Wet-process efficient beater for cake-shaped products of high-pressure grinding roller

The technology of a high-pressure roller mill and a dispersing machine is applied in the field of mining machinery and equipment, and achieves the effects of simple structure, convenient maintenance and low friction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

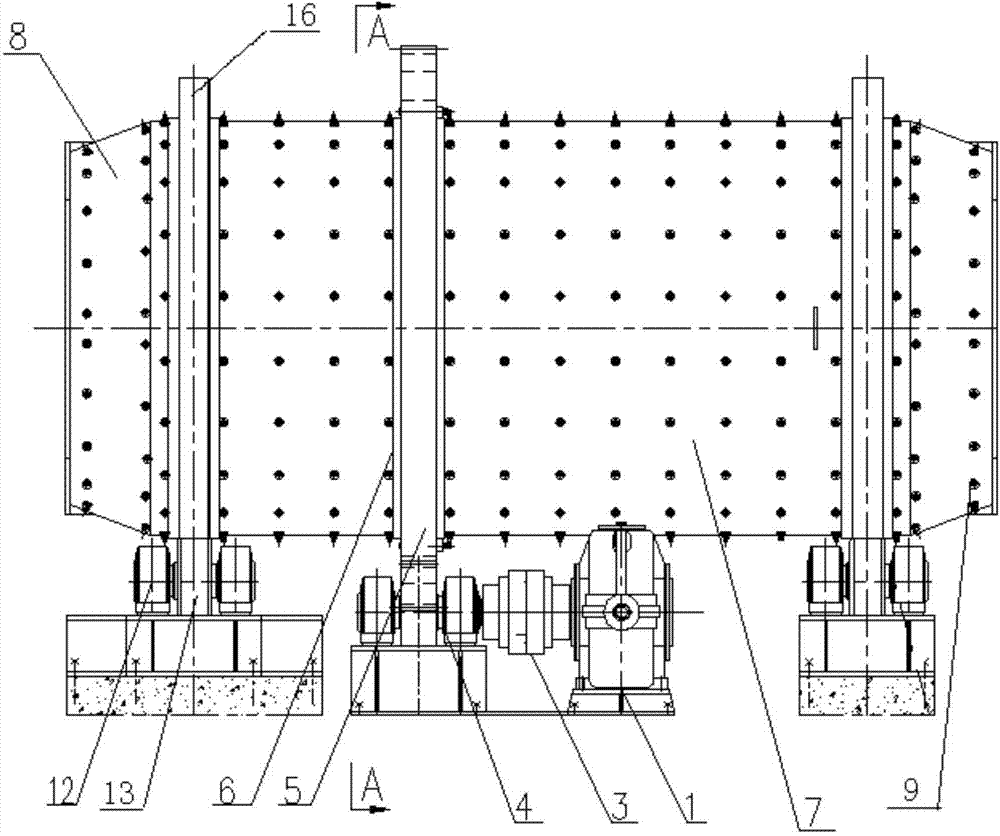

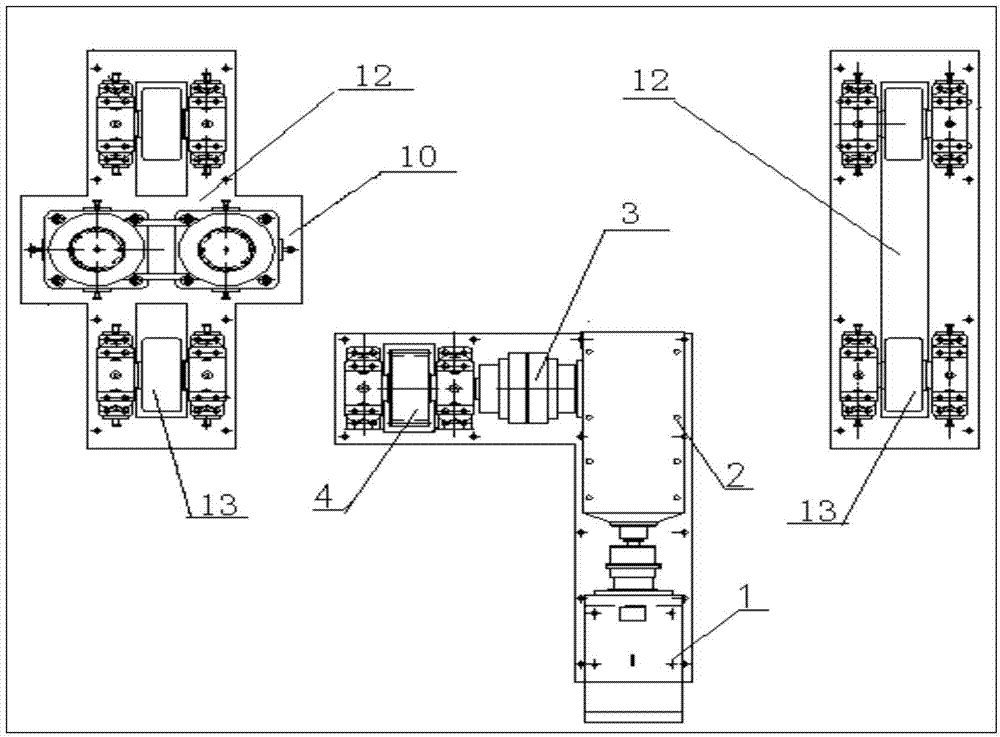

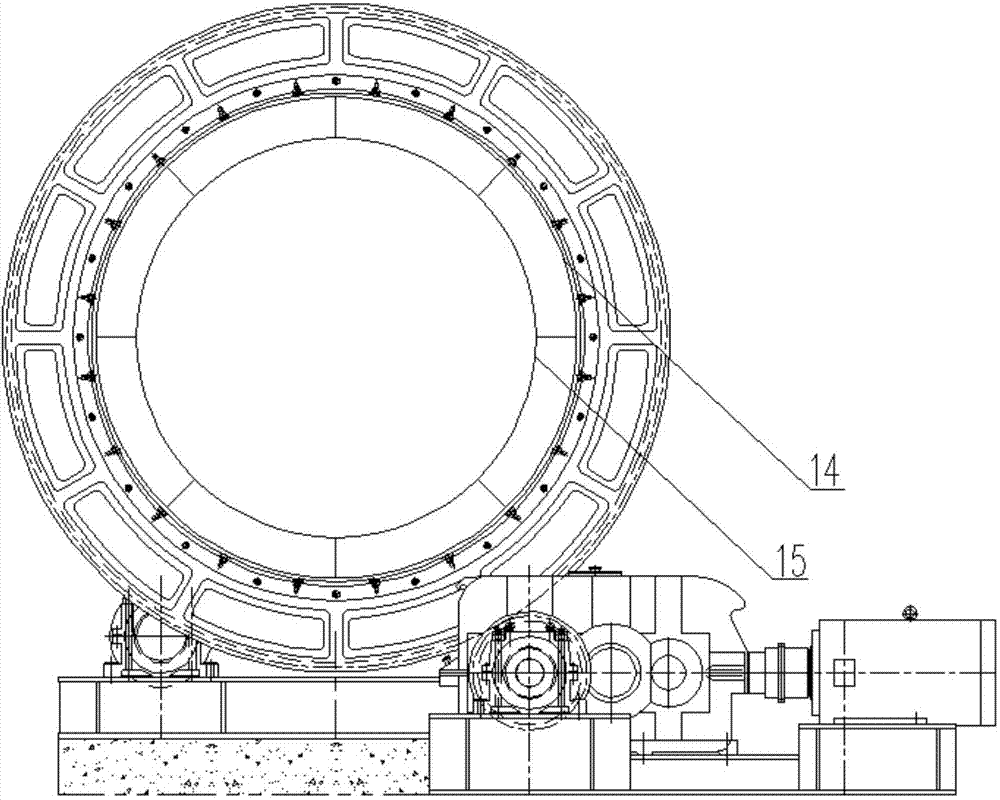

[0039] A high-pressure roller mill cake-shaped product wet-type high-efficiency breaker in this embodiment includes a cylinder 7, a power device and a transmission device, and the power device is fixed on the ground, including a motor 1, a reducer 2 and a coupling 3, Fixed on the ground, it is connected by continuous transmission; the cylinder 7 includes the feed end 8 and the discharge end 9, the specification is ¢2400mm*5400mm, and it is set in an inclined manner with the feed end 8 on the top and the discharge end 9 on the bottom. 1.5 degrees; the outer wall of the cylinder 7 is provided with a ring gear cover 6, and the inner wall is lined with a 20mm thick rubber liner 14, and the material guide plate 15 is fixed along the inner circle of the rubber liner 14, the height of the material guide plate is 50mm, and the spacing is 200mm; The transmission device includes a large gear assembly 5 and a pinion assembly 4 meshing with the large gear assembly 5; the reducer 2 is conne...

Embodiment 2

[0043] A high-pressure roller mill cake-shaped product wet-type high-efficiency dispersing machine of this embodiment has the same basic structure as that of Embodiment 1, except that it also includes a supporting wheel device 12 and a retaining wheel device 10; the supporting wheel device 12 is a rotating shaft Type rolling bearing support wheel group, arranged under the left and right parts of the cylinder body 7, including 4 support wheels and 2 runners 13, divided into two groups of front and rear symmetry, each group is in the form of runners 13 in the middle and support rollers The left and right sides of runner 13 are arranged symmetrically, and runner 13 is connected with the rolling ring 16 made of hard rubber material that is arranged on the left and right sides of cylinder body 7; Degree, consistent with the inclination angle of the cylinder, set between the two runners 13 on the left; motor 1 is a frequency conversion motor; material guide plate 15 is a spiral mater...

Embodiment 3

[0047] A high-pressure roller mill cake-shaped product wet-type high-efficiency breaker of this embodiment has the same basic structure as that of Embodiment 2, except that the angle of the conical surface of the conical retaining wheel device 10 is 0.5 degrees. The number of turns of the spiral material guide plate is 18, and the height is 50mm.

[0048] A high-pressure roller mill cake-shaped product wet-type high-efficiency disperser of this embodiment is designed to require that the material stay in the cylinder 7 for 35 seconds, and the cylinder 7 rotates at a speed of 13 revolutions per minute. It is suitable for smaller specifications (diameters smaller than 40mm) high pressure roller mill cake products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com