Cationic waterborne hydroxy acrylic resin dispersion and siloxane hydrate composition and metal corrosion-protecting paint thereof

A hydroxyacrylic acid, cationic technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of organosiloxane group hydrolysis, side reaction crosslinking curing degree, poor compatibility of the composition, etc., to achieve convenient operation and good Anti-corrosion and anti-rust performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The purpose of this example is to demonstrate the preparation of the composition of cationic waterborne hydroxyl acrylic resin dispersion and silicone hydrolyzate and its coating, as follows:

[0041] (1) Preparation of component A: Add 18g of ethylene glycol monobutyl ether, 18g of 100# solvent naphtha and 1g of di-tert-butyl peroxide into a reaction vessel, blow nitrogen gas, stir and heat up to 145°C, and keep warm for 15min; A mixture of 32g of methyl acrylate, 46g of n-butyl acrylate, 29.2g of hydroxyethyl methacrylate, 12.8g of styrene, 0.96g of α-methylstyrene dimer and 4.8g of di-tert-butyl peroxide was dropped at a constant speed Put it into the reaction container, control the dripping within 1.5h, and continue to keep warm for 10min; add 18g of methyl methacrylate, 26g of n-butyl acrylate, 16.8g of hydroxyethyl methacrylate, 7.2g of styrene, and dimethyl methacrylate A mixture of 12 g of amino ethyl ester and 3.2 g of di-tert-butyl peroxide was added to the re...

Embodiment 2~11

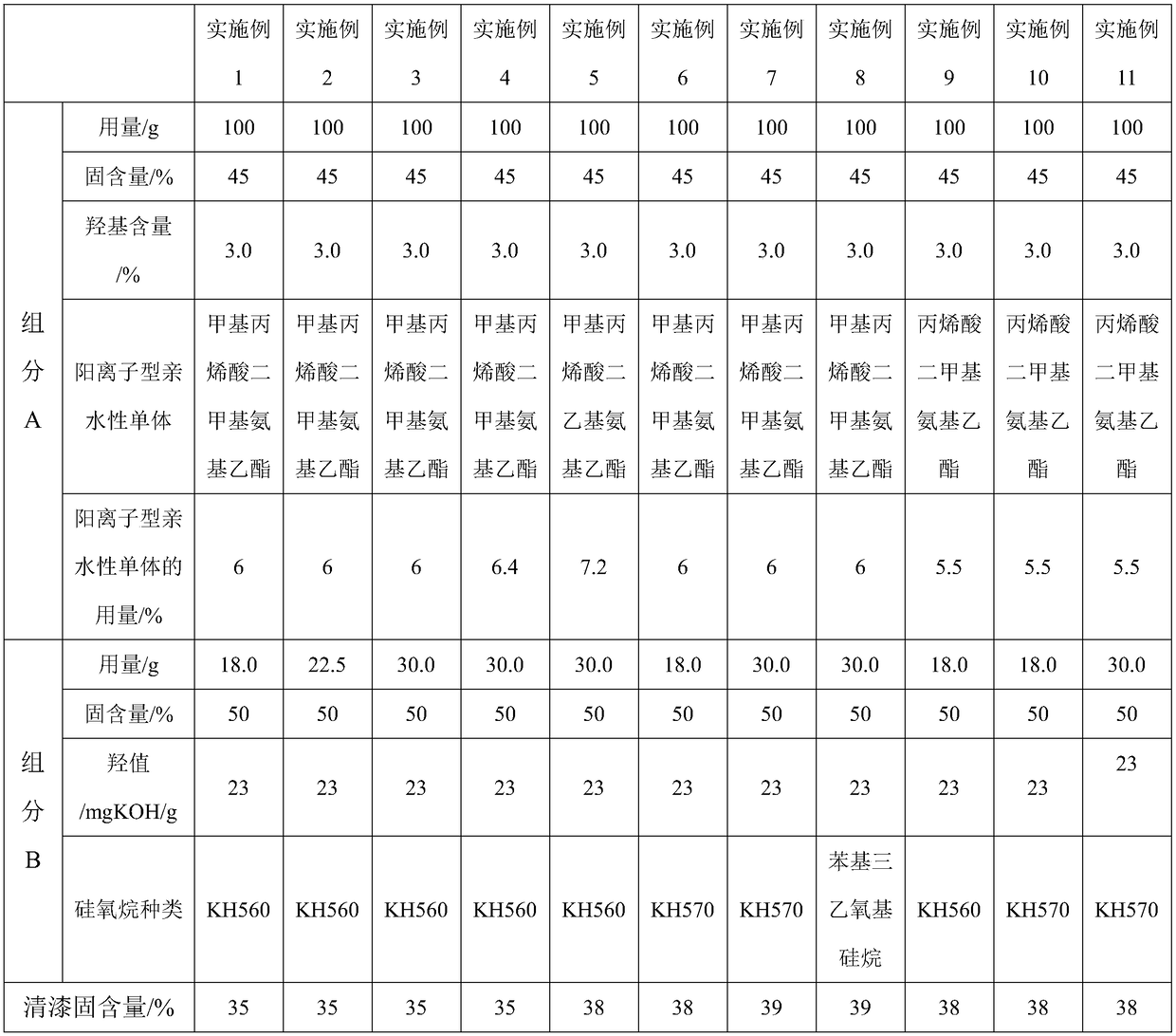

[0045] Comparative example 1, the composition of embodiment 2~11, coating formulation and paint film performance are shown in the following table:

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com