Traditional Chinese medicine pill making machine

A technology of pill making machine and traditional Chinese medicine, which is applied in the direction of making medicines into special physical or ingestible devices, etc., which can solve the problems of low equipment precision, inflexible production methods, and high scrap rate, and achieve low equipment operating costs and high production efficiency. Flexible method, good pellet quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

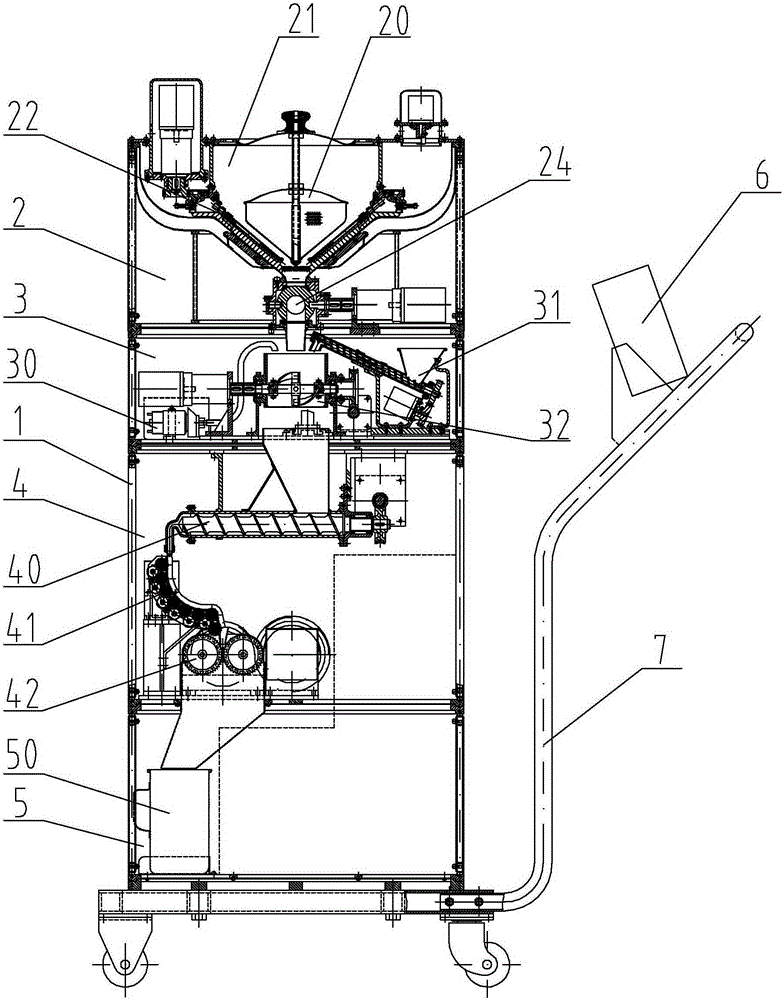

[0041] combine figure 1 As shown, the traditional Chinese medicine pill making machine disclosed in this embodiment includes a frame 1, and the interior of the frame 1 is sequentially provided with a decoction area 2, a stirring area 3, a pill rubbing area 4, a finished product collection area 5, and the frame 1 is equipped with an electric control unit 6; the tormenting area 2, the stirring area 3, the pill rubbing area 4, and the finished product collection area 5 can be controlled by the electric control unit 6;

[0042]The decoction area 2 is provided with a main material feeding mechanism 20, a decoction chamber 21, a material scraping mechanism 22, and a valve mechanism 24. The main material feeding mechanism 20 can be movably arranged inside and outside the decoction chamber 21, and the scraping mechanism 22 can decompose The boiled main material extract in the chamber 21 is scraped off, and the valve mechanism 24 is used to send the main material extract into the stirr...

Embodiment 2

[0065] Such as Figure 5 As shown, in combination with the first embodiment above, more preferably, the main material feeding mechanism 20 in this embodiment includes a hopper 201, a hopper cover 202, and the hopper 201 is used to hold the main material of traditional Chinese medicine to be pelletized, and the hopper cover The edge of 202 is provided with arc-shaped flanging, which is used for clamping with the edge of the hopper 201, so that after the hopper cover 202 and the hopper 201 are closed, it has a better sealing effect; if it is necessary to separate the hopper cover 202 from the hopper 201 , the hopper 201 can be separated by pulling with a certain force manually.

[0066] A through hole 203 is provided on the side wall of the hopper 201. The setting of the through hole 203 can facilitate the boiling of the main ingredients in the hopper 201, which saves the trouble of filtering waste residue in the traditional boiling process.

[0067] The hopper 201 and the hopp...

Embodiment 3

[0074] Such as Image 6As shown, in combination with the first embodiment above, more preferably, a stirring shaft 321 passes through the stirring chamber 32 in this embodiment, and a stirring blade 322 is installed on the stirring shaft 321, and the stirring shaft 321 passes through two symmetrically arranged bearings 323 They are respectively installed on two symmetrically arranged third brackets 324, and a bearing sleeve 325 and a copper sleeve 326 are installed in sequence between the bearing 323 and the third bracket 324. The bearing sleeve 325 is fixedly connected with the mixing chamber 32, and the bearing sleeve 325 One side is also fixedly connected with the turbine 327, the turbine 327 is driven by the fourth motor 328 through the worm screw 329, the rotation of the turbine 327 can drive the bearing sleeve 325, the stirring chamber 32 fixedly connected with the bearing sleeve 325 is turned over, and the stirred Mixture; also includes a fifth motor 330 for driving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com