. A shell segregation board is arranged between the axis of the driving wheel and the axis of the sealing roller. A particle filtering layer is formed on the conveying belt. High-dust semicoke discharging outlets are formed below the shell. The technology and device overcome the defects that the particle layer of an existing fixed bed particle layer filtration high-temperature oil gas dedusting device is backwashed and is difficult to regenerate, and the operating period is short.

Owner:SHAANXI MEISILIN ENERGY SCI & TECH RES INST

Speed regulation control system of wiper blade

InactiveCN110040109AAdjustable running speedReduce reverse noiseVehicle cleaningElectric machineryVoltage

The invention discloses a speed regulation control system of a wiper blade. The speed regulation control system includes a motor, a connecting rod structure, a mould-making module and an induction module, wherein unidirectional movement of the motor is converted into reciprocating movement of the wiper blade on a glass surface through the connecting rod structure, and the induction module is usedfor inducing discrete signals or continuous signals according to one round of unidirectional movement of the motor; a control module is electrically connected with the motor and the induction module and provides target-drive effective voltages corresponding the signals and controlling the motor for the motor according to the feedback signals of the induction module, thus the motor is driven through the target-drive effective voltages corresponding to all the groups of the signals in the unidirectional movement of the motor, and thus the movement speed of the wiper blade is regulated. The driveeffective voltages of the motor are controlled, thus the water-wiper speed is improved, it is guaranteed that the operation speed of the wiper blade can be regulated in the whole water-wiper cycle, elastic deformation of doctor blades in high-speed water-wiper is reduced, and inversion noise of the wiper blade is reduced.

Owner:SHANGHAI YUDIAN ELECTRONICS TECH CO LTD

A device for straightening wire rope with split strands

ActiveCN105290267BDoes not destroy performanceImprove performancePreparing sample for investigationBall screwWire rope

Owner:CHEM MINERALS & METALLIC MATERIALS INSPECTION CENT OF TIANJIN ENTRY EXIT INSPECTION & QUARANTINE BUREAU

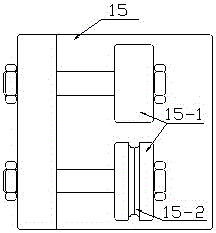

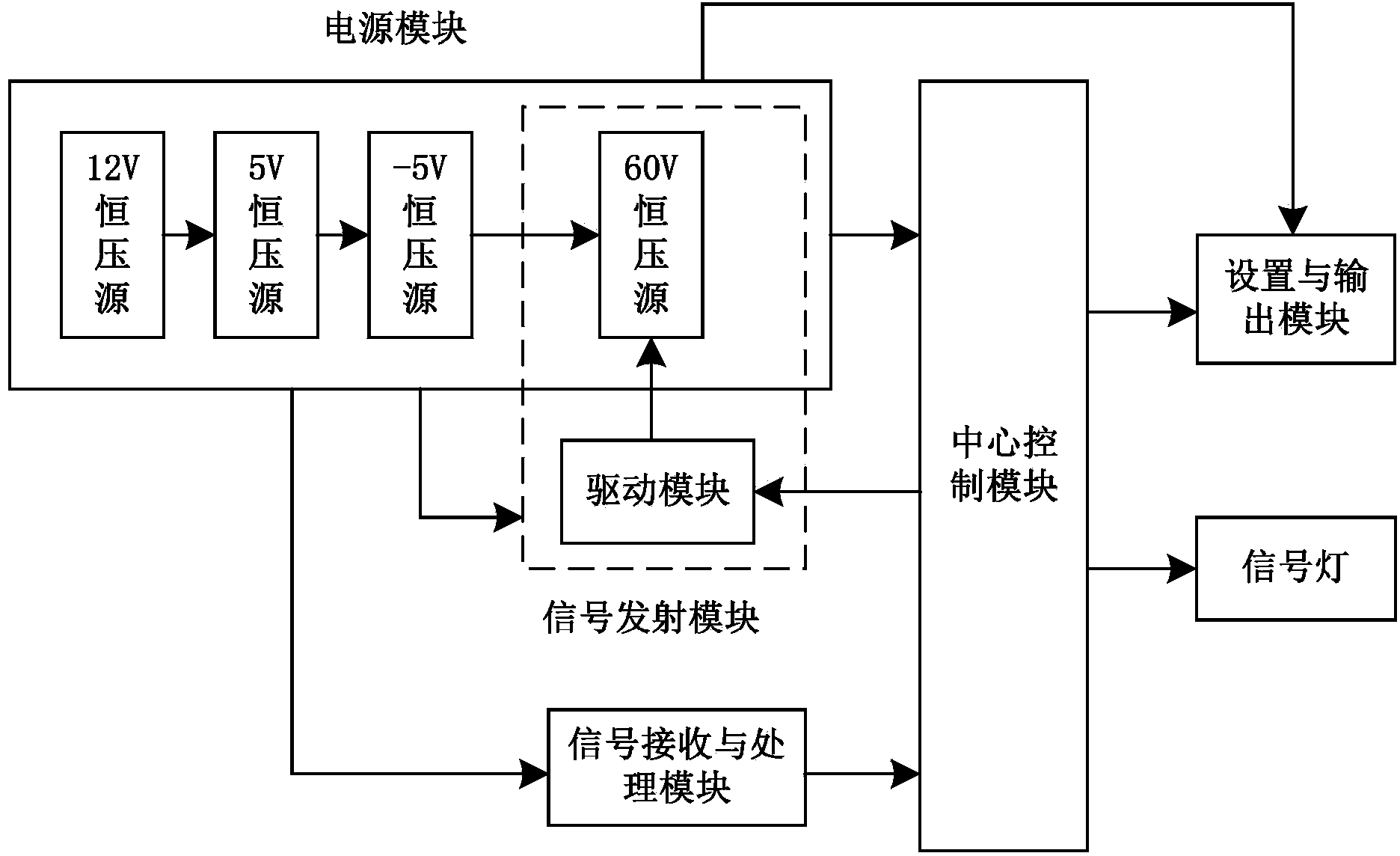

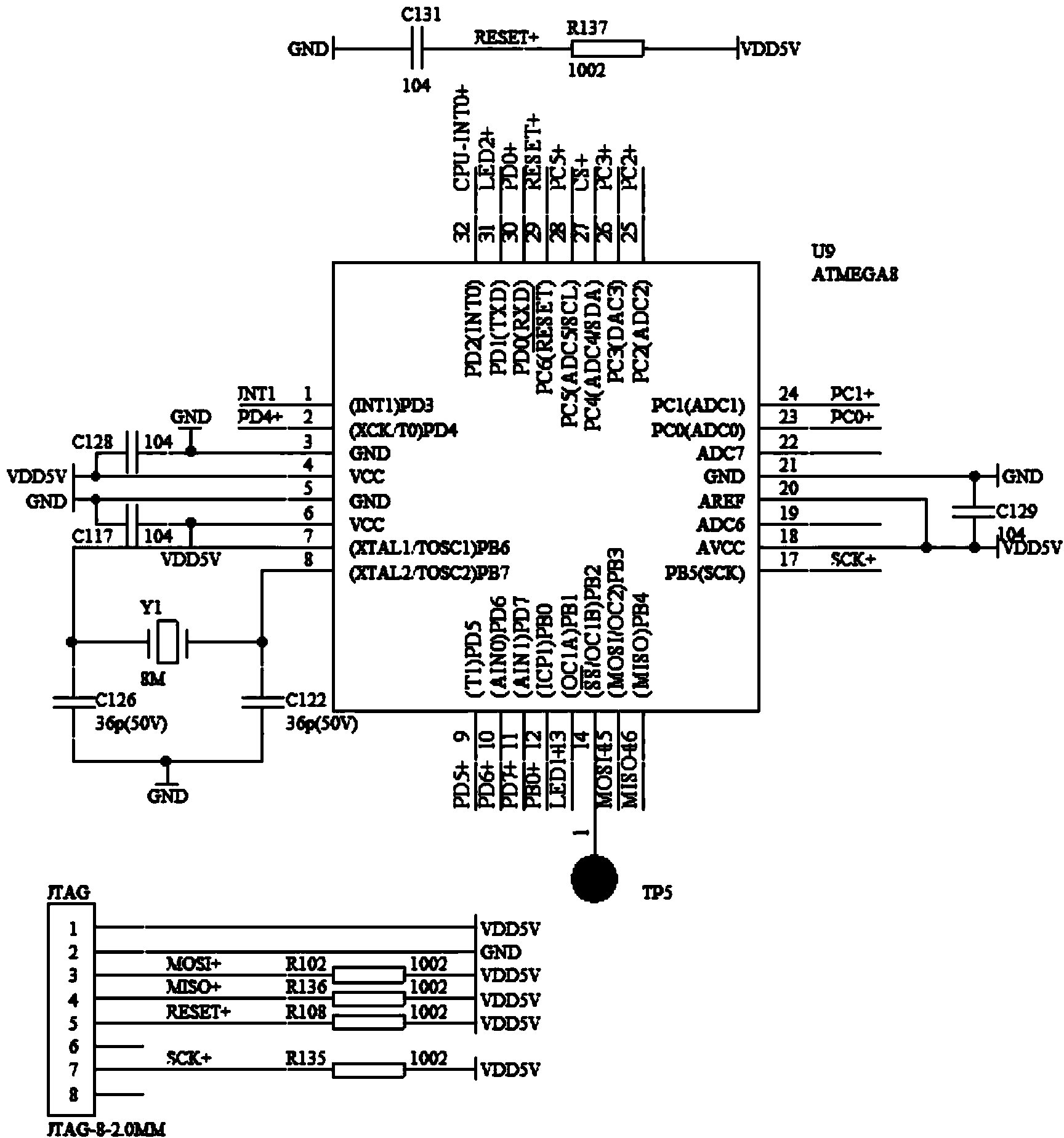

Linear displacement sensor and control method

InactiveCN104374310AImprove compatibilityReduce power consumptionUsing electrical meansElectricityComputer module

The invention belongs to the technical field of sensors, and particularly relates to a linear displacement sensor and a control method. The linear displacement sensor comprises a centralized control module, a power module, a signal transmitting module, a signal receiving and processing module, a sliding block, a setting and outputting module and a signal indicator light. The centralized control module is electrically connected with the signal transmitting module, the signal receiving and processing module, the setting and outputting module and the signal indicator light. The power module is electrically connected with the centralized control module, the signal transmitting module, the signal receiving and processing module and the setting and outputting module. The sliding block is physically connected with the signal transmitting module. The centralized control module controls the signal transmitting module to transmit excitation signals regularly, and the sliding block moves and generates magnetic field induction with the signal transmitting module so that periodic signals can be generated. According to the linear displacement sensor and the control method, the running and processing speed, reliability and output accuracy are high.

Owner:TIANJIN ZHUOSEN TECH

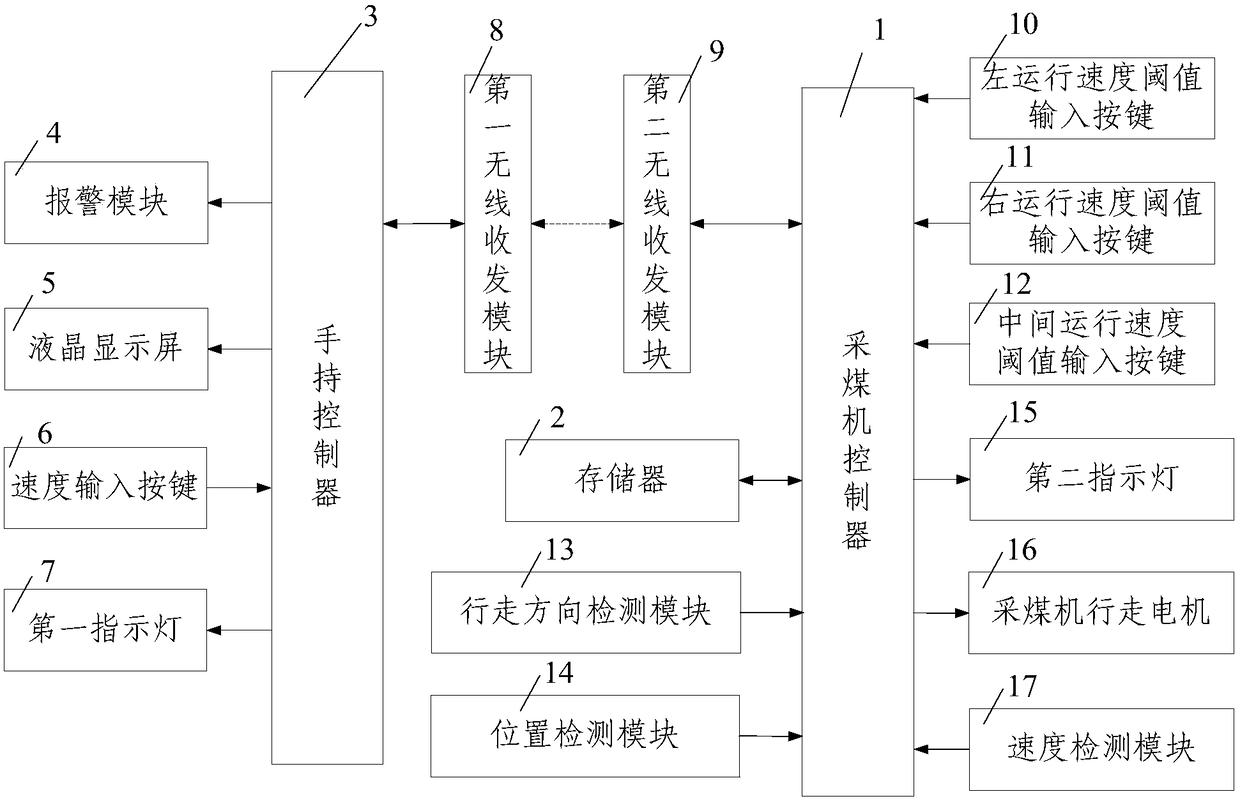

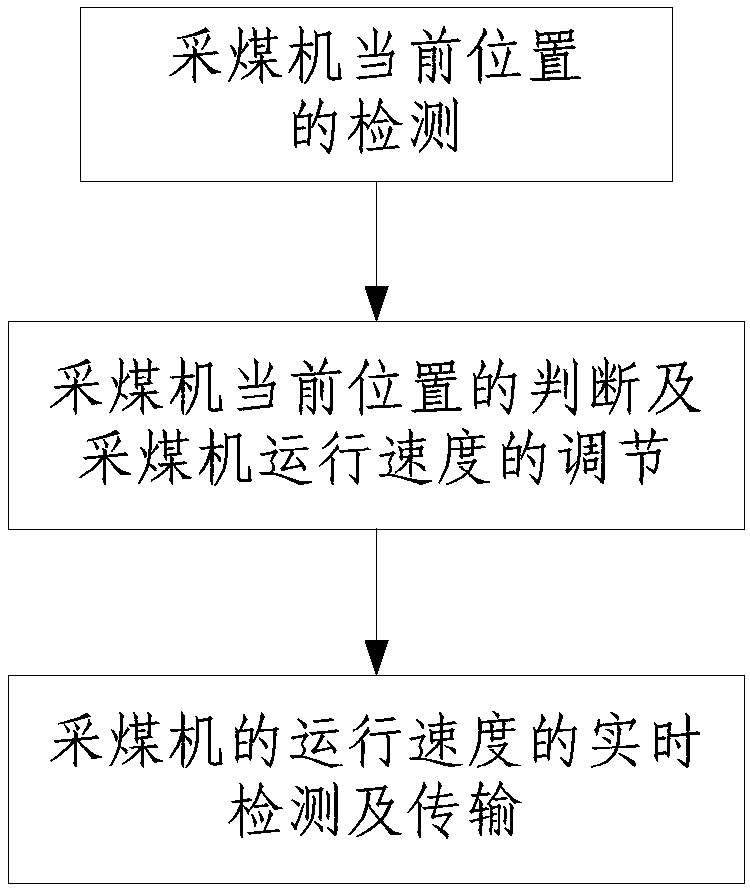

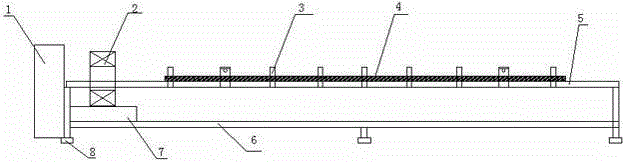

Multi-stage operating speed adjusting device and method under automatic cutting mode of coal cutter

The invention discloses a multi-stage operating speed adjusting device and method under an automatic cutting mode of a coal cutter. The multi-stage operating speed adjusting device comprises a coal cutter control module and a handheld-type adjusting module. The handheld-type adjusting module comprises a handheld controller, a speed input key, a liquid crystal display, an alarming module and a first indicator lamp. The coal cutter control module comprises a coal cutter controller, a second wireless receiving and transmitting module and a storage. The input end of the coal cutter controller is connected with a speed detecting module, a traveling direction detecting module, a position detecting module and a speed threshold value input key module, and the output end of the coal cutter controller is connected with a coal cutter traveling motor and a second indicator lamp. The multi-stage operating speed adjusting method comprises the following steps of 1, detection for the current positionof the coal cutter; 2, judgment on the current position of the coal cutter and adjustment for the operating speed of the coal cutter; and 3, real-time detection and transmission for the operating speed of the coal cutter. According to the multi-stage operating speed adjusting device and method, design is reasonable, the operating speed of the coal cutter under the automatic cutting mode can be adjusted, optimal speed control over automatic coal cutting is achieved, and the practicability is high.

Owner:XIAN COAL MINING MACHINERY +1

Tunnel scanning pass-through demagnetizer

InactiveCN103187140BGuarantee personal safetyGood effectMagnetic bodiesScanning tunneling microscopeEngineering

The invention relates to workpiece demagnetizing equipment, in particular to a tunnel scanning pass-type demagnetizer. The tunnel scanning pass-type demagnetizer comprises a bed body and a control cabinet; the bed body comprises a base and a material loading bridge frame, wherein the material loading bridge frame is positioned above the base and is connected with the base end to end; a sports car is arranged on the base; the base is movably connected with the sports car; the upper part of the sports car is connected with an executive coil by adopting a supporting screw; and the sports car is also provided with a variable frequency motor. By the adoption of the tunnel scanning pass-type demagnetizer, the labor intensity of workers is lightened; the running speed of the sports car, the demagnetizing intensity and the waveform can all be adjusted; safe and efficient demagnetization can be realized; the quality of a workpiece is improved; and therefore, the service life of the workpiece is prolonged.

Owner:杭州飞宇磁电器材有限公司

A pile frame lifting operation mechanism

ActiveCN102795579BAdjustable running speedEasy to operateLifting devicesSpeed control systemControl system

The invention discloses a pile frame lifting operation mechanism which comprises a hoisting machine group, a vertical column, a top pulley yoke, an operating suspension cage, a hoisting machine over-hoisting limiter, a hoisting machine over-releasing limiter, a wire rope, stop dogs and a speed control system. The vertical column is provided with a pair of side guide rails and rib plates distributed at equal intervals; the operating suspension cage is arranged on the side guide rails; a suspension cage body is hinged with a frame; an angling cylinder is respectively connected with the suspension cage body and the frame; the hoisting machine over-hoisting limiter and the hoisting machine over-releasing limiter are respectively installed in proper positions of lower parts of the top pulley yoke and the vertical column; the wire rope is connected with a hoisting frame; the hoisting frame adopts a rod piece, is installed at the upper part of the frame through a hinge pin and can rotate around the hinge pin; a spring connected with the frame is arranged at the lower end part of the hoisting frame; a throttle valve is arranged in the speed control system; and the stop dogs are symmetrically distributed in proper positions at lower parts of the side guide rails. The pile frame lifting operation mechanism ensures that the operating suspension cage is lifted and rotates along the side guide rails of the vertical column, is convenient to operate, stable and reliable, is convenient to mount and dismount, and guarantees the safety of operating personnel.

Owner:上海工程机械厂有限公司

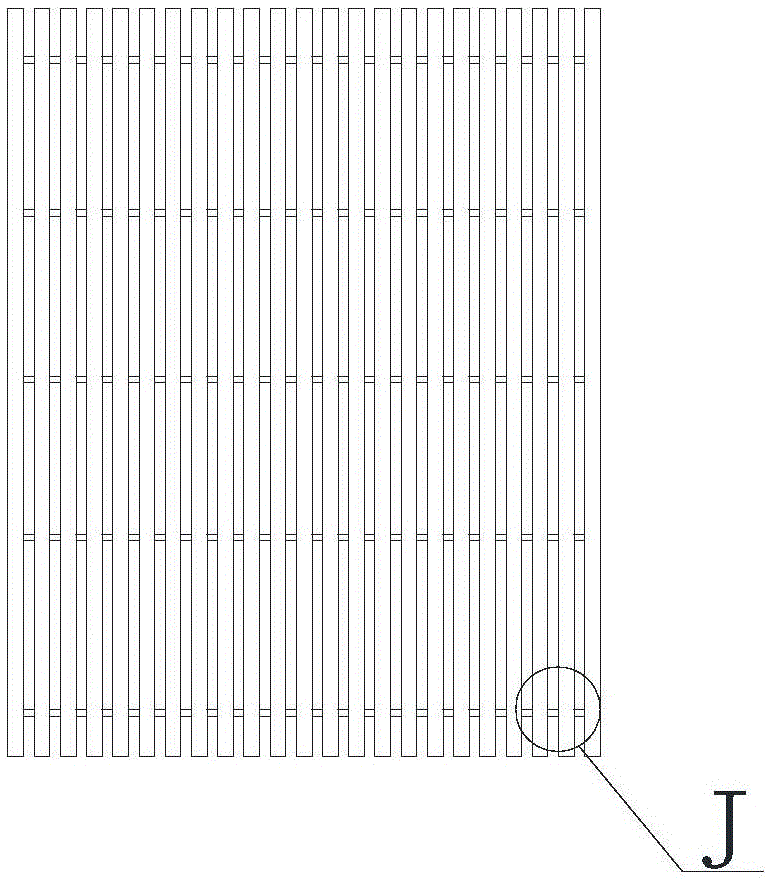

Roller bar furnace for aluminum alloy plate

PendingCN110044174AFully automatedImprove flatnessCharge supportsFurnace typesAutomatic controlMaterial storage

The invention belongs to the technical field of aluminum alloy plate heating equipment, and discloses a roller bar furnace for an aluminum alloy plate. The roller bar furnace comprises a furnace body,a liftable multi-layer material storage table and a feeding and discharging roller bar system, wherein the furnace body is used for heating and insulating the aluminum alloy plate, the liftable multi-layer material storage table is positioned in the furnace body and is used for containing the aluminum alloy plate, and the feeding and discharging roller bar system is used for conveying the aluminum alloy plate; the feeding and discharging roller bar system comprises a plurality of bars which are horizontally laid and are in chain transmission, and the bars transversely penetrate through the furnace body; the liftable multi-layer material storage table comprises a material storage frame and a lifting rod; and the material storage frame comprises a plurality of material storage layers for bearing aluminum alloy plates, two cross beams and a plurality of vertical beams, wherein the vertical beams are connected between the two cross beams so as to erect the material storage layer, and thecross beams are connected to the lifting rod so as to realize the lifting motion of the material storage frame. According to the roller bar furnace, automatic control can be realized, the quality of the plate surface is high, and the problems of scratch, deformation and the like of the conventional plate surface are solved.

Owner:SUZHOU INST OF INDAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com