Powder recycling pipe device of metal 3D printing equipment

A 3D printing and piping device technology, applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., can solve the problems of reduced working efficiency of metal 3D printing equipment, and achieve the effect of simple structure, improved stability, and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

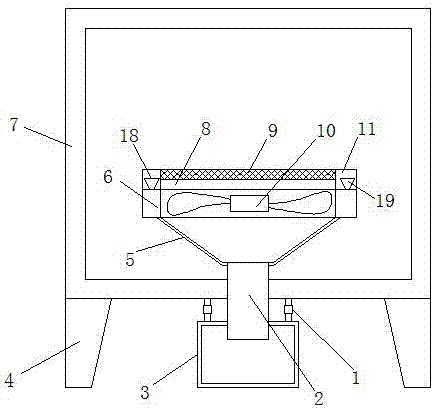

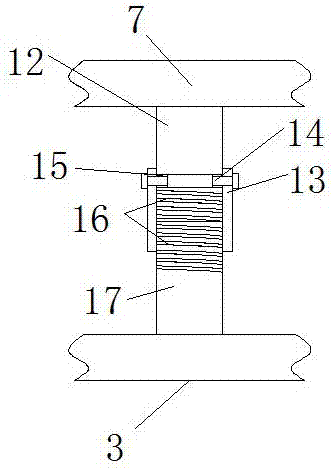

[0015] refer to Figure 1-2 , a metal 3D printing equipment powder return pipeline device, including a 3D printing equipment shell 7 and a workbench 11 inside the shell 7, a plurality of support legs 4 are installed on the bottom of the shell 7, and the support legs 4 are provided with at least four and arranged in a symmetrical manner along the bottom of the housing 7, not only makes the metal 3D printing equipment and the horizontal plane have a certain height, but also facilitates the placement of the powder bucket 3, and the upper surface of the workbench 11 is provided with an opening 8, and the inside of the opening 8 is provided with a steel wire m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com