Environment-friendly wheel and track lubricating grease and method for preparing same

A kind of lubricating grease and environment-friendly technology, which is applied in the field of environment-friendly cold-resistant wheel-rail grease and its preparation, can solve the problems of not considering environmental protection performance, not easy to biodegrade, etc., and achieve excellent extreme pressure and anti-wear performance, anti-friction and wear performance The effect of good, good fluidity and low temperature pumpability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

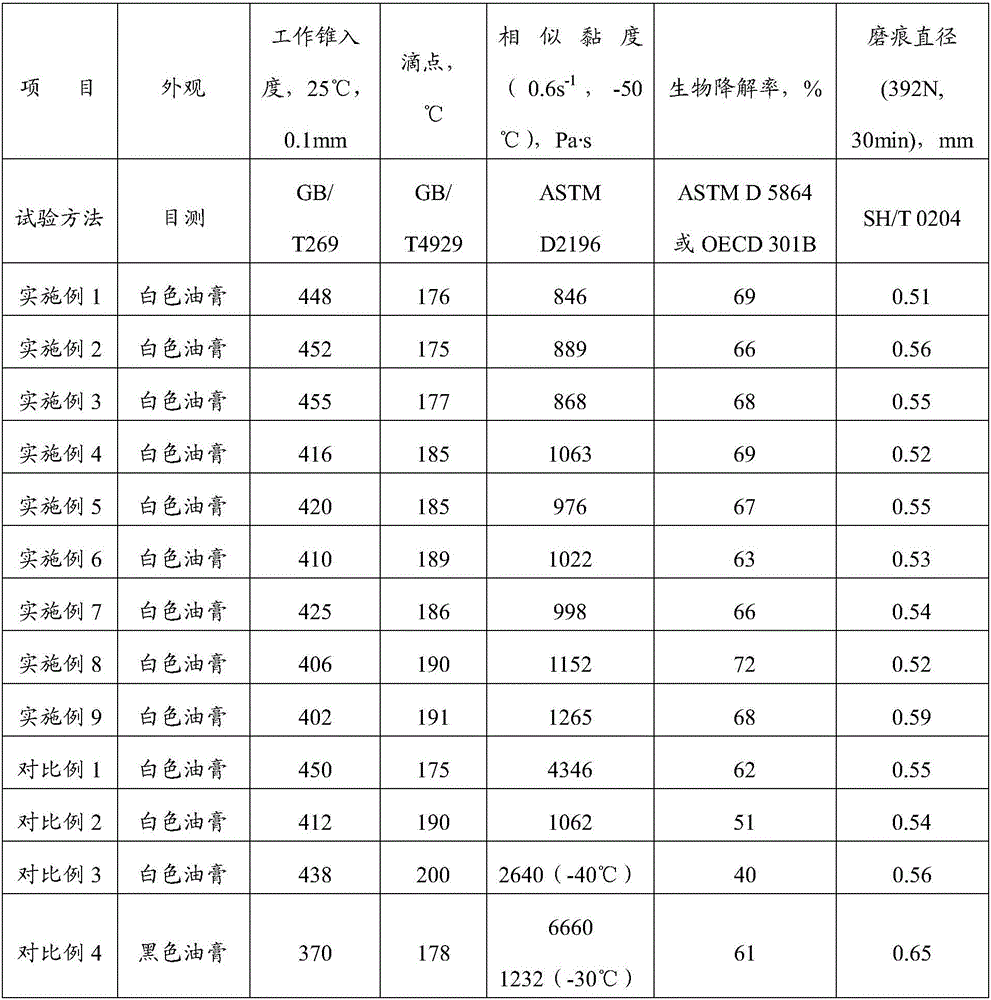

Embodiment 1

[0056] Embodiment 1: the preparation of lubricating grease of the present invention

[0057] Weigh 250g pentaerythritol C 4 -C 12 Saturated fatty acid ester, add 15g of 12-hydroxy lithium stearate soap, after melting completely, heat up to 205°C, add 185g of pentaerythritol C 4 -C 12 Saturated fatty acid ester, cool down to 155°C, add 2g of alkylated diphenylamine (T534), cool down to 90°C, add 15g of dithiocarbamate, 1g of 2,6-di-tert-butylphenol, 1g of benzene Triazole octadecylamine, 0.5g di-n-butylaminomethylene benzotriazole, 0.5g dodecenylsuccinic acid, 15g calcium carbonate, 15g melamine cyanurate, stir well, cool to room temperature, grind for 3 Time, obtain grease 500g of the present invention, its performance is shown in Table 2.

Embodiment 2

[0058] Embodiment 2: the preparation of lubricating grease of the present invention

[0059] Weigh 250g pentaerythritol C 4 -C 12 Saturated fatty acid ester, add 15g of 12-hydroxy lithium stearate soap, after melting completely, heat up to 205°C, add 185g of pentaerythritol C 4 -C 12 Saturated fatty acid ester, cool down to 155°C, add 2g of alkylated diphenylamine (T534), cool down to 90°C, add 15g of dithiocarbamate, 1g of 2,6-di-tert-butylphenol, 1g of benzene Triazole octadecylamine, 0.5g di-n-butylaminomethylene benzotriazole, 0.5g dodecenyl succinic acid and 30g melamine cyanurate, stir evenly, cool to room temperature, grind 3 times to obtain this Invention described grease 500g, its performance is shown in Table 2.

Embodiment 3

[0060] Embodiment 3: the preparation of lubricating grease of the present invention

[0061] Weigh 250g pentaerythritol C 4 -C 12 Saturated fatty acid ester, add 15g of 12-hydroxy lithium stearate soap, after melting completely, heat up to 205°C, add 185g of pentaerythritol C 4 -C 12 Saturated fatty acid ester, cool down to 155°C, add 2g of alkylated diphenylamine (T534), cool down to 90°C, add 15g of dithiocarbamate, 1g of 2,6-di-tert-butylphenol, 1g of benzene Triazole octadecylamine, 0.5g di-n-butylaminomethylene benzotriazole, 0.5g dodecenylsuccinic acid and 30g calcium carbonate, stir evenly, cool to room temperature, grind 3 times to obtain the present invention. Grease 500g, its properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com