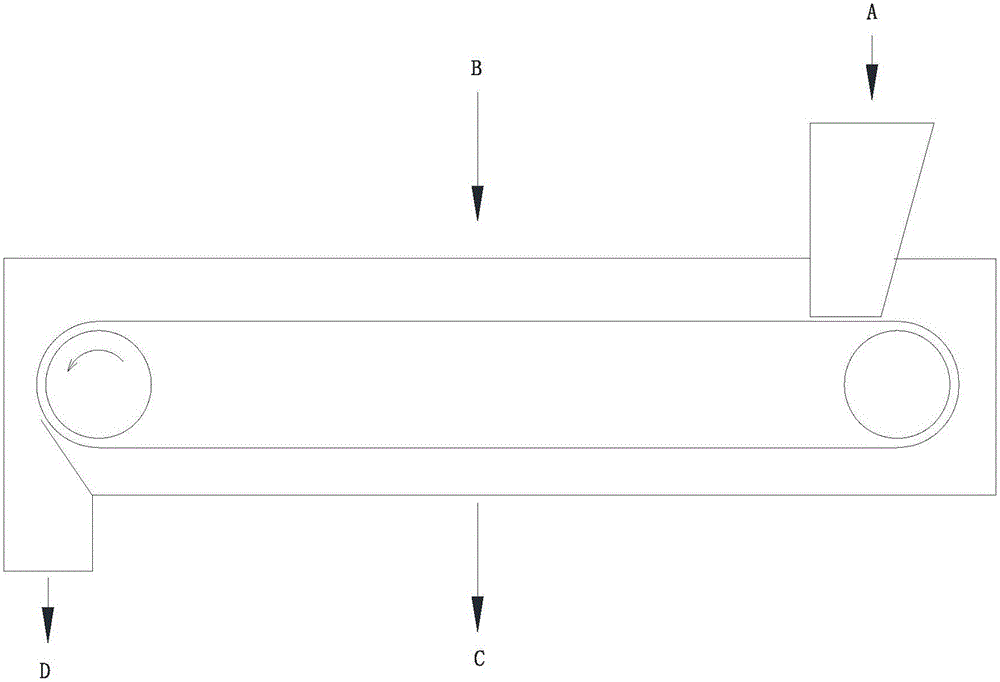

Horizontal type moving bed particle layer filtration high-temperature oil gas dedusting technology and device

A particle layer filtration and moving bed technology, applied in the field of coal pyrolysis, can solve the problems of difficult particle layer recoil regeneration, complex regeneration system, short operation period, etc., and achieve unattended, high dust removal efficiency, and low dust removal resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

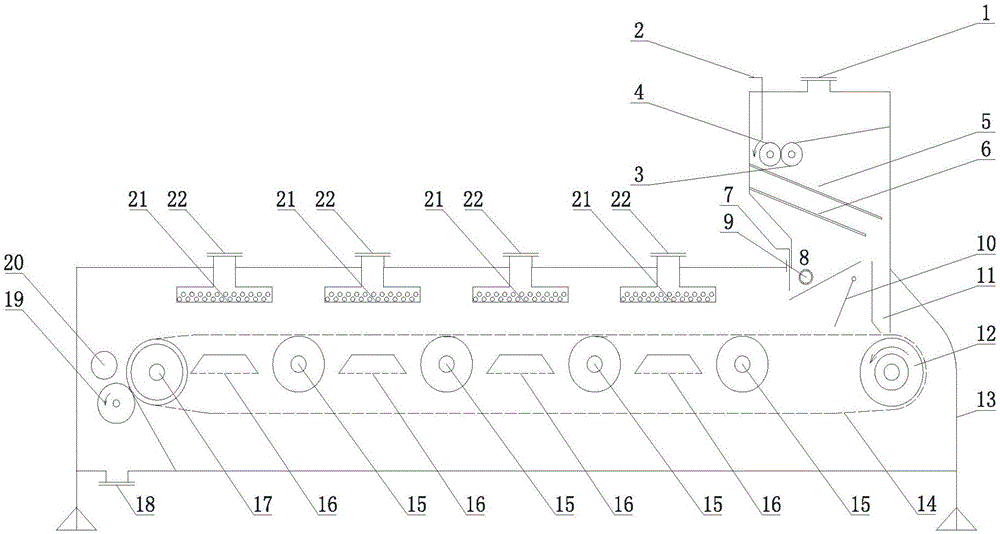

Embodiment 1

[0067] The 550°C high-temperature oil and gas from the known moving bed pulverized coal pyrolysis device enters from the top inlet pipe 22 of the horizontal moving bed particle layer filter high temperature oil and gas dedusting device, and under the action of the gas distribution of the distribution pipe 21, the high temperature The oil and gas are evenly distributed on the surface of the filter material of the particle filter layer. High-temperature oil and gas pass through the granular filter layer of semi-coke accumulation, and the dust particles carried by the high-temperature oil and gas are screened and intercepted by the particle filter layer, so that the dust particles adhere to the geometric surface of the granular filter material and are trapped in the gaps of the granular layer. Purified by particle filter. Due to the continuous movement of the conveyor belt 14, the sub-sieving and layered feeding technology continuously spreads the hot semi-coke produced in the pu...

Embodiment 2

[0069] The 650°C high-temperature oil and gas from the known fluidized bed pulverized coal pyrolysis device enters from the top inlet pipe 22 of the high-temperature oil and gas dust removal device of the horizontal moving bed particle layer filter, and under the action of the gas distribution of the distribution pipe 21, the High-temperature oil and gas are evenly distributed on the surface of the filter material of the particle filter layer. High-temperature oil and gas pass through the particle filter layer of semi-coke accumulation, and the dust particles carried by the high-temperature oil and gas are screened and intercepted by the particle filter layer, so that the dust particles adhere to the geometric surface of the particle filter material and are trapped in the gap of the particle layer. Purified by particle filter. Due to the continuous movement of the conveyor belt 14, the sub-sieving and layered feeding technology continuously spreads the hot semi-coke produced i...

Embodiment 3

[0071]The 450°C high-temperature oil and gas from the known fluidized bed pulverized coal pyrolysis device enters from the top inlet pipe 22 of the high-temperature oil and gas dust removal device of the horizontal moving bed particle layer filter, and under the action of the gas distribution of the distribution pipe 21, the High-temperature oil and gas are evenly distributed on the surface of the filter material of the particle filter layer. High-temperature oil and gas pass through the granular filter layer of semi-coke accumulation, and the dust particles carried by the high-temperature oil and gas are screened and intercepted by the particle filter layer, so that the dust particles adhere to the geometric surface of the granular filter material and are trapped in the gaps of the granular layer. Purified by particle filter. Due to the continuous movement of the conveyor belt 14, the sub-sieving and layered feeding technology continuously spreads the hot semi-coke produced i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com