Production and apparatus for preparing non-dendritic and semi-solid alloy by low-voltage pulse electric field

A pulsed electric field and semi-solid technology, which is applied in the field of semi-solid metal processing, can solve the problems of stirring dead angle, difficult operation, poor safety performance, etc., so as to avoid air suction and slag inclusion, stabilize the melt liquid cavity, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

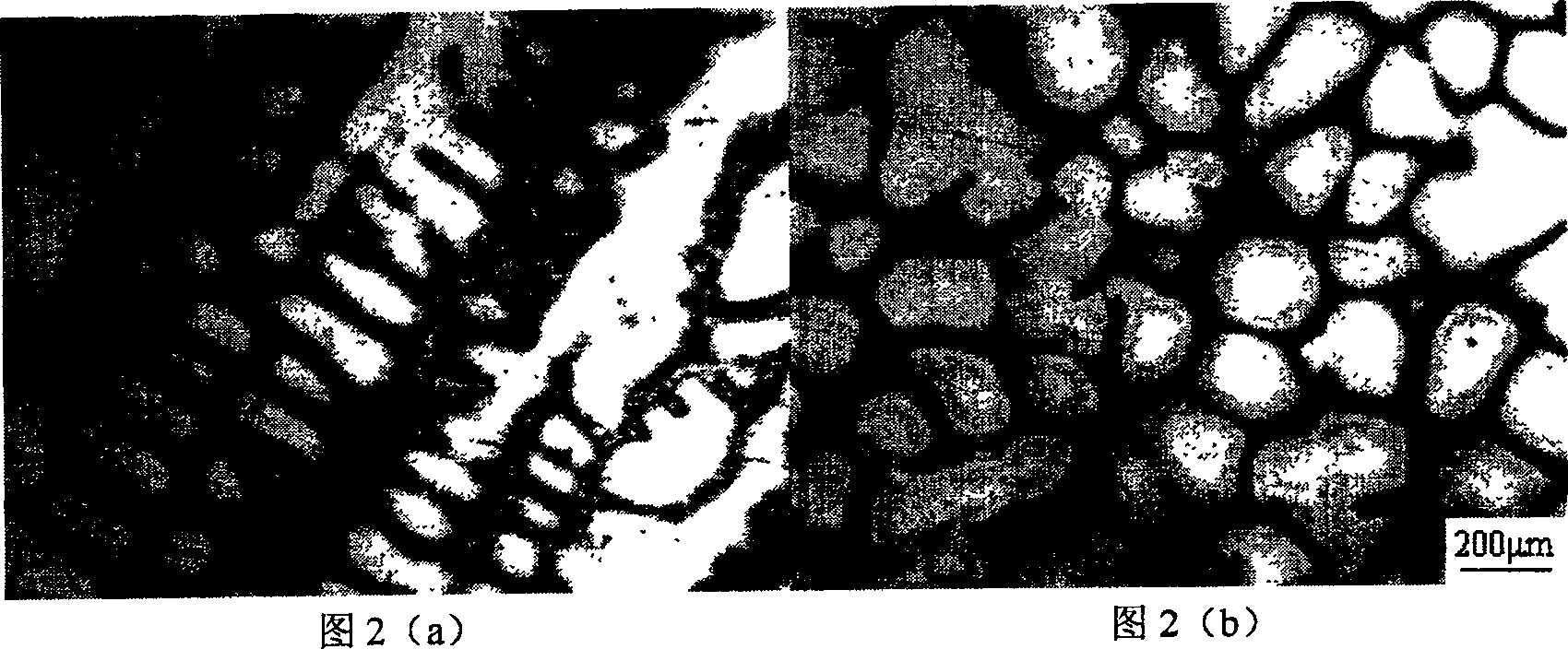

[0048] The Al-4.5% Cu alloy is melted and refined in a heat preservation crucible, and kept at 675° C. for 30 minutes to ensure that the temperature of the alloy liquid is uniform, and the electrode and the alloy melt are well connected. When the temperature of the alloy melt drops to 651°C, start the pulse generating device and begin to discharge the alloy melt. The discharge voltage is 300V, the discharge time is 10 minutes, and the pulse frequency is 0.13Hz. The average cooling of the alloy during the pulse discharge process The speed is controlled at 2°C / min, and the upper electrode is removed after the discharge, and the alloy ingot is cooled with the furnace. It can be seen from Figure 2(a) and Figure 2(b) that the microstructure of the ingot after the low-voltage pulsed electric field treatment changes from the original coarse dendrite to the spherical or granular non-dendritic structure.

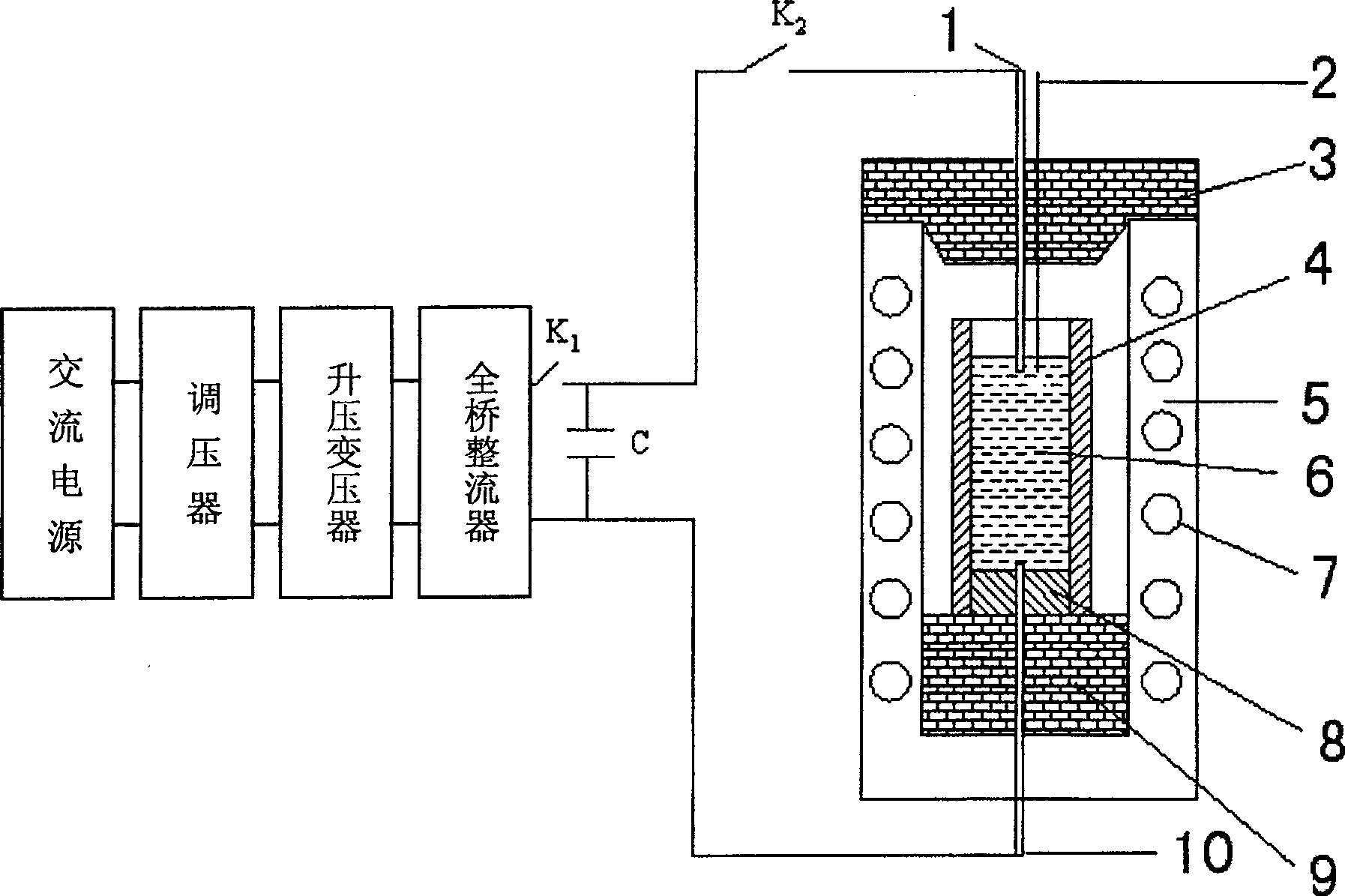

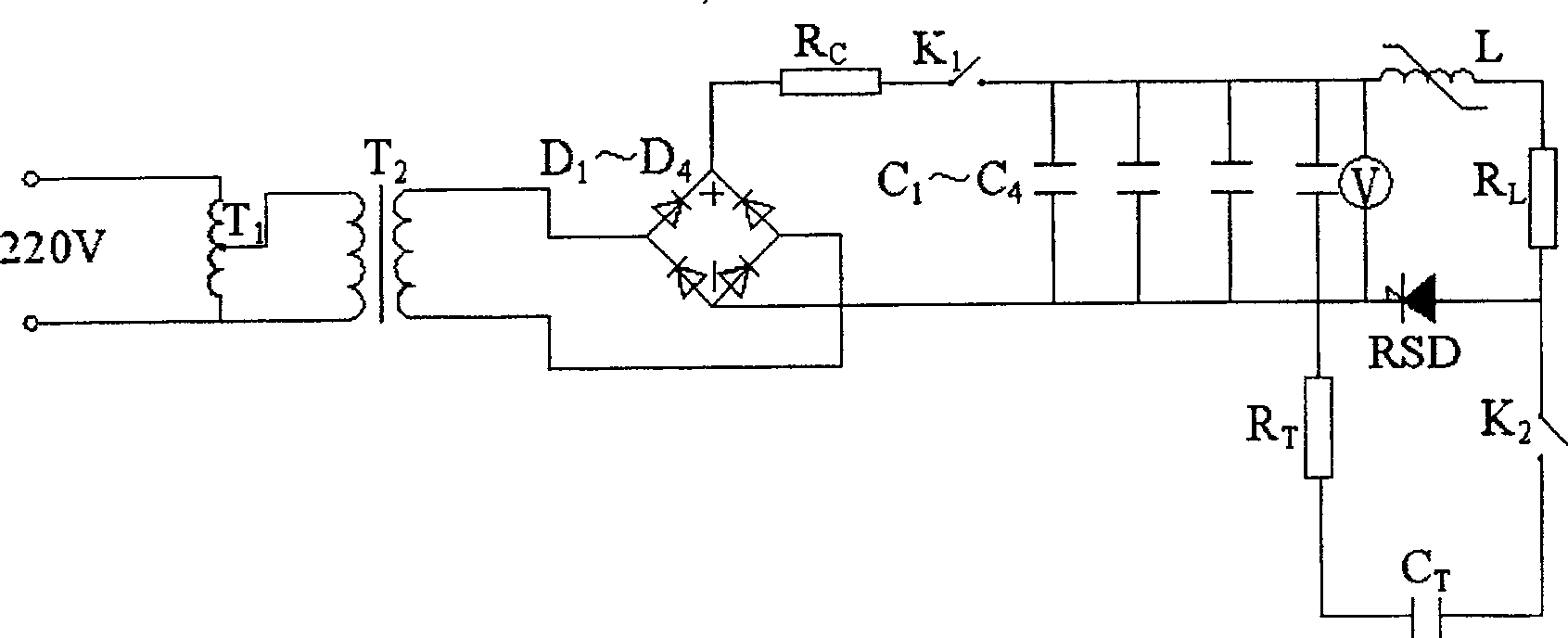

[0049] Additionally, if image 3 As shown, the pulse electric field generating ...

Embodiment 2

[0055] The AZ91D alloy is melted and refined in a heat preservation crucible, and kept at 650°C for 20 minutes to ensure that the temperature of the alloy liquid is uniform, and the electrode is connected to the alloy melt. When the temperature of the alloy melt drops to 593°C, start the pulse generating device and begin to discharge the alloy melt. The discharge voltage is 400V, the discharge time is 20 minutes, and the pulse frequency is 0.125Hz. The average cooling of the alloy during the pulse discharge process The speed is controlled at 15°C / min, and the upper electrode is removed after the discharge, and the alloy ingot is cooled with the furnace.

Embodiment 3

[0057]Melt and refine pure aluminum in an insulated crucible, keep it at 700°C for 40 minutes to ensure uniform temperature of the alloy liquid, and connect the electrodes to the alloy melt. When the temperature of the alloy melt drops to 670°C, start the pulse generating device and begin to discharge the alloy melt. The discharge voltage is 350V, the discharge time is 15 minutes, and the pulse frequency is 0.5Hz. The average cooling of the alloy during the pulse discharge process The speed is controlled at 28°C / min. After the discharge, the upper electrode is removed, and the alloy ingot is cooled with the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com