Method for increasing AZ91D magnesium alloy corrosion-resistant property

A magnesium alloy and corrosion-resistant technology, applied in the field of improving the corrosion resistance of AZ91D magnesium alloy, can solve the problems of material consumption, high cost, time consumption, etc., and achieve the effects of abundant resources, simple installation, and convenient operation and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

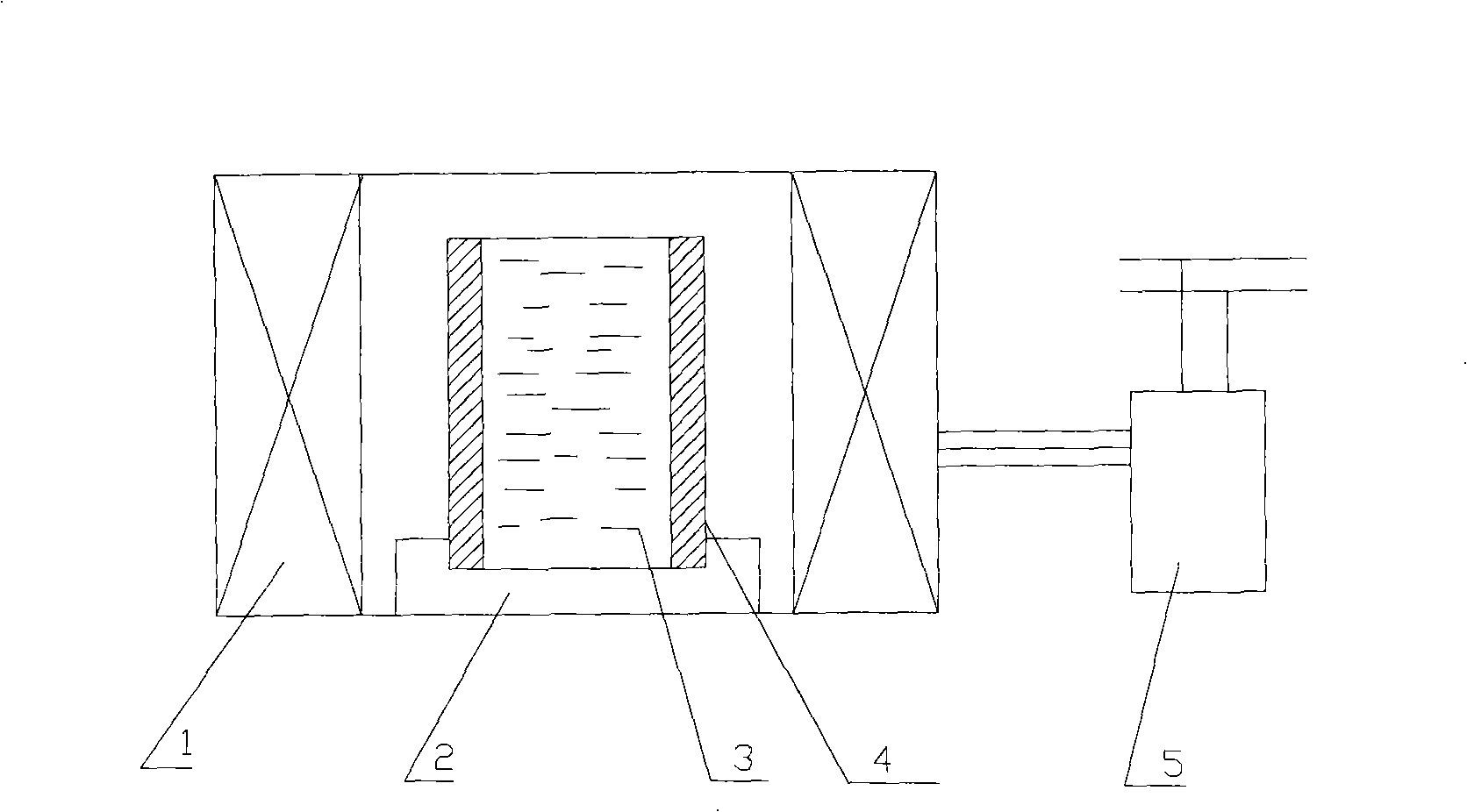

Embodiment 1

[0029] Place the magnesium alloy AZ91D in a crucible, put it in a graphite crucible, heat and smelt in a well-type crucible resistance furnace, when the furnace cavity temperature rises to 600 ℃, pass in CO 2 +SF 6 The mixed gas is protected. When the temperature continues to rise to 720°C, add 0.02% B in the form of an Al-4B (mass fraction, %) master alloy to the alloy liquid, stir it evenly and keep it for 10 minutes, and wait for the temperature to drop. At 685°C, the magnesium alloy is cast into a metal mold (preheated to 350°C), and the mold is placed in a rotating magnetic field generator. After casting, immediately turn on the electricity to start the rotating magnetic field, the current frequency is 50HZ, and the excitation voltage is adjusted to 50V. The alloy is solidified under the action of the rotating magnetic field and cooled at room temperature. After solidification, the rotating magnetic field generator is turned off and the mold is released. The chemical composit...

Embodiment 2

[0033] Put the AZ91D magnesium alloy in a crucible, put it in a graphite crucible, heat and melt in a well-type crucible resistance furnace, when the furnace cavity temperature rises to 600 ℃, let CO 2 +SF 6 The mixed gas is protected. When the temperature continues to rise to 730℃, add 0.05% of B mass fraction to the alloy liquid in the form of Al-4B (mass fraction, %) master alloy, stir it evenly and keep it for 15 minutes, and wait for the temperature to drop. At 690°C, the magnesium alloy is cast into a metal mold (preheated to 300°C), and the mold is placed in a rotating magnetic field generator. After casting, immediately turn on the power to start the rotating magnetic field, the current frequency is 50HZ, and the excitation voltage is adjusted to 100V. The alloy is solidified under the action of the rotating magnetic field and cooled at room temperature. After solidification, the rotating magnetic field generator is turned off and the mold is released.

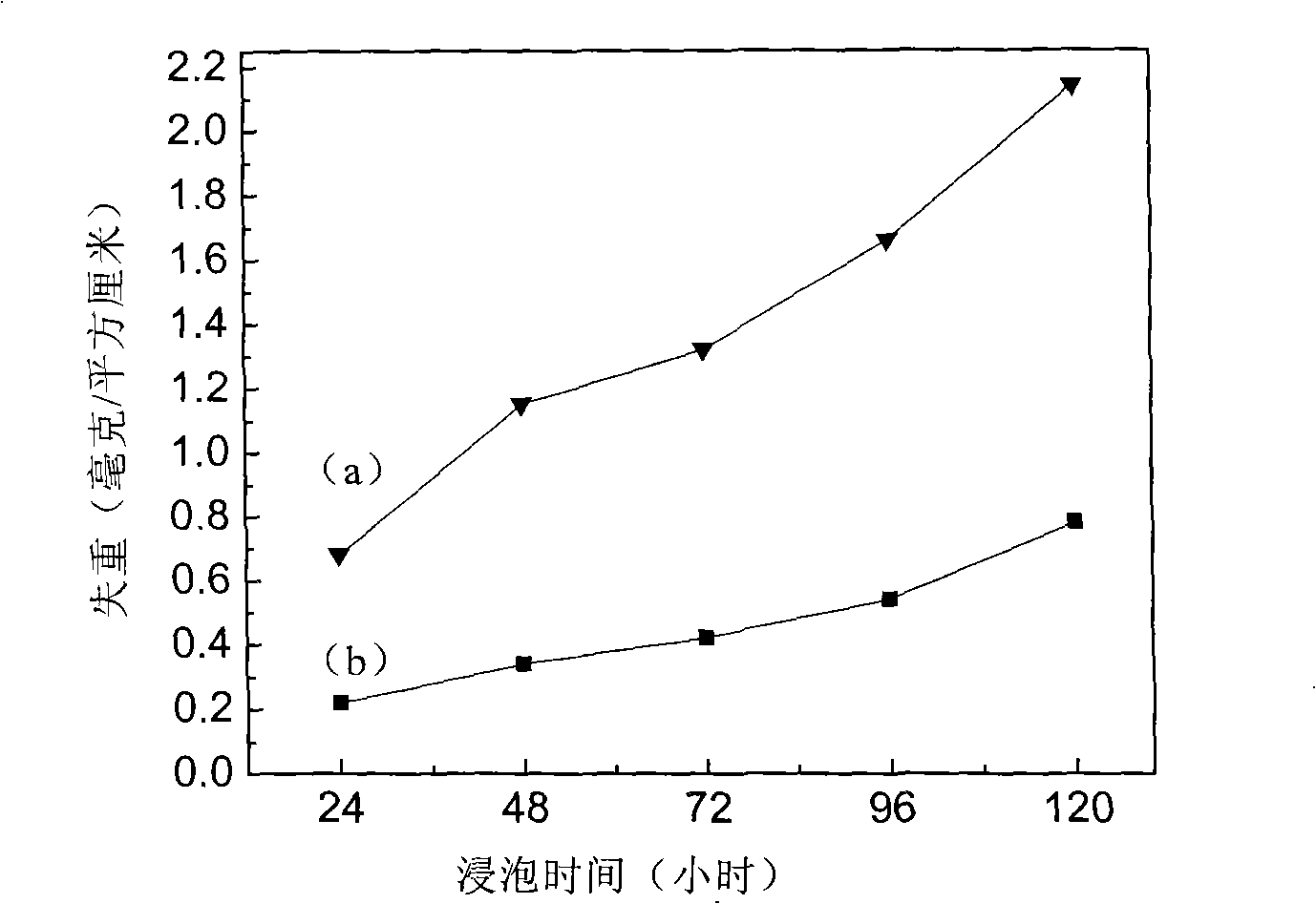

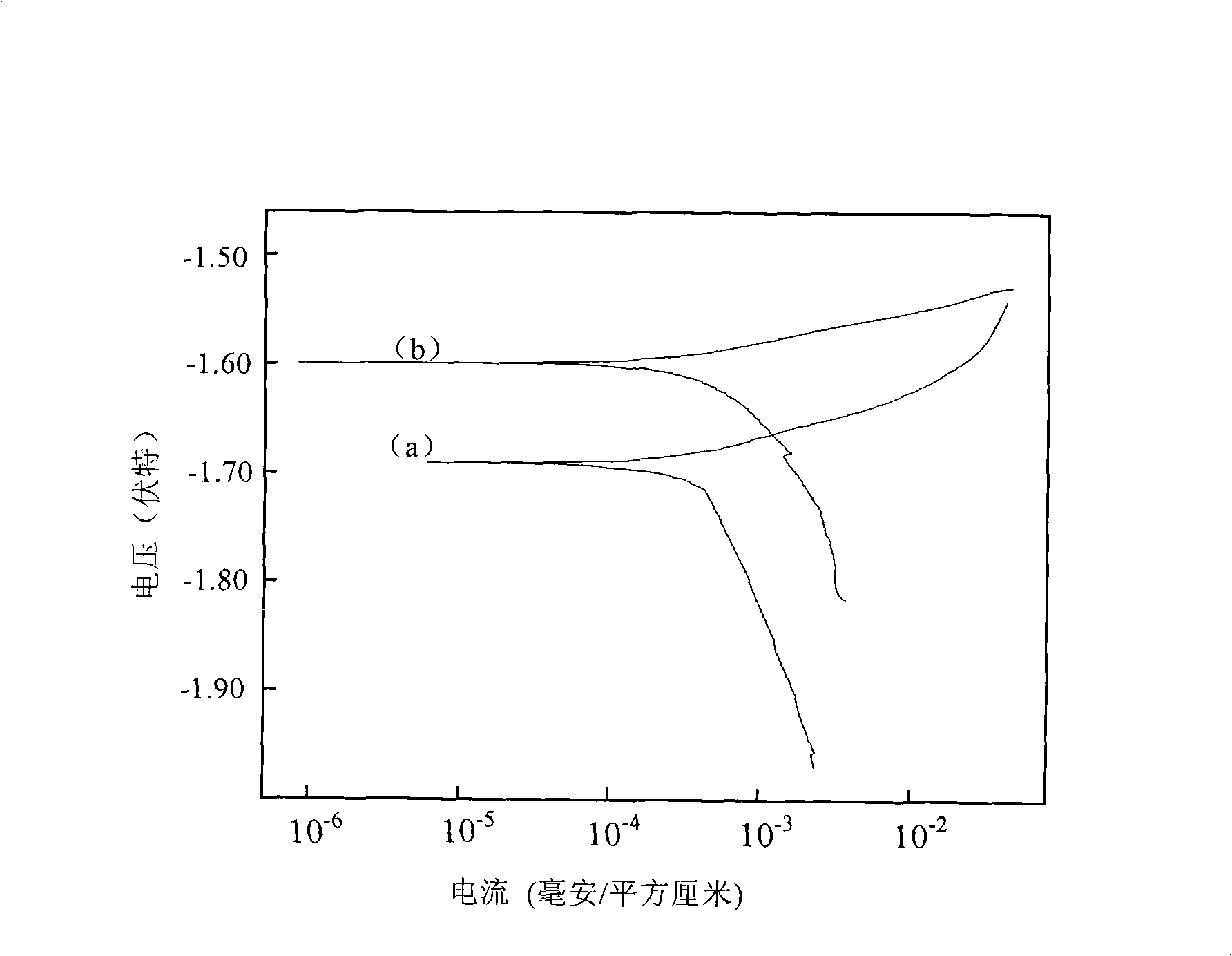

[0034] Potential p...

Embodiment 3

[0035] Example 3: Put AZ91D magnesium alloy in a crucible, put it in a graphite crucible, and heat and melt in a pit crucible resistance furnace. When the temperature of the furnace chamber rises to 590°C, let CO 2 +SF 6The mixed gas is protected. When the temperature continues to rise to 730°C, add 0.03% of B in the form of Al-4B (mass fraction, %) master alloy to the alloy liquid, stir it evenly and keep it for 20 minutes, and wait for the temperature to drop. At 690°C, the magnesium alloy is cast into a metal mold (preheated to 300°C), and the mold is placed in a rotating magnetic field generator. After casting, immediately turn on the electricity to start the rotating magnetic field, the current frequency is 50HZ, and the excitation voltage is adjusted to 120V. The alloy is solidified under the action of the rotating magnetic field and cooled at room temperature. After solidification, the rotating magnetic field generator is turned off and the mold is released.

[0036] The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com