Patents

Literature

239results about How to "Improve anti-corrosion and anti-rust performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

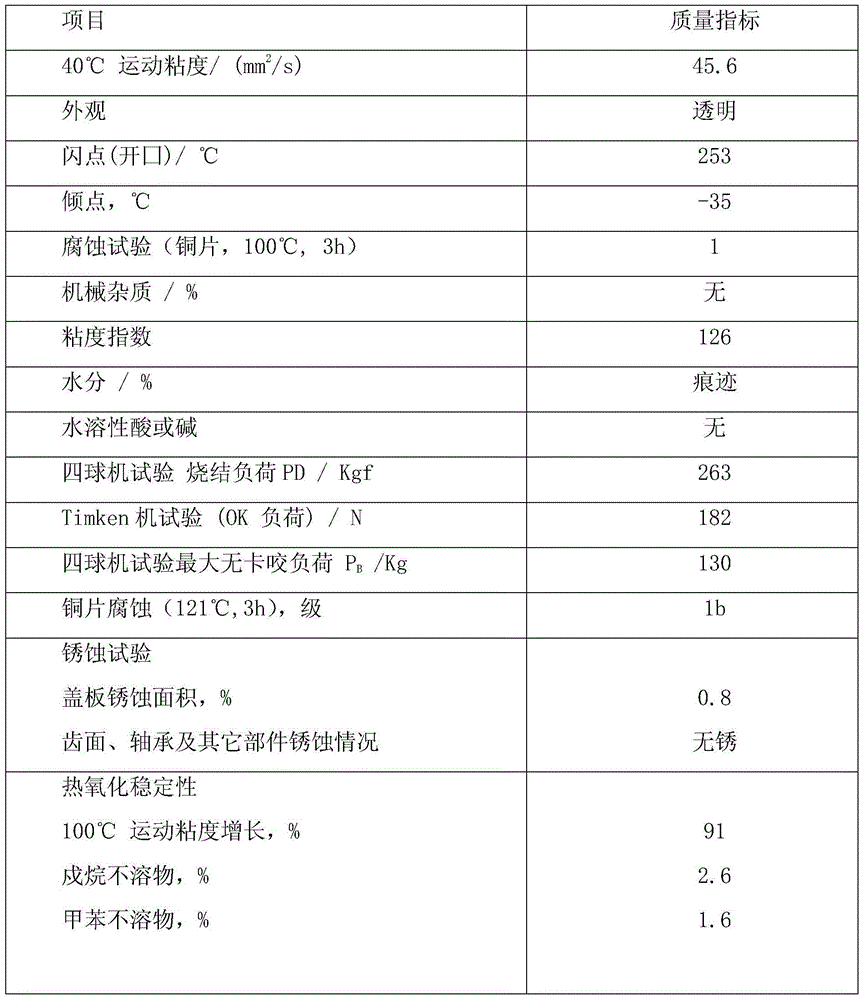

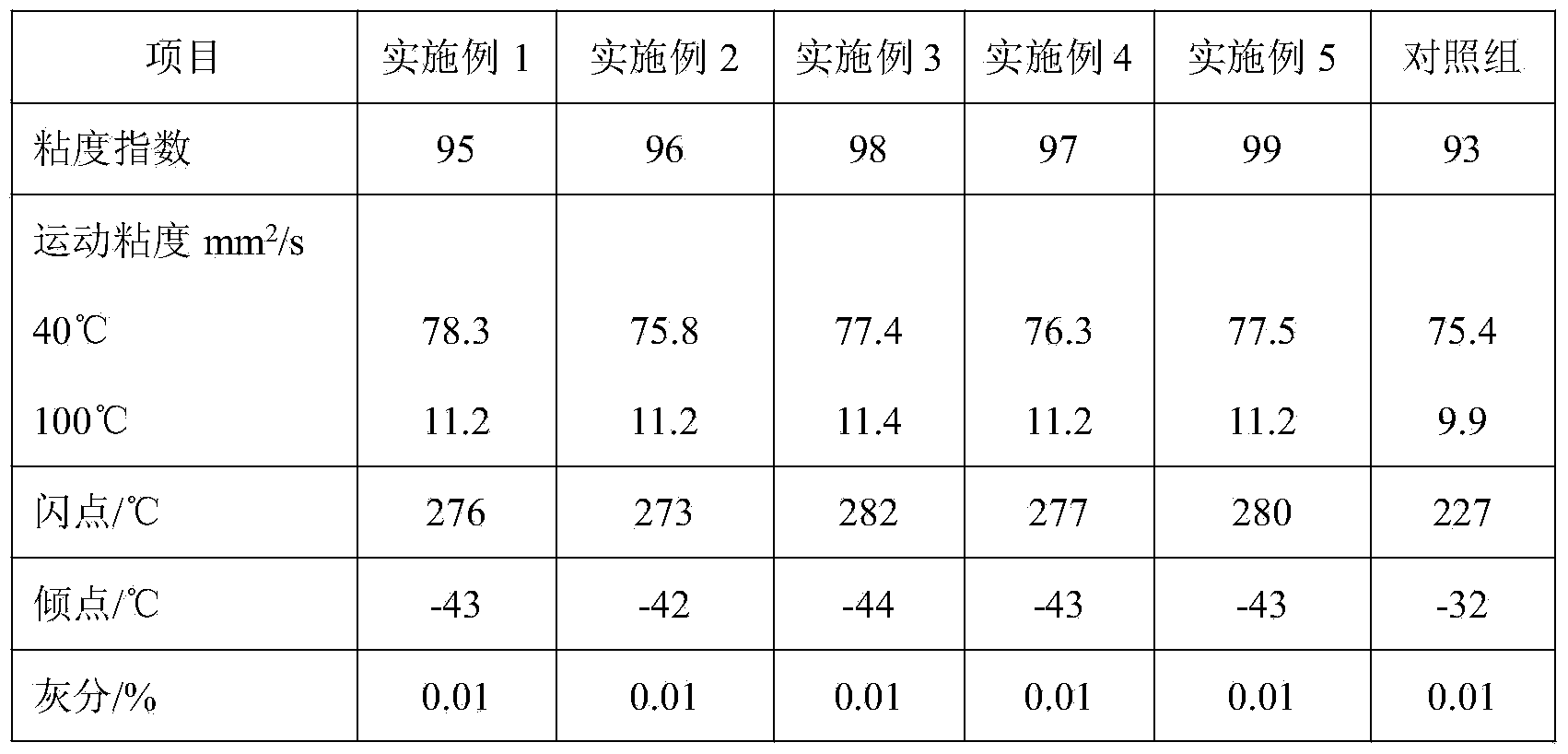

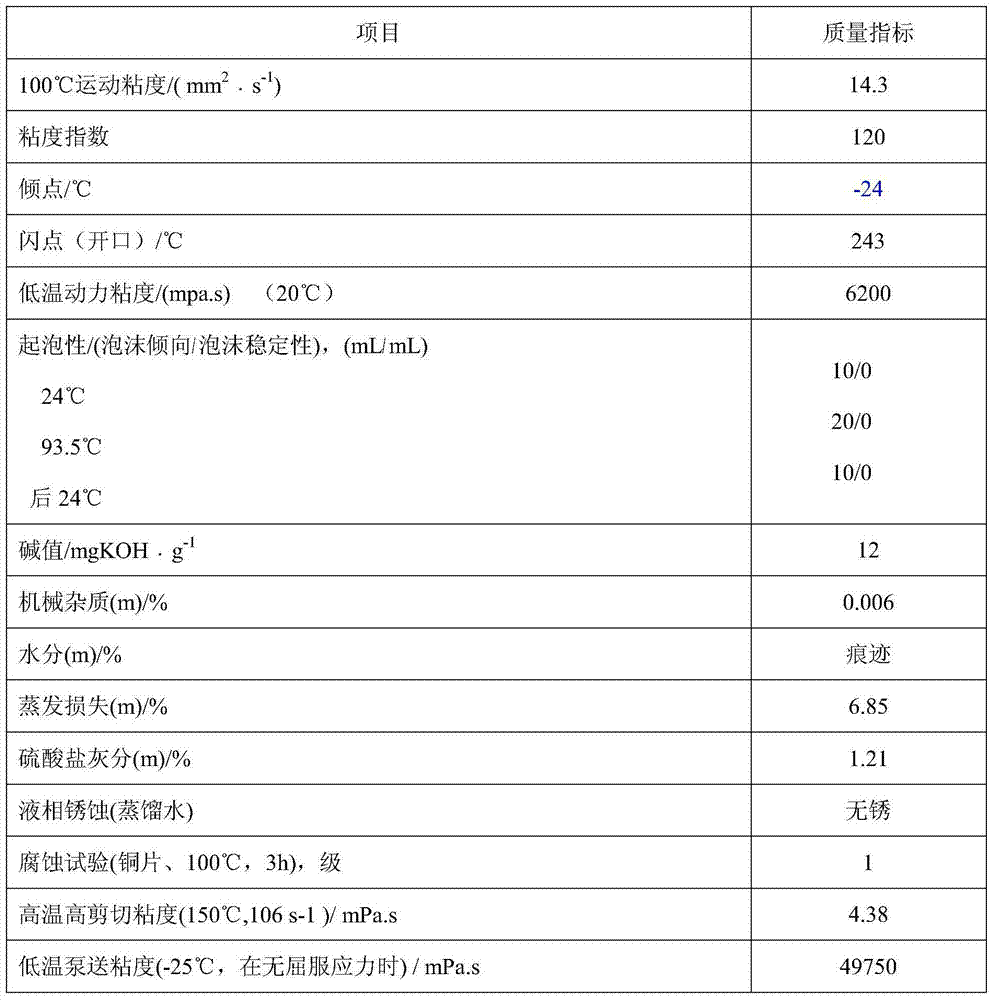

Hydraulic-transmission-braking three-use lubricating oil composition

InactiveCN102952617AAvoid wear and tearPrevent rustLubricant compositionFriction reductionTransmission brake

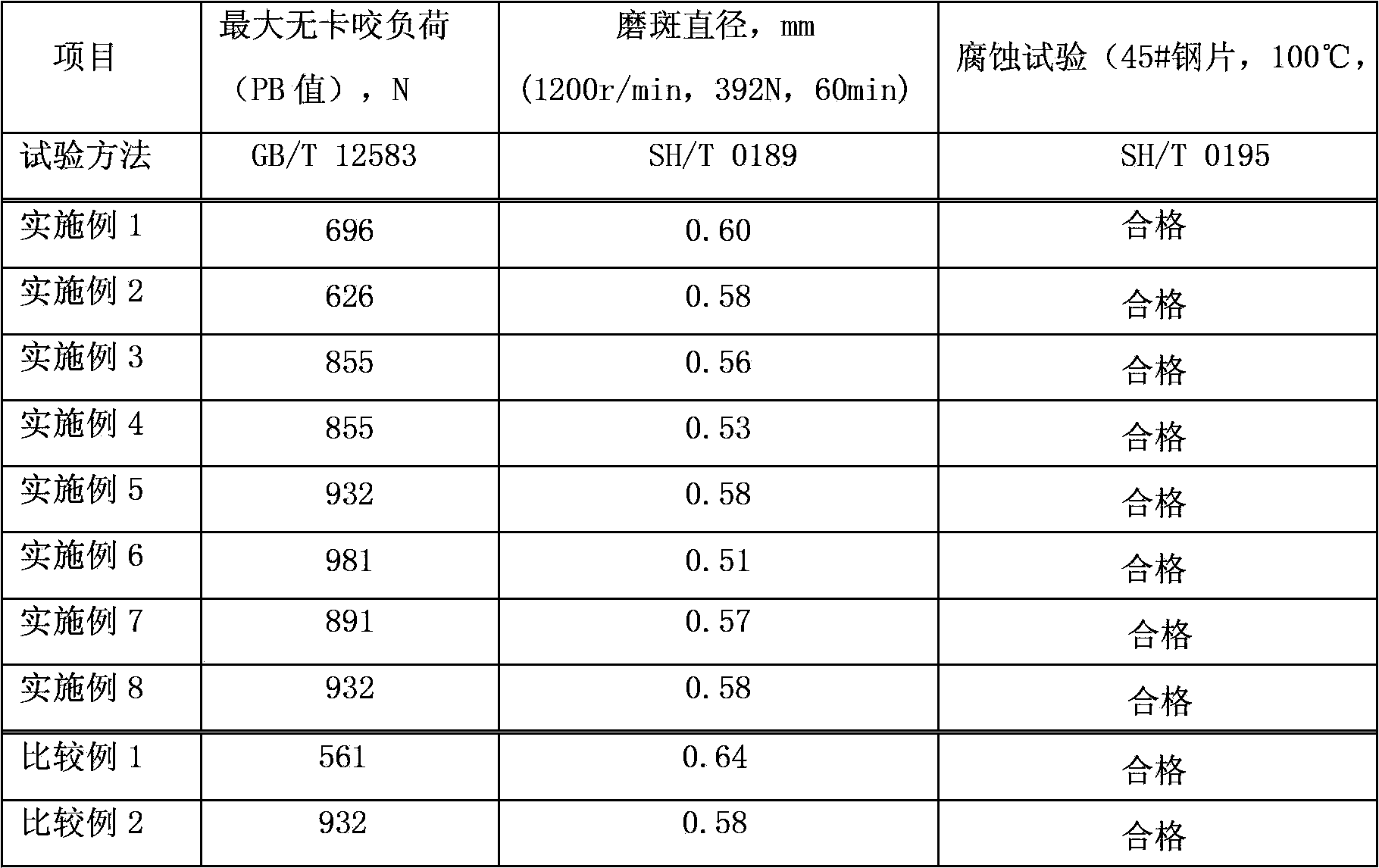

The present invention relates to a hydraulic-transmission- braking three-use lubricating oil composition, which is prepared by mixing the following raw materials, by weight, 85-98% of high viscosity index base oil, 0.1-5% of an extreme pressure wear resistance agent, 0.1-4% of an antioxidant, 0.1-3% of a metal deactivator / antirust agent, 0.1-5% of a friction modifier, and 0.1-2% of a dispersing agent. The hydraulic-transmission- braking three-use lubricating oil composition has beneficial effects of good low temperature fluidity, friction reduction, wear resistance, corrosion resistance, rust resistance, emulsification resistance and foaming resistance, and can meet requirements of universal hydraulic transmission oil used by large-medium-sized tractors and construction machinery so as to achieve complete lubricating protection on hydraulic parts, transmission parts, gear parts, power output parts and braking parts, such that a long service life is provided, equipment operation stability is easily improved, and energy saving and consumption reduction are provided.

Owner:BEIJING ALLUBE PETROCHEM

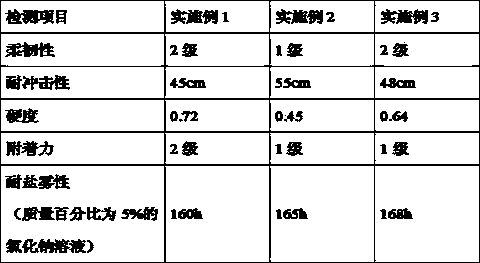

High-temperature-resistant, anti-corrosion and thermal-insulation coating and preparation technology thereof

ActiveCN104673063AReduce internal stressImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentCross linker

The invention discloses a high-temperature-resistant, anti-corrosion and thermal-insulation coating which comprises components in parts by weight as follows: 45-60 parts of film-forming resin, 20-30 parts of a pigment and filler, 15-30 parts of an aid and 25-30 parts of a solvent. The invention further designs a preparation technology of the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The technology comprises steps as follows: firstly, mixing the film-forming resin with the pigment and the filler, sequentially adding an antifoaming agent, a leveling agent, a coupling agent, a crosslinking agent and a curing agent, and evenly stirring the mixture at the normal temperature to obtain the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The coating has the advantages of environment-friendliness, low cost, high hardness, long service life, good heat resistance, good flexibility, good high-temperature resistance and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Antiseptic and anticorrosive treatment method for metal surface

InactiveCN103966593AExtended service lifeEasy to useLiquid surface applicatorsMetallic material coating processesChemical reactionPre treatment

The invention discloses an antiseptic and anticorrosive treatment method for a metal surface. The method comprises the following steps: 1, surface pretreatment; 2, deep treatment. In the manner, by adopting the antiseptic and anticorrosive treatment method for the metal surface disclosed by the invention, a series of treatments are carried out on the metal surface, not only can a protective layer be formed on the metal surface in a chemical reaction manner, but also the antiseptic and anticorrosive capability of the metal surface is also enhanced by a physical manner. The service life of metal is effectively prolonged by working along both lines, and the method is convenient to use.

Owner:WUXI HAITE NEW MATERIAL RES INST

Lubricating anticorrosive oil and use thereof

ActiveCN101328445AExcellent anti-rustImprove the lubrication effectAdditivesPetroleum productOxidation resistant

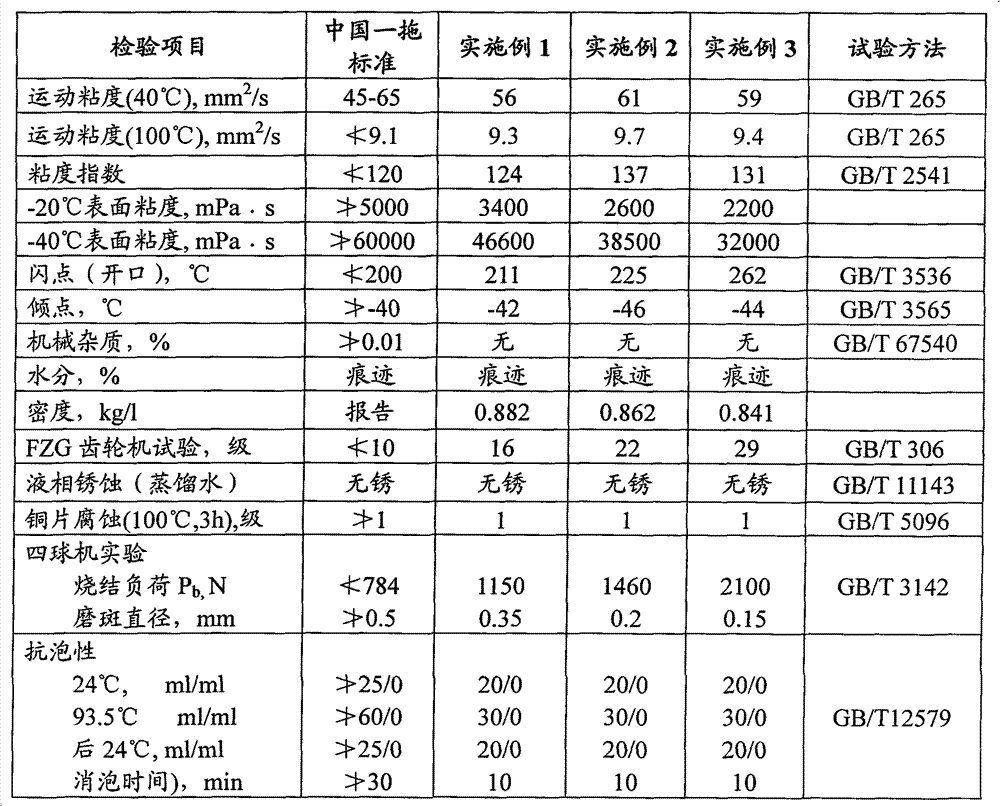

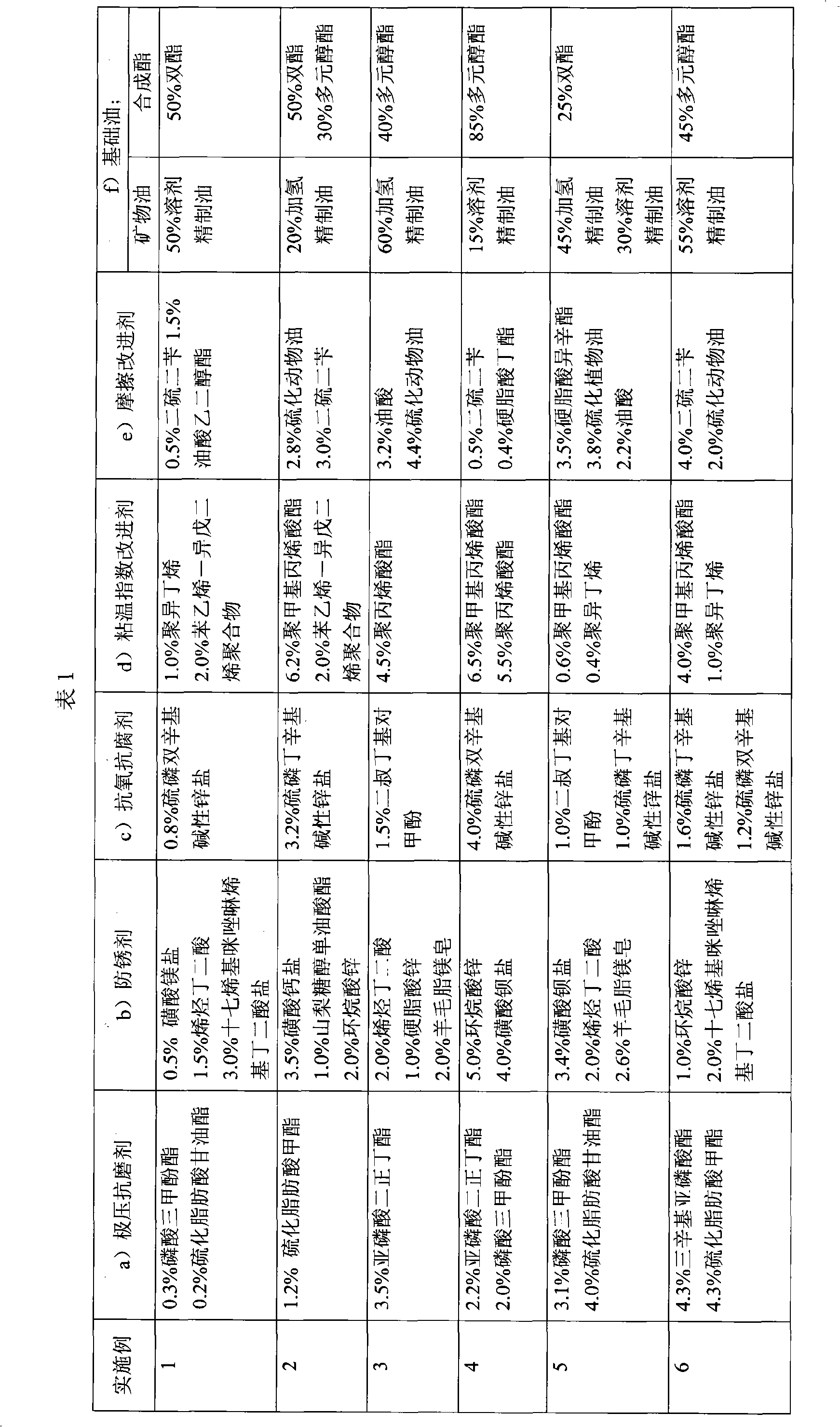

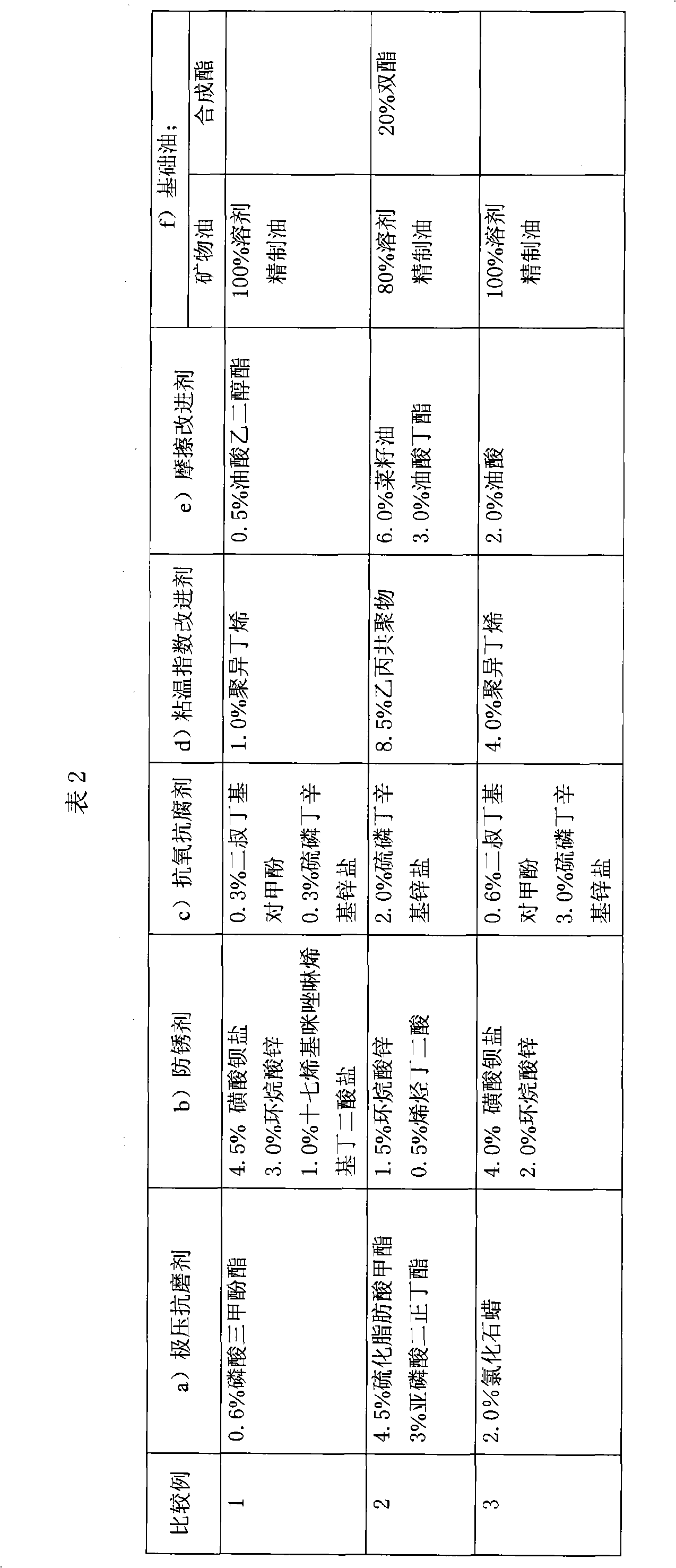

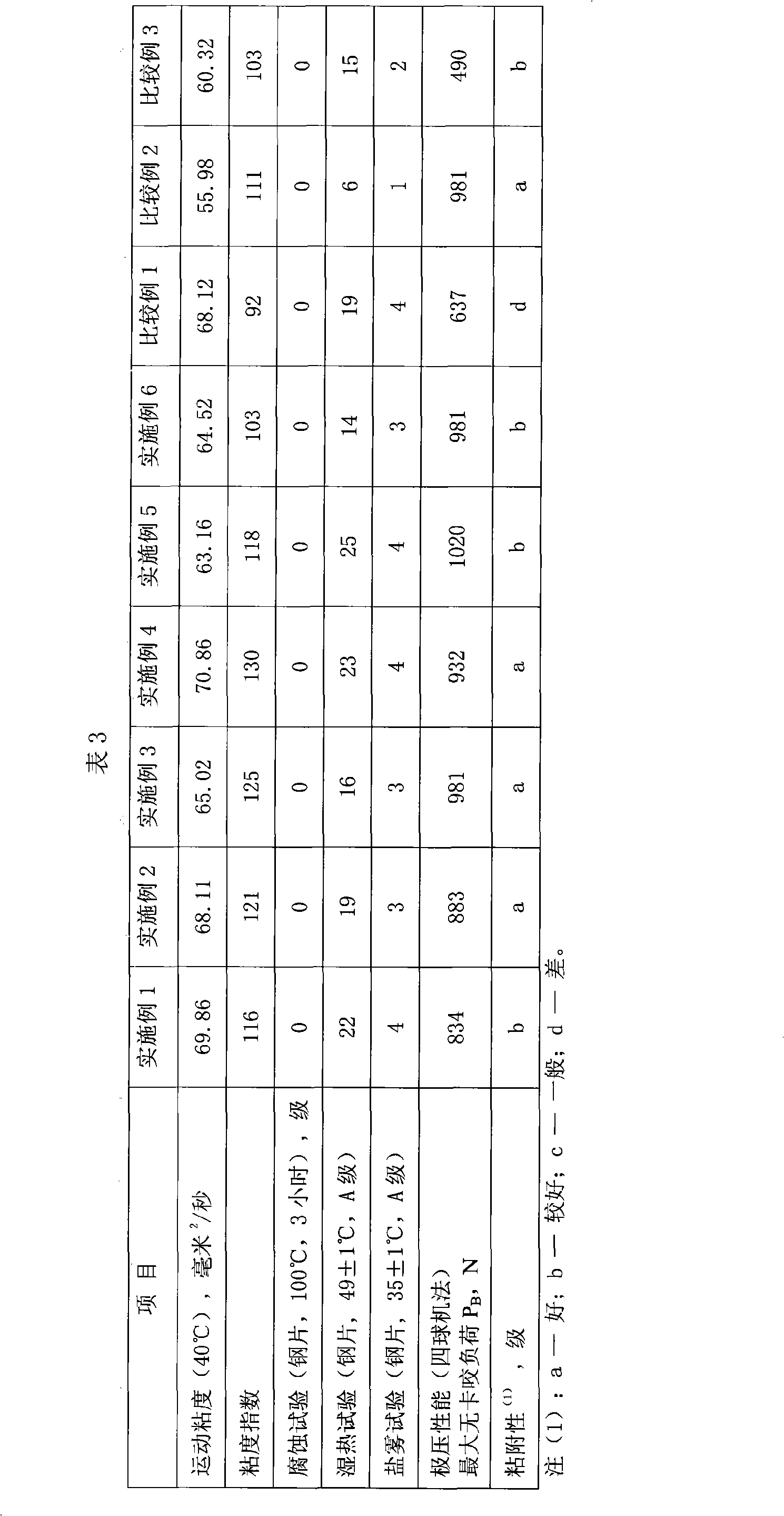

The invention relates to lubricating rust preventive oil and application thereof, mainly aiming to solve the problems of the prior art that: a rustproof product has poor adhering property; and the prior art only lays stress on rustproof property and does not attach equal importance to the extreme pressure property, oxidation resistance and permeability of a petroleum product. The lubricating rust preventive oil solves the problems better through adopting the following technical proposal that: the compositions in percentage by weight of the lubricating rust preventive oil are: (a) 0.1 to 10 percent of extreme pressure antiwear agent, (b) 0.5 to 15 percent of rustproof agent, (c) 0.5 to 5 percent of oxidation and corrosion inhibitor, (d) 0.1 to 15 percent of viscidity temperature index improver, (e) 0.1 to 12 percent of friction improver and (f) the balance being base oil. The lubricating rust preventive oil can be used in fields such as harbor machinery, excavator, travelling crane, cargo winch and commercial elevator cable.

Owner:CHINA PETROLEUM & CHEM CORP

Environment-friendly wheel and track lubricating grease and method for preparing same

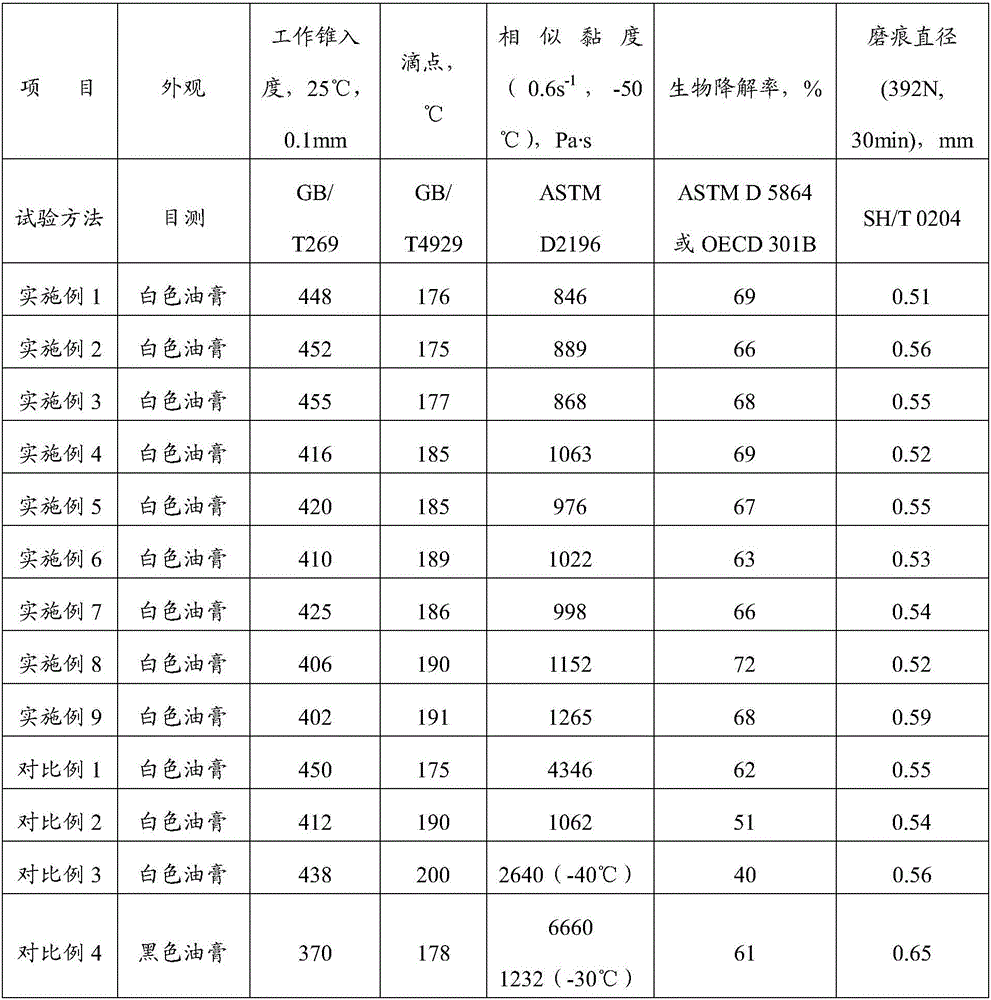

The invention provides environment-friendly wheel and track lubricating grease. The environment-friendly wheel and track lubricating grease comprises, by weight, 70-95 parts of base oil, 1-20 parts of thickening agents, 1-8 parts of anti-wear agents, 0.05-3 parts of antioxidants, 0.02-1.5 parts of anti-corrosion and anti-rust agents and 1-10 parts of solid anti-wear materials. The base oil comprises ester oil and / or synthetic hydrocarbon. The environment-friendly wheel and track lubricating grease has the advantages that the white environment-friendly wheel and track lubricating grease is excellent in low-temperature performance, biodegradability, anti-corrosion property and extreme pressure anti-wear property and free of harmful elements such as heavy metal, is non-toxic (or is low in toxicity) and is easy to pump, spray and uniformly atomize; wear of flanges of wheels can be effectively reduced, the service lives of the wheels and steel tracks can be prolonged, environmental requirements can be met, and the environment-friendly wheel and track lubricating grease is applicable to lubricating the wheels and the tracks for track traffic in wide temperature ranges of -50-150 DEG C.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

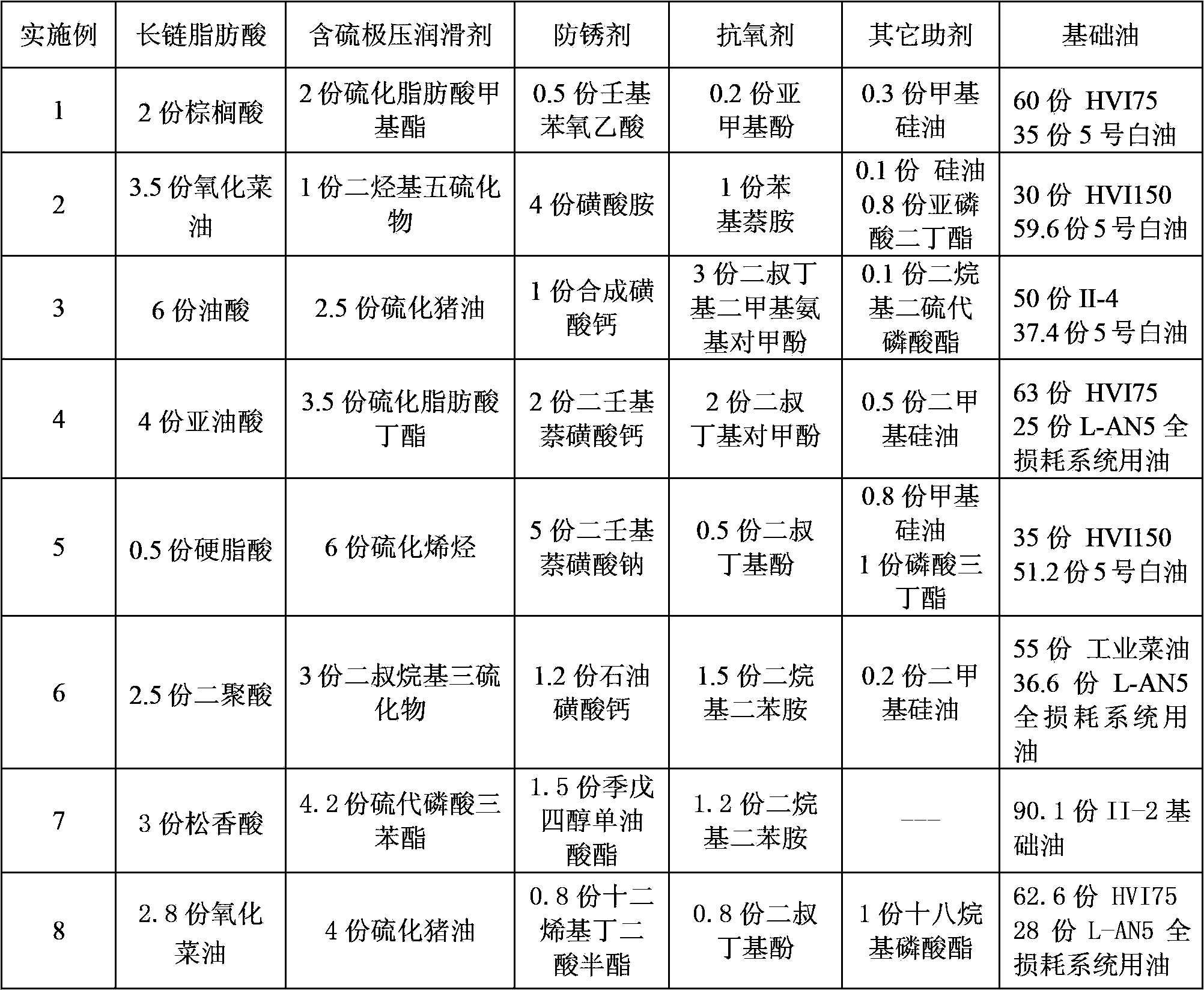

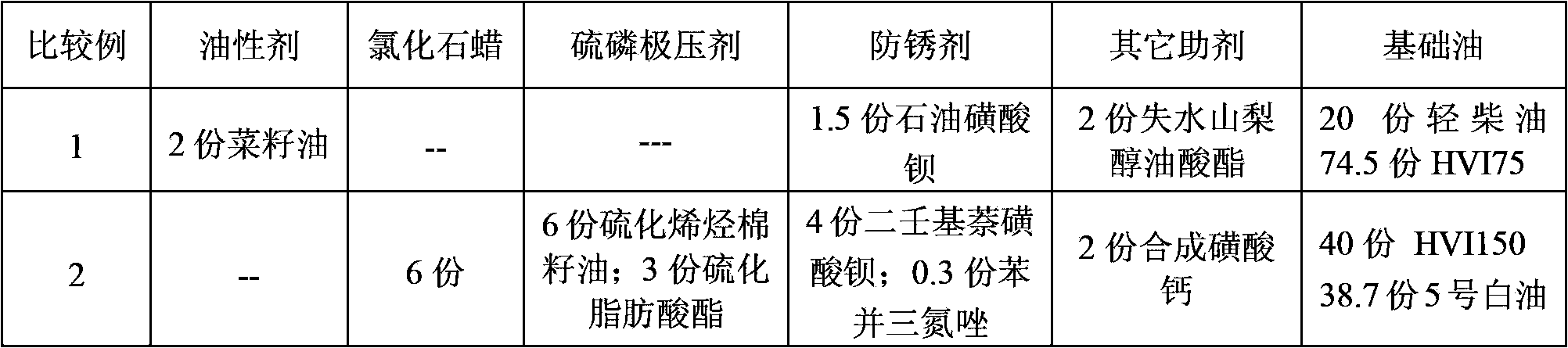

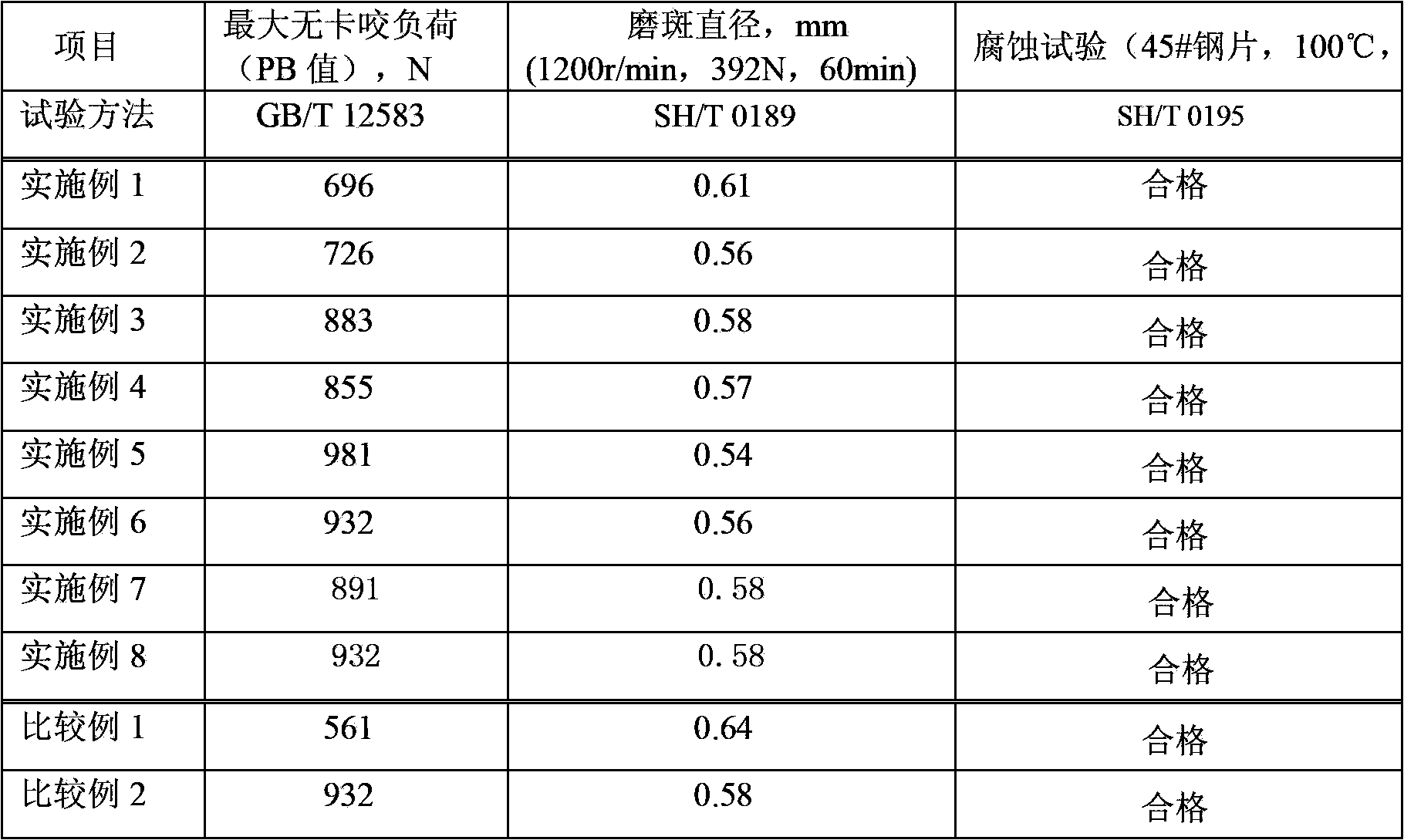

Lubricating oil composition and use thereof

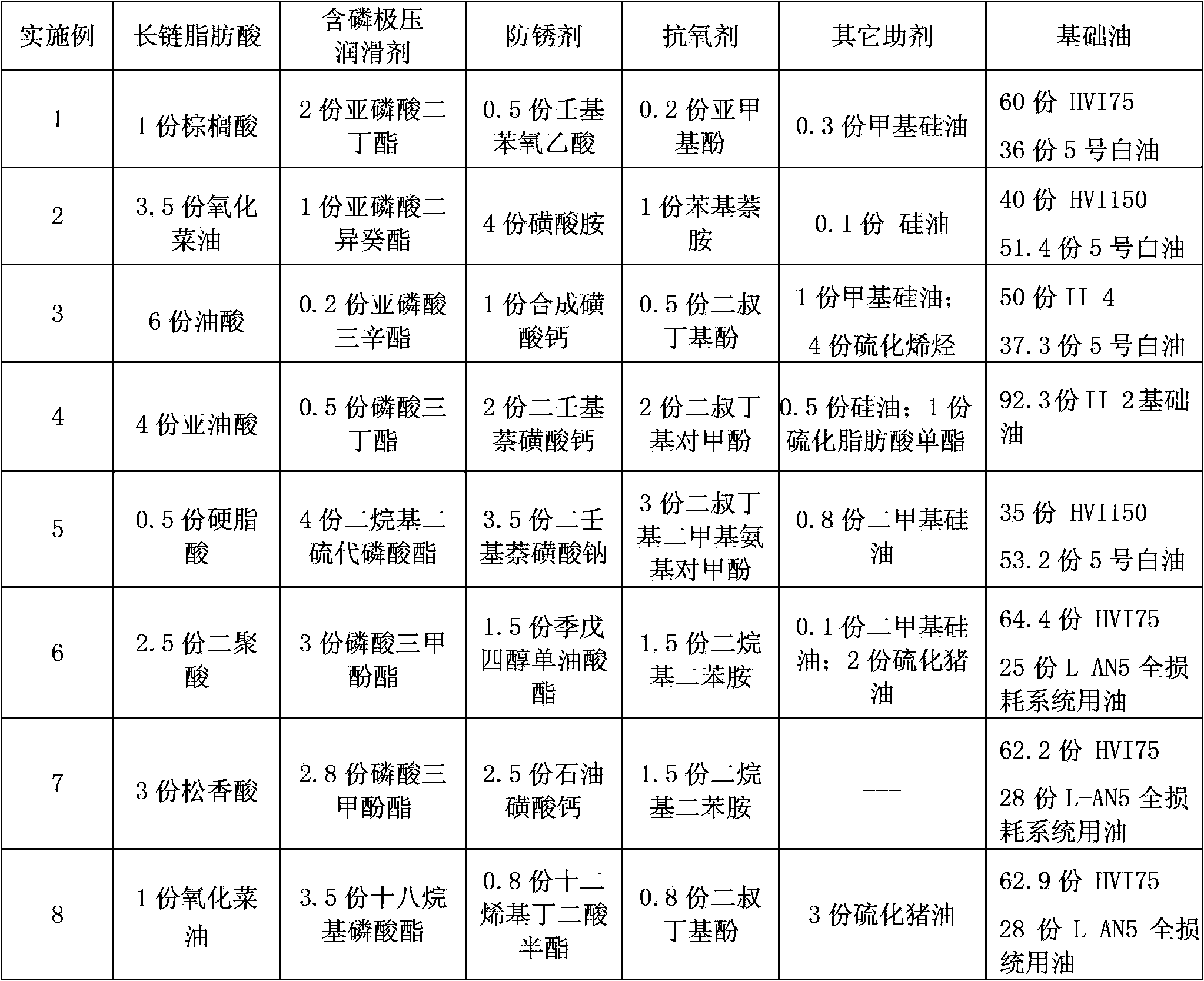

ActiveCN103571590AImprove the finishHigh dimensional accuracyHoning machinesLubricant compositionLong chain fatty acidChemical composition

The invention relates to a lubricating oil composition and use thereof, and is mainly used for solving the problems that the use security is difficult to guarantee since a plurality of lubricating oil compositions for a honing process in the prior art use base oil containing light diesel oil and the like, and a plurality of lubricating oil compositions using chlorinated paraffin extreme-pressure lubricants and barium-containing antirust additives have a certain influence to the environment. The problems are well solved by the technical scheme that the lubricating oil composition comprises the following components in parts by weight: a) 0.5-6 parts of long-chain fatty acid, b) 0.1-4 parts of phosphorus-containing lubricant, c) 0.5-5 parts of antirust agent, d) 0.1-3 parts of antioxidant, and e) 86-96 parts of base oil, wherein the base oil does not contain light diesel oil, and the composition does not contain at least one of the chlorinated paraffin extreme-pressure lubricant or barium-containing antirust additive. The lubricating oil composition can be used for lubricating, cooling and rust prevention in the metal honing process.

Owner:CHINA PETROLEUM & CHEM CORP

Anti-corrosion antirust powder paint

InactiveCN101560359AImprove anti-corrosion and anti-rust performanceGood value for moneyAnti-corrosive paintsPowdery paintsEpoxySocial benefits

The invention discloses anti-corrosion antirust powder paint belonging to the technical field of powder paint of electrostatic coatings. The anti-corrosion antirust powder paint is prepared by the following common raw materials of powder paint in general proportion: epoxy resin, indoor polyester resin, a flatting agent, a degasifying agent, a flexibilizer, a flow promoter, fillings, and the like. The preparation method is carried out by adopting the prior powder paint production technology, and the formulation comprises composite iron-titanium powder and sheet zinc powder which are respectively 10-40 percent and 0-10 percent of the gross weight of the raw materials. The anti-corrosion antirust powder paint does not contain toxic raw materials limited to use, is suitable for the surfaces of steel and iron components treated in various pretreatment modes, and has favorable anti-corrosion antirust performance of the coatings, lower product cost than zinc-based heavy-duty anticorrosive powder paint, favorable performance price ratio and remarkable economic and social benefits.

Owner:徐州正菱涂装工程技术研究中心

Water-based nano polyaniline cutting fluid and preparation method thereof

InactiveCN102876437AImprove conductivityImprove electrochemical activityLubricant compositionSolubilityWater based

The invention relates to a water-based nano polyaniline cutting fluid and a preparation method thereof. The water-based nano polyaniline cutting fluid is characterized in that a component 1 comprises the following components in part by weight: 5 to 10 parts of aniline, 5 to 12 parts of ammonium persulfate, 1 to 5 parts of hydrochloric acid, 3 to 6 parts of dodecylbenzene sulfonic acid, 10 to 16 parts of water soluble phosphate and 30 to 50 parts of water, and is prepared through emulsion polymerization in an ice-water bath for 6 to 8 hours; and a component 2 comprises the following components in part by weight: 20to 30 parts of triethanolamine, 3 to 6 parts of polyethylene glycol, 30 to 50 parts of base oil, 1 to 5 parts of extreme-pressure lubricant, 1 to 5 parts of aqueous anticorrosive agent and 30 to 50 parts of water, and is prepared by adding the components into a reaction kettle, uniformly mixing, heating to the temperature of between 40 and 45DEG C and keeping the temperature for 30 to 50 minutes; and a weight ratio of the component 1 to the component 2 is 1:1-1:2. The nano-scale water-based polyaniline cutting fluid has high water solubility and lubricating property, and the anticorrosive and antirust properties of the cutting fluid are improved.

Owner:XIAOGAN JIANGYAN CHEM

Heavy corrosion-resistant paint for industry and preparation method thereof

InactiveCN104212324AImprove corrosion resistanceStrong anti-salt spray performanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolyamideFirming agent

The invention discloses heavy corrosion-resistant paint for industry. The heavy corrosion-resistant paint comprises the following components in parts by weight: 10-30 parts of epoxy resin, 25-45 parts of polyurethane, 2-15 parts of solvent, 2-4 parts of modified amino silicon oil, 1-5 parts of polysiloxane, 1-3 parts of chlorinated paraffin, 1-3 parts of sodium polycarboxylate, 5-10 parts of polyamide, 8-15 parts of D9050 modified aromatic resin epoxy curing agent and 13-17 parts of additive; the additive comprises the following components in parts by mass: 10-15 parts of dispersing agent, 5-10 parts of thickening agent, 5-10 parts of film-forming additive, 1-5 parts of PH adjusting agent, 5-10 parts of silane coupling agent, 2-6 parts of delustering agent and 1-6 parts of defoaming agent. The heavy corrosion-resistant paint disclosed by the invention has strong corrosion-resistant property and anti-salt-mist property and can be firmly adsorbed on the surface of metal so as to have good corrosion-resistant and anti-rusting property; and the heavy corrosion-resistant paint has the advantages that the corrosion-resistant time is long, the raw materials are easily obtained, the production process is simple, the construction is convenient, the operation is easy, the drying speed is high, the construction period is short and the demolding is not needed in the following processing procedure. The invention also discloses a method for preparing the heavy corrosion-resistant paint for industry.

Owner:JIANGSU MARINE VICTORY COATING

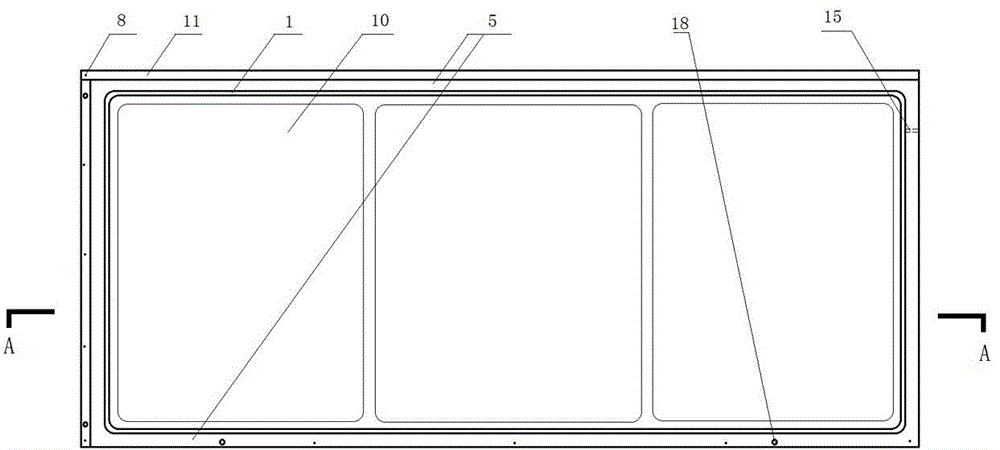

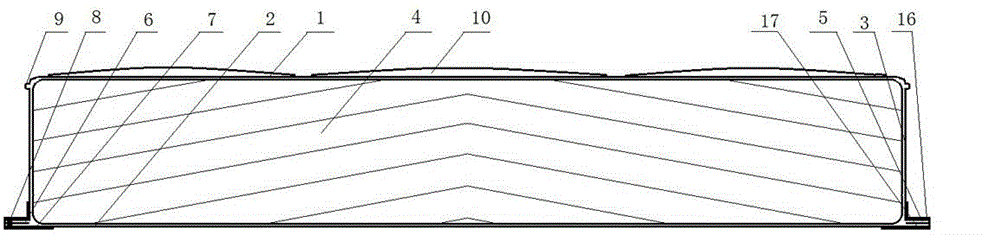

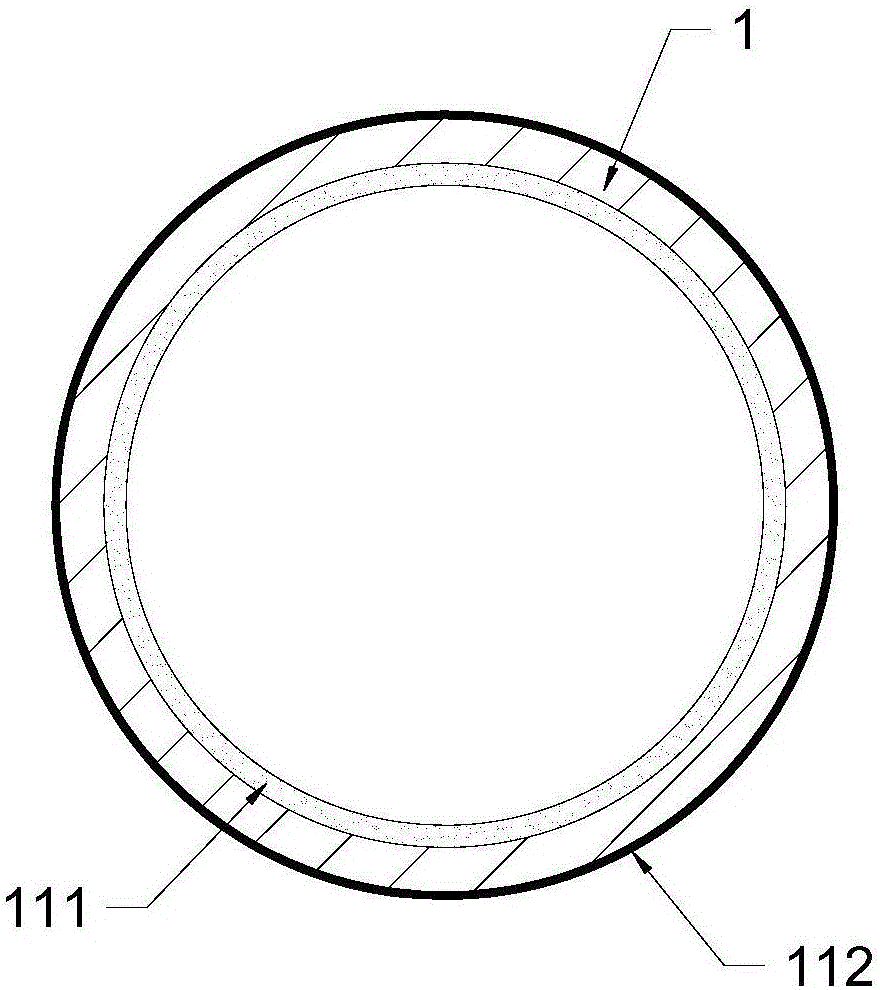

Metal vacuum warming plate and manufacturing method for same

InactiveCN104975661AImprove rigidityIncreased resistance to deformationCovering/liningsClimate change adaptationAlloyCavity wall

The invention discloses a metal vacuum warming plate. A vacuum cavity is formed by sealed cooperative connection between an upper metal plate and a lower metal plate; a supporting core is disposed in the vacuum cavity; a vacuumizing hole is formed in the cavity wall of the vacuum cavity; metal with melting point ranging from 90 to 350 DEG C or related alloy sealing bars are arranged between sealing sides for the sealed cooperative connection between the upper metal plate and the lower metal plate; and the sealing bars are bonded with the upper metal plate and the lower metal plate and sealed with the same. The metal vacuum warming plate is advantaged by high vacuum degree durableness in bad natural environments, excellent sealing property, strong anti-deformation capabilities, great corrosion and rust resisting performance and long service life as long as buildings; fireproof performance is A-level; the metal vacuum warming plate is integrated functions of warming, decoration and construction; the construction period can be obviously shortened; installation cost can be reduced; various shapes can be formed; special demands for building outer wall surface corners and arcs can be met; and the metal vacuum warming plate is suitable for various building outer wall warming and roof insulation.

Owner:许浒

Lubricant composition used in electric mechanical transmission device

InactiveCN104450071AMeet lubricitySatisfy coolingLubricant compositionAntioxidantOxidation resistant

The invention discloses a lubricant composition used in an electric mechanical transmission device. The lubricant composition is prepared from a complex of trimellitate and poly-alpha-olefin serving as base oil as well as a plurality of composite additives comprising a rust inhibitor, an antioxidant, an oiliness agent, an anti-wear agent, a metal deactivator, a friction modifier, an anti-foaming agent, an oxidation-resistant and corrosion-resistant agent, a detergent and a dispersing agent. The lubricant composition disclosed by the invention has excellent detergency and dispersibility, cooling property, lubricating property, sealing property, friction property, rust-inhibiting property, corrosion resistance and extreme pressure anti-wear property; by the lubricant composition, a layer of uniform and continuous oil film having a certain thickness is easily formed in a movement friction pair, the coefficient of friction in the movement is decreased, the carrying capacity is increased and the phenomenon of adhesion of transmission members and vibration and noise are reduced.

Owner:GUANGXI UNIV

Synthetic compressor lubricating oil composition and production method thereof

InactiveCN102952615AReduce vibrationImprove the lubrication effectLubricant compositionSocial benefitsFoaming agent

The present invention relates to a synthetic compressor lubricating oil composition and a production method thereof. The synthetic compressor lubricating oil composition is prepared by mixing the following raw materials, by weight, 80-90 parts of a liquid A and 10-20 parts of a liquid B, wherein the liquid A is prepared by mixing one or a plurality of poly alpha-olefin synthetic base oil with different viscosities, and the liquid B is prepared by mixing the following additives, by weight, 5.0-15.0 parts of an ester, 0.05-2 parts of an antioxidant, 0.01-2 parts of a rust inhibitor, 0.01-0.5 part of a metal deactivator, 0.5-3 parts of an extreme pressure wear resistance agent, 0.005-0.05 part of anti-emulsification agent, and 0.003-0.01 part of an anti-foaming agent. According to the present invention, stability is high, an oil change period is long, compressor energy consumption can be substantially reduced, a service life of the compressor can be prolonged, significant economic and social benefits are provided, and environmental pollution can not be caused.

Owner:BEIJING ALLUBE PETROCHEM

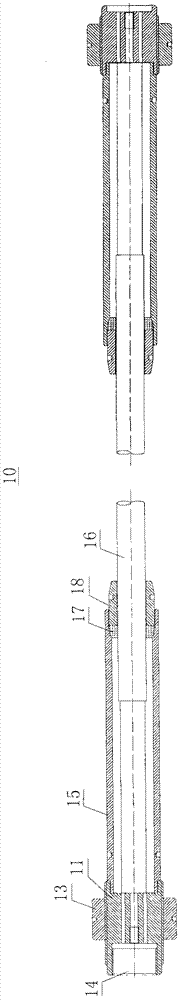

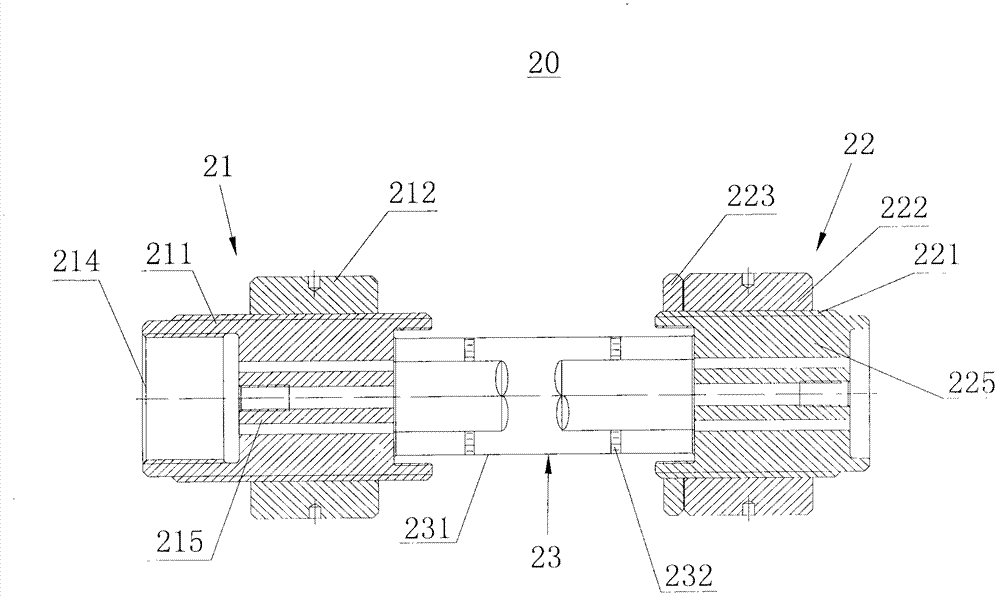

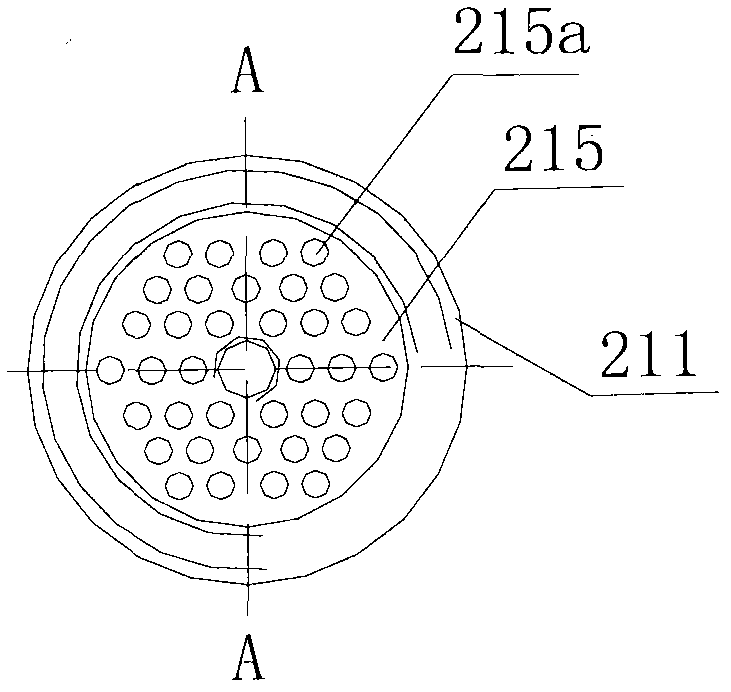

Stainless steel pulling cable device for bridge

ActiveCN103088754AImprove the cumbersome structureHigh strength requirementsBridge structural detailsPull forceEngineering

The invention discloses a stainless steel pulling cable device for a bridge. The stainless steel pulling cable device is arranged on a pulling cable bridge and comprises a cable for bearing tension, a fixed end anchor, a tensioning end anchor and a protective member. The cable is integrated of stainless steel wires; the fixed end anchor and the tensioning end anchor are respectively used for anchoring the cable in matched mode and transmitting the cable force; and the protective member is connected between the fixed end anchor and the tensioning end anchor and used for protecting the part of the cable exposed out of the anchors. The stainless steel pulling cable for the bridge has the good performance of rust protection, corrosion resistance and abrasion resistance and has long service life.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +2

Bearing lubricating oil composition and preparation method thereof

InactiveCN104357180AGood extreme pressure and anti-wear propertiesImprove the lubrication effectLubricant compositionFriction reductionChemical composition

The invention discloses a bearing lubricating oil composition and a preparation method thereof, and relates to the field of industrial lubricating oil. The bearing lubricating oil composition comprises the following components in parts by mass: 55-70 parts of base oil, 8-15 parts of an oiliness agent, 5-12 parts of an anti-wear reagent at extreme pressure, 5-10 parts of a friction improving agent, 3.5-6 parts of an anti-rusting agent, 3.2-5.8 parts of a viscosity index improving agent and 2.2-4.5 parts of an emulsification inhibitor. The preparation method of the bearing lubricating oil composition comprises the steps of (1) weighing; (2) implementation of a jetting mixing method; (3) ultrasonic oscillation; (4) standing. According to the bearing lubricating oil composition and the preparation method thereof which are provided by the invention, the bearing oil with high friction reduction performance at extreme pressure and lubricating performance is provided, and the corrosion resistance and rusting resistance are excellent; the bearing lubricating oil composition is excellent in low-temperature starting property and high-temperature resistance; damage, caused by friction and external erosion, to a bearing can be effectively reduced, and the service life of the bearing is prolonged.

Owner:SUZHOU CHANGSHENG ELECTROMECHANICAL

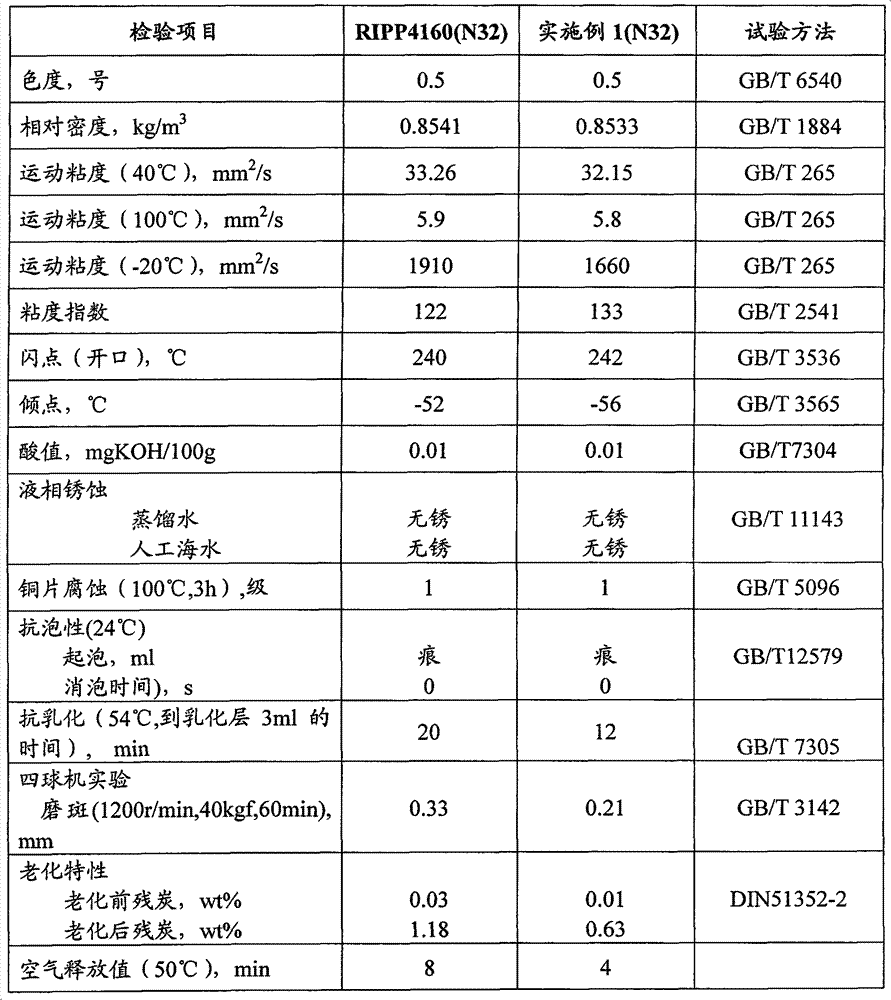

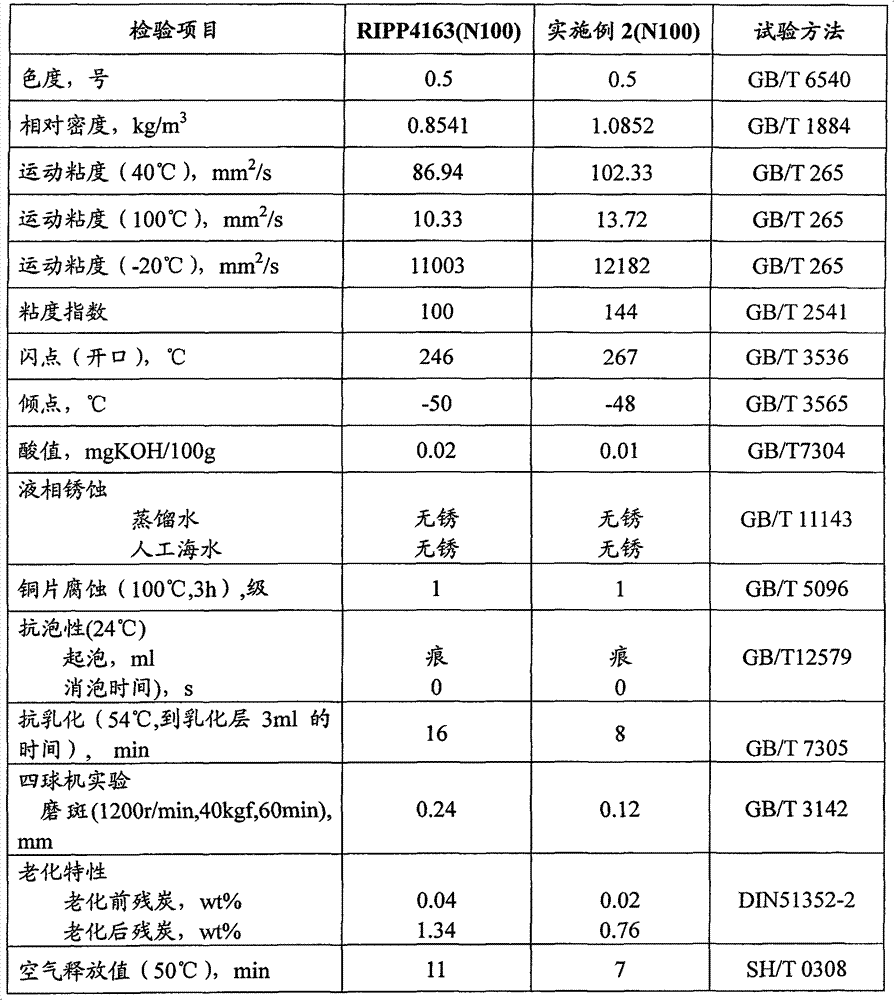

Lubricating oil composition for industrial robot speed reducer

InactiveCN109401820AImprove performanceTechnically difficultLubricant compositionLinear polymerDefoaming Agents

The invention discloses a lubricating oil composition for an industrial robot speed reducer. The lubricating oil composition comprises 84.0-95.91wt% of polyalkylene glycol, 3-10wt% of a sealing applicability improver, 0.1-2.0wt% of an extreme pressure anti-wearing additive, 0.01-1.0wt% of a metallic deactivator, 0.05-1.0wt% of an anti-rusting corrosion inhibitor, 0.5-3.0wt% of an anti-oxidation additive and 10-20mu g / g of a defoaming agent, wherein the polyalkylene glycol is a linear polymer taking ethylene oxide and propylene oxide as main raw materials; the polymer comprises 50-70% of an EO(Ethylene Oxide) unit and 30-50% of a PO (Propylene Oxide) unit; the sealing applicability improver is a saturated polyol ester or diester. The lubricating oil composition has excellent viscosity-temperature performance and low-temperature performance, excellent oxidation stability and good extreme pressure wearing resistance, anti-rusting corrosion resistance and foam resistance, an oil film canbe rapidly formed, operation temperatures can be reduced, energy consumption can be reduced, the transmission efficiency of a speed reducer is degraded, the wearing of tooth surfaces can be reduced, and lubricating requirements of multi-stage speed reducers of multi-axis industrial robots can be met.

Owner:PETROCHINA CO LTD

Oil membrane bearing oil composition and preparation method thereof

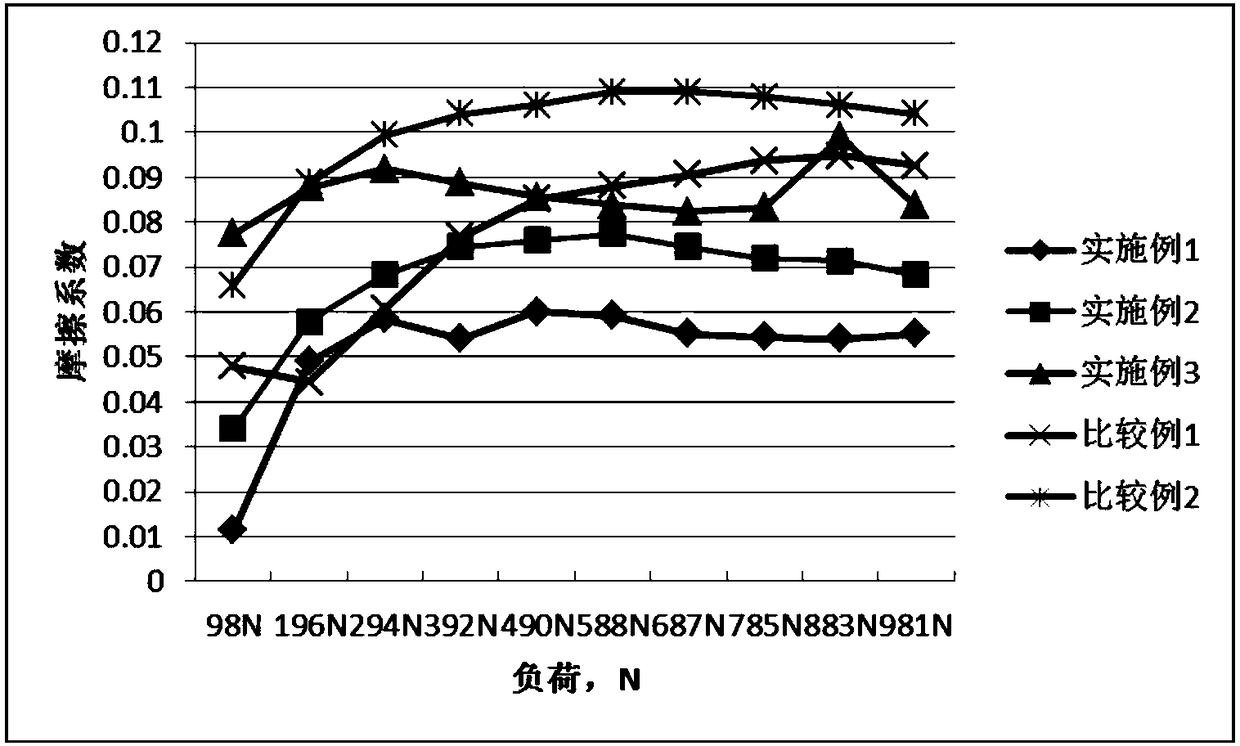

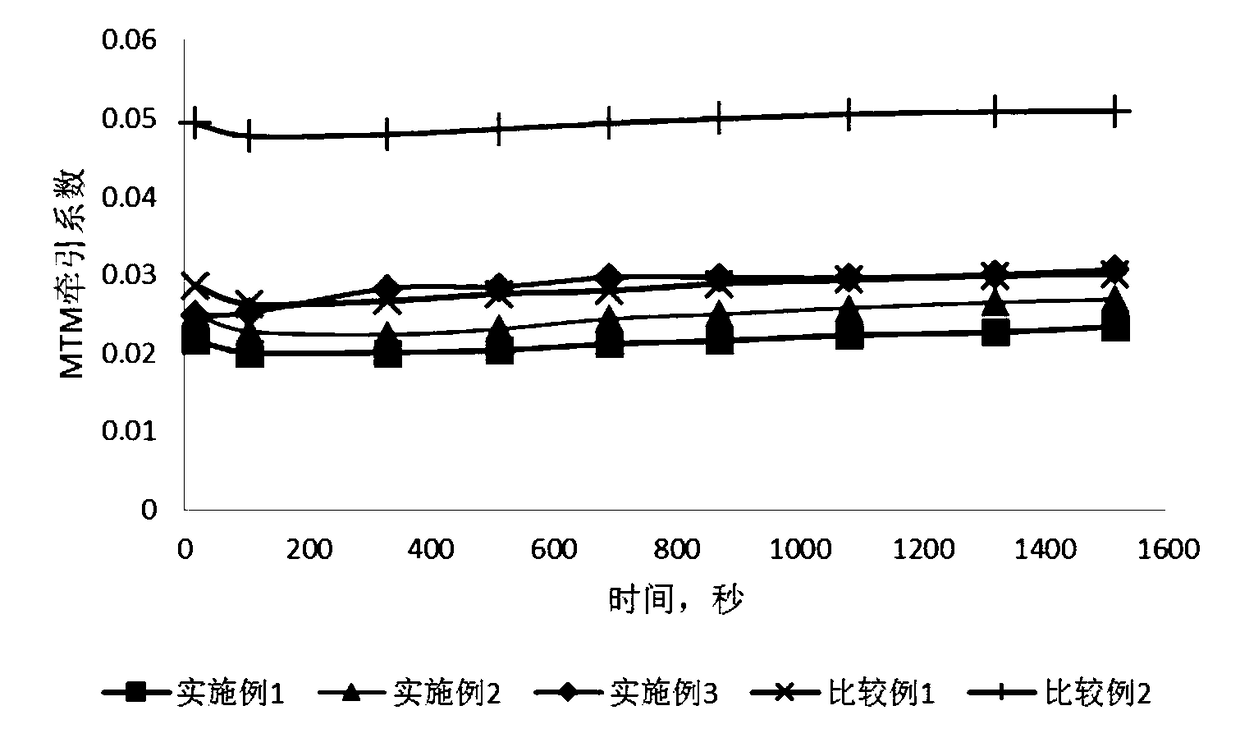

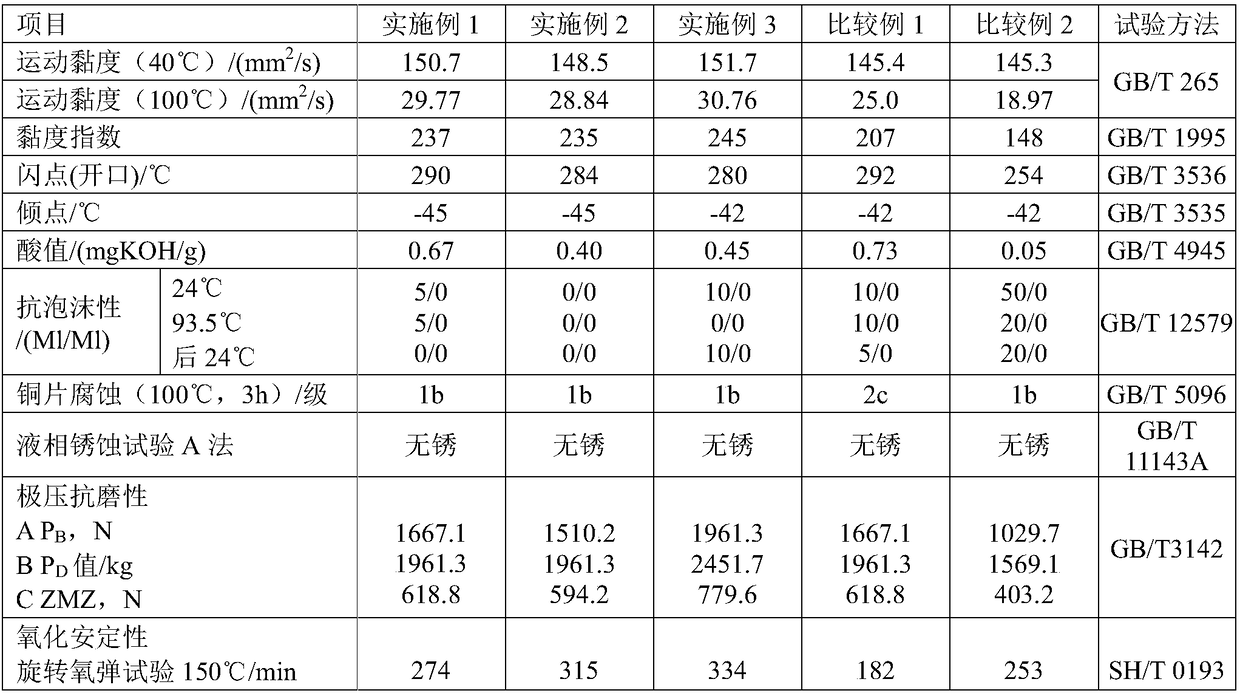

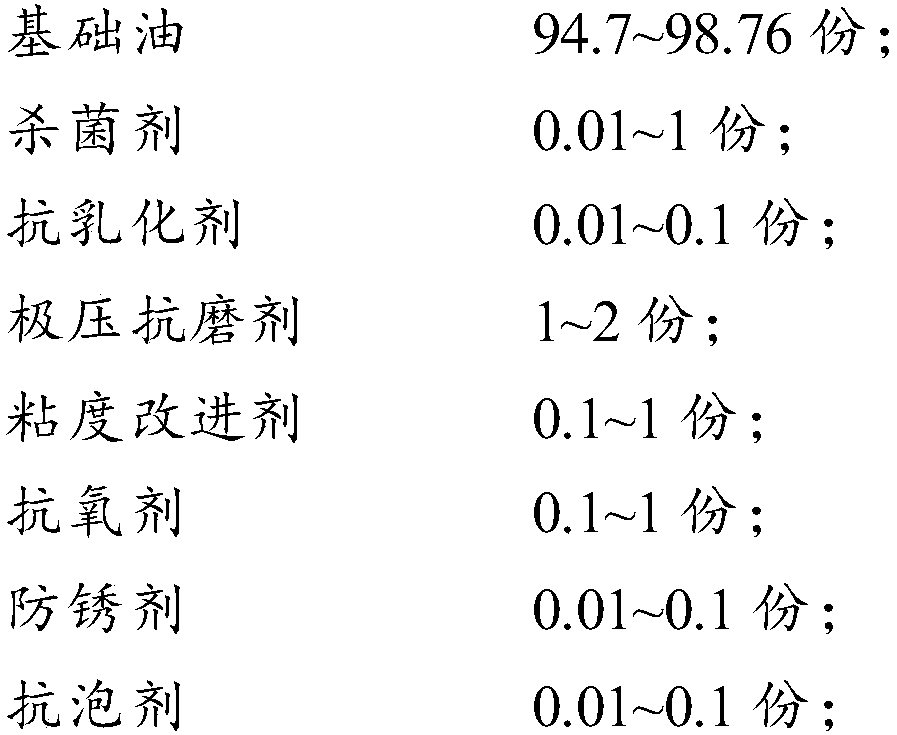

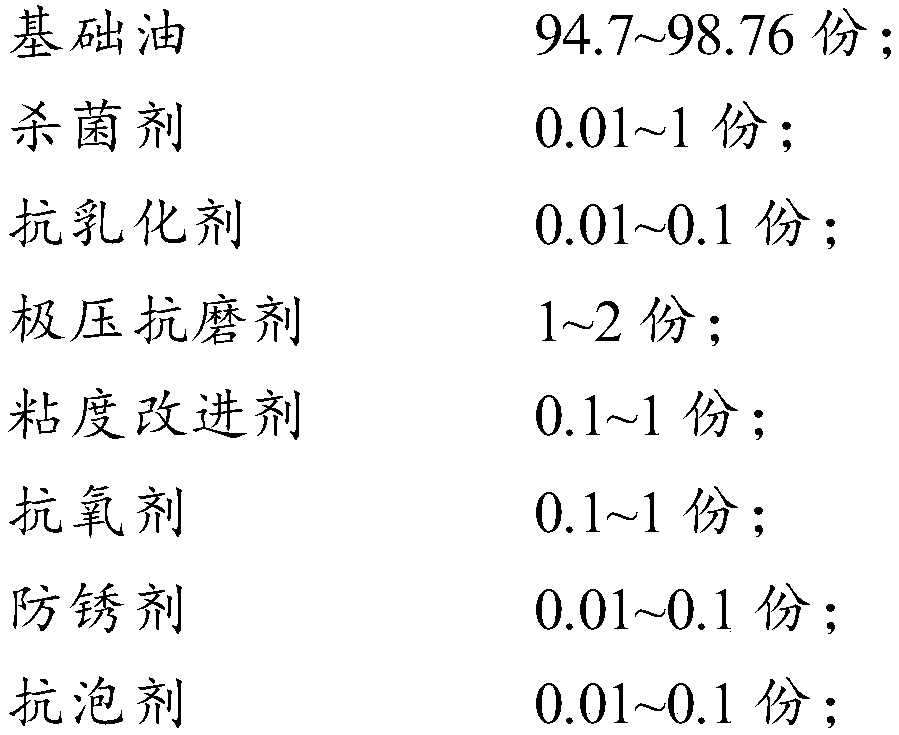

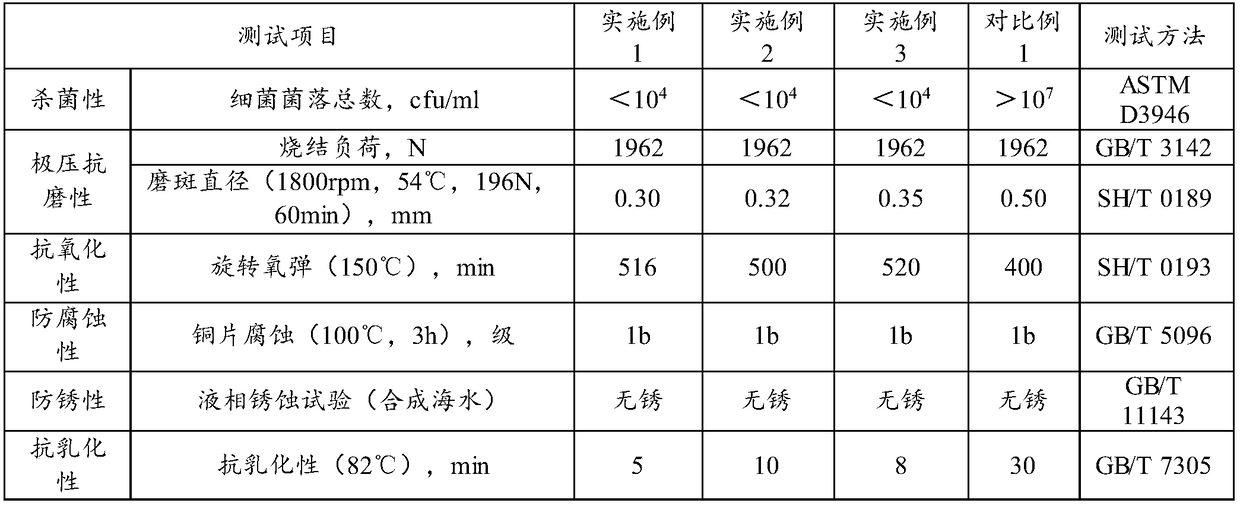

ActiveCN109097171AImprove performanceImprove antibacterial propertiesLubricant compositionAntioxidantSulfur containing

The invention provides an oil membrane bearing oil composition and a preparation method thereof. The oil membrane bearing oil composition provided by the invention comprises the following components:94.7-98.76 parts of basic oil, 0.01-1 part of a sterilization agent, 0.01-0.1 part of a demulsifying agent, 1-2 parts of an extreme pressure anti-wear reagent, 0.1-1 part of a viscosity improver, 0.1-1 part of an antioxidant, 0.01-0.1 part of an anti-rusting agent and 0.01-0.1 part of an anti-foaming agent, wherein the basic oil is selected from one or more of HVII basic oil and HVIII basic oil; the sterilization agent is selected one or more of isothiazolinone and quaternary ammonium salt; the demulsifying agent is selected from one or more of a condensation compound of amino and ethylene oxide and gylcol ester; the extreme pressure anti-wear reagent is selected from one or more of a sulfur-containing extreme pressure anti-wear reagent and a phosphorus containing extreme pressure anti-wear reagent. The bearing oil is not only excellent in antibacterial agent, but also excellent in oxidation resistance, extreme pressure wearing resistance and anti-rusting corrosion resistance, and is capable of well meeting use requirements of an oil membrane bearing.

Owner:CHINA PETROLEUM & CHEM CORP

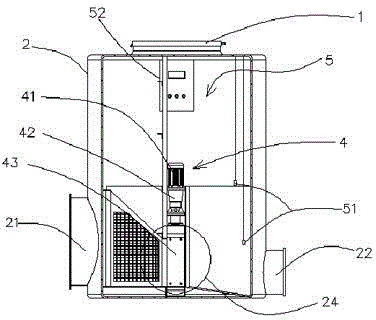

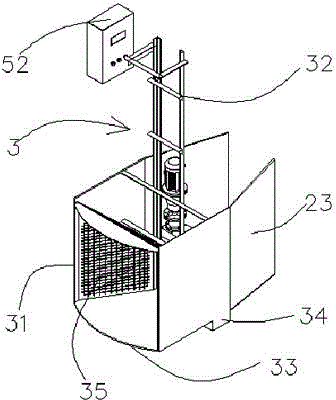

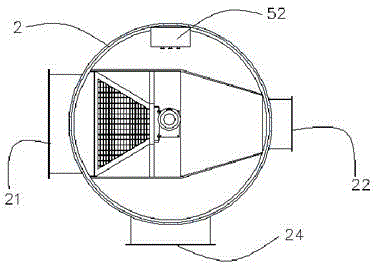

Intelligent anti-clogging integral safety shaft

InactiveCN106149845ASmooth dischargeAvoid cloggingFatty/oily/floating substances removal devicesSewerage structuresProgrammable logic controllerAgeing

The invention discloses an intelligent anti-clogging integral safety shaft. The safety shaft comprises a shaft cover, a cylindrical shaft body, an internal frame, a crushing type grille device and a PLC (programmable logic controller) system, wherein the internal frame comprises a blocking net frame, a ladder and a bottom plate; a water inlet and a water outlet are formed in the side wall of the shaft body, sewage enters from the water inlet, solid impurities contained in the sewage are crushed into fine particles by the crushing type grille device, and the fine particles are discharged from the water outlet; the PLC system comprises a PLC, a liquid level sensor and a display screen, the crushing type grille device and the liquid level sensor are electrically connected with the PLC, and the PLC and the display screen are located in a cabinet at the top of the side wall of the cylindrical shaft body. The safety shaft has the advantages that the quality is stable, the construction period is short, the shaft body is resistant to corrosion, acid-base and ageing, the own weight is low, the impact resistance is high, transportation and mounting are convenient, and by means of the PLC system, automatic sewage discharge,, automatic liquid level detection as well as intelligent monitoring and control can be realized.

Owner:HUANCHUANG XIAMEN TECH

Anticorrosion and anti-rust waterborne acrylic coating and preparation method thereof

InactiveCN107573795AImprove hydrophobicityInhibit entryAnti-corrosive paintsChemical industryAcrylic resin

The invention relates to the technical field of chemical industry and in particular relates to anticorrosion and anti-rust waterborne acrylic coating. Aiming at solving the technical problems, the invention provides the waterborne acrylic coating with excellent anticorrosion performance, good anti-rust effect and good stable performance. By adopting the technical scheme, the anticorrosion and anti-rust waterborne acrylic coating is characterized in that acrylic resin is prepared from the following raw materials in percentage by weight: 1 percent to 10 percent of acrylic acid, 5 percent to 20 percent of n-butyl acrylate, 1 percent to 10 percent of methyl methacrylate, 5 percent to 20 percent of hydroxyethyl acrylate, 1 percent to 10 percent of 2-ethylhexyl acrylate, 40 percent to 60 percentof isobornyl methacrylate, 5 percent to 50 percent of vinyl versatate Veova10, 10 percent to 50 percent of alicyclic acrylate, 0.1 percent to 20 percent of a chain extender, 0.5 percent to 5 percentof an initiator and 30 percent to 50 percent of water; the raw materials are prepared into waterborne acrylic resin with the Tg of -10 DEG C to 80 DEG C.

Owner:LINFEN TIE HUAN PAINT IND

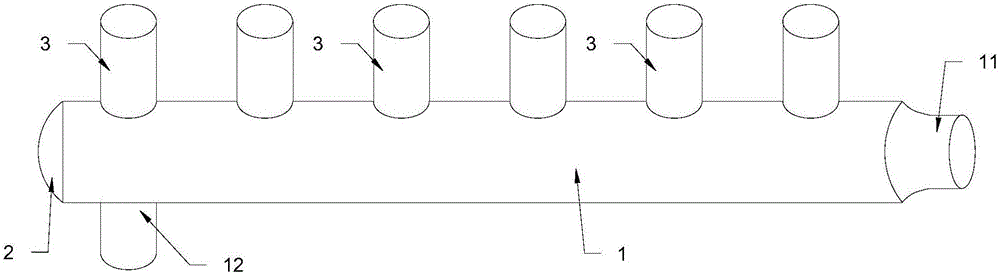

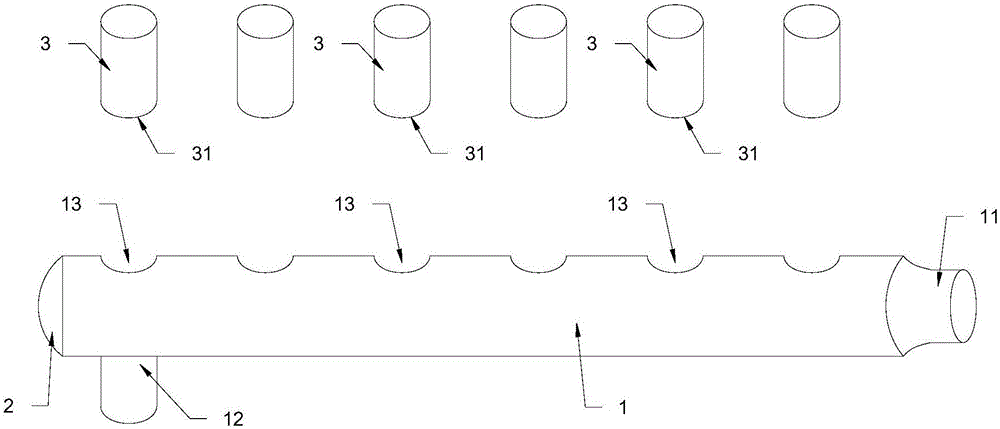

Water distributor and production process thereof

PendingCN106402554AHigh degree of automationIncrease productivityBranching pipesEngineeringButt joint

The invention belongs to the technical field of pipeline connection pieces, and particularly provides a water distributor and a production process thereof. The water distributor comprises a main pipe and a plurality of branch pipes correspondingly communicated with the main pipe; one end of the main pipe is a water inlet end, and an end socket is arranged at the other end of the main pipe; and the water inlet end is subjected to necking down treatment, and the inner diameter of the water inlet end is made to be shrunk by 30-40%. By means of the water distributor, the water hammer effect in the water distributor can be effectively reduced, and water flow is uniformly and stably distributed in the water distributor. The production process of the water distributor has the beneficial effects of being high in automation degree and high in production efficiency; and arc holes and arc concaves which are precisely matched can also be obtained through an arc punching machine and a punching device by means of a numerical control technology, seamless butt joint of the arc holes and the arc concaves is achieved, and the sealing performance and the attractiveness of an obtained product are improved. In the welding step, the relative positions of the main pipe and the branch pipes are fixed by means of point welding of three points, then, the main pipe and the branch pipes are completely welded and sealed through hoop welding, positioning can be facilitated by performing point welding firstly, and it is prevented that the branch pipes deflect in the hoop welding process.

Owner:河南卡斯特流体科技有限公司

Powder coating for metal plate

InactiveCN105482626AImprove toughnessImprove corrosion resistanceFireproof paintsAntifouling/underwater paintsPolyvinyl alcoholAntimony trioxide

The invention discloses a powder coating for a metal plate. The powder coating is prepared from the following raw materials in terms of parts by weight: 5 to 6 parts of dicyandiamide, 5 to 6 parts of light calcium carbonate, 1 to 2 parts of nickel powder, 10 to 13 parts of titanium dioxide, 0.3 to 0.4 parts of polysiloxane, 0.6 to 1 part of leveling agent PV99, 1 to 2 parts of cobalt naphthenate, 1 to 2 parts of hydroxyethyl heptadecenyl glyoxalidine, 2 to 3 parts of antimonous oxide, 1 to 2 parts of grapheme, 3 to 4 parts of hydrogen-containing silicone oil, 1 to 2 parts of butyl rubber, 80 to 90 parts of epoxy resin, 20 to 22 parts of hydroxy acrylic resin, 6 to 8 parts of phenolic resin, 0.1 to 0.2 parts of rare earth chloride, 15 to 18 parts of chitosan and 4 to 5 parts of polyvinyl alcohol. The powder coating for the metal plate disclosed by the invention has the advantages that the effects of high strength, good corrosion resistance, good water resistance, excellent weathering resistance and excellent storage performance are achieved; after the powder coating is coated on the surface of the metal plate, the anti-rust performance and the anti-corrosion performance are excellent, the service life of the metal plate is prolonged, and the powder coating is worthy for popularization.

Owner:TONGLING SIDE TECH

Castor-oil-based ethanol fuel engine oil composition

The invention discloses a castor-oil-based ethanol fuel engine oil composition. Dioctyl sebacate and pentaerythritol ester, which are prepared from castor oil, are compounded into base oil, and a plurality of composite additives comprising a detergent, an antioxidant preservative, a dispersing agent, an antioxidant, an oiliness agent, an antirust agent, an antifoaming agent and a reinforcing agent are matched. According to the castor-oil-based ethanol fuel engine oil composition, a dense protective film is formed on the surface of a kinematic pair of an engine, so that the friction and abrasion of the kinematic pair of the engine can be effectively reduced, and the erosion of an ethanol fuel can be resisted; the composition has high low-temperature flowability, high-temperature oxidation resistance, acid neutralizing capability, detergency and dispersity, and the formation of oil sludge and carbon deposit is reduced; the composition has low volatility and emission performance and high antirust and anticorrosive performance, the power of the engine can be maintained, and the lubricating requirements of an ethanol fuel engine system can be met.

Owner:GUANGXI UNIV

Lubricating oil composition and use thereof

ActiveCN103571591AEnvironmentally friendlyEnsure safetyLubricant compositionChemistryLong chain fatty acid

The invention relates to a lubricating oil composition and use thereof, and is mainly used for solving the problems that the use security is difficult to guarantee since a plurality of lubricating oil compositions for a honing process in the prior art use base oil containing light diesel oil and the like, and a plurality of lubricating oil compositions using chlorinated paraffin extreme-pressure lubricants and barium-containing antirust additives have a certain influence to the environment. The problems are well solved by the technical scheme that the lubricating oil composition comprises the following components in parts by weight: a) 0.5-6 parts of long-chain fatty acid, b) 1-6 parts of sulfur-containing extreme-pressure lubricant, c) 0.5-5 parts of antirust agent, d) 0.1-3 parts of antioxidant, and e) 85-95 parts of base oil, wherein the base oil does not contain light diesel oil, and the composition does not contain at least one of the chlorinated paraffin extreme-pressure lubricant or barium-containing antirust additive. The lubricating oil composition can be used for lubricating, cooling and rust prevention in the metal honing process.

Owner:CHINA PETROLEUM & CHEM CORP

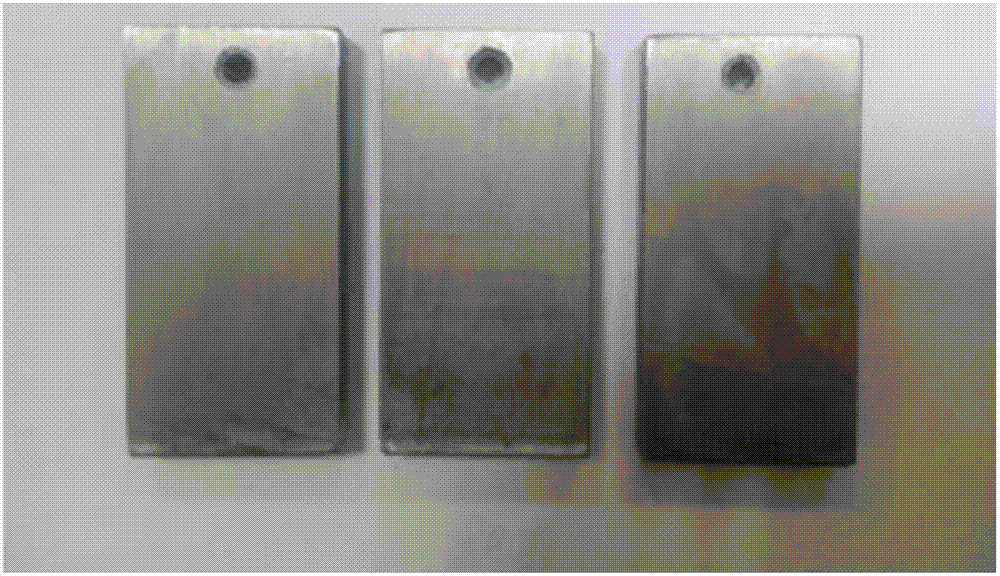

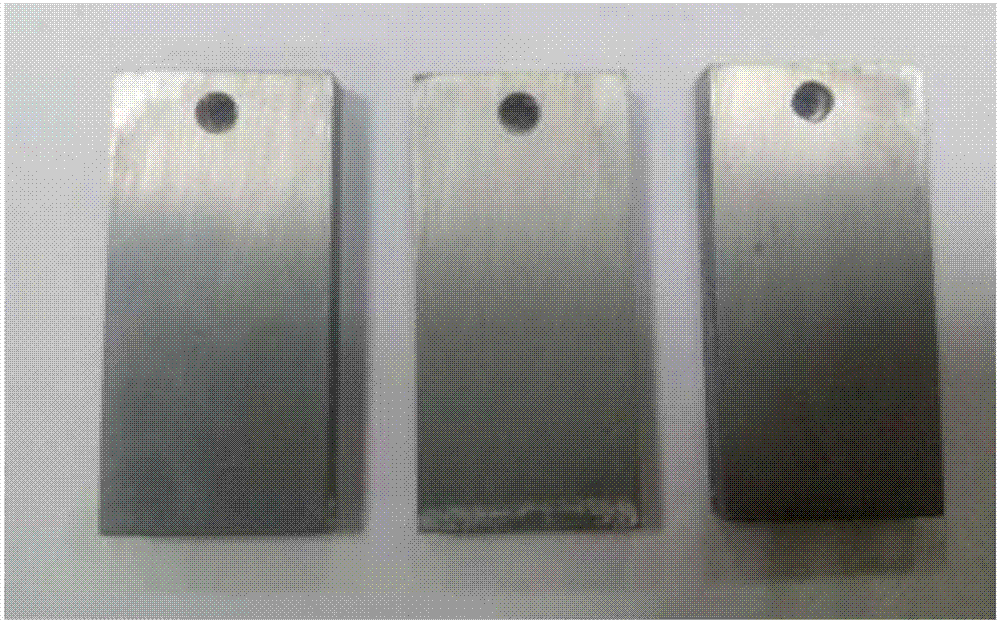

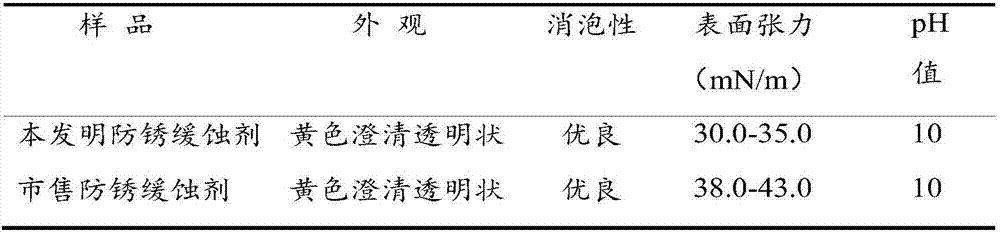

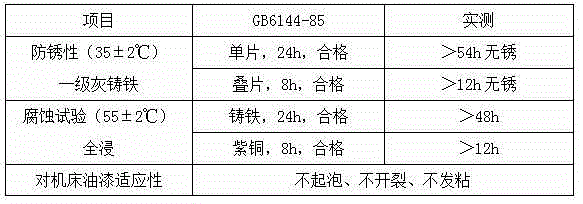

Rustproof corrosion inhibitor and preparation method and application thereof

The invention relates to the technical field of metal corrosion prevention, in particular to a rustproof corrosion inhibitor and a preparation method and application thereof. The rustproof corrosion inhibitor is mainly prepared from, by weight, 1-10 parts of phytic acid, 60-85 parts of water, 0.1-1 part of acrylamide, 0.05-0.3 part of glutamic acid, 1-5 parts of sodium benzoate, 5-15 parts of triethanolamine, 1-5 parts of ethanolamine, 0.1-1 part of disodium hydrogen phosphate, 5-15 parts of sodium molybdate, 0.2-2 parts of a complexing agent, 0.5-3 parts of a film forming agent and 0.1-1 part of a defoaming agent. According to the rustproof corrosion inhibitor and the preparation method and application thereof, the corrosion speed of metal materials can be effectively decreased, and the corrosion resistance and the rust prevention property are good; and the rustproof corrosion inhibitor is particularly suitable for corrosion prevention and rust prevention of steel metal materials washed by ultrahigh-pressure water jet flow, and the problem that after ultrahigh-pressure water jet flow cleaning is conducted during maintenance, naval ships are prone to corrosion before coating can be effectively solved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

Anti-corrosive cutting fluid

InactiveCN104611119AGood hydrophilic and lipophilic propertiesGood emulsifying and dispersing propertiesLubricant compositionPolyethylene glycolPhytosterol

The invention discloses anti-corrosive cutting fluid. The anti-corrosive cutting fluid comprises the following materials in parts by weight: 0.1-0.2 part of phosphotungstic acid, 0.7-1 part of tetramethylammonium nitrate, 1-2 parts of naphthenic soap, 2-3 parts of toluene diisocynate, 1-2 parts of sodium benzoate, 0.6-1 part of methyl isobutyl ketone, 0.1-0.2 part of zinc cyanurate, 3-5 parts of barium petroleum sulfonate, 0.6-1 part of 8-hydroxyquinoline, 0.8-2 parts of calcium lactate, 0.7-2 parts of isopropyl palmitate, 0.5-1 part of phytosterol, 0.8-1 part of methyl tin mercaptide, 70-80 parts of deionized water, 2-3 parts of polyaniline and 6-7 parts of rare-soil function additives. The anti-corrosive cutting fluid disclosed by the invention has the advantages that in the added rare-soil function additives, alkenyl succinate, wool fat and polyethylene glycol 4000 are blended and modified, so that the stable anti-rusting effect can be achieved; due to the added nano silicon dioxide, certain lubricity can be achieved, the cutting force, the friction and the power consumption can be reduced; lanthanum sulfate not only has certain anti-corrosive property, but also can improve the anti-corrosive and slow-release effects; and the additives have good oleophilic and hydrophilic properties and high emulsifying and dispersing performances, and the anti-corrosive property, the lubricity, the anti-rusting property and the stability of finished cutting fluid can be effectively improved.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

Sterilization type strippable high-molecular rust-preventing film with added chitosan

InactiveCN107033688AHave non-aggregateNoncondensationAntifouling/underwater paintsPaints with biocidesPolymer scienceMonoglyceride

The invention discloses a chitosan-added bactericidal peelable polymer antirust film, which is prepared from the following raw materials: aluminum isopropoxide, silane coupling agent KH560, tetraethyl orthosilicate, isostearic acid Monoglyceride, polyethylene glycol, methacryloxypropyltrimethoxysilane, polyvinyl alcohol, borax, chitosan, silver-loaded zirconium phosphate, silane coupling agent A151, glutaraldehyde, naphthenic acid Zinc, triethanolamine, benzotriazole, sodium lauryl sulfate, appropriate amount of lauryl dimethyl amine oxide, appropriate amount of nitric acid, appropriate amount of hydrochloric acid, appropriate amount of absolute ethanol, appropriate amount of acetic acid, appropriate amount of deionized water; the present invention The prepared antirust agent can form a thin film on the surface of the workpiece, which is antibacterial, hydrophobic, oleophobic, not easy to break, has good heat resistance and weather resistance, plays a good antirust and anticorrosion effect, and is easy to peel off later, which is worth promoting.

Owner:江海涛

Halloysite nanotube-added abrasion-resistant type strippable macromolecular antirust film

InactiveCN106590226AHave non-aggregateNoncondensationAnti-corrosive paintsPolyether coatingsPolymer sciencePolyvinyl alcohol

The invention discloses a halloysite nanotube-added abrasion-resistant type strippable macromolecular antirust film. The halloysite nanotube-added abrasion-resistant type strippable macromolecular antirust film is prepared from the following raw materials of aluminum isopropoxide, silane coupling agent KH570, tetraethyl orthosilicate, Span 80, polyethylene glycol, i-butyltriethoxanesilane, polyvinyl alcohol, emulsifier OP10, glycerin, Tween 80, lauryl sodium sulfate, triethanolamine, benzotriazole, sodium benzoate, halloysite, borax, a proper amount of peregal, a proper amount of nitric acid, a proper amount of hydrochloric acid, a proper amount of absolute ethyl alcohol, and a proper amount of deionized water. The halloysite nanotube-added abrasion-resistant type strippable macromolecular antirust film has the advantages that a thin film can be formed on the surface of a workpiece, the waterproof and oilproof effects are realized, the easiness in cracking is avoided, the heat-resistant and aging-resistant properties are good, the antirust and anti-corrosive functions are good, the later stripping is convenient, and the antirust film is suitable for being popularized.

Owner:江海涛

High-strength titanium alloy steam turbine blade

InactiveCN108624783ALow costDoes not affect the chemical compositionAntifouling/underwater paintsBlade accessoriesEpoxyTitanium alloy

The invention discloses a high-strength titanium alloy steam turbine blade. The surface of the steam turbine blade is further provided with a protection layer, and the protection layer is prepared from, by mass, 10-15 parts of modified ethylene-propylene-diene monomer rubber, 15-20 parts of methyl phenyl silicone resin, 8-11 parts of organosilicon-modified epoxy resin, 5-7 parts of nanometer SiC powder, 13-15 parts of filler and pigment, 3-5 parts of dispersing agent, 10-15 parts of coupling agent, 13-15 parts of curing agent, 7-9 parts of defoaming agent and 1-3 parts of anti-mildew bactericide. The high-strength titanium alloy steam turbine blade has good strength, and is good in corrosion resistance, simple in preparation process, low in cost and long in service life.

Owner:南京赛达科技有限公司

Polyaniline-epoxy resin corrosion-resistance composite passive film

InactiveCN106835100AImprove corrosion resistanceImprove heat resistanceMetallic material coating processesMethacrylateEpoxy

The invention discloses a polyaniline-epoxy resin corrosion-resistance composite passive film. The composite passive film is prepared from dodecafluoroheptyl methacrylate, hexafluorobutyl methacrylate, silane coupling agent KH560, azodiisobutyronitrile, silane coupling agent KH570, a proper amount of silane coupling agent KH580, silane coupling agent KH550, trifluoromethyl trimethylsilane, lauryl sodium sulfate, carbon nanotube, aniline, ammonium persulfate, sodium molybdate, phosphoric acid, hydrogen peroxide, silica sol, epoxy resin, curing agent, a proper amount of anhydrous ethanol, a proper amount of tetrahydrofuran, a proper amount of dilute nitric acid and a proper amount of de-ionized water. The prepared passivating solution is simple in preparation method, low in cost, free of poison and environmentally friendly; the provided passivation method can largely shorten the treatment time, and omits the oiling process; and the formed passive film is excellent in wear resistance, corrosion resistance, heat resistance and fingerprint resistance, relieves corrosion of a zinc coat, and is excellent in application prospect.

Owner:张庆

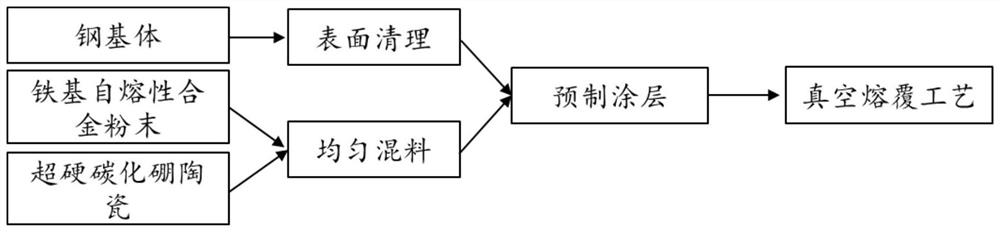

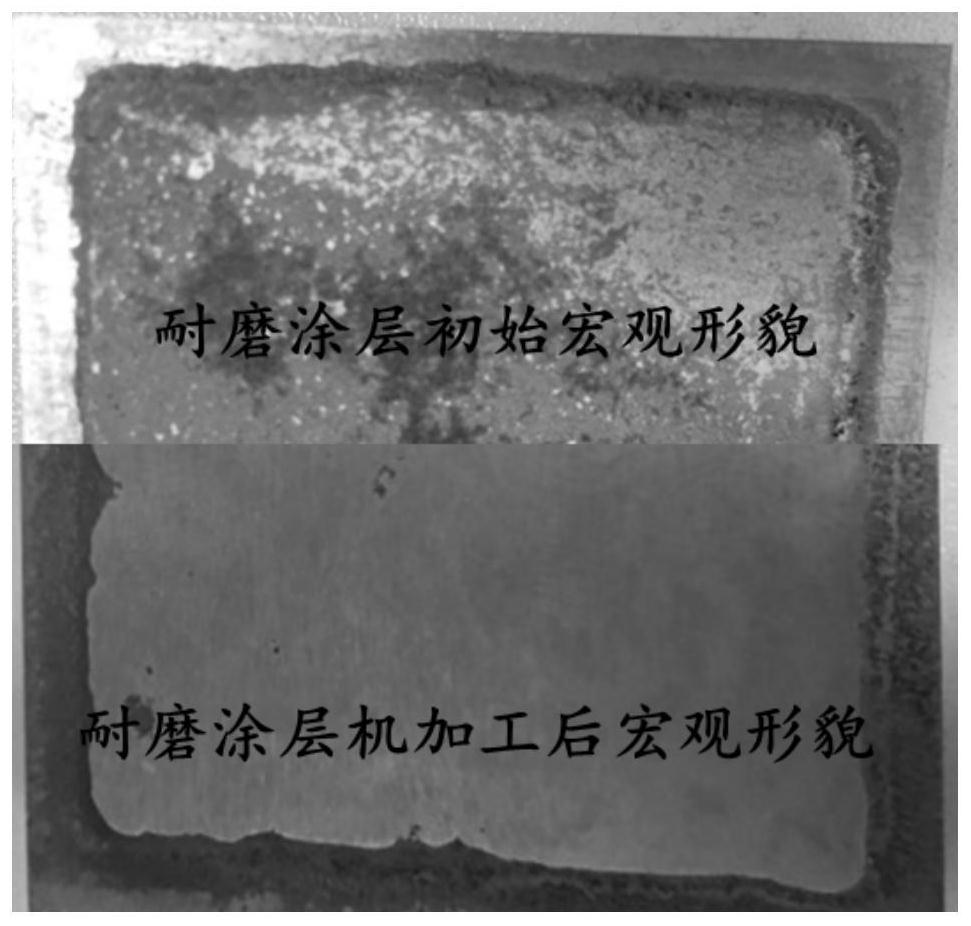

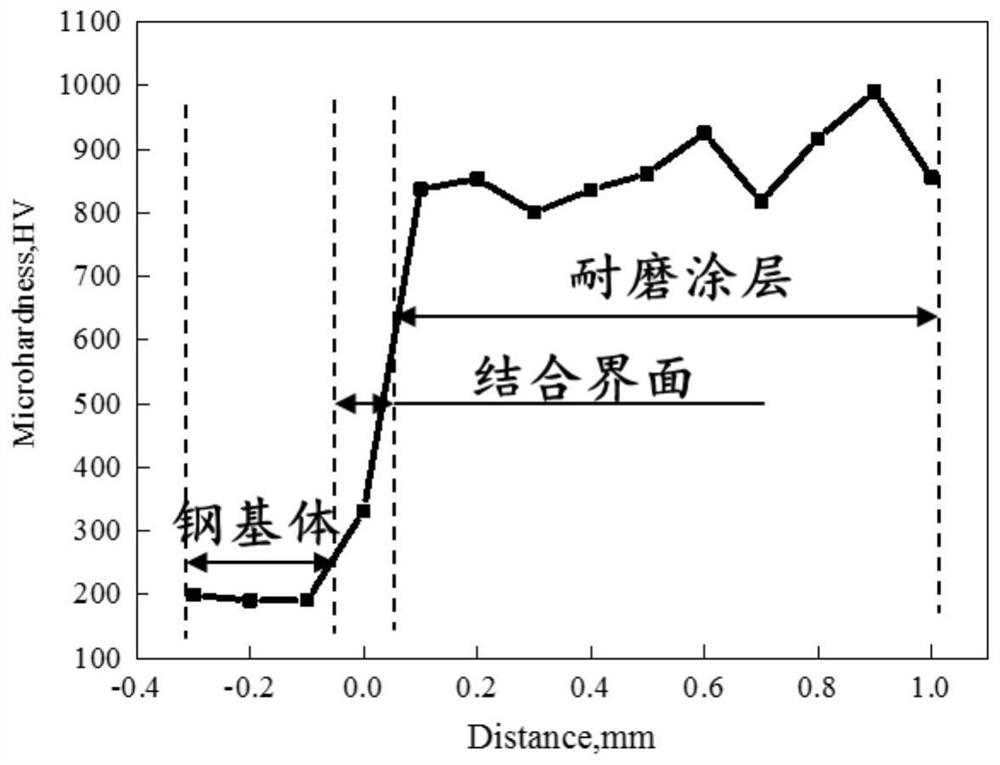

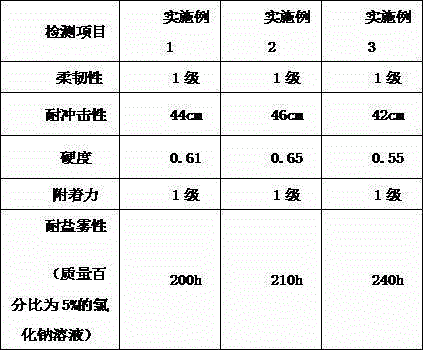

Preparation method of superhard boron carbide ceramic reinforced iron-based alloy composite wear-resistant coating

ActiveCN112708883AWide source of powderWide variety of sourcesMetallic material coating processesCrazingCeramic particle

The invention relates to a preparation method of a superhard boron carbide ceramic reinforced iron-based alloy composite wear-resistant coating. The preparation method comprises the following steps: (1) preparing boron carbide ceramic particles and iron-based self-fluxing alloy powder as raw materials; (2) preparing a steel substrate of which the surface is treated to form a surface to be cladded; (3) putting the boron carbide ceramic particles and the iron-based alloy powder into a ball mill for dry ball milling and mixing; (4) adding a binder into the mixed powder, uniformly stirring to form viscous paste, and coating the surface of the steel substrate with the viscous paste; (5) drying after air drying; and (6) carrying out vacuum cladding and then carrying out furnace cooling. The coating prepared by the method provided by the invention has no cracks and micropores penetrating through the whole thickness, is a continuous closed coating, and can significantly improve the wear resistance of mechanical parts, prolong the service life and improve the safety performance.

Owner:NORTHEASTERN UNIV

Corrosion-resistant water-borne coating and preparation method thereof

InactiveCN105176269AGood adhesionEasy accessAnti-corrosive paintsEpoxy resin coatingsMeth-Acrylic resin

The invention discloses a corrosion-resistant water-borne coating. The components of the corrosion-resistant water-borne coating include in parts by weight: 40 to 45 parts of acrylic resin, 20 to 23 parts of bisphenol-A epoxy resin, 5 to 8 parts of potassium methylsilanol, 7 to 9 parts of magnesium stearate, 10 to 15 parts of epoxy-modified organic silicone resin, 8 to 12 parts of silicon carbide, 12 to 15 parts of titanium dioxide, 20 to 30 parts of deionized water, 35 to 40 parts of water, 5 to 8 parts of alkyd resin, 15 to 18 parts of talcum powder and 3 to 4 parts of propylene glycol monomethyl ether. Not only is the corrosion resistance of the coating good, but also the adhesion is good, so the coating cannot easily shed; the surface friction coefficient of the coating is small, so the coating can resist abrasion; moreover, colors are diversified; the service life is long, and problems, such as blistering, cracking, whitening and even leafing, cannot take place after the coating is used for a long time; moreover, the coating can be used under harsh environments, so the range of application is wide.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com