Multifunctional epoxy vegetable oil-based UV curing prepolymer and its preparation method and application

A technology of multifunctional epoxy and epoxy vegetable oil, which is applied in application, epoxy resin coating, modified epoxy resin adhesive, etc., can solve the problems of application limitation, limited usage, low reactivity, etc., and achieve production The effect of low cost, reducing dependence and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

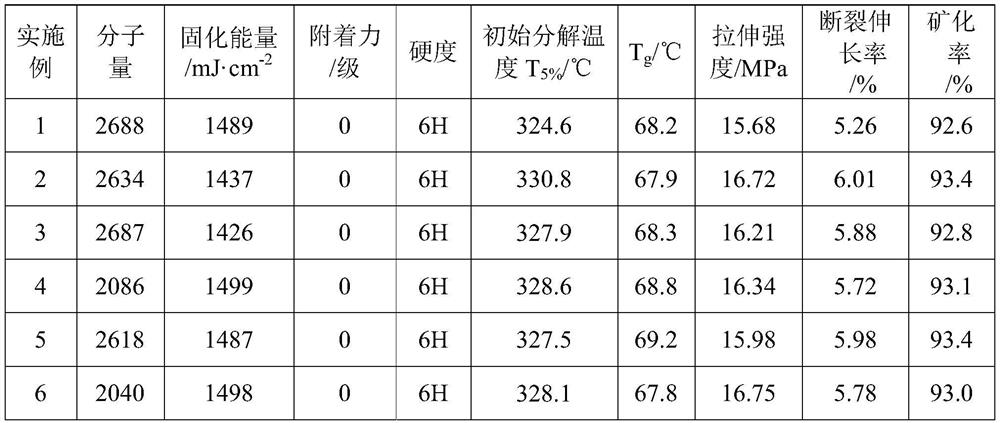

Examples

Embodiment 1

[0035] Preparation of epoxidized soybean oil-ricinoleic acid-based UV-curable prepolymer:

[0036] (1) Add 5 parts of epoxidized soybean oil (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.), triethylamine and acetone successively in a four-neck flask with a mechanical stirring device, a condensing reflux device and a thermometer (amounts of 0.5% and 1 times of the total mass of epoxy vegetable oil and vegetable oleic acid) after stirring evenly, the oil bath is heated to 120 ℃ for insulation, and 20 parts of ricinoleic acid (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.) is added dropwise, and the flow rate of adding It is 1 drop per second. After the dropwise addition is completed, keep warm and continue to react for 5 hours. After the reaction is completed, filter while it is hot, transfer the liquid to a separatory funnel and dissolve it with petroleum ether. Wash three times respectively with saturated sodium bicarbonate solution and sa...

Embodiment 2

[0039] Preparation of epoxy soybean oil-soybean oleic acid based UV curing prepolymer:

[0040] (1) Add 10 parts of epoxidized soybean oil (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.), N,N-dimethylethanolamine and Butanone (the amount is 1% and 3 times of the total mass of epoxy vegetable oil and vegetable oleic acid, respectively) was stirred evenly, the oil bath was heated to 110°C to keep warm, and 60 parts of soybean oleic acid (purchased from Shanghai Lisen Chemical Co., Ltd.) was added dropwise. , The dropping flow rate is 10 drops per second. After the dropping is completed, keep warm and continue to react for 5 hours. After the reaction is completed, filter while hot, transfer the liquid to a separatory funnel and dissolve it with petroleum ether. Wash three times respectively with saturated sodium bicarbonate solution and saturated sodium chloride solution, separate liquids to obtain the upper organic phase, then dry and filter the organic phase ...

Embodiment 3

[0043] Preparation of epoxidized soybean oil-tungoleic acid-based UV-curable prepolymer:

[0044] (1) Add 5 parts of epoxidized soybean oil (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.), triethylamine and tetrahydrofuran (amounts of 0.7% and 2 times of the total mass of epoxy vegetable oil and vegetable oleic acid) after stirring evenly, the oil bath is heated to 130 ℃ of insulations, and 30 parts of tungoleic acid (purchased from Shandong Greentown Chemical Co., Ltd.) are added dropwise, and the dripping flow rate is 5 seconds per second. After the dropwise addition is completed, keep warm and continue to react for 5 hours. After the reaction is completed, filter while hot, transfer the liquid to a separatory funnel and dissolve it with petroleum ether. Wash three times respectively with saturated sodium bicarbonate solution and saturated sodium chloride solution, separate liquids to obtain the upper organic phase, then dry and filter the organic phase wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com