Agricultural greenhouse planting automatic irrigation device

An automatic irrigation and greenhouse technology, applied in agriculture, water supply devices, fertilization devices, etc., can solve problems such as difficulty in using rainwater, achieve the effects of accelerating collection speed, increasing spraying range, and improving irrigation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

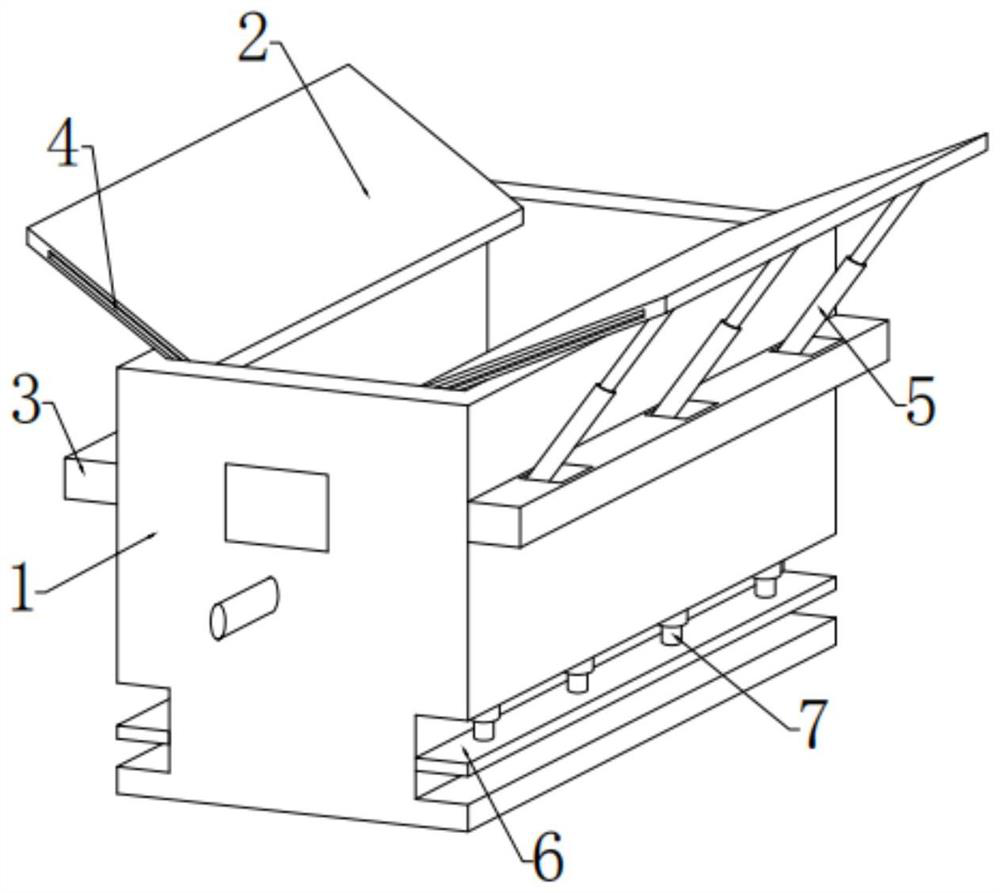

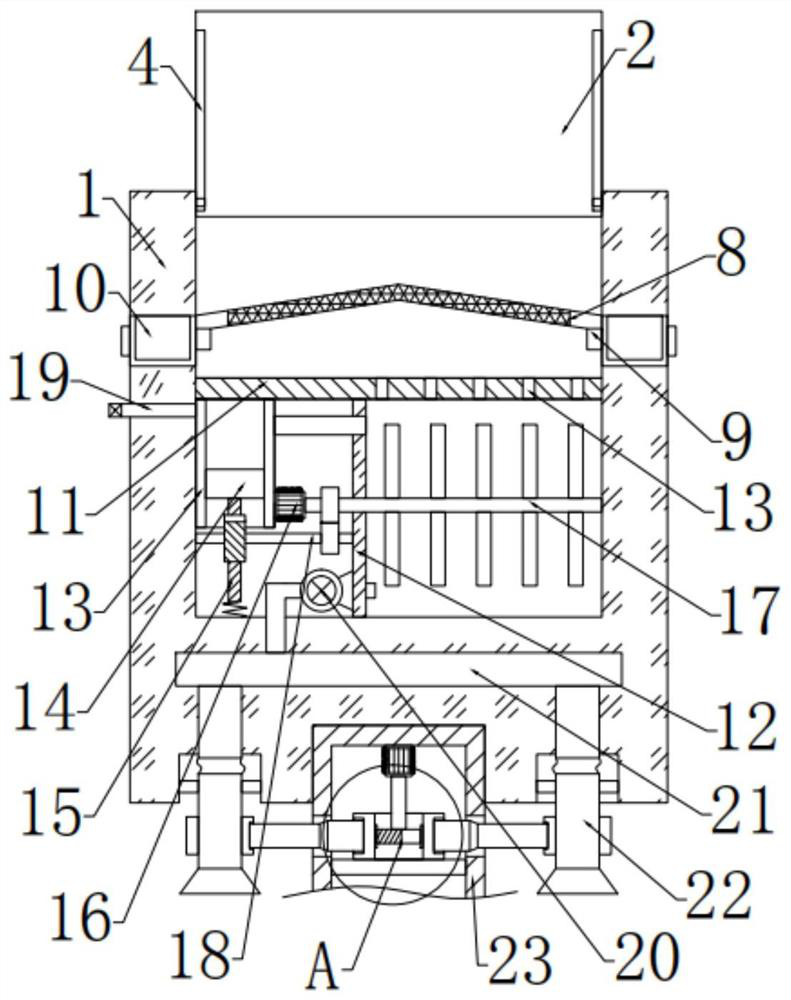

[0026] see Figure 1-3 , in an embodiment of the present invention, an automatic irrigation device for planting in agricultural greenhouses, comprising a housing 1, the bottom of the housing 1 is threadedly provided with a support rod 23, and the inner top of the housing 1 is provided with a rainwater collection mechanism. The output end of the rainwater collection mechanism is connected to the spray mechanism arranged at the bottom of the casing 1, and the left and right sides of the casing 1 are provided with connecting mechanisms for fixing the film.

Embodiment 2

[0028] In this embodiment, the rainwater collection mechanism includes a partition 11 fixedly connected to the inside of the casing 1, and a fixed plate 12 is fixedly connected between the bottom end of the partition 11 and the casing 1. The fixed plate 12 The rear side is provided with a water storage tank, the partition plate 11 is located inside the upper part of the water storage tank and is provided with several filter holes, and the front side of the fixed plate 12 is provided with a nutrient solution adding mechanism, and the rainwater can be collected by setting a rainwater collection mechanism and storage, and use the collected rainwater for crop irrigation, which is more environmentally friendly.

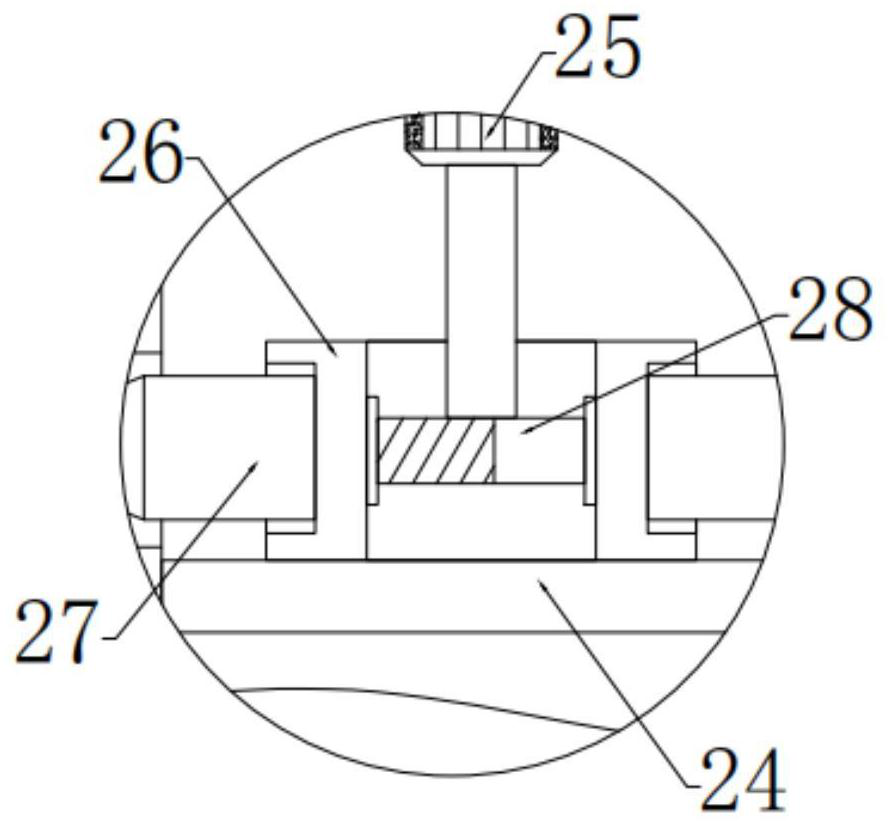

[0029] In this embodiment, the nutrient solution adding mechanism includes a nutrient solution tank 13 fixedly connected to the bottom of the partition 11, the outer side of the nutrient solution tank 13 is bolt-connected and provided with a first motor 16, and the output e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com