Anti-abrasion protective coating for surface of metal substrate and preparation method and application of anti-abrasion protective coating

A technology for metal substrates and protective coatings, applied in metal material coating processes, coatings, ion implantation plating, etc., can solve the problems of reducing the mechanical properties of parts, increasing manufacturing costs, and large coating thicknesses, achieving improved Effects of mechanical strength, improved corrosion resistance, high corrosion and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In some more specific embodiments, the preparation method includes:

[0041] (1) Pre-treat the surface of the substrate: use 120#~3000# SiC metallographic sandpaper to polish the metal substrate in turn, and then use Al with a particle size of 0.2~0.3μm 2 o 3 The abrasive paste is used to polish the metal substrate for 10-15 minutes;

[0042] Clean the polished metal substrate sequentially with acetone, ethanol, and deionized water for 5 to 15 minutes, and dry it with cold air;

[0043] Place the metal substrate in the thin film deposition vacuum chamber and evacuate to 2.0×10 -5 Torr, then heat the chamber at 120-150°C, then feed argon gas with a gas flow rate of 30-36 sccm into the vacuum chamber, turn on the linear ion source and pulse bias voltage to perform bias etching and cleaning on the substrate for 30-45 minutes, wherein The linear ion source current and pulse bias voltage are 0.20~0.25A and -200~-250V respectively.

[0044] (2) Using DC magnetron sputteri...

Embodiment 1

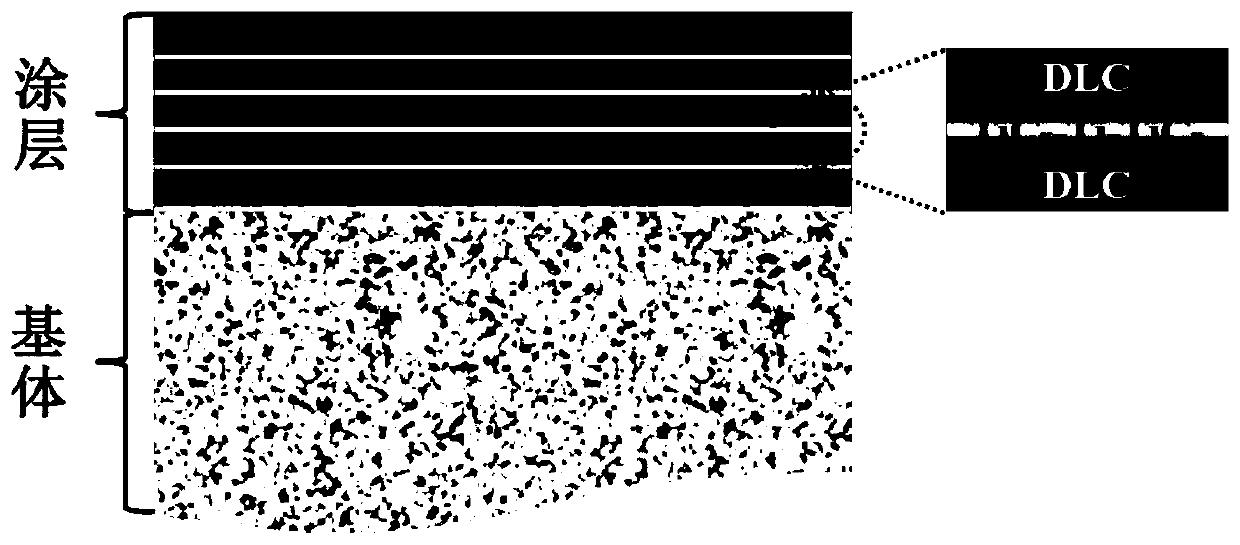

[0054] In this embodiment, the base material is AISI 316L austenitic stainless steel, and the structure of the coating is as follows figure 1 Shown, where the total thickness of the coating is 1.6 μm.

[0055] The coating preparation steps on the above-mentioned 316L surface are as follows:

[0056] Step 1: Use 120#~3000# SiC metallographic sandpaper to polish the 316L substrate in turn, and then use Al with a particle size of 0.2~0.3μm 2 o 3 The abrasive paste is used for metallographic polishing of the stainless steel substrate for 15 minutes;

[0057] Step 2: Place the polished 316L stainless steel substrate in acetone, ethanol and deionized water in sequence for ultrasonic cleaning for 10 minutes, and then dry it with cold air for later use;

[0058] Step 3: Place the 316L stainless steel substrate in the film deposition vacuum chamber, and successively use a mechanical pump and a turbomolecular pump to evacuate to 2.0×10 -5 After Torr, turn on the heater and set the h...

Embodiment 2

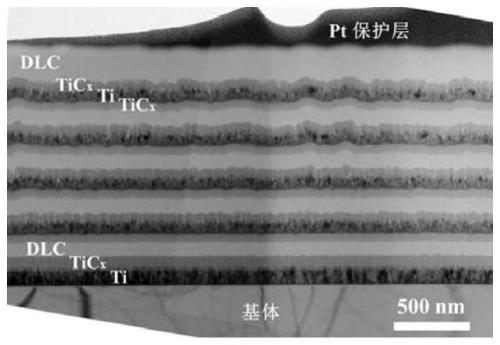

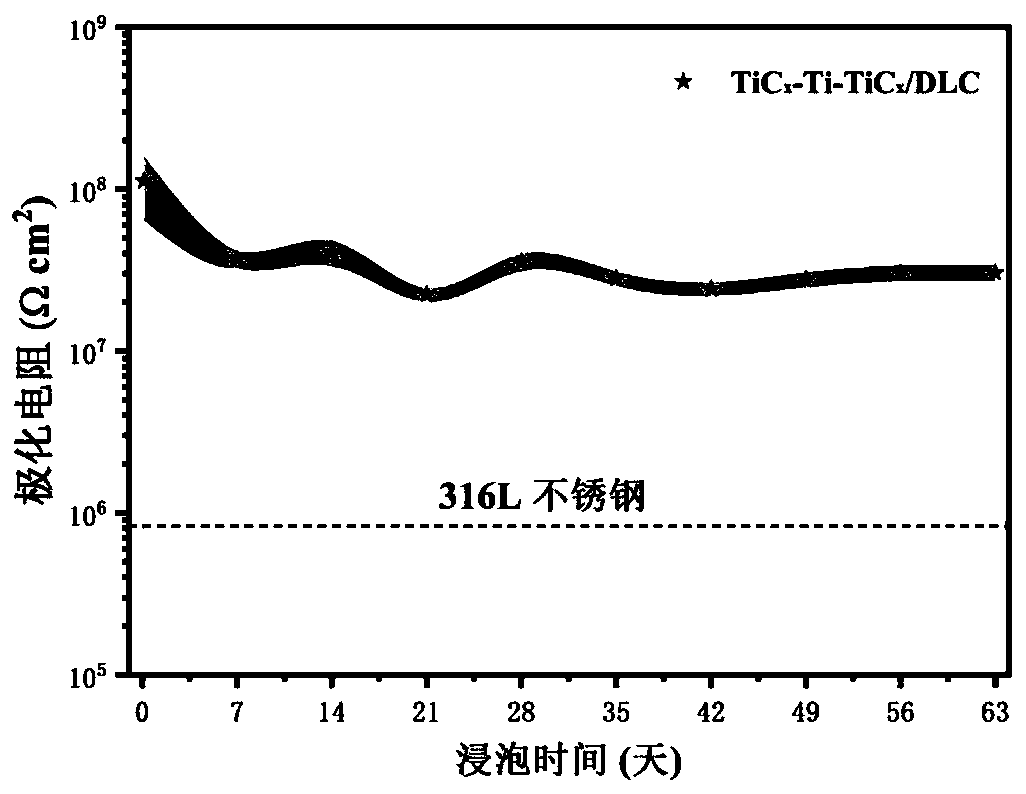

[0066] In this example, the base material is UNS S32750 (SAF 2507) super duplex stainless steel, and the coating is TiC x / Ti / TiC x Layers and DLC layers are periodically stacked alternately in a multilayer structure, in which the surface of S32750 is a Ti transition layer, and the total thickness of the coating is 2.3 μm.

[0067] The coating preparation steps on the surface of the above S32750 are as follows:

[0068] Step 1: Use 120#~3000# SiC metallographic sandpaper to polish the S32750 substrate in turn, and then use Al with a particle size of 0.2~0.3μm 2 o 3 The abrasive paste is used for metallographic polishing of the substrate for 12 minutes;

[0069] Step 2: Place the polished S32750 substrate in acetone, ethanol and deionized water in sequence for ultrasonic cleaning for 10 minutes, and then dry it with cold air for later use;

[0070] Step 3: Place the S32750 substrate in the thin film deposition vacuum chamber, and successively use mechanical pump and turbomo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com