NbBN composite coating and preparation method thereof

A technology of composite coating and B target, applied in the direction of coating, metal material coating process, ion implantation plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A preparation method of NbBN composite coating, the steps are as follows:

[0020] (1) The cemented carbide or ceramics used as the substrate is ultrasonically cleaned for 15 minutes with water, acetone, and absolute ethanol successively, dried and fixed on the rotatable substrate stage of the sputtering chamber, and the sample baffle is closed;

[0021] (2) Nb targets and B targets with a purity of 99.9% are respectively fixed on the radio frequency gun;

[0022] (3) Pump the air pressure of the sputtering chamber to 6.0×10 -4 Below Pa;

[0023] (4) Passing into the argon gas with a purity of 99.999%, the flow control is 10 sccm, and the sputtering chamber pressure is maintained at 0.25 Pa;

[0024] (5) Adjust the power of Nb target and B target to 60W, and sputter for 10 minutes to clean various impurities on the surface of the target;

[0025] (6) Adjust the power of the Nb target to 200W, close the B target, open the sample baffle, keep the sample rotation speed ...

Embodiment 1

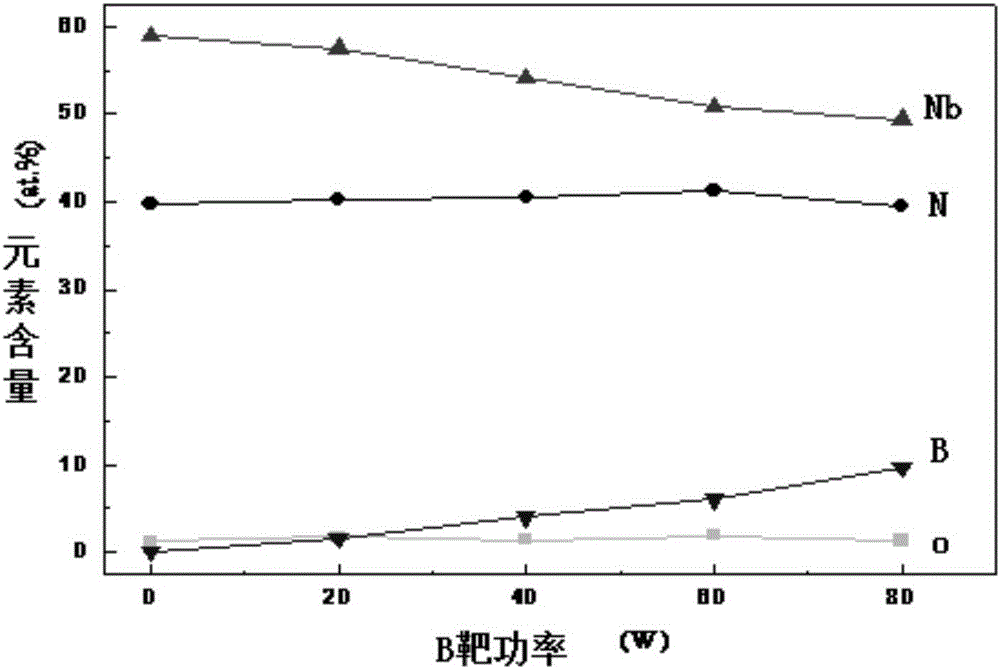

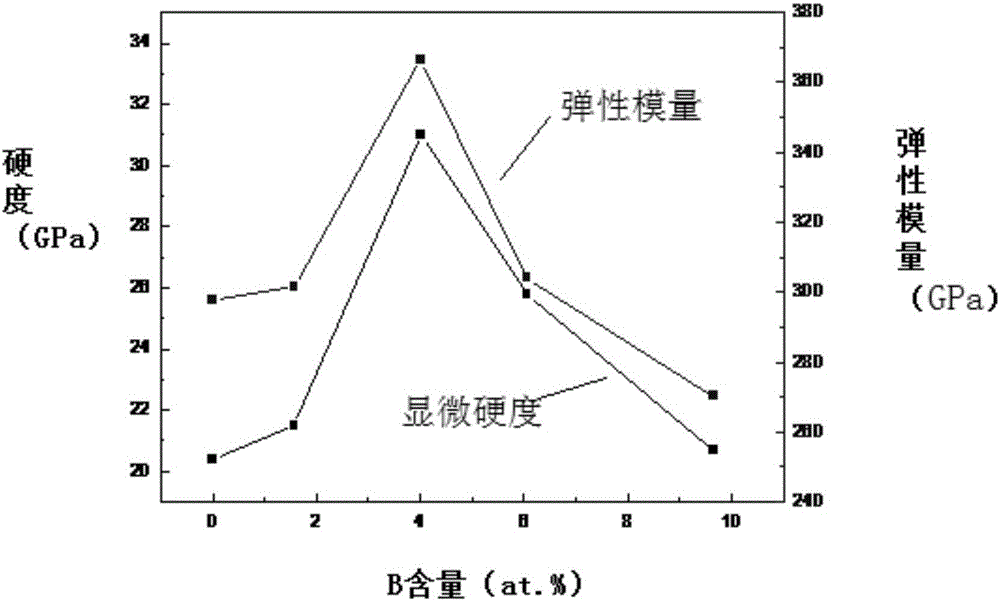

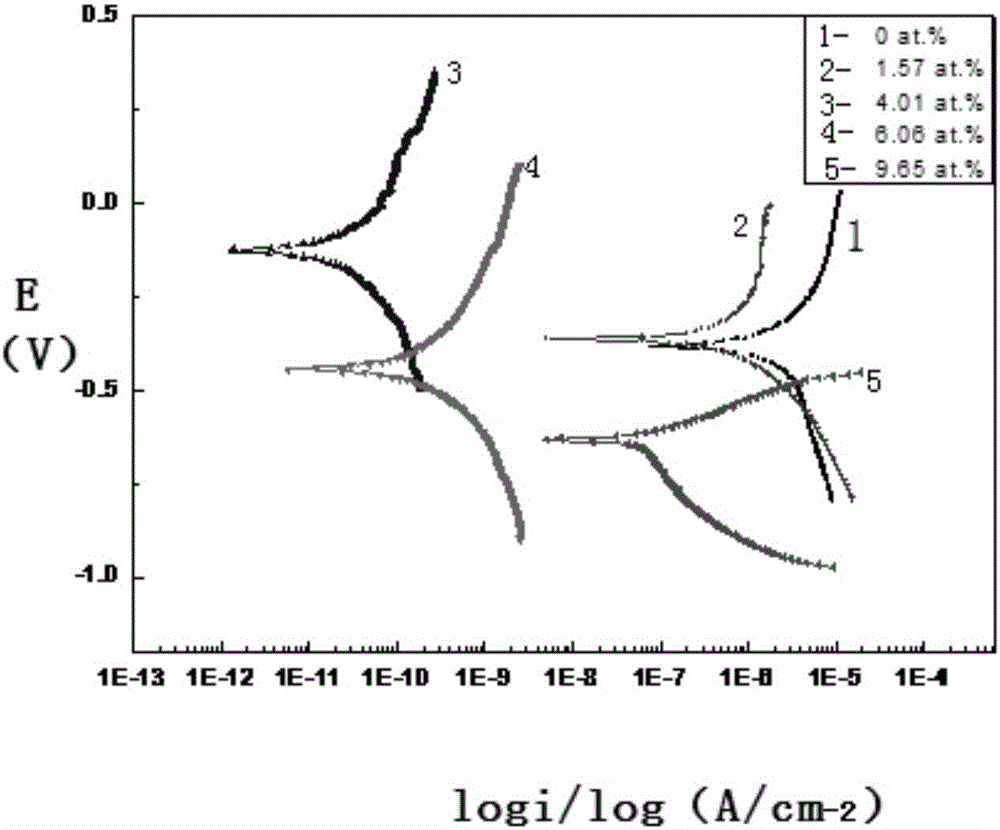

[0029] Change the B target power, when the B target power is 0W, the Nb component is 58.92at.%, the B component is 0at.%, the N component is 39.8at.%, and the O component is 1.28at.%. The microhardness is 20.39GPa , the elastic modulus is 297.93GPa, the self-corrosion voltage is -0.386V, and the self-corrosion current density is 1.13×10 -6 A / cm 2 , The wear at room temperature is 1.88×10 -7 mm -3 N -1 mm -1 、The wear rate at 350℃ is 8.89×10 -7 mm -3 N -1 mm -1 、The wear rate at 500℃ is 1.11×10 -6 mm -3 N -1 mm -1 .

Embodiment 2

[0031] When the B target power is 20W, the Nb component is 57.53at.%, the B component is 1.57at.%, the N component is 40.19at.%, and the O component is 1.71at.%. The microhardness is 21.5GPa, and the elastic modulus is 301.7GPa, self-corrosion voltage of -0.365V, self-corrosion current density of 8.95×10 -7 A / cm 2 , The wear at room temperature is 1.31×10 -7 mm -3 N -1 mm -1 、The wear rate at 350℃ is 6.67×10 -7 mm -3 N -1 mm-1 、The wear rate at 500℃ is 7.22×10 -7 mm -3 N -1 mm -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com