Piling and printing method of cotton fabric by reactive dye

A technology of reactive dyes and printing methods, applied in the field of printing and dyeing, can solve the problems of high energy consumption and high water consumption, and achieve the effects of less equipment investment, low energy consumption and excellent permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The pure cotton plain weave fabric is deboiled, scoured and bleached for later use;

[0041] Industrial pure reactive yellow KN-G (reactive dye), industrial pure urea, food grade sodium alginate (thickener), industrial pure sodium carbonate (alkali agent), industrial pure hexadecimal Sodium phosphate and add deionized water to 100% to prepare color paste; the specific method is as follows:

[0042] ①Slowly add sodium alginate to deionized water and stir to prepare the original paste;

[0043] ②Dissolve the weighed dye, urea, and sodium carbonate in deionized water to form a solution;

[0044] ③ Add the dye solution and urea solution prepared in step ② to the original paste prepared in step ① in turn, stir while adding, and finally add the sodium carbonate solution prepared in step ②.

[0045] Print pure cotton plain fabric with prepared color paste;

[0046] Wrap the printed pure cotton plain weave fabric with a plastic film and stack it for the time specified in Tab...

Embodiment 2~ Embodiment 8

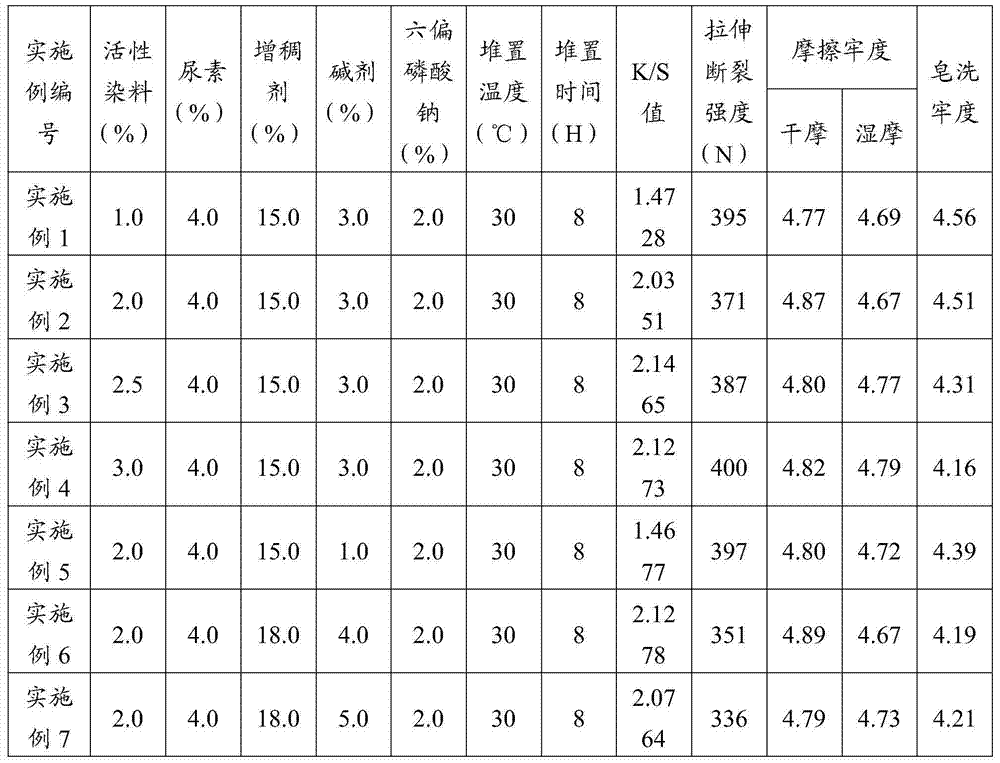

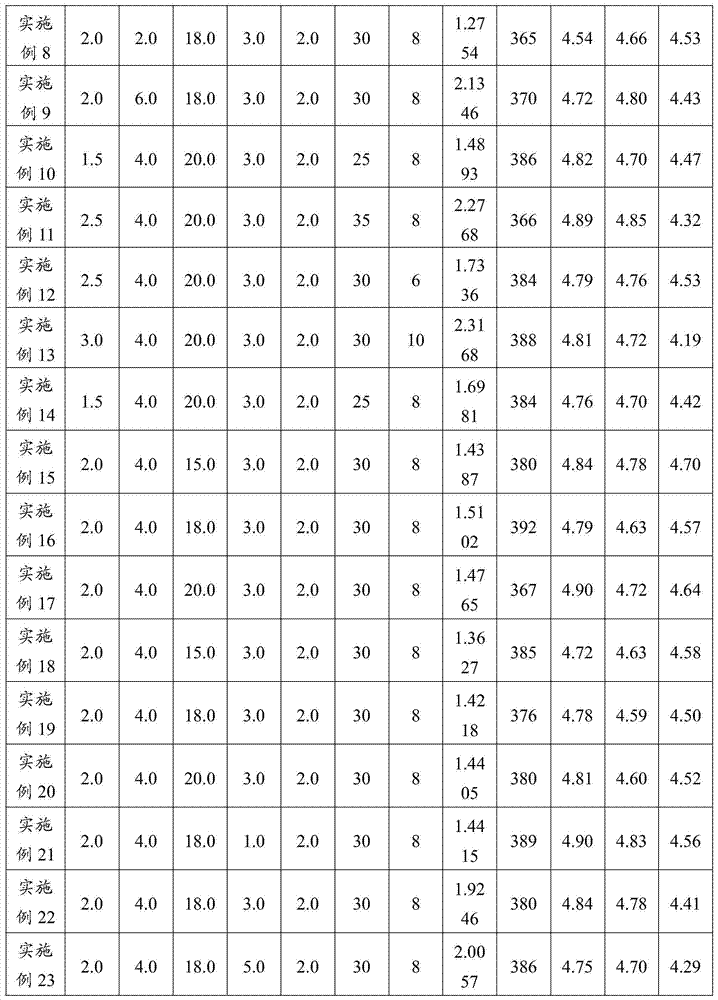

[0057] The procedure of Example 1 was repeated at the component contents and storage temperature and storage time specified in Table 1 below, the test results are listed in Table 1.

Embodiment 9~ Embodiment 11

[0059] Repeat the method of embodiment 1 by the specified component content and stacking temperature and stacking time in the following table 1, but replace reactive yellow KN-G with reactive brilliant blue KN-R, test result is listed in table 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com