Patents

Literature

56results about How to "Reduced self-corrosion current density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of anticorrosion epoxy resin embroidered coating containing coupled, dispersed and modified pigment fillings

InactiveCN107779052AGood dispersionImprove surface conditionFireproof paintsAnti-corrosive paintsEpoxySlurry

The invention discloses a preparation method of an anticorrosion epoxy resin embroidered coating containing coupled, dispersed and modified pigment fillings. The preparation method is characterized bycomprising the following steps: mixing talcum powder, iron oxide red, zinc phosphate and aluminum triphosphate, adding a dispersing agent, a titanate coupling agent and deionized water, dispersing, and grinding to obtain pigment slurry; adding a mixed solvent and KH550 into a graphene nanosheet, and carrying out uniform ultrasonic treatment, so as to obtain coupled and modified graphene nanosheetslurry; uniformly mixing KH560, ethyl orthosilicate and isopropanol, so as to obtain a component A; mixing isopropanol with deionized water, dropwise adding the mixed solution into the component A, and carrying out hydrolysis and polycondensation, so as to obtain hybridized silicon sol; dropwise adding diethanol amine and polyether amine into epoxy resin for reaction, dropwise adding glacial acetic acid for reaction, adding deionized water, stirring for emulsification so as to obtain an epoxy resin emulsion, mixing the epoxy resin emulsion with the obtained materials in foresaid steps, addinga polyurethane flatting agent, a film forming aid and a defoaming agent, uniformly mixing, and mechanically dispersing, so as to obtain the coating.

Owner:马鞍山天宇船舶制造有限公司

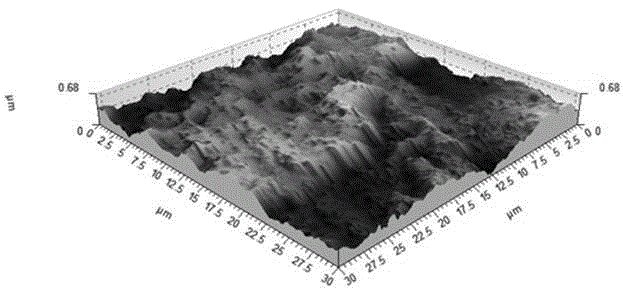

Titanium and titanium alloy surface anodic oxidation coloring method

InactiveCN105239133ASimplify the anodizing processIncreased self-corrosion potentialSurface reaction electrolytic coatingElectrolysisTitanium

The invention discloses a titanium and titanium alloy surface anodic oxidation coloring method and belongs to the technical field of metal surface treatment. The method includes the following steps that a cleaned commercial pure titanium sample is put in a solution with a proportion of HF: HNO3: H2O for electrolytic polishing; the cleaned and dried sample is put in a mixed solution of concentrated sulfuric acid and methanesulfonic acid for anodic oxidation treatment; and the sample obtained after being subjected to the anodic oxidation treatment is rapidly cleaned through ethyl alcohol and deionized water and then dried under the vacuum condition so that the colored sample can be obtained. Anodic oxide films in different colors are obtained through control over anodic oxidation voltage and treatment time, and the anodic oxide films are bright and uniform in color and luster and good in corrosion resistance.

Owner:KUNMING UNIV OF SCI & TECH

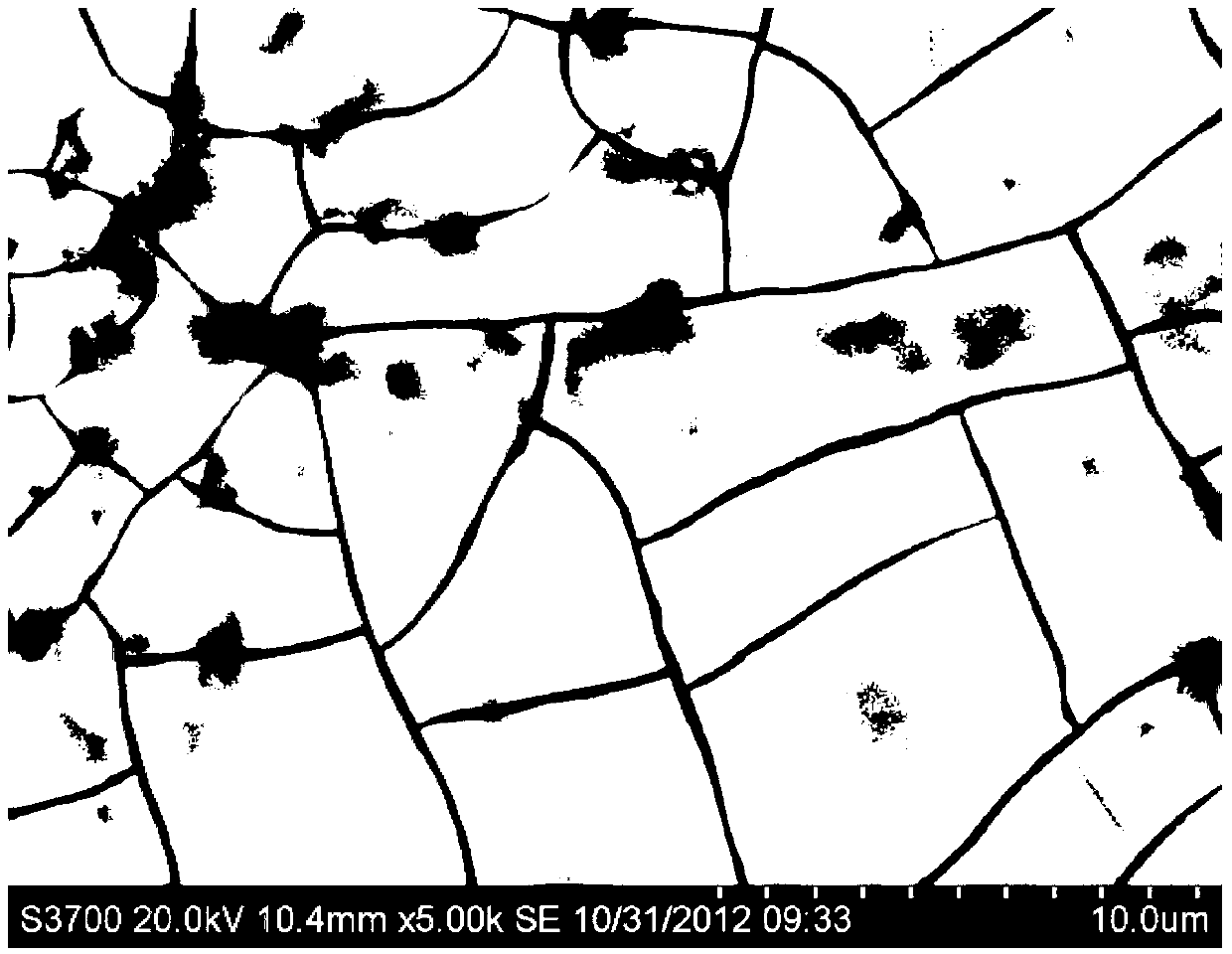

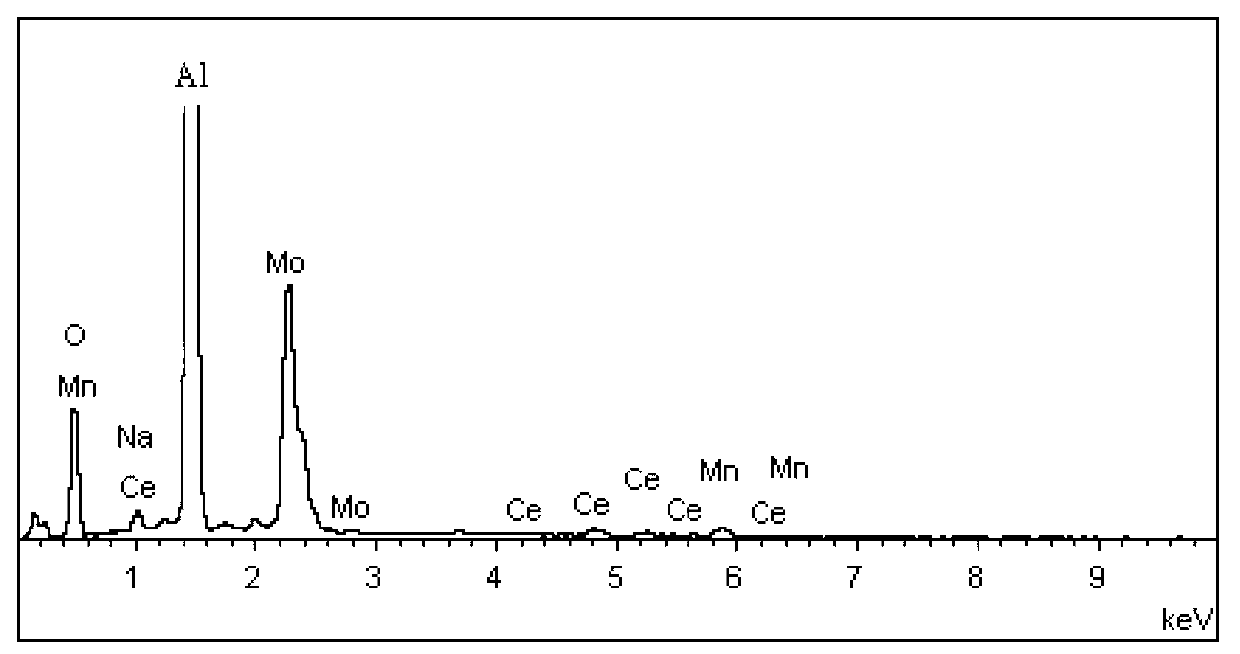

Method for preparing cerium-manganese/molybdenum multi-element composite conversion coating on surface of aluminum alloy

ActiveCN103276387AReduce the temperatureSave energyMetallic material coating processesWeather resistanceCerium

The invention discloses a method for preparing a cerium-manganese / molybdenum multi-element composite conversion coating on the surface of aluminum alloy. The method comprises the following steps of: (1) pretreating and activating the aluminum alloy; and (2) placing the aluminum alloy treated in the step (1) in Ce-Mn conditioning fluid so as to prepare the golden cerium-manganese conversion coating on the surface of the aluminum alloy; and (3) placing the aluminum alloy treated in the step (2) in Mo-containing conditioning fluid to obtain the cerium-manganese / molybdenum multi-element composite conversion coating. The conditioning fluids adopted in the method do not contain toxic substances. The multi-element composite conversion coating with excellent corrosion resistance and weather resistance as well as relatively good wear resistance can be prepared on the surface of aluminum alloy. The method is relatively simple in technology, simple and convenient to operate, low in cost and easy to industrialize.

Owner:SOUTH CHINA UNIV OF TECH +1

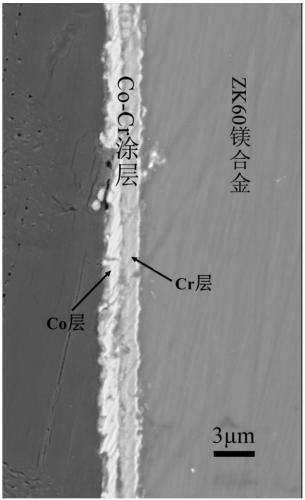

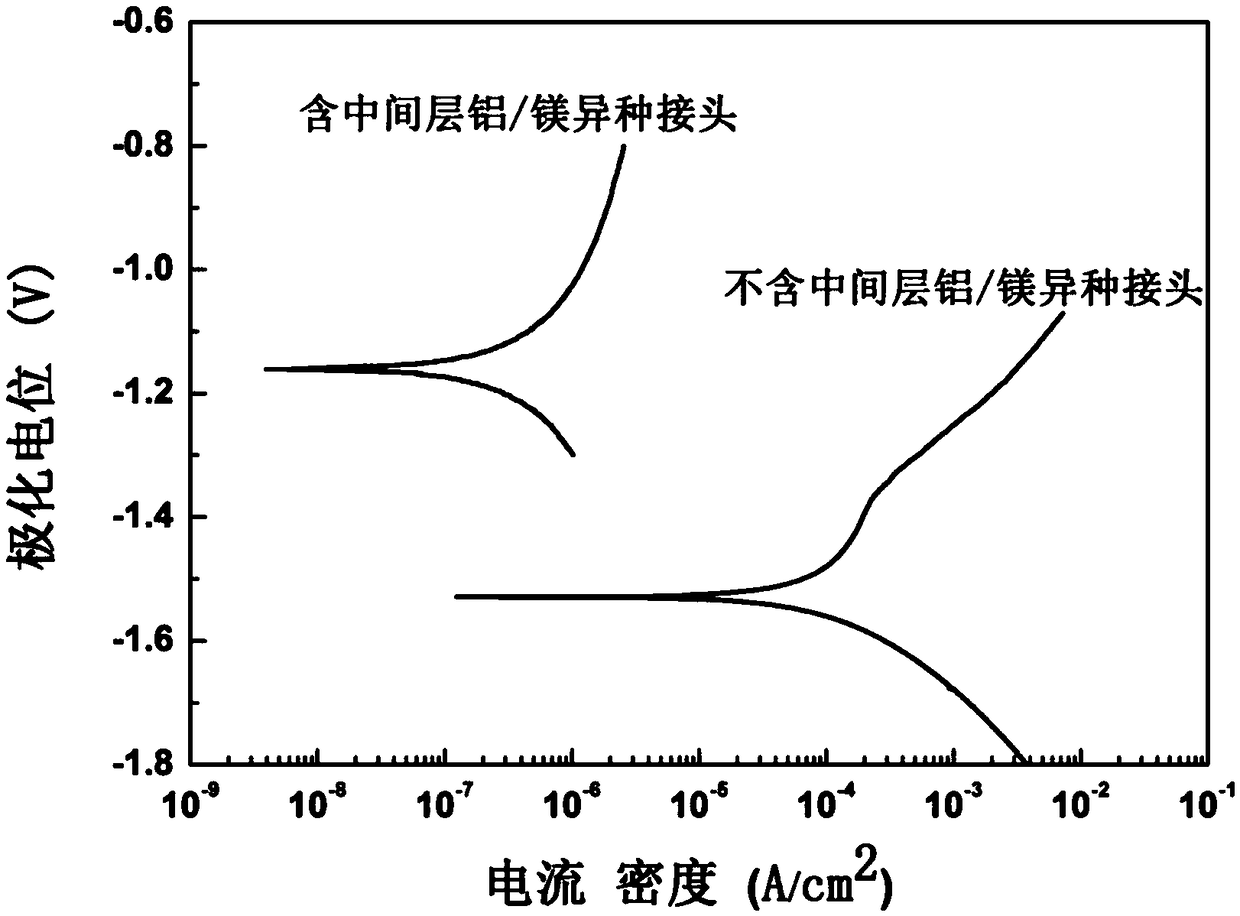

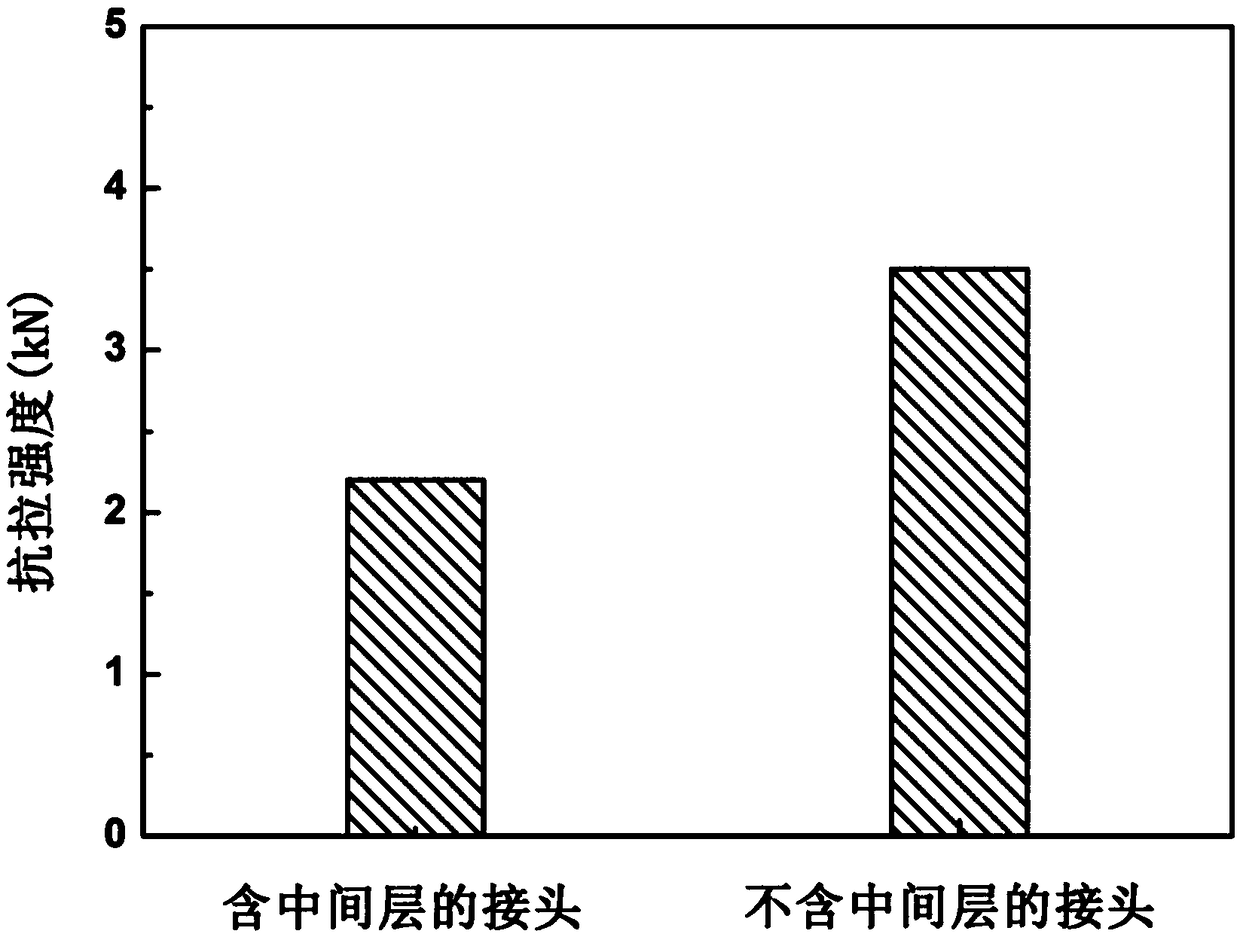

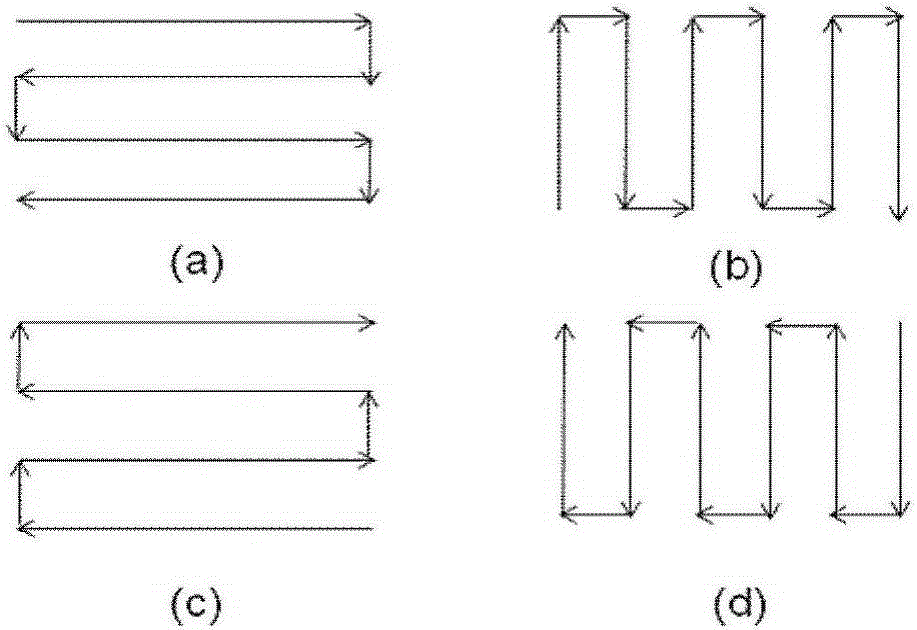

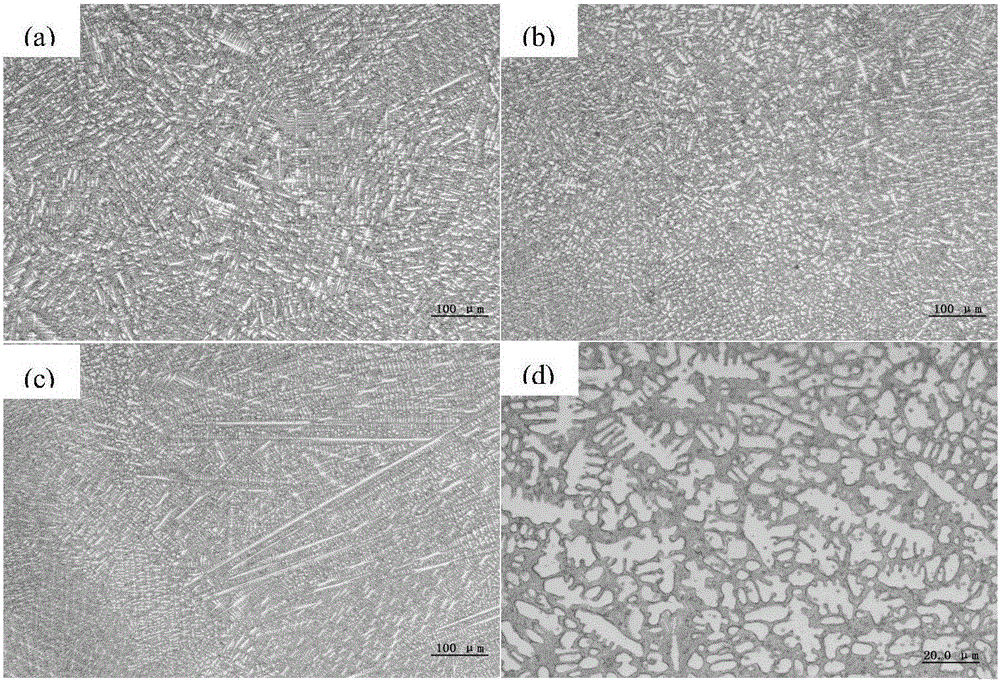

High-strength anti-corrosion aluminum/magnesium dissimilar alloy connector containing middle layer and preparing method of connector

ActiveCN108950508AImprove bindingHigh bonding strengthVacuum evaporation coatingSputtering coatingMetal coatingMulti material

The invention relates to a high-strength anti-corrosion aluminum / magnesium dissimilar alloy connector containing a middle layer. The alloy connector is sequentially provided with an aluminum alloy, the middle layer and a magnesium alloy from top to bottom; the aluminum alloy is 5-series or 6-series aluminum alloy plates, the magnesium alloy is AZ-series or ZK-series magnesium alloy plates, and themiddle layer is a Co-Cr composite metal coating; and the thickness of the Co-Cr composite metal coating is 2.8 microns-6.6 microns. By means of the high-strength anti-corrosion aluminum / magnesium dissimilar alloy connector and the preparing method, reacting between the Al and the Mg can be effectively slowed down, forming of Al-Mg intermetallic compounds at the interface position is restrained, the microstructure of the connector is improved, the mechanical strength and the corrosion property of the connector are further improved, and the using requirement of the aluminum / magnesium dissimilaralloy connector in a multi-material car body is met.

Owner:HEBEI UNIV OF TECH

Biotic bone composite material and preparing method thereof

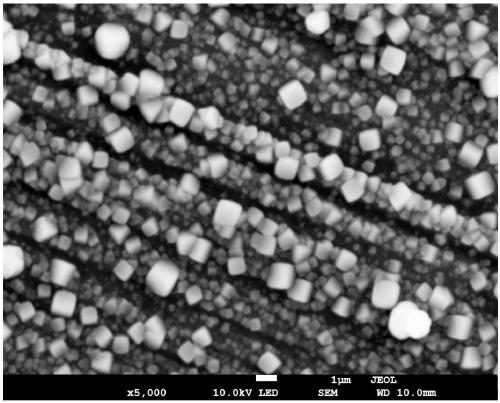

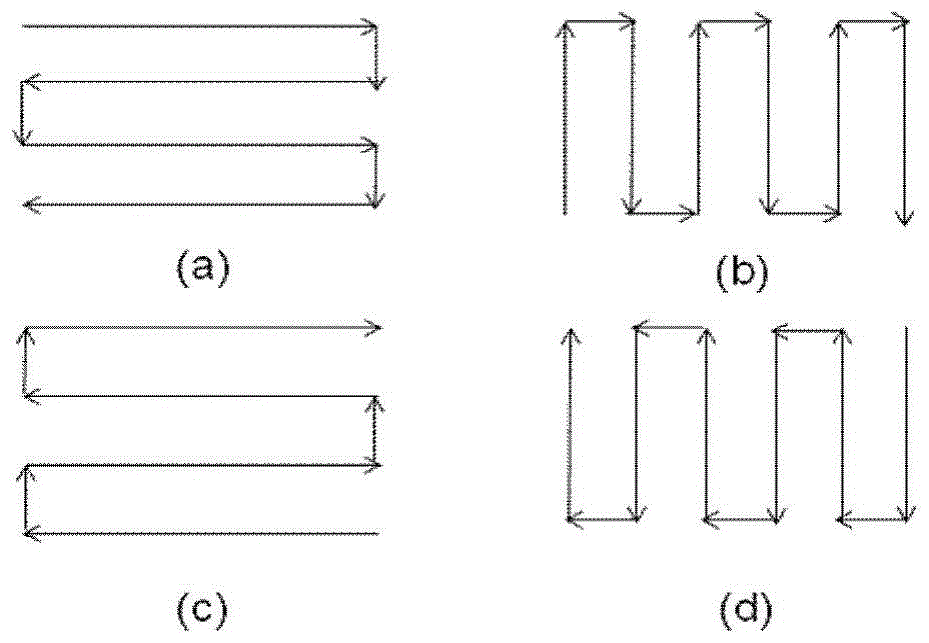

ActiveCN105256174AHigh hardnessImprove wear resistanceAdditive manufacturing apparatusIncreasing energy efficiencyContinuous scanningSpherical shaped

The invention discloses a biotic bone composite material and a preparing method thereof and belongs to the technical field of materials. The composite material is formed by combining CoCrMo alloy powder, CeO2 alloy powder and ZrO2 alloy powder and comprises, by mass, 92-98% of CoCrMo alloy powder, 1-3% of CeO2 alloy powder and 1-5% of ZrO2 alloy powder. The particle size range of the CoCrMo powder is 100-200 meshes, the particle size range of the CeO2 powder is 0.5-1 microns, and the particle size range of the ZrO2 powder is 30-80 nm, wherein the three kinds of powder are in spherical shapes. The preparing method includes the steps that firstly, the composite powder is mixed; secondly, a base material which is directly deposited and formed with lasers is pretreated; and thirdly, the technological method for direct depositing and forming with lasers is adopted, a laser 3D printer is adopted, inert gas shielding is conducted, and a laser device conducts continuous scanning for n layers and returns to the position of XY plane origin coordinates. The composite material has good toughness, wear resistance and corrosion resistance, rigidity reaches 619 HV, the tensile strength reaches 686 MPa, the biotic bone composite material is soaked in manual simulation saliva for 7 days, and the concentration of the Cr ion is 0.11 mg / L. The composite material is applied to preparing of artificial bone false teeth.

Owner:NORTHEASTERN UNIV

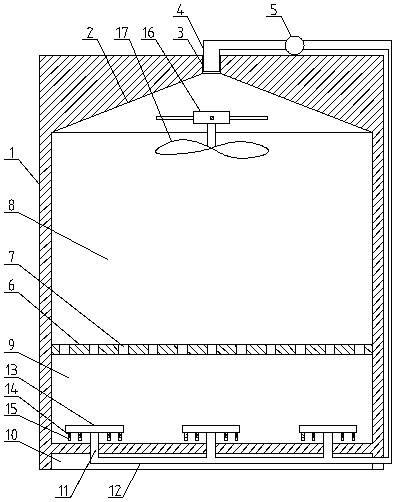

Dust-proof temperature control type computer mainframe box

InactiveCN108459684AGood synergyImprove anti-aging propertiesAntifouling/underwater paintsPaints with biocidesTemperature controlEngineering

The invention discloses a dust-proof temperature control type computer mainframe box. The dust-proof temperature control type computer mainframe box comprises a mainframe box body, the mainframe box body is a closed type structure, the top of the inner side of the mainframe box body is an inverted funnel-shaped structure, and an opening at the upper end of the inverted funnel-shaped structure is communicated with an air inlet of a micro air pump arranged outside the mainframe box body through a first pipeline; the portion, close to the bottom, in the mainframe box body is provided with a transverse partition plate, the transverse partition plate is provided with an air inlet, the transverse partition plate divides the inner portion of the mainframe box body into an equipment cavity used for containing a computer mainframe hardware and located on the upper portion and a water containing cavity used for containing cooling water and located on the lower portion, the bottom of the mainframe box body is provided with a groove used for containing the pipelines, and the top of the groove is provided with a plurality of second pipelines of which the upper portions stretch into the water containing cavity. The dust-proof temperature control type computer mainframe box has the advantages that the whole closed type structure is adopted, the hot air in the mainframe box body is cooled andthen transported into the mainframe box body by utilizing the cooling water, thereby having a temperature control effect and effectively preventing dust from entering the mainframe box body, and a method of an anti-corrosion layer coated on the outer surface of parts in contact with the cooling water is adopted to improve antibacterial, water-resistant and anti-corrosion performance of the parts.

Owner:NANYANG MEDICAL COLLEGE

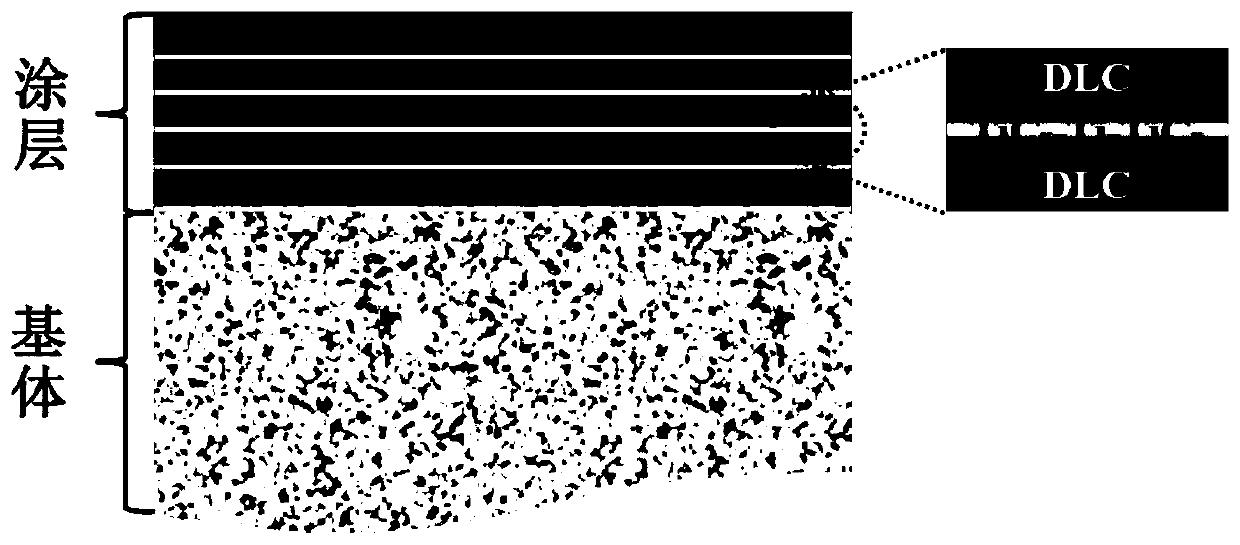

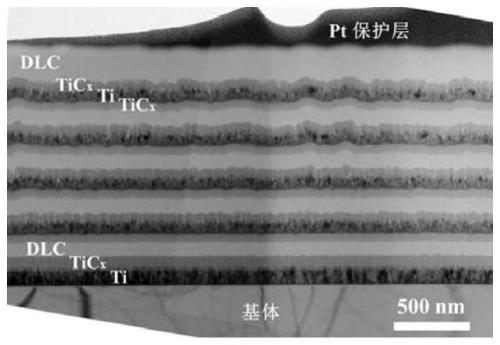

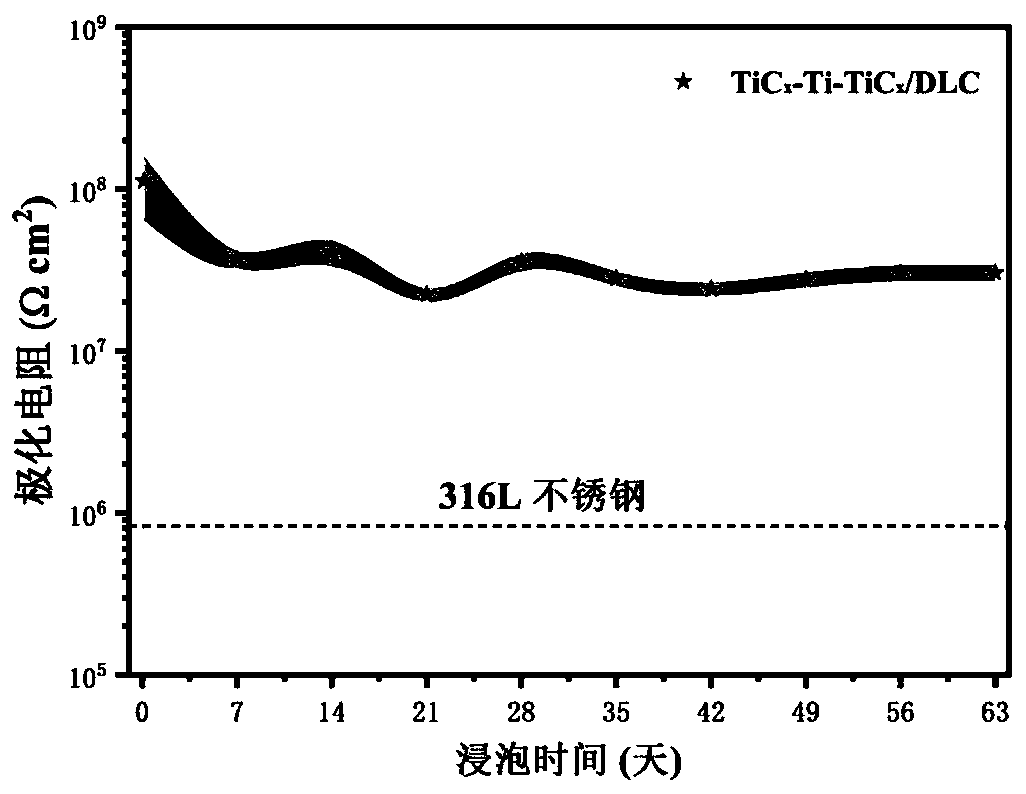

Anti-abrasion protective coating for surface of metal substrate and preparation method and application of anti-abrasion protective coating

ActiveCN110438465AImprove corrosion resistanceReduce stressVacuum evaporation coatingSputtering coatingMechanical propertyDirect current magnetron sputtering

The invention discloses an anti-abrasion protective coating for the surface of a metal substrate and a preparation method and application of the anti-abrasion protective coating. The anti-abrasion protective coating comprises a Ti transition layer, a TiCx gradient layer, a first DLC layer, a TiCx / Ti / TiCx / DLC alternating layer stacking layer and a top layer which are sequentially formed on the surface of the metal substrate by adopting a linear ion source compound direct-current magnetron sputtering technology; the TiCx / Ti / TiCx / DLC alternating layer stacking layer is formed by alternately stacking a TiCx / Ti / TiCx sandwiched layer and a second DLC layer alternating layer; the TiCx / Ti / TiCx sandwiched layer comprises two TiCx layers and a Ti layer arranged between the two TiCx layers; the top layer comprises a third DLC layer; and the value range of the TiCx is 0.8-1.3. The anti- abrasion protective coating is of a structure of alternative multilayer, interfacial gradient and top layer extending and spreading, so that the coating has high comprehensive mechanical property and high corrosion resistance and abrasion resistance. The anti- abrasion protective coating can still maintain a good antifriction lubricating effect in a certain time after being worn out, and shows high abrasion failure tolerance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

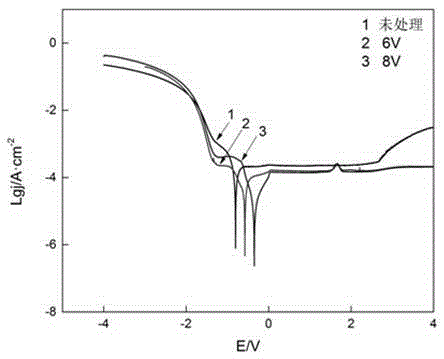

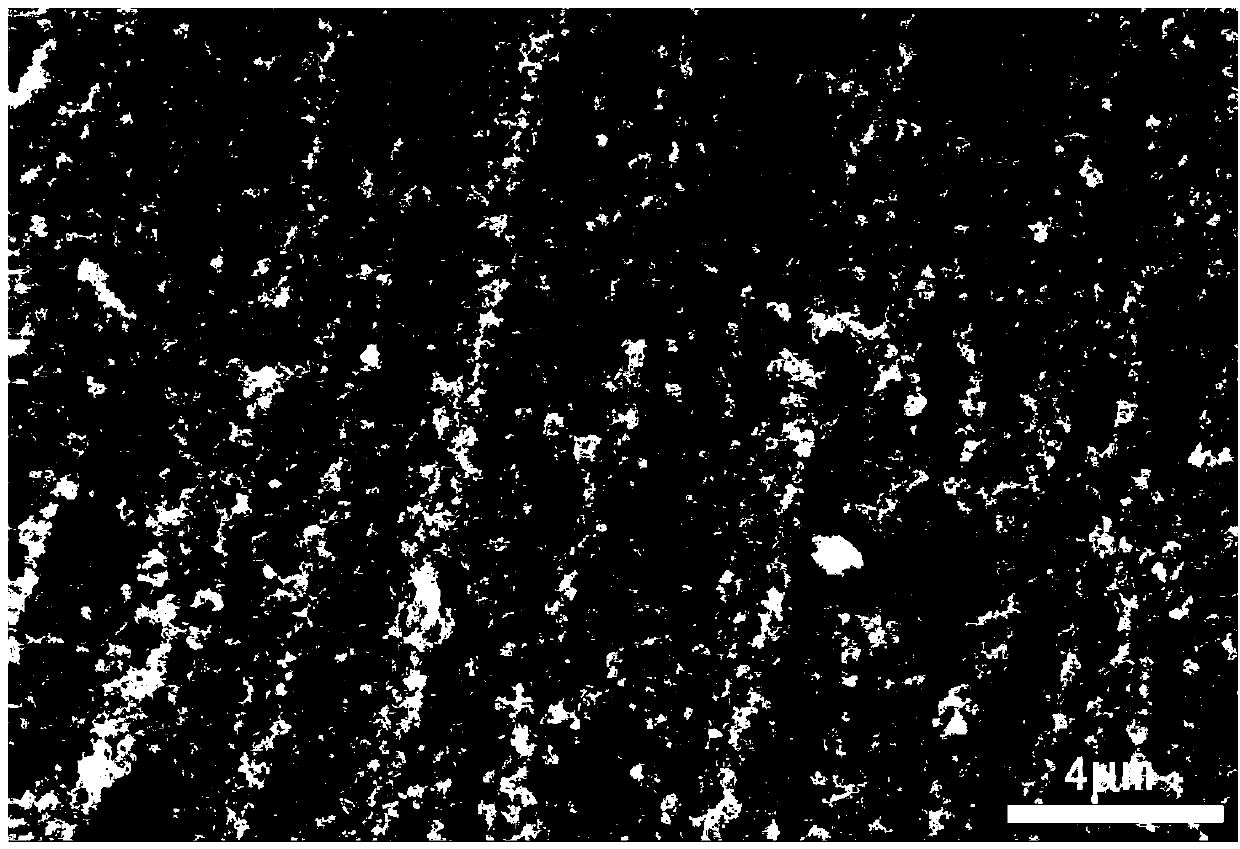

Surface anti-corrosion treatment method of aluminum alloy pump cover

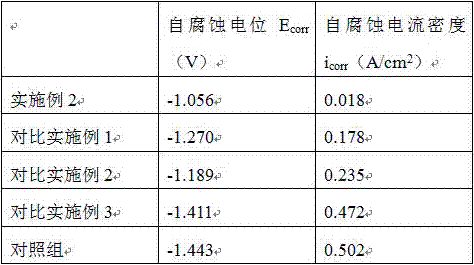

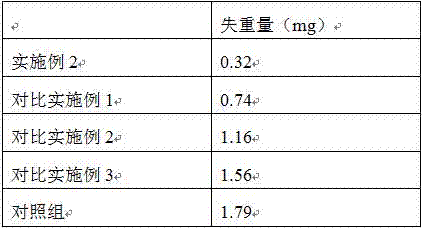

ActiveCN107400894AReduced self-corrosion current densityAccelerated corrosionCoatingsSilanesHardness

The invention discloses a surface anti-corrosion treatment method of an aluminum alloy pump cover. The method is characterized by comprising steps as follows: (1) cleaning treatment, (2) oil removing and degreasing treatment, (3) acid-base cleaning treatment, (4) surface polishing treatment, (5) drying treatment, (6) preparation of a silane treating agent, (7) silanization treatment and (8) cleaning and drying treatment. In the organosilane treatment process of the aluminum alloy pump cover, the forming speed and quality of a pump cover surface silane film are effectively promoted and improved, the self-corrosion current density of the aluminum alloy pump cover is remarkably reduced, the corrosion resistance and the surface hardness are effectively improved, the service life is prolonged by 4 times or longer, and the aluminum alloy pump cover treated with the method has high market competitiveness.

Owner:ANHUI TENGLONG PUMP VALVE MFG CO LTD

Hole sealing method for magnesium alloy surface rare earth chemical conversion coating

InactiveCN105624664AImprove corrosion resistanceImprove compactnessMetallic material coating processesRare earthPre treatment

The invention discloses a hole sealing method for a magnesium alloy surface rare earth chemical conversion coating. The hole sealing method includes the following steps that firstly, a magnesium alloy is pretreated; secondly, a pretreated magnesium alloy workpiece is soaked in a rare earth chemical conversion coating solution to be soaked for 10 min to 60 min, and the magnesium alloy rare earth chemical conversion coating is obtained; and thirdly; the magnesium alloy workpiece obtained in the second step is soaked in an oxidized graphene supernatant solution with a certain condensation for 20 min to 30 min and is dried at the temperature of 30 DEG C to 60 DEG C for 1 h to 3 h, and the magnesium alloy surface rare earth chemical conversion coating with holes sealed by oxidized graphene is obtained. According to the hole sealing method, the magnesium alloy rare earth conversion coating layer is soaked in the oxidized graphene supernatant solution, the oxidized graphene is soaked in conversion coating microcracks, the compactness of the rare earth conversion coating layer is enhanced, the problems that the crack-like structure of the rare earth conversion coating is generated, the conversion coating is discontinuous and the degree of covering a base body is low are solved, and the corrosion resistance of the magnesium alloy rare earth chemical conversion coating is improved remarkably.

Owner:GANNAN NORMAL UNIV

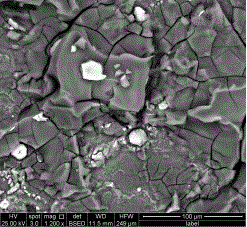

Composite coating material based on 45# steel substrate and preparing method of coating

InactiveCN105803454AImprove wear and corrosion resistanceThe preparation process can be completed under normal environment, and the preparation process is simpleMetallic material coating processesWear resistanceHeat treated

The invention discloses a composite coating material based on a 45# steel substrate and a preparing method of a coating. The coating comprises, by weight percent, 0% to 10% of WC powder, 0% to 1% of Y2O3 powder, and the balance 304 stainless steel powder. The WC powder, the Y2O3 powder and the 304 stainless steel powder which are prepared according to the ratio are mixed and are added into a ball milling tank together with ball milling media, and after ball milling is carried out for 4h to 6h, mixed powder is obtained; the mixed powder is subject to drying treatment under the vacuum environment, and the coating material is obtained; the surface of the 45# steel substrate is ground to be flat; a dedicated powder preset tool is used for flatly laying the coating material on the surface of the 45# steel substrate; and finally, laser heat treatment equipment is used for carrying out laser cladding on the material, and the coating is obtained. The obtained coating has the good wear resistance, and higher corrosion resistance, the preparing technology is simple, the cost is low, and batch production is easily achieved.

Owner:GUIZHOU UNIV

Preparation of super-hydrophobic surface composite film and application of super-hydrophobic surface composite film in metal corrosion protection

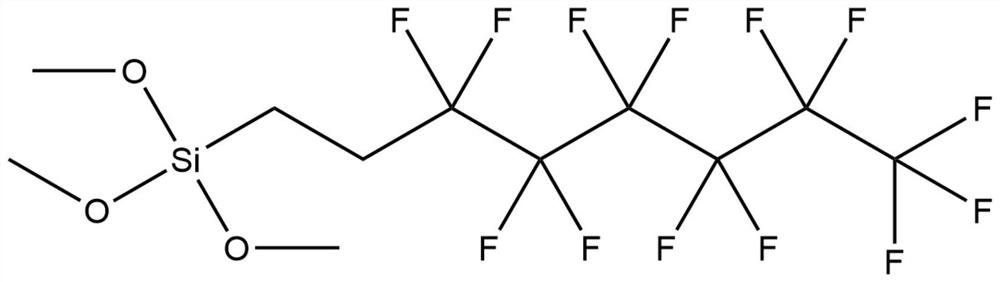

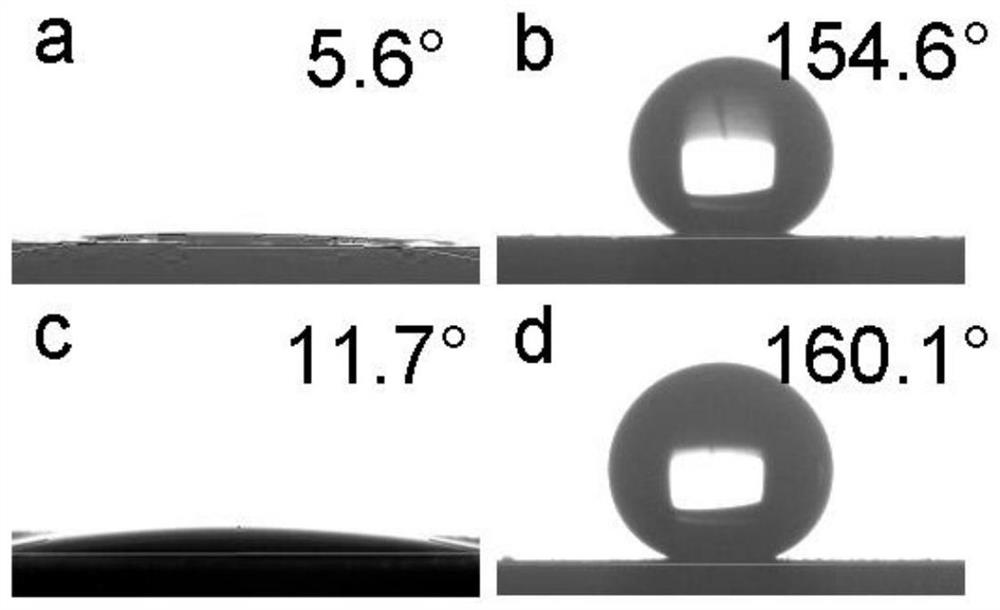

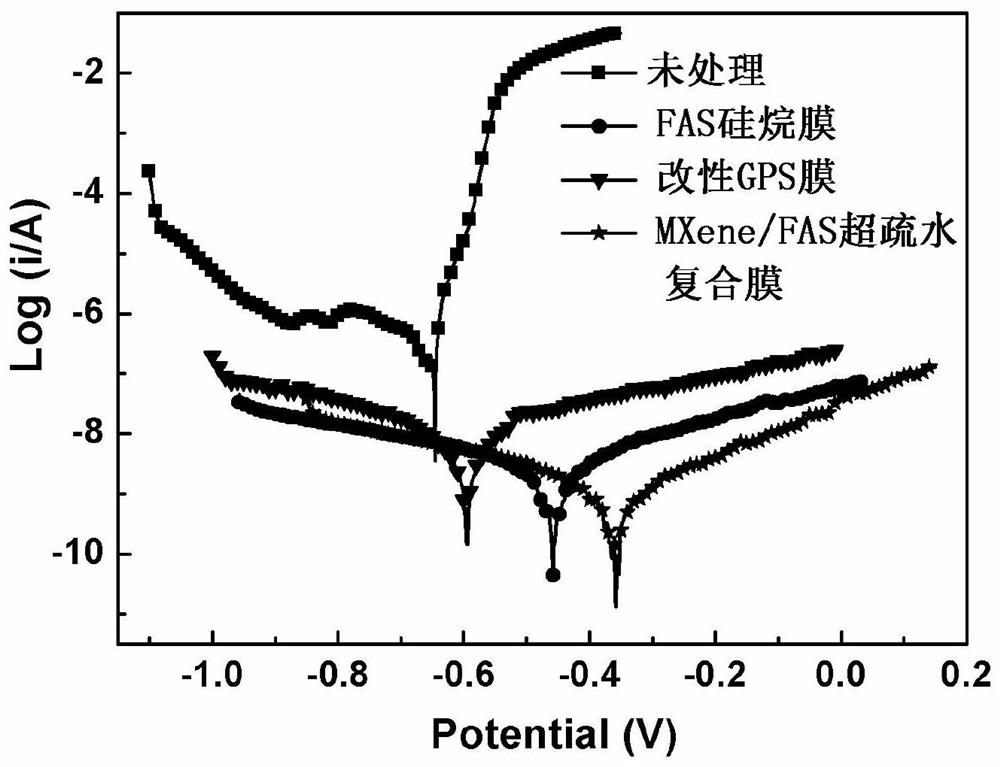

PendingCN112111188AImprove corrosion resistanceOvercoming the disadvantages of insufficient wear resistancePretreated surfacesAnti-corrosive paintsSio2 nanoparticleMetallic materials

The invention belongs to the field of metal corrosion protection, and particularly relates to preparation of an MXene / fluorosilane (FAS) super-hydrophobic surface composite film and application of theMXene / FAS super-hydrophobic surface composite film in metal corrosion protection. The application method comprises the following steps: pretreating the surface of a metal sample, modifying SiO2 nanoparticles with gamma-GPS silane, preparing dispersion liquid, preparing an MXene / FAS mixed solution, sequentially spin-coating the surface of the pretreated metal sample with the two dispersion liquidsto form a film, drying the spin-coated metal sample at room temperature, and then conducting curing in a drying oven to form the film. The MXene / FAS super-hydrophobic composite film surface protection technology is adopted, so that the composite film has excellent super-hydrophobic self-cleaning performance and corrosion resistance, and the durable cleaning and corrosion resistance of the surfaceof the metal material can be remarkably improved. In addition, the protective film prepared by the invention is simple to operate and meets the requirement of environmental protection. Doping of MXene can effectively hinder diffusion of a corrosive medium, and the corrosion resistance of the composite film is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

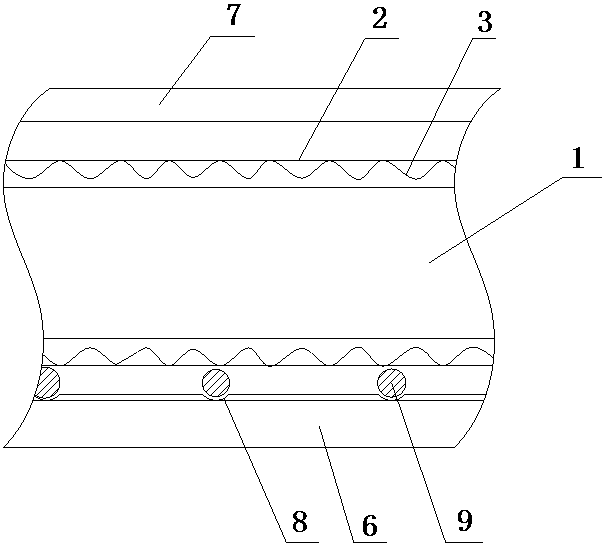

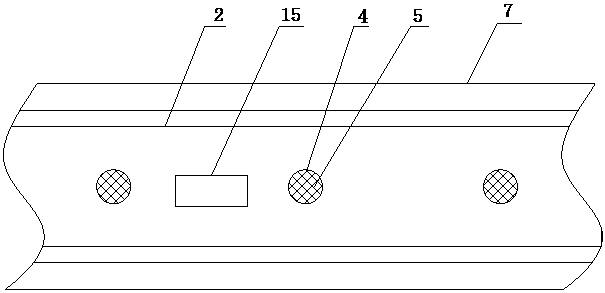

Power cable protection assembly

InactiveCN107731392AReduce hard crash damageEasy to optimizeAntifouling/underwater paintsPaints with biocidesPower cableEngineering

The invention provides a power cable protection assembly, and belongs to the technical field of a cable. The power cable protection assembly comprises a cable body, a protection sleeve and a supporting mechanism; the cable body consists of an aluminum alloy conductive core, an insulating layer, an inside liner layer, a water-blocking layer, a metal sheath, an outer protection layer and a corrosionresistant layer from inside to outside in sequence; flexible arc-shaped convex strips are uniformly arranged on the inner surface of the protection sleeve at intervals in the longitudinal direction;the longitudinal sections of the flexible arc-shaped convex strips are waveform; through holes are formed, among the flexible arc-shaped convex strips, in the protection sleeve; a filtering net is arranged on the through holes; the supporting mechanism comprises a bottom plate and vertical plates arranged on the two sides of the bottom plate; a first groove is formed in the bottom plate; a rotaryshaft is arranged between the vertical plates in an interval manner; the rotary shaft is partially arranged in the first groove and is in smooth contact with the inner surface of the first groove; andthe top parts of the vertical plates are sealed through a cover plate. The comprehensive performance of the power cable protection assembly is improved and the cable construction difficulty can be lowered, so that the cable can be protected from natural damage or man-made sabotage.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

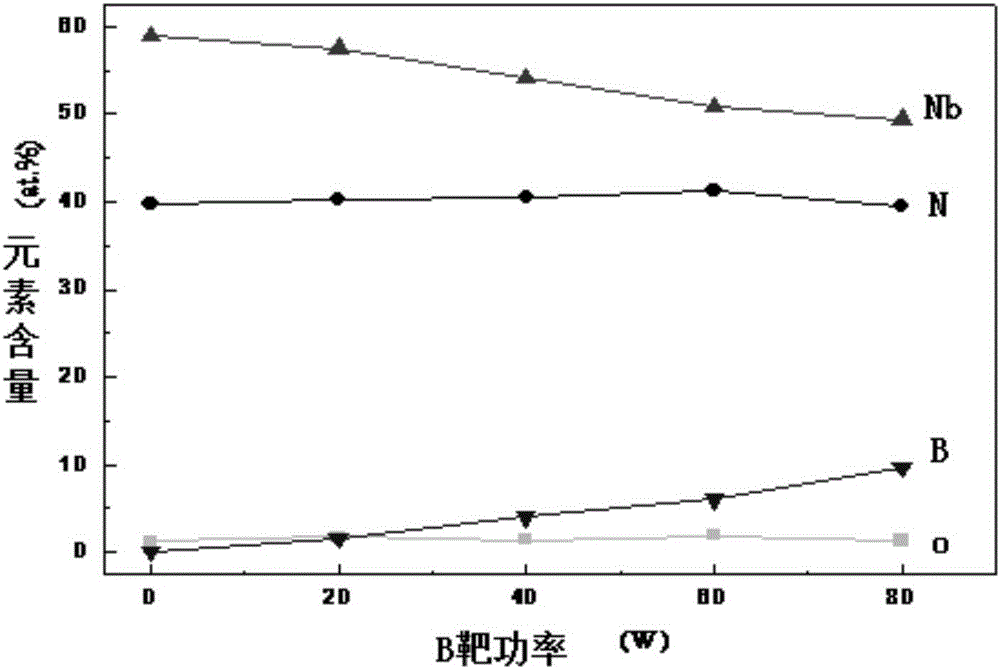

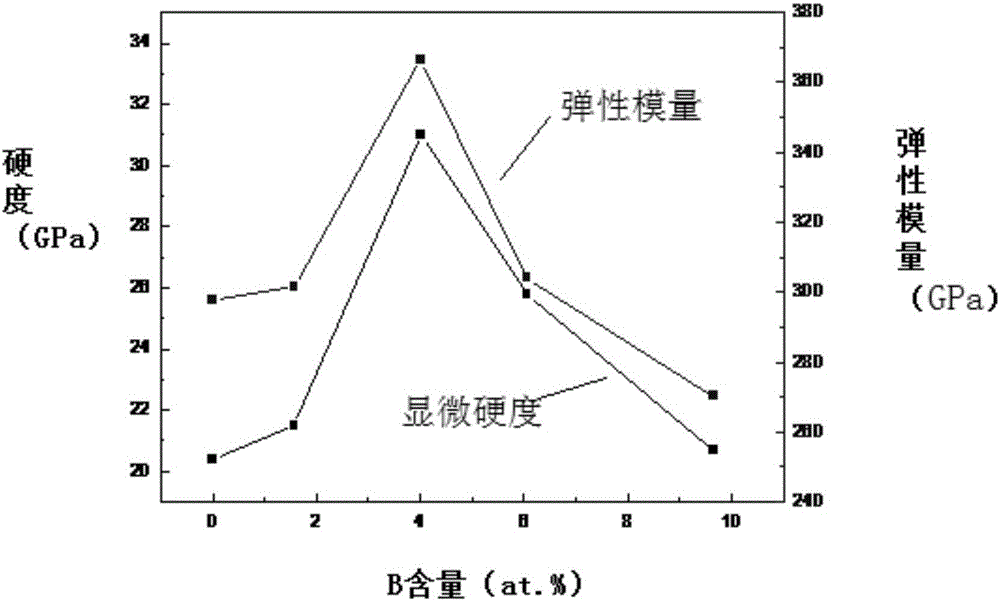

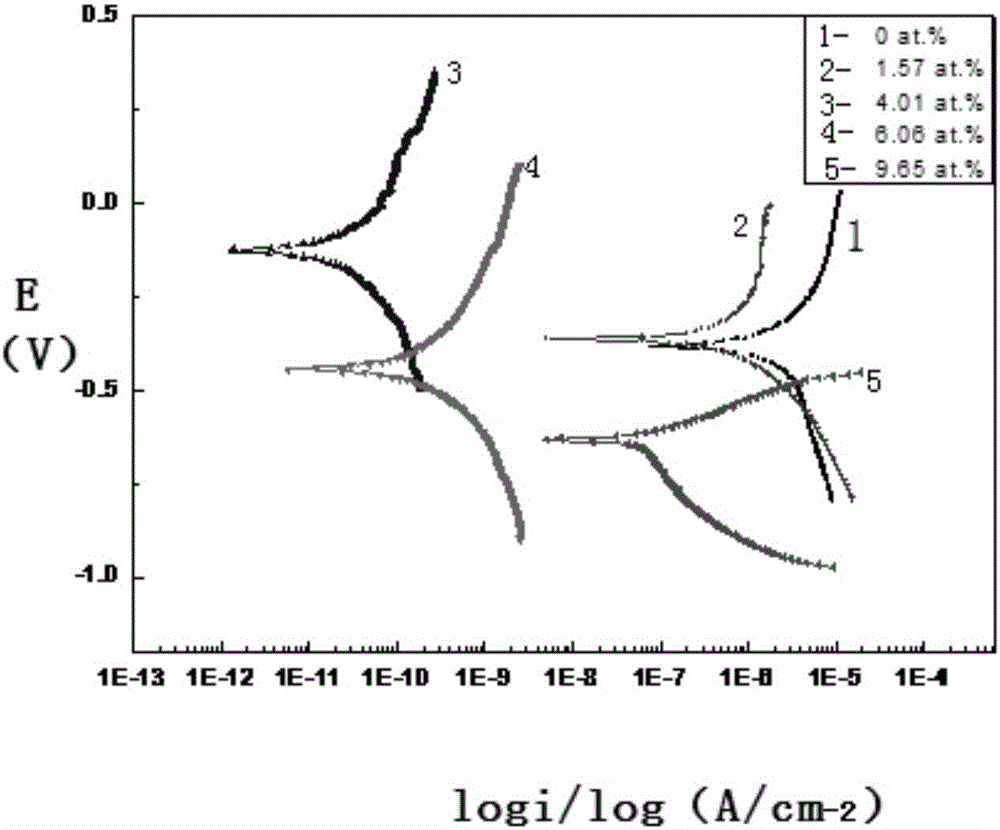

NbBN composite coating and preparation method thereof

InactiveCN106191771AIncreased microhardnessHigh elastic modulusVacuum evaporation coatingSputtering coatingRadio frequencyCemented carbide

The invention discloses a NbBN composite coating and a preparation method thereof. The NbBN composite coating is prepared by sputtering on a cemented carbide or ceramic substrate at a room temperature according to a double-target confocal radio-frequency reactive magnetron sputtering method, is 1.5 to 2.5 [mu]m thick, and comprises 0 to 9.65 at.% of the B component, 49.43 to 58.92 at.% of the Nb component, 39.8 to 41.2 at.% of the N component, and the balance of O. According to the NbBN composite coating and the preparation method, the mechanical properties, the corrosion resistance and the wear resistance of a NbN coating are further improved; and the NbBN composite coating is a protective coating with excellent overall properties, so as to be applied to the fields of high speed, dry cutting, corrosion protection and the like more widely.

Owner:JIANGSU UNIV OF SCI & TECH

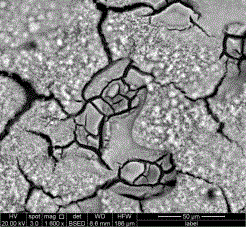

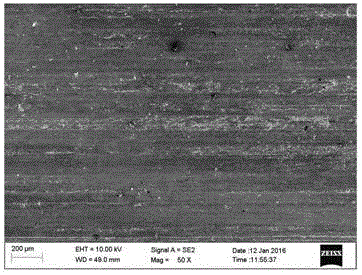

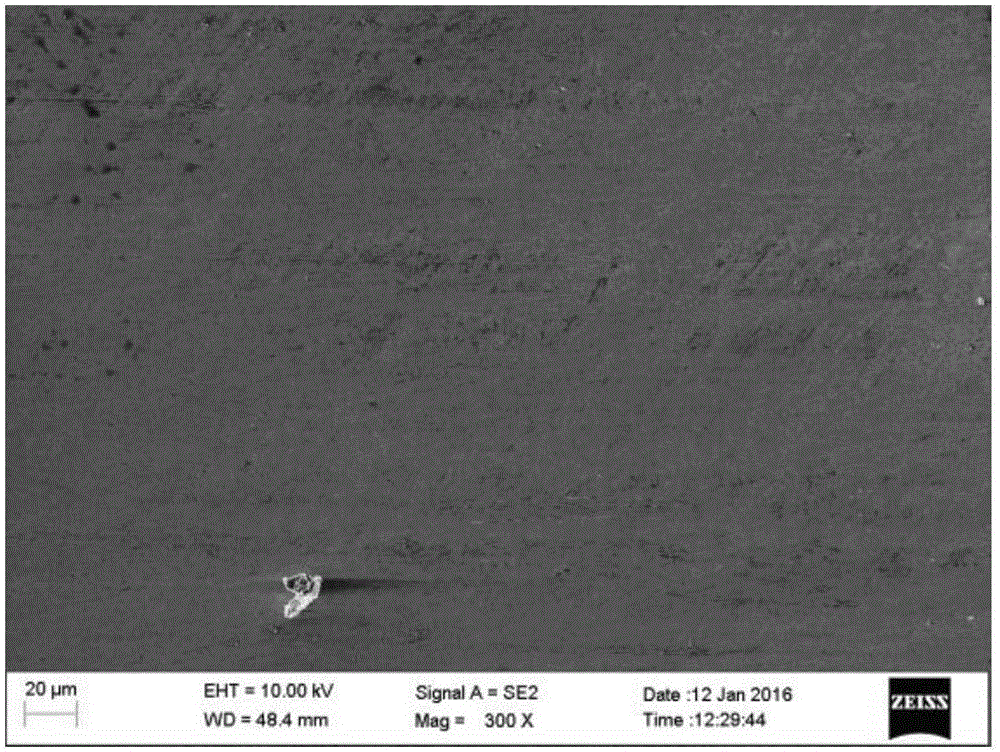

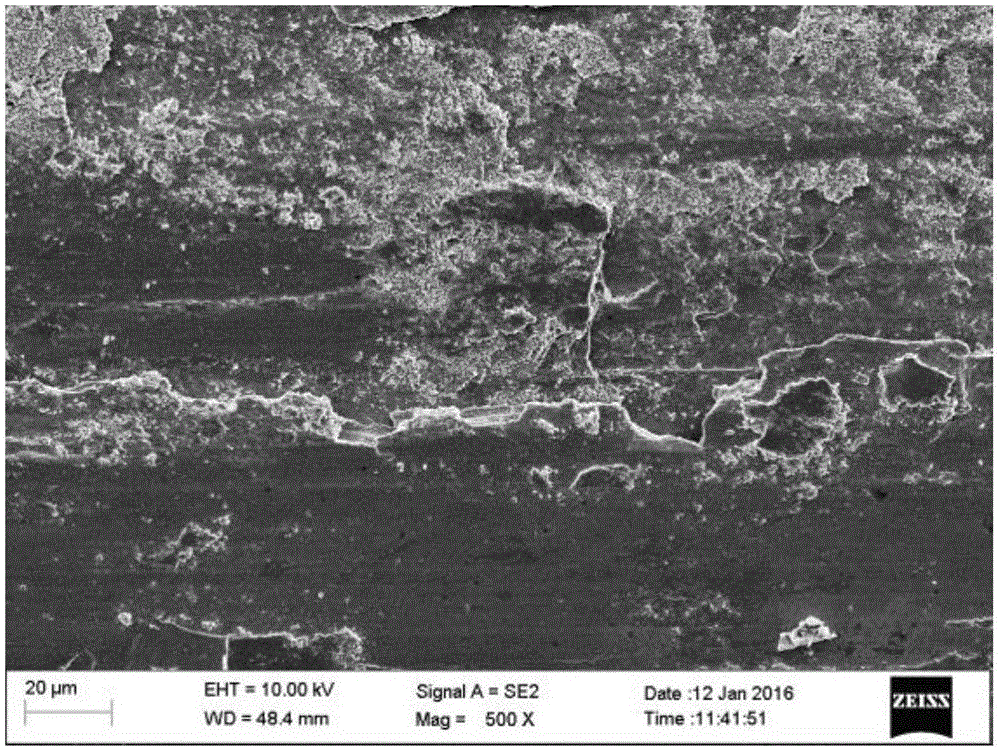

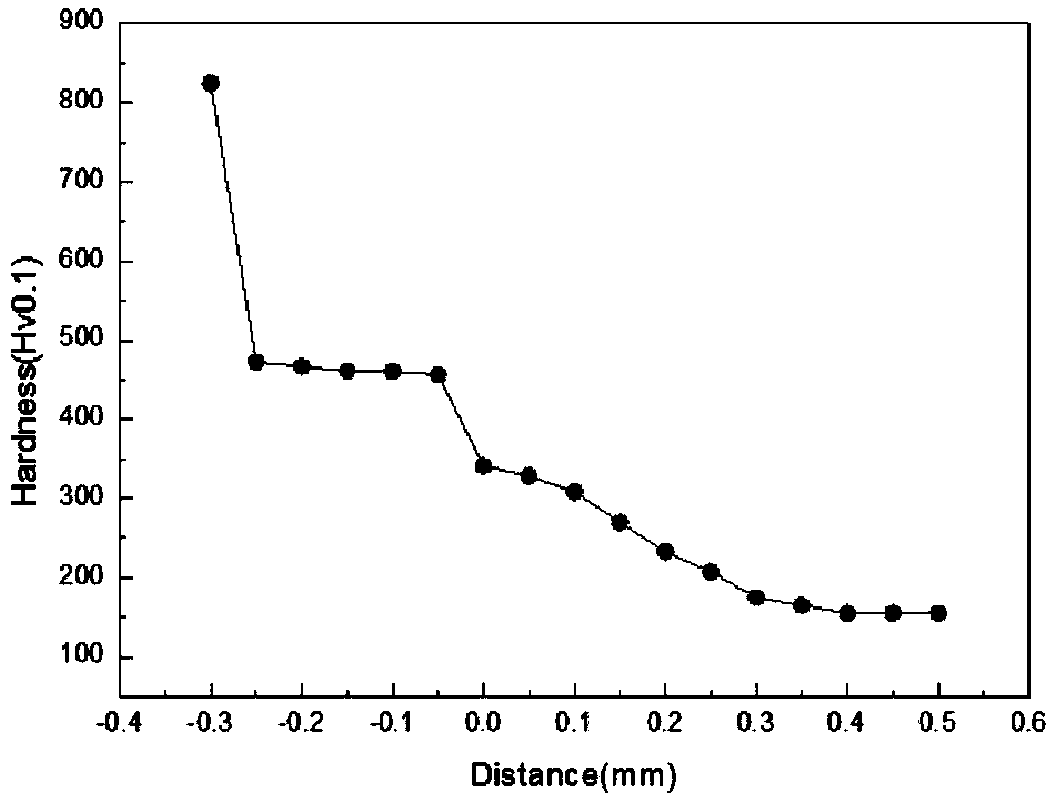

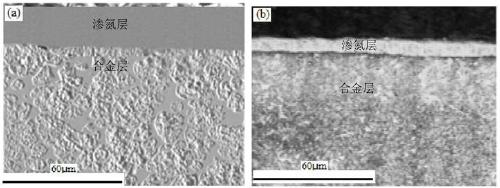

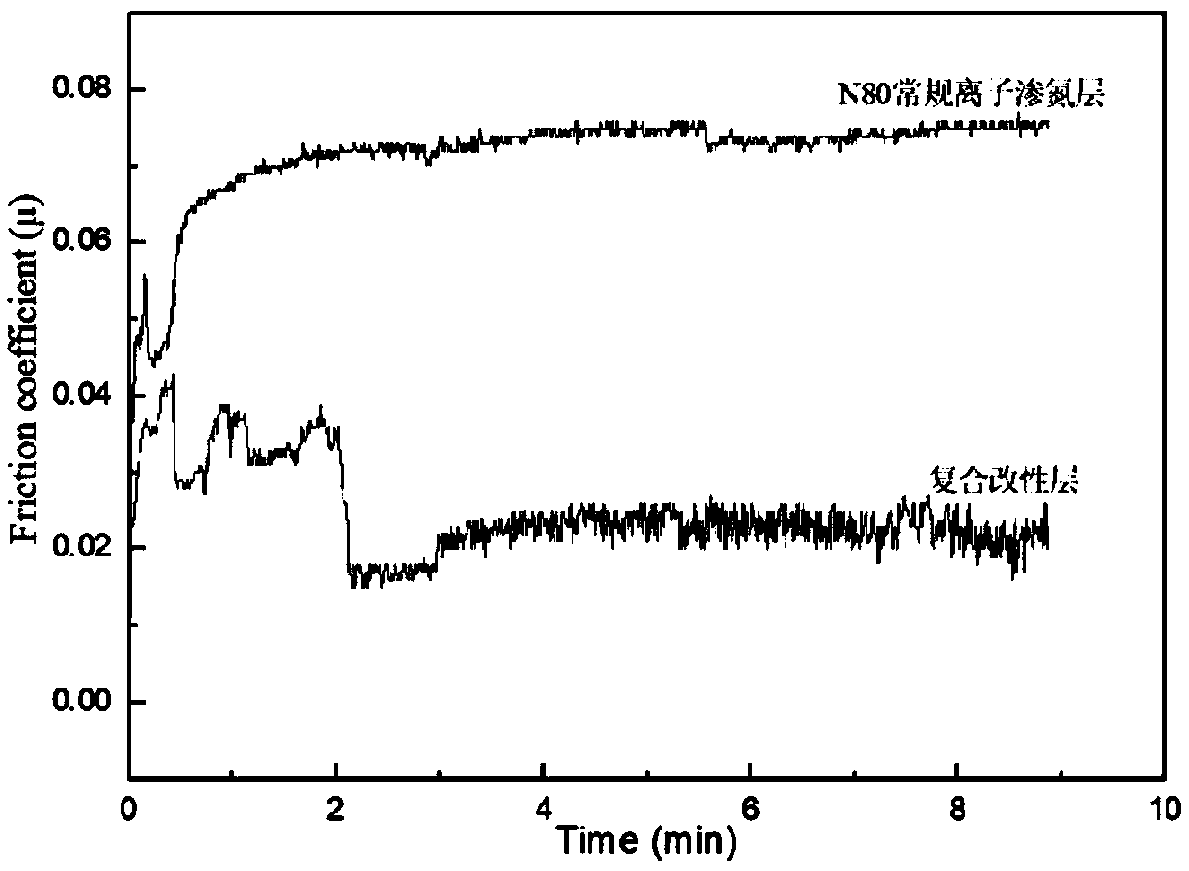

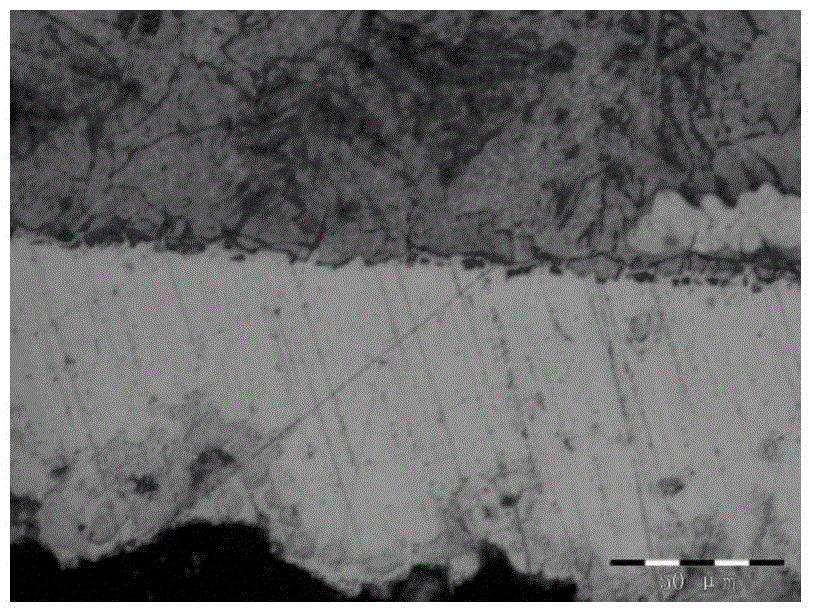

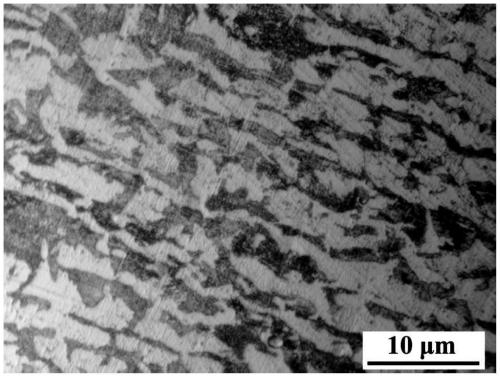

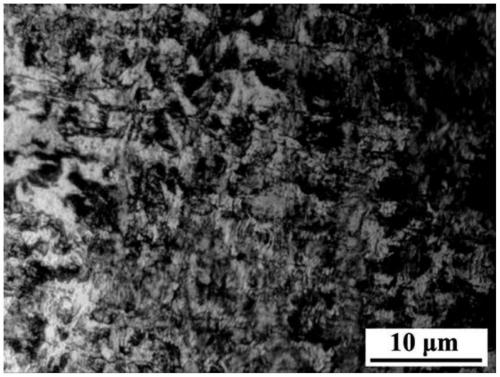

Steel base surface alloying-ion nitriding wear-resistant corrosion-resistant composite modified layer and preparation method thereof

ActiveCN109136829AHigh strength supportImproved hardness gradientSolid state diffusion coatingWear resistantRare earth

The invention relates to the field of metallic materials, and in particular relates to a steel base surface alloying-ion nitriding wear-resistant corrosion-resistant composite modified layer and a preparation method thereof. An alloying technique is combined with a rare-earth catalytic ion nitriding technology, and the Cr-Ni-Ti-La alloying-ion nitriding wear-resistant corrosion-resistant compositemodified layer is prepared on the steel base surface. The problems that carbon steel is low in nitriding speed, long in production cycle, low in efficiency, shallow in nitriding layer, large in hardness gradient and relatively high in brittleness in the conventional nitriding treatment, and the occurrence of brittle spalling of the nitriding layer in fatigue wear is easily caused, and the wear resistance and corrosion resistance are relatively low in improvement degree compared with that of a matrix can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

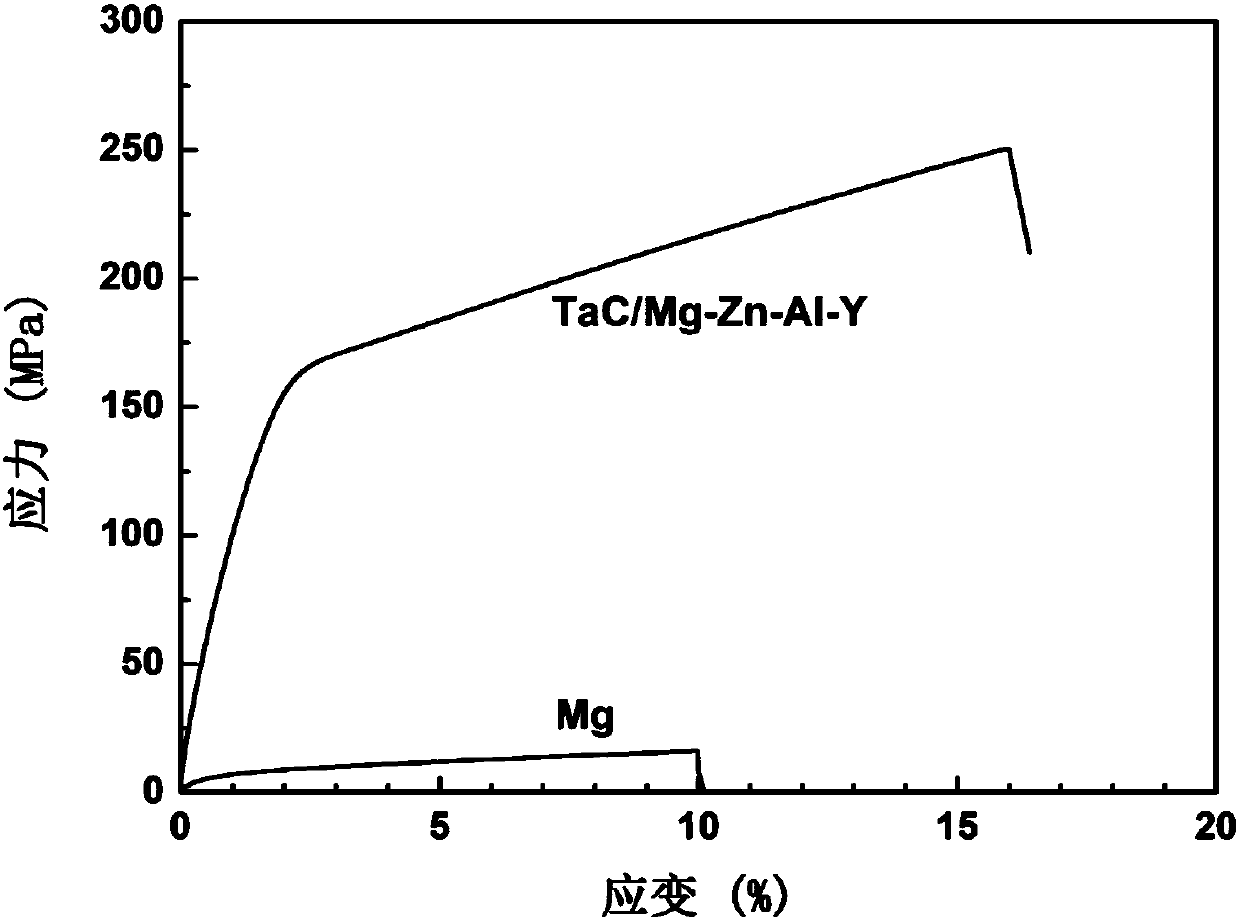

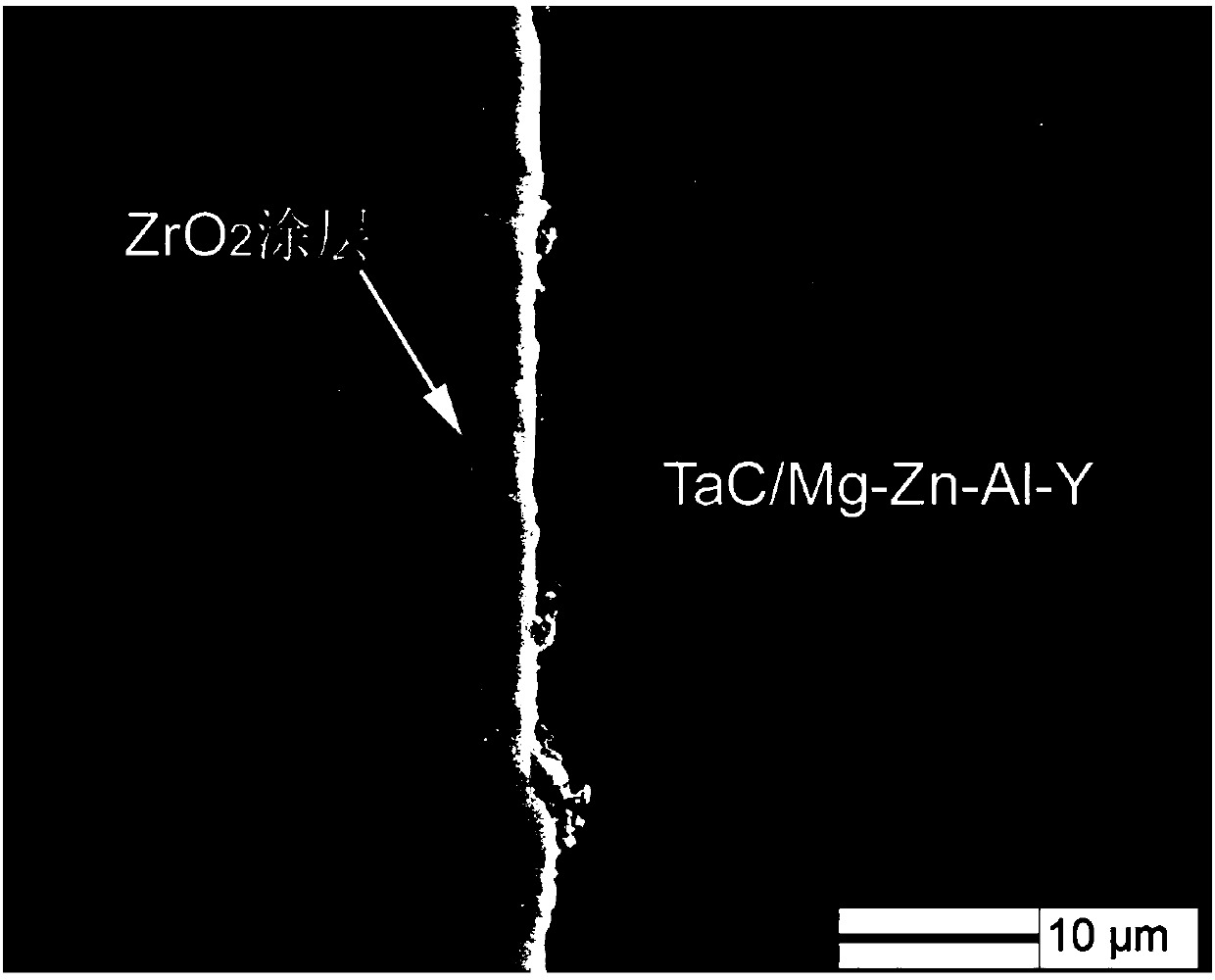

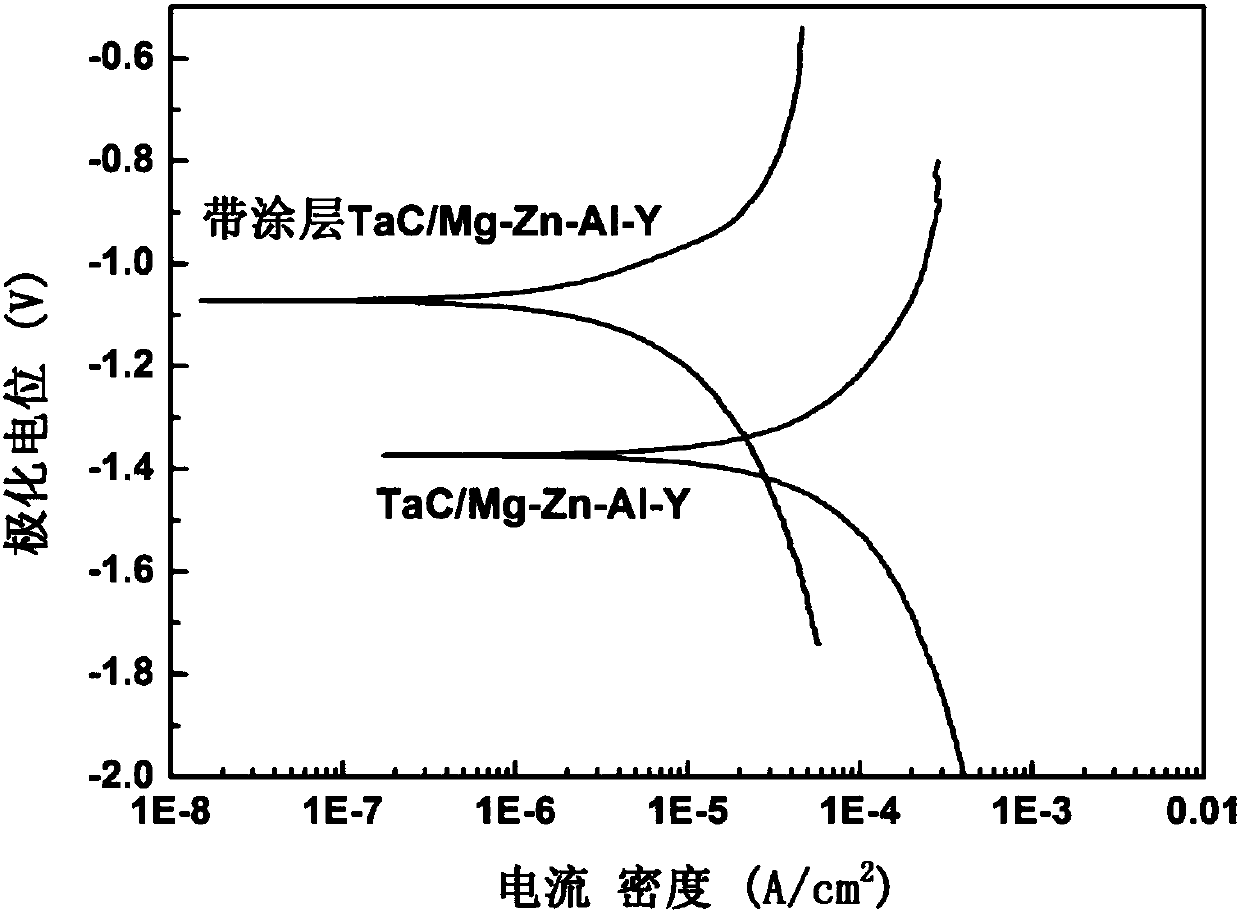

A kind of high-strength corrosion-resistant magnesium alloy composite material for automobile wheel hub and preparation method thereof

ActiveCN107488801BImprove mechanical propertiesImprove corrosion resistanceHubsVacuum evaporation coatingIntermetallicUltimate tensile strength

The invention discloses a high-strength corrosion-resistant magnesium alloy composite material for an automobile hub, and a preparation method thereof. From composition, the composite material comprises a matrix and a surface coating of the matrix, wherein the matrix is a magnesium alloy, and comprises the following components in percentage by weight: 1-5% of Zn, 4-12% of Al, 6-15% of Y, 10-30% of TaC particles and the balance Mg. The surface coating is a ZrO2 coating formed in a manner of ion implantation deposition. The material achieves the effects of precipitation strengthening and aging hardening through the synergistic effect of the alloy elements Zn, Al and Y as well as the TaC particles, intermetallic compounds Mg-Zn-(Y) and Mg-Al-(Y) in the matrix, and the discrete TaC particles generate pinning for dislocations in a deformation process, so that the mechanical property of the magnesium alloy composite material is improved; and meanwhile, the ZrO2 coating prepared by virtue of the ion implantation deposition has a gradient structure, so that the bonding strength between the coating and the matrix, and the corrosion resistance of the matrix are remarkably improved.

Owner:HEBEI UNIV OF TECH

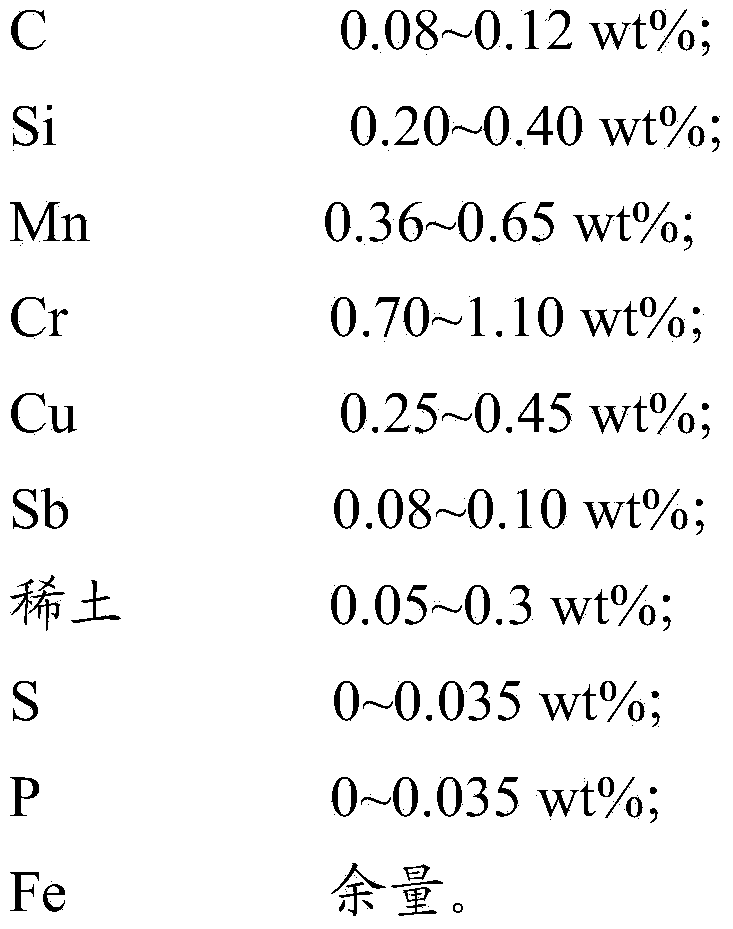

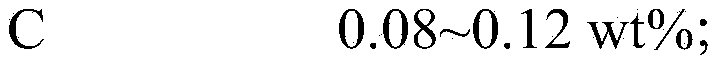

Corrosion resistance steel and production method thereof

InactiveCN103397280ACorrosion weight loss reductionReduced self-corrosion current densityRare-earth elementOxygen

The present invention provides a corrosion resistance steel and a production method thereof. The method comprises: carrying out mixing smelting on C, Si, Mn, Cr, Cu, S, P and Fe to obtain molten steel; placing rare earth into the bottom of a pouring ladle, pouring a first part by volume of the molten steel, adding Sb, pouring a second part by volume of the molten steel, and stirring to obtain a sample; and carrying out a heat treatment to obtain the corrosion resistance steel. Compared with the corrosion resistance steel in the prior art, the corrosion resistance steel of the present invention has the following characteristics that: 1, rare earth is adopted as trace elements to be added to the steel, such that the structure can be refined, and the rare earth can react with sulfur and oxygen in the steel to produce high melting point rare earth compounds so as to reduce harms of sulfur and oxygen inclusions and increase corrosion resistance of the steel; 2, rare earth elements have large atomic radiuses, such that brittleness precipitation in the second phase grain boundary can be reduced so as to increase corrosion resistance of the steel; and 3, with addition of rare earth and Sb, burning loss of rare earth elements can be reduced, utilization rates of rare earth elements can be increased, and the metal Sb can be completely and uniformly dissolved so as to uniformize structure components and increase corrosion resistance of the steel.

Owner:ZUORAN JINGJIANG EQUIP MFG +1

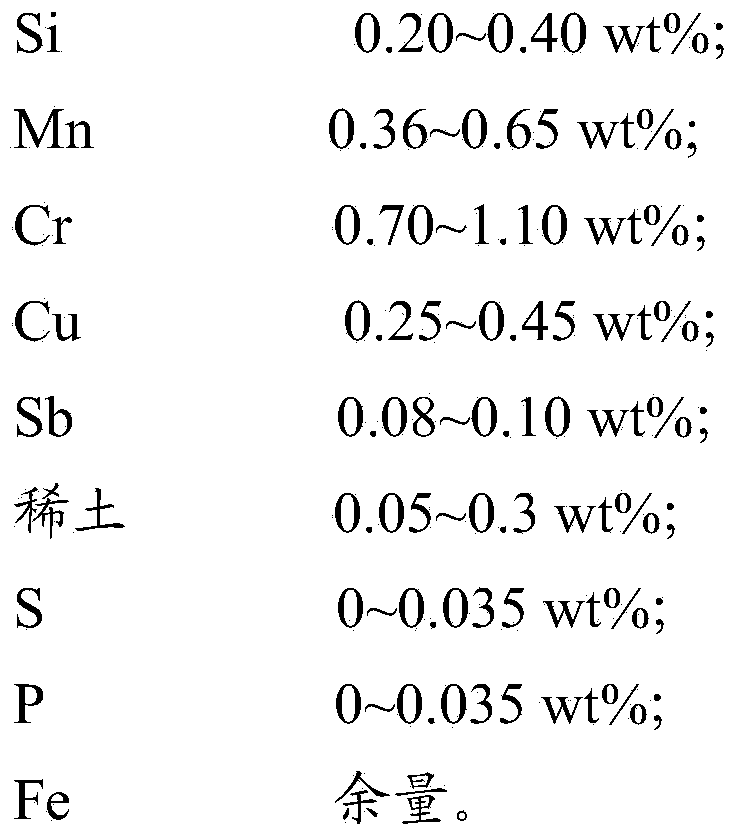

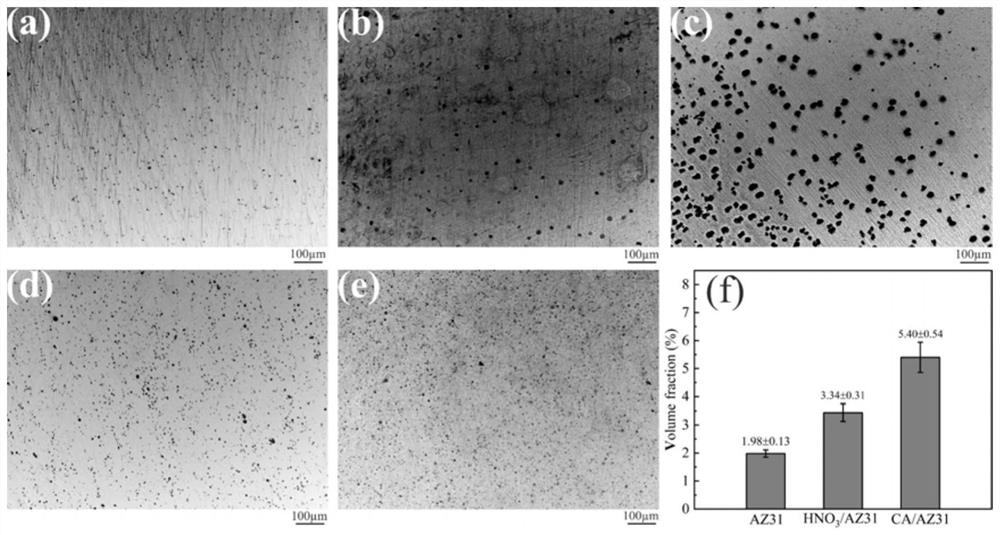

Method for preparing hydrotalcite coating on magnesium alloy surface by combining acid pretreatment and steam method

PendingCN113564590ADense surfaceIncrease phase densityMetallic material coating processesOXALIC ACID DIHYDRATEHydrotalcite

The invention discloses a method for preparing a hydrotalcite coating on the surface of a magnesium alloy by combining acid pretreatment and a steam method, and mainly solves the technical problem that the corrosion resistance of a hydrotalcite coating in the prior art is not ideal. The method comprises the following steps: (1) pretreating the surface of a magnesium alloy matrix; (2) carrying out acid pretreatment on the pretreated magnesium alloy matrix; and (3) preparing the hydrotalcite coating on the surface of the magnesium alloy matrix subjected to acid pretreatment through an in-situ steam method, wherein an acid solution adopted in acid pretreatment is an organic weak acid solution, and the organic weak acid is at least one of oxalic acid, an acetic acid solution or citric acid. The hydrotalcite coating obtained by the invention has the characteristics of compact structure, strong adhesive force, good corrosion resistance and long service life.

Owner:SHANDONG UNIV OF SCI & TECH

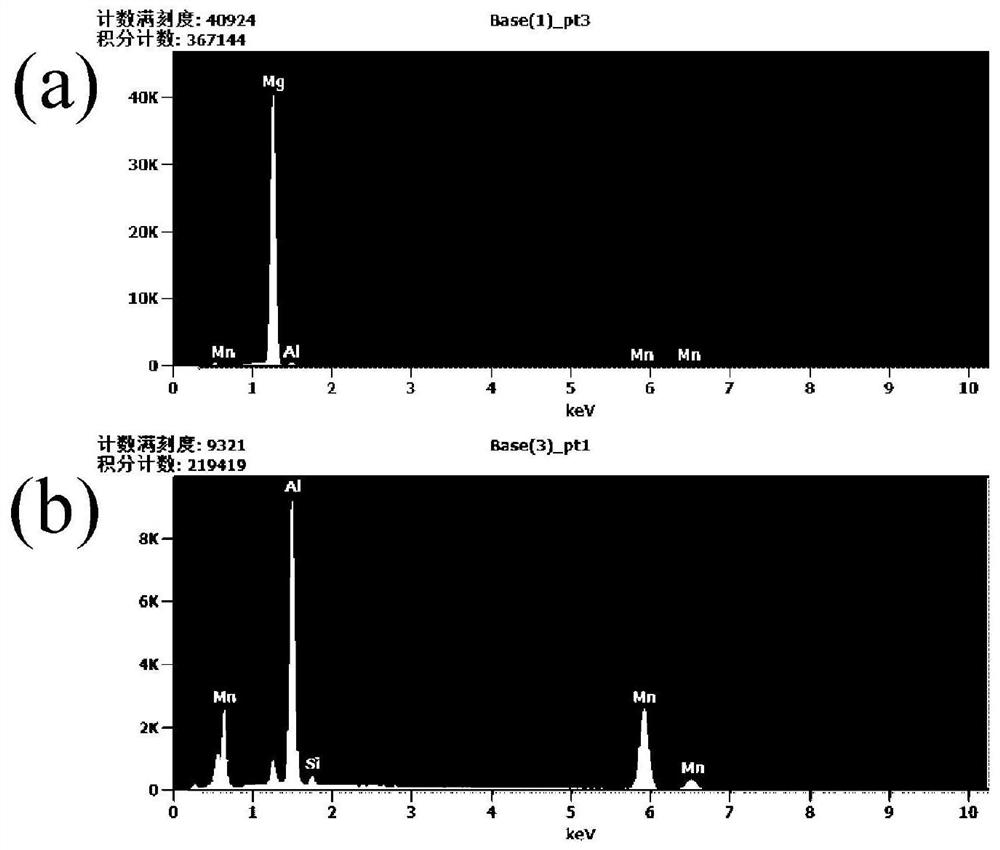

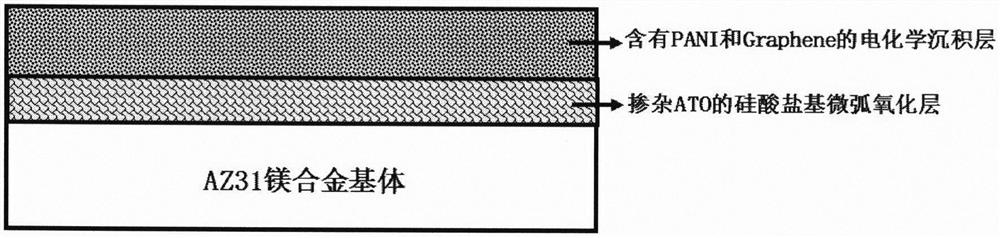

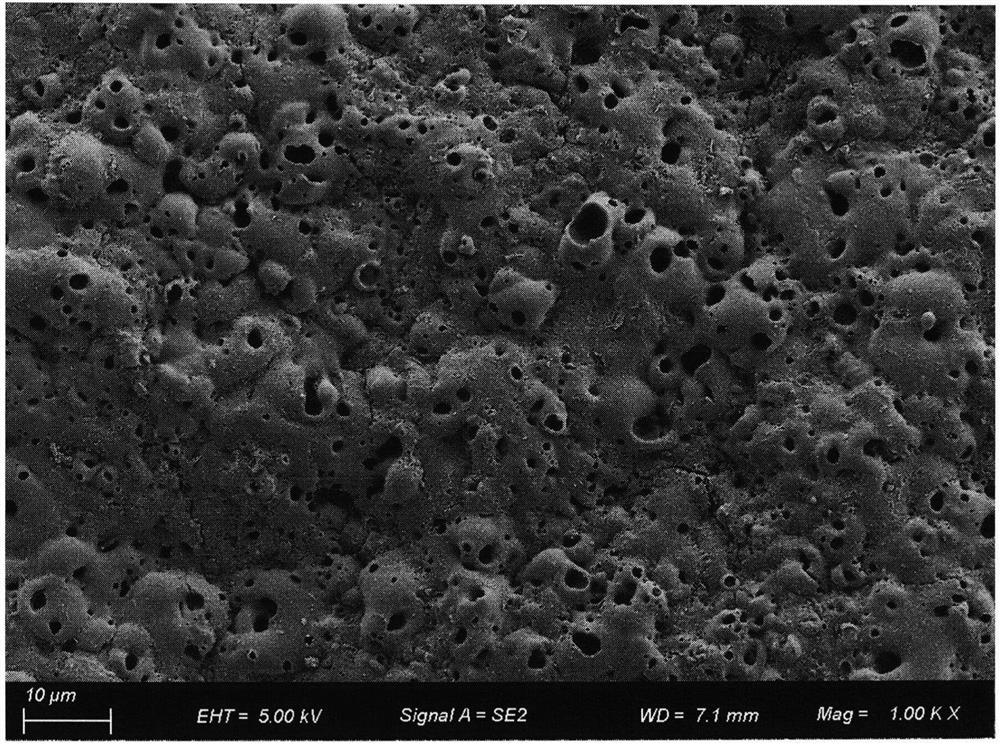

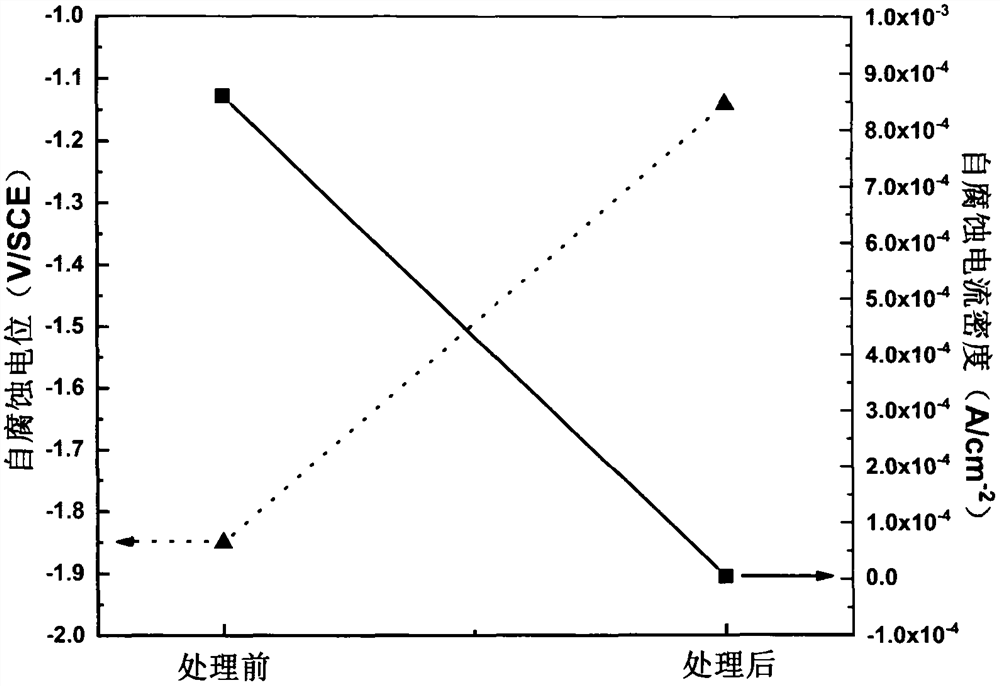

Corrosion-resistant conductive coating on surface of magnesium alloy and preparation method of corrosion-resistant conductive coating

ActiveCN113584551AImprove conductivityIncreased self-corrosion potentialAnodisationElectrolytic organic material coatingMicro arc oxidationCyclic voltametry

The invention provides a corrosion-resistant conductive coating on the surface of a magnesium alloy and a preparation method of the corrosion-resistant conductive coating. The magnesium alloy is a common commercial AZ-series, ZK-series, WE-series and other as-cast, rolled and extruded magnesium alloy. The corrosion-resistant conductive coating is a double-layer-structure composite coating containing ATO, PANI and Graphene at the same time, the inner layer is an ATO-doped silicate-based micro-arc oxidation layer, the outer layer is an electrochemical deposition layer which is prepared through a cyclic voltammetry method and contains PANI and Graphene, and the thickness of the coating ranges from 8.5 micrometers to 20.6 micrometers. The preparation method comprises the steps of mechanical grinding, friction stir processing, micro-arc oxidation, cyclic voltammetry and annealing treatment. The magnesium alloy with the outer surface coated with the corrosion-resistant conductive coating prepared through the method provided by the invention can be used in the field of military electronic equipment.

Owner:TIANJIN POLYTECHNIC UNIV

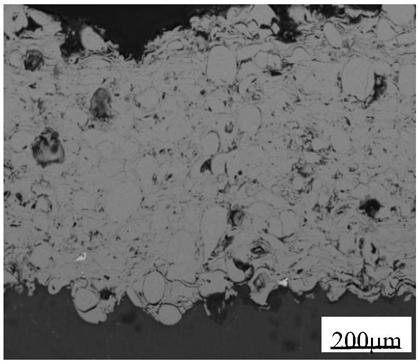

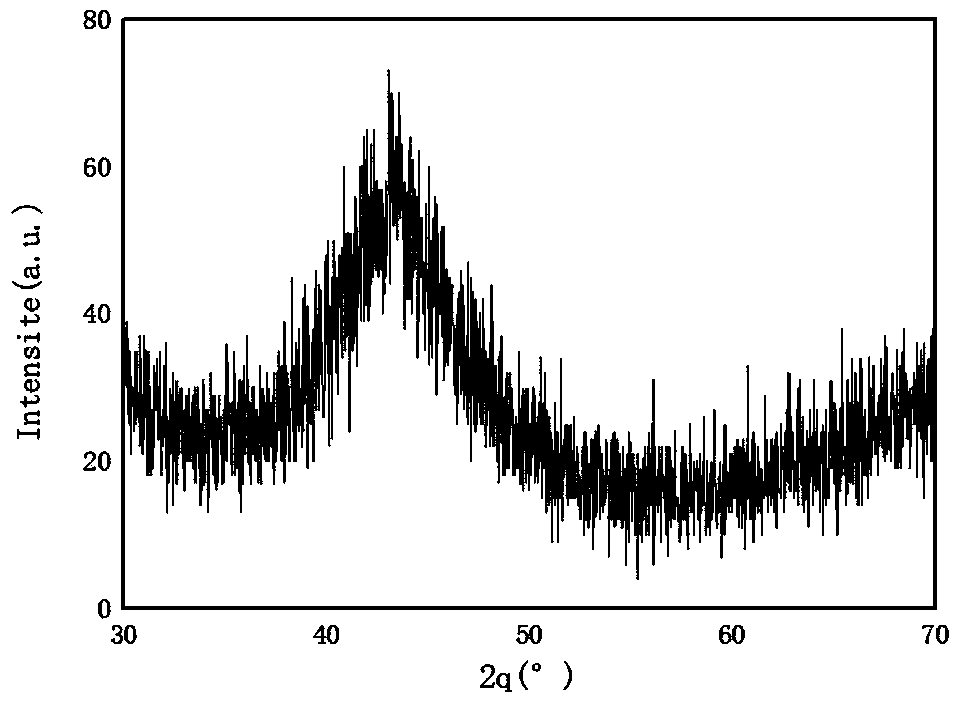

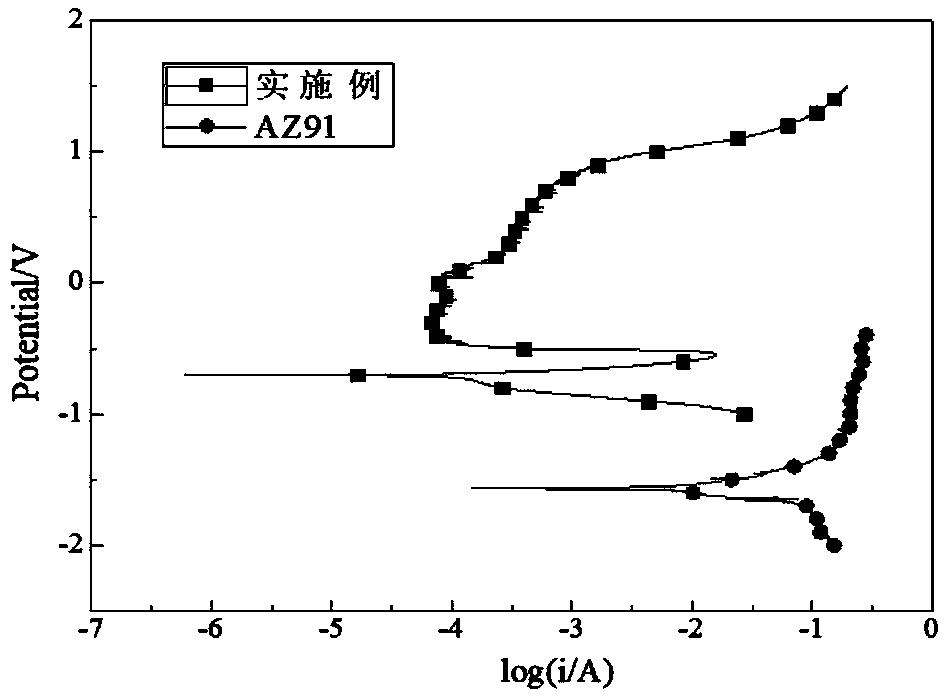

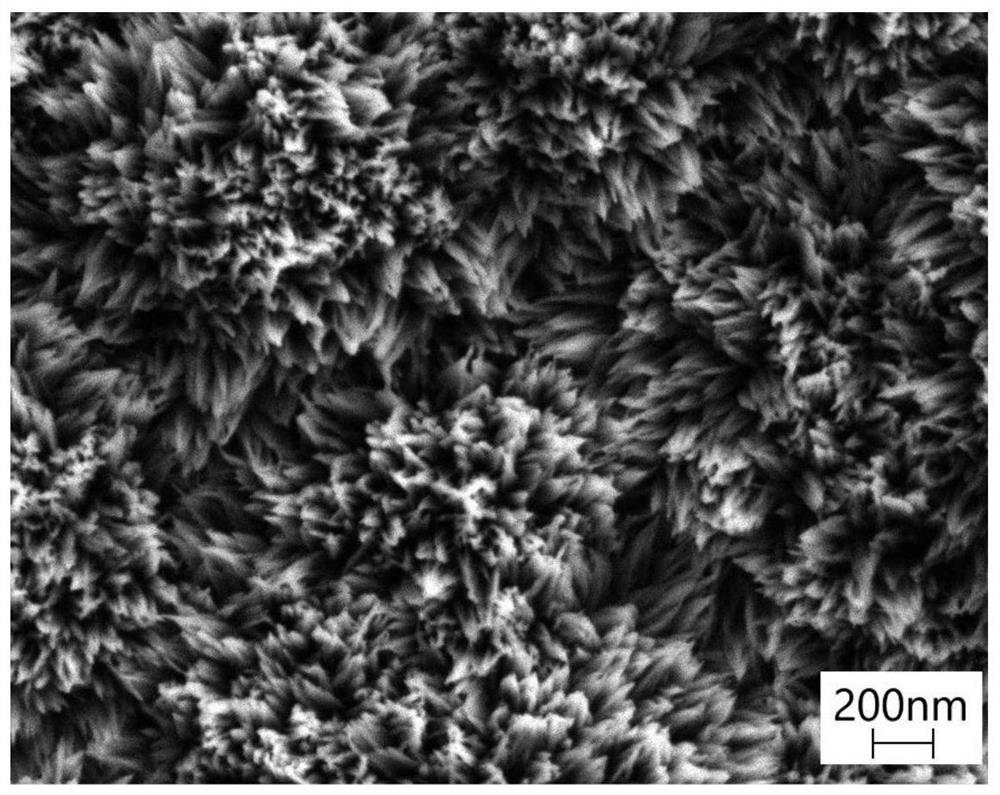

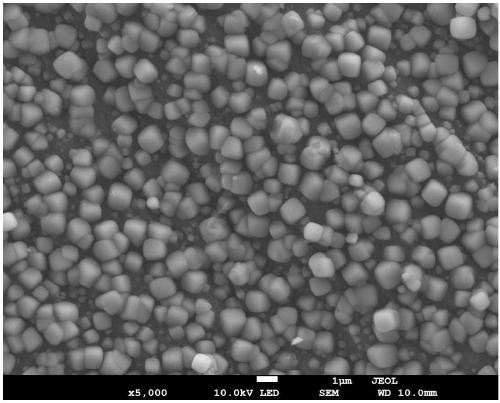

Preparation method of magnesium alloy surface anticorrosive coating

ActiveCN109652754AHigh hardnessImprove corrosion resistanceMolten spray coatingHardnessCorrosion current density

The invention belongs to the technical field of magnesium alloy corrosion prevention, specifically provides a preparation method of a magnesium alloy surface anticorrosive coating, comprising the following steps of: (1) pretreating a magnesium alloy matrix; (2) heating the magnesium alloy matrix pretreated in the step (1) to 60-100 DEG C, then maintaining the temperature of the magnesium alloy matrix at 60-100 DEG C, taking iron-based amorphous alloy particles as a paint to be sprayed, carrying out hypersonic flame spraying on the surface of the magnesium alloy matrix, and obtaining an iron-based amorphous alloy anticorrosive coating on the surface of the magnesium alloy matrix. The preparation method provided by the invention does not deform the magnesium alloy matrix, the surface hardness reaches 580 HV 0.2, the self-corrosion potential of the iron-based amorphous alloy anticorrosive coating is higher than that of AZ91 magnesium alloy, and the self-corrosion current density is lowerthan that of AZ91 magnesium alloy.

Owner:NANCHANG HANGKONG UNIVERSITY

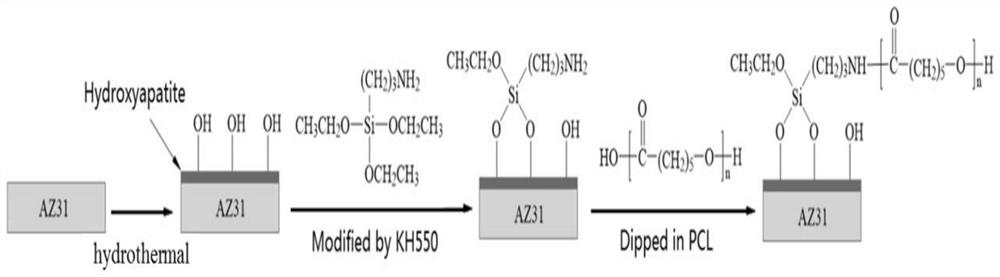

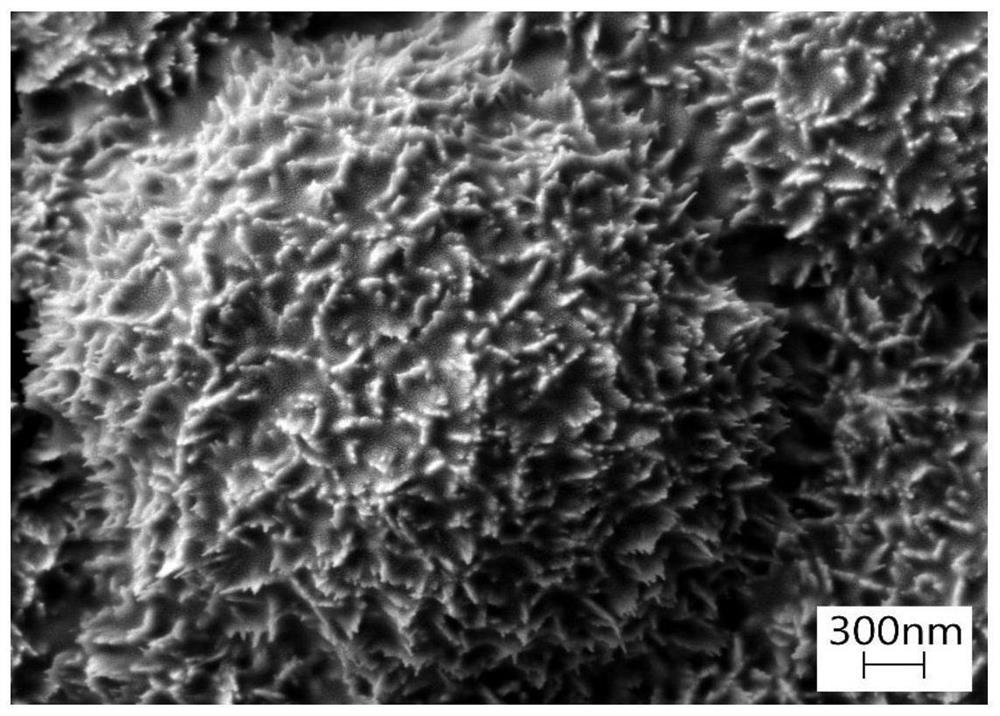

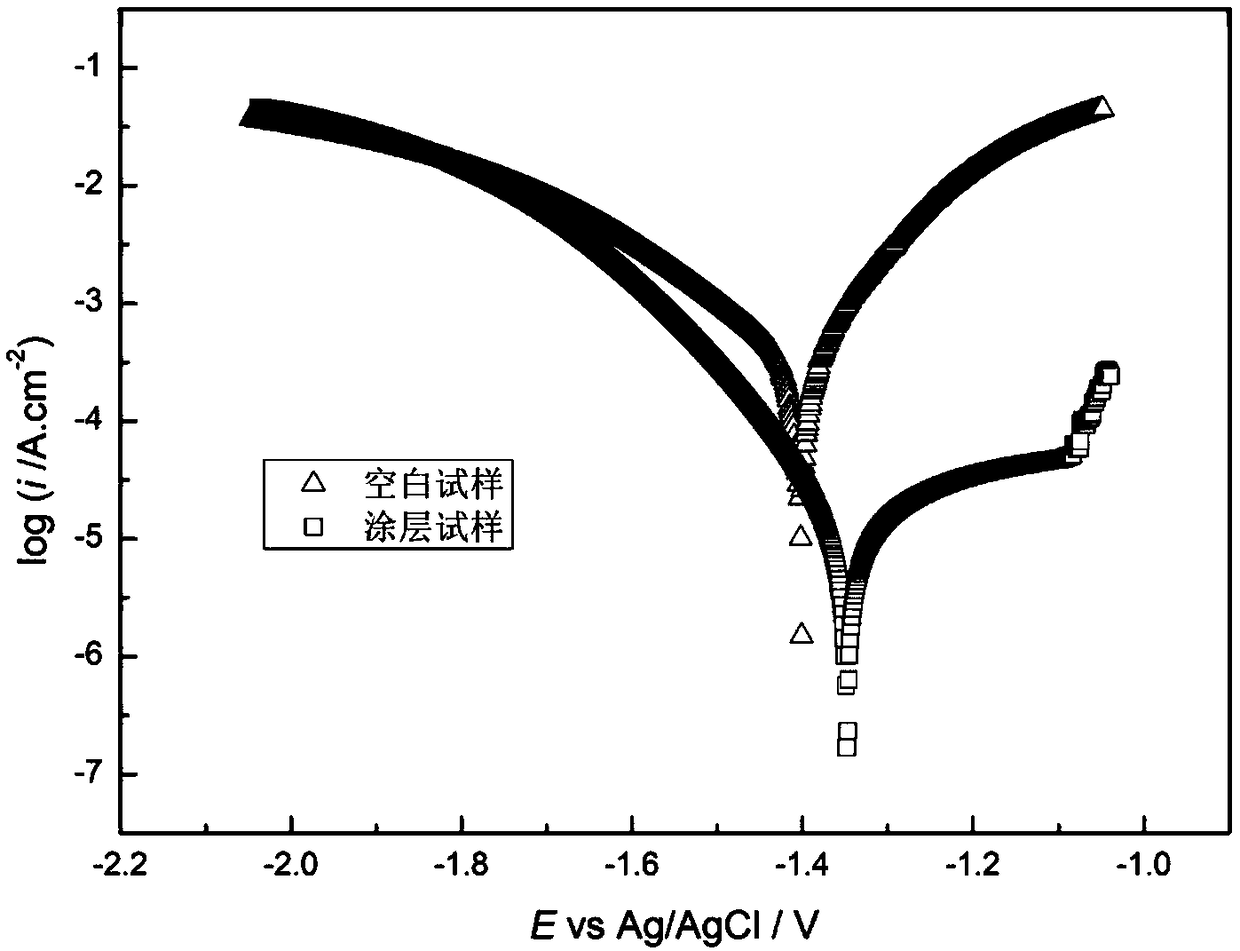

Magnesium alloy gradient composite coating and application thereof

InactiveCN113384751AImprove adhesionImprove corrosion resistancePharmaceutical delivery mechanismMetallic material coating processesMicro nanoMg alloys

The invention discloses a magnesium alloy gradient composite coating and application thereof. A hydroxyapatite crystal layer with micro-nano gaps grows on the surface of magnesium alloy through a hydrothermal method, then KH550 is used for modification treatment, dichloromethane is used as a solvent for preparing a 30-70g / L PCL solution, and the hydroxyapatite crystal layer with the micro-nano gaps of the magnesium alloy is put into the PCL solution for lifting; and drying is carried out, and the magnesium alloy gradient composite coating is prepared. The technical problems that the bonding strength of an existing composite coating and the magnesium alloy is low, the coating is prone to cracking, layering and peeling, uneven dispersion is prone to happening, and consequently the coating is unevenly degraded are solved; and the bonding performance reaches the first level in GB / T 9286-1998, the self-corrosion current density is reduced by 8 times compared with a single hydroxyapatite coating, the electrochemical corrosion speed is reduced by 8 times, the coating breaking potential is increased by 0.28V, a gradient layer is formed, and the functions that after the coating is implanted into a living body, the initial drug concentration is high, and the drug concentration is gradually reduced along with time are achieved through cooperation of the gradient layer and the drug loading performance of the composite layer.

Owner:CHONGQING UNIV OF TECH

Stannate/zirconate composite conversion solution for magnesium alloy surface treatment and preparation method and using method thereof

InactiveCN109055925AEasy to operateIndustrially simple to prepareMetallic material coating processesSodium acetateZirconate

The invention relates to a stannate / zirconate composite conversion solution for magnesium alloy surface treatment and a preparation method and using method thereof, and belongs to the technical fieldof magnesium alloy surface treatment. The composite conversion solution comprises 30-50 g / L of stannate, 2-6 g / L of zirconate, 4-8 g / L of sodium hydroxide, 10-18 g / L of sodium acetate, 2-4 g / L of citric acid and 10-30 g / L of sodium carbonate, and the pH value of the composite conversion solution is 9-11. The composite conversion solution is an environmental-friendly conversion solution, a composite conversion film generated on the surface of a magnesium alloy after the treatment by the composite conversion solution is further environmental friendly, the surface of the film is smooth, level, compact and good in corrosion resistance, the self- corrosion current density is two orders of magnitude lower than that of a magnesium alloy base body, the corrosion resistance of the magnesium alloy is improved, and foundation is laid for follow-up protection treatment. The composite conversion solution is simple in industrial preparation and easy to operate, does not need complex equipment, is suitable for industrial production, and is convenient to use.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

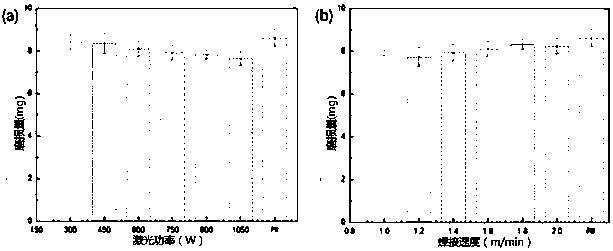

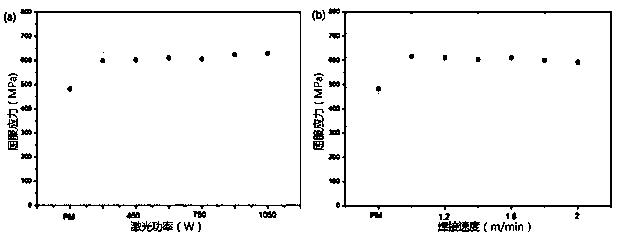

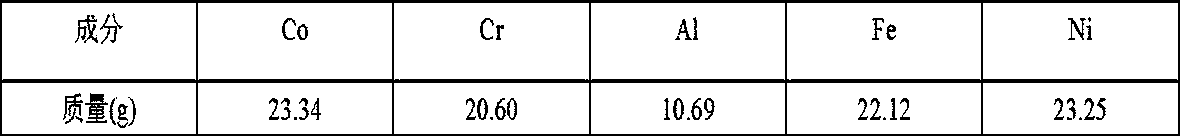

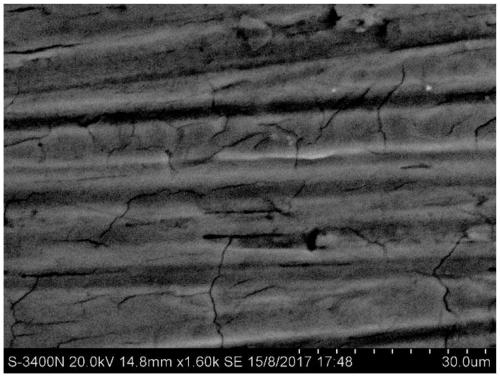

Laser-clad welding high-entropy alloy AlCoCrFeNi/27SiMn steel composite layer and preparing method thereof

ActiveCN110842364AReduce coefficient of frictionReduce wearLaser beam welding apparatusHigh entropy alloysLaser soldering

The invention provides a preparing method of a laser-clad welding high-entropy alloy AlCoCrFeNi / 27SiMn steel composite layer. The preparing method comprises the following steps of 1) preparing a high-entropy alloy AlCoCrFeNi raw material, putting the raw material into a melting furnace, and using an extraction system to extract the vacuum degree to be within 5*10<-3> Pa, then stopping the extraction system, and filling the smelting furnace with argon until the pressure is 0.01 atm; 2) adjusting a smelting electric arc gun to the position over the raw material to conduct smelting, and then cooling the raw material; 3) processing the smelted high-entropy alloy AlCoCrFeNi into metal flakes, covering 27SiMn steel cylinders with the metal flakes, and adopting laser welding to perform multiple overlap welding on the metal flakes and the cylinders; and 4) extruding the metal flakes so that the metal flakes are attached to the cylinders, conducting diameter reduction and fusing, and preparingthe high-entropy alloy AlCoCrFeNi / 27SiMn steel composite layer. The yield stress of the composite layer prepared by the method is greater than that of a high-entropy alloy AlCoCrFeNi base material, the friction coefficient of the composite layer is smaller than that of the high-entropy alloy AlCoCrFeNi base material, and the wear resistance and corrosion resistance of the composite layer are moreexcellent.

Owner:CHINA UNIV OF MINING & TECH

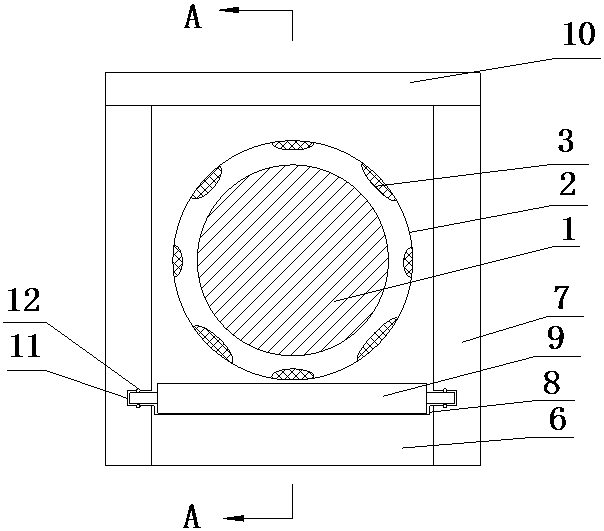

Surface treatment technology for aluminum-magnesium alloy coupling for pump

The invention discloses a surface treatment technology for an aluminum-magnesium alloy coupling for a pump. The surface treatment technology comprises steps as follows: (1), surface pretreatment; (2), preparation of a modified silane treatment solution; (3), modification treatment. On the basis of characteristics of an aluminum-magnesium alloy, the surface treatment technology for the coupling is reasonably adjusted and improved, specifically modified nano-silica particles are added and introduced to a silane coupling agent in a specific organosilane treatment process, so that molding speed and film formation quality of a silane film on the surface of the coupling are increased and improved effectively respectively, self-corrosion current density of the aluminum-magnesium alloy coupling is reduced obviously, overall corrosion resistance and surface characteristics are effectively improved, the service life of the coupling is prolonged 5 times or more, use performance of the pump is greatly improved, and the popularization value is higher.

Owner:ANHUI TENGLONG PUMP VALVE MFG CO LTD

Cationic waterborne hydroxy acrylic resin dispersion and siloxane hydrate composition and metal corrosion-protecting paint thereof

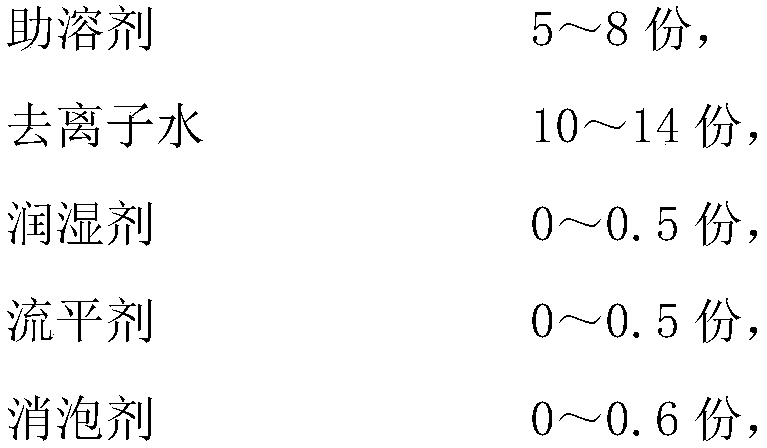

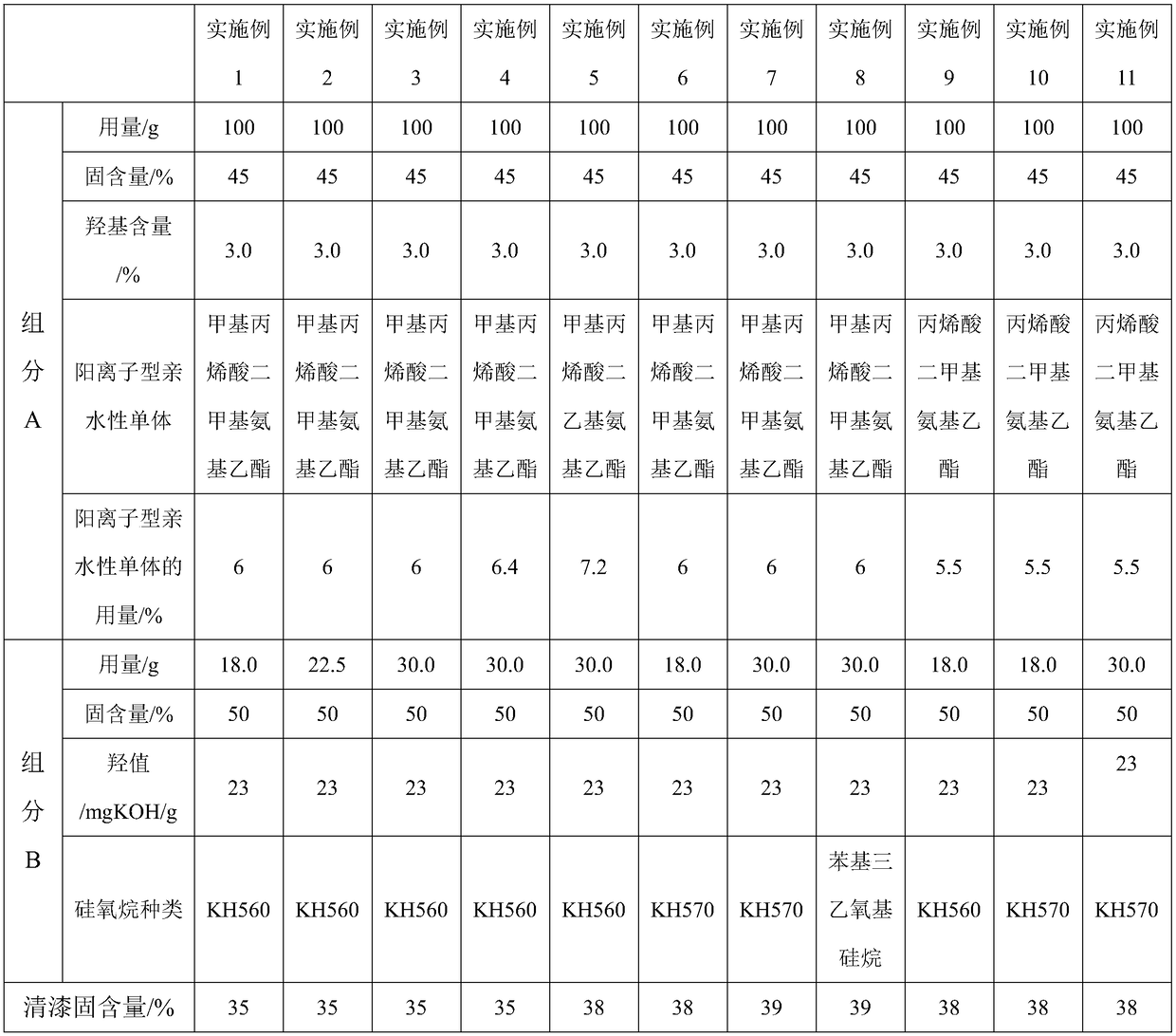

InactiveCN109486327AReaction is easy to controlSimple processAnti-corrosive paintsPolymer scienceAcrylic resin

The invention discloses a cationic waterborne hydroxy acrylic resin dispersion and siloxane hydrate composition and a metal corrosion-protecting paint thereof. The cationic waterborne hydroxy acrylicresin dispersion and siloxane hydrate composition is prepared by preparing a cationic waterborne hydroxy acrylic resin dispersion, namely, a component A through a double-solution free radical polymerization method, then preparing a siloxane hydrate, namely, a component B, and lastly, mixing the components at a solid weight ratio of 5:1-1:1. The cationic waterborne hydroxy acrylic resin dispersionand siloxane hydrate composition is applicable to the metal corrosion-protecting waterborne paint and can form a coating film with good adhesion, corrosion-protecting and anti-rust performance.

Owner:SHANGHAI UNIV +1

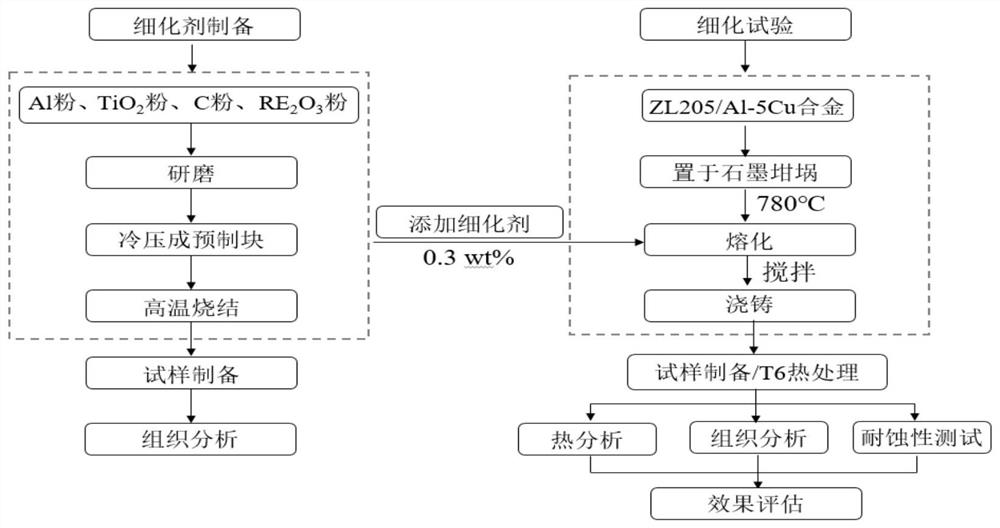

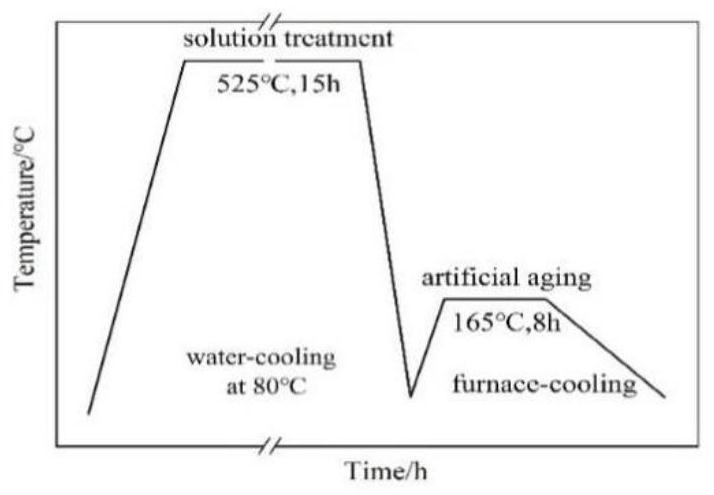

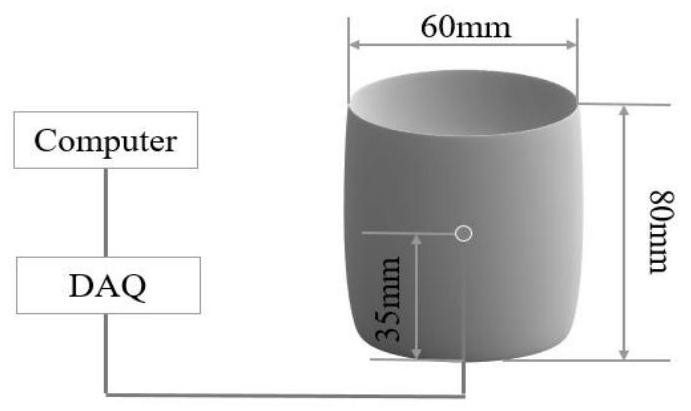

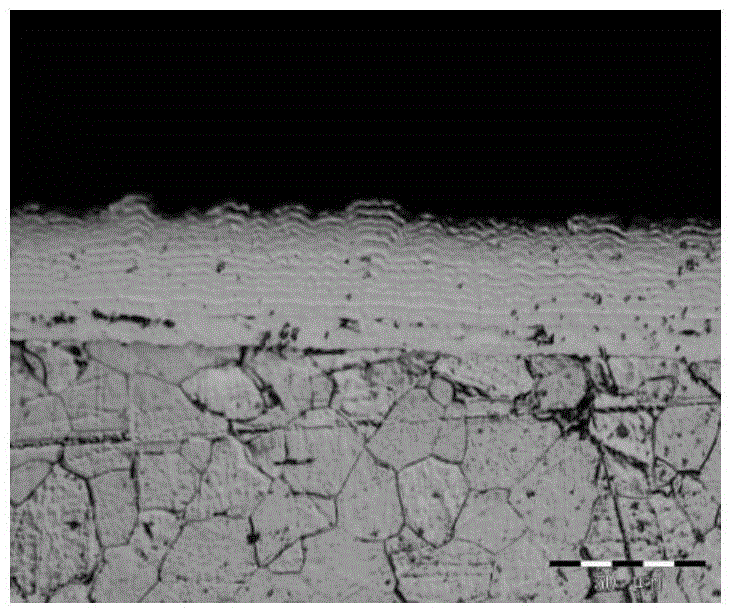

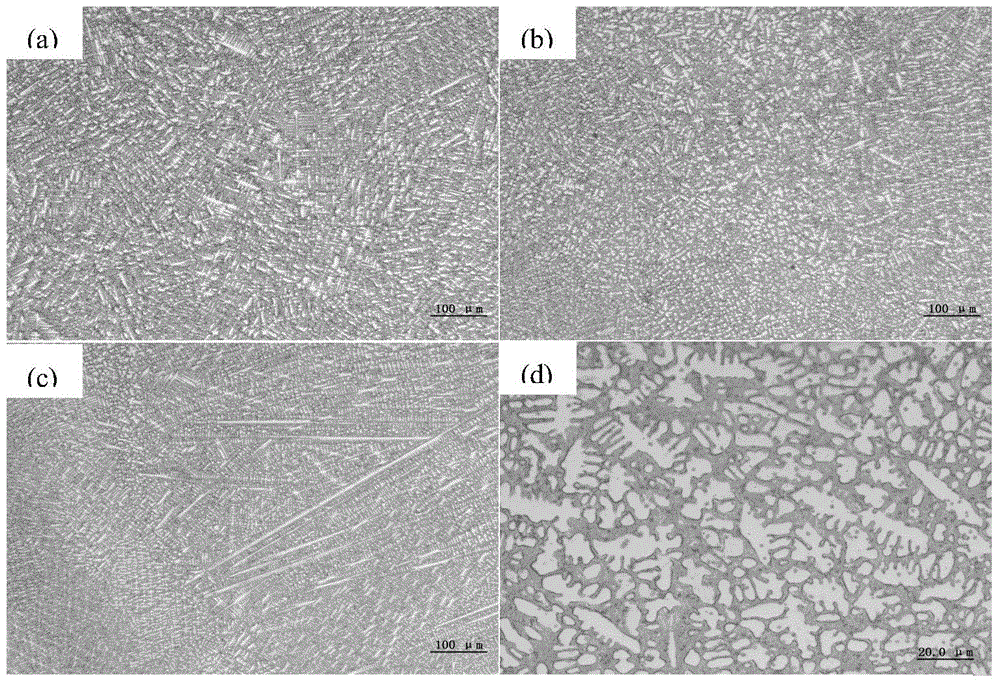

Al-TiO2-C-XRE2O3 composite refiner, corrosion-resistant ZL205 alloy and preparation method of Al-TiO2-C-XRE2O3 composite refiner

The invention discloses an Al-TiO2-C-XRE2O3 composite refiner, a corrosion-resistant ZL205 alloy and a preparation method of the Al-TiO2-C-XRE2O3 composite refiner. The Al-TiO2-C-XRE2O3 composite refiner is prepared by the following steps: firstly, uniformly mixing Al powder, TiO2 powder and C powder to obtain a mixed raw material A, then adding rare earth oxide RE2O3 powder into the mixed raw material A, and uniformly mixing to obtain mixed raw material powder; placing the mixed raw material powder in a ball mill for ball milling to obtain mixed ball-milled powder; pressing the mixed ball-milled powder into a precast block; placing the precast block in a corundum crucible, and filling the periphery of the precast block with Al2O3 powder; placing the corundum crucible filled with the precast block in a drying oven for drying; and drying the corundum crucible filled with the precast block, transferring the corundum crucible into a sintering furnace for sintering, and performing cooling along with the furnace after sintering is finished, so as to obtain the A l-T i O2-C-XRE2O3 composite refiner. The corrosion-resistant ZL205 alloy is prepared by adding the Al-Ti O2-C-XRE2O3 composite refiner into the ZL205 alloy. The refining agent provided by the invention is low in cost and good in refining effect, and the corrosion resistance of the ZL205 alloy can be effectively improved.

Owner:INNER MONGOLIA UNIV OF TECH

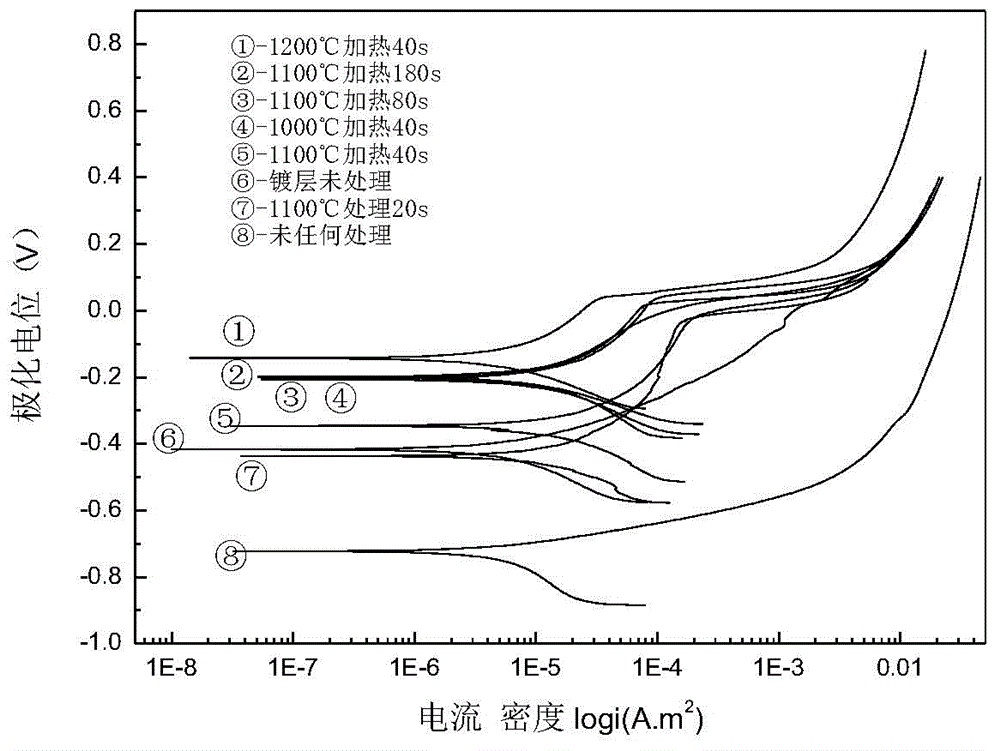

Preparation method of low-cost high-corrosion-resistance Monel metal coating

The invention provides a preparation method of a low-cost high-corrosion-resistance Monel metal coating. The preparation method is implemented by brush-plating a Ni coating and a Cu coating on a steel surface subjected to surface pretreatment by an electric brush plating process, and comprises the following steps: (1) positively connecting to the voltage, and brushing an electrocleaning solution on the surface; (2) negatively connecting to the voltage, and brushing a second activating solution on the surface; (3) negatively connecting to the voltage, and brushing a third activating solution on the surface; (4) while not connecting to the voltage, brushing special nickel on the surface; (5) positively connecting to the voltage, and brushing special nickel on the surface; (6) positively connecting to the voltage, and brushing quick nickel on the surface; (7) positively connecting to the voltage, and brushing alkaline copper on the surface; (8) positively connecting to the voltage, and brushing quick nickel on the surface; and (9) repeating the steps (7) and (8) 12-36 times, and carrying out heat treatment on the coating. The Monel metal layer prepared on the steel surface by the electric brush plating process has the advantages of high bonding strength with the base and excellent corrosion resistance, and can greatly lower the production cost.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

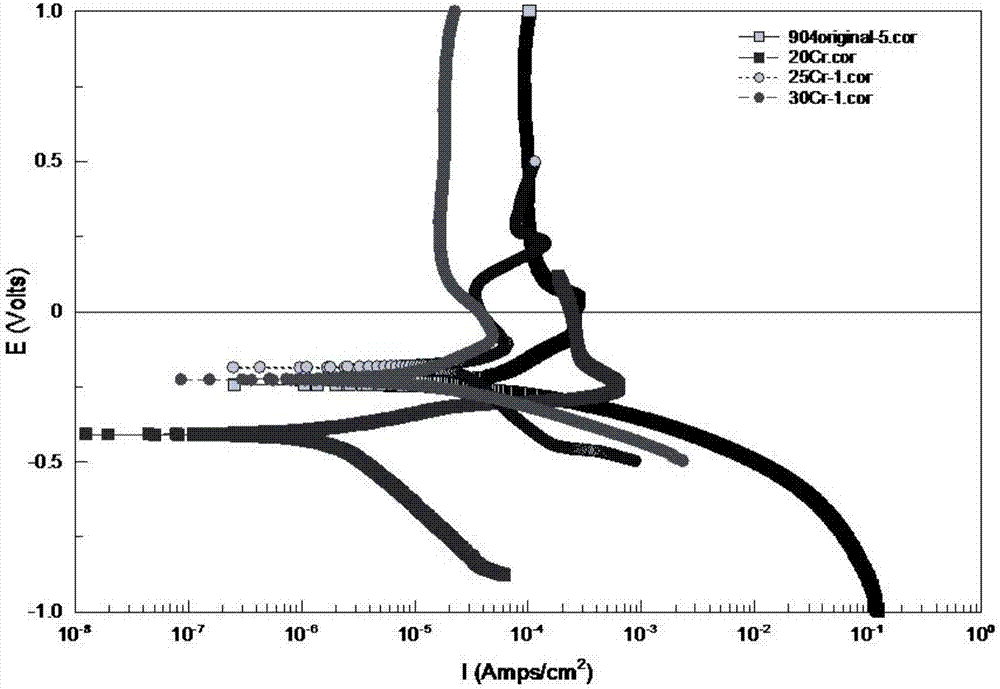

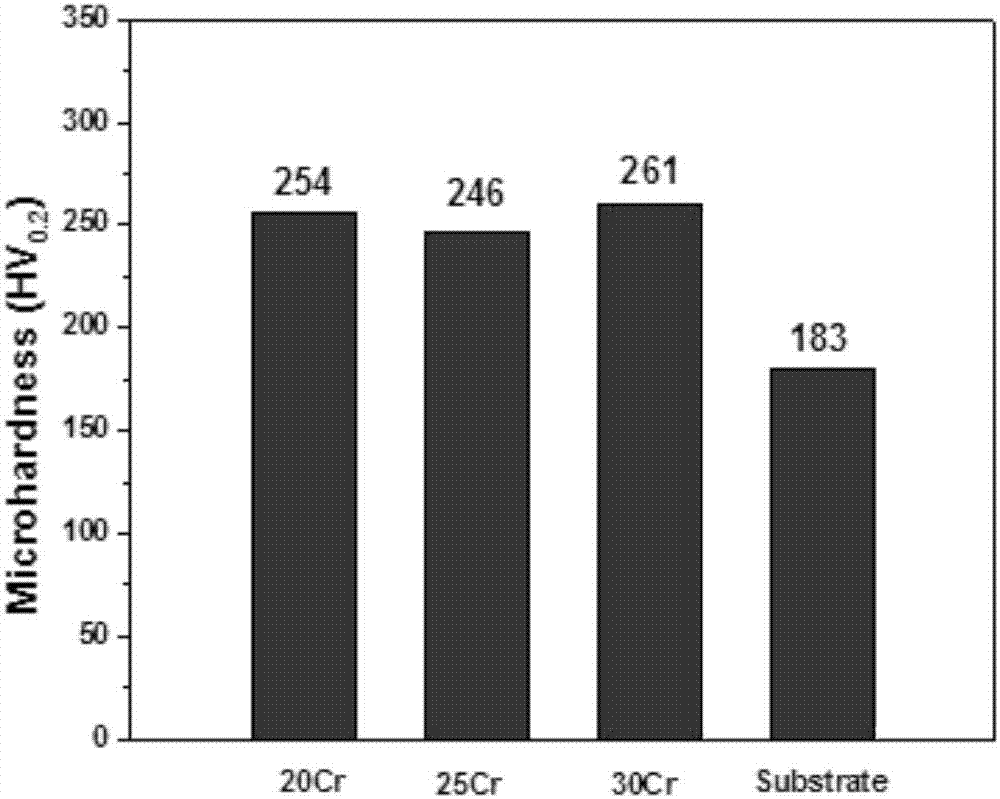

Super corrosion-resistant stainless steel powder as well as application thereof and application method thereof

ActiveCN106890993AHigh temperature oxidation resistanceCorrosion resistantMetallic material coating processesAlloyHardness

The invention discloses super corrosion-resistant stainless steel powder as well as an application thereof and an application method thereof. The powder consists of powder of the following components in parts by mass: 19-29 parts of Fe, 25-35 parts of Cr, 25-35 parts of Ni, 0.5-1.5 parts of Mn, 1-10 parts of Mo, 1-3 parts of Cu, 1-10 parts of Al2O3 and 0.5-1.5 parts of Y2O3. Compared with the prior art, alloy powder prepared has better flowability; a coating is good in quality after the alloy powder is laser-clad; the coating is free of crack holes and is compact in structure, and average hardness is improved; and moreover, according to an electrochemical test on the coating, corrosion resistance of 904L stainless steel is greatly improved.

Owner:GUIZHOU UNIV

Surfactant-added composite modified anti-corrosion zinc-rich coating and preparation method thereof

PendingCN113174154AShorten drying timeReduce crackingAnti-corrosive paintsEpoxy resin coatingsSilicic acidActive agent

The invention provides a surfactant-added composite modified anti-corrosion zinc-rich coating. The coating comprises, by weight, 20-40 parts of epoxy resin, 10-30 parts of polyamide, 5-10 parts of a curing agent, 5-15 parts of a leveling agent, 0.5-1 part of a toughening agent, 0.1-0.5 part of a degassing agent, 0.1-0.6 part of a flow promoter, 5-15 parts of a potassium silicate solution, 20-50 parts of zinc powder and 5-20 parts of a filler. A preparation method of the composite modified anti-corrosion zinc-rich coating comprises the following steps: weighing the components in parts by weight; heating and stirring epoxy resin and polyamide to obtain a first mixed solution; pouring the curing agent, the leveling agent, the toughening agent, the degassing agent and the flow promoter into the first mixed solution, and heating and stirring to obtain a second mixed solution; and finally, adding the potassium silicate solution, the zinc powder and the filler into the second mixed solution, stirring at a high speed to obtain a third mixed solution, and cooling to obtain the composite modified anti-corrosion zinc-rich coating. The mechanical property and the corrosion resistance of the composite modified anti-corrosion zinc-rich coating are improved, and the surface drying time of the coating is shortened by 20%.

Owner:SANMING UNIV

A kind of carbon steel surface treatment method

ActiveCN107604351BSmall crystal particlesUniform crystal particlesMetallic material coating processesMetallurgyCorrosion current density

The invention provides a carbon steel surface treatment method. The carbon steel surface treatment method comprises the following steps: the surface shot blasting treatment is performed on carbon steel; and the surface of the shot-blasted carbon steel is blackened. Compared with the prior art, the carbon steel surface treatment method effectively combines the surface shot blasting with the blackening treatment; as the shot blasting treatment is firstly performed on the surface of the carbon steel, crystal particles of blackening films formed by subsequent blackening treatment are fine, uniformand compact; through the shot blasting treatment, the self-corrosion potential of the blackening films is improved, and the self-corrosion current density is reduced; and meanwhile, through the shotblasting treatment, the resistance of the blackening films is increased, and the saline immersion resistance is higher. As the shot blasting treatment is performed before the blackening treatment, thecorrosion resistance of the prepared blackening films can be improved.

Owner:GUANGDONG UNIV OF TECH

A kind of biological bone composite material and preparation method thereof

ActiveCN105256174BHigh hardnessImprove wear resistanceAdditive manufacturing apparatusIncreasing energy efficiencyContinuous scanningSpherical shaped

A biological bone composite material and a preparation method thereof belong to the field of material technology. The composite material is composed of CoCrMo alloy powder, CeO2 alloy powder and ZrO2 alloy powder; among them, in terms of mass percentage, CoCrMo alloy powder: CeO2 alloy powder: ZrO2 alloy powder = (92~98): (1~3): (1 ~5); CoCrMo powder particle size ranges from 100 to 200 mesh, CeO2 powder particle size ranges from 0.5 to 1 μm, and ZrO2 powder particle size ranges from 30 to 80nm. All three powders are spherical in shape. The preparation method is: (1) mixing of composite powder; (2) matrix material pretreatment for laser direct deposition forming; (3) laser direct deposition forming process method, using laser 3D printer, inert gas protection; laser continuous scanning n The layer returns to the origin coordinates of the XY plane. The composite material has good strength, toughness, wear resistance and corrosion resistance; the hardness reaches 619HV and the tensile strength reaches 686MPa; after being soaked in artificial simulated saliva for seven days, the Cr ion concentration is 0.11mg / L. Composite materials are used in the preparation of artificial bone dentures.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com