Braking part and oil wiping device used for same

A technology for brake parts and oil parts, applied in the direction of brake parts, brake parts, valve devices, etc., can solve the problems of heavy oil rubbing workload such as guide rails, affecting the friction braking mechanism, and high safety risks in working conditions, etc. Achieve the effect of reducing labor intensity, reducing the risk of safety devices, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

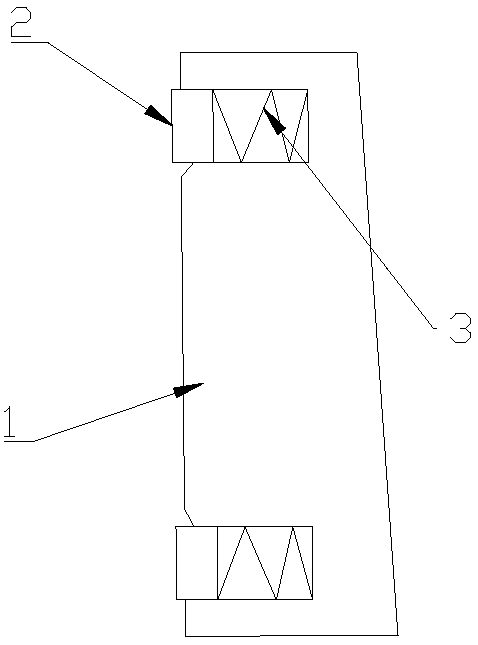

[0033] see figure 1 , 2 , the brake member 1 with oil wiping function in this embodiment forms two installation holes, the installation holes are connected with the outside world through the braking friction surface 101 of the brake member 1, and the opening of the installation hole is equipped with an oil wiper 2 (such as a sponge Body, fiber, rubber, polyurethane), the elastic member 3 (such as a spring) is installed between the inner surface of the oil wiper 2 and the inner bottom surface of the installation hole, the outer surface 102 of the oil wiper 2 protrudes from the installation hole and the outer surface is positive For counterparts (such as guide rails).

[0034] The lower edge of the opening of the upper mounting hole of the brake member 1 is chamfered to form an oil discharge groove 103; the upper edge of the opening of the lower mounting hole is also chamfered to form another oil discharge groove. Both ends of the oil discharge groove extend to both sides of t...

Embodiment 2

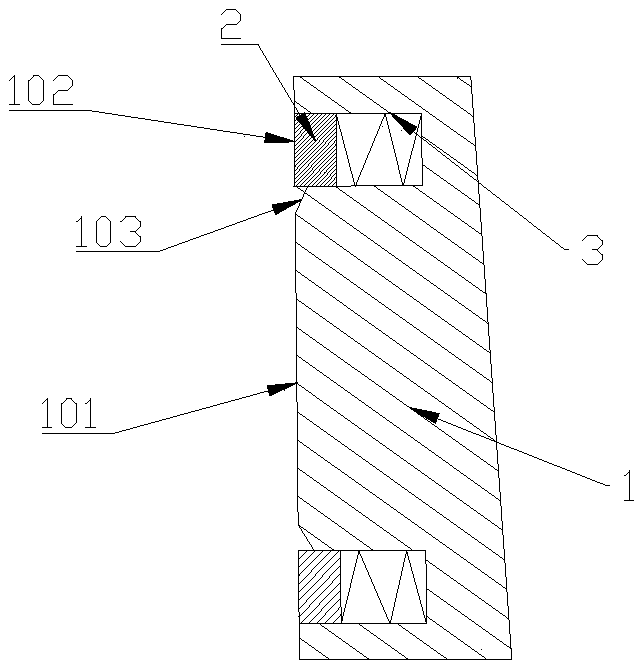

[0037] see image 3 , the braking member 1 of the present embodiment forms two mounting holes, the mounting holes communicate with the outside world through the braking friction surface 101 of the braking member 1, the mounting holes are filled with elastic oil wiper 2 (such as rubber), and the elastic oil wiper 2 The outer side 102 protrudes from the mounting hole.

[0038] The lower edge of the opening of the upper mounting hole of the braking member 1 is chamfered to form an oil discharge groove 103; the upper edge of the opening of the lower mounting hole is also chamfered to form an oil discharge groove. Both ends of the oil discharge groove extend to both sides of the brake piece 1 .

[0039] Under normal circumstances, the elastic oil wiper 2 is in a non-compressed state, and the outer surface of the elastic oil wiper 2 protrudes from the braking friction surface 101 of the brake piece 1; when braking, the elastic oil wiper 2 is first compressed, and the elastic Under...

Embodiment 3

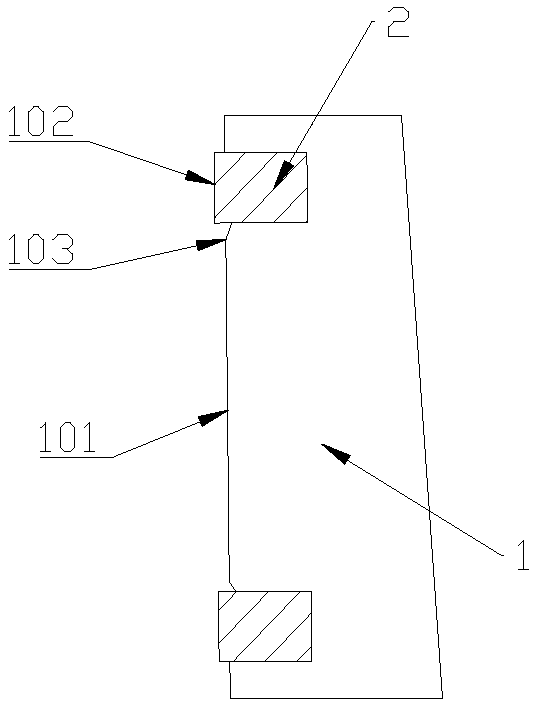

[0041] see Figure 4 , The difference between this embodiment and Embodiment 2 is that this embodiment only has one elastic oil wiper 2 .

[0042] Other content of this embodiment can refer to Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com