Patents

Literature

79results about How to "Flexible production methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Milky tea powder and preparing method thereof

InactiveCN101248818AAbundant resourcesLow costMilk preparationPre-extraction tea treatmentBrickPlate heat exchanger

The invention discloses milk-tea powder as well as a preparation method thereof, which is prepared by fresh milk, white sugar, non-dairy creamer, green brick tea, and solid essence powder according to a certain proportion. The preparation method comprises the following steps: A. comminution: the brick tea is comminuted into superfine tea powder; B. mixture: a proper amount of the fresh milk is taken and heated by a plate heat exchanger, via a water-powder mixer, the tea powder, the white sugar, the non-dairy creamer, and the solid essence powder are added and stirred circularly, and the rest raw milk is added; C. sterilization; D. concentration: the material is sterilized and concentrated by a double effect falling film vacuum evaporator to obtain the concentrated material; E. spray drying: the concentrated material is sprayed and dried by a high pressure pump; F. redrying by a fluidized bed to obtain the milk-tea powder. The milk-tea powder has reasonable formula, convenient drinking, easy method and simple technique, thereby minimizing the energy consumption in the milk-tea processing technique, shortening the productive time with enhanced stability of the milk-tea quality, and increasing the utility ratio of the tea in the milk-tea manufacturing process without waste and pollution.

Owner:NEW HOPE DAIRY HLDG

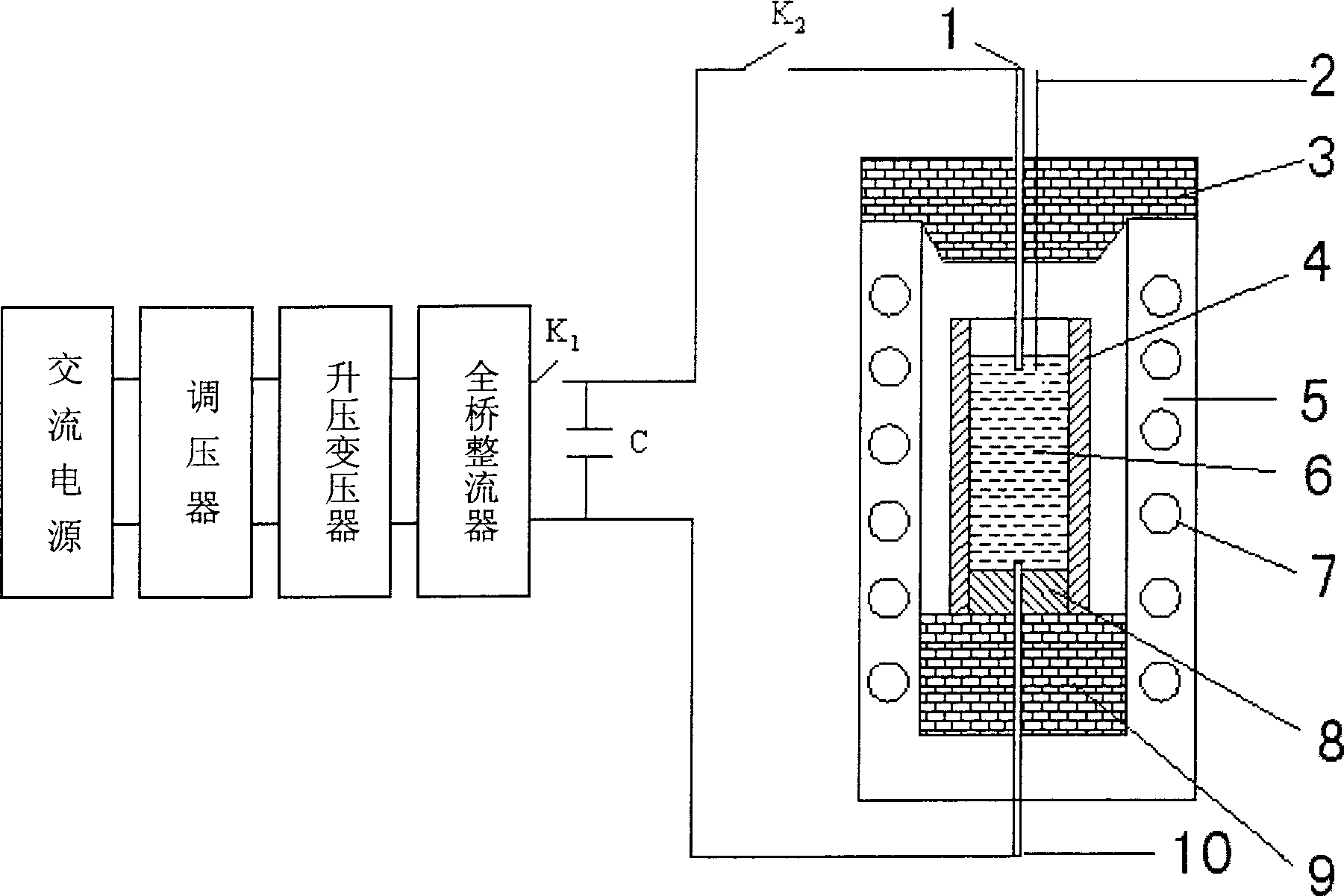

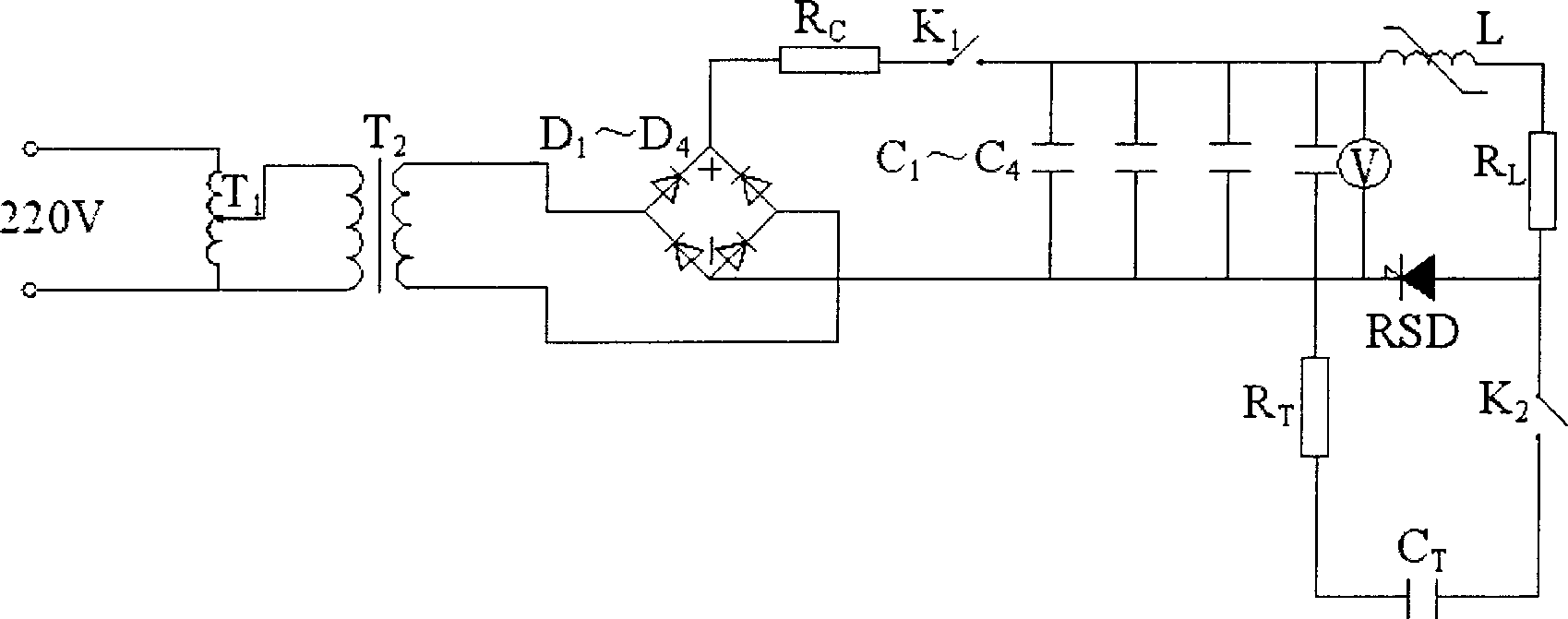

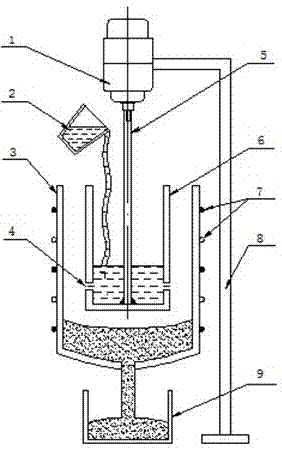

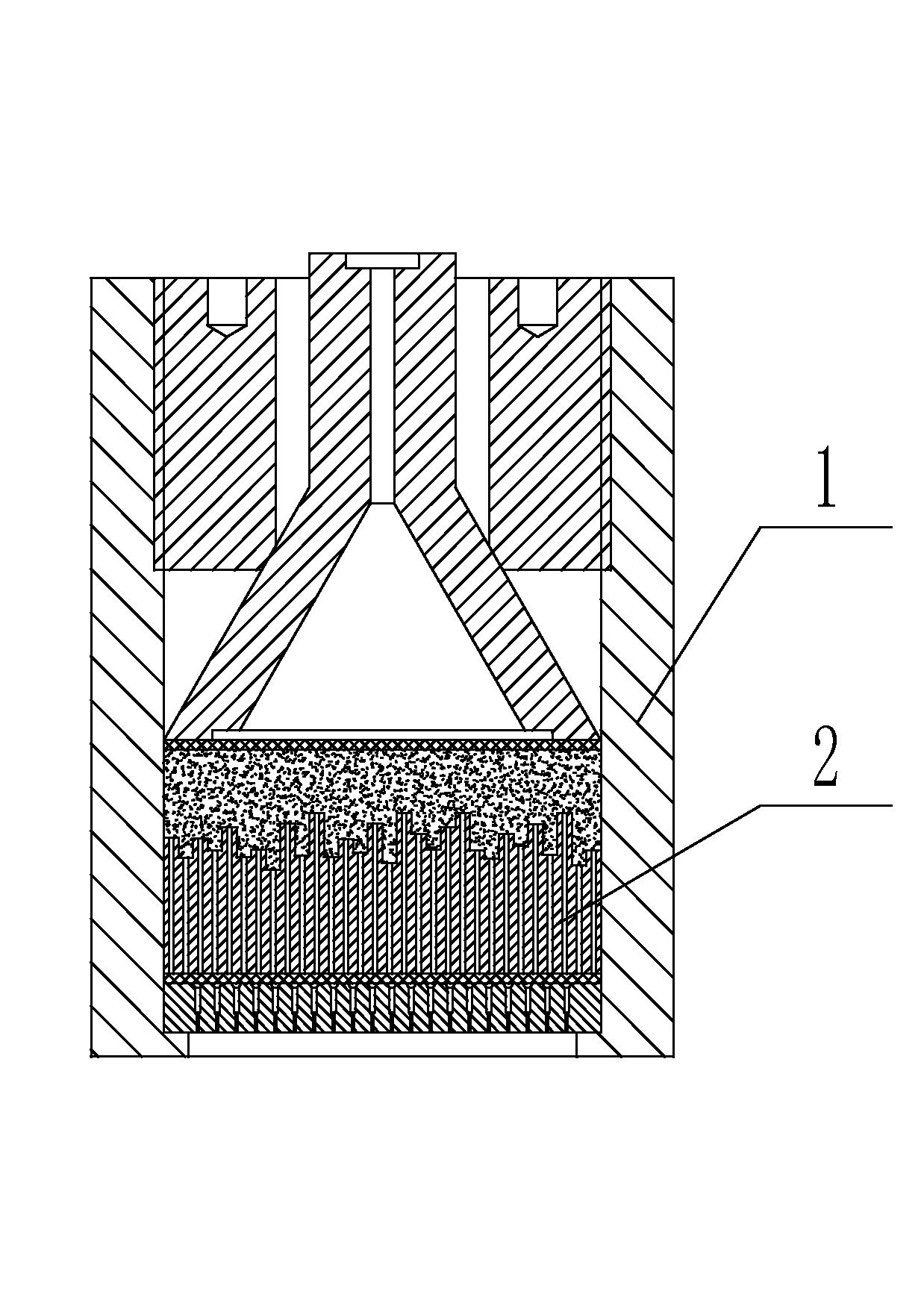

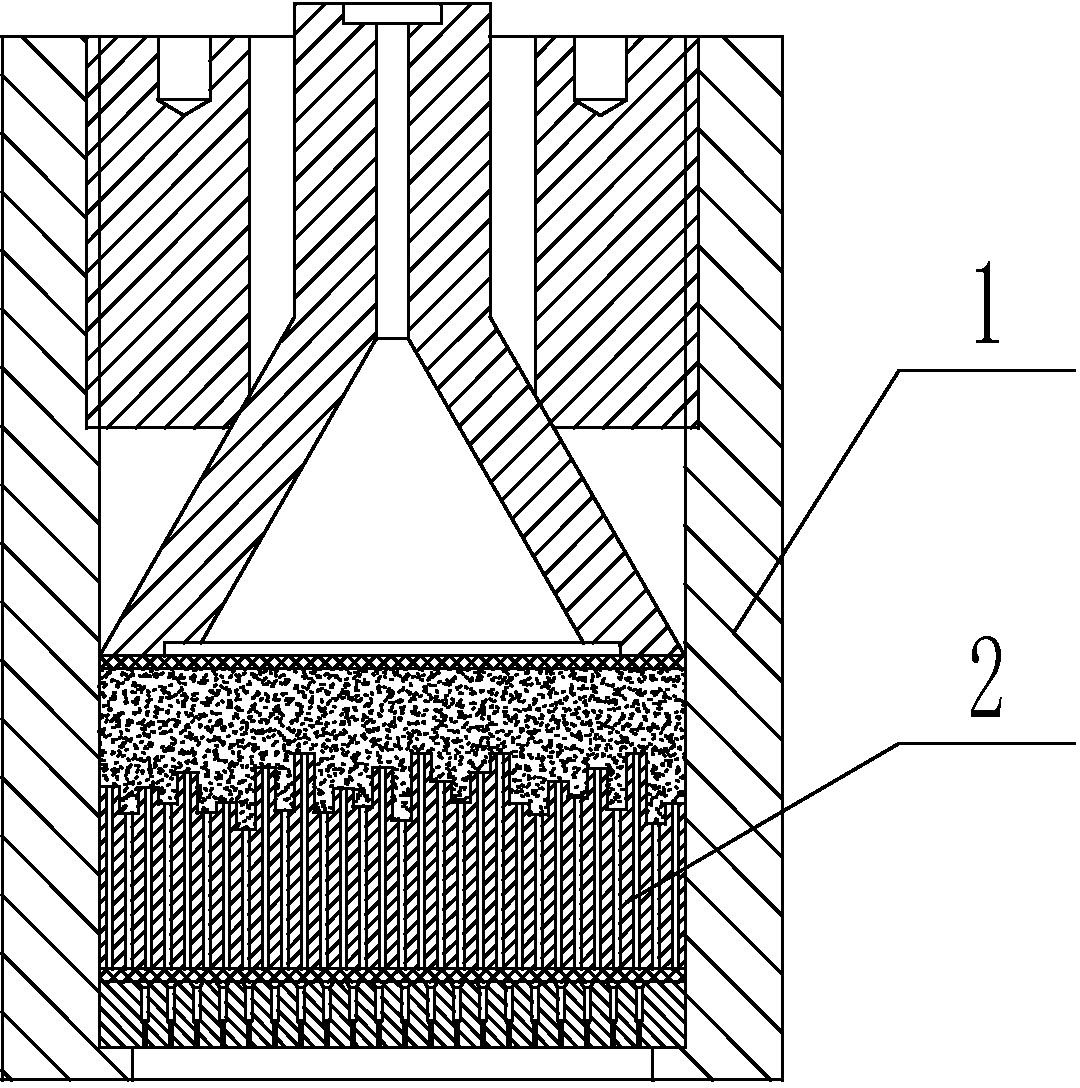

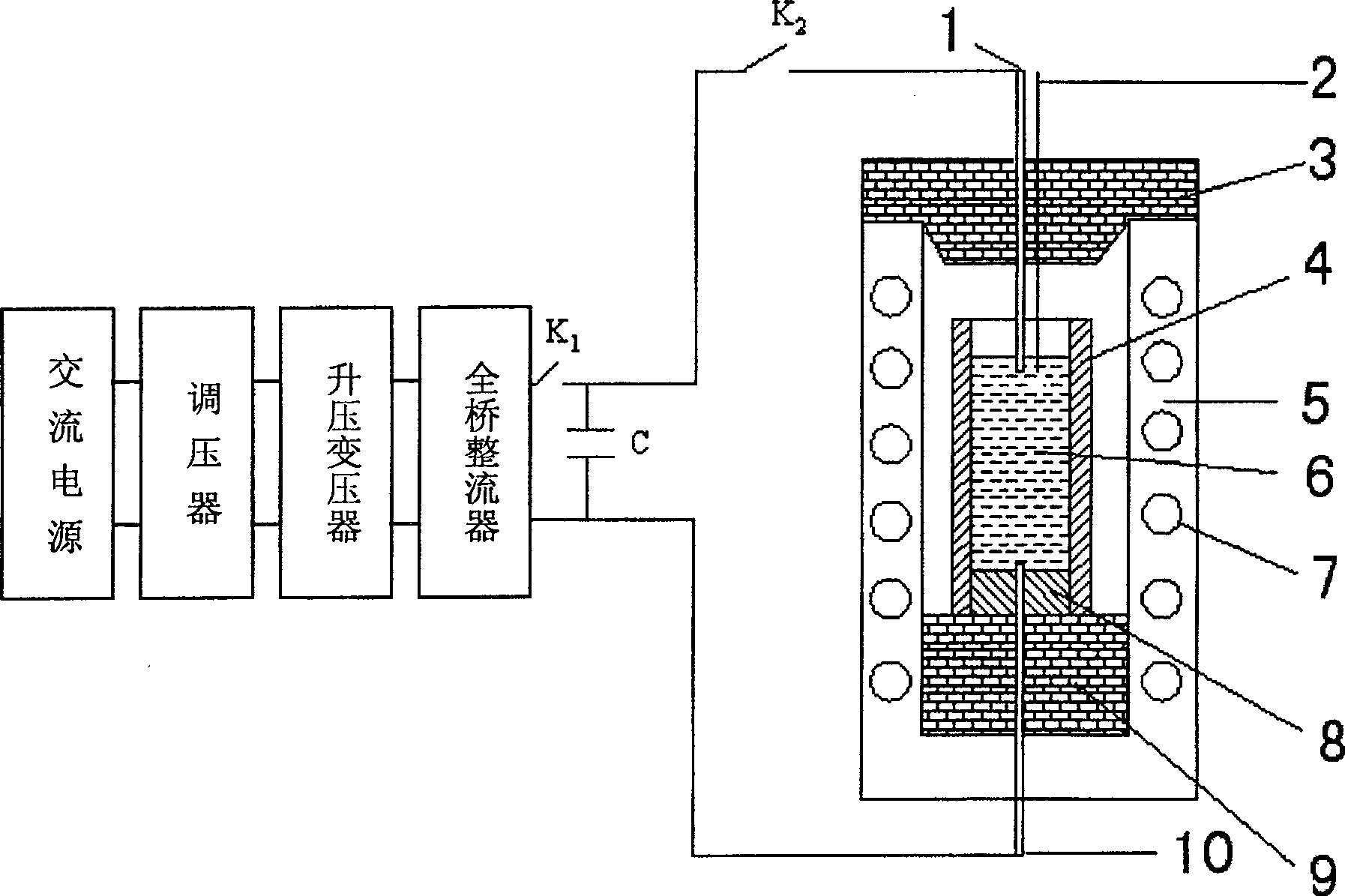

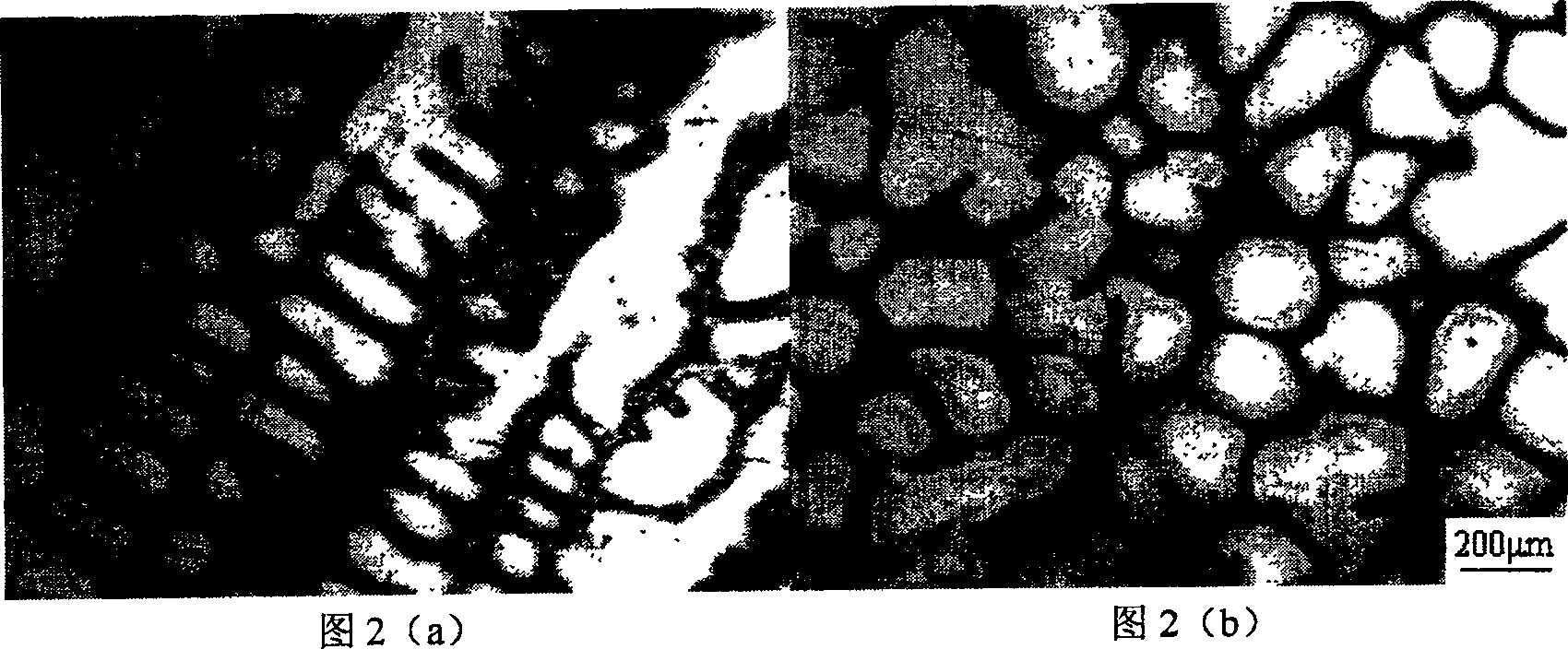

Production and special apparatus for low-voltage pulse electric field of non tree-like-crystal and semi-solid alloy

A process for preparing the non-dendritic semi-solid alloy by low-voltage pulse electric field includes such steps as smelting alloy in crucible, holding its temp, connecting the positive and negative outputs of a pulse power supply respectively to both end of molten alloy, applying a pulse electric field to the molten alloy, and solidifying. Its apparatus is composed of pulse electric field generator, pulse electric field applicator, and heating-insulating unit.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

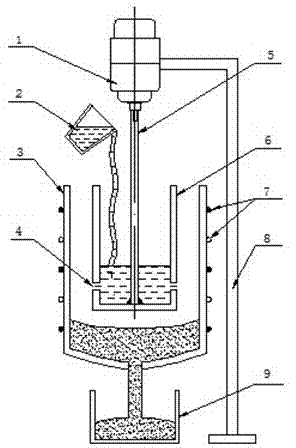

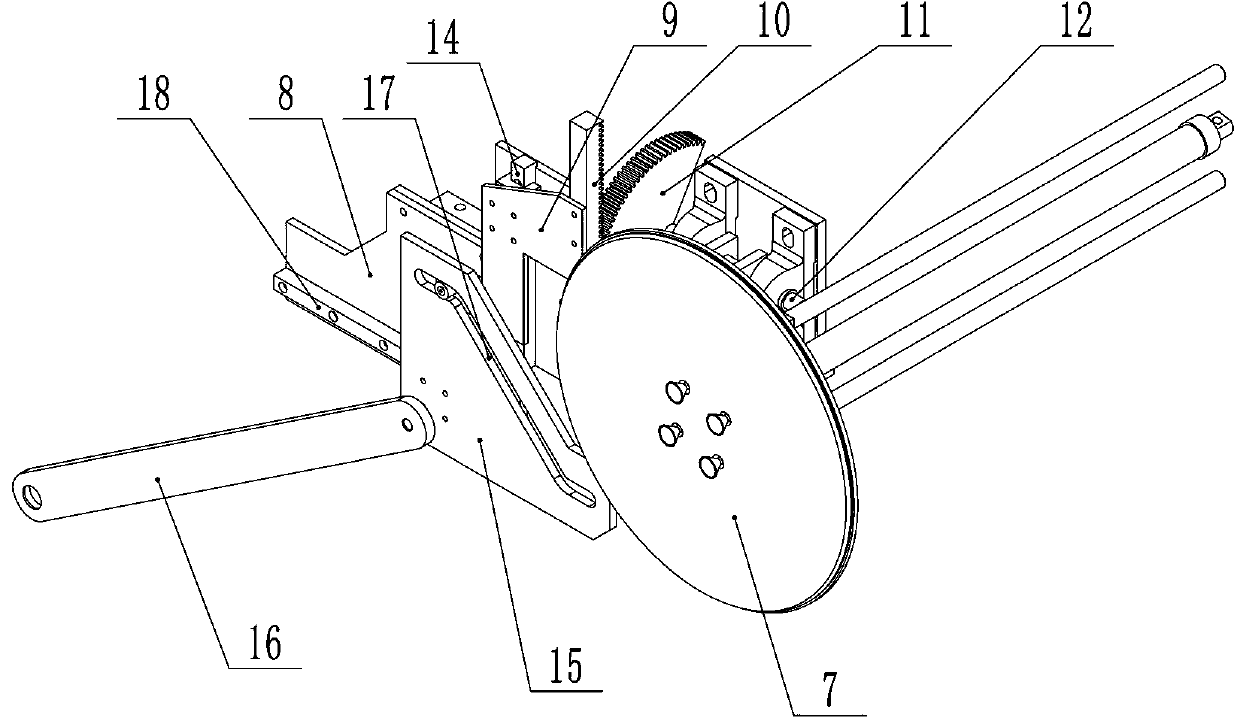

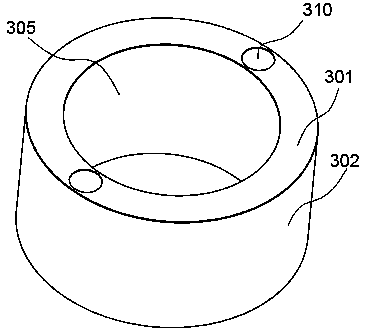

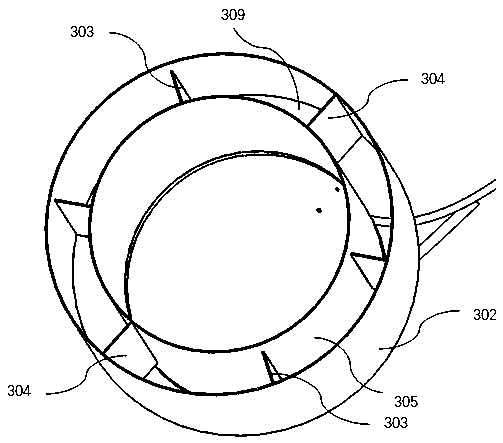

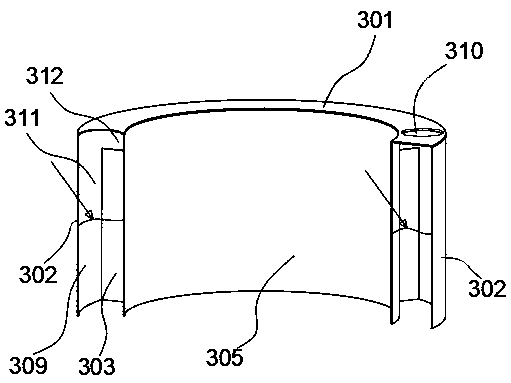

Method for preparing semisolid alloy through centrifuging and chilling

The invention relates to a semisolid alloy preparation method, in particular a method for preparing a spherical primary crystal semisolid alloy through centrifuging and chilling. The method comprises the following steps of: first, melting the alloy to a certain temperature; and then pouring the melt in a centrifugal barrel; throwing the melt to the inner wall of a chilling barrel after rotating the melt through centrifugal force; carrying out mixed convection on the melt in the centrifugal barrel under the double effects of centrifugal force and chilling force; and finally, obtaining a non-dendritic semisolid alloy blank or slurry with spherical or granular primary phase under the mutual effect of numerous nucleation and dendrite breaking of the outer barrel. The method for preparing the spherical primary crystal semisolid alloy through centrifuging and chilling, provided by the invention, has the characteristics of simple equipment, high production efficiency, wide application range of alloy, fine and rounded primary phase with semi-solid structure and the like, and can be used for the preparation and molding production of the metal semisolid alloy.

Owner:NANCHANG HANGKONG UNIVERSITY

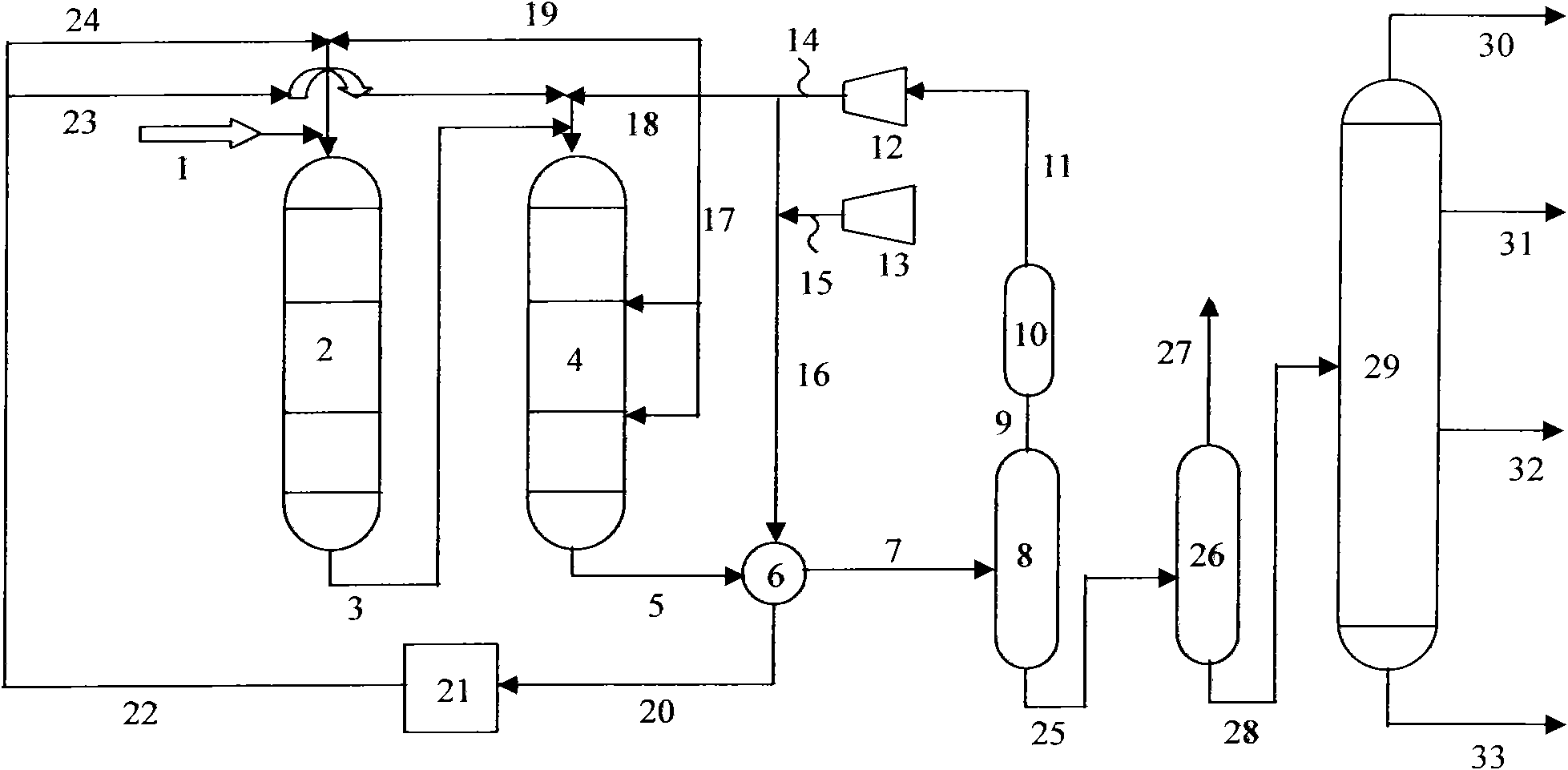

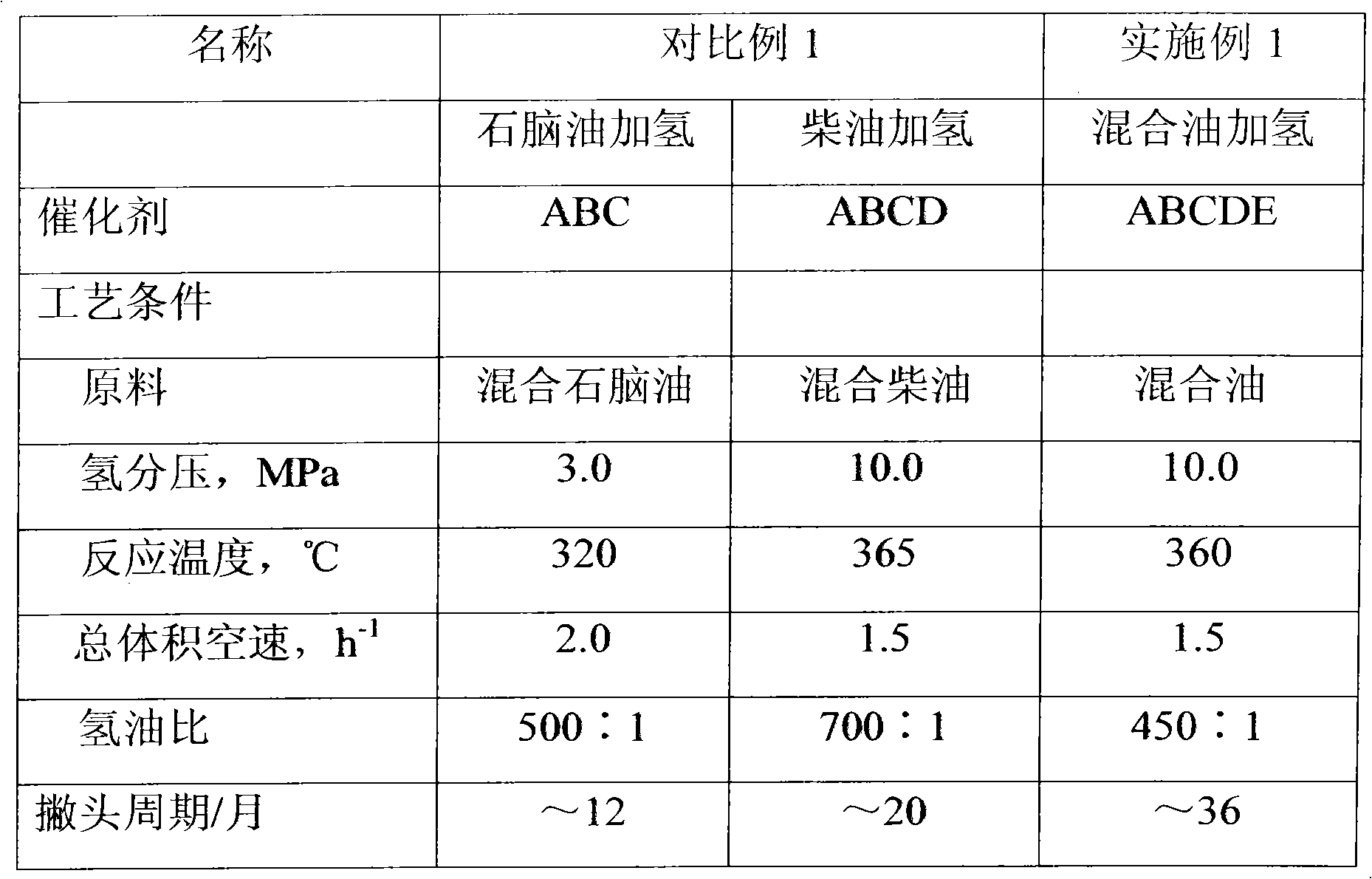

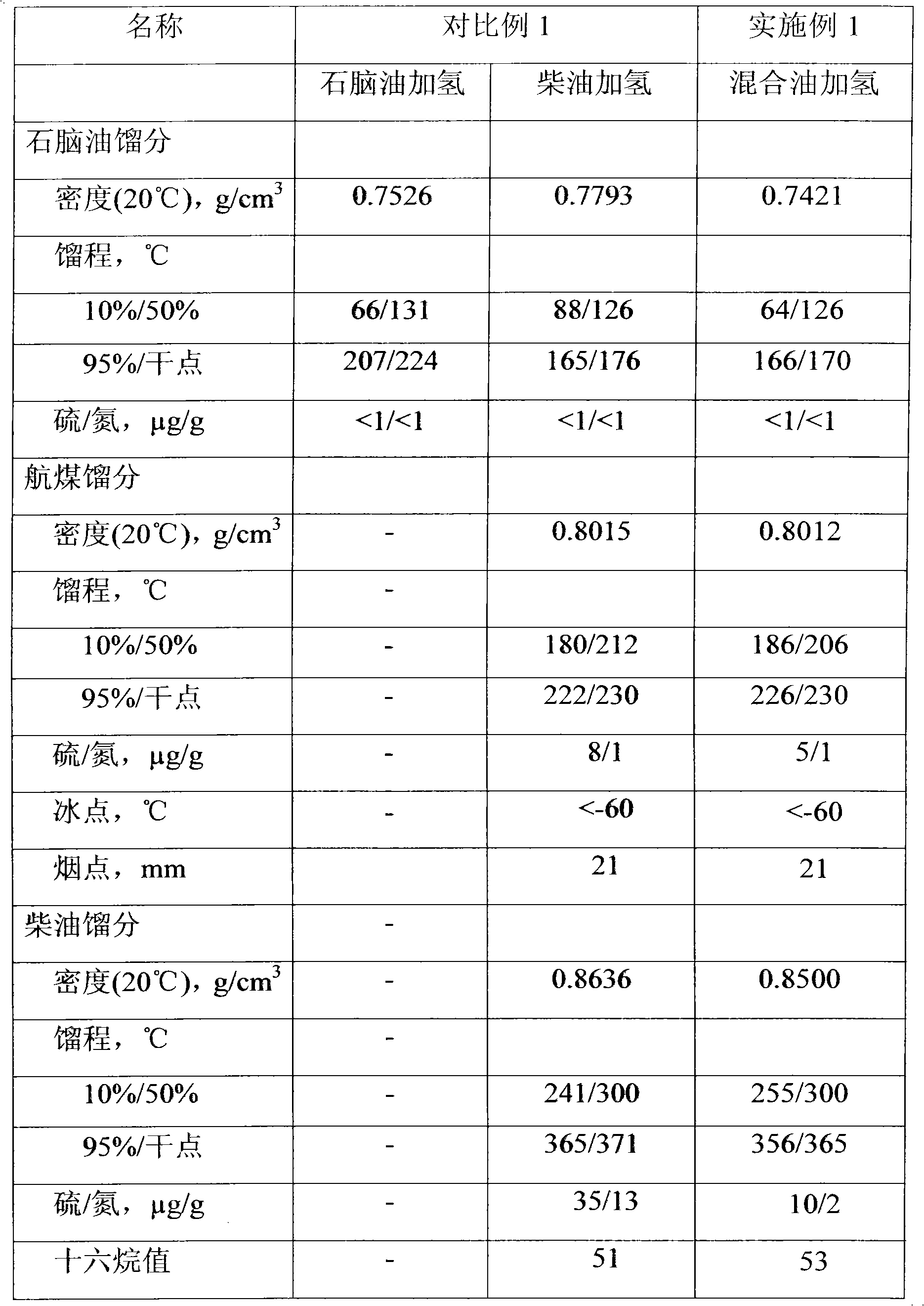

Hydrogenation modification method for coking gasoline and diesel distillates

ActiveCN102465023AAvoid Coking ProblemsFlexible production operationsTreatment with hydrotreatment processesChemistryKerosene

The invention discloses a hydrogenation modification method for coking gasoline and diesel distillates. A coking gasoline and diesel raw material is mixed with heated hydrogen and then introduced to pass through a low-temperature hydrorefining reactor and a hydrogenation modification reactor in sequence; a reaction effluent is separated and modified, and obtained liquid is distilled to obtain gas, gasoline, kerosene and diesel. In the method disclosed by the invention, a process flow of mixing hydrogen behind a furnace is adopted, the heating furnace is only used for heating the hydrogen, the mixed raw material does not pass through the heating furnace, and the temperature of the reactor is controlled based on the quantities of hot hydrogen and cold hydrogen. Compared with the prior art, the hydrogenation modification method disclosed by the invention has the advantage of saving equipment investment and being flexible in production scheme, can be used for flexible production by adjusting process conditions and production distribution according to the differences of raw material properties and product schemes; by implementation of hydrogen mixing behind the furnace, the coking raw material can be effectively prevented from being coked at a furnace tube; and by arrangement of a low-temperature protective agent reactor, olefin saturation is performed at lower temperature so as to reduce coking, meanwhile, coke powder is distributed at a protective agent bed as uniform as possible, so that the long-term operation of a hydrogenation device is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

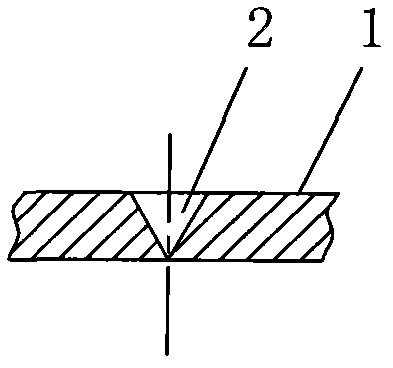

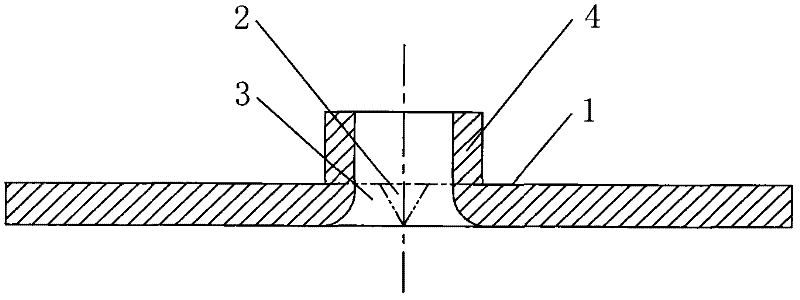

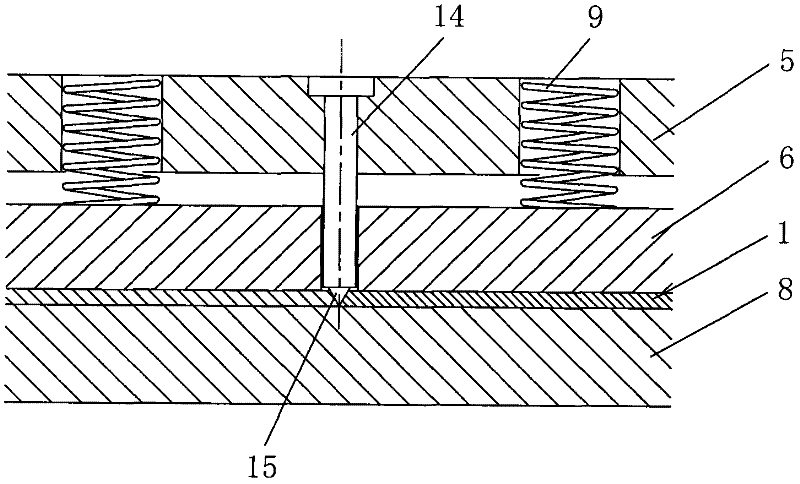

Hole flanging method and die for forming high flange on thin plate

The invention discloses a hole flanging method and dies for forming a high flange on a thin plate. The hole flanging method comprises the following steps of: extruding a taper hole, flanging the hole reversely and setting molding, namely extruding the taper hole which does not pierce a sheet metal, flanging the taper hole reversely, and drawing to form a high flange which is subjected to the hole flanging. According to the dies for forming the high flange on the thin plate, hole prepressing and hole flanging can be performed by using two sets of dies, and disposable hole prepressing and hole flanging also can be performed by using a set of dies. According to the hole flanging method and the dies, scrap materials are avoided, the height of the flange formed by the hole flanging is high, and the extruded taper hole can prevent materials from cracking during post-hole flanging, so that a pointed sharp corner is not formed at the margin of the flange which is subjected to the hole flanging, and potential safety hazards are avoided; a production mode is flexible, namely the flange can be formed by two-time hole flanging and also can be formed directly by one-time hole flanging; and the dies for the process have a simple structure, so that the improvement of the machining efficiency is facilitated.

Owner:深圳亿和模具制造有限公司

Production process of grained pyrograph

ActiveCN108608751AReduce manufacturing costIncrease productivityDuplicating/marking methodsPolyesterEngineering

The invention discloses a production process of a grained pyrograph. The process includes the steps of: making a grained carrier; performing drying, and letting silicone rubber generate grains on thesurface of a PET rubber sheet; then applying screen printing waterborne polyurethane ink to the surface layer of the dried carrier, and using a dye blocking agent for screen printing at the back of the pattern to serve as a backing; then conducting screen printing of a transparent waterborne high elastic polyurethane resin layer by a screen printing plate larger by 0.18mm; and conducting drying bya 140DEG C tunnel furnace for about 2min to melt polyester powder and form a bonding layer on the surface. The process provided by the invention can reduce the production cost and improve productionefficiency, also can achieve personalized customization of any grain effect at will without increasing the cost, has no need of making any mold, after transfer printing, the color is bright, the product only needs 1-2min of drying every time in the production process, and the old production process generally needs hours of drying totally and consumes a lot of energy.

Owner:东莞精萃烫画章有限公司

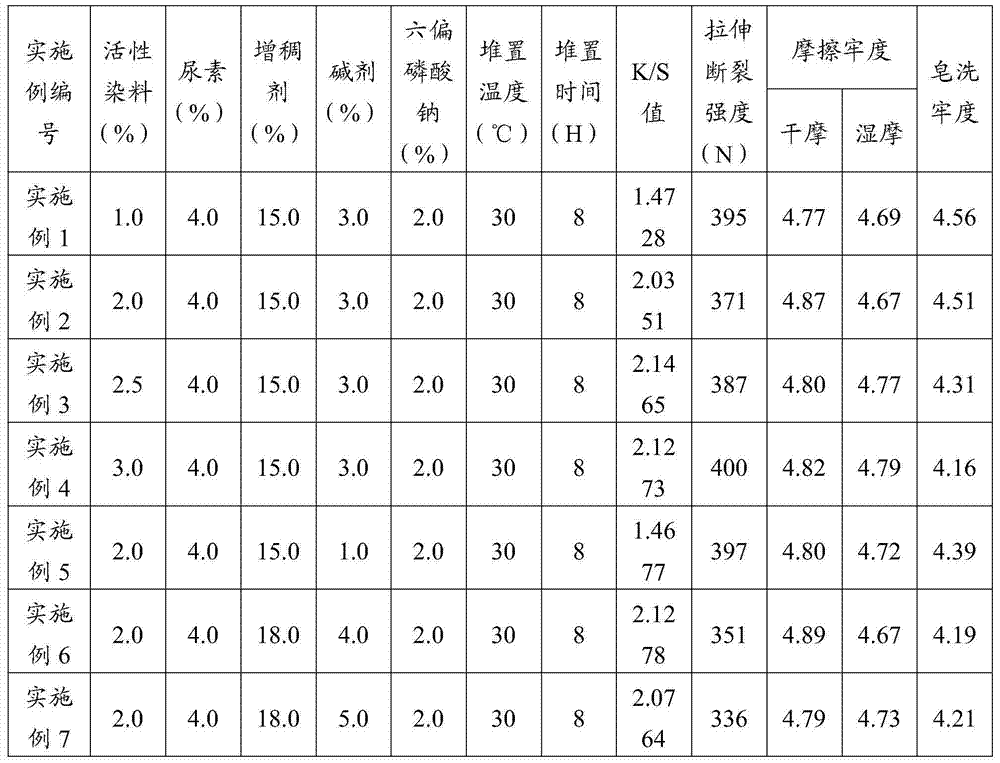

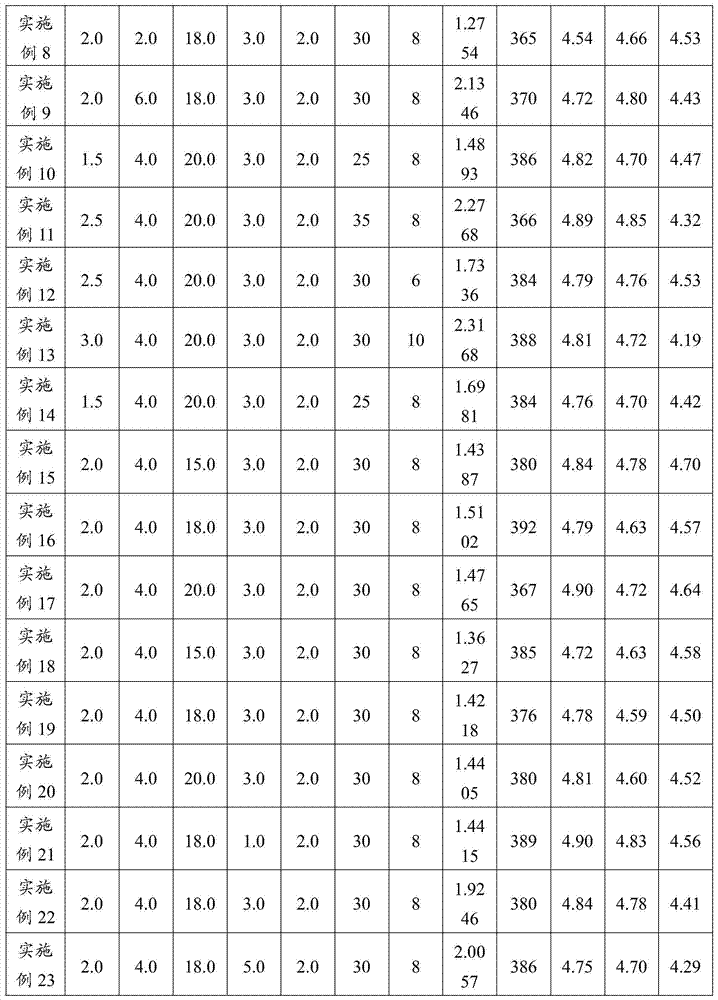

Piling and printing method of cotton fabric by reactive dye

The invention discloses a piling and printing method of a cotton fabric by a reactive dye. The method comprises the following steps: adding water into 1-3% by weight of the reactive dye, 2-6% by weight of urea, 15-20% by weight of a thicker and 1-5% by weight of an alkaline agent to 100% and preparing a mill base; then, printing the cotton fabric by the mill base; then, piling the printed cotton fabric for 6-10 hours at 25-35 DEG C for fixation; and finally, washing, soaping and washing and airing the fixed cotton fabric. The method disclosed by the invention is low in energy consumption, less in environmental pollution, high in color fastness, uniform in dyeing, simple in process and good in product quality.

Owner:NANTONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF THE PEOPLES REPUBLIC OF CHINA

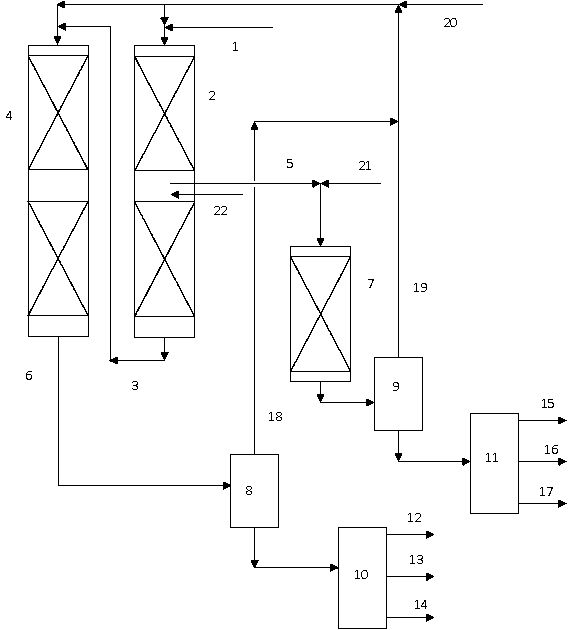

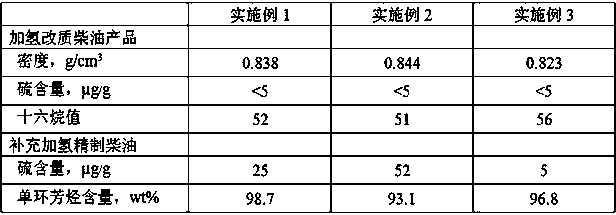

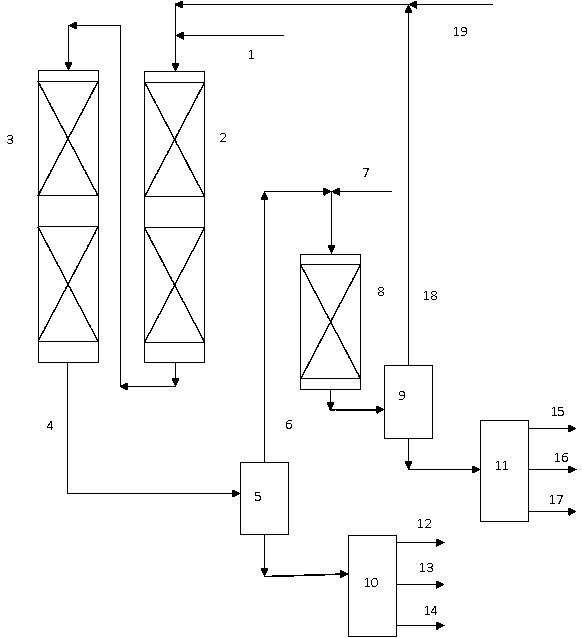

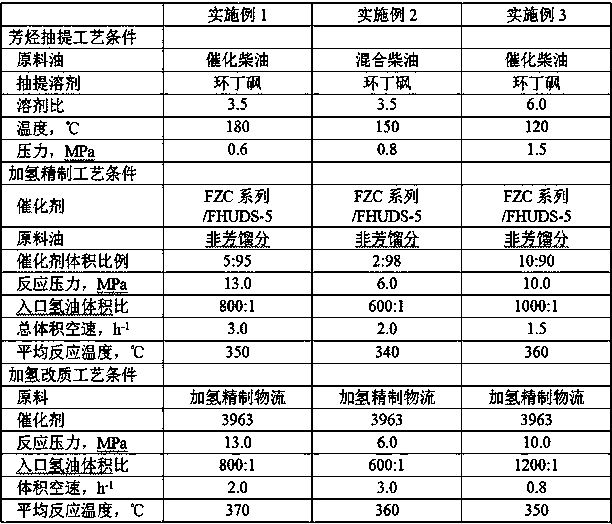

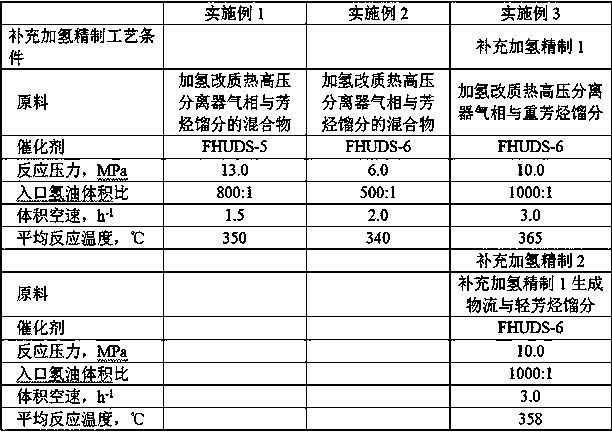

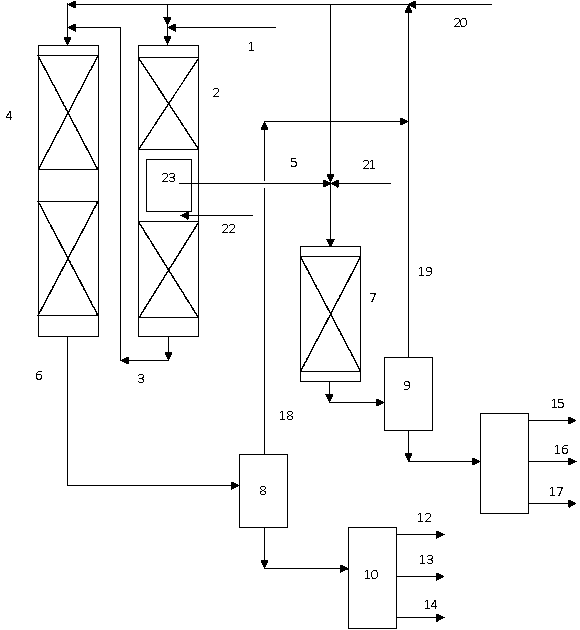

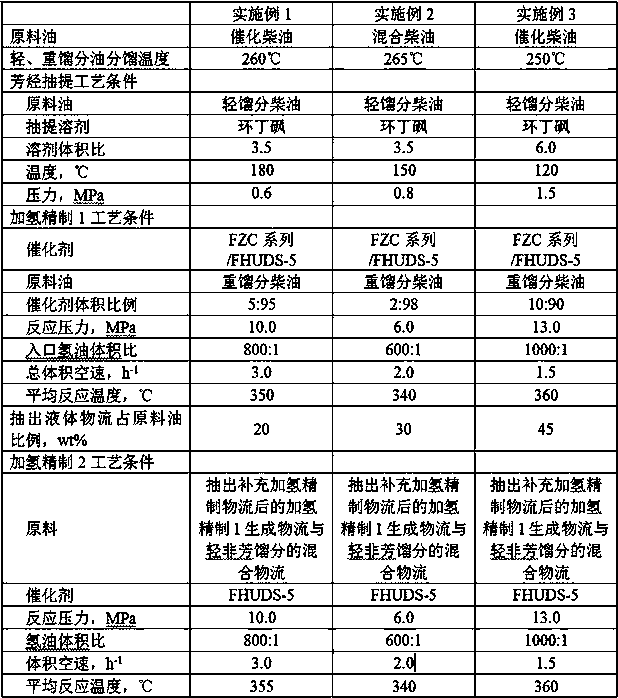

An inferior diesel oil hydro-upgrading and hydrofining combined process

ActiveCN109988645AFlexible production methodsEffective distributionTreatment with hydrotreatment processesHydrocarbon oils treatment productsFractionationHydrogenation process

The invention discloses an inferior diesel oil hydro-upgrading and hydrofining combined process. A diesel oil raw material is firstly fractionated into a light fraction and a heavy fraction; the lightfraction is subjected to aromatic hydrocarbon extraction to obtain a light aromatic hydrocarbon fraction and a light non-aromatic hydrocarbon fraction; the heavy fraction enters a hydrofining reactor, and the material passing through a first hydrofining catalyst bed layer is divided into two streams; one material stream is extracted out of the hydrofining reactor and mixed with the light aromaticfraction, and the mixture enters a hydrofinishing reactor for hydrofinishing reaction; the other material stream is mixed with the light non-aromatic fraction and then flows downwards through a hydrofining catalyst bed layer at the lower part; the hydrofined material flow enters a hydro-upgrading reactor; and an obtained hydro-upgrading reaction material and an obtained hydrofinishing reaction material are respectively subjected to gas-liquid separation and fractionation to obtain high-quality diesel oil products and a high-quality FCC feed material. The invention provides the hydrogenation combined process for simultaneously producing more than two kinds of diesel fractions with different purposes on one set of hydrogenation process equipment for the first time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inferior diesel oil hydro-upgrading and hydrofining combined method

ActiveCN109988650AFlexible production methodsEfficient removalTreatment with hydrotreatment processesGas phaseFractionation

The invention discloses an inferior diesel oil hydro-upgrading and hydrofining combined method. A diesel oil raw material is firstly subjected to aromatic hydrocarbon extraction to obtain an aromatichydrocarbon fraction and a non-aromatic fraction; the non-aromatic fraction enters a hydro-upgrading reaction zone under hydro-upgrading conditions, hydro-upgrading materials passing through a hydro-refining catalyst bed layer and a hydro-upgrading catalyst bed layer enters a hot high-pressure separator for obtaining of a gas phase and a liquid phase, and the liquid phase is subjected to separation and fractionation, so that high-quality naphtha and high-quality diesel oil products are obtained; and the gas phase of the hot high-pressure separator is mixed with the aromatic hydrocarbon fraction, the formed mixture enters a supplementary hydrofining reaction zone under hydrofining process conditions, and a supplementary hydrofining material flow obtained by a hydrofining catalyst bed layeris continuously subjected to gas-liquid separation and fractionation, so that a high-quality FCC feed is obtained. According to the invention, firstly the hydrogenation combined method for simultaneously producing two or more diesel fractions with different meshes by one set of hydrogenation process device is provided, heat carried by a part of hydrogenation modification materials can be fully utilized, and the effective utilization of energy is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

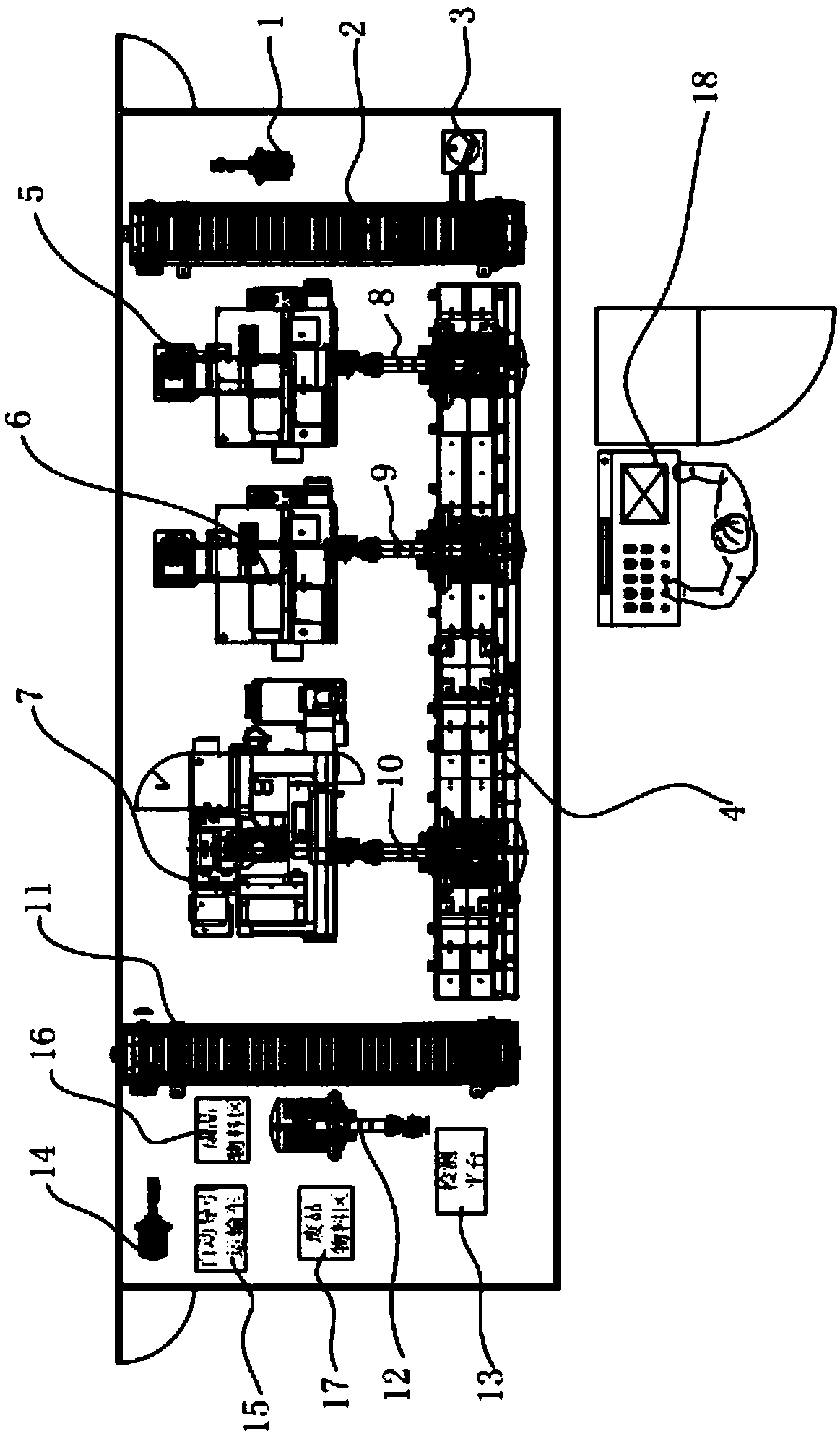

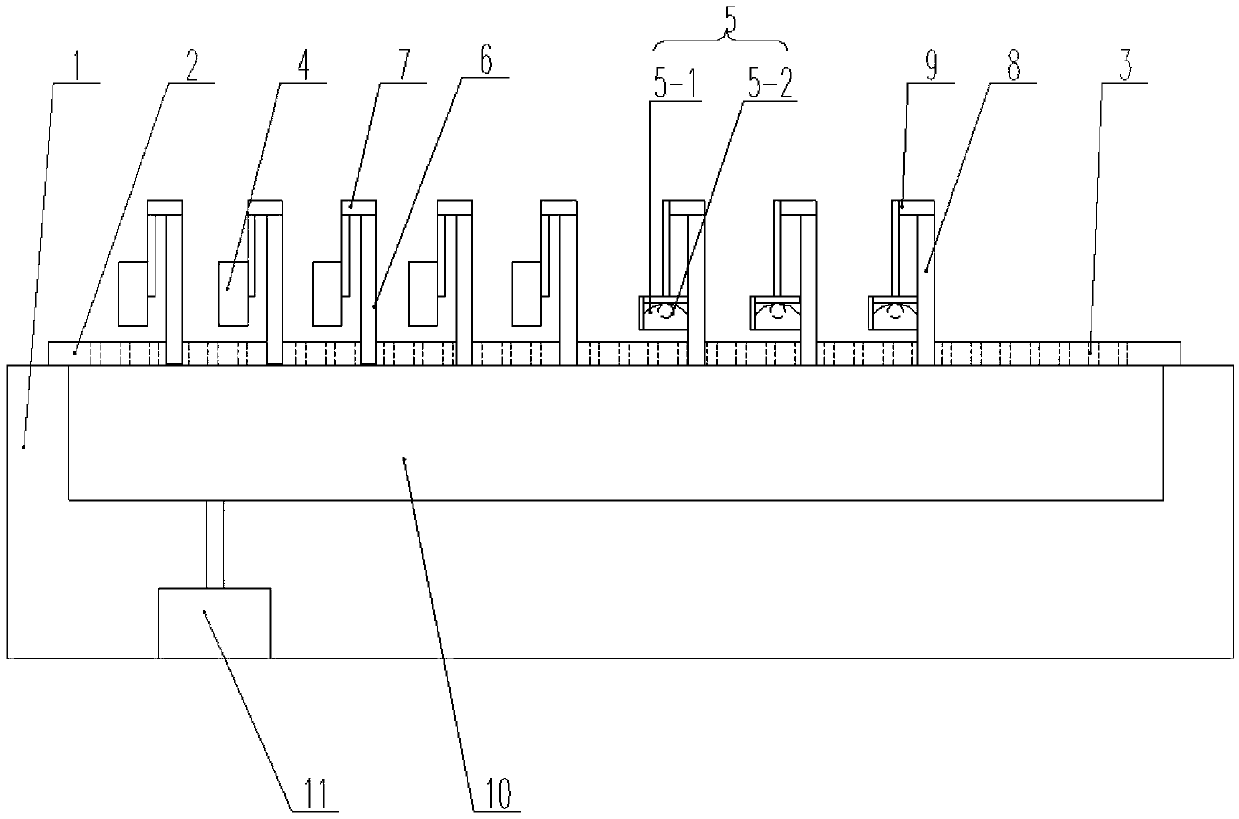

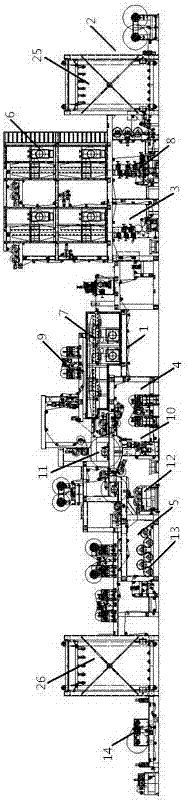

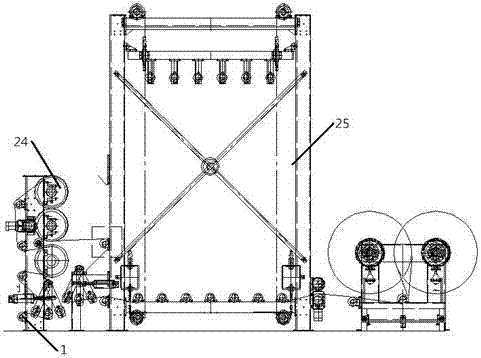

Flexible production line for intelligent manufacturing based on Internet of Things and production method thereof

InactiveCN107589731AFlexible production methodsImprove learning effectElectric/hybrid propulsionTotal factory controlElectricityIntelligent design

The invention aims to provide a flexible production line for intelligent manufacturing based on Internet of Things and a production method thereof. The flexible production line is used for solving thetechnical problems of intelligent and flexible manufacturing products and achieving the effect meeting the teaching requirement. The flexible production line comprises a master control chamber and aprocessing manufacturing subsystem, a processing post-processing subsystem, a part measuring subsystem and a loading subsystem which are electrically connected with the master control chamber. The invention has the beneficial effects that the product design is reasonable, a production period is short, the product yield is high and the increasing of the production efficiency is benefited through intelligent design and production; the customization is performed according to the client requirement; the production mode of the production line is flexible; the intelligent flexible production is performed; the excellent learning effect of the student is achieved.

Owner:WEIHAI OCEAN VOCATIONAL COLLEGE

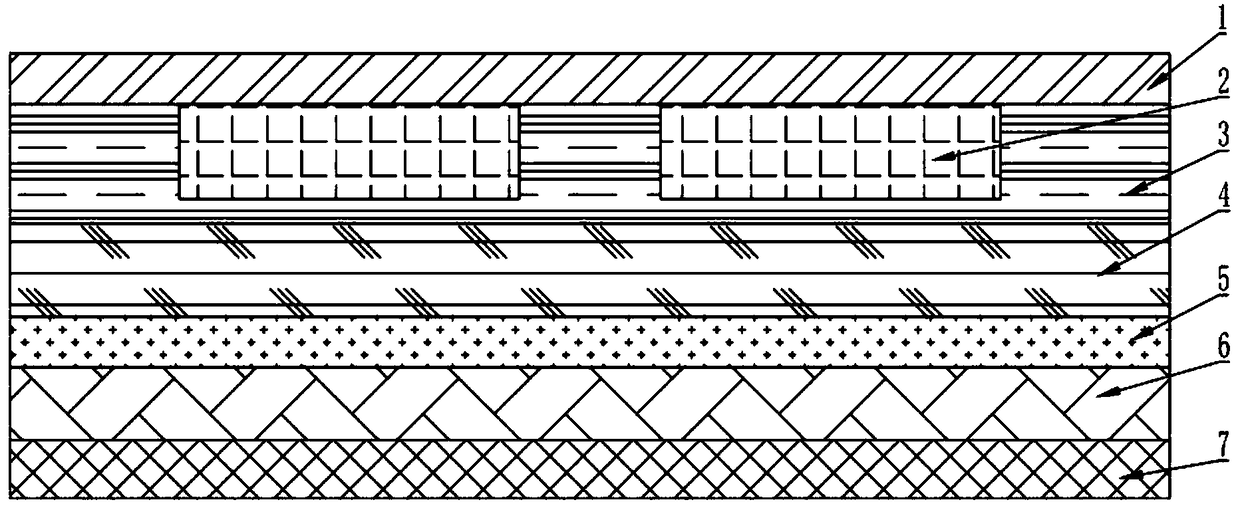

Washable type flame-retardant shading polyester fabric and production method thereof

The invention relates to a washable type flame-retardant shading polyester fabric and a production method thereof, and belongs to the technical field of functional fabrics. The method includes: taking non-flame-retardant polyester filaments as warps and flame-retardant polyester filaments 5000-7000ppm in phosphorus content as wefts, interweaving the warps and the wefts to form gray fabric of a double-side-satin middle-weft structure, wherein the warp count in the gray fabric is 80-165 / cm, and the weft count is 20-45 / cm; subjecting the woven gray fabric to one bath dyeing via a flame retardant, taking disperse dye as dye, and adding a one bath flame retardant 0.3-10.0% of the weight of the gray fabric into bath liquid; dying at the temperature of 125-135 DEG C for 30-50minutes, and cooling after dyeing prior to finish dyeing. The shading fabric produced by the method is excellent in fabric quality, good in flame retardation and low in cost.

Owner:SHAOXING SANLIDA TEXTILE FLAME RETARDANT NEW MATERIALS

Multifunctional screen printer

ActiveCN109532215ARealize rotary feedingImprove productivityScreen printersReciprocating motionEngineering

Owner:许振松

An inferior diesel oil hydro-upgrading and hydrofining combined process

ActiveCN109988643AFlexible production methodsFlexible productionTreatment with hydrotreatment processesHydrogenation processFractionation

The invention discloses an inferior diesel oil hydro-upgrading and hydrofining combined process. A diesel oil raw material is fractionated to obtain a light fraction and a heavy fraction; the light fraction is subjected to extraction with aromatic hydrocarbon to obtain a light aromatic hydrocarbon fraction and a light non-aromatic hydrocarbon fraction; the heavy fraction enters a hydrofining reactor, and the material passing through a first hydrofining catalyst bed layer is divided into two streams; one material stream enters a separator, and the obtained liquid is extracted out of the hydrofining reactor and enters a hydro-finishing reactor together with the light aromatic hydrocarbon fraction for a hydro-finishing reaction; the other material stream is mixed with the light non-aromatic fraction and then flows downwards through a second hydrofining catalyst bed layer; a hydrofined material flow enters a hydro-upgrading reactor; and a hydro-upgrading reaction product and a hydro-finishing reaction product are respectively subjected to gas-liquid separation and fractionation to obtain high-quality diesel oil products and high-quality FCC feed materials. The invention provides the hydrogenation combined process for simultaneously producing more than two kinds of diesel fractions with different purposes on a set of hydrogenation process equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for printing three-dimensional pattern in form of varnish spraying

InactiveCN109572232AImprove experienceFlexible production methodsTypewritersOther printing apparatusPrinting inkEngineering

The invention relates to a device and method for printing a three-dimensional pattern in form of varnish spraying. The device and method for printing the three-dimensional pattern in form of the varnish spraying comprises a printing machine tool and a controller, wherein the printing machine tool is provided with a printing table used for bearing a substrate, a negative pressure adsorption mechanism is arranged in the printing machine tool, and a plurality of adsorption holes communicated with the negative pressure adsorption mechanism are uniformly formed in the printing table; a plurality ofinkjet printing mechanisms are arranged on the printing machine tool, and curing devices are arranged on the printing machine tool; and the controller is electrically connected with the inkjet printing mechanisms, and the controller is electrically connected with the curing devices for controlling the opening and closing of the curing devices. A code spraying mode is adopted by the inkjet printing mechanisms, the jet printing ink can be firmly attached to any substrate, a traditional production mode is exceeded as the production mode is more flexible, variable data are applied, and even one piece of paper can be arranged for printing, so that the requirements of the lowest number threshold for printing is greatly lowered, the needs of blind people for personalized products are met, and the user experience of the blind people is improved.

Owner:CHONGQING HONGJIN PRINTING

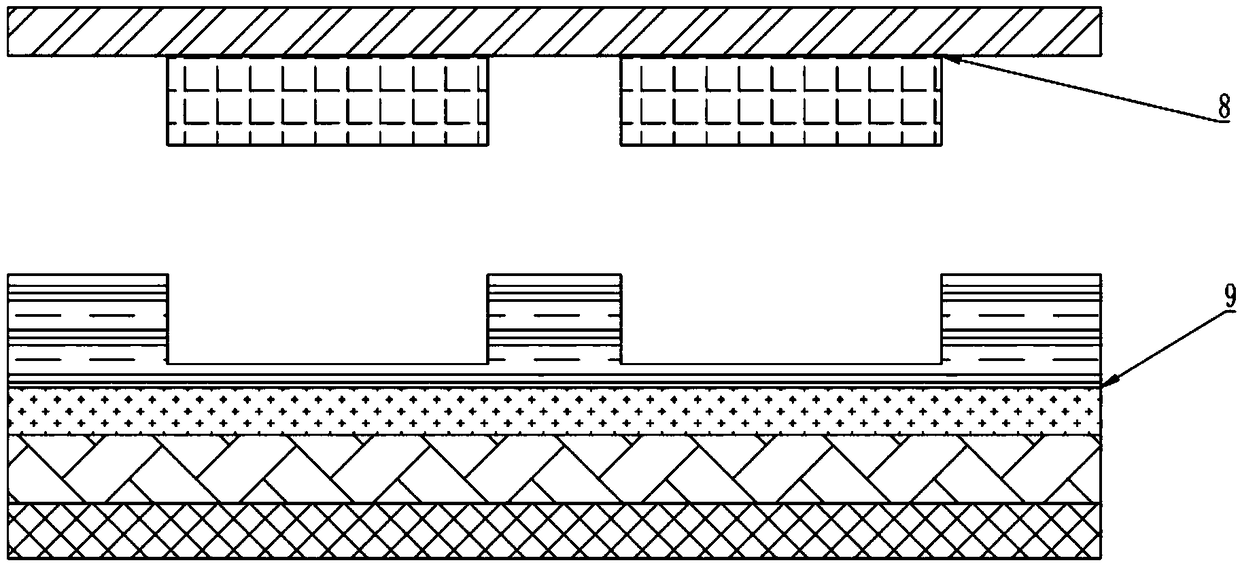

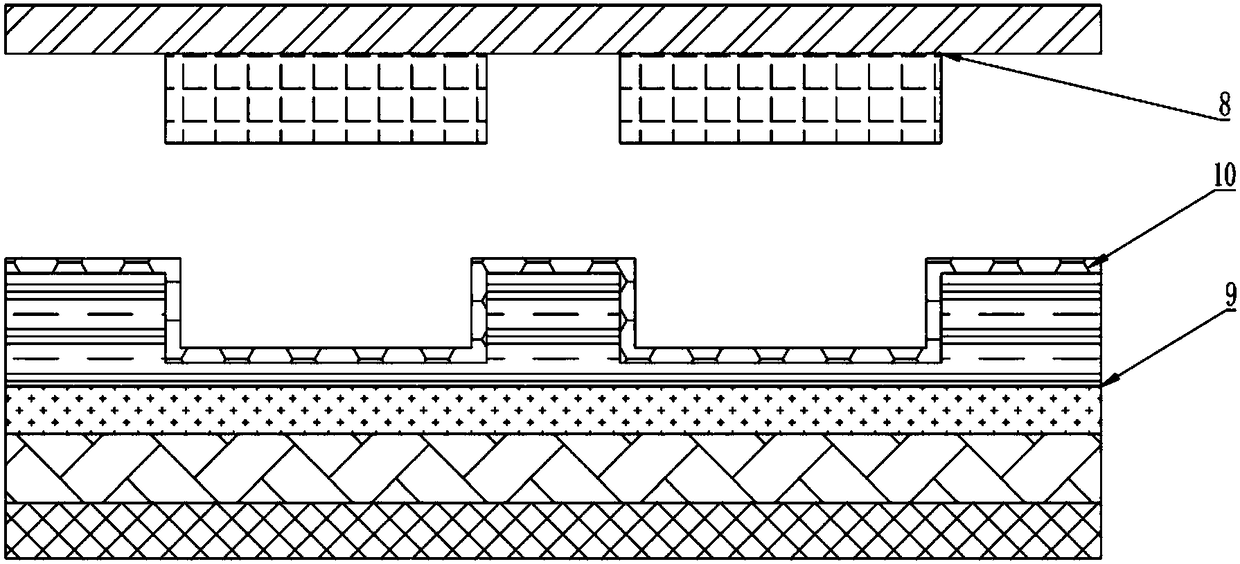

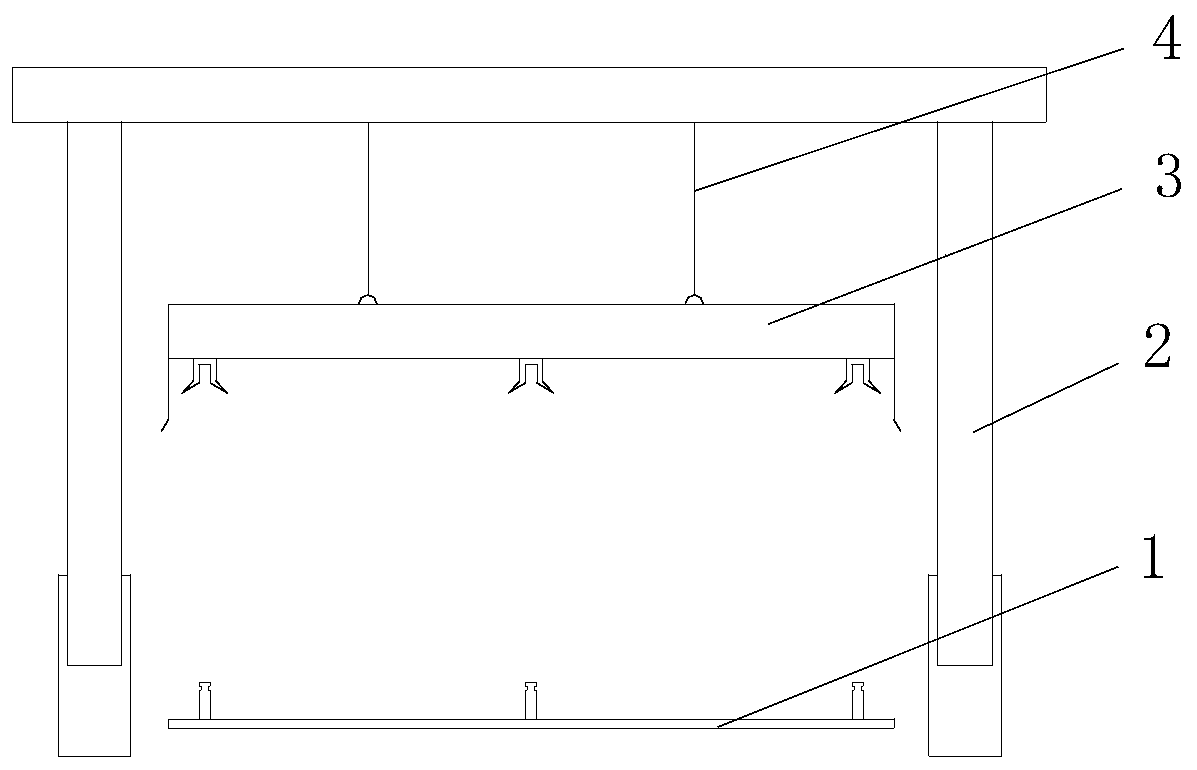

Movable integrated device for producing precast concrete planks and production process

PendingCN111409185ATake advantage ofLow capital requirementsDischarging arrangementBase supporting structuresPlankArchitectural engineering

The invention belongs to the technical field of precast concrete plank production, and particularly relates to a movable integrated device for producing precast concrete planks and a production process. The device comprises a form table, a travelling portal frame, a form table lifting appliance, a portal lifting cable, a material distributing machine, a form table base and a form releasing liftingappliance, wherein the form table is arranged on a form table station and used for forming the prefabricated concrete planks, the form table base is used for overlapping form tables, the travelling portal frame stretches across the two sides of the form table and can travel, the portal lifting cable is arranged at the top of the travelling portal frame, the form table lifting appliance is connected to the portal lifting cable on the travelling portal frame and is used for lifting the form table, the material distributing machine is connected to the portal lifting cable on the travelling portal frame and used for pouring concrete on the form table, and the from releasing lifting appliance is used for lifting the formed precast concrete planks. According to the device and the process, the basic construction requirement is low, open-air production can be achieved, a standard temporary workshop can also be adopted, the occupied area is greatly reduced, the capacity is only about 20% of that of an existing production mode, and the space is fully utilized.

Owner:赵红玲

Automobile lightweight component adopting composite formation technology

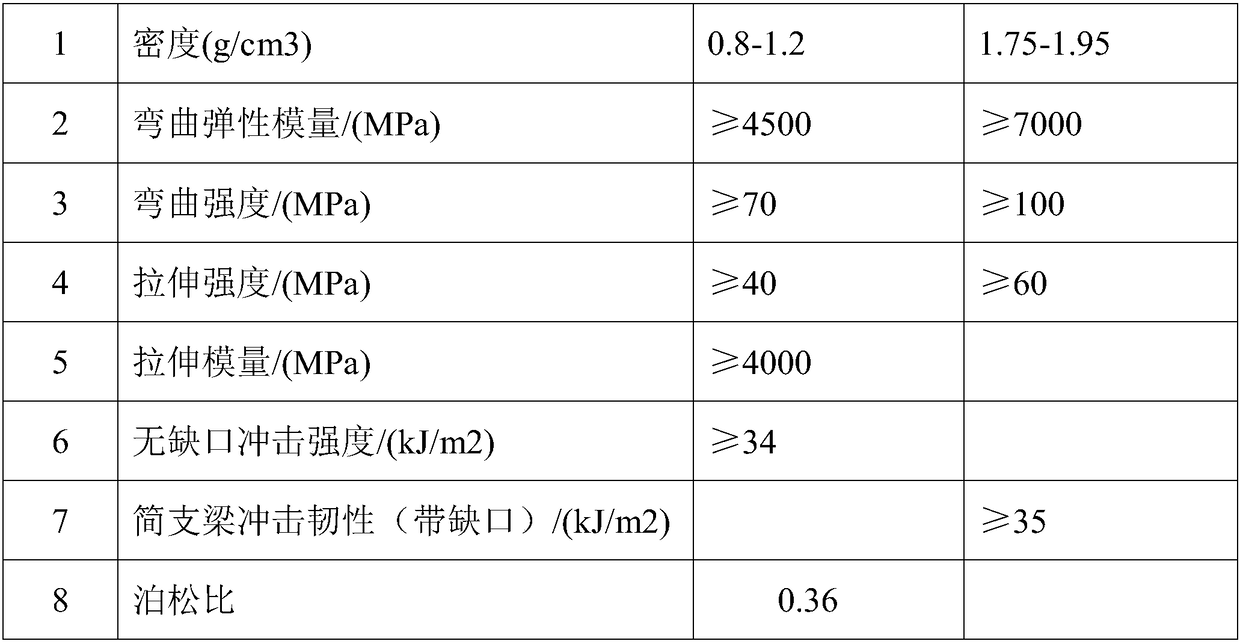

The invention discloses an automobile lightweight component adopting the composite formation technology. According to the automobile lightweight component adopting the composite formation technology,after blister formation is conducted on long glass fiber, foamed hot-press forming is conducted on a formed surface layer and polyurethane glass fiber, and then the automobile lightweight component isobtained. The automobile lightweight component adopting the composite formation technology has the characteristics of overall appearance, high rigidity, light weight, low investment cost, flexible production manner and the like. The automobile lightweight component has good thermal stability and excellent mechanical performance. The automobile lightweight component, as a molded piece, can achievemore excellent mechanical performance and good appearance.

Owner:JIANGSU XINQUAN AUTOMOTIVE TRIM

Hot extrusion forming method of stainless steel rail

PendingCN112207145AEasy to produceMolding process is stableExtrusion diesMaterials scienceHeat treating

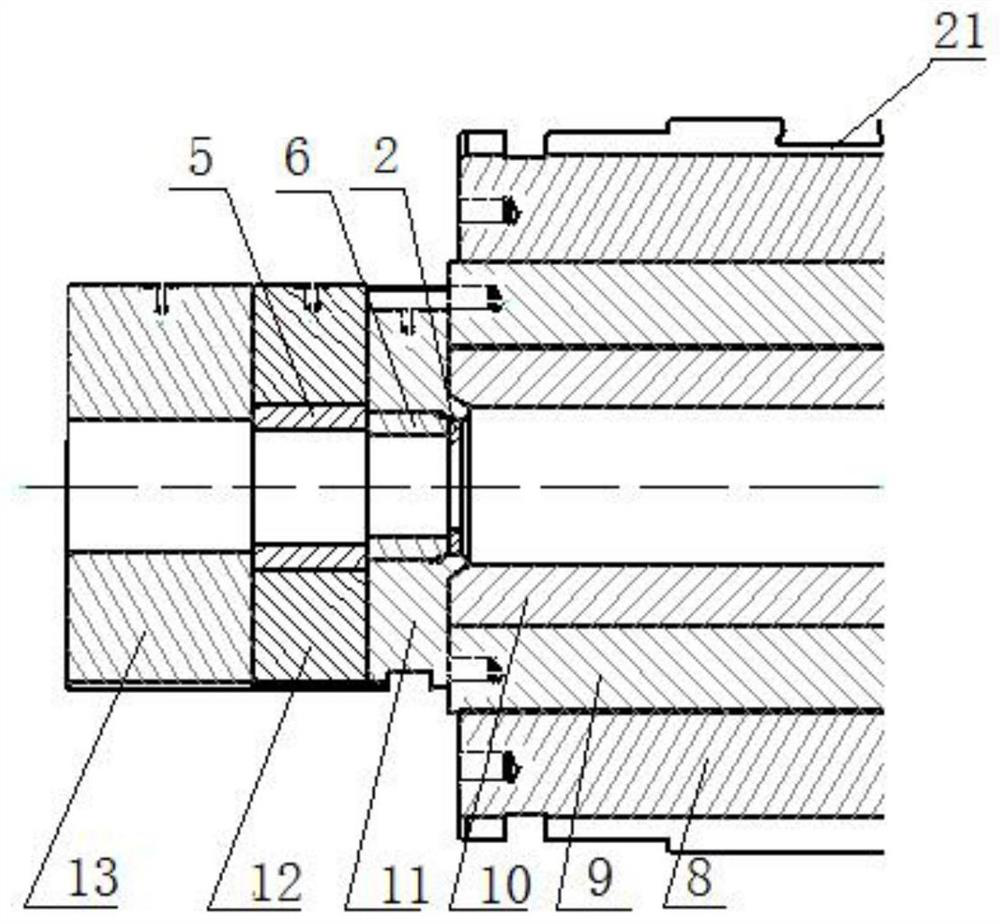

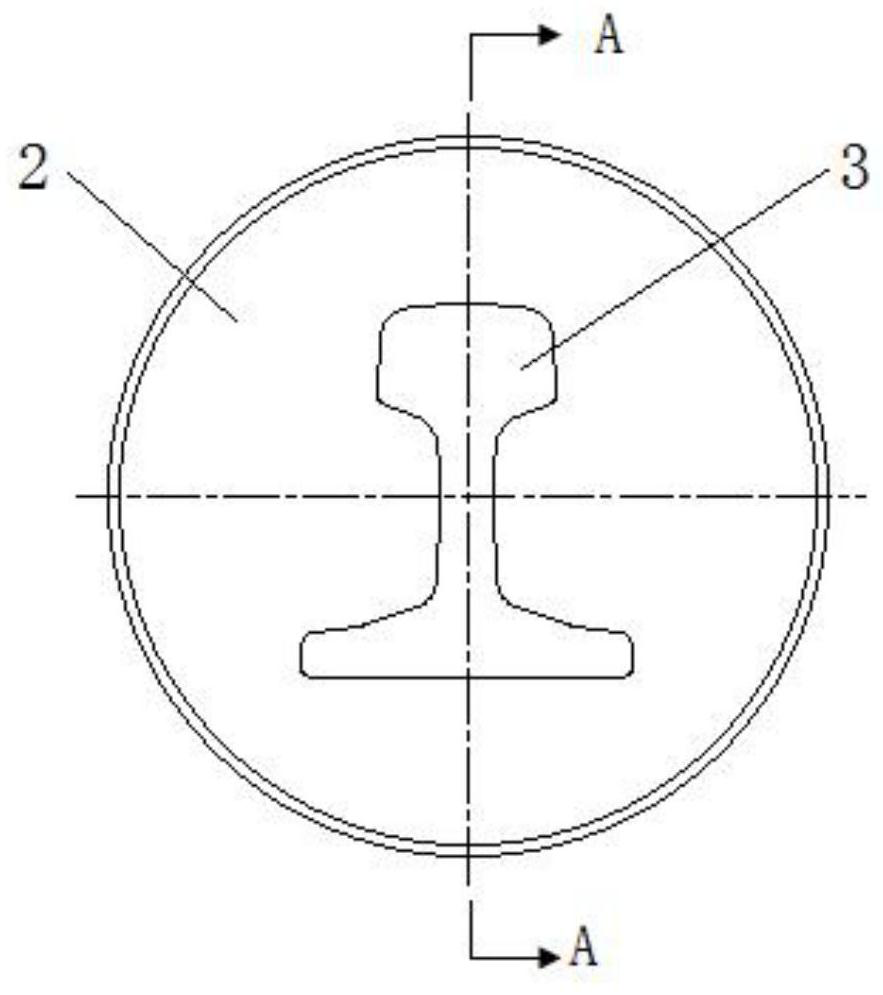

The invention relates to a hot extrusion forming method of a stainless steel rail. A hot extrusion forming system comprises machining equipment, heating equipment, lubricating equipment, hot extrusionequipment, a cooling bed, heat treatment equipment and inspection equipment. The hot extrusion forming method comprises the following steps: (1) blank processing: sawing a forged polished blank roundsteel, lathing and polishing the outer surface; (2) induction heating: heating the blank by a multi-section heating and temperature equalizing method; (3) tool and mold preparation: adopting an extrusion mold with the same hole pattern as the steel rail; (4) lubricating: lubricating the outer surface of the blank and extrusion mold glass; (5) hot extrusion: performing hot extrusion on the blank to form the steel rail; (6) cooling: carrying out air cooling on the extruded steel rail; (7) heat treatment: performing heat treatment on the steel rail; and (8) inspection: inspecting the surface quality, size, mechanical property and physicochemical property of the steel rail. By reasonably integrating the production process, the production process is optimized, the produced stainless steel railmeets the quality requirement, the production cost is reduced, and the economic efficiency of enterprises is improved.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

Manufacturing method for irregular-section differential-shrinkage polyester filament yarn

ActiveCN102154719AFlexible production methodsNo increase in manufacturing costsArtificial thread manufacturing machinesFilament/thread formingMechanical engineeringRaw material

The invention relates to a manufacturing method for an irregular-section differential-shrinkage polyester filament yarn; the steps of the manufacturing method are as follows: polyester is used as a spinning raw material, polyester melts are squeezed out and measured and then are sent to a spinning component for spinning so as to obtain spun filament tows, wherein a distributing plate arranged in the spinning component is irregularly concave-convex type; and the spun filament tows are cooled, oiled, drafted, webbed and wound so as to obtain the irregular-section differential-shrinkage polyester filament yarn product, wherein the winding speed of the spinning is 4500 to 5300m / min. The manufacturing method is suitable for manufacturing the irregular-section differential-shrinkage polyester filament yarn, only needs the polyester to be used as the spinning raw material and has simple spinning path.

Owner:SUZHOU LONGJIE SPECIAL FIBER

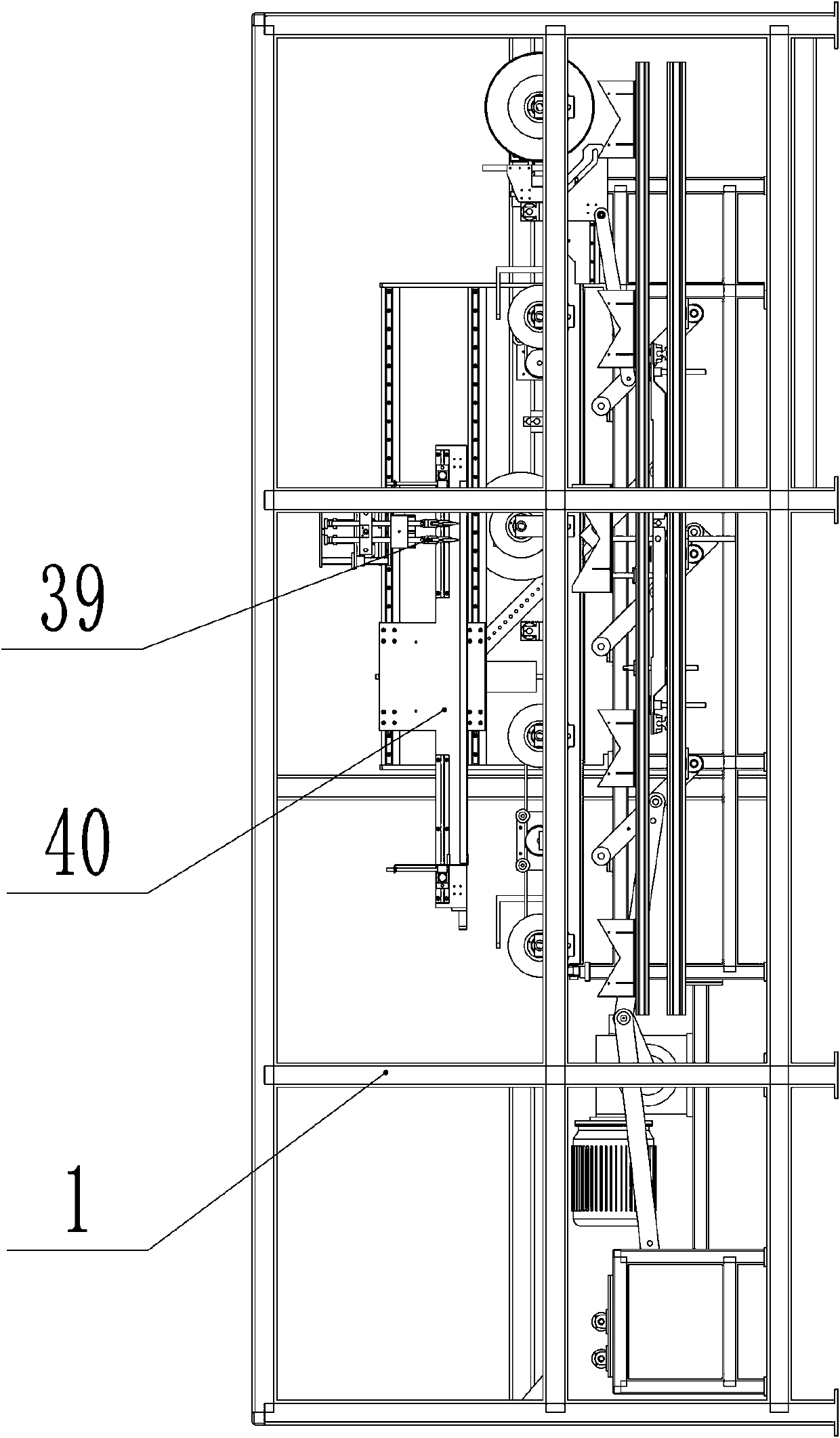

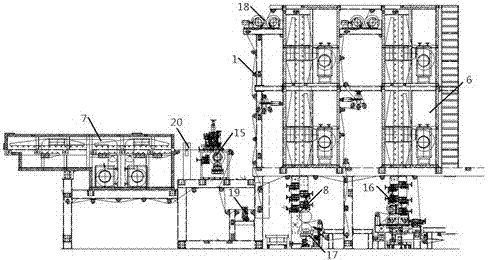

Frame for fuel cell membrane electrode and bonding system of frame and membrane

PendingCN112786936ANeat edgesImprove adhesionFinal product manufactureFuel cellsFuel cellsPtru catalyst

The invention belongs to the field of fuel cell manufacturing equipment, and provides a frame for a fuel cell membrane electrode and a frame and membrane bonding system, the system comprises a membrane system, a lower frame system and an upper frame system, the system realizes production continuity, and the membrane system, the lower frame system and the upper frame system are structurally improved, and the bonding effect of the film and the frame is improved. Before the membrane is coated with the catalyst, an assembly with a double-sided frame is formed for the membrane, the product is a membrane electrode assembly early-stage intermediate product which is connected by a coiled material frame material and can be folded and packaged or continuously conveyed, the membrane electrode assembly early-stage intermediate product can be subsequently conveyed to be coated with the catalyst to form a five-in-one product, and then the five-in-one product and a diffusion layer form a seven-in-one product; in the process, connection of each single piece of the product is kept, favorable conditions are provided for production continuity, and the catalyst layer has neat edges on the membrane.

Owner:大连锐格新能源科技有限公司

Hericium erinaceus-hawthorn wine

InactiveCN106032502AFlexible production methodsLow costAlcoholic beverage preparationFiltrationFireberry hawthorn

The invention discloses a soaking wine or fermenting wine adopting hericium erinaceus fruiting body or mycelium and hawthorn as raw materials, and belongs to the field of health wine processing. According to the present invention, the adding amount of the hericium erinaceus is 5-15% (dried product), and the adding amount of the hawthorn is 10-35% (fresh fruit); extraction with high quality Baijiu on the hericium erinaceus fruiting body or mycelium and the hawthorn, blending, clarifying filtration, filling, packaging and other steps are performed to obtain the soaking wine; treatment on the raw materials, slurry preparation and adjusting with sugar, inoculation fermentation, separation, aging, clarifying filtration, blending, sterilization, packaging, and finished product warehousing are performed to obtain the fermenting wine; the production method of the present invention has characteristics of simpleness, easy operation, low cost, and easy popularization and popularization, the standardized and standardized production is easily achieved, and the factory production can be achieved; and the hericium erinaceus-hawthorn wine is the new health wine, and is the ideal health wine for patients with stomach diseases.

Owner:于汇

Industrial Cloth Laminating Machine

ActiveCN106335265BQuality assuranceImprove processing efficiencyLamination ancillary operationsLaminationPulp and paper industryTextile

The invention relates to an industrial fabric laminating machine. The industrial fabric laminating machine is characterized by comprising a fabric delivering mechanism, a coating mechanism, a film sticking mechanism and a material collecting mechanism which are serially connected together through a material pass roller table, wherein the coating mechanism comprises a vertical drying oven, a horizontal drying oven and an impregnation device, the film sticking mechanism comprises a sending table, a film treatment device and a large cylinder, and the material collecting mechanism comprises a main press table, a cooling belt and a take-up device. The industrial fabric laminating machine is simple in structure and very high in production efficiency and can meet various industrial fabric production demands, and the production cost is also remarkably reduced.

Owner:HUBEI JINLONG NEW MATERIALS

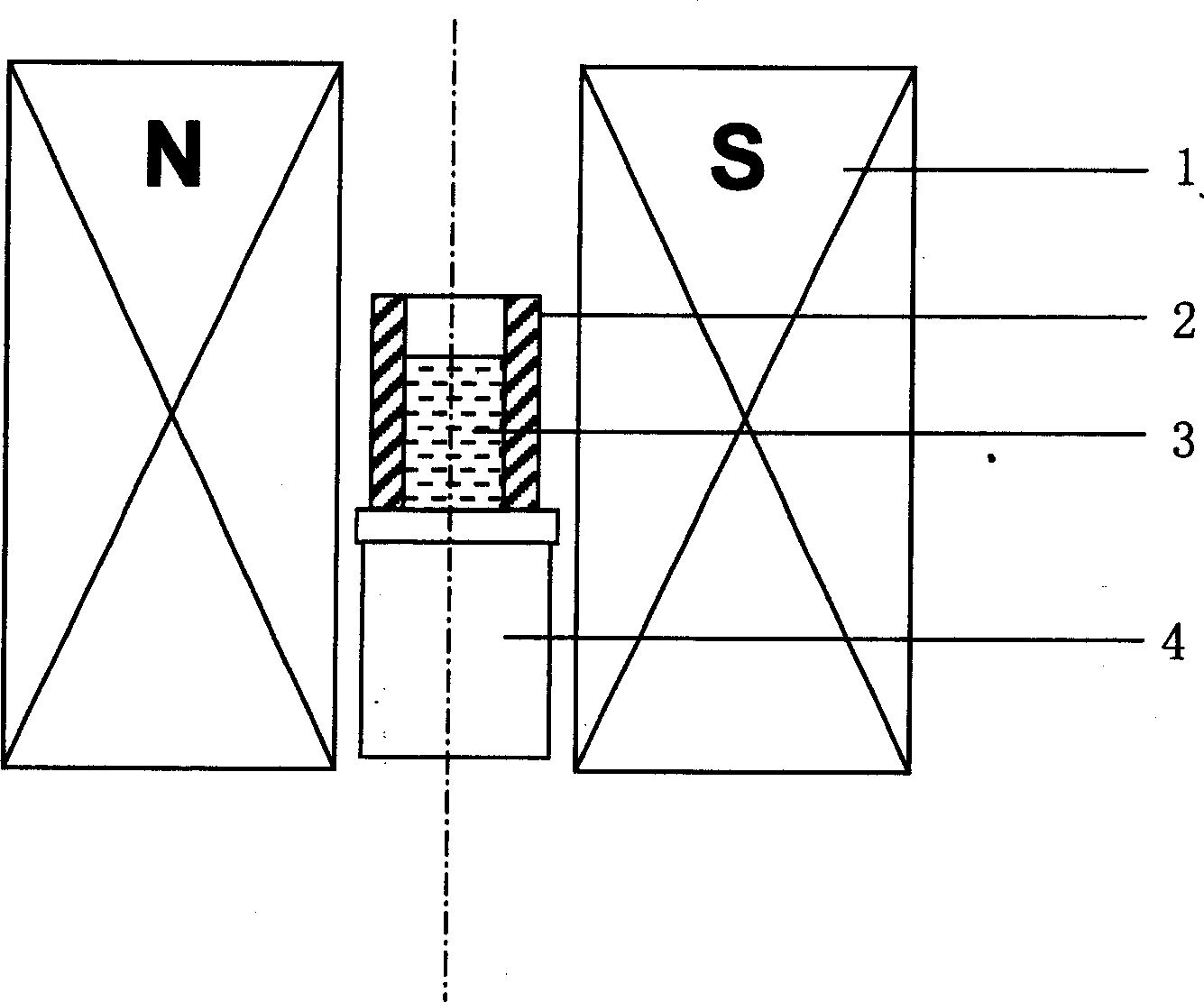

Process of preparing calcium-adding fireproof magnesium alloy in magnetic field

InactiveCN1847431AHigh ignition pointImprove mechanical propertiesUltimate tensile strengthMagnesium alloy

The present invention relates to preparation process of magnesium alloy with raised mechanical performance, and is especially preparation process of calcium-adding fireproof magnesium alloy in magnetic field. During smelting, calcium in the amount of 2-5 wt% of the alloy is added into magnesium alloy to avoid oxidation and burning of the alloy during smelting and casting, and the alloy melt is solidified in magnetic field of 0.2-1.0 T to avoid oxidation and burning of the alloy during smelting and casting and raise the strength and plasticity of the alloy. The present invention has simple apparatus and convenient operation and can raise the mechanical performance of magnesium alloy at normal temperature and high temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

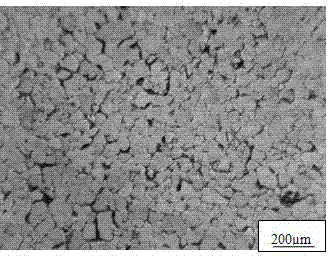

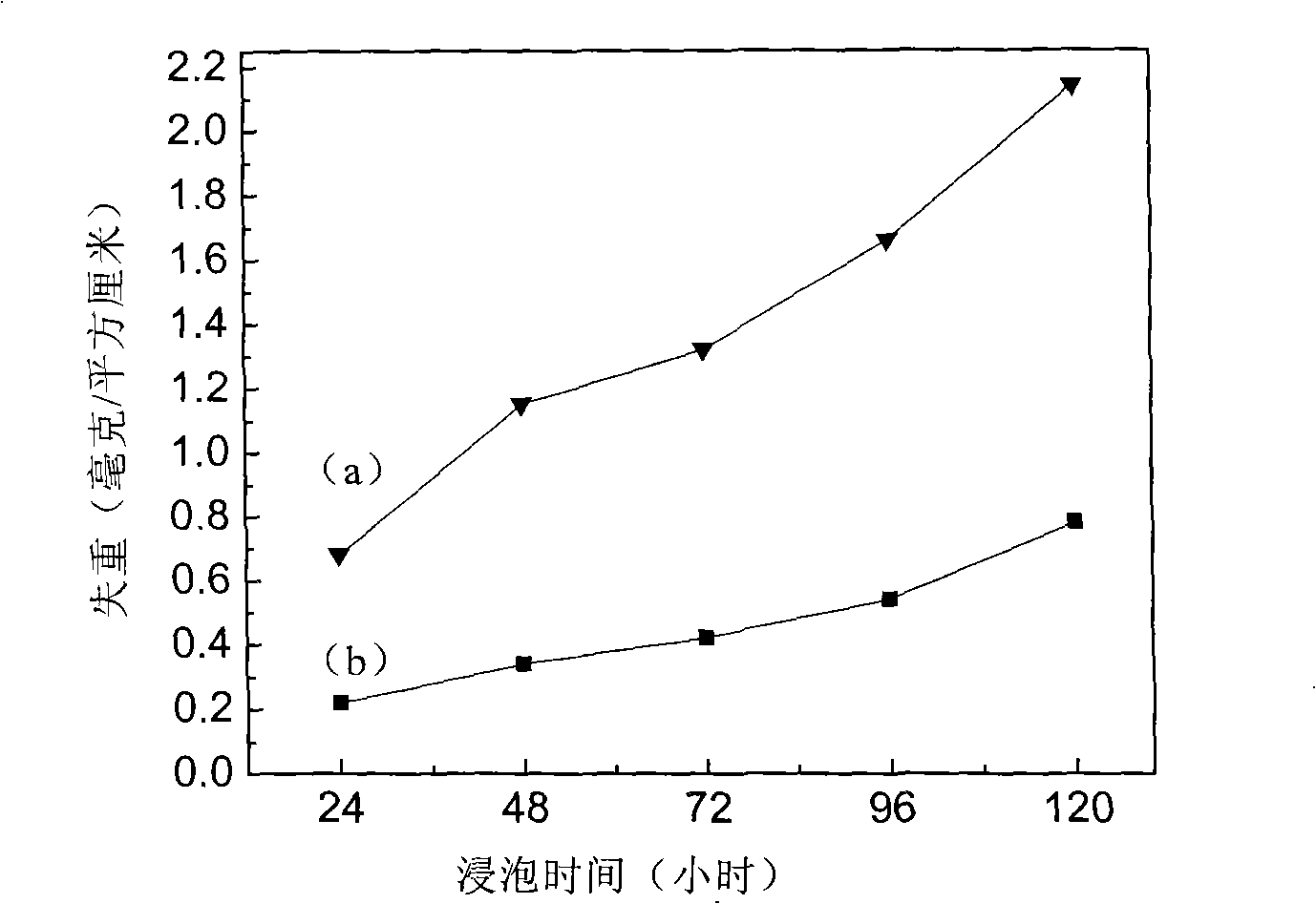

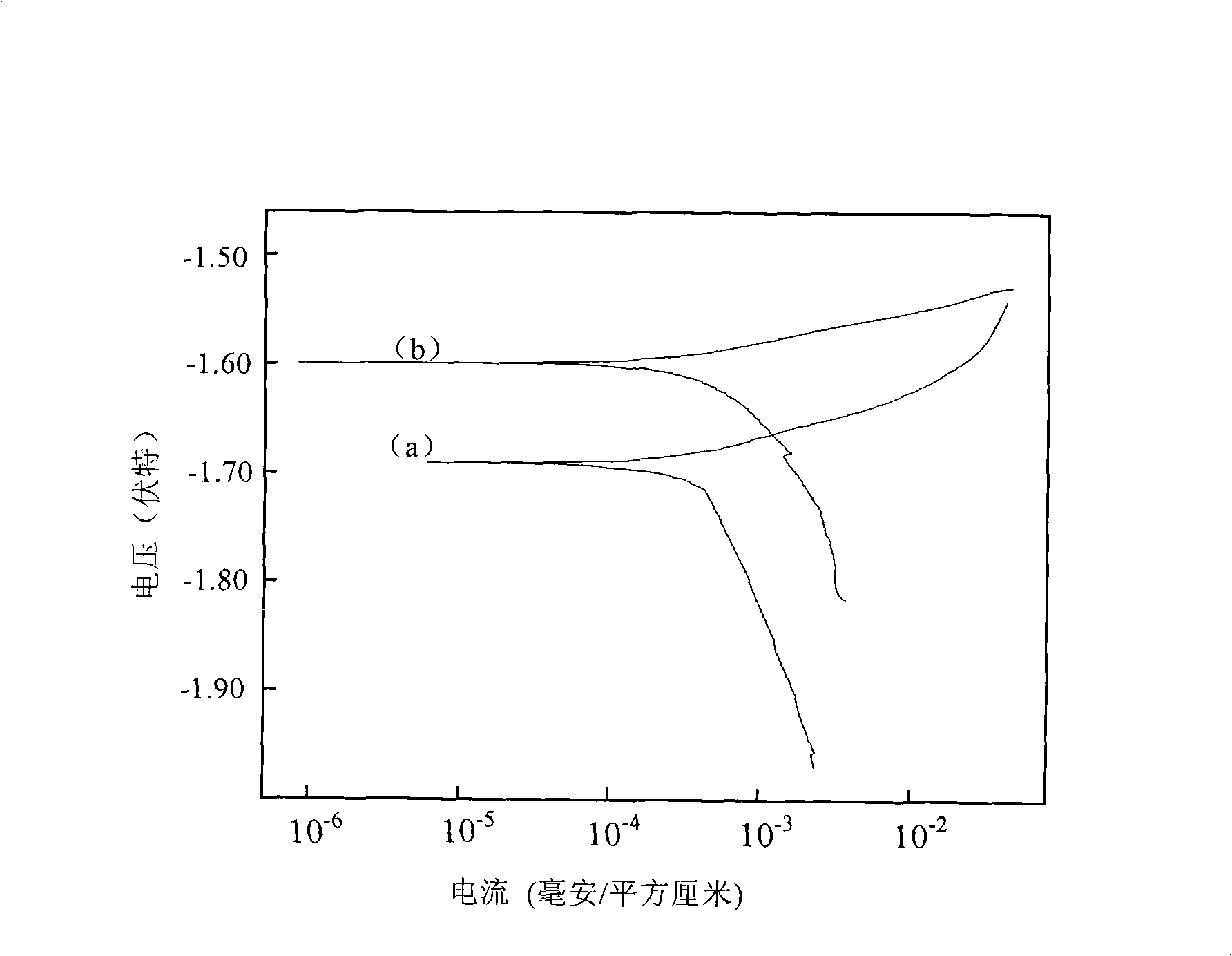

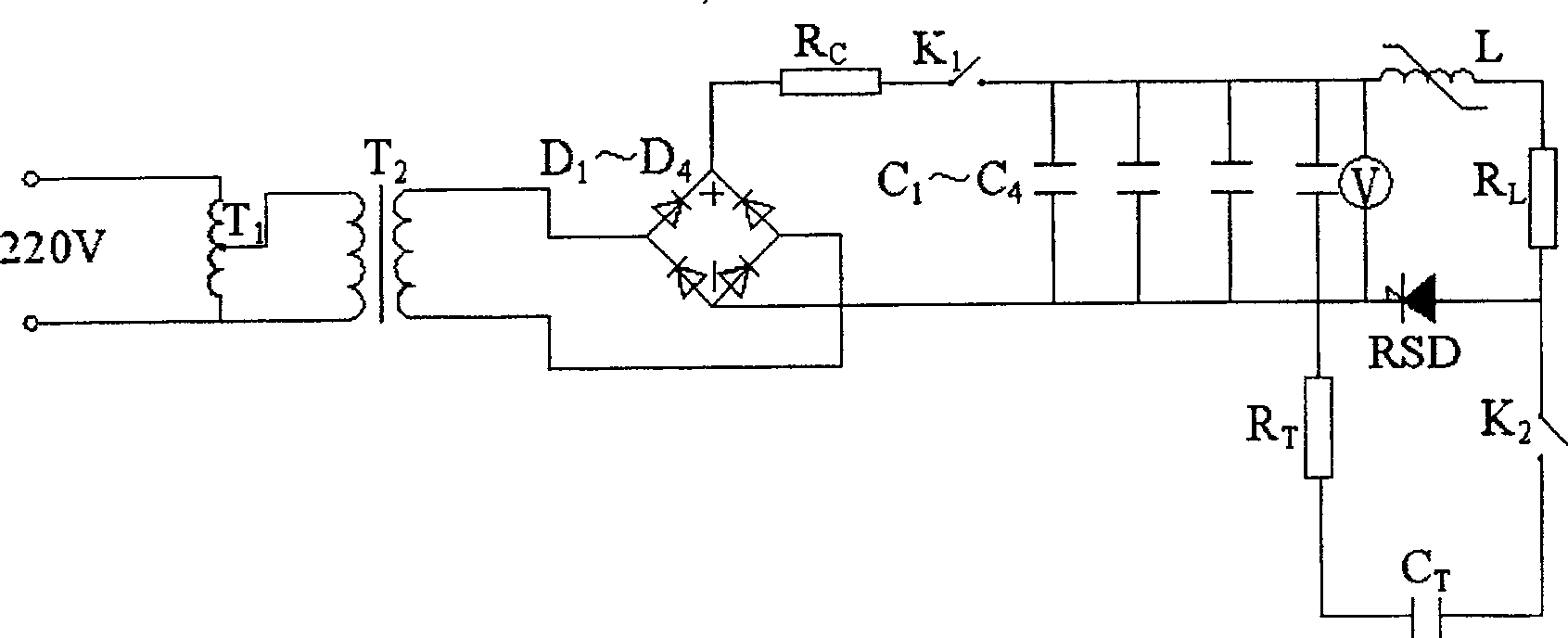

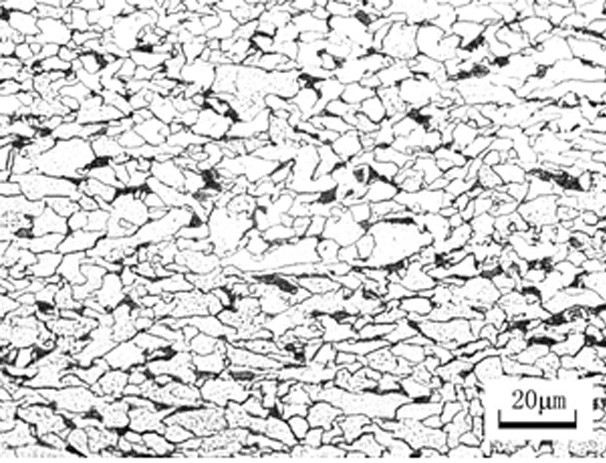

Method for increasing AZ91D magnesium alloy corrosion-resistant property

The invention relates to a method for improving corrosion-resistant performance of AZ91D magnesium alloy, comprising the steps of: heating to melt AZ91D magnesium alloy ingot, introducing protective CO2 and SF6 mixed gas at 590-610 DEG C, heating to 720-740 DEG C, adding boron to the magnesium alloy liquid in the Al-4B intermediate alloy form, stirring, standing to obtain boron-magnesium complex liquid, cooling to 680-700 DEG C, pouring the boron-magnesium complex liquid into a preheated metal mould (200-400 DEG C), and placing the mould into a rotating magnetic field; and powering on to start up a rotating magnetic field generating device, allowing the boron-magnesium complex liquid to solidify under the action of rotating magnetic field, cooling at room temperature, powering off the rotating magnetic field generating device, and demoulding. The inventive method can improve the corrosion-resistant performance of AZ91D magnesium alloy; and has the advantages of no pollution, low energy consumption, and remarkably refined magnesium alloy crystal grains.

Owner:WUHAN UNIV OF TECH

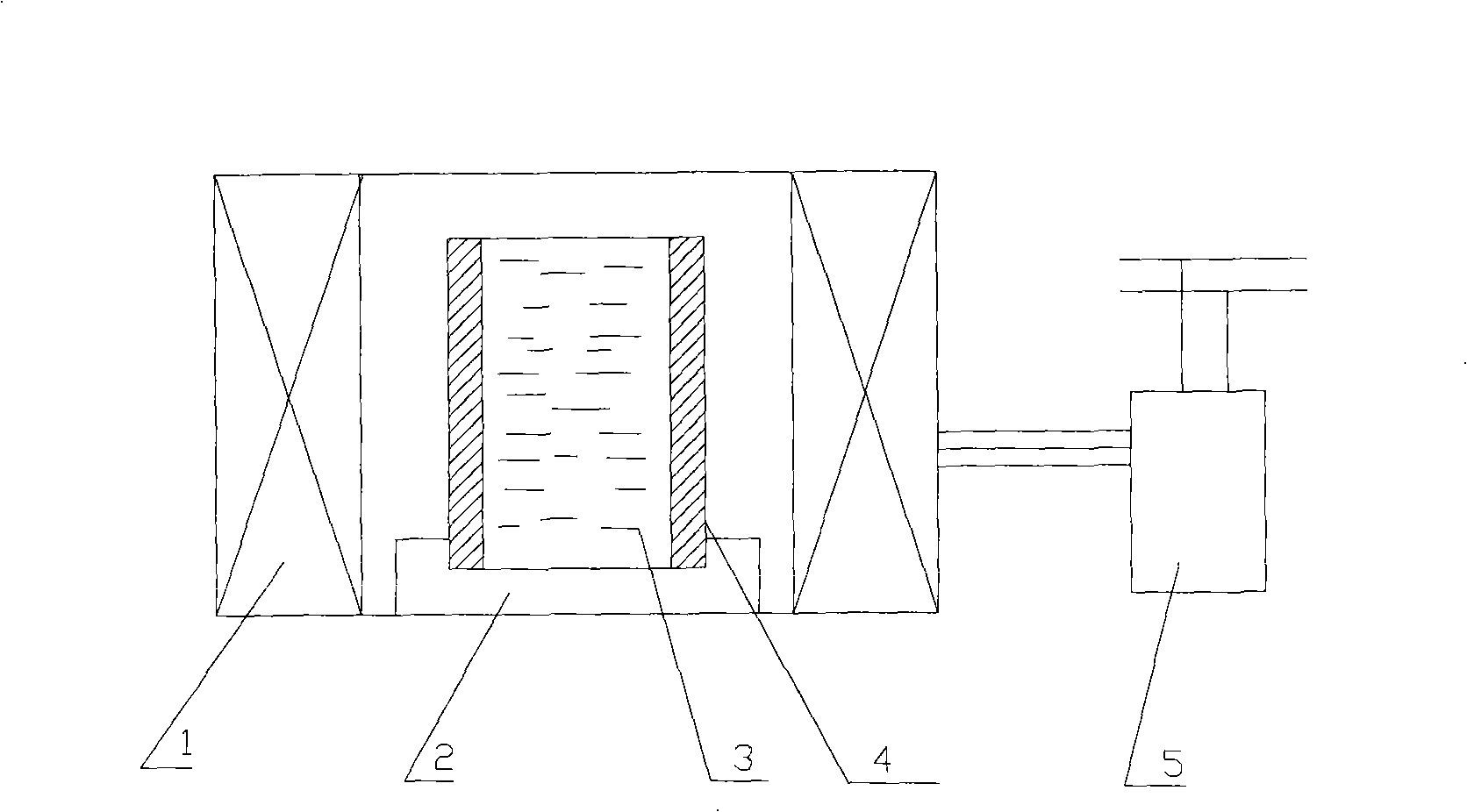

Production and apparatus for preparing non-dendritic and semi-solid alloy by low-voltage pulse electric field

The invention relates to a low-voltage pulse electric field preparation method and special equipment for semi-solid metal slurry or blank. Preparation method: first melt the alloy and keep it warm in the heat preservation crucible. The upper and lower ends of the alloy melt are respectively connected to the positive and negative electrodes of the output end of the pulse power supply. Before the solidification starts, start the pulse power supply to perform pulse discharge on the alloy melt. Apply a pulsed electric field. Special equipment: It consists of three parts: pulse electric field generator, pulse electric field effect device and heating and heat preservation device. The pulse current generated by the pulse electric field generator is applied to the alloy melt placed in the heat preservation device through the pulse electric field effect device. Adjust the pulse discharge voltage, discharge time and pulse frequency according to the type and composition of the alloy, and control the solidification speed of the alloy during the pulse discharge, and finally obtain a non-dendritic semi-solid alloy blank or slurry with a spherical or granular primary phase , can be used in the production of metal semi-solid alloy preparation and forming.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for smelting ultra-low carbon stainless steel through intermediate frequency furnace

ActiveCN105463156AFast melting speedImprove battery saving performanceProcess efficiency improvementElectric furnaceElectricityIntermediate frequency

The invention discloses a method for smelting ultra-low carbon stainless steel through an intermediate frequency furnace. The method comprises the specific steps of firstly, molten iron pretreatment; secondly, intermediate frequency smelting; thirdly, oxygen blowing and carbon reducing; fourthly, microelement adding; fifthly, deoxidation treatment; sixthly, casting shaping; and seventhly, electroslag remelting. An intermediate frequency furnace smelting manner and an electroslag remelting refining manner are adopted to produce the ultra-low carbon stainless steel, the production manner is flexible, and the material supply manner of small batches, multiple specifications and urgent demands of a customer can be met; the intermediate frequency furnace is high in smelting speed, good in power-saving effect, few in burning loss and low in energy consumption; the smelting efficiency is improved; and electroslag remelting refining is adopted to enable the inner structure of a steel ingot to be more compact, and the ultra-low carbon stainless steel is high in purity, low in sulfur containing, less in nonmetallic inclusion, smooth in surface, clean, even and compact and even in gold phase structure and chemical component.

Owner:四川民盛特钢锻造有限公司

Preparation method of functional composite theabrownin

InactiveCN107372933AIncrease productivityImprove product qualityTea extractionFunctional compositeTheabrownin

The invention relates to the technical field of biochemistry. In order to solve the problems that at present, theabrownin production raw materials are in short and cost is high, the invention provides a preparation method of the functional composite theabrownin, and the preparation method comprises the steps of mixing, fermenting, extracting and the like. The preparation method is low in process investment, is simple in process, is high in yield, and greatly improves production efficiency and quality of theabrownin.

Owner:杭州丹娜生物科技有限公司

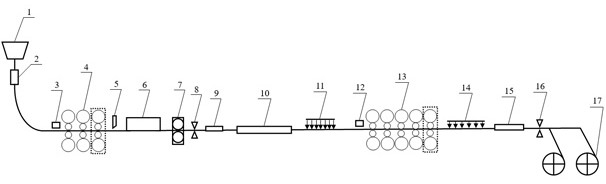

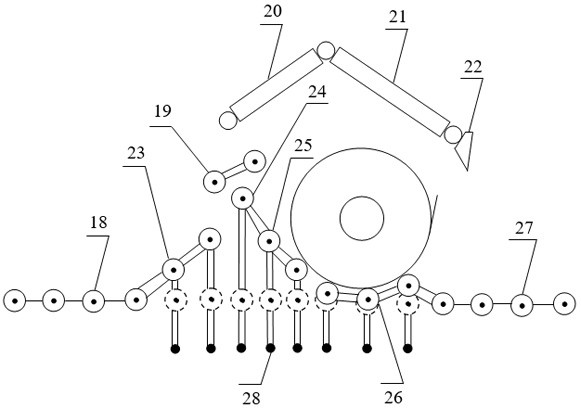

Multi-mode energy-saving hot-rolled strip steel production line and using method thereof

ActiveCN111842483AReduce energy consumptionImprove internal organizationWork treatment devicesMetal rolling arrangementsTundishScrap

The invention discloses a multi-mode energy-saving hot-rolled strip steel production line. The multi-mode energy-saving hot-rolled strip steel production line mainly involves a continuous casting tundish, a mold, a descaling machine 3, a roughing mill, a swing shear, an intermediate billet manipulator, a hot coil box, a rolling shear, a scrap steel removing device, a soaking pit furnace, an intermediate cooling device, a descaling machine 12, a finishing mill, a laminar cooling device, an induction soaking device, a flying shear and a recoiling machine, wherein the intermediate cooling deviceis arranged between the soaking pit furnace and the finishing mill, the scrap steel removing device is arranged behind the rolling shear, the scrap steel removing device do not communicate with the soaking pit furnace, the movable hot coil box is arranged between the intermediate billet manipulator and the rolling shear, and the induction soaking device is arranged between the laminar cooling device and the flying shear; and a using method comprises the following steps of smelting; casting into a blank; descaling for the first time; rough rolling; heating; cooling; descaling for the second time; finish rolling; cooling; electromagnetic induction heating; and coiling. The method not only has austenite rolling, but also can realize ferrite rolling, single-billet rolling and continuous rolling can be further achieved, and a product is uniform in mechanical property, low in comprehensive energy consumption and wide in thickness coverage range.

Owner:WUHAN UNIV OF SCI & TECH

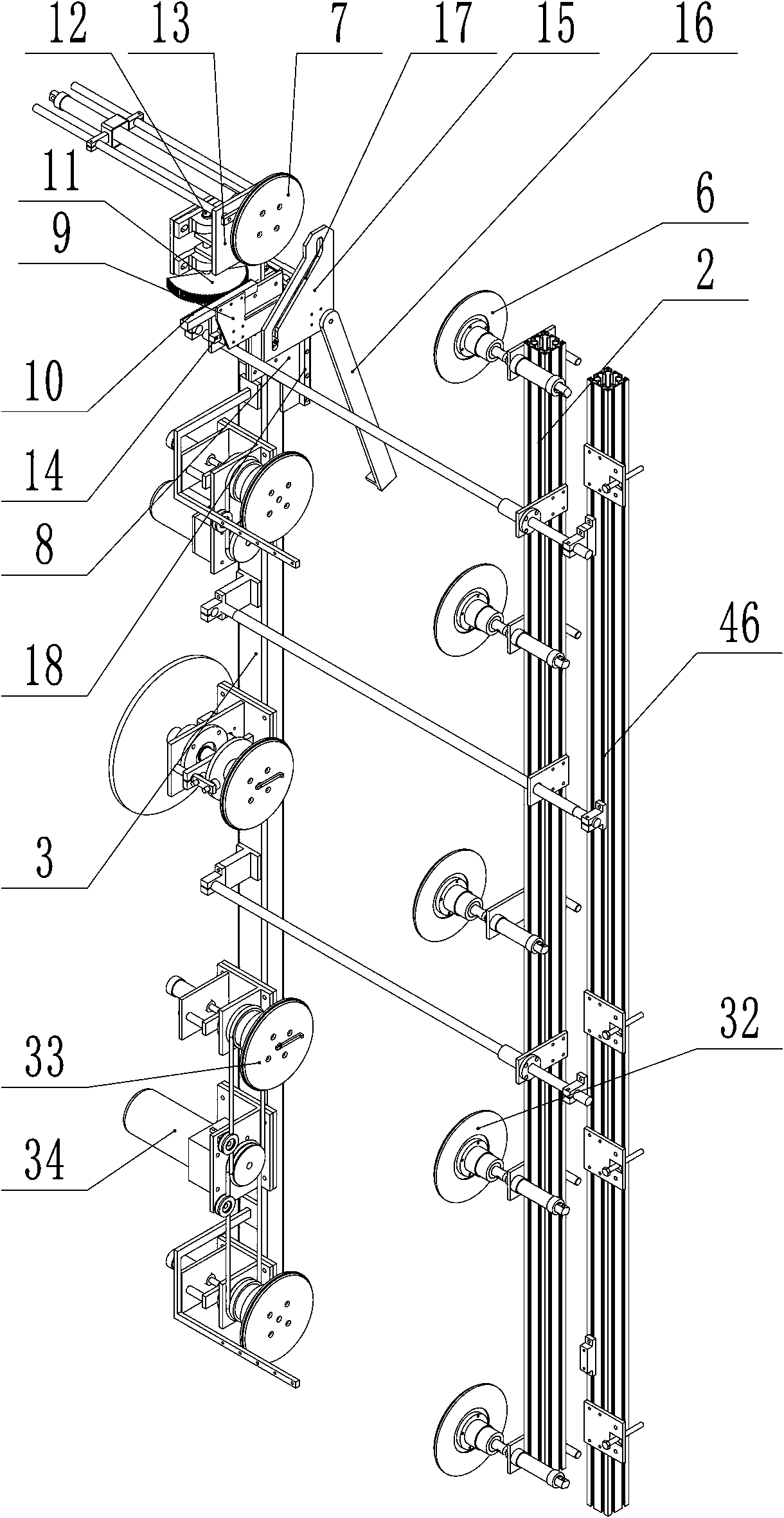

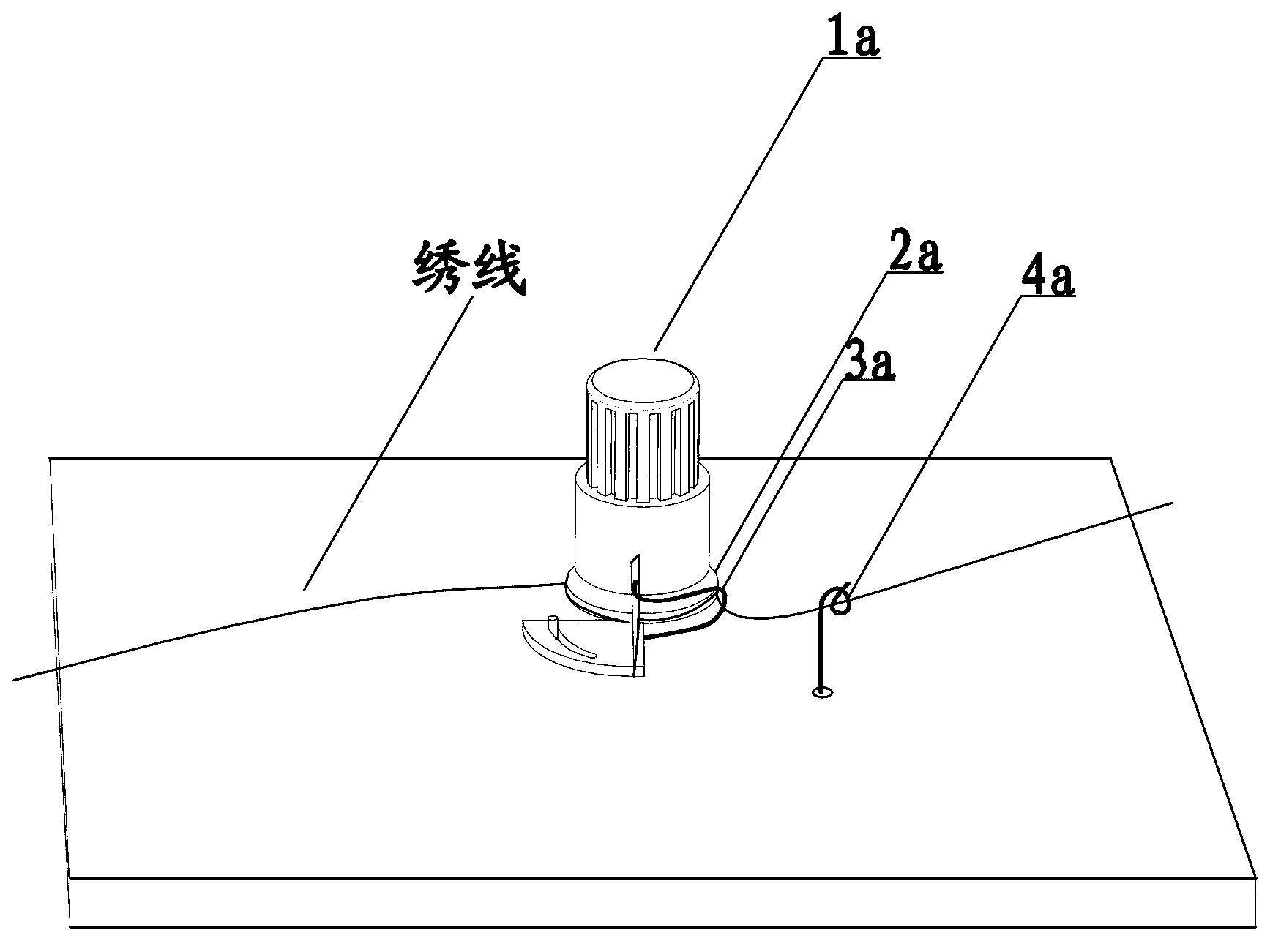

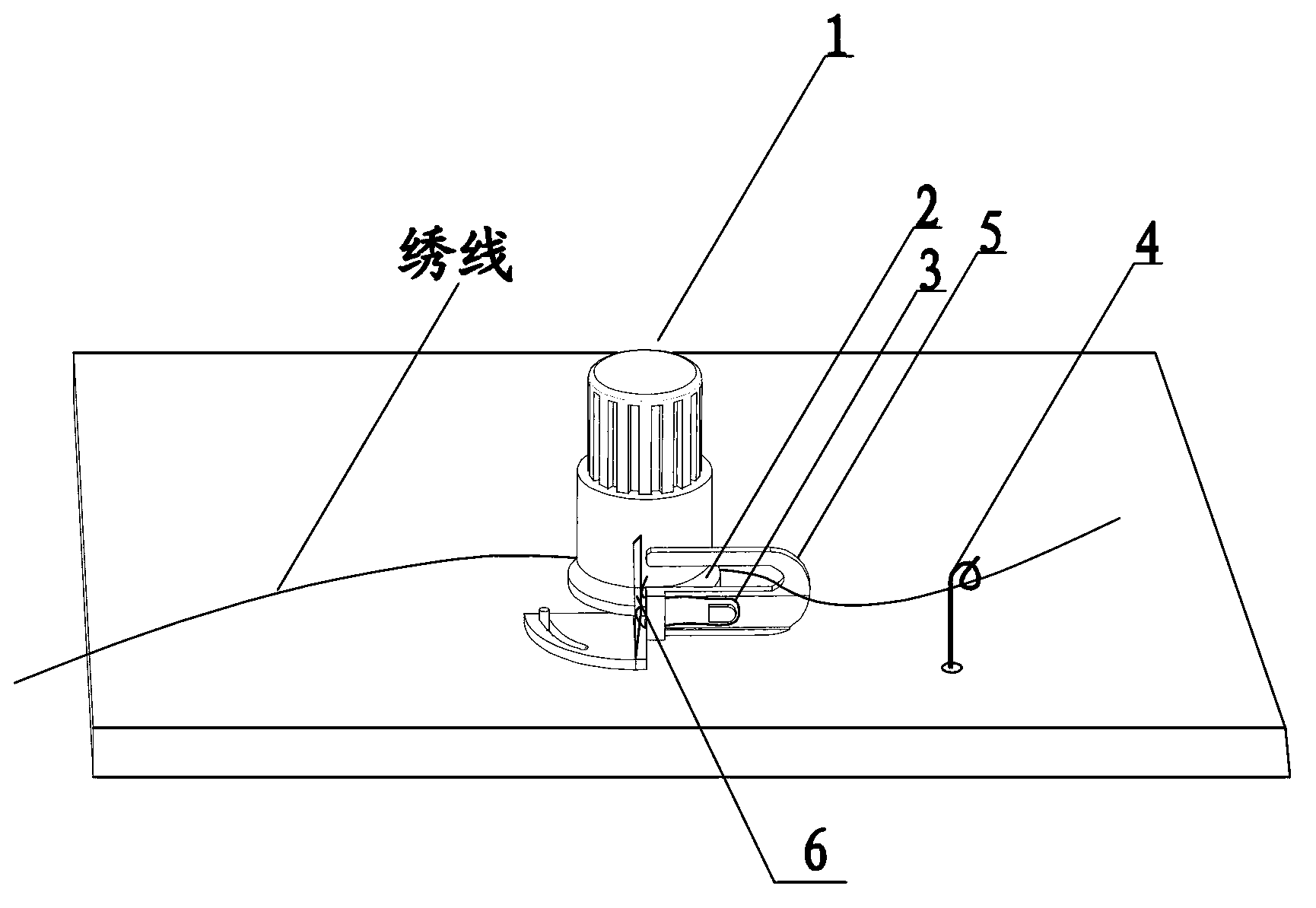

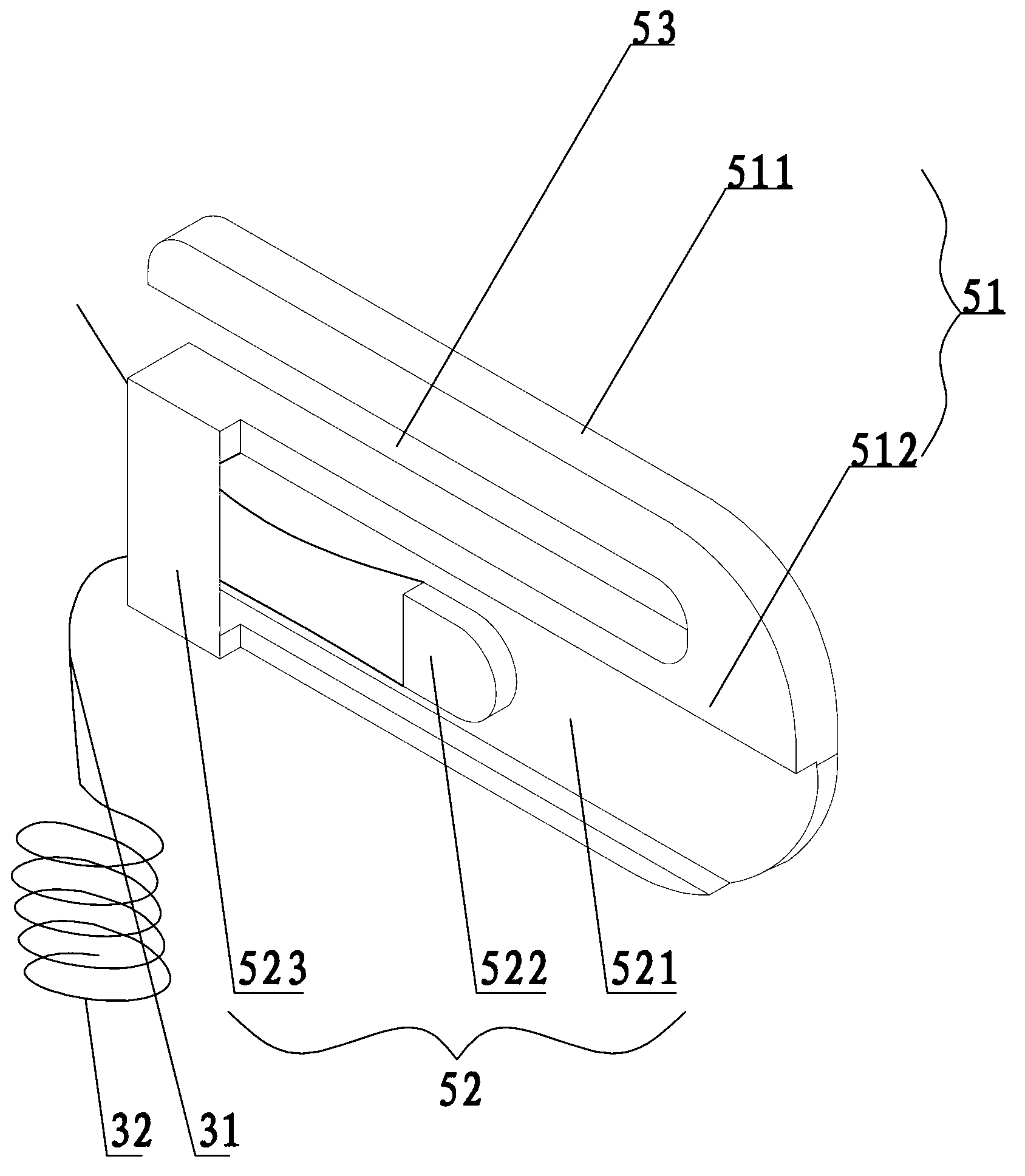

Alarm device for embroidery machine

ActiveCN103184665AExtended service lifeOvercome easy broken springAuxillary devicesEngineeringAlarm device

The invention relates to an alarm device for an embroidery machine, which belongs to the technical field of additional devices of an embroidery machine. The alarm device comprises a wire through wheel and an alarm part, wherein the wire through wheel is mounted on a wheel base; the alarm part is mounted on the wheel base, and is on the same side of the wire through wheel; the alarm part comprises a hook structure, a fixing structure and a wire through groove, as well as an alarm contact spring and a sensor sheet used in coordination with the alarm contact spring; the hook structure is divided into a hook part and a main body; the wire through groove is formed by the groove between the hook part and the main body; the fixing structure is arranged on the main body; and the bottom of the alarm contact spring is mounted below the wire through wheel, while the top end is mounted on the fixing structure in coordination, and is used for fixing the alarm part. The alarm device for the embroidery machine, provided by the invention, has the advantages of high alarm accuracy, static electricity resistance, long service life and the like, and can be applied to computer embroidery machines and normal embroidery machines.

Owner:黄站

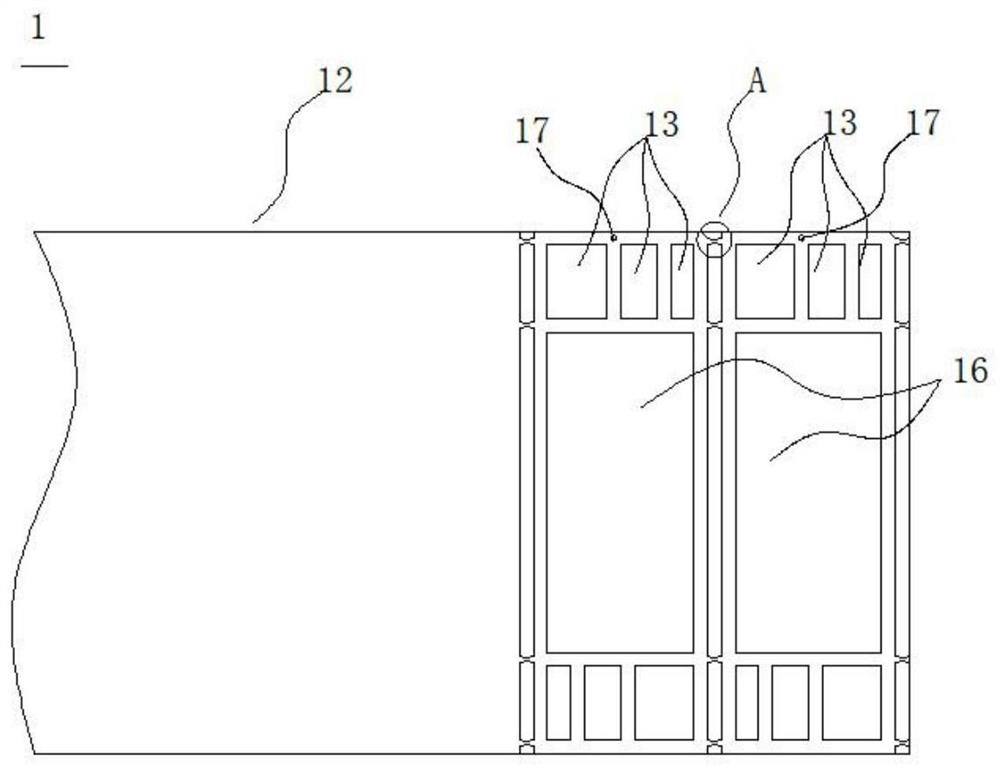

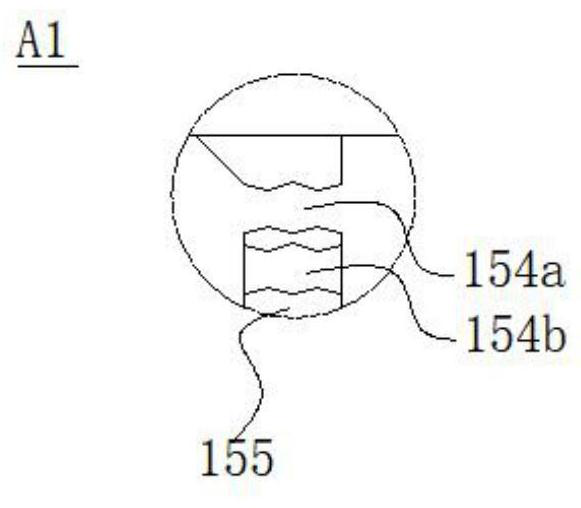

External gas-liquid cabin and wave energy power generation device

PendingCN111456885AIncrease the function of wave energy generationLow costWaterborne vesselsPV power plantsBuoyTurbine

The invention relates to the technical field of ocean renewable energy utilization, and particularly discloses an external gas-liquid cabin and a wave energy power generation device. The external gas-liquid cabin is used for being arranged on the outer side of a floating body, and the wave energy power generation device comprises the floating body, the external gas-liquid cabin arranged on the outer side of the floating body, and an air turbine and a power generator system arranged on the external gas-liquid cabin. The external gas-liquid cabin is arranged on the outer side of the floating body, the space of the top of the floating body is not occupied, meanwhile, an existing ocean buoy or floating body can be conveniently transformed, and the existing ocean buoy or floating body is additionally provided with a wave energy power generation function to supplement electric energy supply; and due to the fact that transformation of the existing ocean buoy or floating body can be achieved through low cost and a simple process, industrial popularization of the technology is facilitated.

Owner:HANGZHOU HUGEWAVE ENERGY TECH CO LTD

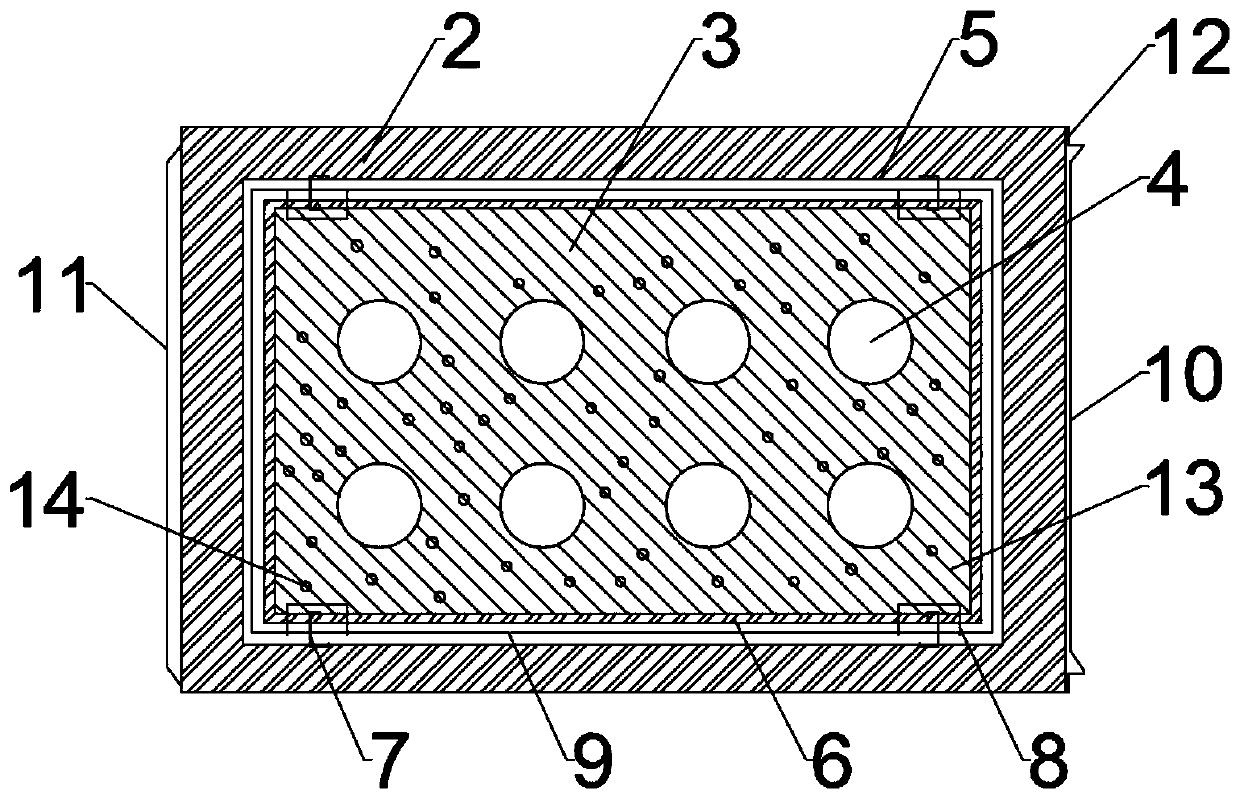

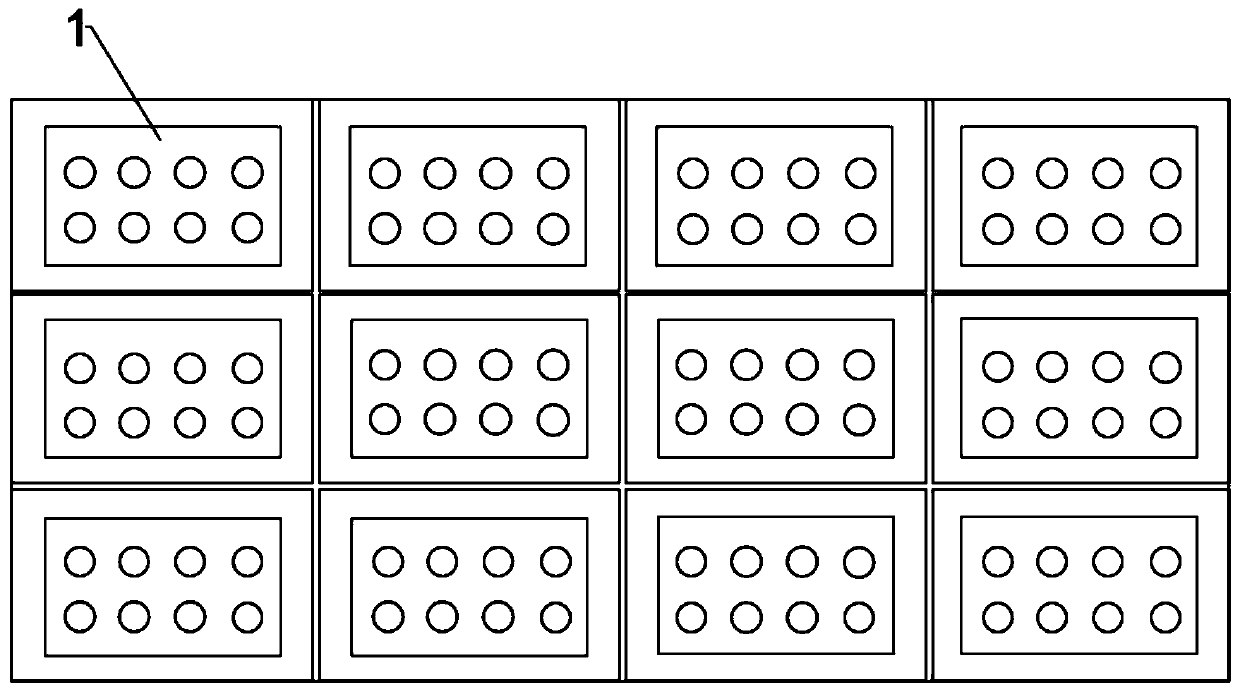

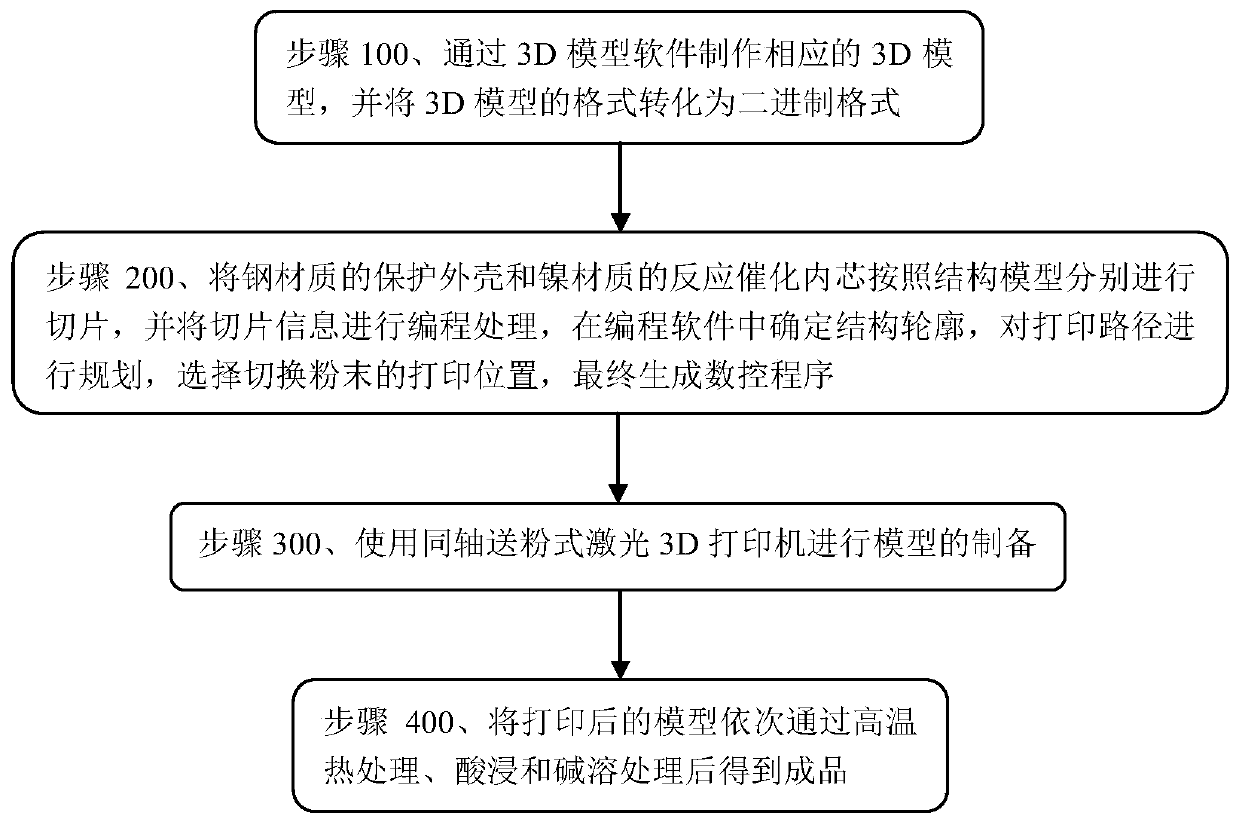

3D printing microchannel reactor for production of natural gas by coal gas and printing process thereof

ActiveCN110802228AStable manufacturingSave materialAdditive manufacturing apparatusIncreasing energy efficiency3d printPtru catalyst

The embodiment of the invention discloses a 3D printing microchannel reactor for production of natural gas by coal gas. The 3D printing microchannel reactor is formed by a plurality of same modular units which are connected in series and / or in parallel in array arrangement. Each module unit comprises a protecting shell made from steel and a reaction catalytic inner core made from nickel. A plurality of catalytic channels are arranged in the reaction catalytic inner core. Microporous reaction interfaces are formed by high-temperature induction on the inner surfaces of the catalytic channels andpickling and alkali dissolution. The invention also discloses a 3D printing process which is characterized by comprising a printing process of a 3D model and a post-processing process of the D3 printing model. The microchannel reactor can be prepared quickly and stably, can be formed primarily without assembling and secondary processing, and the microchannel reactor can be accumulated modularly.Meanwhile, catalysts formed in the microchannel pores are wear-resistant without carbon deposition and pulverization to block the channels, so that the reaction speed is high and the production efficiency can be improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com