Organosilicon and titanium modified boron containing phenolic resin composite material and preparation method thereof

The technology of boron phenolic resin and composite material is applied in the field of organosilicon and titanium modified boron phenolic resin composite material and its preparation field, which can solve the problems of complex preparation process and poor process stability, achieve stable preparation process and improve high temperature and humidity resistance. Effect of performance and water absorption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

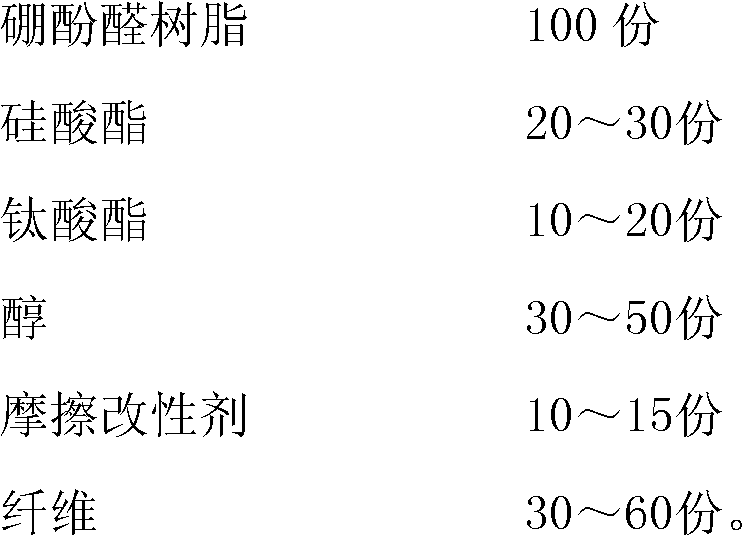

[0038] Preparation of boron-modified phenolic resin: First, suck 94g of preheated molten phenol and 162g of formaldehyde into the reactor by vacuum, then add 1.75g of zinc acetate, adjust the pH value of the reaction solution to 6-7 with ammonia water, and heat up while stirring to 80-85°C, react until the muddy point of the mixed solution reaches 40-45°C, then add 18.6g of boric acid, raise the temperature to 90-100°C, react until the muddy point of the mixed liquid reaches 100°C, and perform dehydration under reduced pressure. Promptly obtain 154.6g of said boron modified phenolic resin.

[0039] Take 100g of the above-mentioned boron phenolic resin, 25g of tetraethyl orthosilicate, 10g of ethyl titanate, 40g of ethanol, 7g of graphite and 8g of molybdenum disulfide, mix them uniformly to form a solution, and add them to 45g of glass fibers to preform the glass fibers. The volatile content of the impregnated prepreg is not more than 2.5%; then put it into the drying equipm...

Embodiment 2

[0041]Preparation of boron-modified phenolic resin: firstly suck 84.6g of preheated molten phenol, 22.8g of bisphenol A and 162g of formaldehyde into the reaction kettle by vacuum, then add 1.97g of zinc acetate, and use ammonia water to adjust the pH value of the reaction solution to 6 ~7, heat up to 80-85°C while stirring, react until the muddy point of the mixture reaches 40-45°C, then add 6.2g of boric acid, heat up to 90-100°C, and react until the muddy point of the mixture reaches 100°C dehydration under reduced pressure to obtain 155.8 g of the boron-modified phenolic resin.

[0042] Take 100g of the above-mentioned boron modified phenolic resin, 10g of ethyl orthosilicate, 10g of isopropyl orthosilicate, 15g of isopropyl titanate, 30g of methanol, 2g of graphite, 4g of molybdenum disulfide, 2g of aluminum oxide, zirconia 2g, mix it evenly to form a solution, and add it to 30g chopped carbon fiber to prepreg the chopped carbon fiber. The volatile content of the prepreg ...

Embodiment 3

[0044] Preparation of boron-modified phenolic resin: first suck 84.6 grams of preheated molten phenol and 162 grams of formaldehyde into the reaction kettle by vacuum, then add 2.19 g of zinc acetate, adjust the pH value of the reaction solution to 6-7 with ammonia water, and stir While raising the temperature to 80-85°C, react until the muddy point of the mixture reaches 40-45°C, then add 18.6g of boric acid, raise the temperature to 90-100°C, react until the muddy point of the mixed liquid reaches 100°C, and decompress After dehydration, add 22.8 grams of double portions of A to obtain 154.0 g of the boron-modified phenolic resin.

[0045] Take 100g of the above-mentioned boron-modified phenolic resin, 15g of vinyl silicate, 15g of isopropyl orthosilicate, 6g of ethyl titanate, 6g of isopropyl titanate, 8g of butyl titanate, 50g of ethanol, 6g of graphite, Mix 2g of zirconium and 5g of silicon carbide to form a solution, and add 30g of high silica glass fiber and 30g of chop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com