Method for preparing hydrotalcite coating on magnesium alloy surface by combining acid pretreatment and steam method

An acid pretreatment, magnesium alloy technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of high cost, environmental pollution, the thickness of hydrotalcite coating is guaranteed and loose, etc., to slow down the corrosion rate, production process Environmental protection, the effect of increased thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

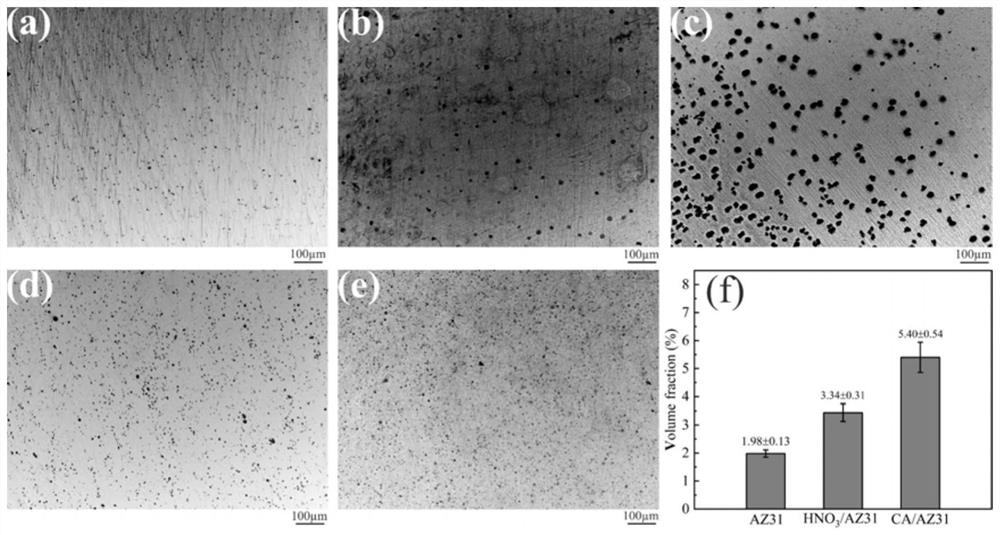

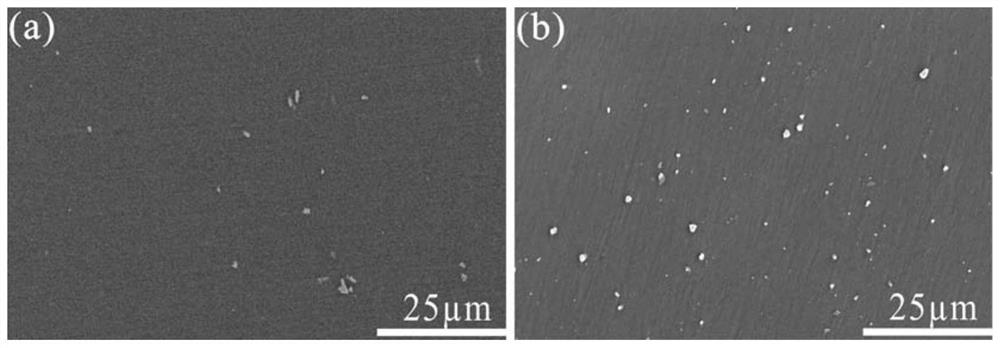

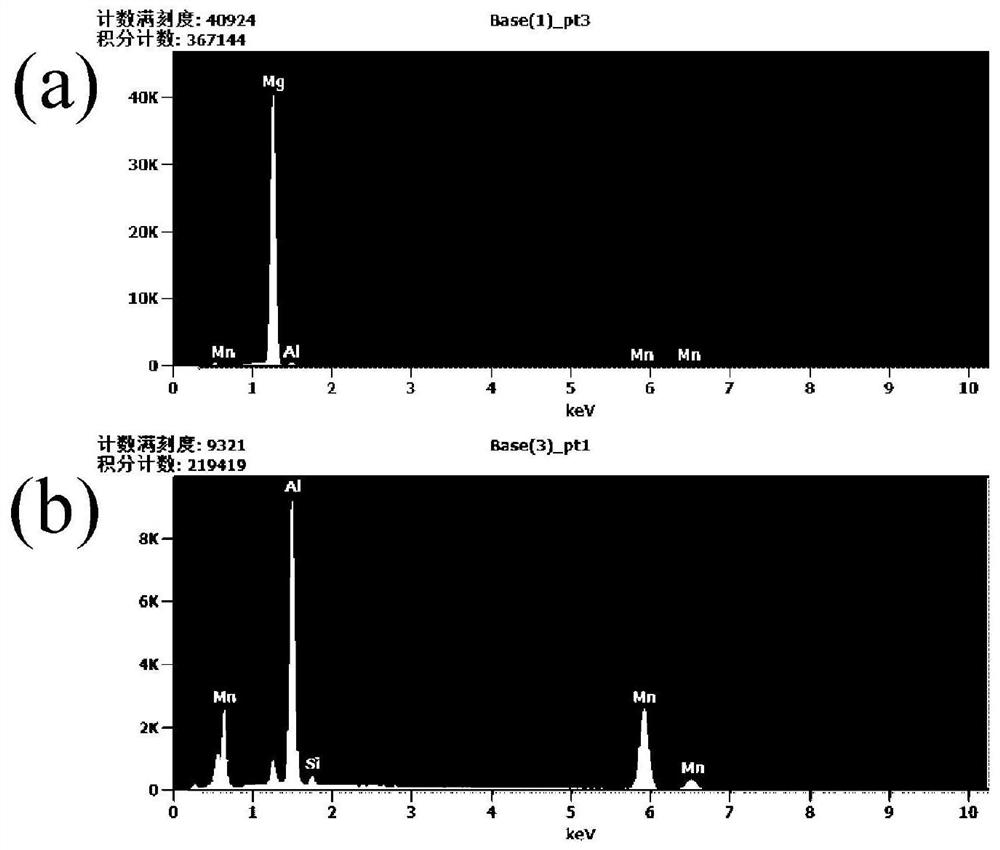

[0061] The substrate material is extruded magnesium alloy AZ31, and the steps for preparing hydrotalcite coating on the surface of extruded magnesium alloy AZ31 are as follows:

[0062] (1) Pretreatment of the surface of the extruded magnesium alloy AZ31: the extruded magnesium alloy AZ31 sample was polished to remove the surface oxide layer, and after there were no obvious burrs on the surface of the substrate, it was cleaned with an organic solvent and dried. Ethanol solution can be used;

[0063] (2) Carry out acid pretreatment to the magnesium alloy sample after step (1) pretreatment: prepare the citric acid solution of 30g / L, immerse the AZ31 magnesium alloy sample in the citric acid solution, take out after soaking for 30s, and then Cleaning and drying to obtain the magnesium alloy sample after acid pretreatment for subsequent use;

[0064] (3) Prepare hydrotalcite coating on the surface of magnesium alloy sample after acid pretreatment by in-situ steam method: suspend ...

Embodiment 2

[0067] The substrate material is extruded magnesium alloy AZ80, and the steps for preparing hydrotalcite coating on the surface of extruded magnesium alloy AZ80 are as follows:

[0068] (1) Pretreatment of the surface of the extruded magnesium alloy AZ80 substrate: take 4 magnesium alloy samples from the same magnesium alloy plate, grind the extruded magnesium alloy AZ80 sample to remove the surface oxide layer, and After the surface has no obvious burrs, clean it with an organic solvent and dry it;

[0069] (2) Carry out acid pretreatment to the magnesium alloy sample after the pretreatment of step (1): prepare 20g / L citric acid solution, immerse the extruded AZ80 magnesium alloy sample in the citric acid solution, and soak for 0s respectively (i.e. without acid pretreatment), take out after 10s, 20s, 30s, then clean and dry, obtain the magnesium alloy sample after acid pretreatment for subsequent use;

[0070] (3) The in-situ steam method was used to prepare hydrotalcite co...

Embodiment 3

[0075] The substrate material is extruded magnesium alloy AZ61, and the steps for preparing hydrotalcite coating on the surface of extruded magnesium alloy AZ61 are as follows:

[0076] (1) Pretreatment of the surface of the magnesium alloy substrate: the magnesium alloy sample is polished to remove the surface oxide layer, and after there are no obvious burrs on the surface of the substrate, it is cleaned with an organic solvent and dried;

[0077] (2) Carry out acid pretreatment to the magnesium alloy sample after step (1) pretreatment: prepare the citric acid solution of 20g / L, immerse the AZ61 magnesium alloy sample in the citric acid solution, take out after soaking for 40s, and then Cleaning and drying to obtain the magnesium alloy sample after acid pretreatment for subsequent use;

[0078] (3) Prepare hydrotalcite coating on the surface of magnesium alloy sample after acid pretreatment by in-situ steam method: suspend the magnesium alloy sample after citric acid pretrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com