Al-TiO2-C-XRE2O3 composite refiner, corrosion-resistant ZL205 alloy and preparation method of Al-TiO2-C-XRE2O3 composite refiner

A technology of al-tio2-c-xre2o3, 1.al-tio2-c-xre2o3, applied in the field of aluminum alloy preparation, can solve the problem of "poisoning stability and other problems, reduce the corrosion sensitivity of the alloy, improve the quality, strong resistance corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

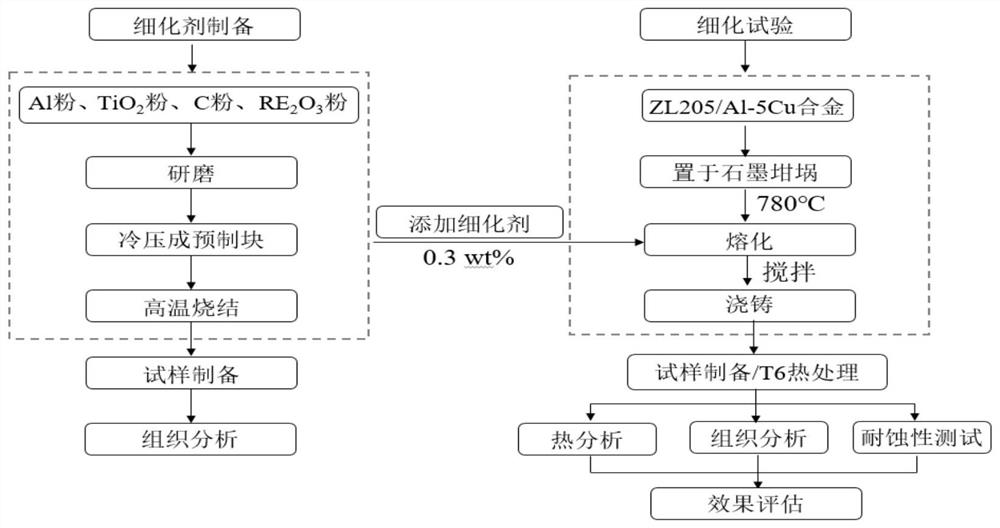

[0139] 1. Al-TiO 2 -C-XRE 2 o 3 Composite refiner and corrosion-resistant ZL205 alloy and its preparation method

[0140] 1.1 Al-TiO 2 -C-XRE 2 o 3 Composite refiner

[0141] Al-TiO 2 -C-XRE 2 o 3 The composite refiner is prepared by the following steps:

[0142] Step A: Al powder, TiO 2 Powder and C powder are mixed evenly to obtain mixed raw material A, and then rare earth oxide RE is added to mixed raw material A 2 o 3 powder, mixed evenly to obtain mixed raw material powder; TiO 2 The mass fraction of the powder is 12wt%, and the molar ratio of titanium element to carbon element is 10:1; in the mixed raw material powder: rare earth oxide RE 2 o 3 The mass ratio of powder to mixed raw material A is 0.06; rare earth oxide RE 2 o 3 Powder is E 2 o 3 powder;

[0143]Step B: placing the mixed raw material powder in a ball mill and milling for 60 minutes to obtain a mixed ball milled powder;

[0144] Step C: Press the mixed ball-milled powder into a prefabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com