Air reverse skid conveying system

A conveying system and skid technology, which is applied in the field of skid-type conveying equipment, can solve problems such as occasions where the conveyed objects are not suitable for hanging conveyance, oil dripping, polluting the operating environment, etc., and achieve the effect of solving the pollution problems of oil and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

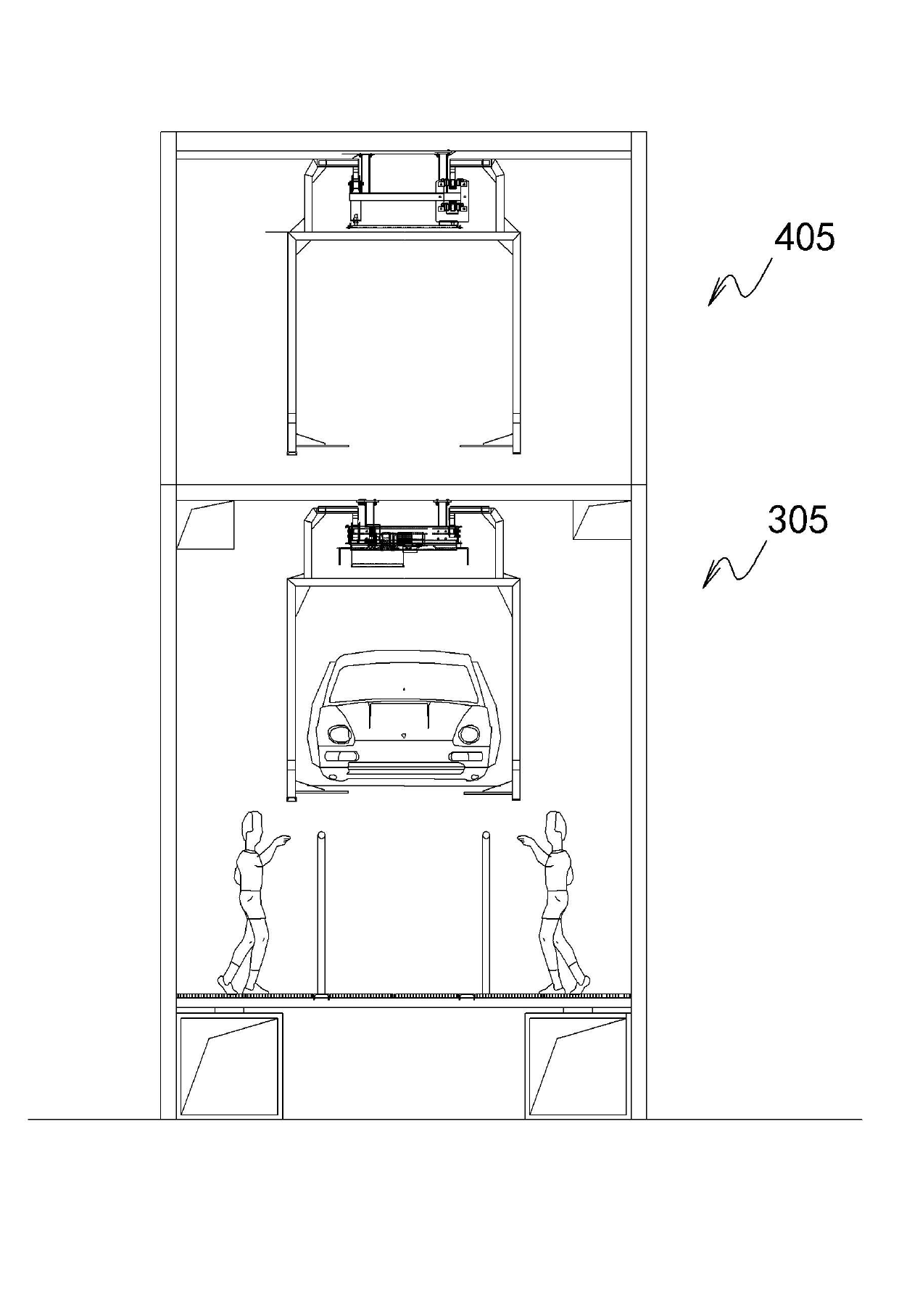

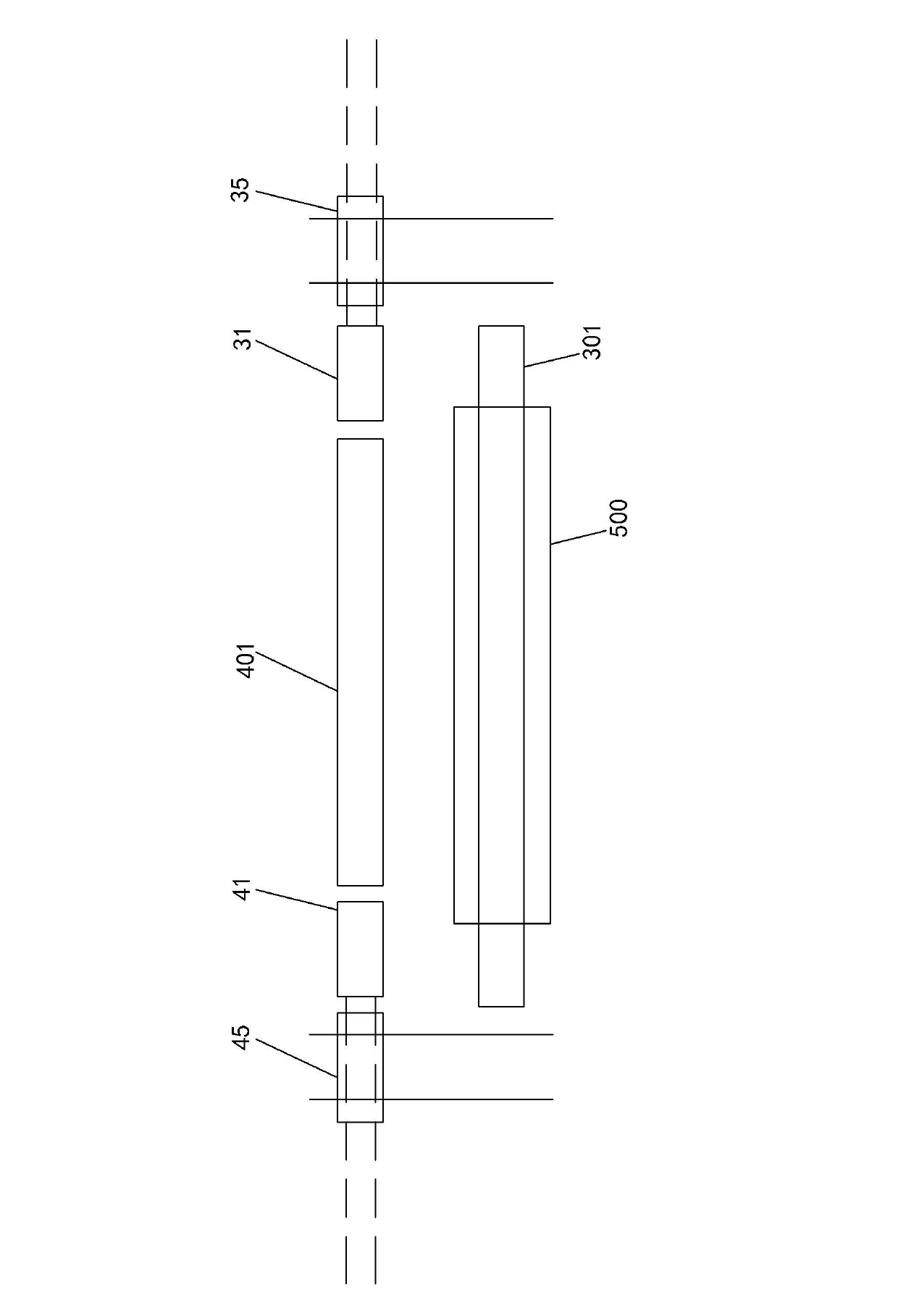

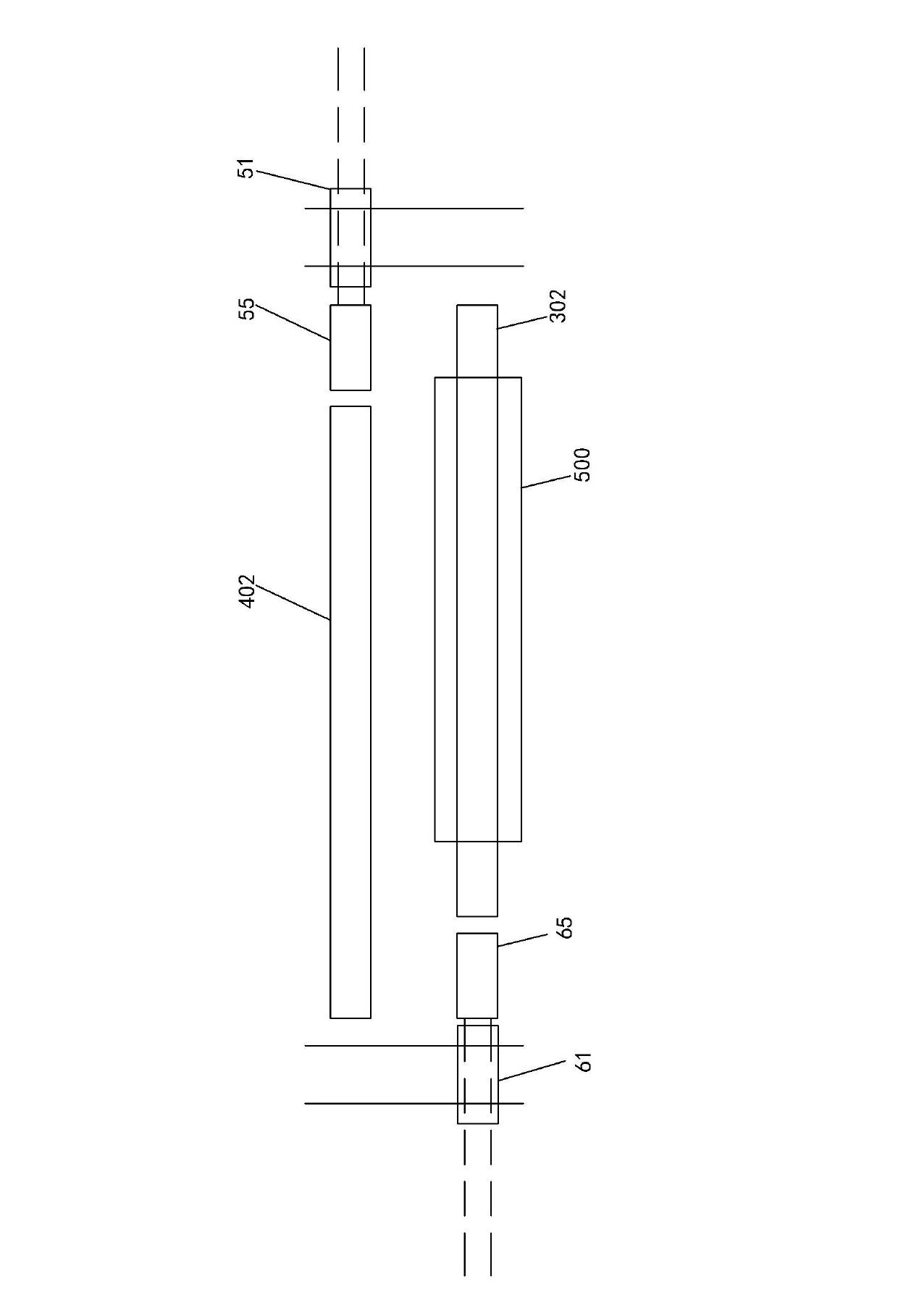

[0020] Such as Figure 1-Figure 4 Shown, embodiment 1 of the air reverse skid conveying system of the present invention is used for automobile bottom spraying, and this system comprises a plurality of air reverse skids 9 and reverses air reverse between the inlet and outlet positions of the system. The inlet transfer device 100 and the outlet transfer device 200 for the sledge 9 to be transported circularly, and two aerial reverse skid transfer devices that extend in parallel along a straight line and have opposite conveying directions, are connected between the two transfer devices. The two reverse skid conveying devices in the air are respectively an operation conveying device 300 and a return conveying device 400 , wherein the middle part of the operation conveying device is arranged in the primer operation area 500 .

[0021] In Embodiment 1, the operation conveying device 300 and the return conveying device 400 are distributed side by side in the horizontal direction. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com