Axial-flow type cutter claw combined type biomass fuel comprehensive crusher

A technology of biomass fuel and crusher, which is applied in grain processing, solid separation, sieving, etc., can solve the problems of low processing efficiency and crushing quality, easy blockage of feeding materials, and large power consumption, so as to improve crushing efficiency and processing quality, solve the effect of uneven delivery, and avoid impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

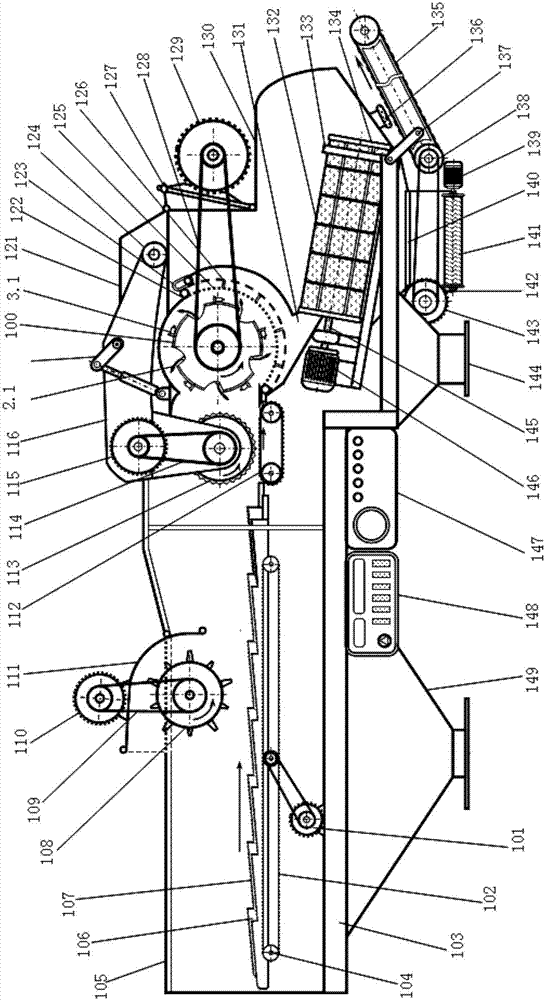

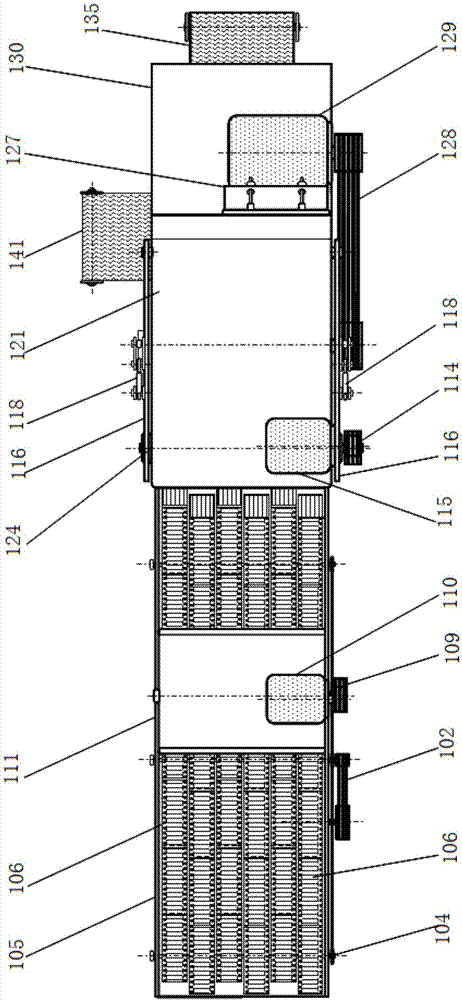

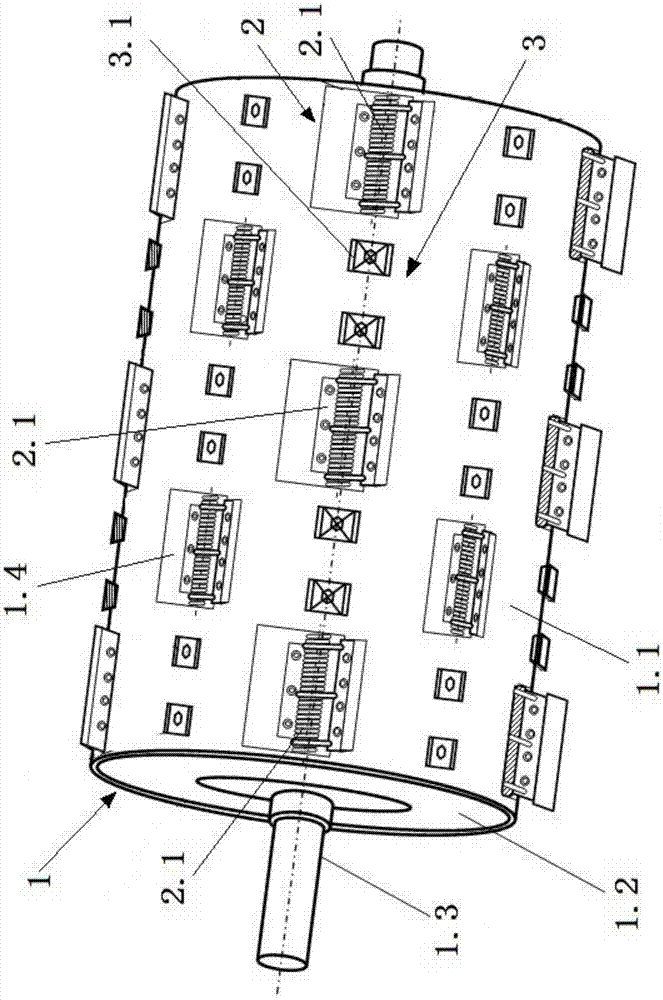

[0034] Such as figure 1 , figure 2 The shown axial-flow knife-claw combined biomass fuel comprehensive crusher includes a frame 103, the lower part of the frame 103 is fixed with a front base 149 and a rear base 144, a feeding bin 105, a crushing processing bin 121 and a screening out The feed bin 130 is arranged on the top of the frame 103 successively from the front to the back; the feed bin 105 is provided with a draft device-type horizontal feed conveyor 106, and the draft device-type horizontal feed conveyor 106 is composed of a single row draft device 107, The draft chaser crank shaft 104, the feeding conveyor transmission mechanism 102 and the feeding conveyor motor 101 are composed of six single row draft chasers 107 that are hinged and instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com