Electro-filtration duplex double-phase dust remover

A precipitator and duplex technology, applied in the field of electric filtration duplex duplex precipitators, can solve the problems of easily damaged filter bags, high operating costs, inability to apply high temperature and high corrosion, etc., to improve collection speed and efficiency, improve dust removal efficiency, The effect of increased collection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

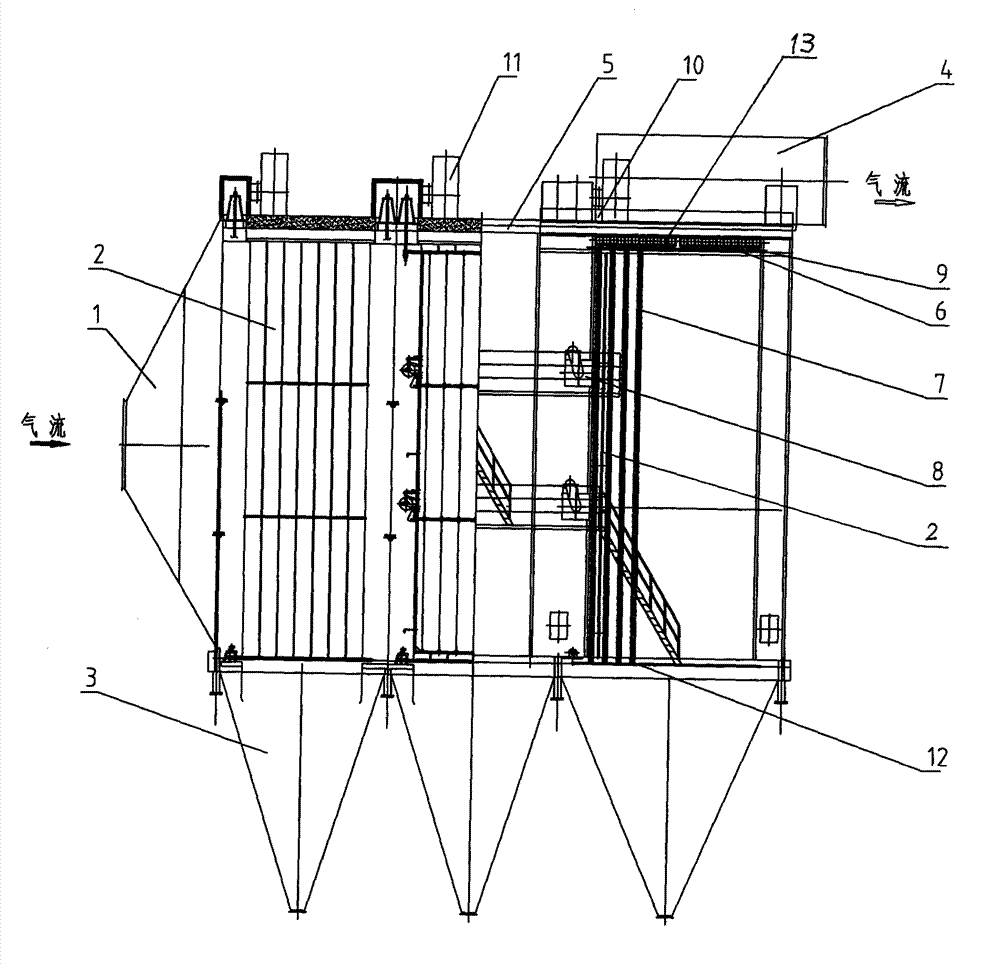

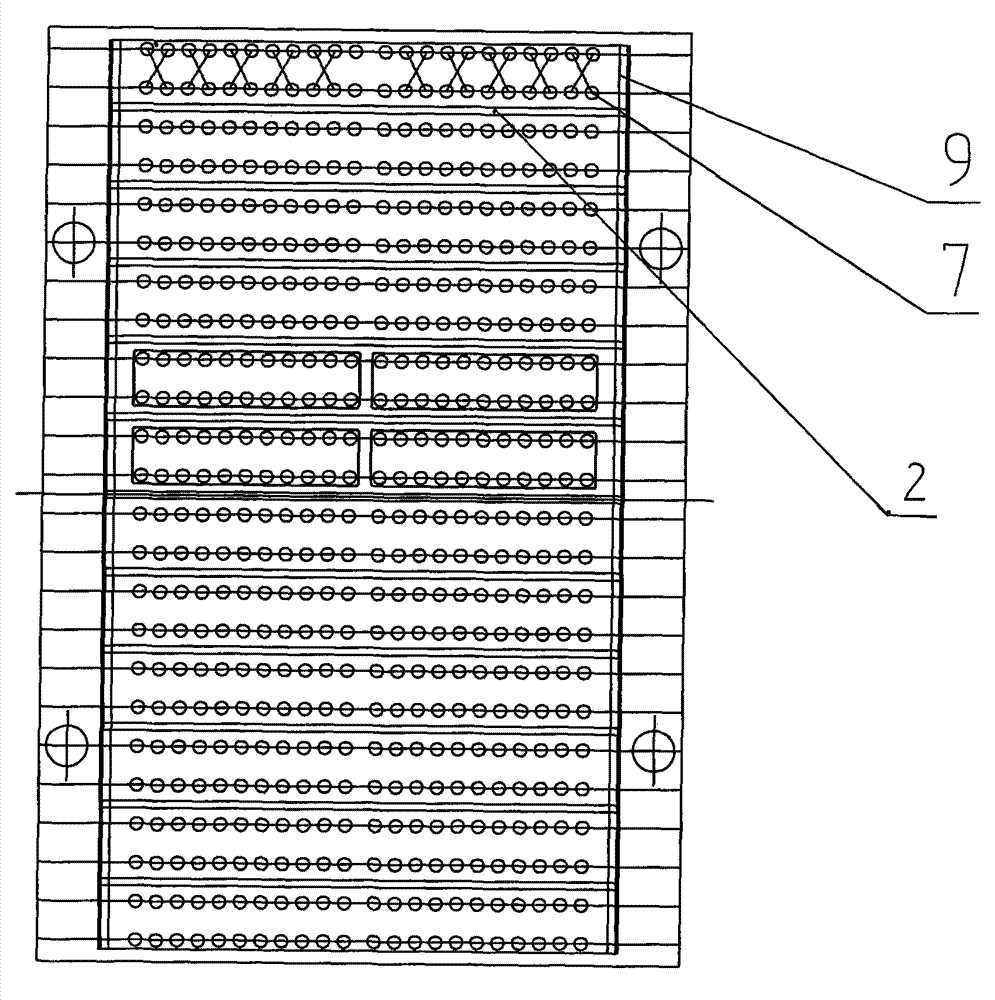

[0025] Such as figure 1 As shown, the electric filter compound two-phase dust collector provided by the present invention includes: several electric fields arranged in sequence from the air inlet 1 to the air outlet 4 are arranged in the dust collector housing 5, and electric fields are set between adjacent electric fields channel; the air inlet 1 in the middle of the dust collector is provided with an air distribution plate, the air outlet 4 is located above the other side of the body, and each electric field at the bottom of the shell is equipped with an ash hopper 3; each electric field consists of several The discharge electrode row 2 composed of cathode wires and the dust collection anode row are composed. The discharge electrode row and the anode row are arranged in a staggered manner. The discharge electrode row 2 is hung on the top beam 10 of the dust collector through the cathode hanging device; the discharge electrode row and the anode row They are respectively conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com