Intelligent anti-clogging integral safety shaft

An anti-clogging and safe technology, applied in chemical instruments and methods, water/sludge/sewage treatment, drainage structures, etc., can solve the problems of long construction period, poor quality stability, easy injury of maintenance personnel, etc., to save labor costs , saving management costs, good anti-corrosion and anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

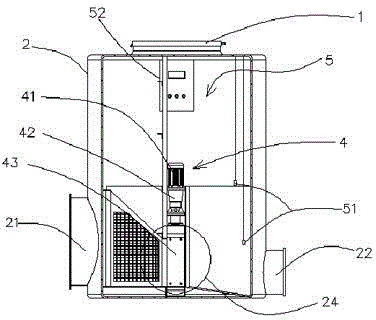

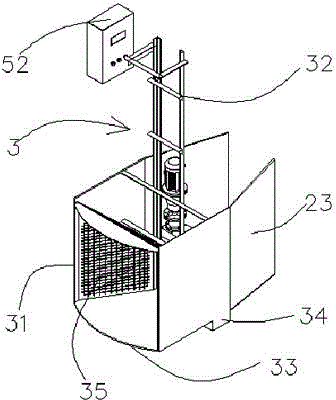

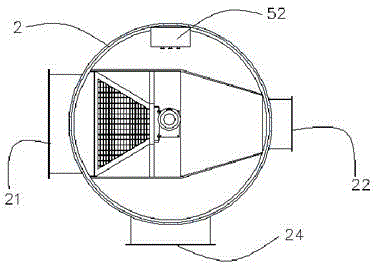

[0019] Example: see figure 1 , figure 2 , image 3 As shown, an intelligent anti-clogging integrated safety well includes a well cover 1, a cylindrical well body 2, an internal frame 3, a pulverized grid device 4 and a PLC control system 5, and the internal frame 3 includes a block frame 31, a ladder 32 and a bottom plate 33, the block frame 31 is welded on the bottom plate 33, the ladder 32 is welded on the block frame 31 and the bottom plate 33, and extends to the wellhead, the bottom plate 33 is provided with a grid slot 34, the The bottom plate 33 is fixed to the bottom of the cylindrical well body 2 by bolts. The side wall of the well body 2 is provided with a water inlet 21 and a water outlet 22. The sewage enters through the water inlet 21, and the garbage contained in the sewage is crushed into a grid. The grid device is crushed into fine particles and discharged through the water outlet 22. The water inlet end of the pulverized grid device 4 is provided with a slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com