High-wear-resistance photocuring aromatic ether-based epoxy acrylate/nanosilicon dioxide composite material and preparation method thereof

A technology based on epoxy acrylate and nano-silica, which is used in epoxy resin coatings, fireproof coatings, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

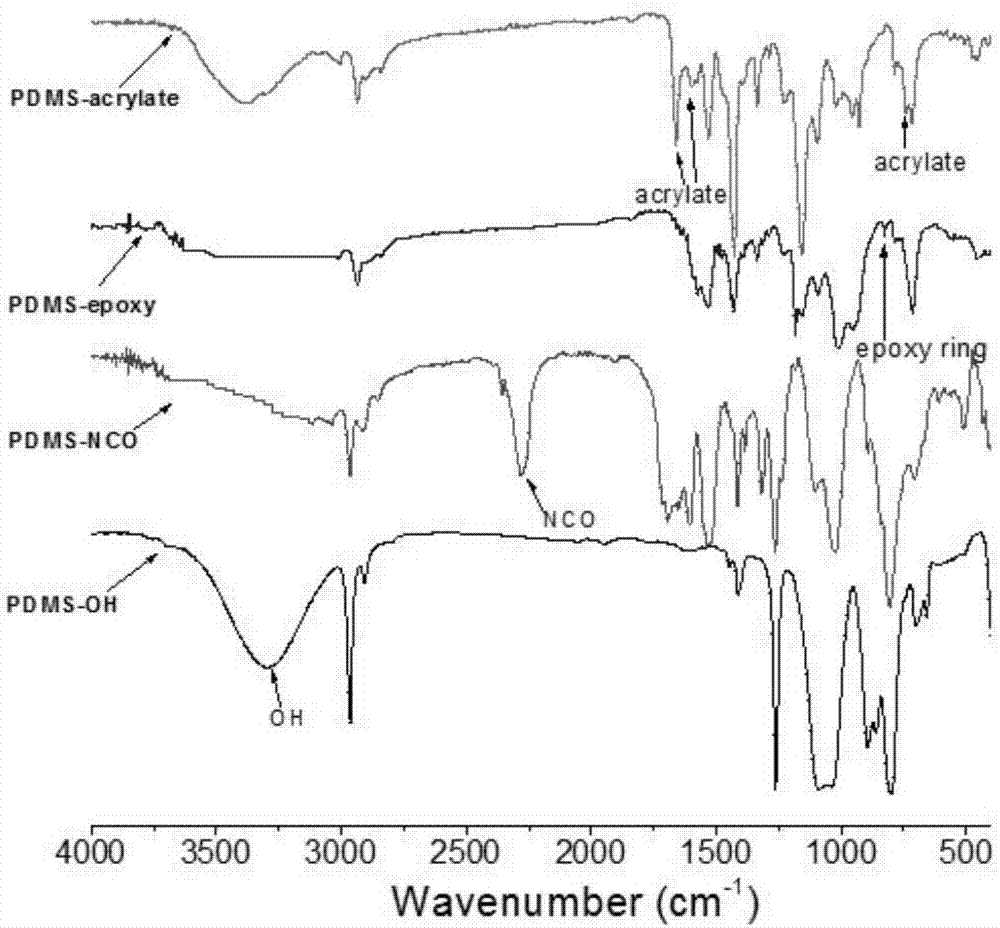

Method used

Image

Examples

Embodiment 1

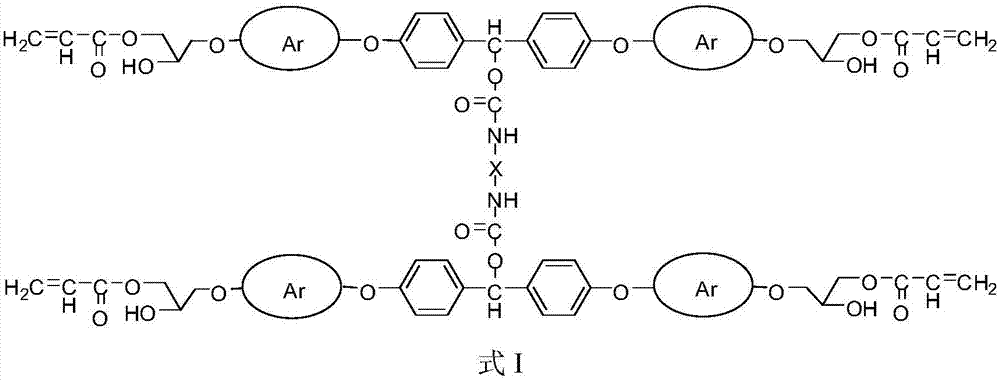

[0049] Embodiment 1 hydroquinone type photocurable epoxy acrylate / nano silicon dioxide composite material

[0050] (1) Preparation of aryl ether ketone bisphenols based on hydroquinone: equipped with condenser, water separator, mechanical stirring and N 2 160mmol of hydroquinone, 80mmol of 4,4-difluorobenzophenone, 192mmol of potassium carbonate, 160mL of DMSO and 20mL of toluene were added to the dry three-necked flask of the catheter. in N 2 Heated under the protection of the reactant until the reactants were dissolved, refluxed and dehydrated at 150°C for 2h, then evaporated the water-carrying agent, and reacted at 175°C for 10h. The product was settled in 1000 mL of distilled water, filtered, and then vacuum-dried at 60° C. for 48 hours to obtain bisphenol containing aryl ether ketone segments in the form of yellow-white powder with a yield of 96%.

[0051] (2) Preparation of aryl ether alcohol-containing bisphenols based on hydroquinone: in a dry three-necked flask, add...

Embodiment 2

[0057] Embodiment 2 Bisphenol A type photocurable epoxy acrylate / nano silicon dioxide composite material

[0058] (1) Preparation of aryl ether ketone bisphenols based on bisphenol A: when equipped with reflux condenser, water separator, mechanical stirring and N 2 Into the dry three-necked flask of the introduction tube, add 160mmol of bisphenol A, 80mmol of 4,4-difluorobenzophenone, 200mmol of potassium carbonate, 160mL of DMSO and 120mL of toluene. in N 2 Heated under the protection of the reactant until the reactants were dissolved, refluxed and dehydrated at 150°C for 2h, then evaporated the water-carrying agent, and reacted at 175°C for 10h. The product was settled in 1000 mL of distilled water, filtered, and then vacuum-dried at 60° C. for 48 hours to obtain bisphenol containing aryl ether ketone segment in the form of white powder with a yield of 94%.

[0059] (2) Preparation of bisphenol containing aryl ether alcohol based on bisphenol A: 120mmol NaBH 4 Add to 50mL...

Embodiment 3

[0065] Embodiment 3 is based on biphenol and bisphenol S type photocurable epoxy acrylate / nanometer silicon dioxide composite material

[0066] (1) Preparation of aryl ether ketone bisphenols based on biphenol and bisphenol S: in a dry three-necked flask, add biphenol 80mmol and bisphenol S 80mmol, 4,4-difluorobenzophenone 80mmol, potassium carbonate 200mmol, 160mLDMSO and 120mL toluene were mixed homogeneously, in N 2 Heated under the protection of the reactant until the reactants were dissolved, refluxed and dehydrated at 150°C for 2h, then raised the temperature to 175°C to distill the water-carrying agent toluene, and reacted at 175°C for 10h. The product was extracted three times with a small amount of chloroform and an appropriate amount of distilled water, and the organic phase was taken, and the solvent was removed by rotary evaporation at 60°C, and then vacuum-dried at 60°C for 48 hours to obtain a white solid powder containing a bisphenol monomer containing an aryl e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com