Multi-stage operating speed adjusting device and method under automatic cutting mode of coal cutter

A technology of running speed and adjusting device, which is applied in the direction of earthwork drilling, cutting machinery, etc., can solve the problems of changing the running speed of the shearer, and achieve the effect of simple structure, strong practicability and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

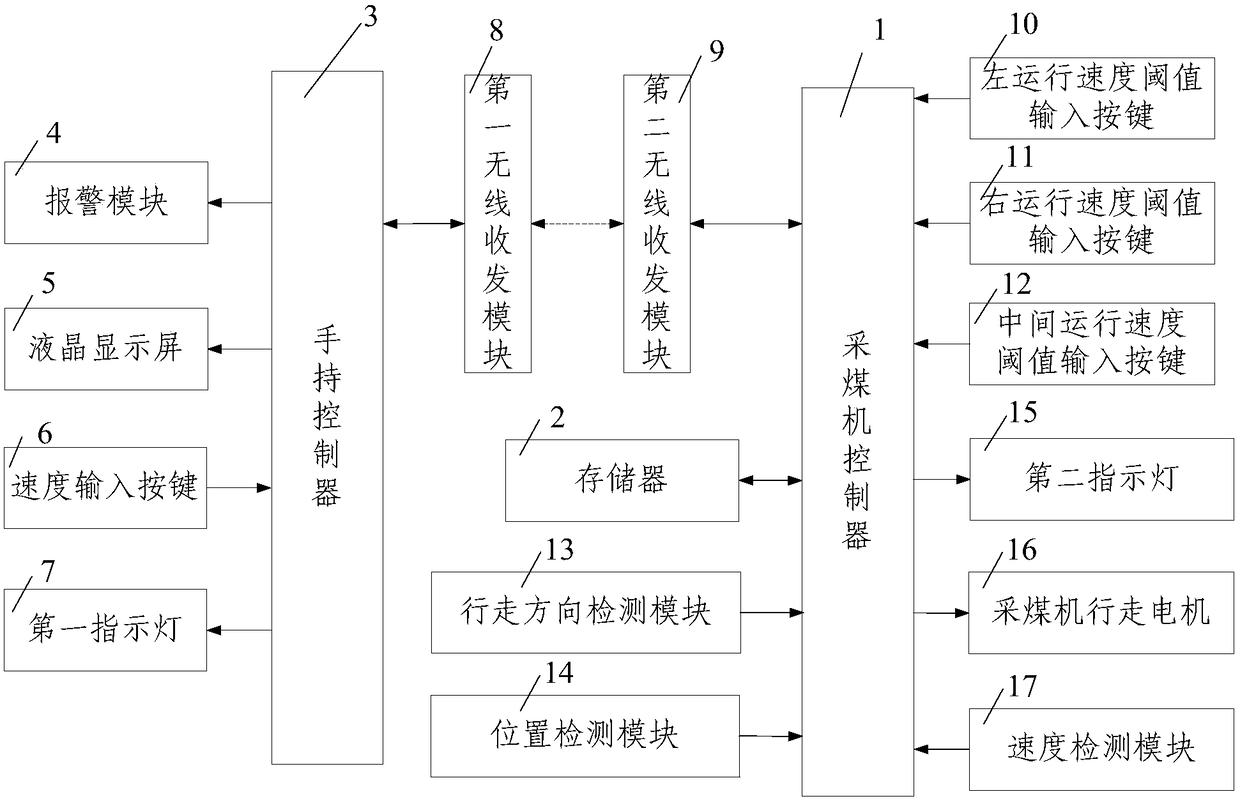

[0044] Such as figure 1 The multi-stage operation speed adjustment device in the automatic cutting mode of the shearer is shown, including a shearer control module arranged on the shearer and a hand-held adjustment module for adjusting the operating speed of the shearer, The hand-held adjustment module includes a hand-held controller 3 and a first wireless transceiver module 8 connected to the hand-held controller 3, the input terminal of the hand-held controller 3 is connected with a speed input button 6, and the hand-held controller 3 The output end is provided with a liquid crystal display 5, an alarm module 4 and a first indicator light 7, and the shearer control module includes a shearer controller 1 and a second wireless transceiver module 9 connected to the shearer controller 1 and memory 2, the input of the shearer controller 1 is connected with a speed detection module 17, a walking direction detection module 13 and a position detection module 14, and a speed threshol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com