Filter plate type electrostatic precipitator

An electrostatic precipitator and precipitator technology, applied in the direction of electrostatic separation, electrode structure, electrode cleaning, etc., can solve the problems of easy damage of filter bags, high operating costs, and inability to apply high temperature and high corrosion, so as to improve collection speed and efficiency, Increased dust removal efficiency and increased collection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

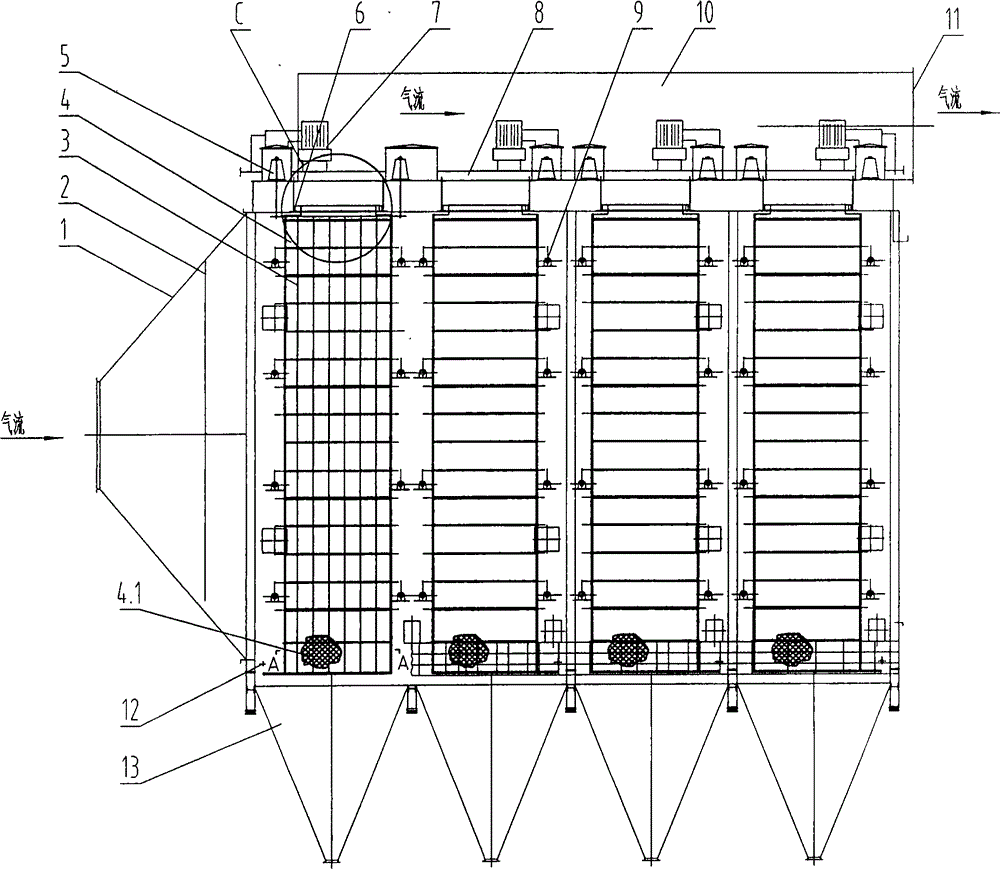

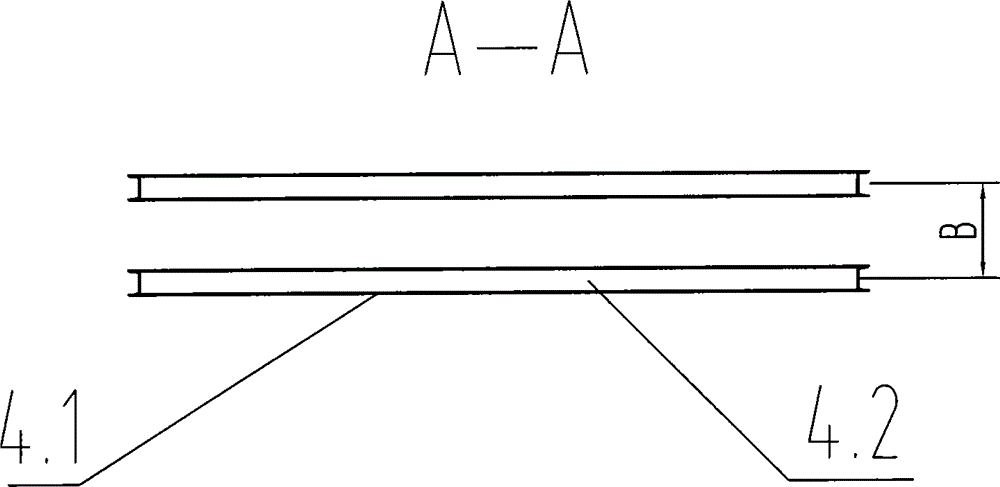

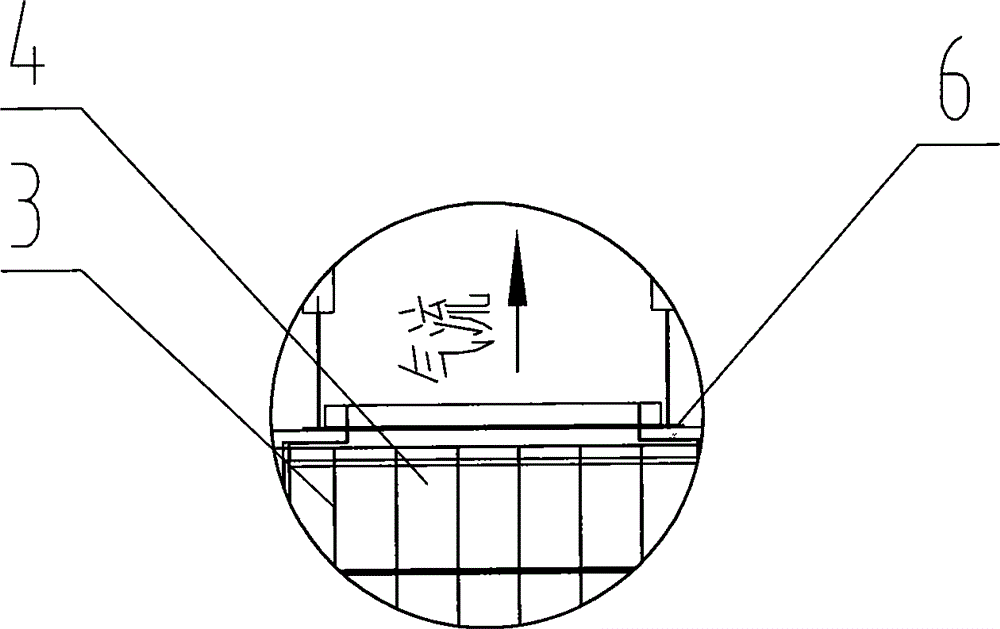

[0025] like figure 1 As shown, the filter plate type electrostatic precipitator provided by the present invention includes the following components and structures: in the dust collector housing 8, several electric fields arranged in sequence from the air inlet 1 to the air outlet 11 are arranged, and between adjacent electric fields The electric field channel is set; the air inlet 1 located in the middle of the dust collector is provided with an air flow distribution plate 2, and the air outlet 11 is arranged above the other side of the body; each electric field is composed of a discharge electrode row 3 composed of a number of parallel cathode lines and a dust collector. Composed of anode rows, the discharge electrode row and the anode row are staggered and respectively connected to the high-voltage power supply of the transformer 7 to provide high-voltage static electricity (V=72,000 volts to 100,000 volts) for the electric field; the discharge electrode row 3 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com