Linear displacement sensor and control method

A linear displacement and sensor technology, applied in the field of sensors, can solve problems such as low operating processing speed, affecting measurement results, and reducing the accuracy of slide rail resistance, and achieves adjustable operating speed, flexible output range, and extreme stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

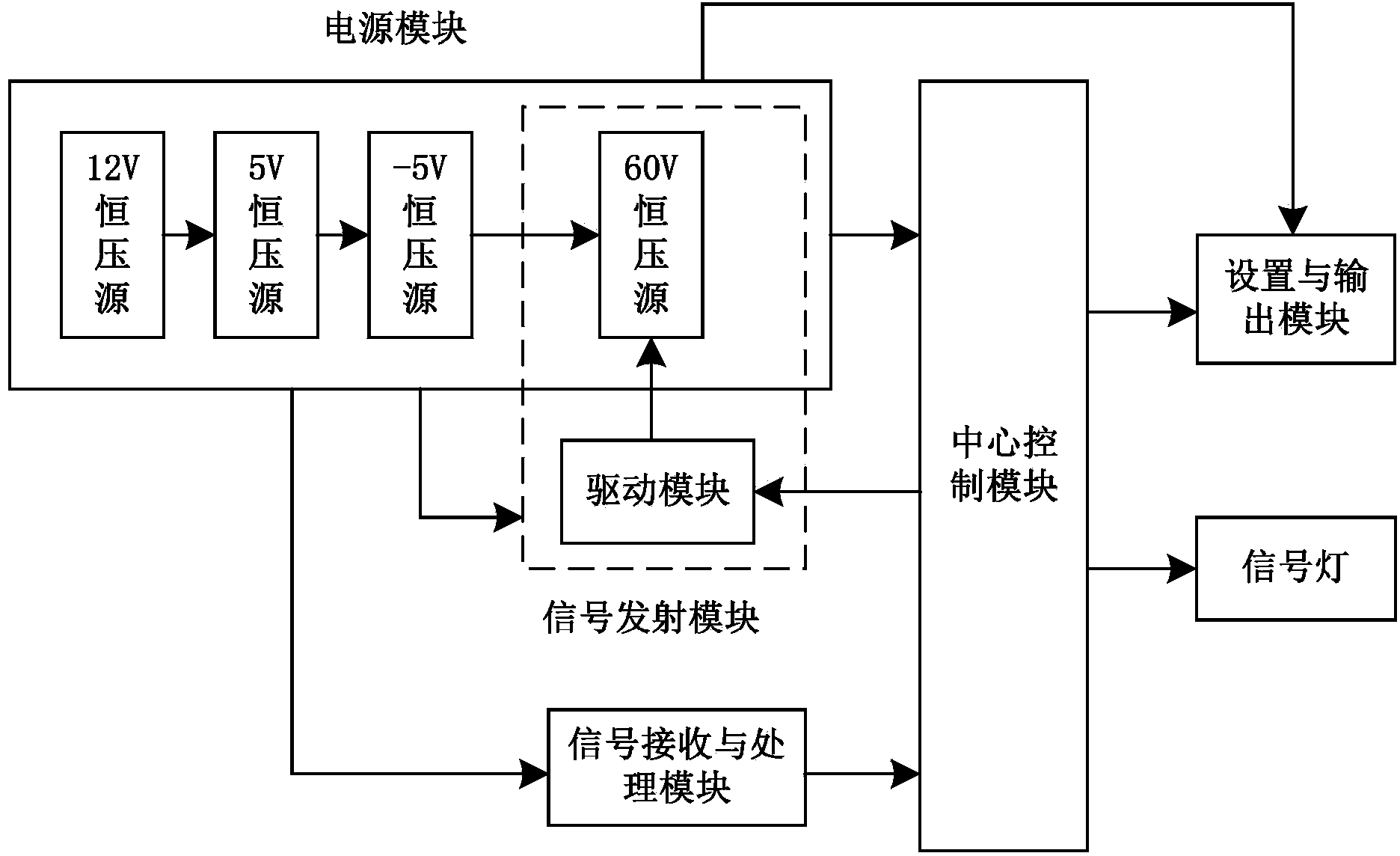

[0042] The technical solution of the present invention involves two subjects, a linear displacement sensor and a control method, which will be described in detail below.

[0043] like figure 1 As shown, a linear displacement sensor includes: a central control module, a signal transmission module, a signal reception and processing module, a setting and output module, and a power supply module; the power supply module supplies power to the above-mentioned modules;

[0044] The central control module controls the signal transmission module to periodically send the excitation signal,

[0045] The signal transmitting module is connected with a slider, and when the slider moves, a magnetic field induction periodic signal is generated with the excitation signal sent by the signal transmitting module,

[0046] The signal receiving and processing module receives the above-mentioned periodic signal and performs filtering, amplification and modulation processing,

[0047] The central c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com