Patents

Literature

284results about How to "Excellent friction and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard-material-coated bodies and method for their production

ActiveUS7767320B2Improve the immunityExcellent friction and wear resistanceNatural mineral layered productsChemical vapor deposition coatingLattice constantChemical measurement

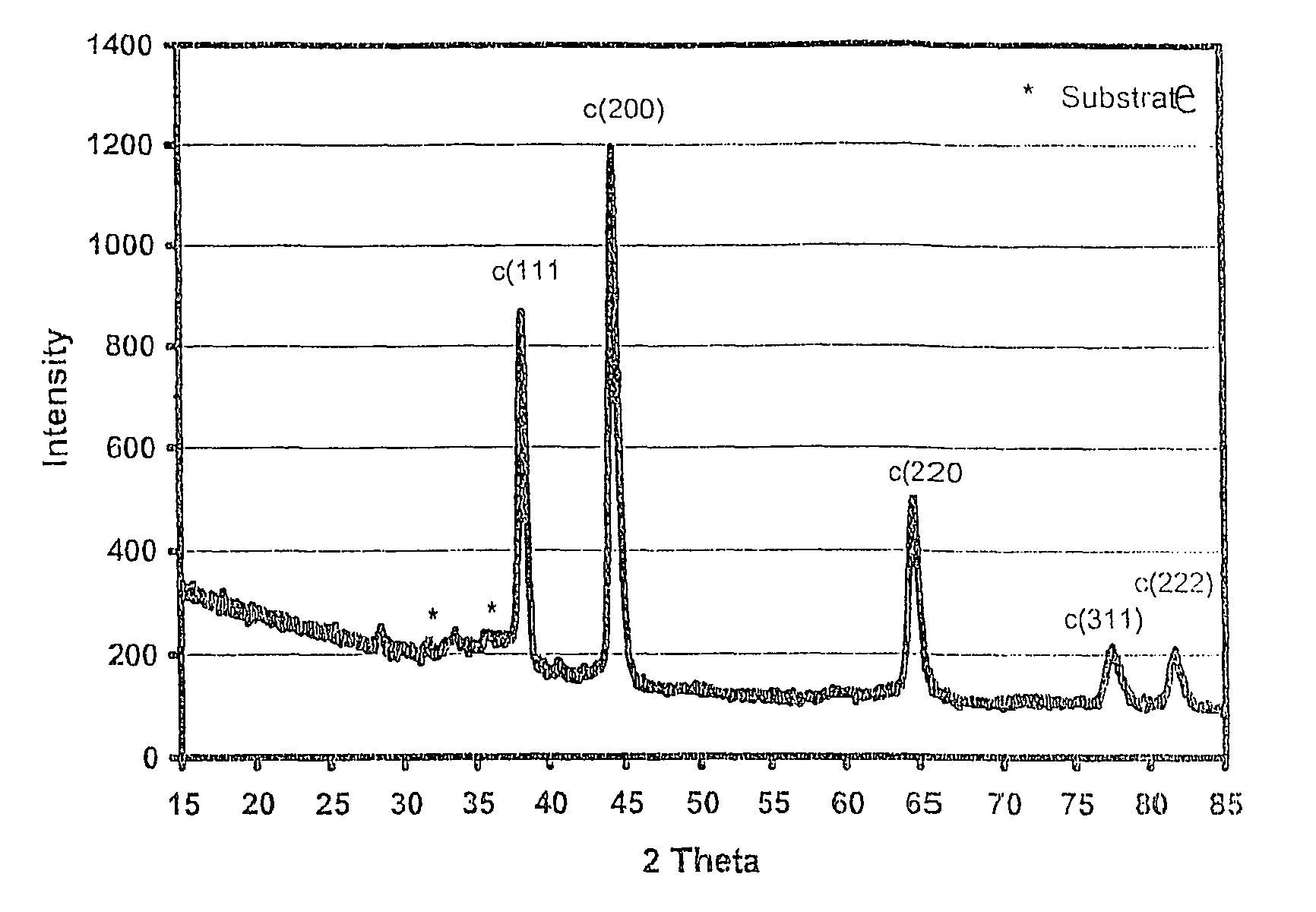

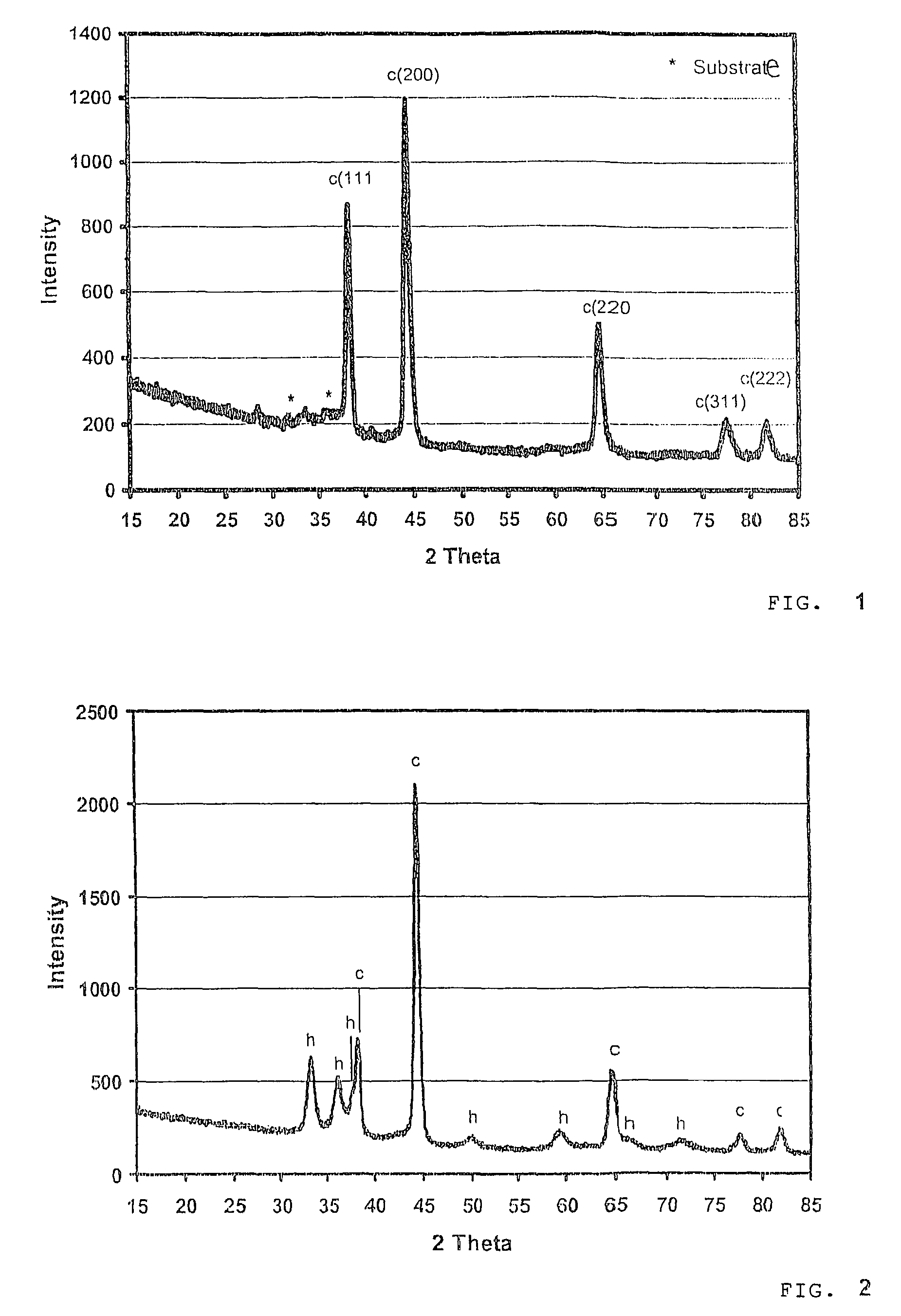

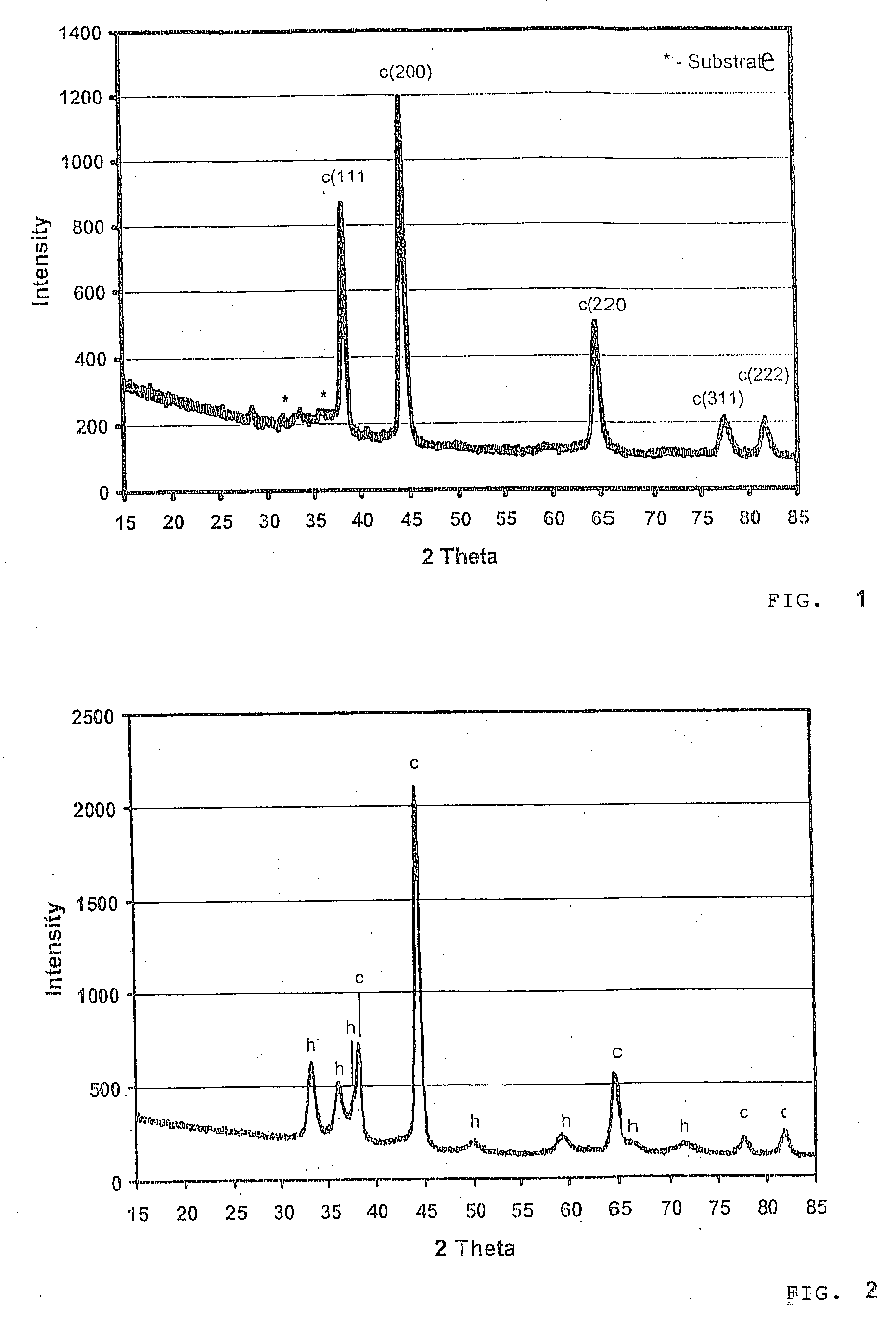

The invention relates to hard-coated bodies with a single- or multi-layer system containing at least one Ti1-xAlxN hard layer and a method for production thereof. The aim of the invention is to achieve a significantly improved wear resistance and oxidation resistance for such hard-coated bodies. Said hard-coated bodies are characterised in that the bodies are coated with at least one Ti1-xAlxN hard layer, generated by CVD without plasma stimulation present as a single-phase layer with cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, or as a multi-phase layer, the main phase being Ti1-xAlxN with a cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, with Ti1-xAlxN with a wurtzite structure and / or as TiNx with NaCl structure as further phase. Another feature of said hard layer is that the chlorine content is in the range of only 0.05 to 0.9 atom %. The invention further relates to a method for production of the body, characterised in that the body is coated in a reactor at temperatures from 700° C. to 900° C. by means of CVD without plasma stimulation with titanium halides, aluminium halides and reactive nitrogen compounds as precursors, mixed at elevated temperatures. Said coating can be applied to tools made from steel, hard metals, cermets and ceramics, such as drills, millers and indexable inserts.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

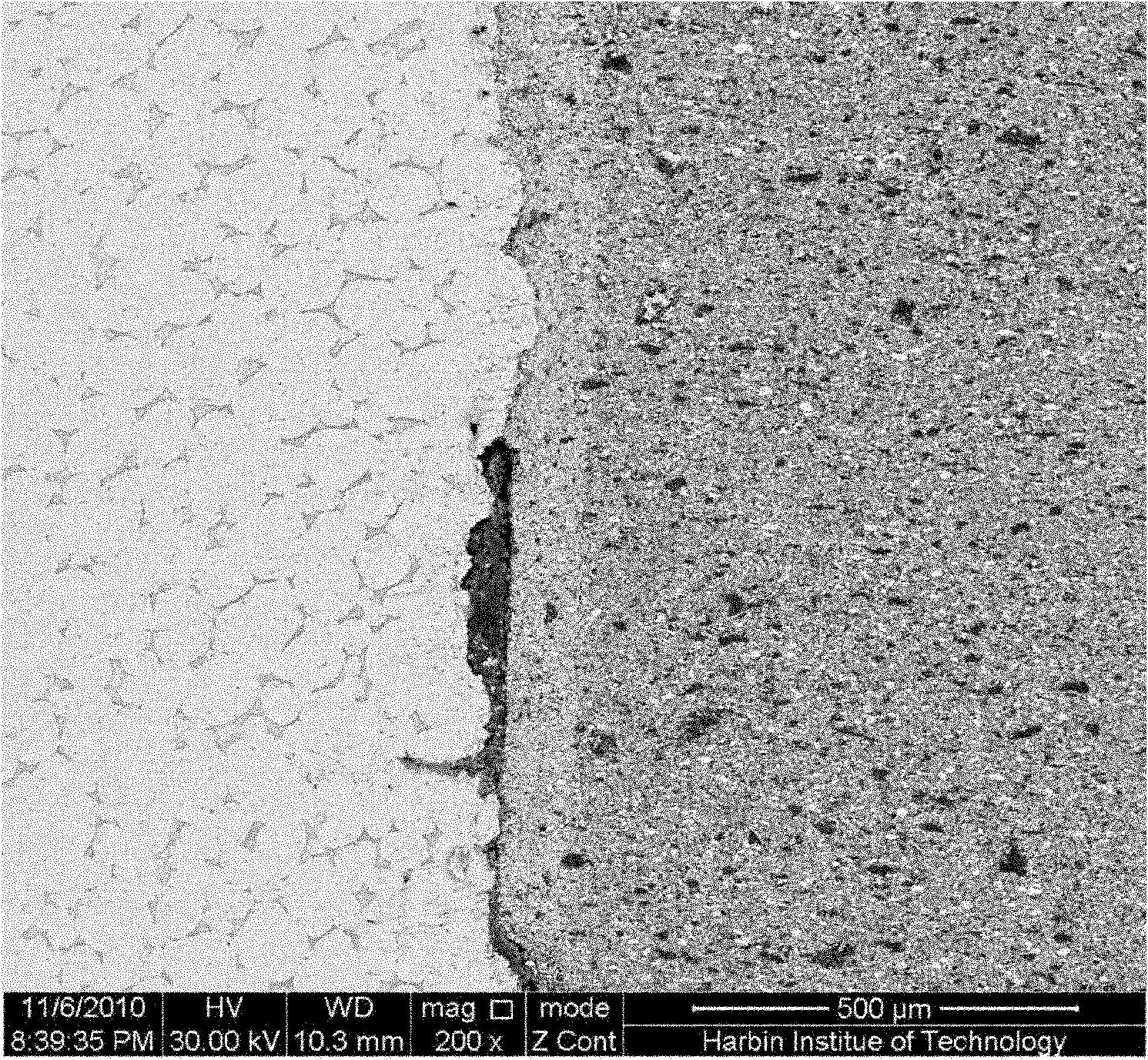

Ceramic composite material for thin-strip casting side sealing plate and preparation method thereof

The invention provides a ceramic composite material for a thin-strip casting side sealing plate and a preparation method thereof, relating to a ceramic composite material and a preparation method thereof and solving the problems that the traditional side sealing plate has high heat conductivity, serious abrasion, poor seal, high preparation cost and large energy consumption, can not be secondarily processed or reused. The ceramic composite material consists of zirconia, boron nitride and additives. The preparation method comprises the following steps: 1, weighing raw materials; 2, ball milling and mixing the raw materials; 3, drying to obtain uniform mixed powder; and 4, carrying out hot pressed sintering, pressureless sintering, air pressure sintering or hot isostatic pressed sintering on the mixed powder, so as to obtain the ceramic composite material for a thin-strip casting side sealing plate. The compactness of the ceramic composite material is 94%-99%, the bending strength of the ceramic composite material, tested by a three-point bending test at room temperature, is 260-420MPa, and the fracture toughness of the ceramic composite material, tested by a unilateral coped beam method, is 3-8 MPa.m<1 / 2>. The ceramic composite material can be widely applied to the field of side sealing plate materials.

Owner:HARBIN INST OF TECH

Hard-Material-Coated Bodies and Method for Their Production

ActiveUS20090123779A1Improve the immunityExcellent friction and wear resistanceNatural mineral layered productsChemical vapor deposition coatingLattice constantChemical measurement

The invention relates to hard-coated bodies with a single- or multi-layer system containing at least one Ti1-xAlxN hard layer and a method for production thereof. The aim of the invention is to achieve a significantly improved wear resistance and oxidation resistance for such hard-coated bodies. Said hard-coated bodies are characterised in that the bodies are coated with at least one Ti1-xAlxN hard layer, generated by CVD without plasma stimulation present as a single-phase layer with cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, or as a multi-phase layer, the main phase being Ti1-xAlxN with a cubic NaCl structure with a stoichiometric coefficient x>0.75 to x=0.93 and a lattice constant afcc between 0.412 nm and 0.405 nm, with Ti1-xAlxN with a wurtzite structure and / or as TiNx with NaCl structure as further phase. Another feature of said hard layer is that the chlorine content is in the range of only 0.05 to 0.9 atom %. The invention further relates to a method for production of the body, characterised in that the body is coated in a reactor at temperatures from 700° C. to 900° C. by means of CVD without plasma stimulation with titanium halides, aluminium halides and reactive nitrogen compounds as precursors, mixed at elevated temperatures. Said coating can be applied to tools made from steel, hard metals, cermets and ceramics, such as drills, millers and indexable inserts.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Ultrahigh strength abrasion resistant steel and method of preparing the same

InactiveCN101250673AHigh yield strengthImprove impact toughnessTemperature control deviceFurnace typesChemical compositionWear resistant

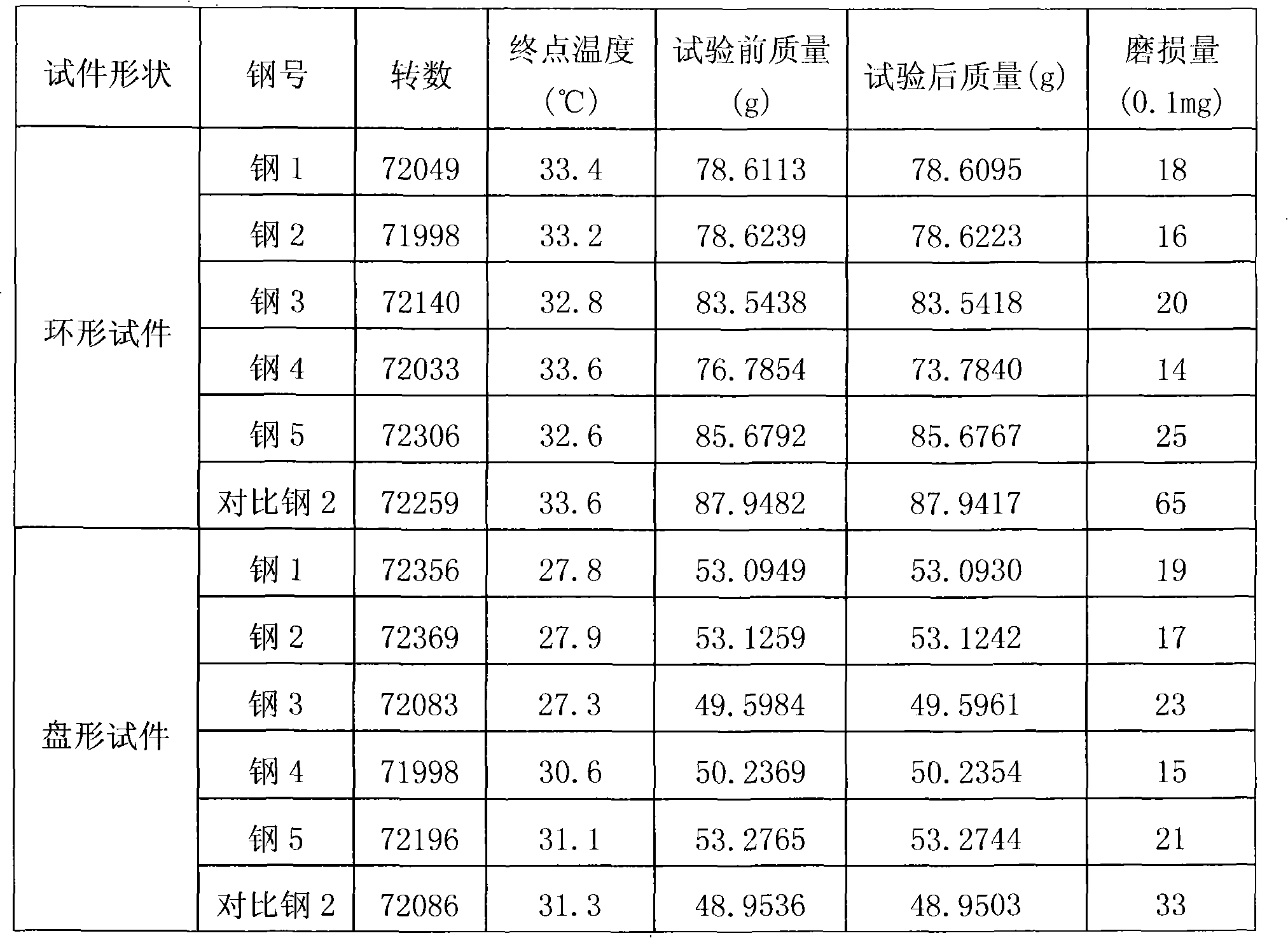

The invention discloses a superhigh intensity wear-resistant steel and the manufacturing method, which belongs to the manufacturing field of low alloying steels, according to percentage by weight, the chemical components of the steel are that C 0.10-0.17%, Si 0.25-0.50%, Mn 1.20-1.50%, P<=0.018%, S<=0.008%, Cr 0.20-0.05%, Ni0.25-0.50%, Mo 0.10-0.40%, Als 0.02-0.06%, B<=0.005%, RE<=150g / t, and the allowance is Fe and unavoidable impurities, and the content of carbon is Ceq(%)<=0.60, Ceq(5)=C+Mn / 6+(Mo+Cr+V) / 5+(Ni+Cu) / 15. The specific method for producing the steel comprises the following steps: smelting ultra-pure steel, desulfurizing molten iron, compounding and converting the top and the bottom of a converter, doing vacuum treatment, feeding rare earth (RE) silk through a crystallizer, casting into bar plates, heating the bar plates, roughing, planishing, air cooling or feeding middle pressure, water cooling, quenching and tempering steel plates. V does not contain in the chemical components of the steel, inner stress of steel is low, steel welding property is improved, and steel has excellent abrasion resistance and ultra-high strength and toughness properties, which is beneficial for popularization and application.

Owner:武钢集团有限公司

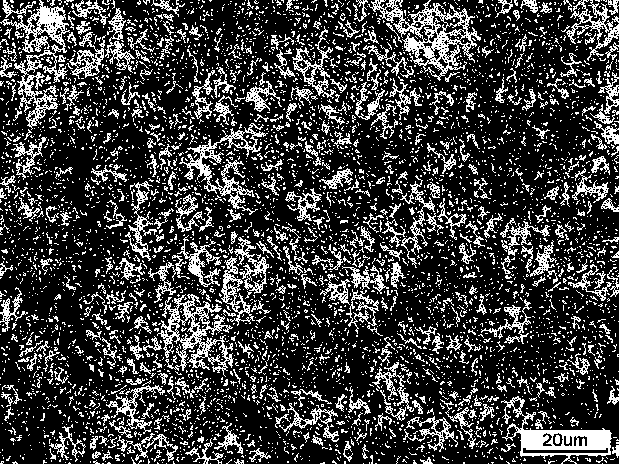

Tungsten carbide particle-enhanced iron-based powder metallurgy material and preparation method thereof

The invention relates to plastic forming technology and powder metallurgy technology, in particular to a tungsten carbide particle-enhanced iron-based powder metallurgy material and a preparation method thereof. According to a specific formula, the iron-based powder metallurgy material comprises the following components in percentage by mass: 85.0 to 90.0 percent of matrix material and 10.0 to 15.0 percent of enhanced phase tungsten carbide, wherein the matrix material comprises the following components in percentage by mass: 1.4 to 2.0 percent of copper, 1.7 to 2.0 percent of nickel, 0.9 to 1.2 percent of molybdenum, 0.7 to 1.6 percent of carbon and the balance of iron. In the invention, quick spark plasma sintering is adopted; and the obtained material has the characteristics of nearly full densification, high hardness, high indoor temperature bending strength, high high-temperature mechanical property and the like, can be used as a wear-resistant material, a tool material and the like, and can reduce the dependency of Chinese tool material production on import of precious metals such as vanadium, chromium and the like. The material has high cost performance and a good industrial production prospect.

Owner:SOUTH CHINA UNIV OF TECH

Ultrahigh thermal conductivity wear-resistant hot stamping die steel and manufacturing method thereof

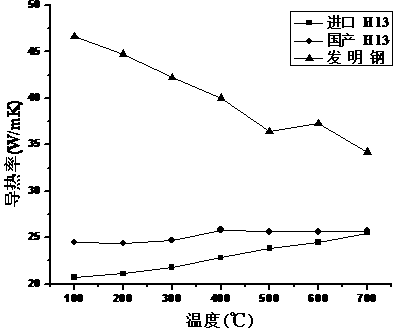

Belonging to the technical field of alloy steel preparation processes, the invention relates to an ultrahigh thermal conductivity wear-resistant hot stamping die steel and a manufacturing method thereof. Current hot stamping die steel on the market is mainly various improved H13, H11 and other high alloy hot work die steel. The steel provided by the invention comprises the following components by mass percent: 0.33-0.40% of C; less than 0.30% of Si; less than 0.30% of Mn; 1.0-2.0% of W; 4.0-5.0% of Mo; less than 0.30% of Cr; 0.10-0.20% of V; and the balance Fe and inevitable impurities. And in the impurity elements, S is smaller than or equal to 0.01%; P is smaller than or equal to 0.01%; and O is smaller than or equal to 30ppm. The steel is characterized in that: simple C, Mo and W are adopted as the main elements to coordinate the ratio of carbides; low Mn, low Cr and low Si content are maintained; after electric furnace smelting, electroslag remelting, annealing, high temperature homogenization, forging and annealing, the material has good machining properties; and after heat treatment, the material has excellent impact toughness, tempering stability and thermal fatigue performance. With ultrahigh thermal conductivity, the steel can be more suitable for hot stamping.

Owner:SHANGHAI UNIV +1

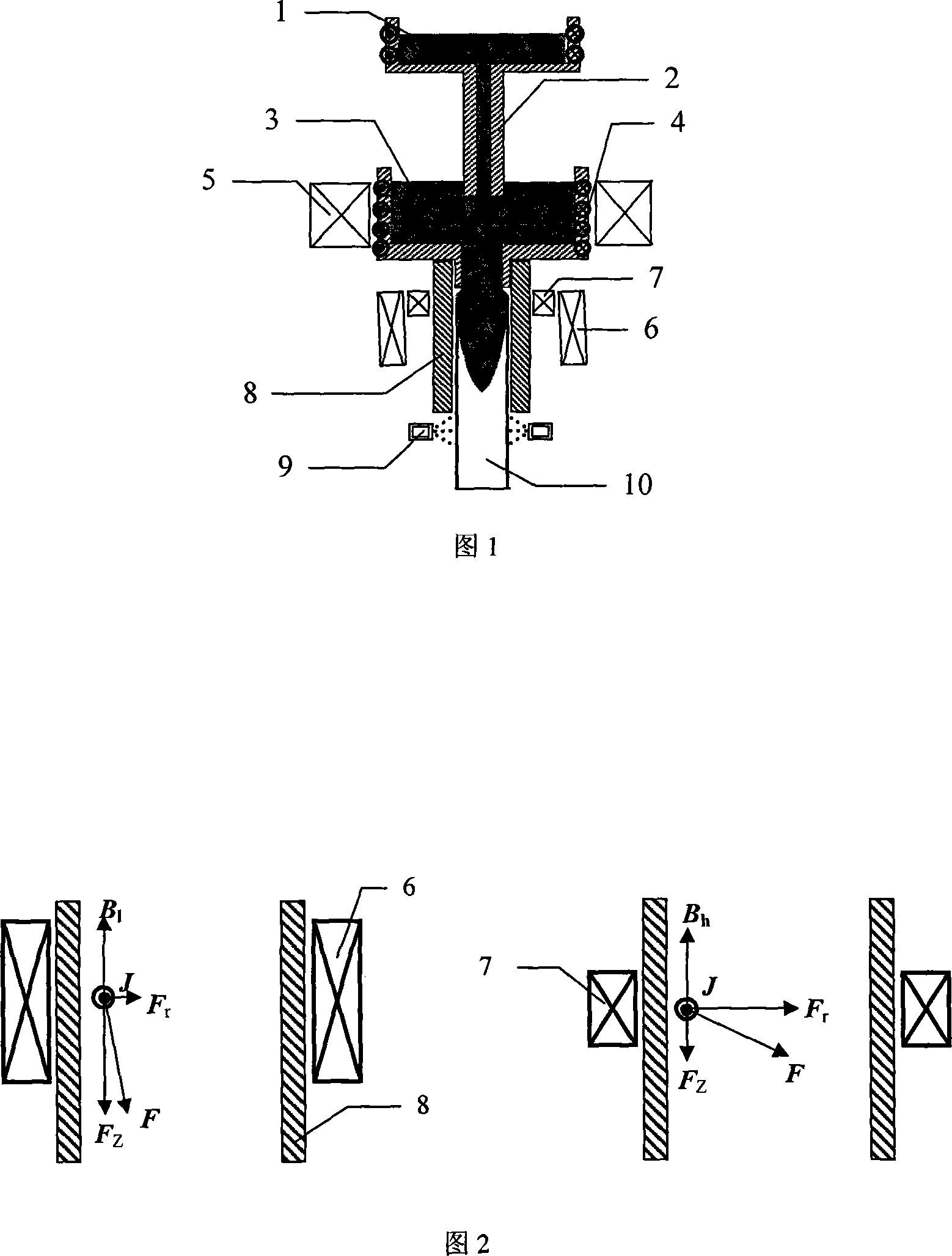

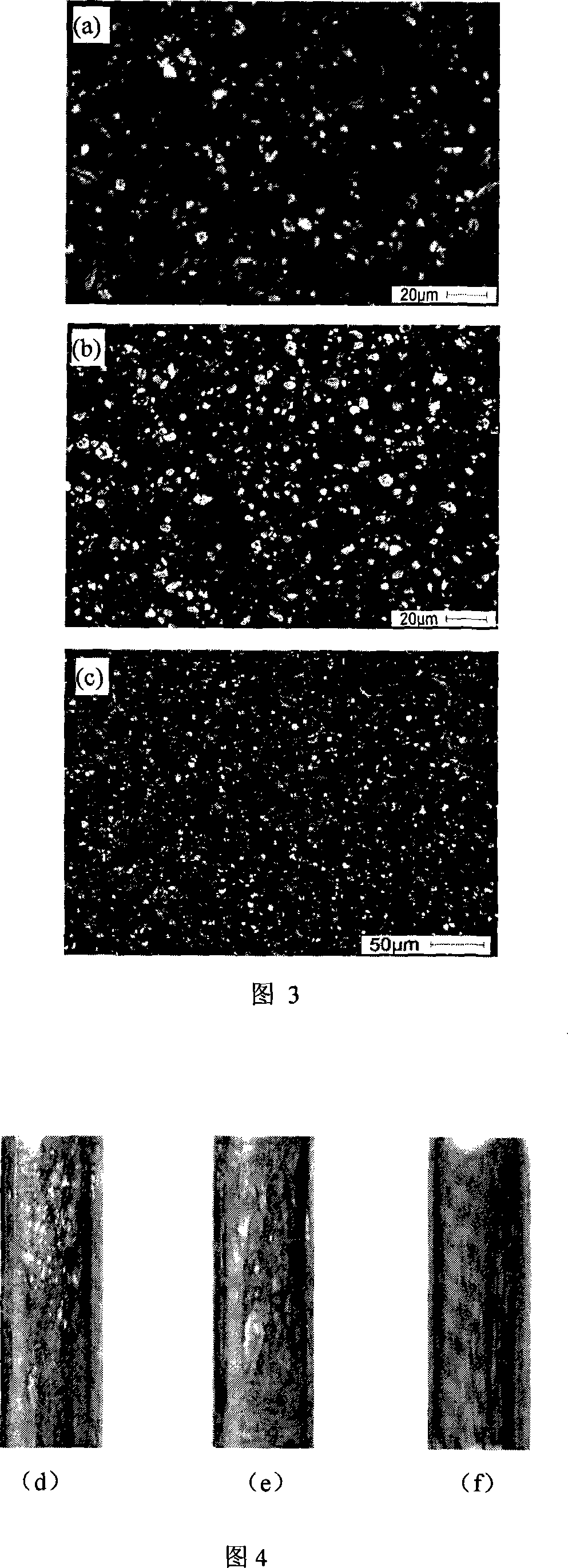

Method of continuous casting particulate reinforced metal matrix composites on different frequency multi-electromagnetic field

Disclosed is a method of particle reinforced metal matrix composite continuous casting in compound magnetic field at different frequency, relating to material processing technology field; in the process of the preparation of the composites melt, low-frequency alternating magnetic field is applied: the frequency is from 5 to 50 Hz, the power range is from 5 to 60 kW; electromagnetic stirring is carried out, making the particles to be fined and evenly distributed; in the process of continuous casting, low-frequency alternating magnetic field is applied to the crystallizer zone: the frequency is from 5 to 50 Hz, the power range is from 5 to 20 kW; electromagnetic stirring is carried out to improve the internal quality; meanwhile, the high-frequency alternating magnetic field is applied in initial solidification zone in crystallizer: the frequency is from10 to 50 kHz, the power range is from 20 to 100Kw, soft contact is applied to improve the surface quality of casting billet. The composites article reinforcement prepared by the method are evenly distributed and fined, the internal organization is compact without any structural defects such as rarefaction or shrinkage hole, the casting billet has high surface finish without any defects.

Owner:JIANGSU UNIV

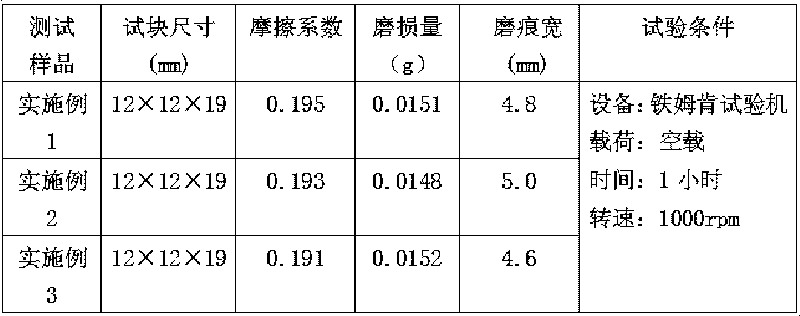

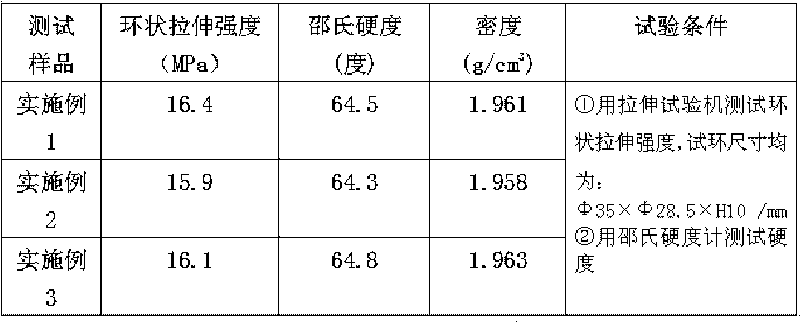

Bearing retainer material and preparation method thereof

ActiveCN101696311AImprove thermal stabilityWide temperature rangeBearing componentsMaterials scienceMetal

The invention discloses a bearing retainer material and a preparation method thereof. The material is prepared from the following raw materials in percentage by weight: 2 to 5 percent of molybdenium disulfide, 8 to 12 percent of polyimide, 9 to 15 percent of polybenzoate, the balance of polytetrafluoroethylene. The preparation method comprises the following steps of: weighting the raw materials; mixing the raw materials; grinding the mixture; loading the mixture into a mould; pressurizing to prepare a blank; sintering the blank; and processing the blank into a finished product. The retainer material has the advantages of high temperature resistance, low temperature resistance, dimension stability, small erosion to metal and rubbed surfaces and good abrasion resistance. A retainer made of the bearing retainer material can be used under harsh conditions of no magnetism, ambient temperature changed between -19 and +55 DEG C, and rotation speed up to 7,200r / min so as to improve the performance of bearings.

Owner:LUOYANG BEARING RES INST CO LTD

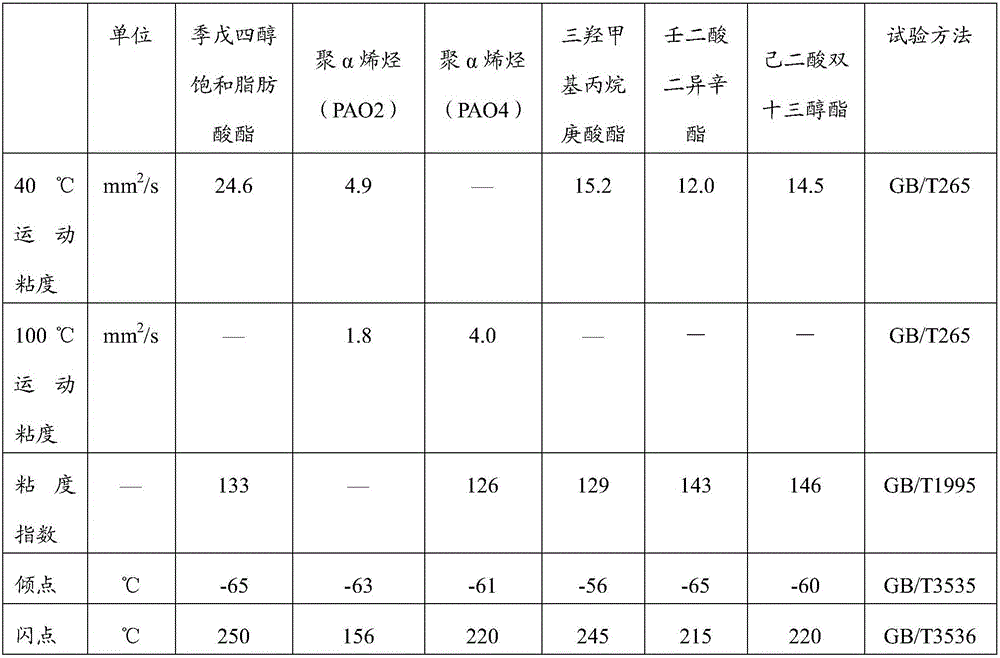

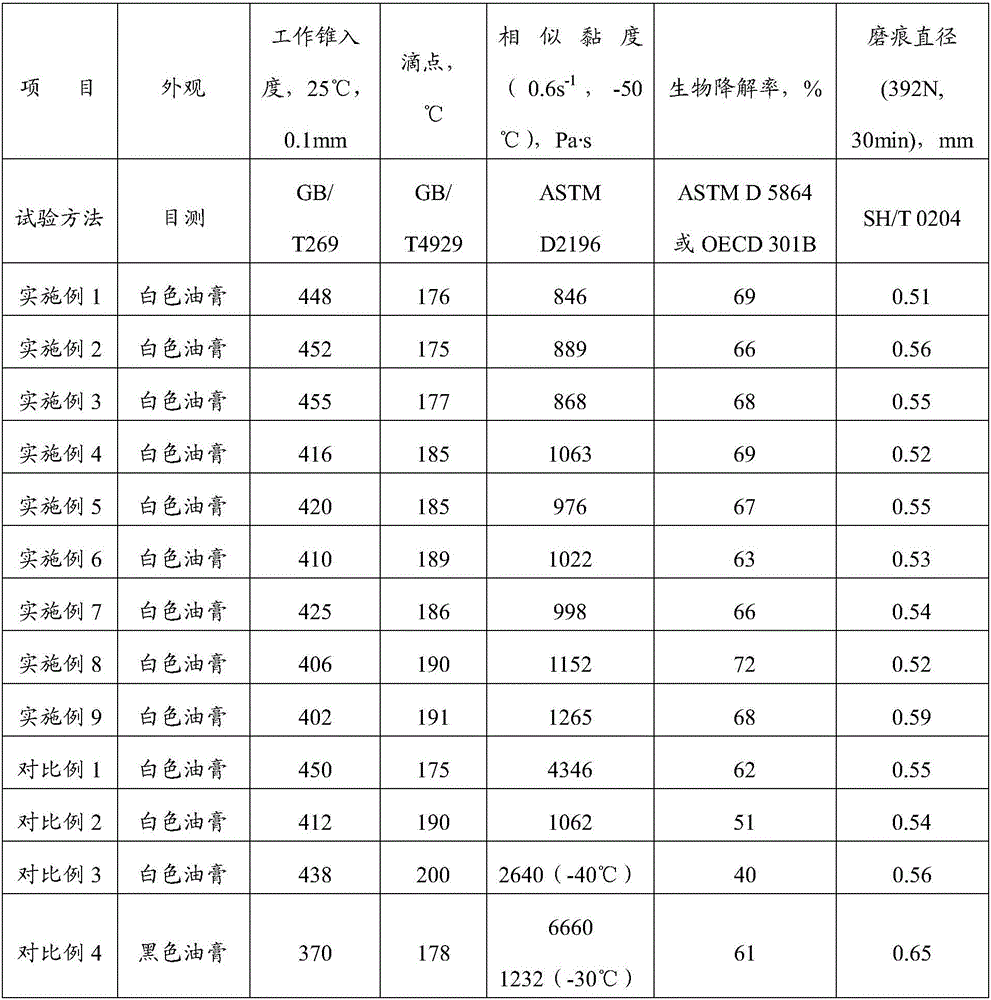

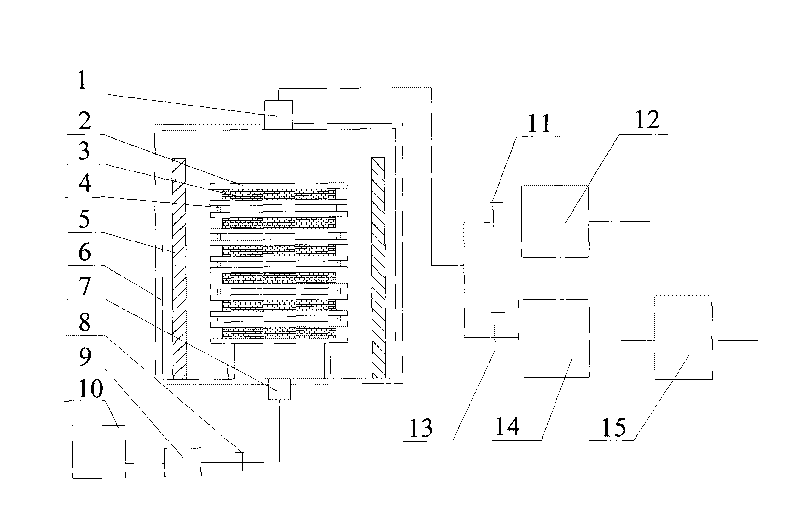

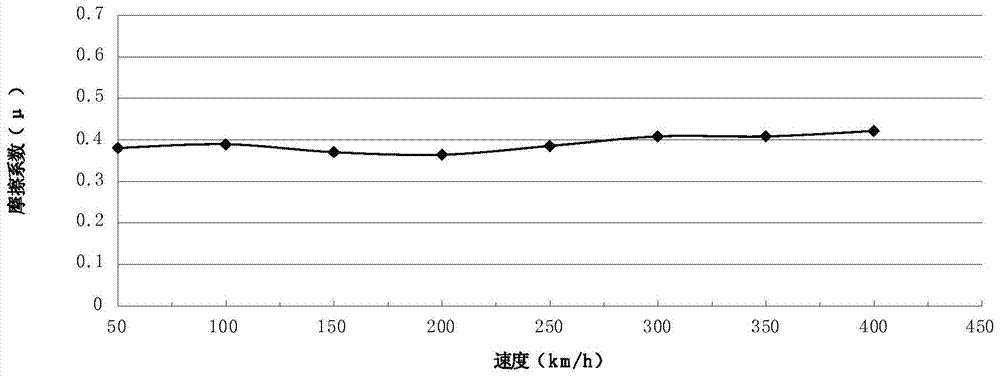

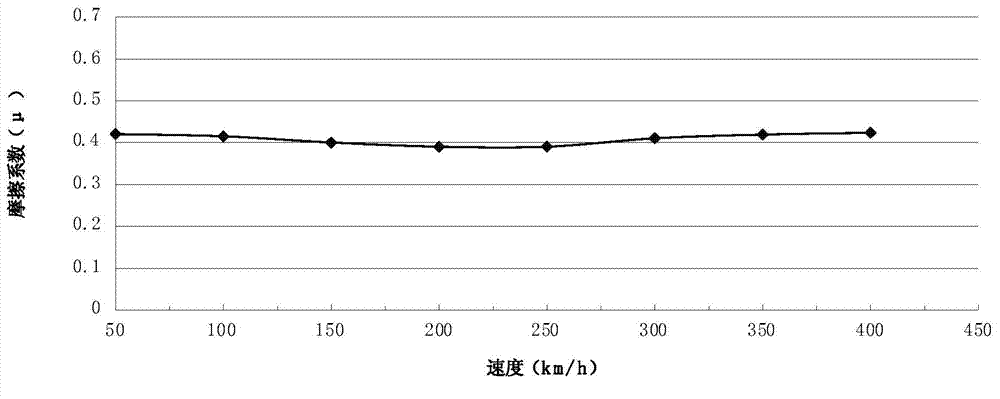

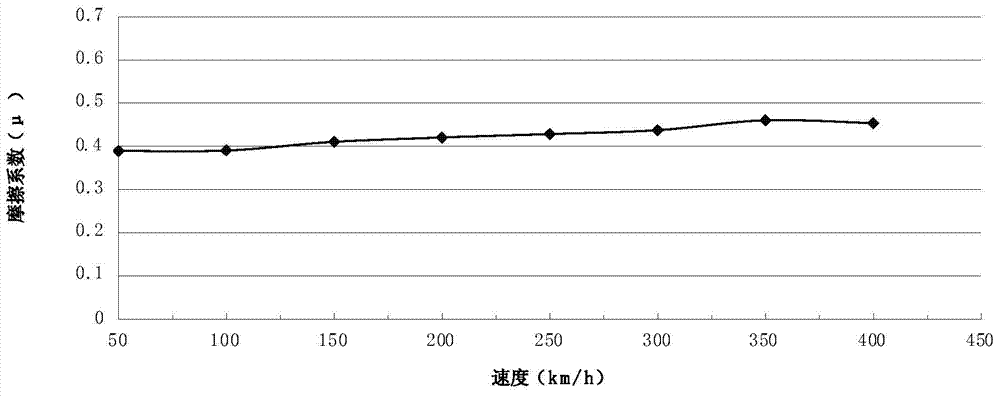

Environment-friendly wheel and track lubricating grease and method for preparing same

The invention provides environment-friendly wheel and track lubricating grease. The environment-friendly wheel and track lubricating grease comprises, by weight, 70-95 parts of base oil, 1-20 parts of thickening agents, 1-8 parts of anti-wear agents, 0.05-3 parts of antioxidants, 0.02-1.5 parts of anti-corrosion and anti-rust agents and 1-10 parts of solid anti-wear materials. The base oil comprises ester oil and / or synthetic hydrocarbon. The environment-friendly wheel and track lubricating grease has the advantages that the white environment-friendly wheel and track lubricating grease is excellent in low-temperature performance, biodegradability, anti-corrosion property and extreme pressure anti-wear property and free of harmful elements such as heavy metal, is non-toxic (or is low in toxicity) and is easy to pump, spray and uniformly atomize; wear of flanges of wheels can be effectively reduced, the service lives of the wheels and steel tracks can be prolonged, environmental requirements can be met, and the environment-friendly wheel and track lubricating grease is applicable to lubricating the wheels and the tracks for track traffic in wide temperature ranges of -50-150 DEG C.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

Method for preparing carbonitride modified film on surface of medical titanium alloy implant material

InactiveCN101555586ASuperior mechanicsChemically stableVacuum evaporation coatingSputtering coatingDirect current magnetron sputteringImplant material

Owner:SOUTHEAST UNIV

Preparation and carbonization method of needle-punched pre-oxidative fiber prefabricated part

ActiveCN101691684ASolve the easy broken needleSolve problems such as broken wiresHeating/cooling textile fabricsNon-woven fabricsFiberCarbon fibers

The invention relates to a preparation and carbonization method of a needle-punched pre-oxidative fiber prefabricated part, comprising two steps: step I: the preparation of the prefabricated part; long pre-oxidative fibers are chosen to be paved into a laid fabric, the pre-oxidative fibers are cut short to be paved into a mesh tire; step II: the carbonization of the prefabricated part: the prefabricated part is fixed by a graphite plate 2 and is filled in a carbide furnace, gas valves 8 and 13 are closed, a gas valve 11 is opened, a vacuum pump is started to vacuumize to be below 0.1MPa, and then the valve 11 is closed, the valve 8 is opened, and then high-purity nitrogen is blown in to lead air pressure to be 0.1MPa, temperature programming carbonization is carried out at a certain speed, after the temperature reaches to set temperature, the room temperature is cooled naturally under the protection of nitrogen at normal pressure. The method breaks through the limitation that the carbon matrix composite prefabricated part is prepared domestically by carbon fibers mainly, simplifies the preparation procedures and reduces the preparation cost, and the prepared prefabricated part can well meet the requirements of preparing the high-performance carbon matrix composite material.

Owner:BEIHANG UNIV

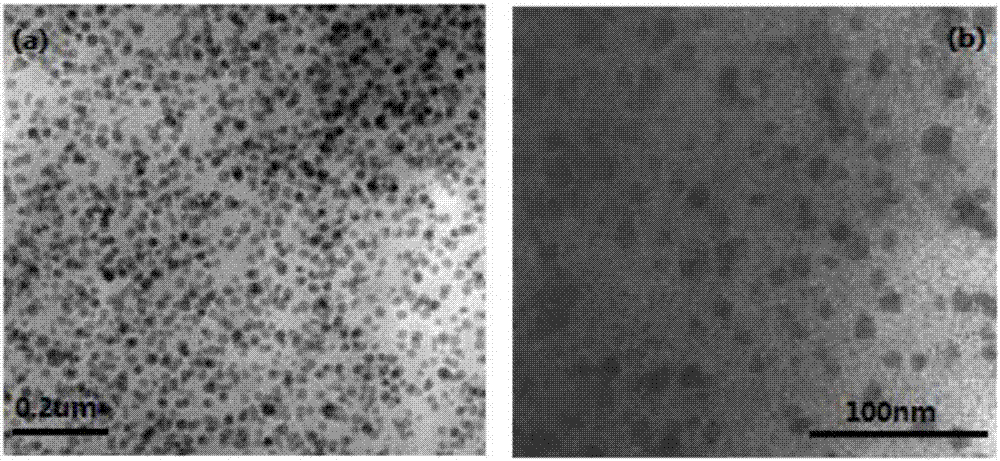

Copper-based powder dispersion ceramic as well as preparation method and application thereof

InactiveCN103667772AStrong impact pressureHigh mechanical strengthBraking membersCopperUltimate tensile strength

The invention relates to copper-based powder dispersion ceramic as well as a preparation method and application thereof, and relates to the field of ceramic materials. The copper-based powder dispersion ceramic is prepared from an anti-abrasion constituent element as one of the raw materials, wherein the anti-abrasion constituent element comprises the following components by mass percent of all the raw materials: 1-5 percent of diamond powder and 1-5 percent of titanium diboride powder. The copper-based powder dispersion ceramic is high in impact pressure resistance, high in mechanical intensity, high in friction and abrasion resistance, long in service life, high in heat dissipation property and heat recovery property, high in high-temperature and low-temperature resistance, high in acid, alkaline, oil, water and the like corrosion resistance and the like.

Owner:刘伟

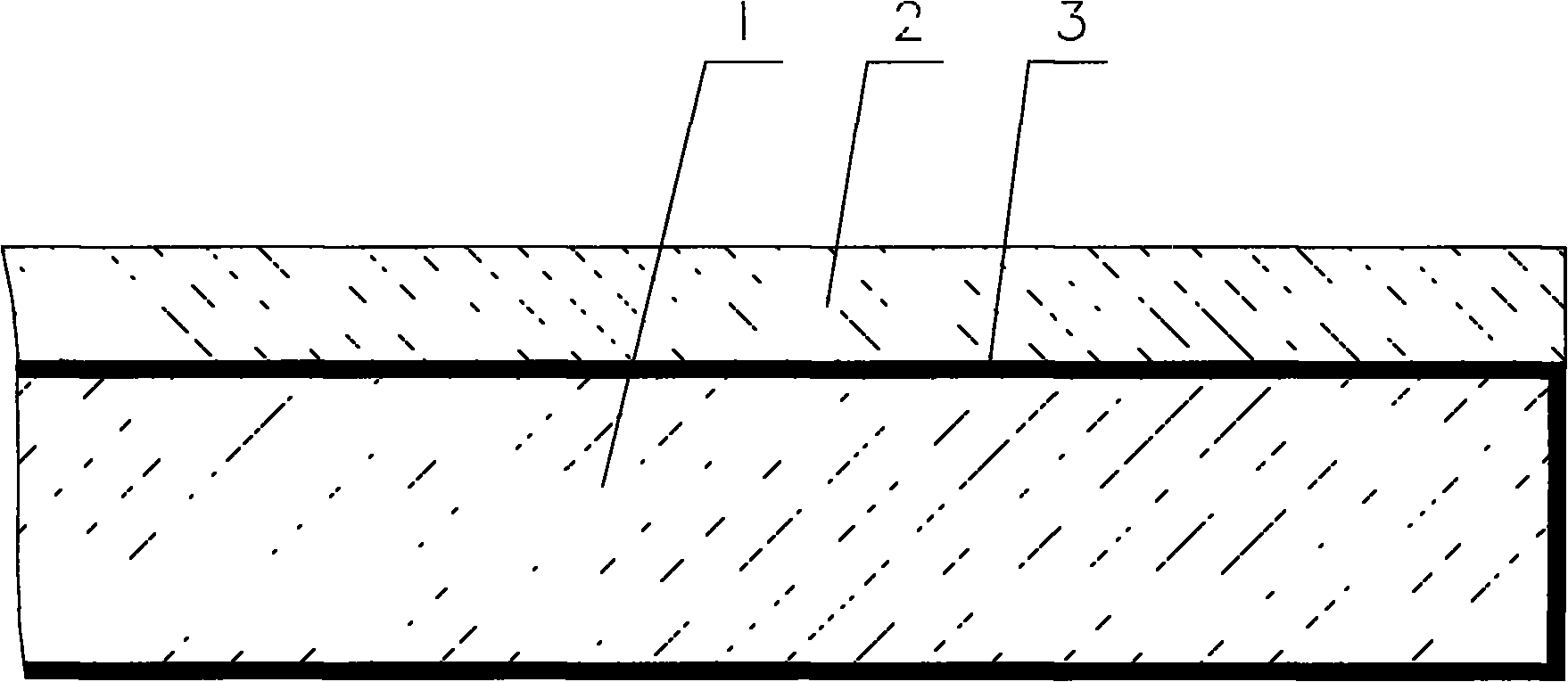

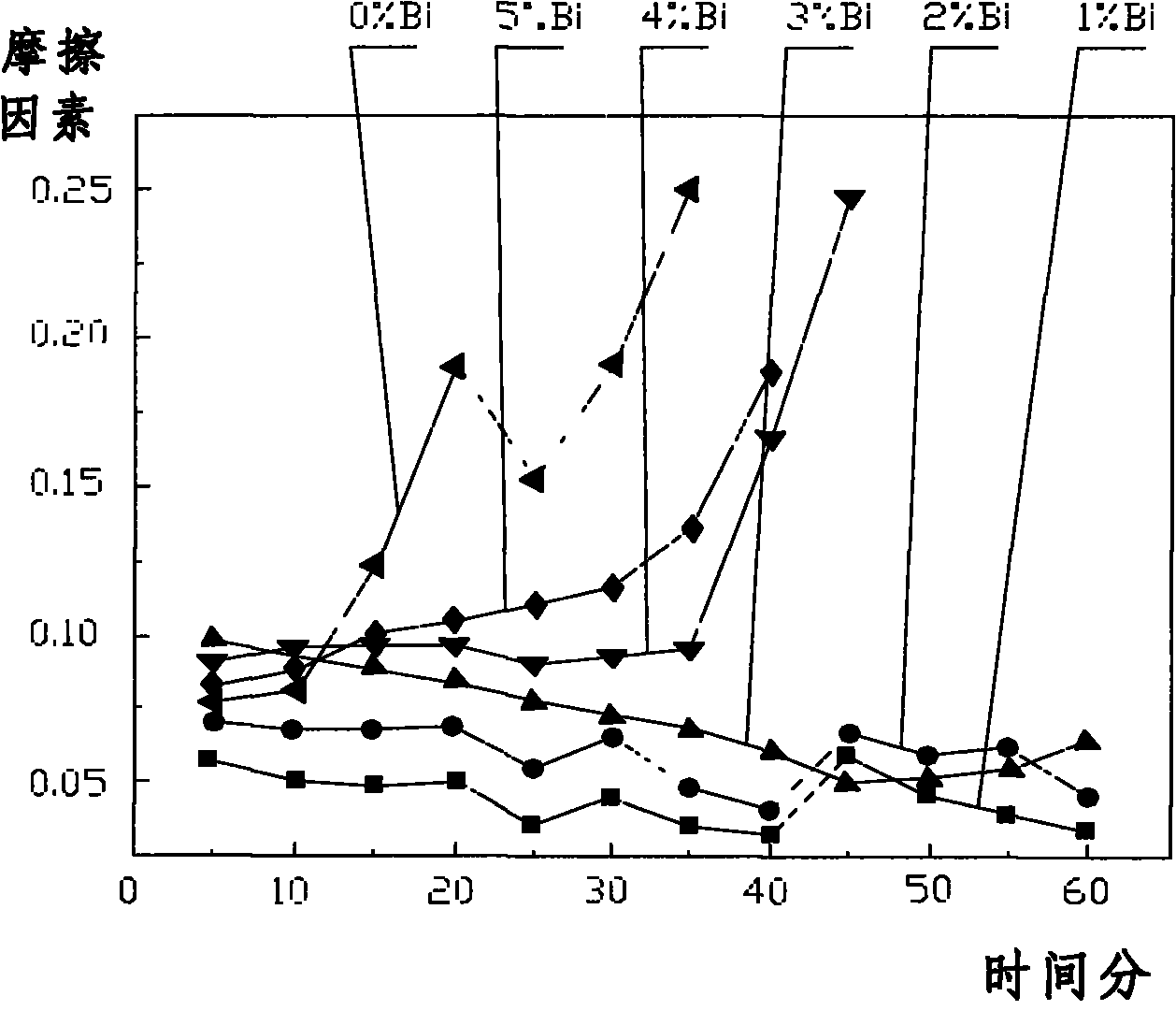

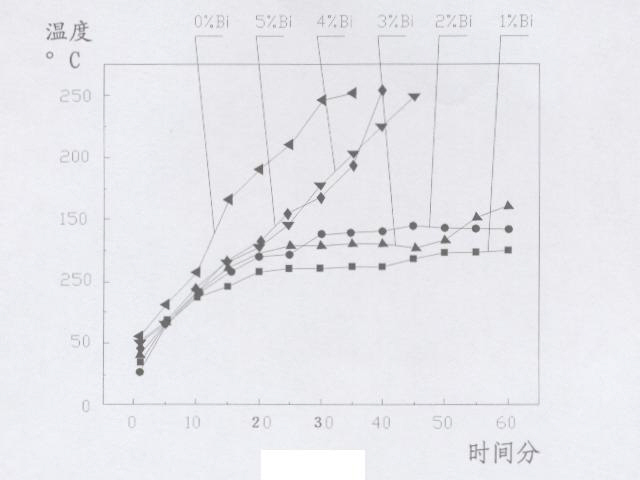

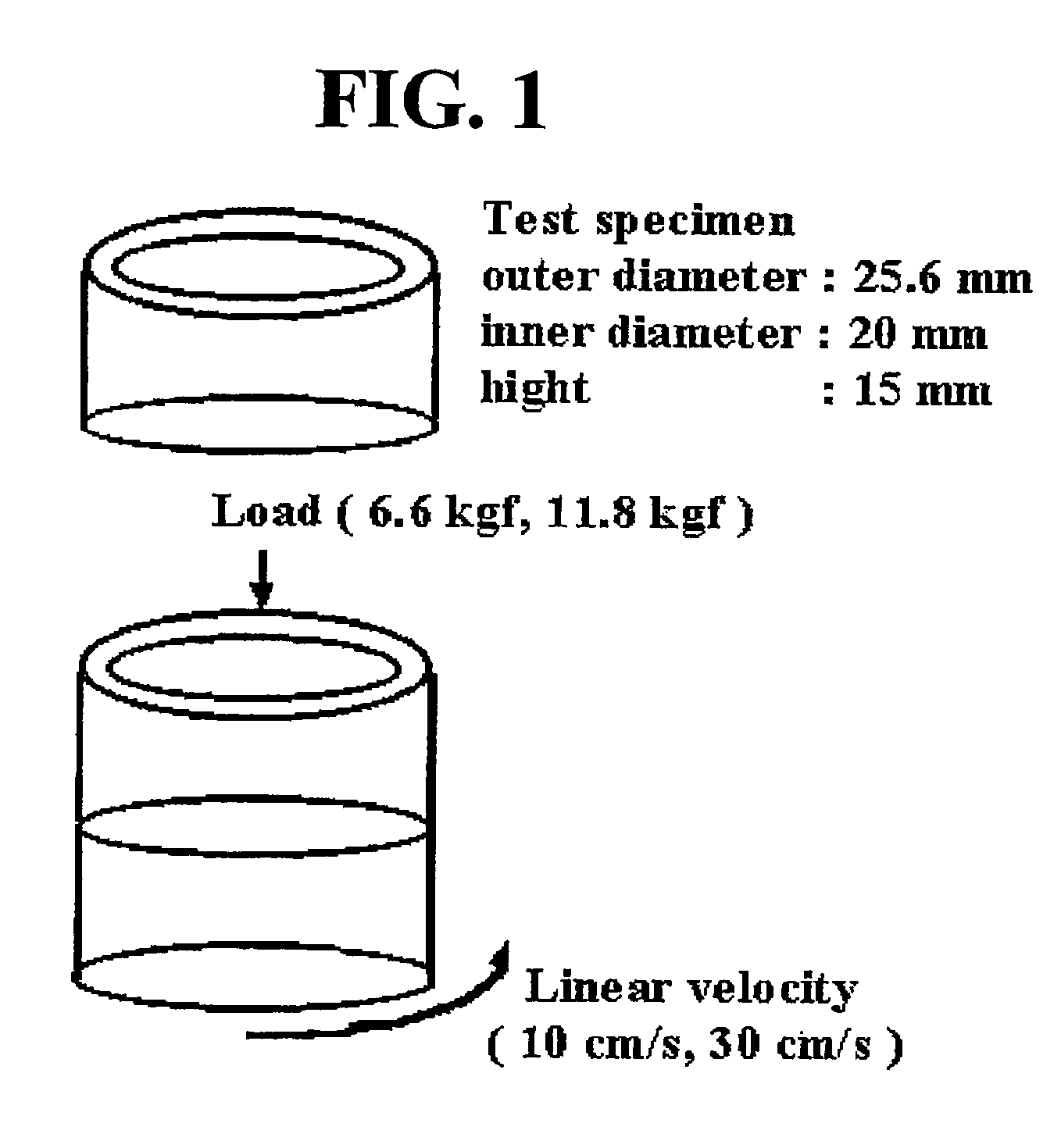

High-performance environmentally-friendly copper-bismuth dual-metal bearing material and manufacturing method thereof

The invention discloses a high-performance environmentally-friendly copper-bismuth dual-metal bearing material and a manufacturing method thereof and aims to provide a high-performance environmentally-friendly copper-bismuth dual-metal bearing material without containing lead which is harmful to a human body and a manufacturing method thereof. The high-performance environmentally-friendly copper-bismuth dual-metal bearing material is prepared by sintering a steel plate and a copper-based alloy wear-resisting layer and is characterized in that the copper-based alloy wear-resisting layer comprises the following components in percentage by weight: 1%-3% of bismuth, 5%-11% of tin and the balance of copper. The manufacturing method comprises the steps of: shearing and blanking of the steel plate, inspecting, powder spreading, primary sintering, rolling, secondary sintering, rerolling, and finally obtaining the finished plate product of the high-performance environmentally-friendly copper-bismuth dual-metal bearing material. As the bismuth is used for replacing lead in the copper-based alloy, the high-performance environmentally-friendly copper-bismuth dual-metal bearing material does not contain lead, is non-hazardous to the human body, does not pollute the environment and is an environmentally-friendly copper-based-steel dual-metal bearing material. Simultaneously, when the content of bismuth is 1.0-3.0wt%, the best frictional wear resistance of the high-performance environmentally-friendly copper-based-steel dual-metal bearing material is achieved; in addition, as the density of bismuth is less than that of lead, the manufactured bearing material is lighter than that containing lead.

Owner:HEFEI UNIV OF TECH +1

Wear-resistant hard composite material using graphene as filler and preparation method thereof

The invention belongs to the field of macromolecular composite materials and in particular relates to a wear-resistant hard composite material using a novel nanocarbon material graphene as a filler and a preparation method thereof. The composite material is a hard composite material plate formed by blending and hot-pressing a polymer matrix and the graphene, and is prepared through the following steps: mixing the graphene, the polymer matrix and a rare earth stabilizing agent uniformly; melting and blending by using a torque rheometer to obtain a block-shaped composite; hot-pressing by using a flat vulcanizing machine to obtain the hard composite plate, wherein the composite material comprises 0.1-3wt% of two-dimensional graphene nanocarbon material. The polymer-based composite material using the carbon material as the filler has the characteristics of light weight, easiness in processing, corrosion resistance, friction resistance and the like, and is widely applied in the fields of national defense industry and automobiles. The composite material can meet the increasingly higher tribological performance requirements of the fields of aviation, aerospace, automobiles, machinery and the like on the existing high-performance polymer composite materials; the preparation process of the composite material is simple; industrial production is realized easily.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

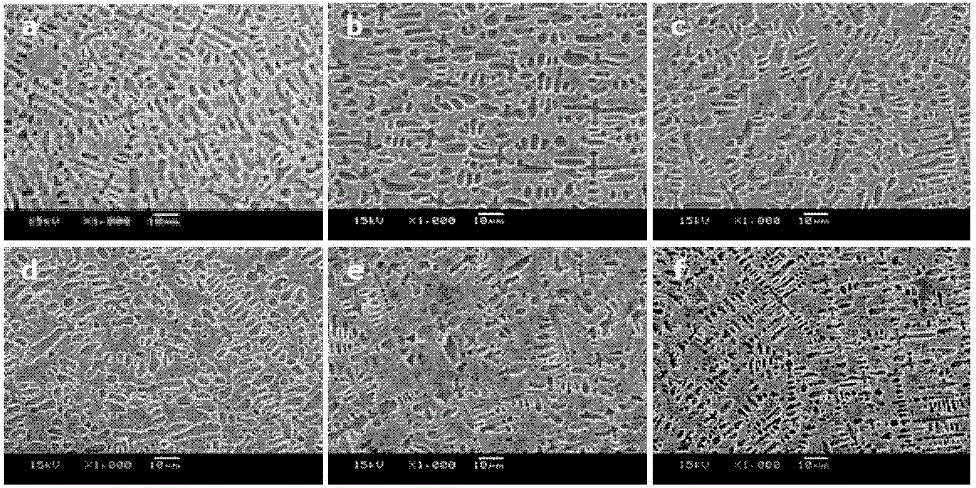

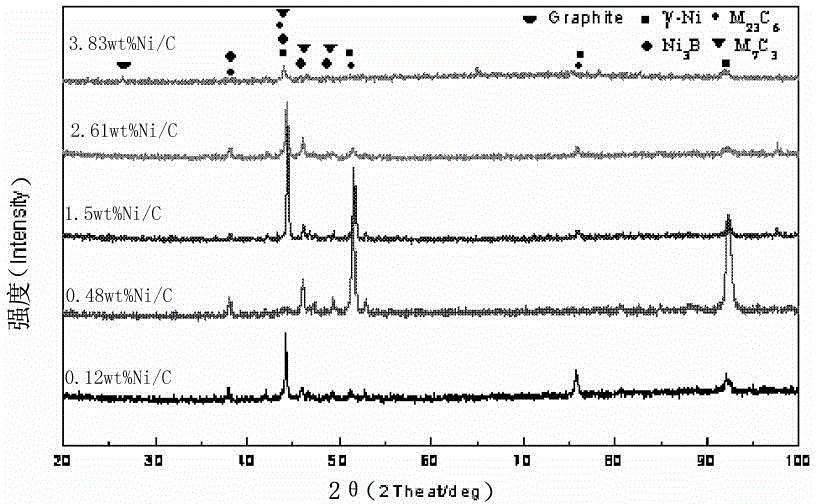

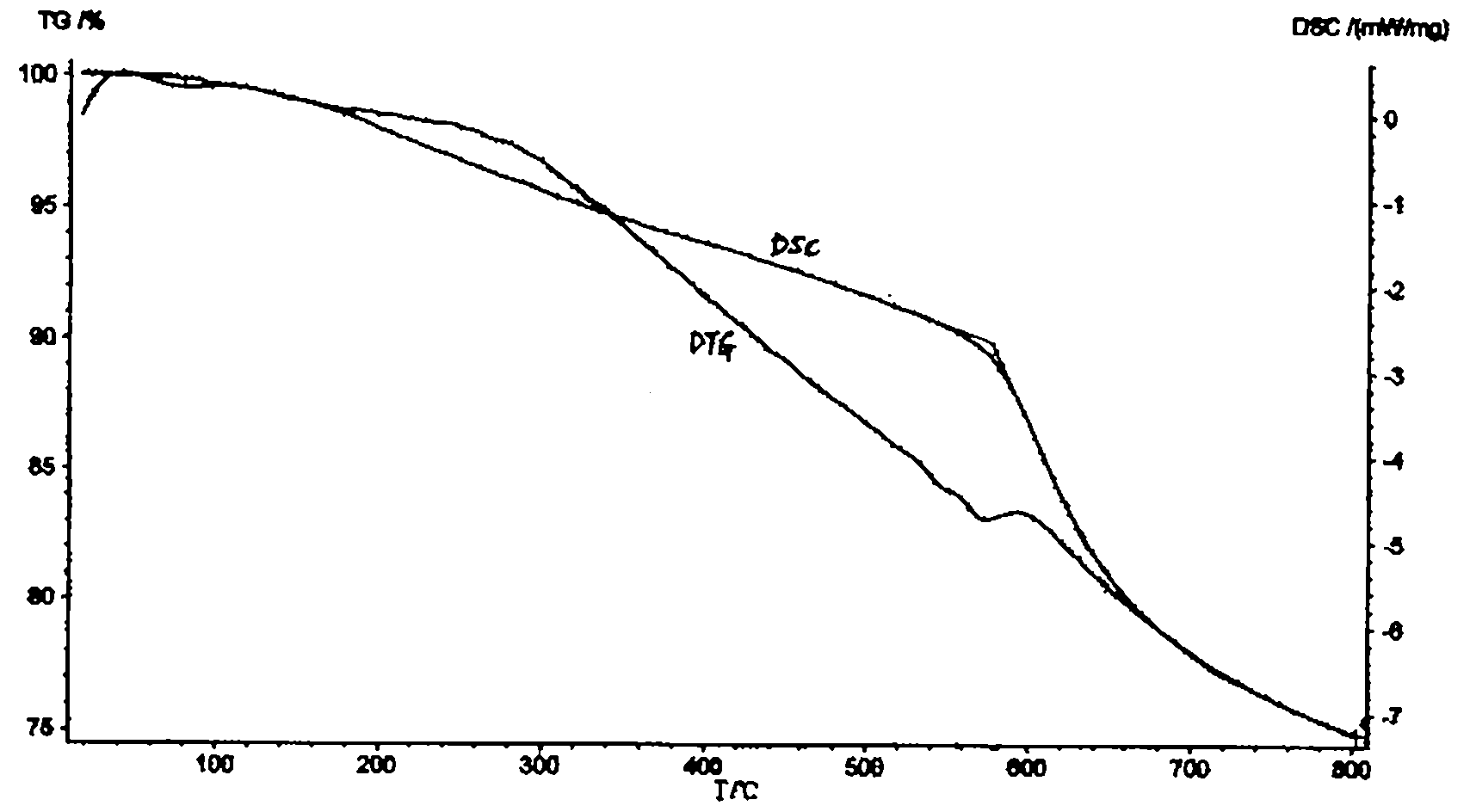

Nickel-coated graphite self-lubricating composite material and application thereof

ActiveCN103060614AGood wear resistanceGood wetting propertiesMetallic material coating processesCarbon steelGrinding

The invention relates to a nickel-coated graphite self-lubricating composite material and an application thereof. An employed technical scheme is that the nickel-coated graphite self-lubricating composite material is composed of, by weight percent: 95.0-99.9 % of self-melting alloy powder and 0.1-5.0 % of nickel-coated graphite. A laser cladding coating process comprises taking the self-melting alloy powder and the nickel-coated graphite, uniformly mixing by a ball milling method or a grinding method, using a preset method or a powder feeding method, and using a continuous CO2 laser device for laser cladding on a substrate. A content of the nickel-coated graphite varies widely. The nickel-coated graphite is uniform and dense in coating structure, excellent in wear resistance and antifriction performances, and good in metallurgy combination with substrates, can meet requirements of carbon steel and alloy steel for friction and wear performance in different working conditions. A coating preparation process is high in scale and automation degree, and thus the nickel-coated graphite self-lubricating composite material can be widely applied in fields of aerospace, machinery, automobile, military industry, etc.

Owner:SHENYANG AIRCRAFT CORP

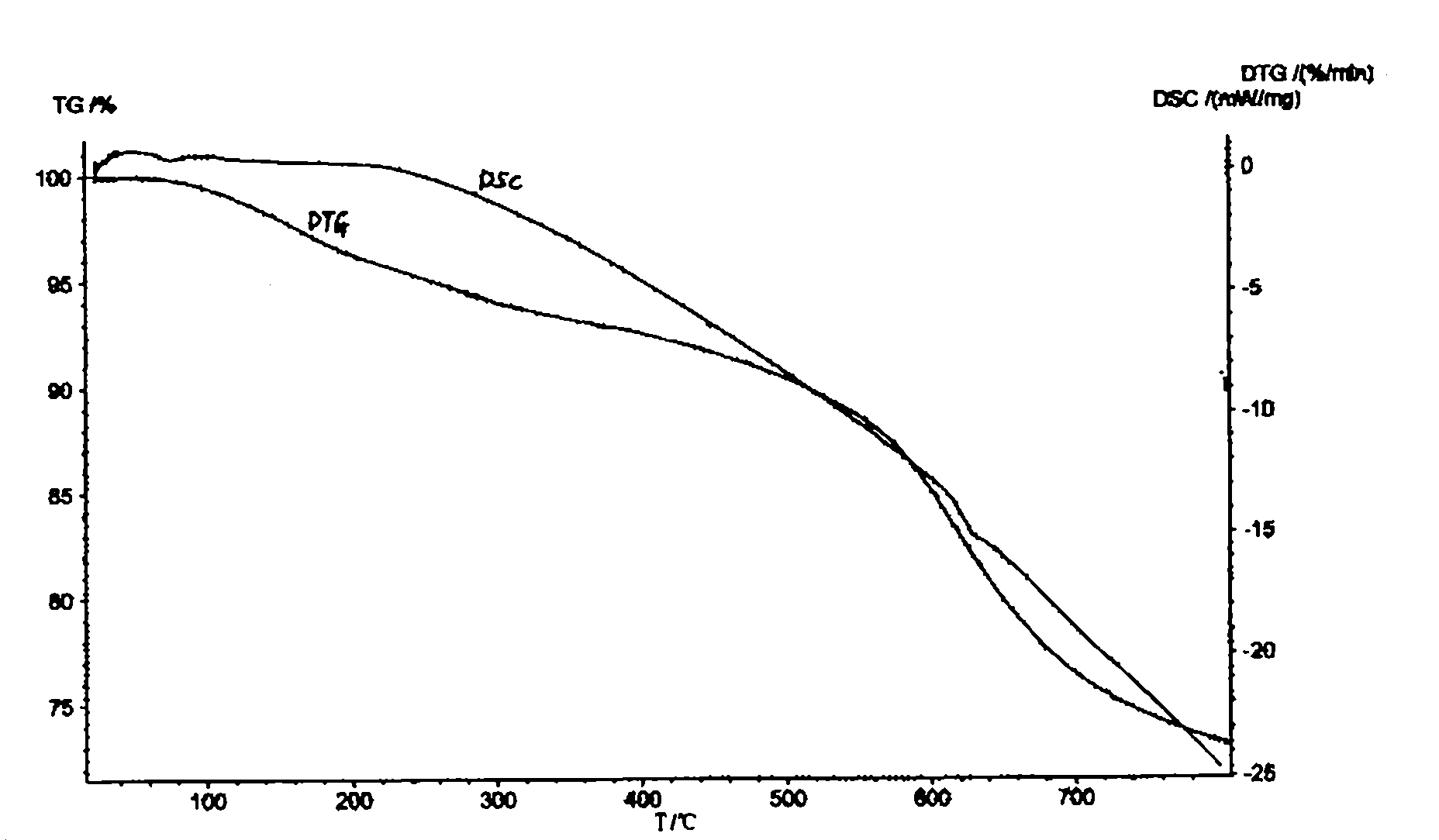

Organosilicon and titanium modified boron containing phenolic resin composite material and preparation method thereof

ActiveCN102329474AExcellent friction and wear resistanceImprove high temperature resistanceFiberOperability

The invention discloses an organosilicon and titanium modified boron containing phenolic resin composite material and a preparation method thereof. The composite material comprises 100 parts of boron containing phenolic resin, 20 to 30 parts of silicate ester, 10 to 20 parts of titanate, 30 to 50 parts of alcohol, 10 to 15 parts of friction modifier and 30 to 60 parts of fiber. A special raw material formula is adopted and the prepared composite material has excellent frictional wear resistance, high temperature resistance, moisture resistance and self-lubricating property; a preparation process for the modified phenolic resin is stable, high in operability and easy for industrial production; the composite material prepared from the modified phenolic resin is suitable for water scraping plates, sliding plates and the like in hot rolling and cold rolling production lines in the steel industry, friction plates in the fields of automobiles and high-speed rails, and other fields of high-temperature and low-temperature brake; and a manufacturing process is simple and is suitable for large-scale industrial production.

Owner:太仓力达莱特精密工业有限公司

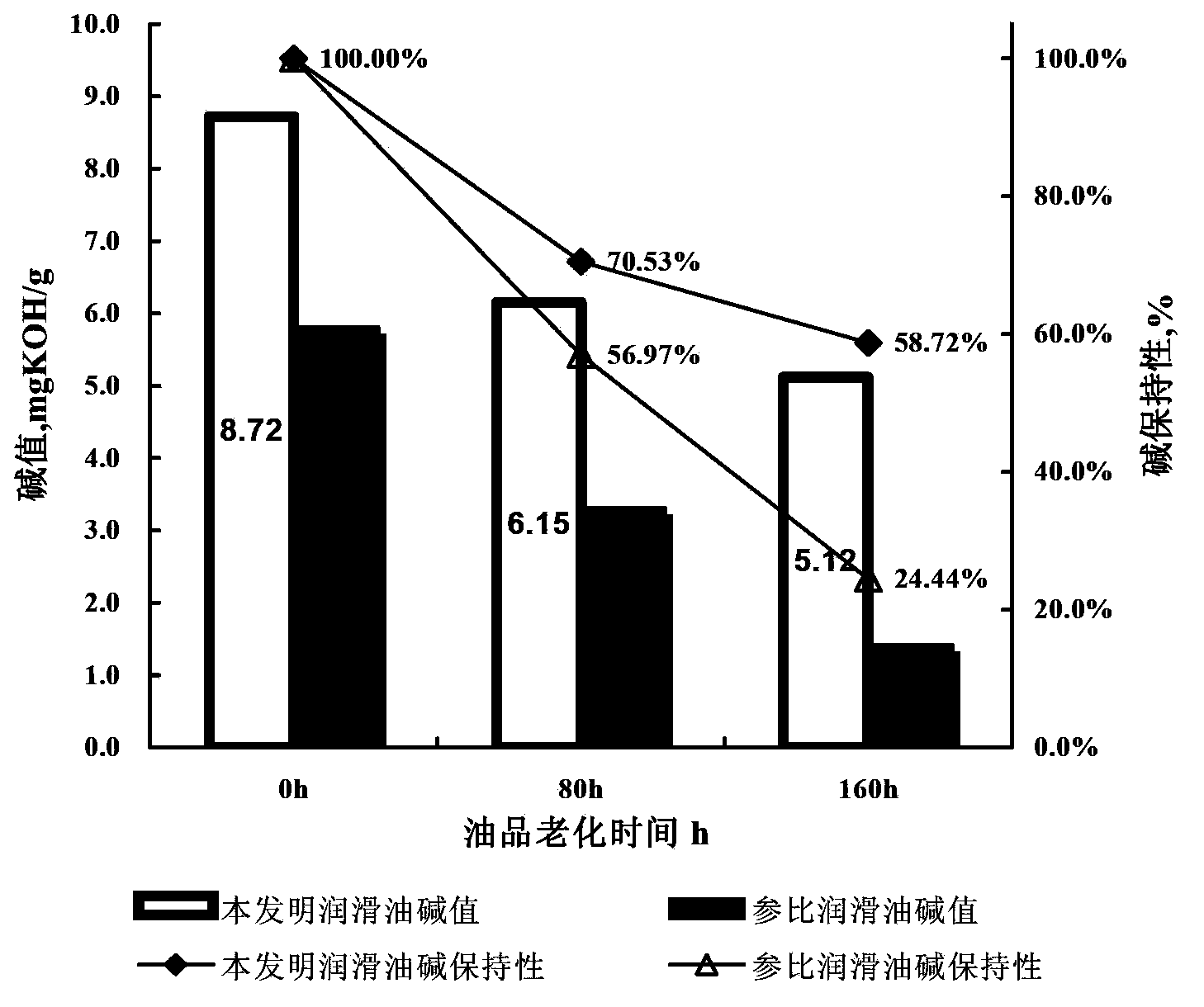

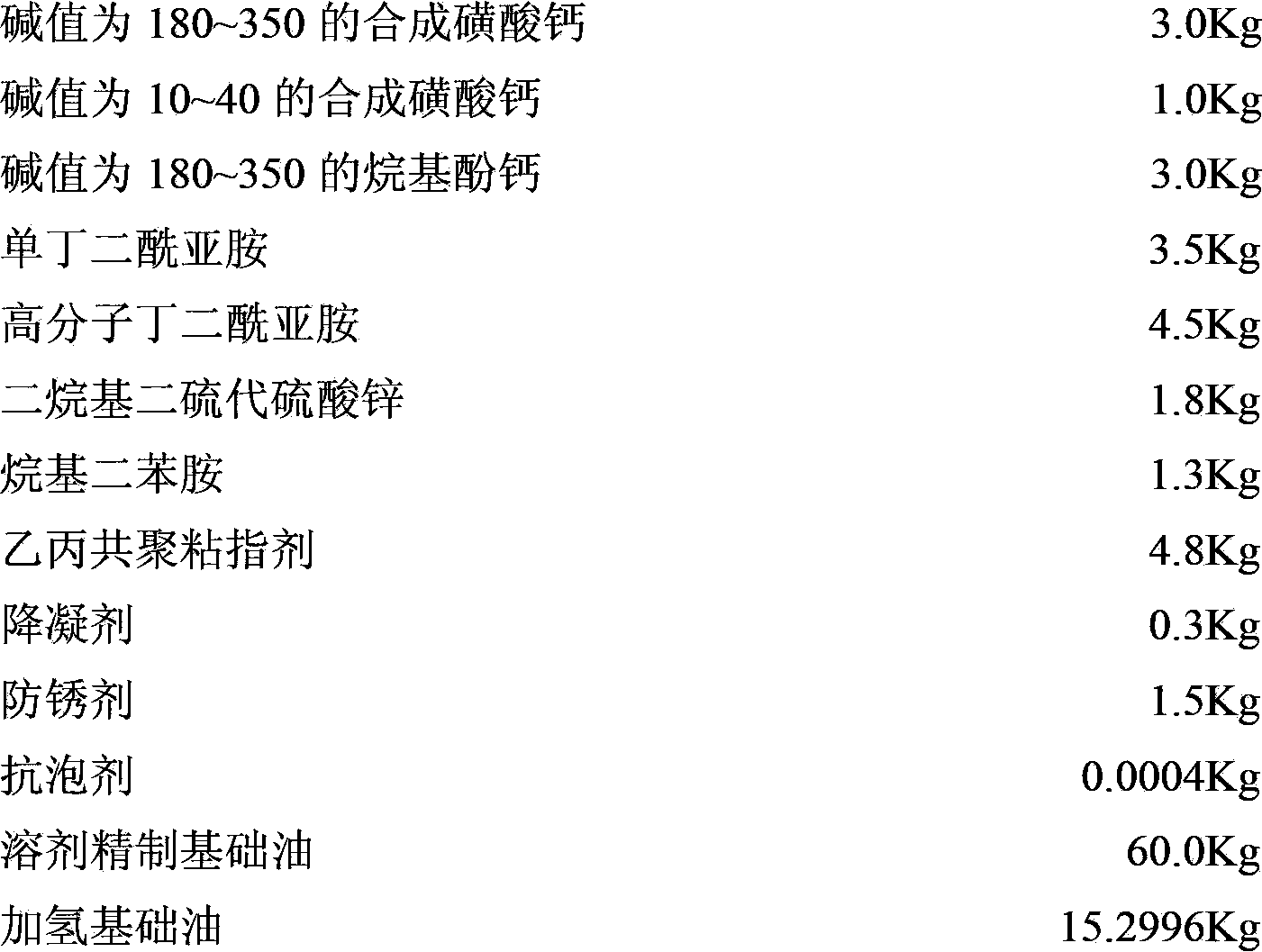

Lubricating oil composition for engine employing methanol or methanol gasoline as fuel

ActiveCN103509634AImprove performanceAvoid corrosion and wearAdditivesLubricationProcess engineering

The invention discloses a lubricating oil composition for an engine. The lubricating oil composition can be used for lubricating the engine employing methanol or methanol gasoline as a fuel. A prepared lubricating oil composition product can be used for better solving the problems of corrosion and abrasion of the engine employing the methanol gasoline, and has high acid neutralization performance, alkaline holding performance, abrasion resistance, detergency, dispersibility and oxidation resistance, the lubrication requirements of the engine employing the methanol gasoline can be met, and the lubrication requirements of the engine employing the methanol gasoline (M5 to M100) with any proportion can be met. The lubricating oil composition comprises at least one metal detergent, an ashless dispersant, an anti-oxidative, anticorrosive and anti-wear agent, a viscosity index improver, a pour point depressant, an antirusting agent, an anti-foaming agent and base oil.

Owner:PETROCHINA CO LTD

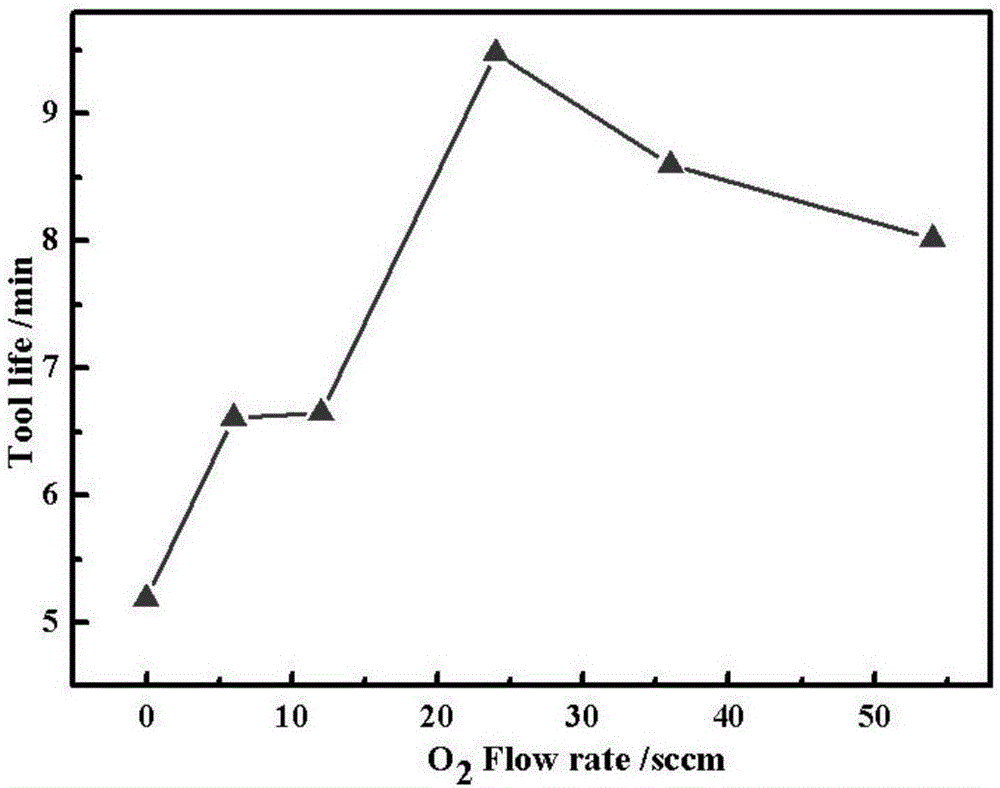

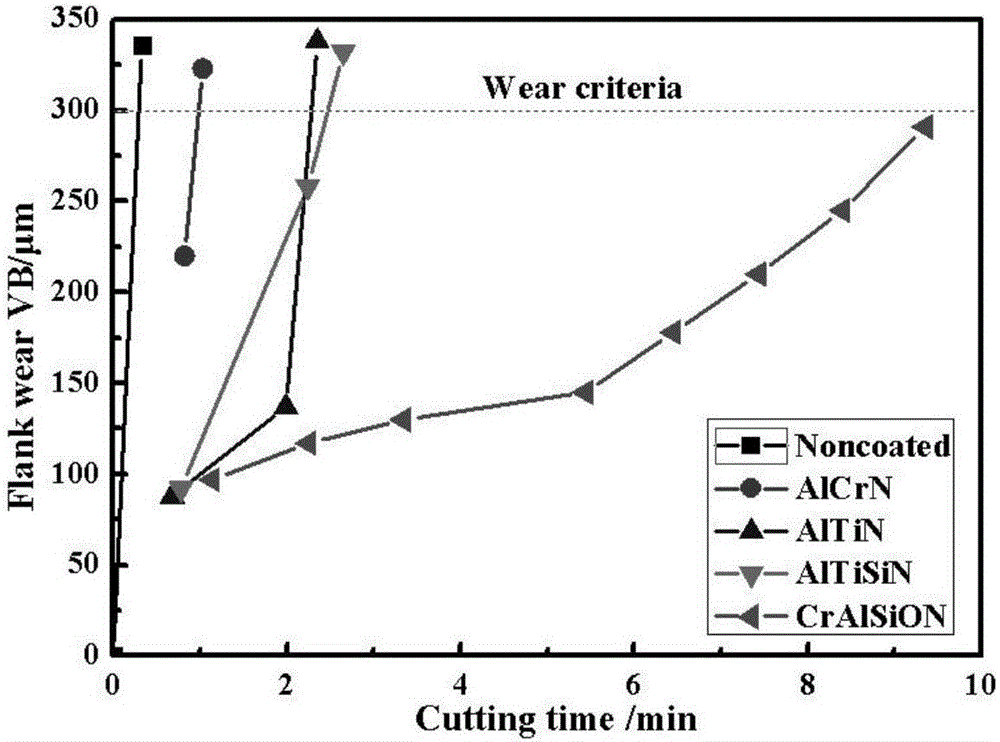

High-temperature abrasion-resistant CrAlSiON based nano-composite coating and preparation method and application thereof

ActiveCN106702331AReduce coefficient of frictionImprove bindingVacuum evaporation coatingSputtering coatingHardnessOxygen

The invention discloses a high-temperature abrasion-resistant CrAlSiON based nano-composite coating. The high-temperature abrasion-resistant CrAlSiON based nano-composite coating mainly comprises an AlTiN transition layer, a CrAlSiN supporting layer and a CrAlSiON functional layer. A multi-arc ion plating technology is adopted in the coating, and the CrAlSiON based nano-composite coating with different components can be obtained by changing technological parameters. An oxygen element is led into the CrAlSiON based nano-composite coating, the existence form of oxygen in the coating is controlled by changing the depositional condition, one or more sorts of oxide which is low in friction coefficient and resistant to abrasion can be pre-formed in the coating, and the binding force between coating bodies is increased; and meanwhile, the stress between the coating bodies and the friction coefficient under a high temperature condition are lowered, and friction resistance, abrasion resistance and thermal stability of the coating are improved, so that the coating is more suitable for a more demanding high-speed cutting and high-hardness environment, and the high-temperature abrasion-resistant CrAlSiON based nano-composite coating has great application prospects in the fields of cutters and surface protection.

Owner:GUANGDONG UNIV OF TECH

Metal ceramic powders used for thermal spraying on furnace roller surface

ActiveCN102191448AExcellent friction and wear resistanceReduced build-up resistanceMolten spray coatingThermal sprayingAlloy

The invention provides metal ceramic powders used for thermal spraying on a furnace roller surface. The metal ceramic powders, consisting of alloy powders and ceramic powders, comprise, by weight, 13-25% of Cr, 3-10% of Al, 0.1-1% of Y, less than 12% of Ta and balance being at least one of Co and Ni. The metal ceramic powders are characterized in that: the ceramic powders contain TiB2 and Al2O3, which account for, by weight, 15-25% of total weight of the metal ceramic powders. In the invention, anti-buildup performance and friction and wear resistance performance of thermal spray coatings made by the metal ceramic powders can be effectively improved. Excellent comprehensive properties can be maintained in harsh conditions of real production.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Vehicle braking composite material reinforced by confusion of natural fiber and crystal whisker and preparing method thereof

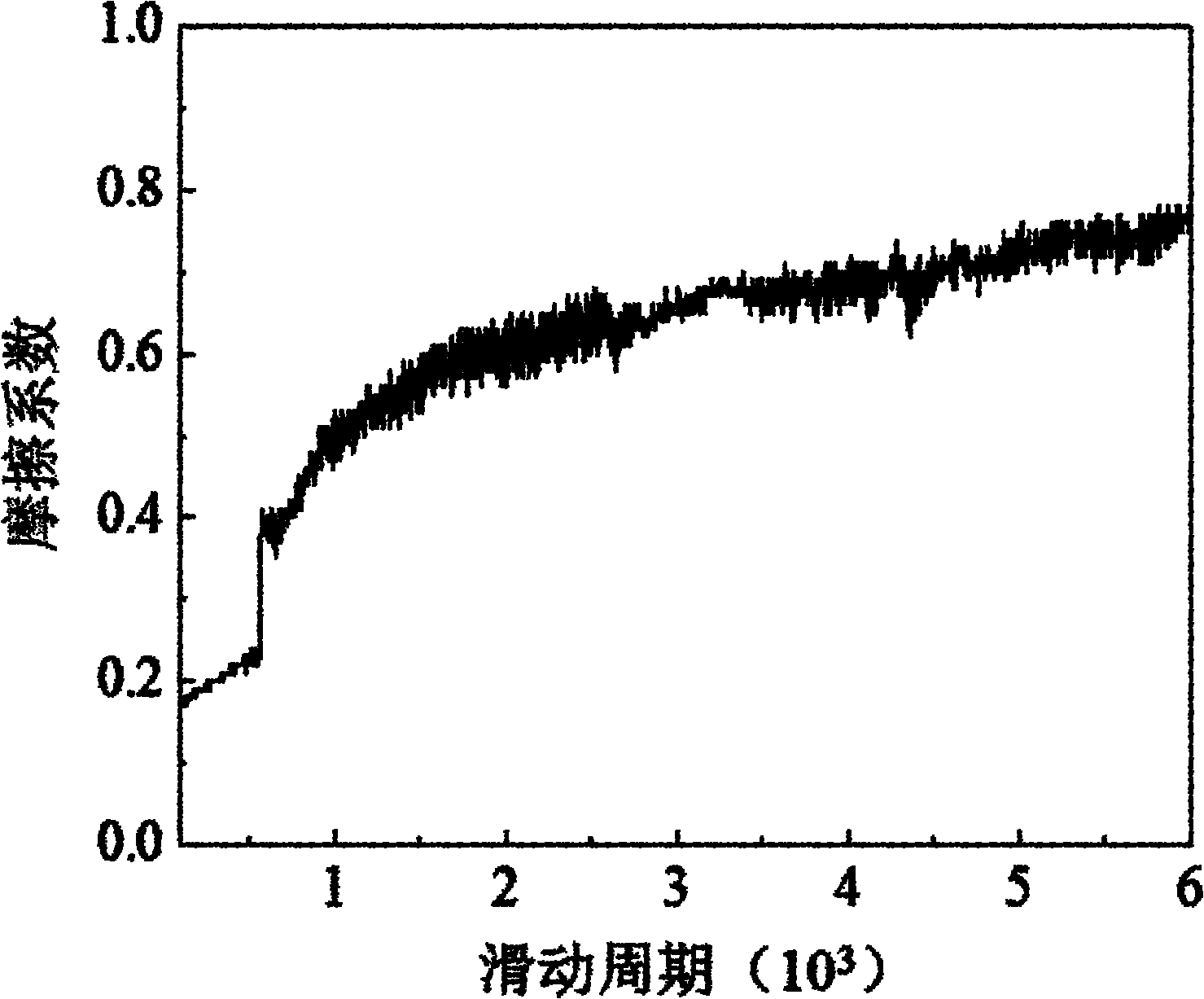

InactiveCN101514251AStable coefficient of frictionReduce wear rateFriction liningPyrophylliteConfusion

The present invention provides a vehicle braking composite material reinforced by confusion of natural fiber and crystal whisker and preparing method thereof. The raw materials of composite friction material is composed of bamboo fiber, phenolic resin, magnesium sulfate crystal whisker, steel fiber, copper powder, graphite dust, pyrophyllite powder, aluminum oxide, iron oxide, barium sulfate and zinc stearate. The preparing method comprises the following steps: preprocessing the raw materials, mixing the raw materials, hot pressing shaping and heat processing. The invention uses the bamboo fiber with low cost for reinforcing the phenolic resin. The proper amount of wear-increasing agent, anti-wear agent and filling agent for exerting the cooperative coupling function among the substrate, the fiber / crystal whisker and filling agent, thereby obtaining the novel vehicle braking composite material which has the advantages of stable friction coefficient under different temperatures, low wear rate, high heat fading resistance, excellent braking effect, shock absorbing, noise reduction and low cost.

Owner:FUZHOU UNIV

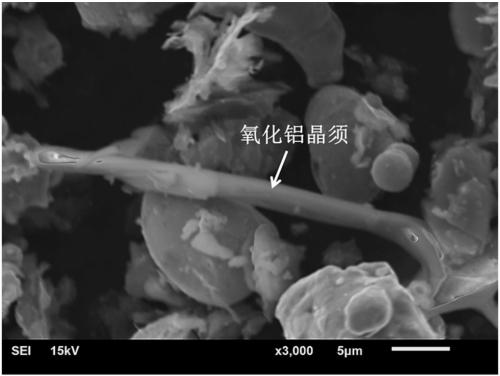

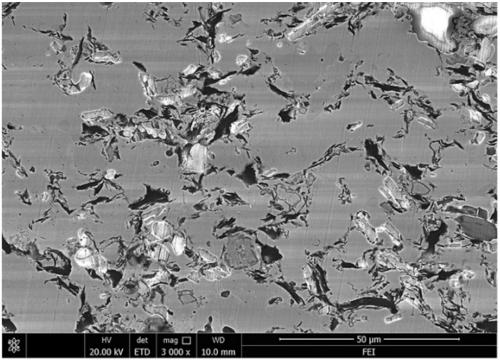

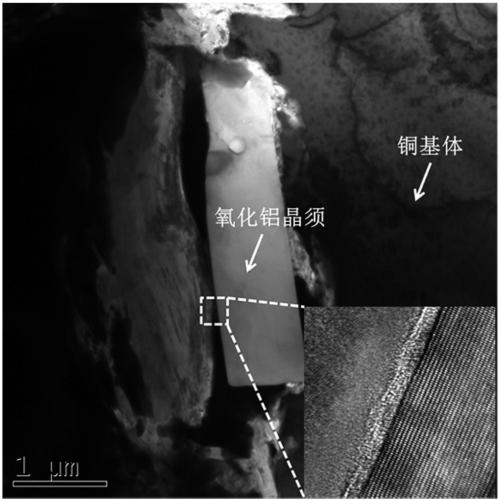

Aluminum oxide reinforced copper base composite material and preparation method thereof

The invention discloses an aluminum oxide reinforced copper base composite material. The aluminum oxide reinforced copper base composite material is characterized by comprising the following components in percentage by weight: 1-6% of modified ceramic aluminum oxide, 2-10% of graphite, 0.5-5% of Ti3SiC2, 2-8% of nickel, 2-8% of iron, 2-10% of tin, 1-5% of bismuth, 0.1-1% of zirconium oxide, 0.1-0.5% of lanthanum, and the balance of copper; and the modified ceramic aluminum oxide is surface-modified Al2O3 particles and surface-modified Al2O3 whiskers. The surfaces of the Al2O3 particles and theAl2O3 whiskers for the copper base composite material are modified by lauryl sodium sulfate water solution; through surface modification, the impurity content of the ceramic aluminum oxide is obviously reduced; multiple metal elements are matched for assisting and cooperating with a welding structure, so that the dispersibility is excellent, the ceramic aluminum oxide and a copper basal body arefirmly bonded, and the acceleration effect is prominently improved; and when the effect of external force is suffered, through excellent combined interfaces, the load transfer effect can be effectively achieved, the stress concentration is reduced, and defects are reduced.

Owner:SOUTHWEST JIAOTONG UNIV

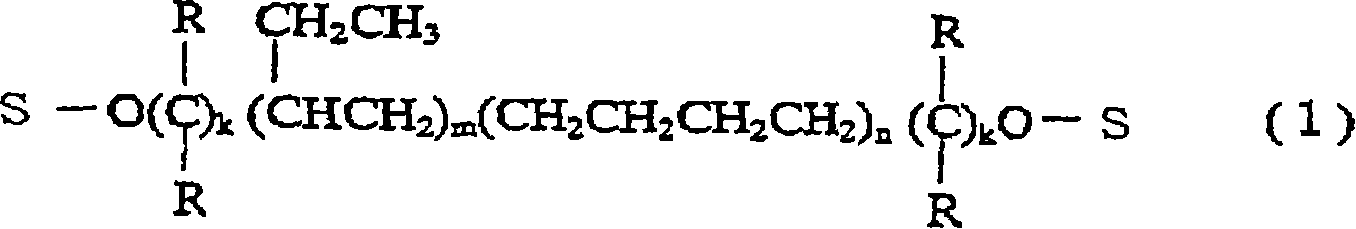

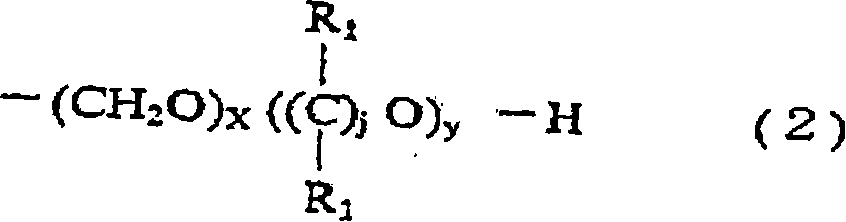

Polyoxymethylene resin composition and moldings thereof

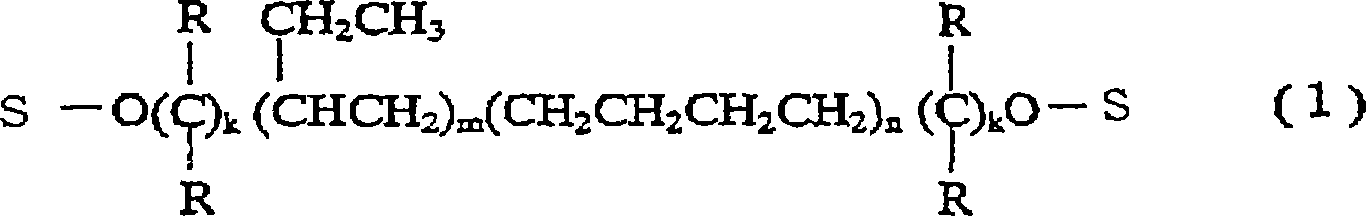

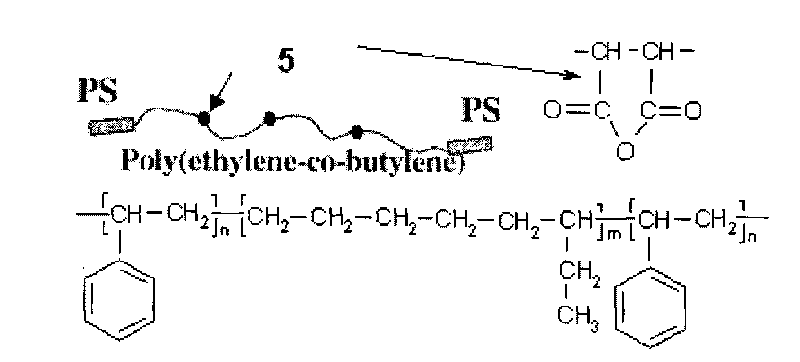

A polyoxymethylene resin composition which comprises (A) a polyoxymethylene resin, (B) a polymer having at least one block made of a hydrogenated aromatic vinyl-conjugated diene random copolymer having the main dispersion peak of tan delta at 60 DEG C or below in the viscoelastic spectrum, and, if necessary, (C) a polyolefin resin with the provisos that the amount of (A) is 10 to 99.5 parts by weight and the total amount of (B) and (C) is 0.5 to 90 parts by weight, each per 100 parts by weight of the sum of (A), (B) and (C) and that the (B) / (C) weight ratio is 100 / 0 to 20 / 80.

Owner:ASAHI KASEI KK

High-hardness wear-resistant wheel steel and wheel preparation method

InactiveCN106435365AImprove the hardnessExcellent overall performanceFurnace typesHeat treatment furnacesWear resistantChemical composition

The invention relates to wheel steel for a wheel and a preparation method therefor. The wheel steel comprises the chemical components in percentages by weight: 0.70-0.80% of C, 0.70-1.80% of Si, 0.40-1.00% of Mn, 0.15-0.30% of Cr, 0.05-0.13% of V, less than or equal to 0.012% of P, less than or equal to 0.012% of S and the balance of Fe and inevitable impurity elements. A C-Cr-V high-hardness wear-resistant wheel is prepared through the steps of electric furnace smelting continuous casting, ingot-slicing rolling, thermal treatment and the like. Compared with an AAR-C wheel steel, the prepared wheel can obviously improve the strength and hardness of the wheel, and a good comprehensive performance is obtained. Meanwhile, the high-temperature mechanical property and the friction-resistant and abrasion-resistant properties of the wheel are improved. At the same time, the wheel prepared from the wheel steel provided by the invention can maintain the texture of the original wheel, and the difficulty of preparing the wheel is not increased.

Owner:MAANSHAN IRON & STEEL CO LTD

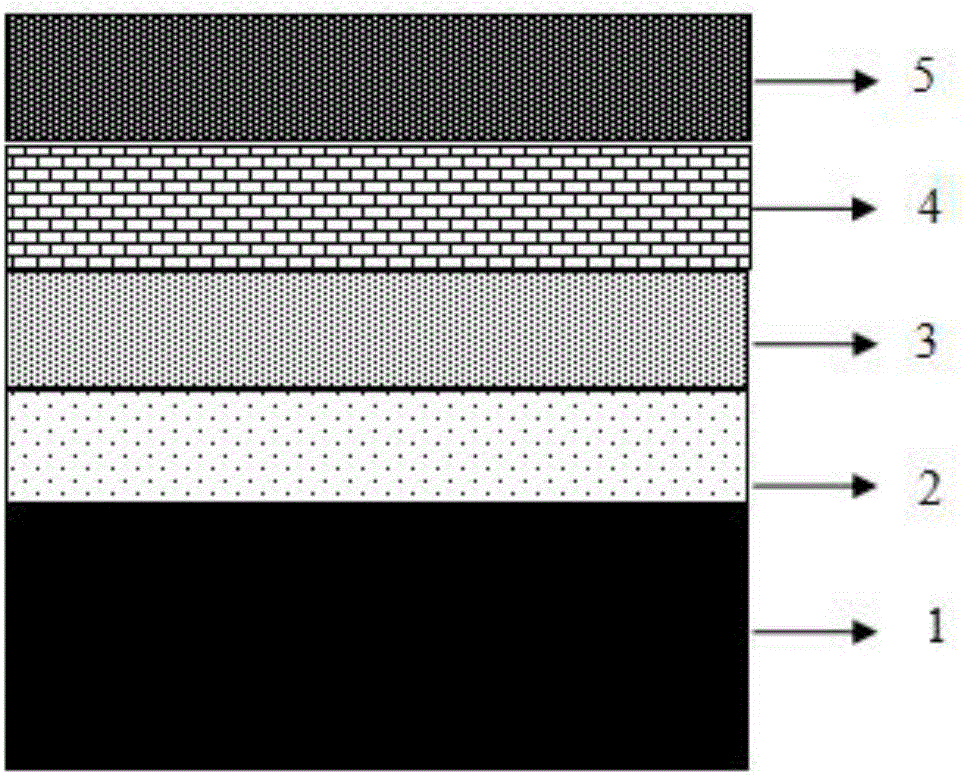

Multilayer film for low load working condition of micro electro mechanical system and preparation method thereof

InactiveCN101734610AExcellent friction and wear resistanceReduce energy dissipationTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElastomerChemical reaction

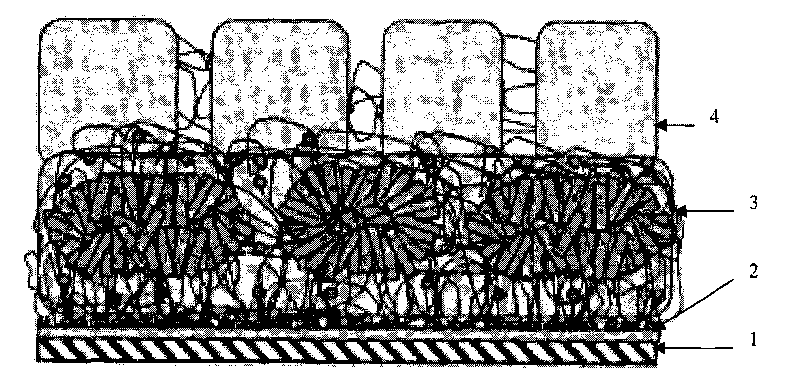

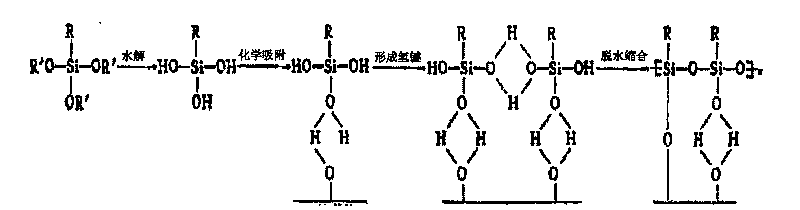

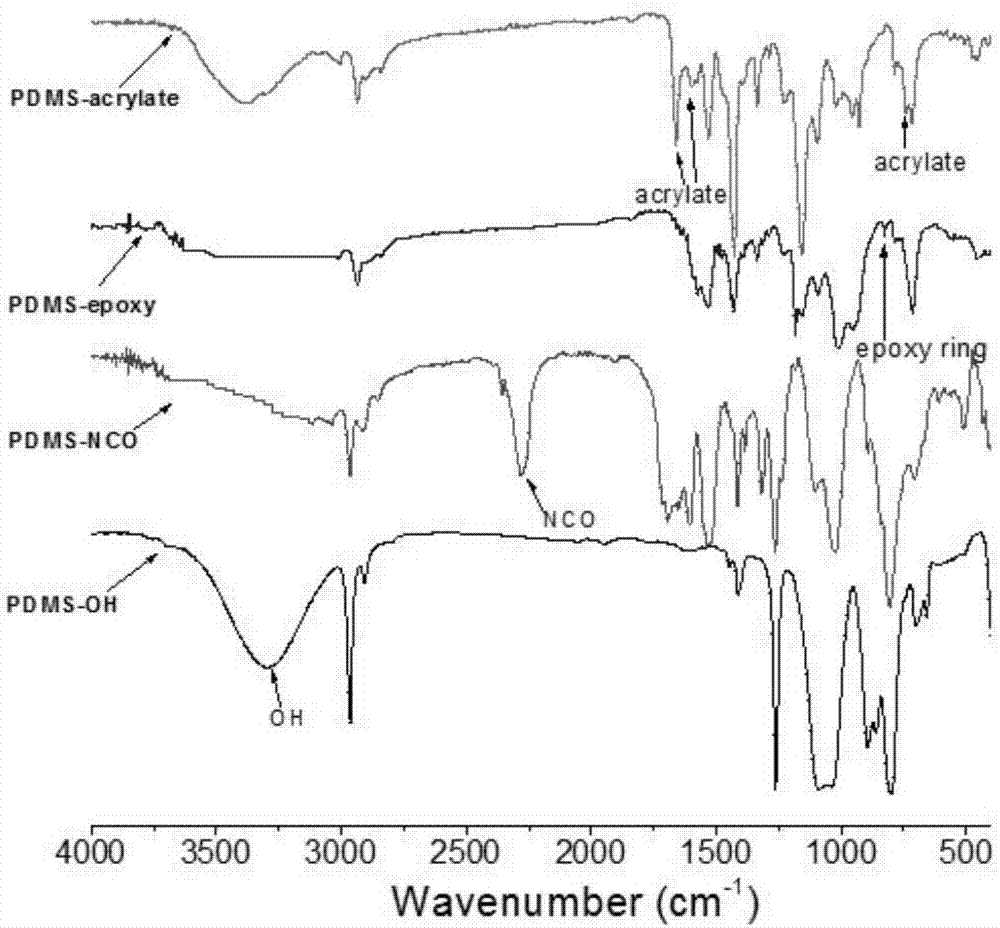

The invention provides a multilayer film for a low load working condition of a micro electro mechanical system and a preparation method thereof. The multilayer film comprises a coupling agent layer, an elastomer layer and a hard film layer sequentially from bottom to top, wherein, the coupling agent layer and the elastomer layer are combined by chemical reaction, and the hard film layer is deposited on the surface of the elastomer layer. The preparation method comprises the following steps: cleaning an Si chip to remove organic impurities and surface oxide; carrying out hydroxylation on the cleaned silicon chip; allowing a commercially available silane coupling agent containing ethoxy to react with the hydroxylated silicon surface by a self-assembly technique so as to link the coupling agent with the silicon surface through chemical bonds; then allowing maleic anhydride on thermoelastic plastics to react with amido on the coupling agent by the self-assembly technique again to complete the chemical bond linkage of the coupling agent and the elastomer; and depositing an DLC film on the surface of the elastomer. The film prepared by the invention can improve the friction and wear resistance of silicon devices, reduce energy dissipation generated in the friction process of materials, and improve the tribological performance of the materials.

Owner:JIANGSU UNIV

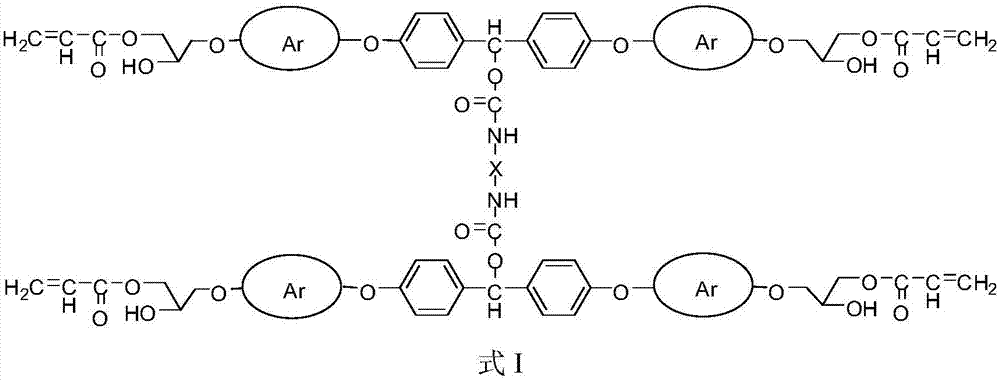

High-wear-resistance photocuring aromatic ether-based epoxy acrylate/nanosilicon dioxide composite material and preparation method thereof

InactiveCN106928659AHigh UV curing activityHigh tetrafunctionalityFireproof paintsEpoxy resin coatingsKetoneSilicon dioxide

The invention discloses an aromatic ether-based epoxy acrylate / nanosilicon dioxide composite material and a preparation method and applications thereof. The preparation method comprises the following steps: synthesizing a bisphenol compound of an aromatic ether ketone chain segment based on substitution reaction, performing reduction of carbonyl, phenolic hydroxyl epoxy acylation, and bridging of isocyanate group of alcoholic hydroxyl group, to prepare a four-degree-functionality epoxy acrylate compound, then mixing sulfdryl-modified nanosilicon dioxide particles, and performing ultraviolet photocuring to prepare an aromatic ether-based epoxy acrylate / nanosilicon dioxide composite material. The method is simple to operate, convenient and easy. Compared with a pure acrylate material, the composite material has the advantages of high wear resistance, high hardness, excellent thermal / chemical stability and the like after being subjected to ultraviolet photocuring, thus having wide industrial application prospects.

Owner:CENT SOUTH UNIV

Polyacetal resin composition having excellent wear resistance and abruption-preventing effect

InactiveUS7098262B2Excellent friction and wear resistanceExcellent abruption-preventing effect upon moldingConveyorsOrganic compound preparationPolyethylene vinyl acetateHeat resistance

Disclosed is a polyacetal resin composition including a polyoxymethylene homopolymer or copolymer, an antioxidant, a thermal stabilizer, a polyethylene vinylacetate copolymer and hydroxyl pentacrythritol fatty acid ester. The polyacetal resin composition is excellent in mechanical properties, chemical resistance, heat resistance, dimensional stability, and electrical properties. Further, the composition is advantageous in terms of superior wear resistance and abruption-preventing effect.

Owner:KOREA ENG PLASTICS CO LTD

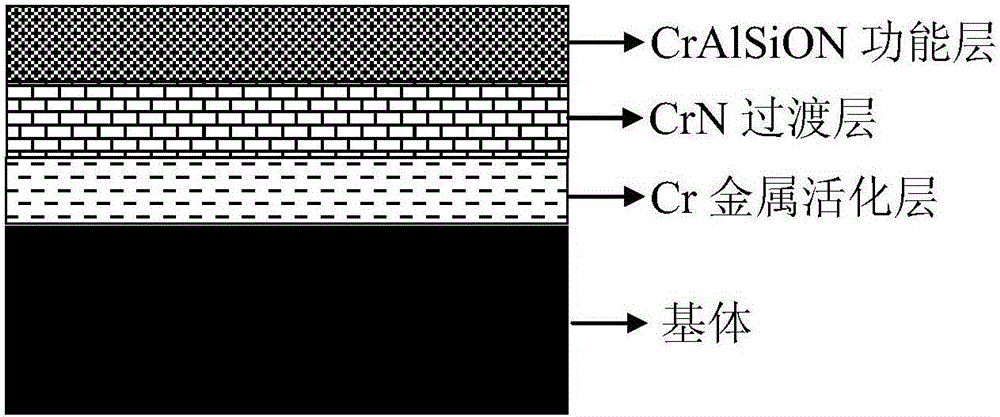

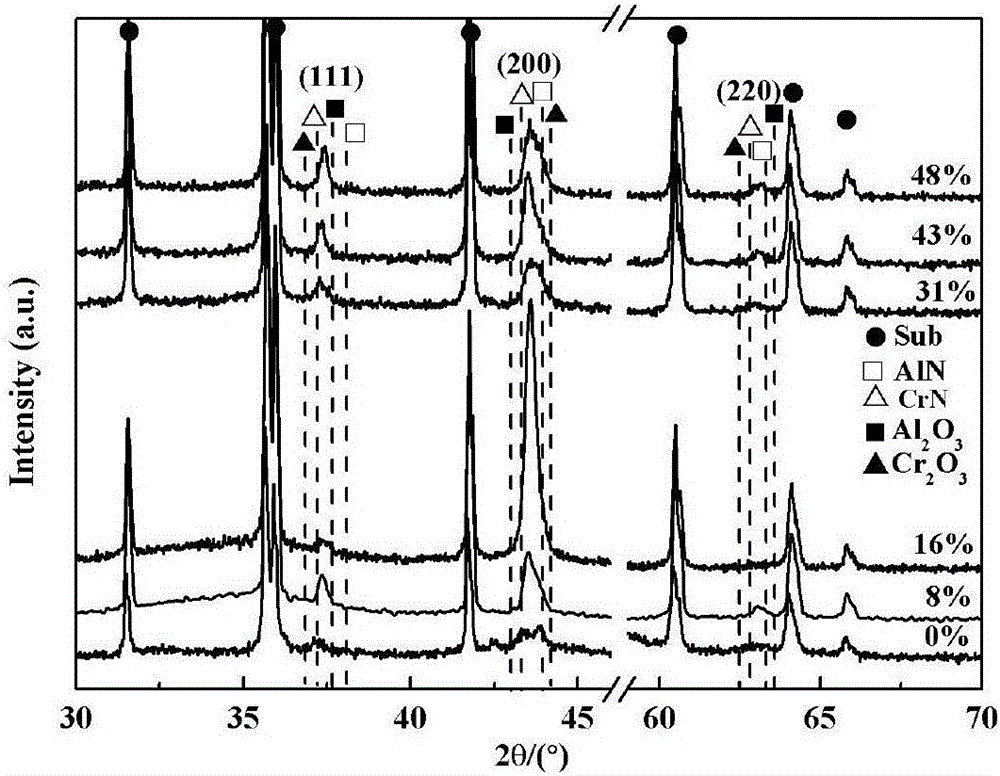

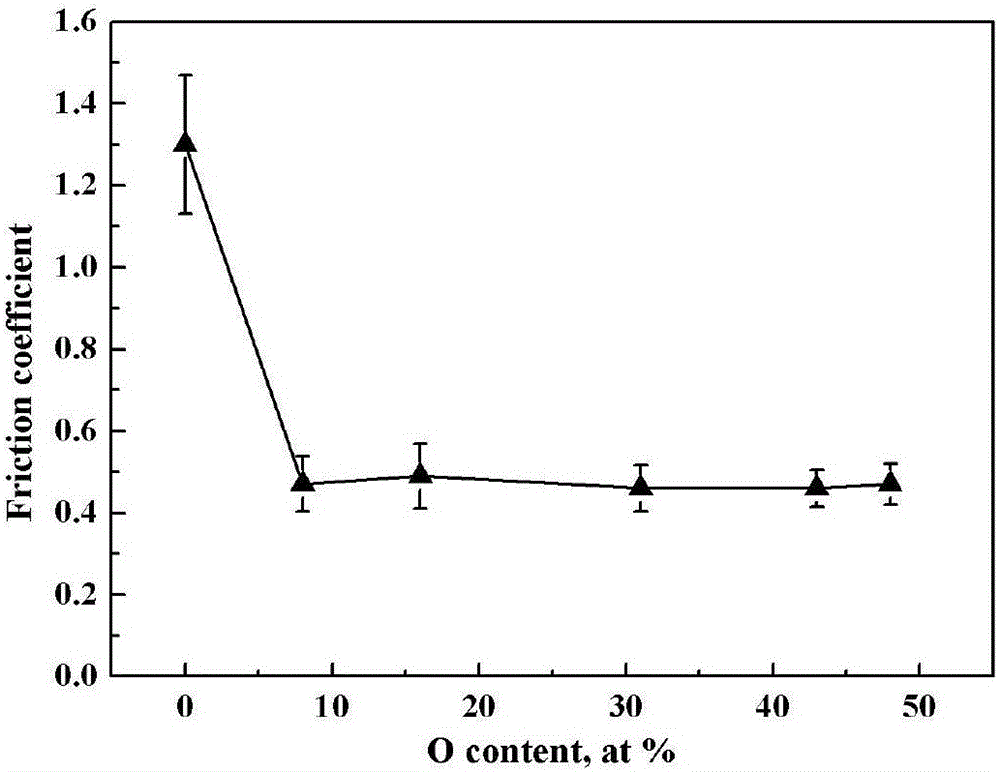

High-temperature low-friction CrAlSiON nanometer composite coating and preparation method thereof

InactiveCN106191791AImprove coating adhesionReduce coefficient of frictionVacuum evaporation coatingSputtering coatingBinding forceOxide

The invention discloses a high-temperature low-friction CrAlSiON nanometer composite coating which comprises a CrN transition layer and a CrAlSiON functional layer. The coating with different components can be obtained by adopting a multi-arc ion plating technique through changing technological parameters. According to a preparation method of the coating, oxygen element is introduced into the CrAlSiON nanometer composite coating, and the existence form of oxygen in the coating is controlled by changing depositional conditions, so that one or more oxides being low in friction coefficient and resistant to abrasion can be preformed in the coating; accordingly, while the binding force of the coating is improved and the stress is reduced, the friction coefficient of the coating under the high-temperature condition can be lowered, as well as the friction resistance, the abrasion resistance and the thermal stability of the coating can be improved; and the coating is more suitable for a severer application environment.

Owner:GUANGDONG UNIV OF TECH

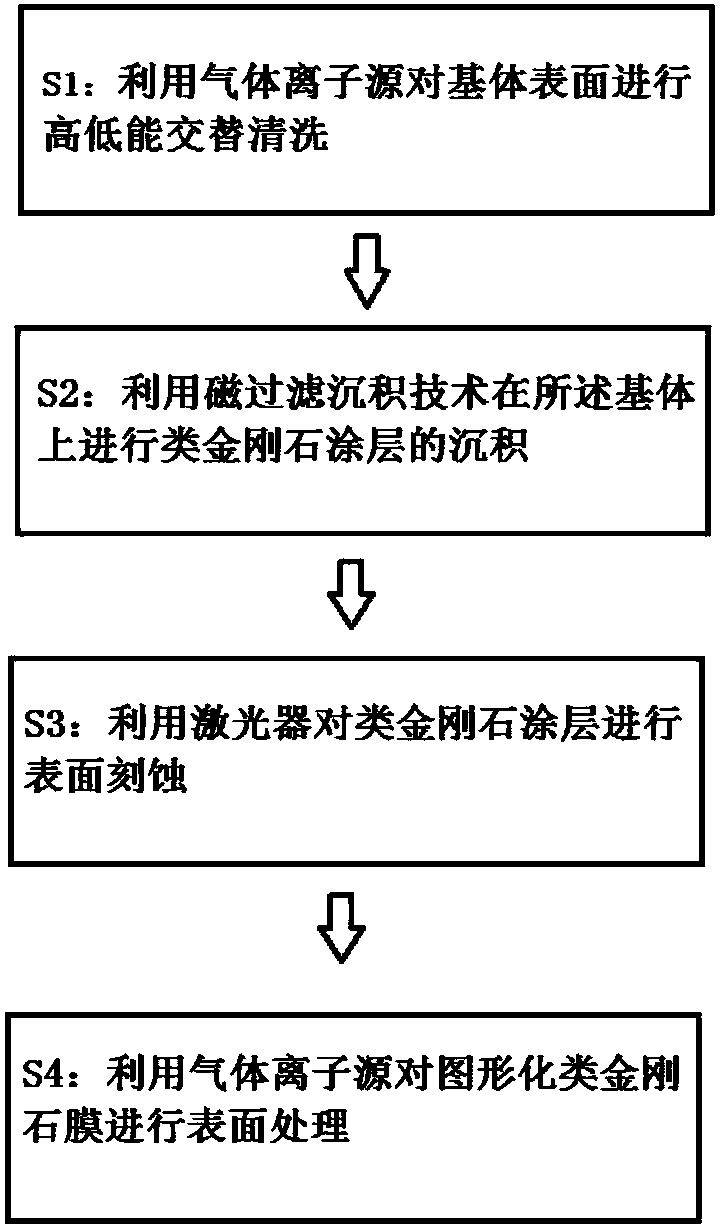

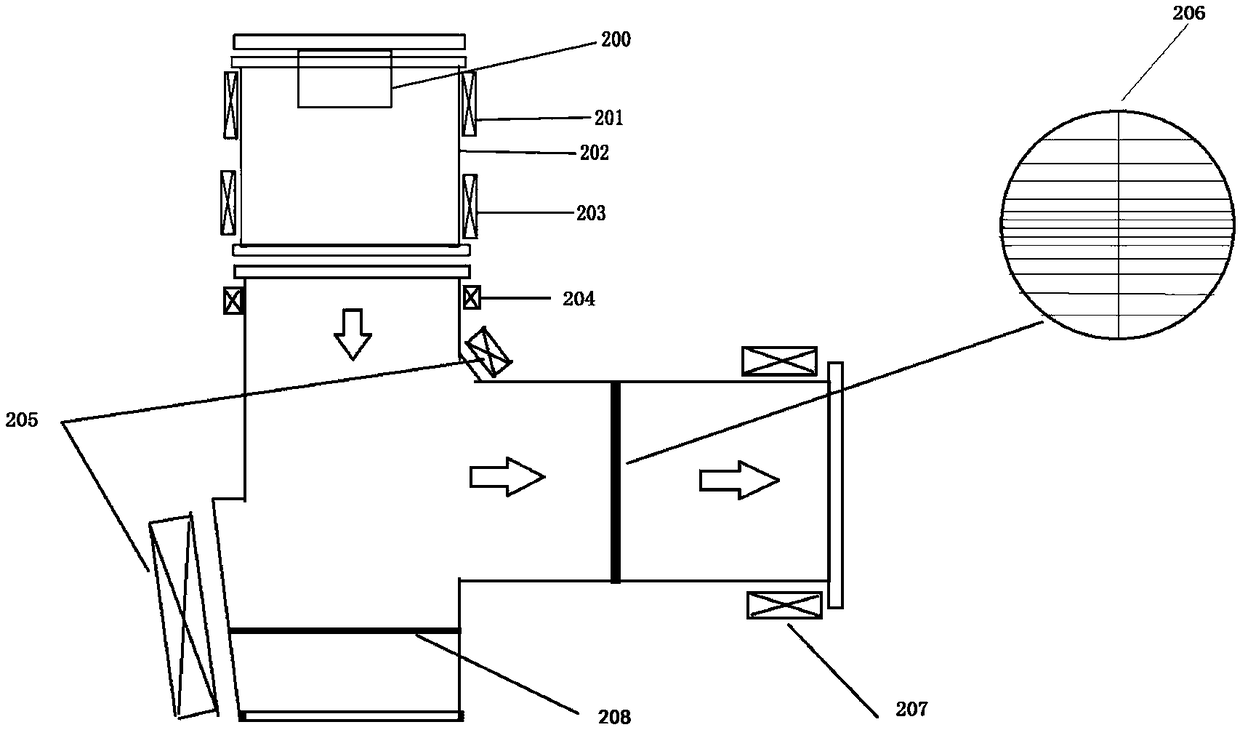

Preparation method of anti-abrasion diamond-like carbon coating layer

ActiveCN108359942AImprove compactnessExcellent friction and wear resistanceVacuum evaporation coatingSputtering coatingCarbon filmCarbon coating

The invention discloses a preparation method of an anti-abrasion diamond-like carbon coating layer. The preparation method comprises the following steps that S1, the surface of a substrate is subjected to high and low energy alternate cleaning through a gas ion source; S2, a diamond-like carbon coating layer is deposited on the substrate is through a magnetic filtering deposition technique with acarbon target as a cathode, wherein the method is high in deposition rate, low in cost and capable of achieving mass production; S3, the diamond-like carbon coating layer is subjected to surface etching through a laser device, and the etching interval is 2-10 [mu]m; and S4, a graphical diamond-like carbon film is subjected to surface treatment through the gas ion source. The coating layer preparedthrough the method is of a structure that the high-sp3 content and low-sp3 content of tetrahedron armorphous carbon are alternately changed; and the coating layer has the anti-abrasion performance and is higher in crack growing preventing capacity and friction and abrasion preventing performance compared with hydrogen containing diamond-like carbon, diamond-like carbon high in sp3 content and diamond-like carbon low in sp3 content.

Owner:BEIJING NORMAL UNIVERSITY

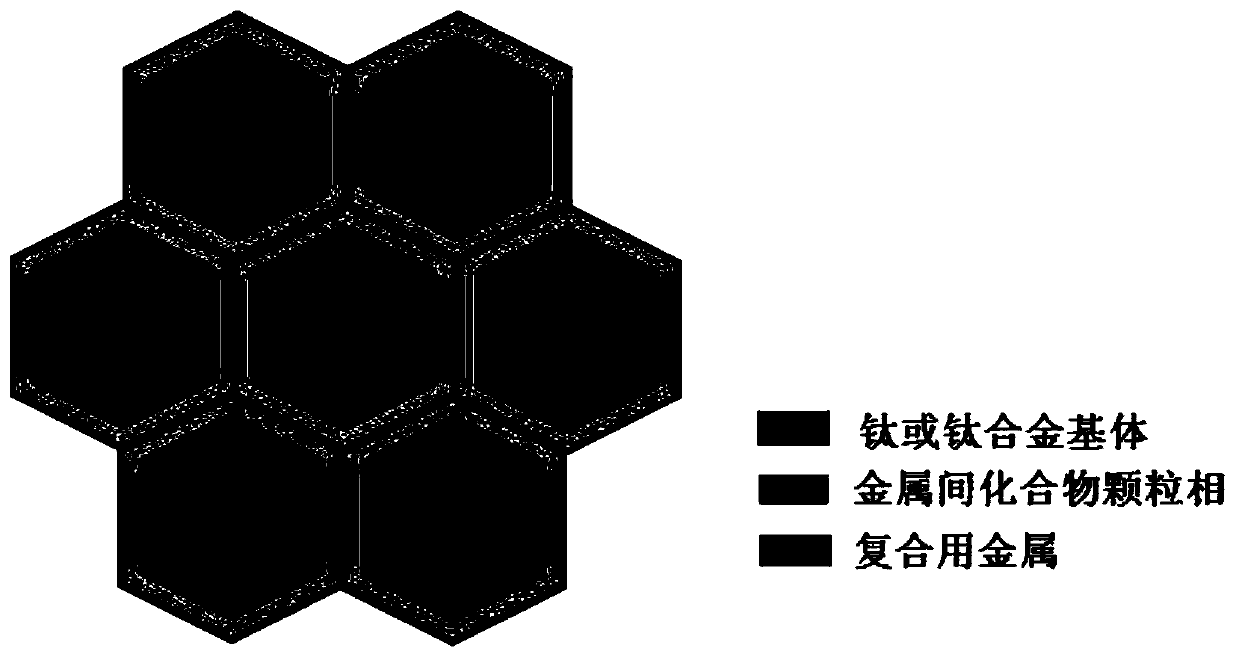

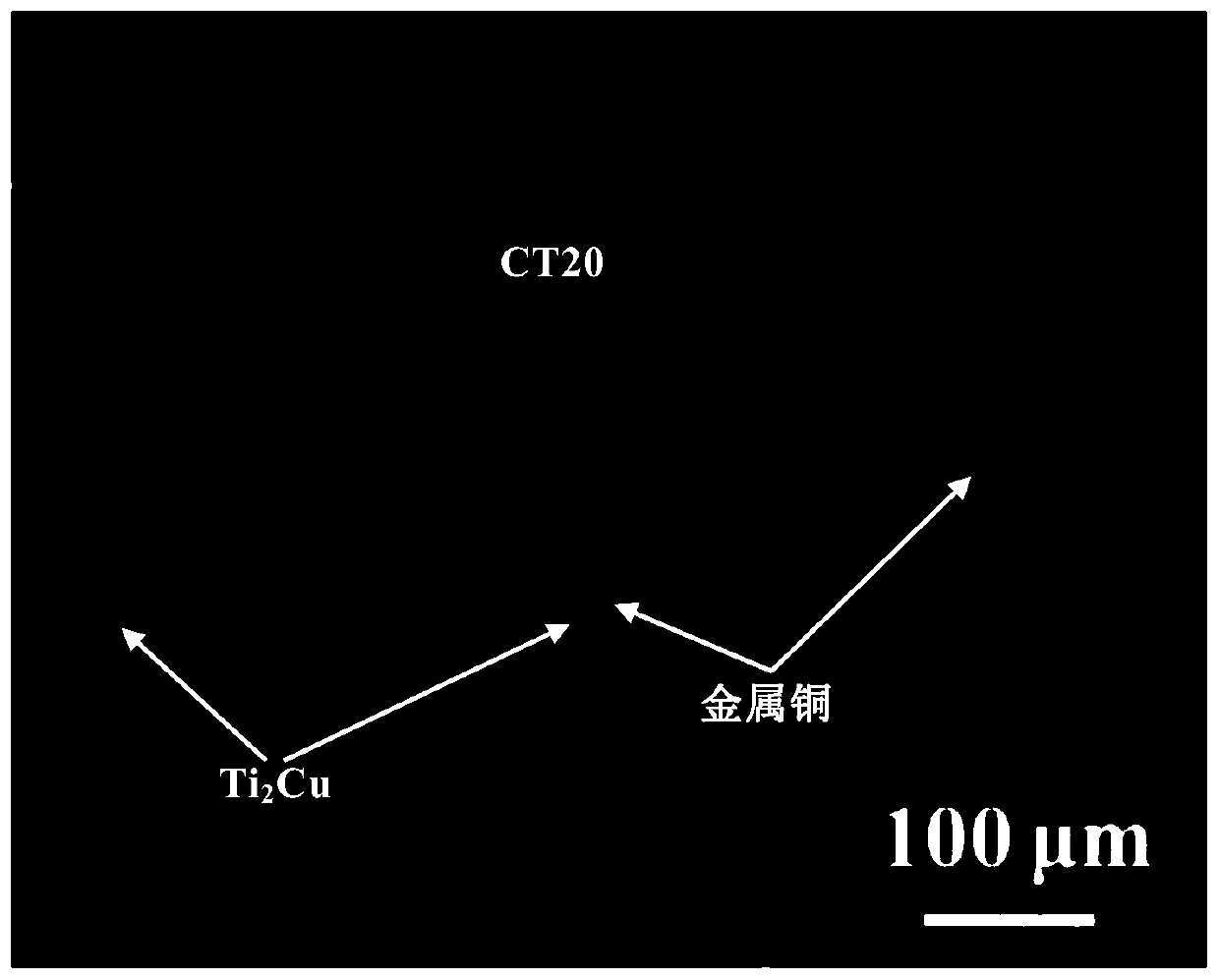

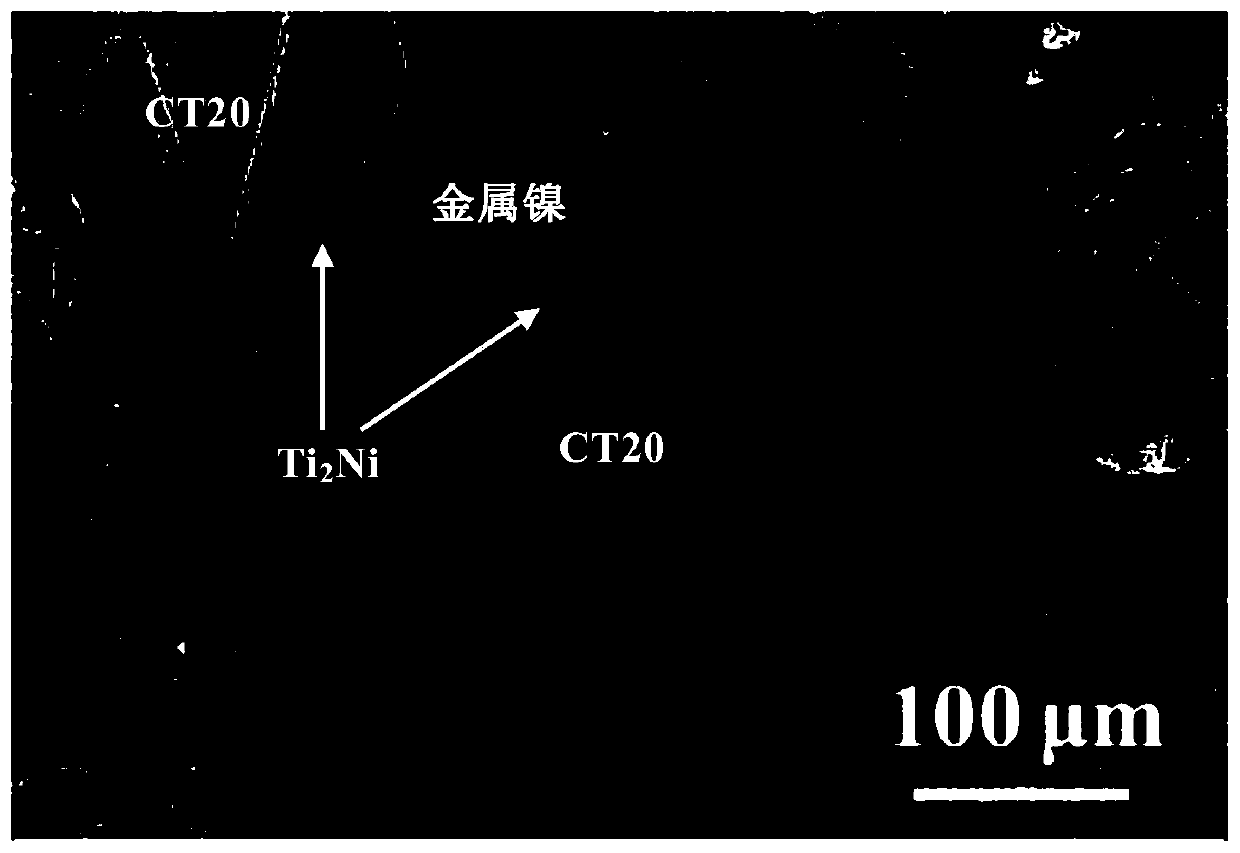

High-hardness wear-resistance netty structured double-metal titanium base composite material and preparation method thereof

ActiveCN110592429AExcellent friction and wear resistanceGood self-lubricating effectHigh energyTitanium

The invention discloses a high-hardness wear-resistance netty structured double-metal titanium base composite material. With titanium or titanium alloys as basal bodies, metal for compounding, intermetallic compound particle phases automatically generated on the titanium or titanium alloy basal bodies in situ, and the metal for compounding are distributed on the surfaces of the titanium or titanium alloy basal bodies in a lantern form in sequence to form the netty structured double-metal titanium base composite material. The invention further discloses a preparation method of the high-hardnesswear-resistance netty structured double-metal titanium base composite material; and in the method, the high-energy ball milling compounding is performed on basal body powder and metal powder for compounding after high-energy ball milling; and then, the sintering is performed. The friction and wear resistance and the hardness of the double-metal titanium base composite material are improved by using an excellent self-lubricating effect of the metal for compounding and a distribution strengthening effect of the intermetallic compound particle phases; and the double-metal titanium base compositepowder is prepared by adopting the high-energy ball milling method without needing cleaning, sensitization and activation of the raw materials, so that the process is simple, the operability is high,and the large-scale industrialization is facilitated.

Owner:西安稀有金属材料研究院有限公司

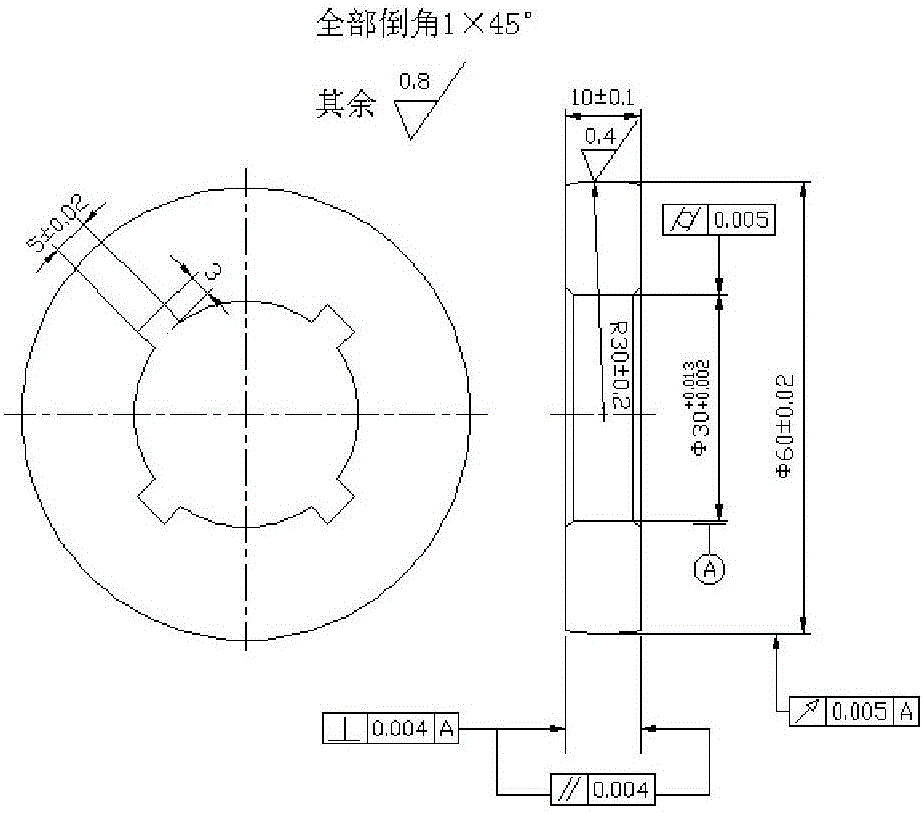

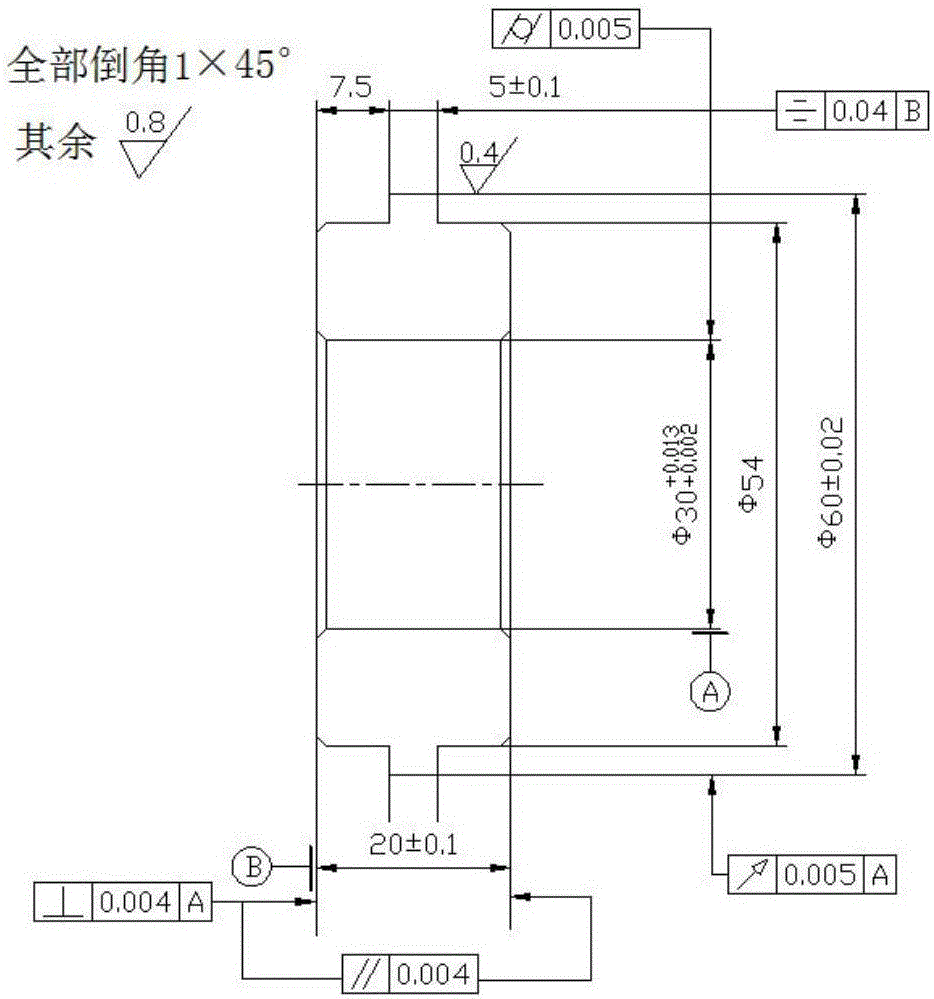

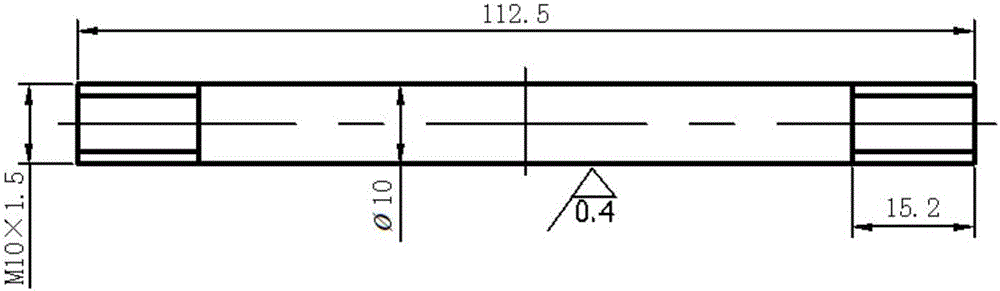

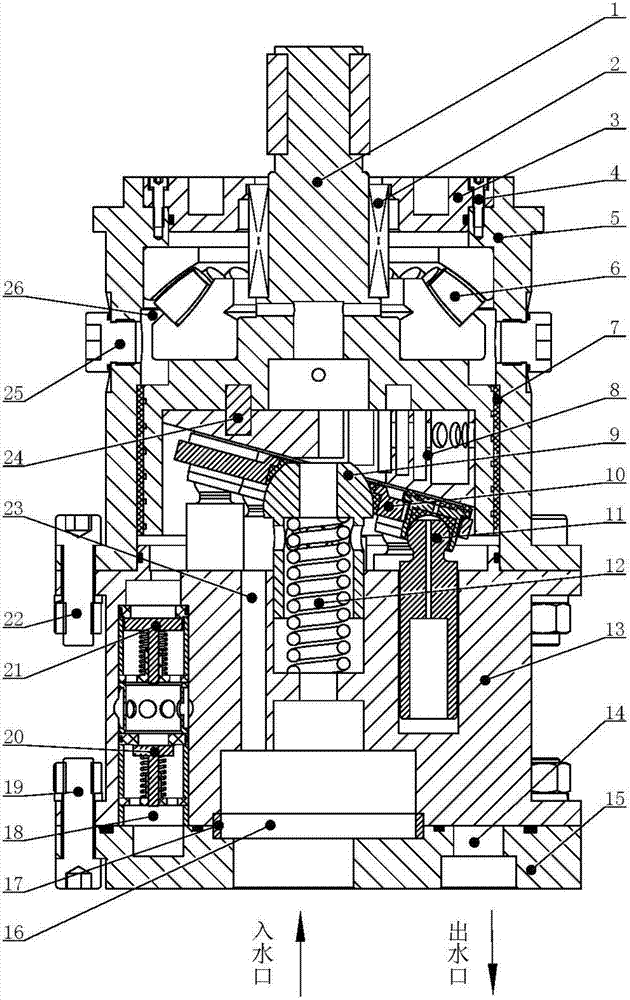

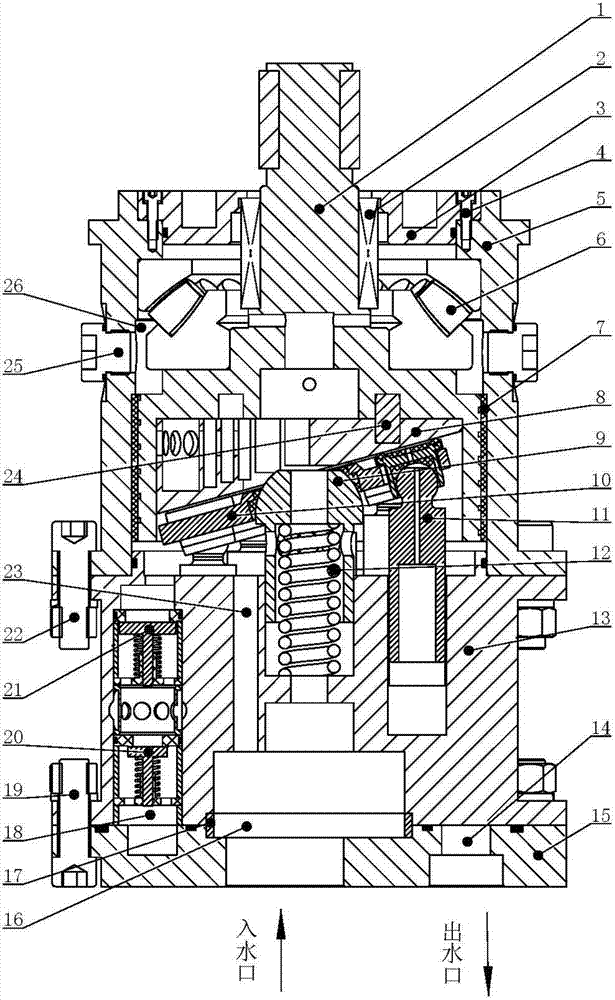

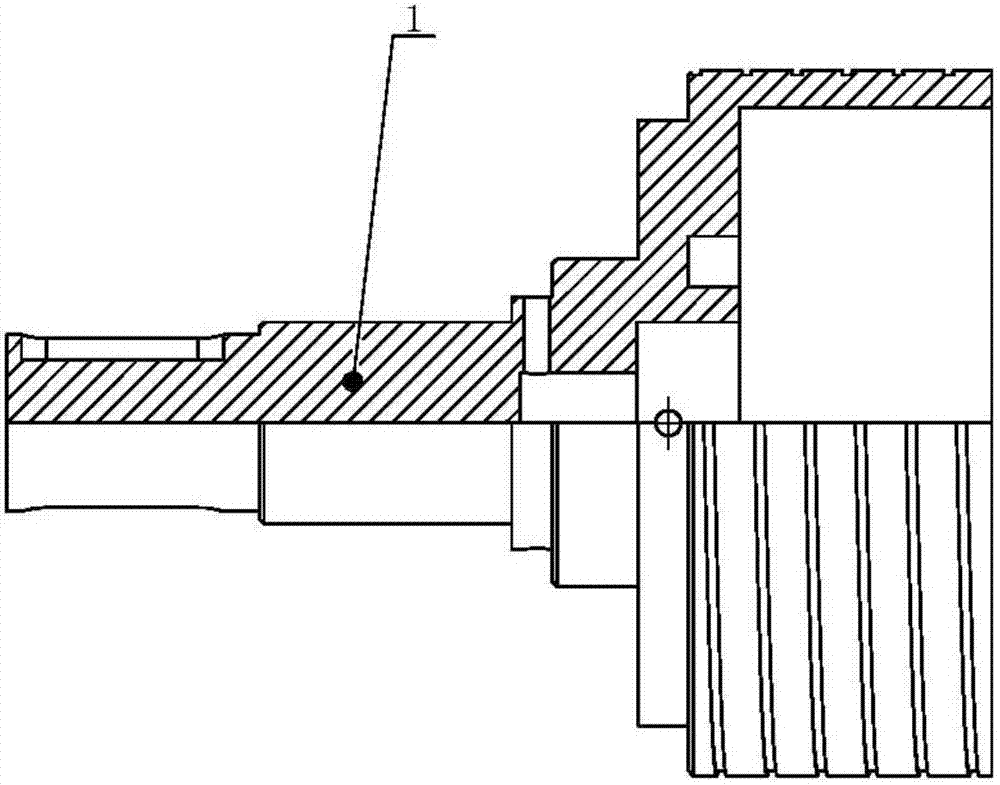

Fully water-lubricated valve distribution plunger pump

ActiveCN102734109AReduce volumeLower thermal equilibrium temperaturePositive displacement pump componentsPositive-displacement liquid enginesHydraulic pumpEngineering

The invention discloses a fully water-lubricated valve distribution plunger pump which comprises a pump main body, a rotary unit, a supporting unit and a plunger distribution unit, wherein the pump main body comprises a cavity, and a water inlet and a water outlet which are communicated with the cavity; the rotary unit comprises a rotation spindle one end of which is arranged in the cavity of the pump main body; the supporting unit consists of an axial supporting unit and a radial supporting unit; the plunger distribution unit consists of a distribution valve assembly and a plunger shoe assembly, the plunger shoe assembly does periodic movement under the rotation of the rotation spindle, thus driving the on and off of valves in the distribution valve assembly, and leading a fluid to flow into the cavity from the water inlet or a fluid in the cavity to be discharged from the water outlet so as to realize flow distribution; a helical groove is arranged on the peripheral surface where the rotation spindle and the radial supporting unit are matched, and the pumping action of the helical groove leads the fluid to circularly flow in the cavity at two end surfaces of the rotation spindle. The fully water-lubricated valve distribution plunger pump fully utilizes the spaces of the shell and the spindle, and the radial sliding bearing design greatly improves the bearing capability of the spindle, and extends the service life of the hydraulic pump.

Owner:WUHAN HUAXI HYDRAULIC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com