Controllable-optical-property shape-memory polymer film and preparation method thereof

A technology for memory polymers and optical properties, applied in the field of preparation and application of intelligent polymer materials, can solve problems such as the inability to form thin films, and achieve the effects of low cost, wide application fields, and good industrial application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

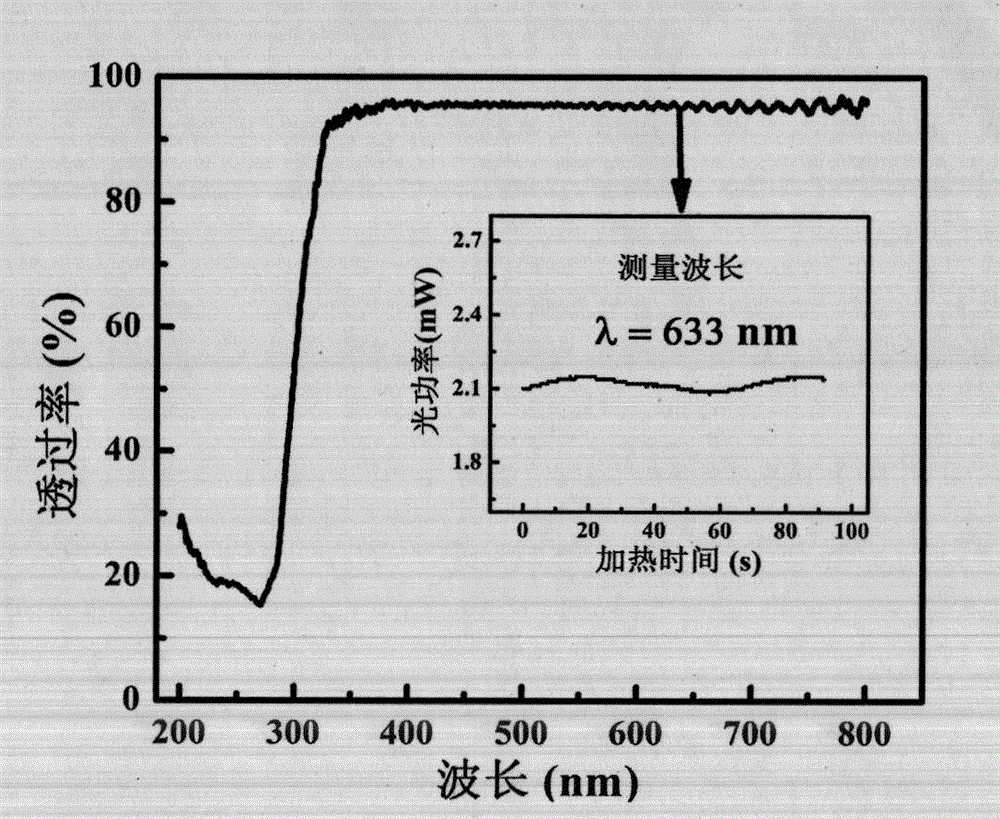

Embodiment 1

[0030] Mix styrene, butyl acrylate and benzoyl peroxide in a ratio of 30:20:1, prepare a solution with a glass transition temperature of about 70°C, stir at room temperature, and the stirring rate is 300rad / min. for 30 minutes until the solution is clear and transparent, and a uniformly dispersed styrene-based shape memory polymer solution is obtained. Place the fully mixed solution system in a vacuum box at room temperature to remove air bubbles, and continue vacuuming for 15 minutes after the air pressure reaches 0.1 MPa. In order to better analyze the optical, mechanical and thermal properties of this kind of film, a 4-inch silicon wafer polished on one side was selected as the substrate of the spin-coated film to prepare a smooth-surfaced shape-memory polymer film sample. The substrate used as a template is soaked in absolute ethanol and acetone for 10 minutes before use, and then washed twice with deionized water, and then placed in deionized water for ultrasonic cleaning...

Embodiment 2

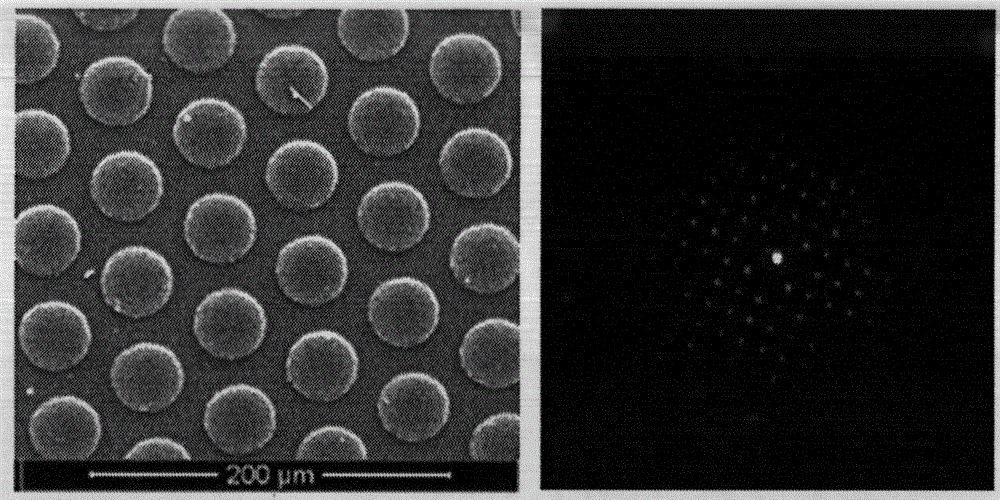

[0032] Mix styrene, butyl acrylate and benzoyl peroxide in a ratio of 10:40:1, prepare a solution with a glass transition temperature of about 30°C, stir at room temperature, and the stirring rate is 300rad / min. for 30 minutes until the solution is clear and transparent, and a uniformly dispersed styrene-based shape memory polymer solution is obtained. Place the fully mixed solution system in a vacuum box at room temperature to remove air bubbles, and continue vacuuming for 15 minutes after the air pressure reaches 0.1 MPa. A 4-inch silicon wafer with a cylindrical micropit array etched on the surface is used as a template for backup. The substrate used as a template is soaked in absolute ethanol and acetone for 10 minutes before use, and then washed twice with deionized water, and then placed in deionized water for ultrasonic cleaning for 10 minutes. After the above steps are completed, take out the substrate with tweezers and put it in Dry in an incubator at 80°C for later ...

Embodiment 3

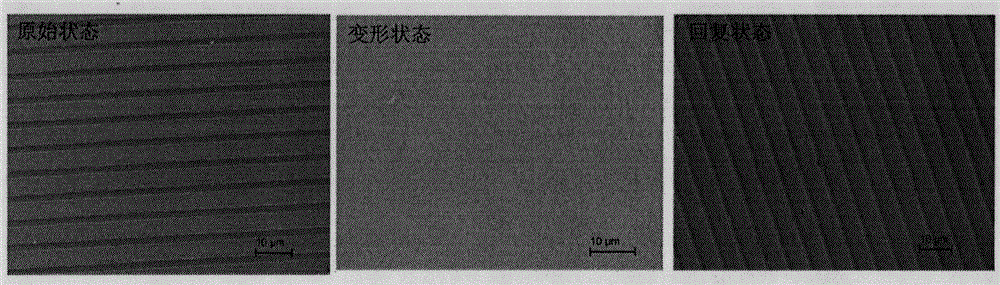

[0034]Mix styrene, butyl acrylate and benzoyl peroxide in a ratio of 30:20:1, prepare a solution with a glass transition temperature of about 70°C, stir at room temperature, and the stirring rate is 300rad / min. for 30 minutes until the solution is clear and transparent, and a uniformly dispersed styrene-based shape memory polymer solution is obtained. Place the fully mixed solution system in a vacuum box at room temperature to remove air bubbles, and continue vacuuming for 15 minutes after the air pressure reaches 0.1 MPa. A 4-inch silicon wafer with an array of hexagonal micropit etched on its surface was used as a template for backup. The substrate used as a template is soaked in absolute ethanol and acetone for 10 minutes before use, and then washed twice with deionized water, and then placed in deionized water for ultrasonic cleaning for 10 minutes. After the above steps are completed, take out the substrate with tweezers and put it in Dry in an incubator at 80°C for late...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com