Patents

Literature

38results about How to "Good wetting properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

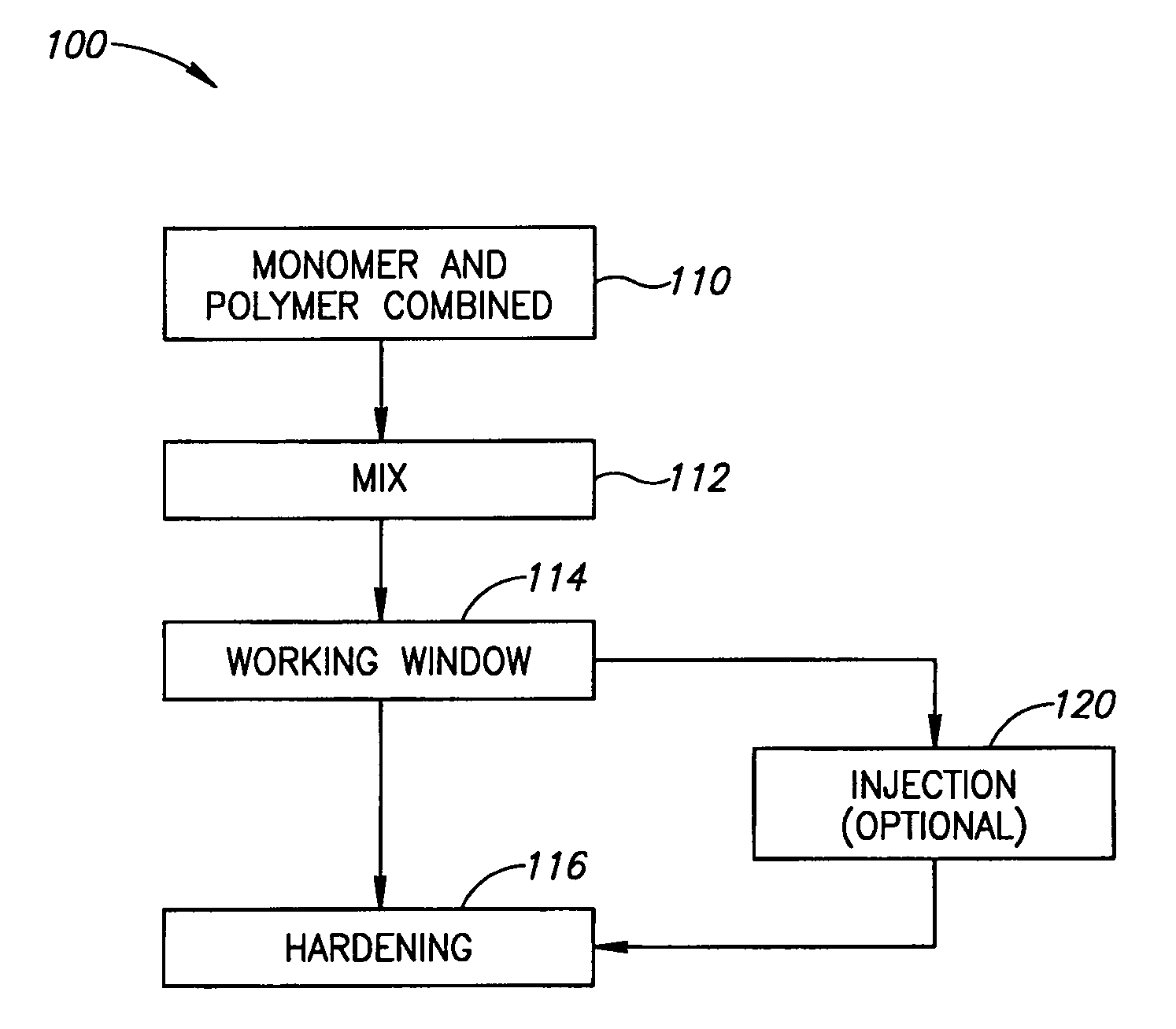

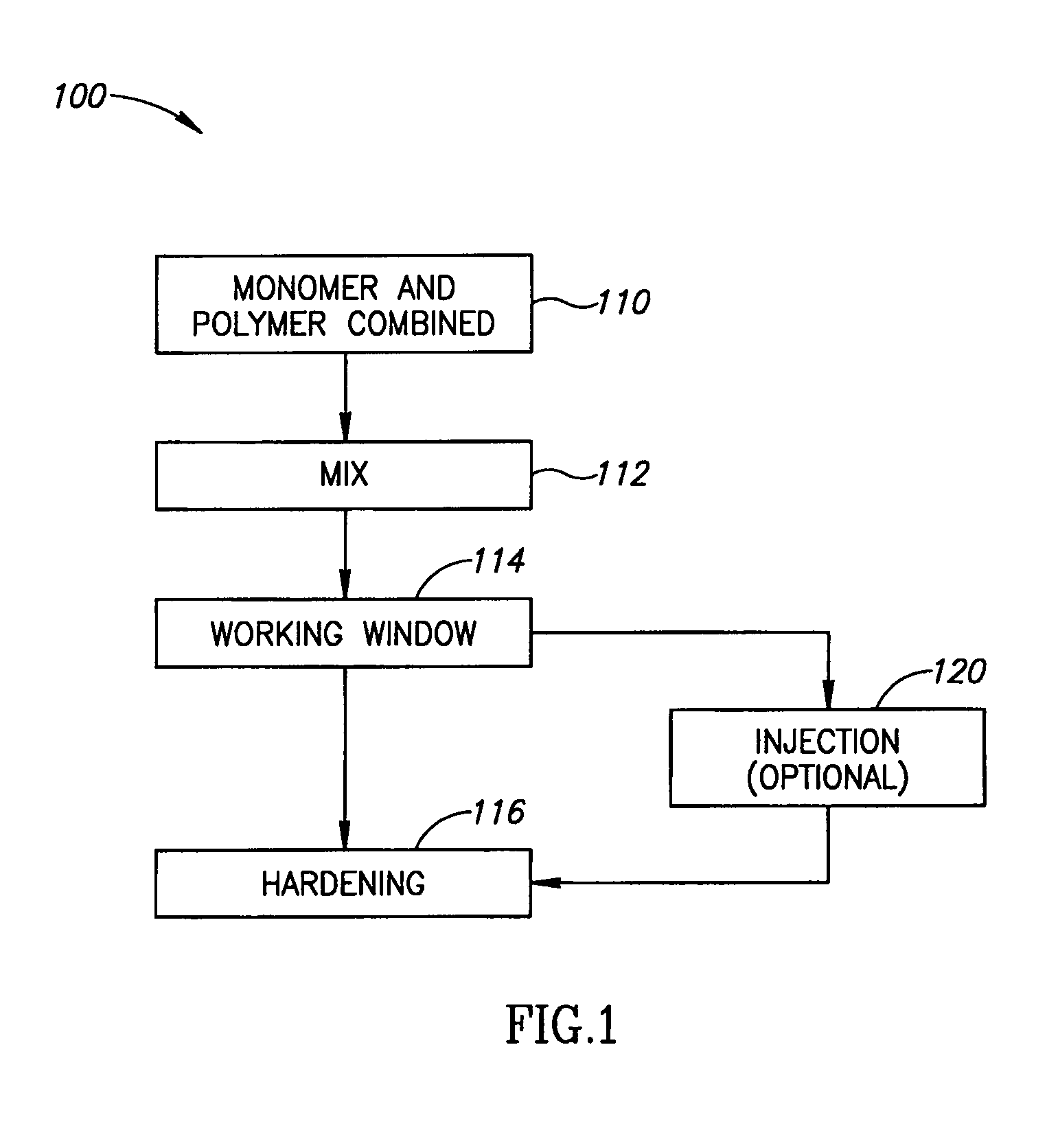

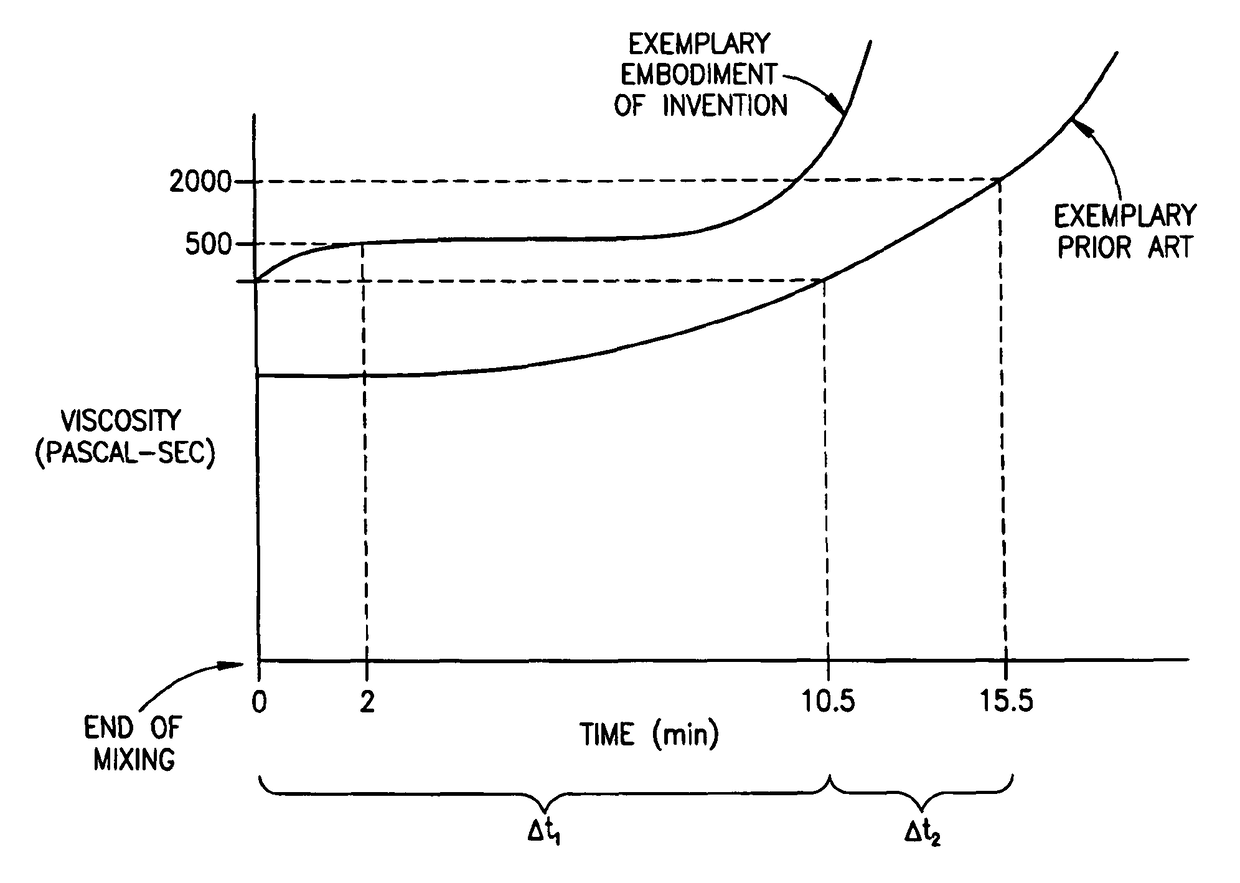

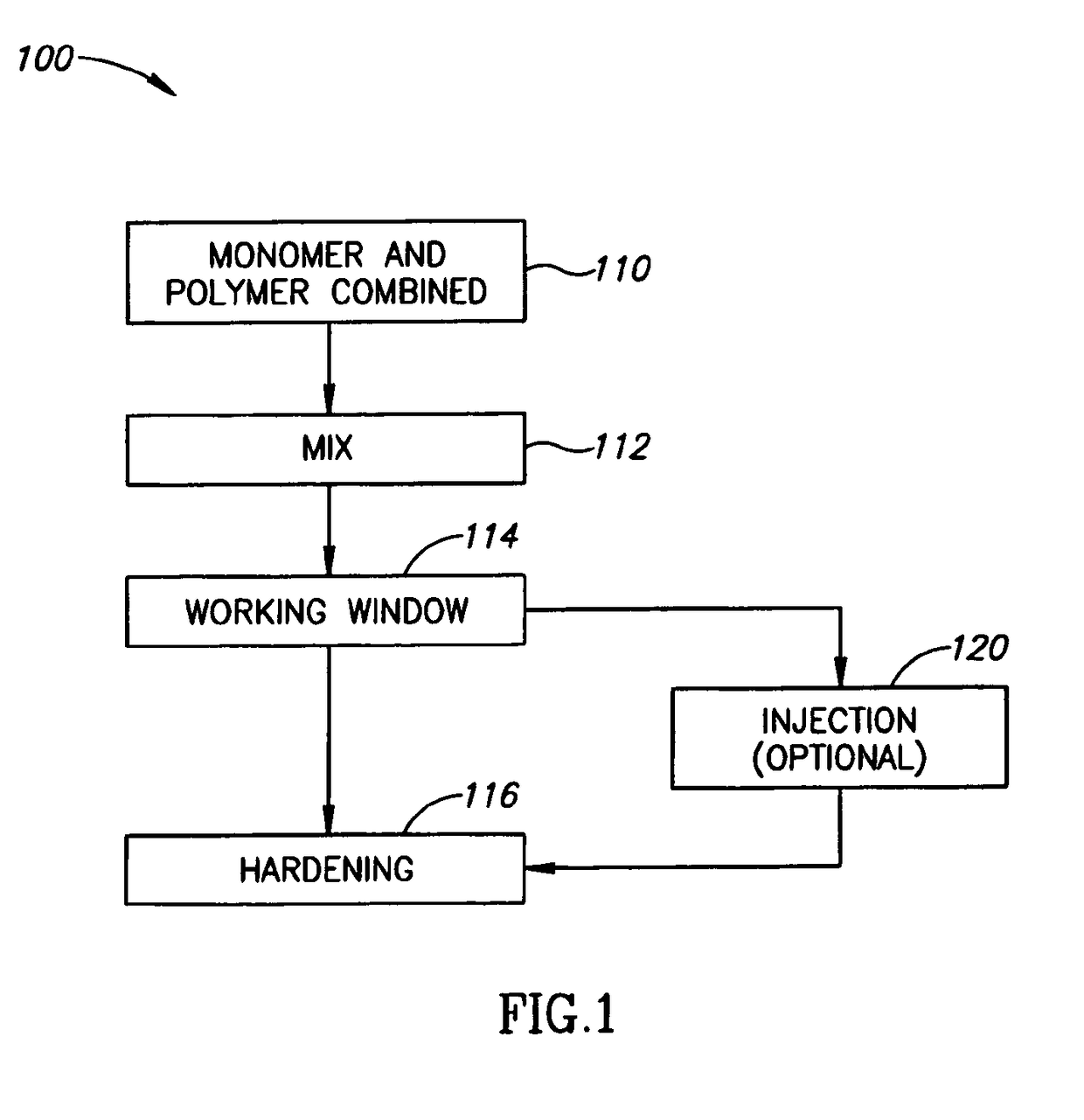

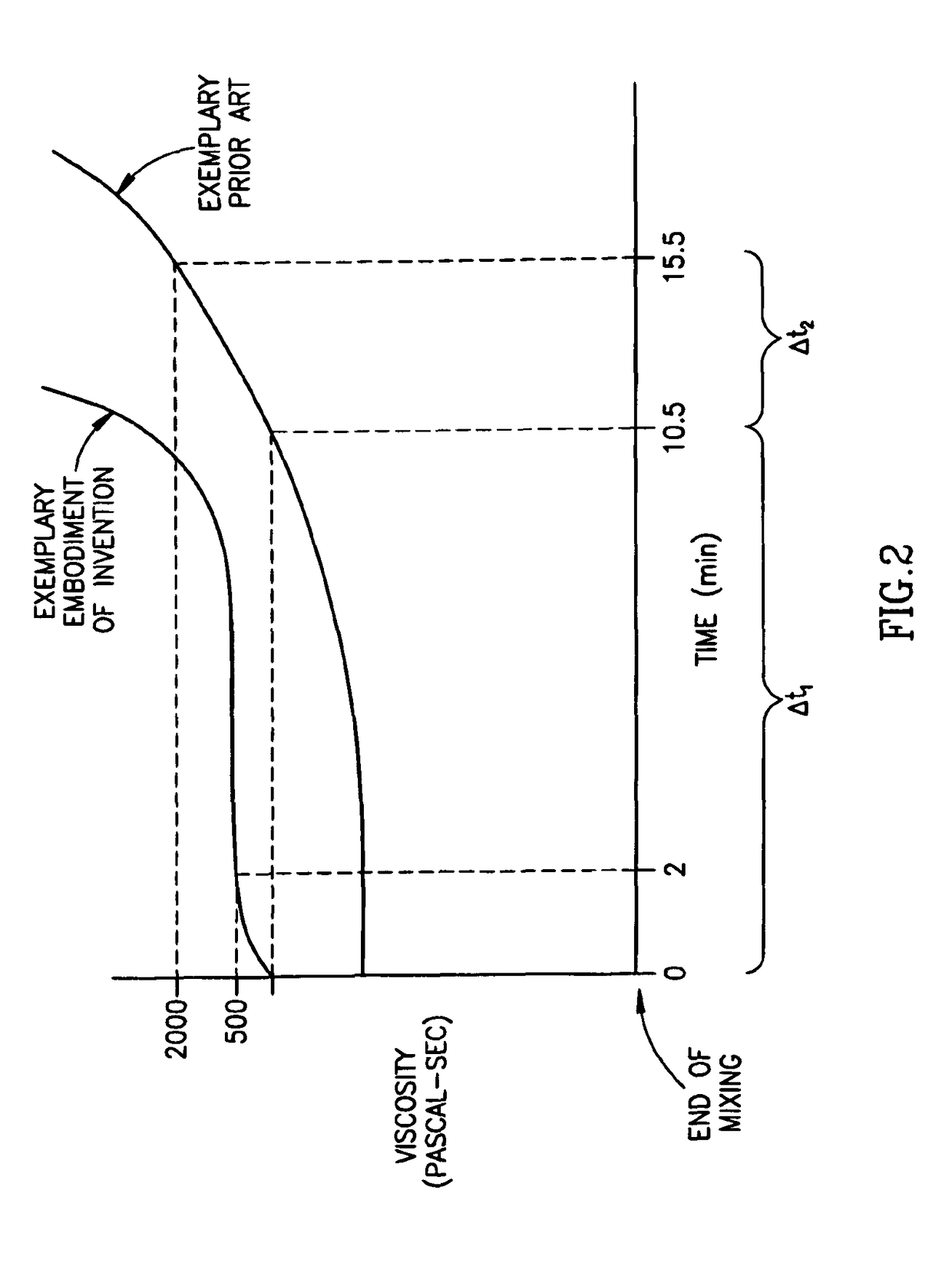

Bone cement and methods of use thereof

ActiveUS20100168271A1High unit weightImprove wettabilityImpression capsSurgical adhesivesBone cementViscosity

A bone cement comprising an acrylic polymer mixture which is formulated to have a relatively high viscosity for a relatively long window, due to distributions of molecular weights and / or sizes of acrylic beads.

Owner:DEPUY SYNTHES PROD INC

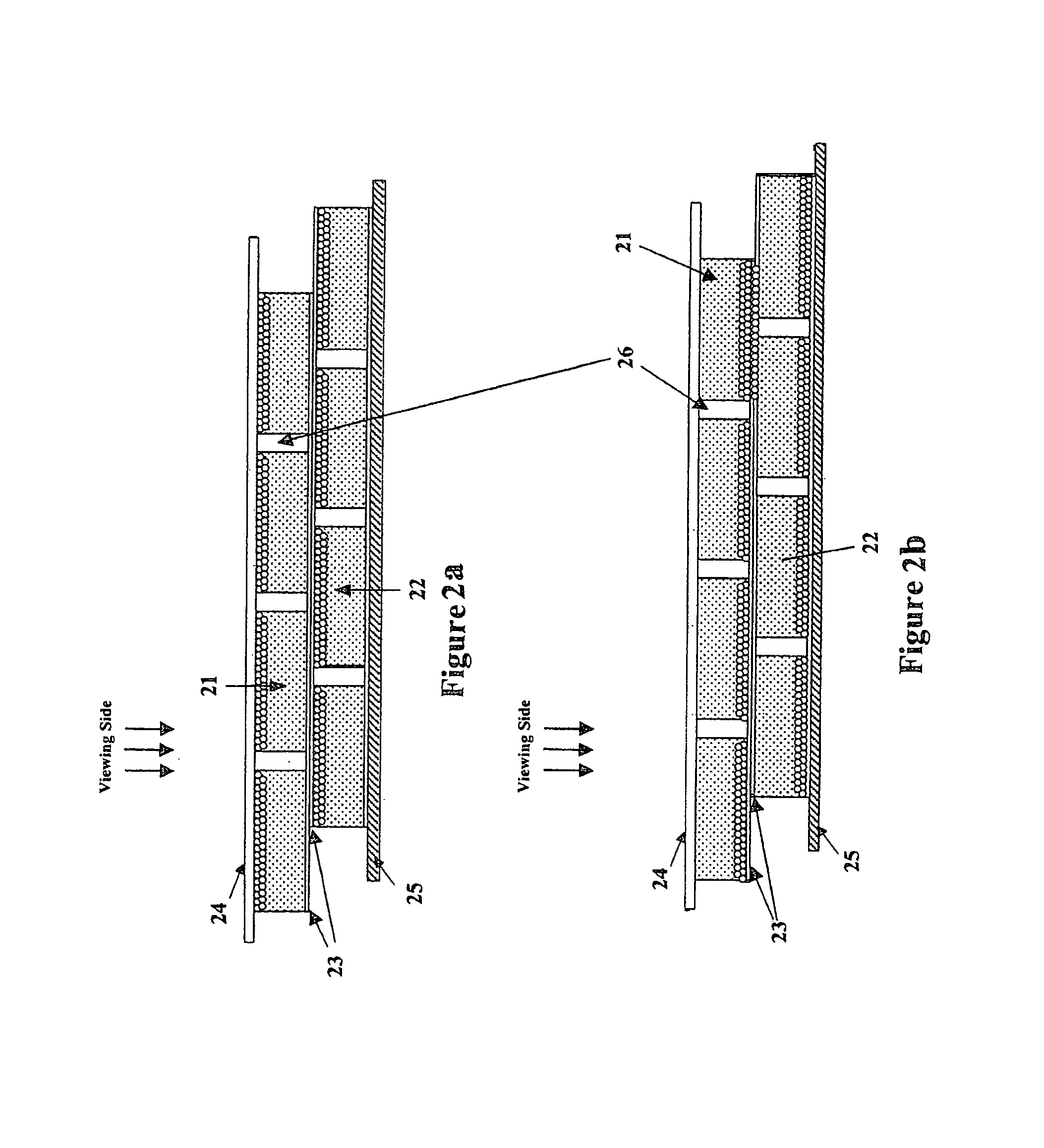

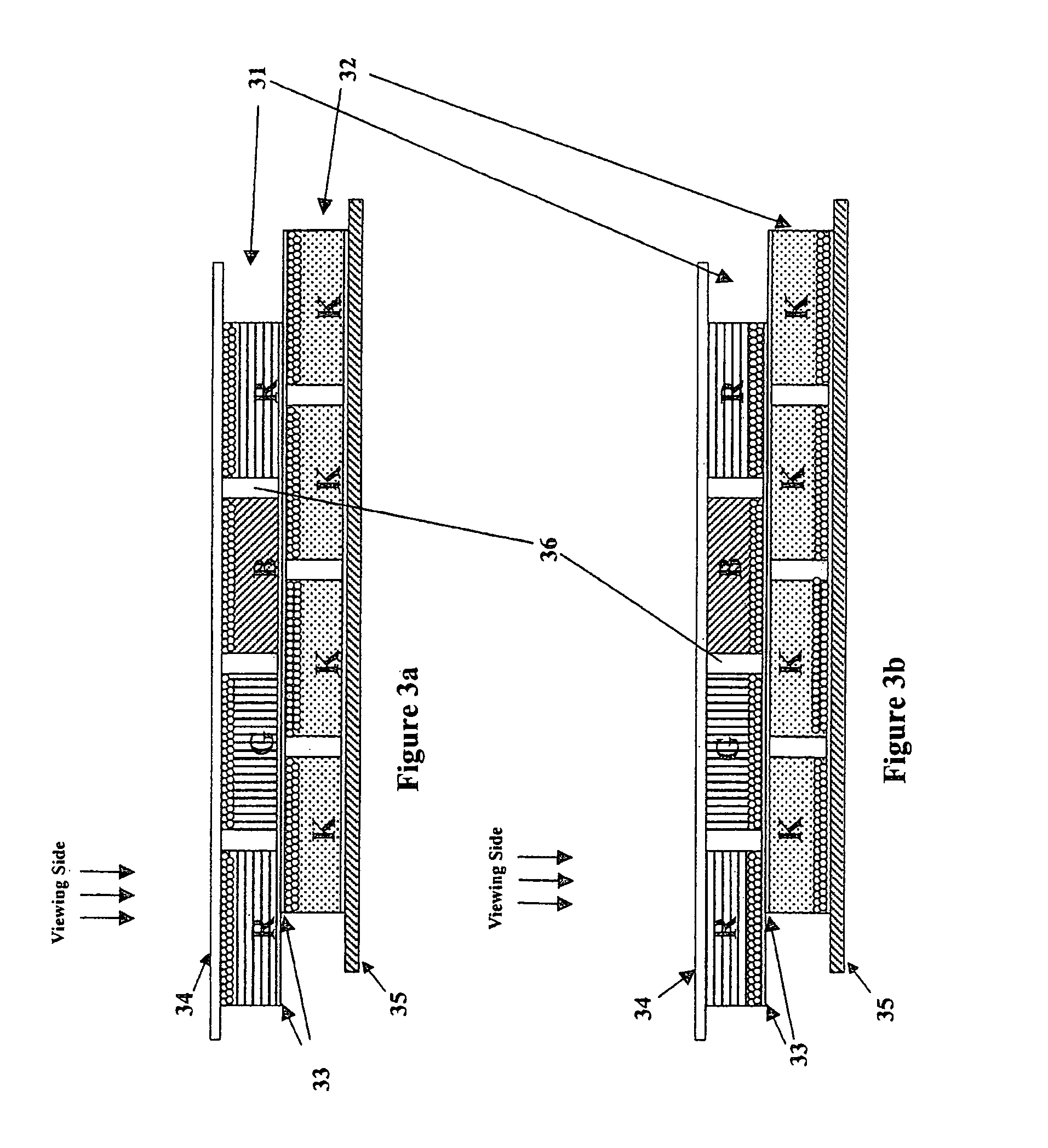

Composition and process for the manufacture of an improved electrophoretic display

InactiveUS7205355B2Free from defectGood wetting propertiesStatic indicating devicesAdhesivesReflectivityDisplay device

The invention relates to a display having improved contrast ratio, switching performance, reflectivity at the Dmin state and structural integrity and methods for its manufacture.

Owner:E INK CALIFORNIA

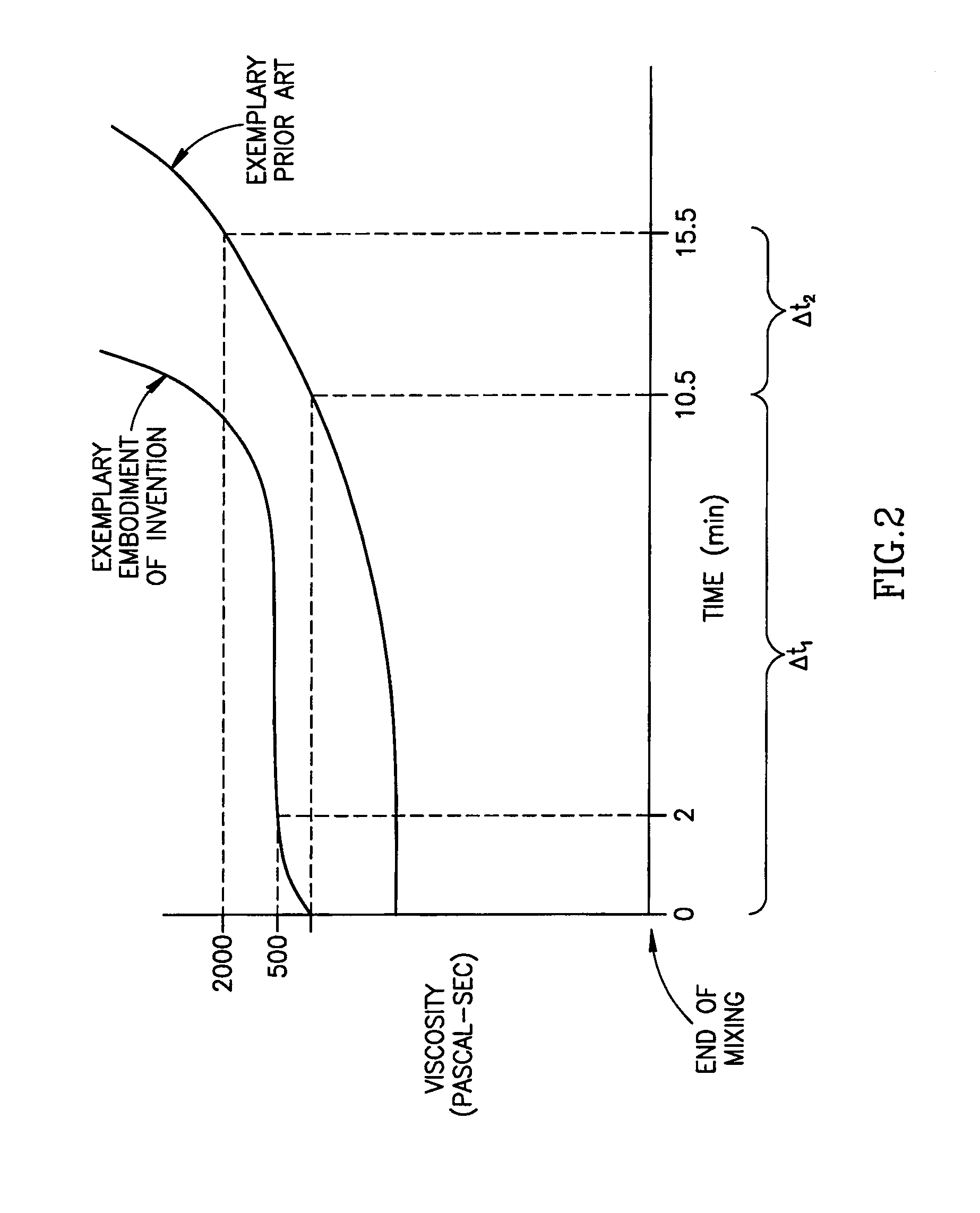

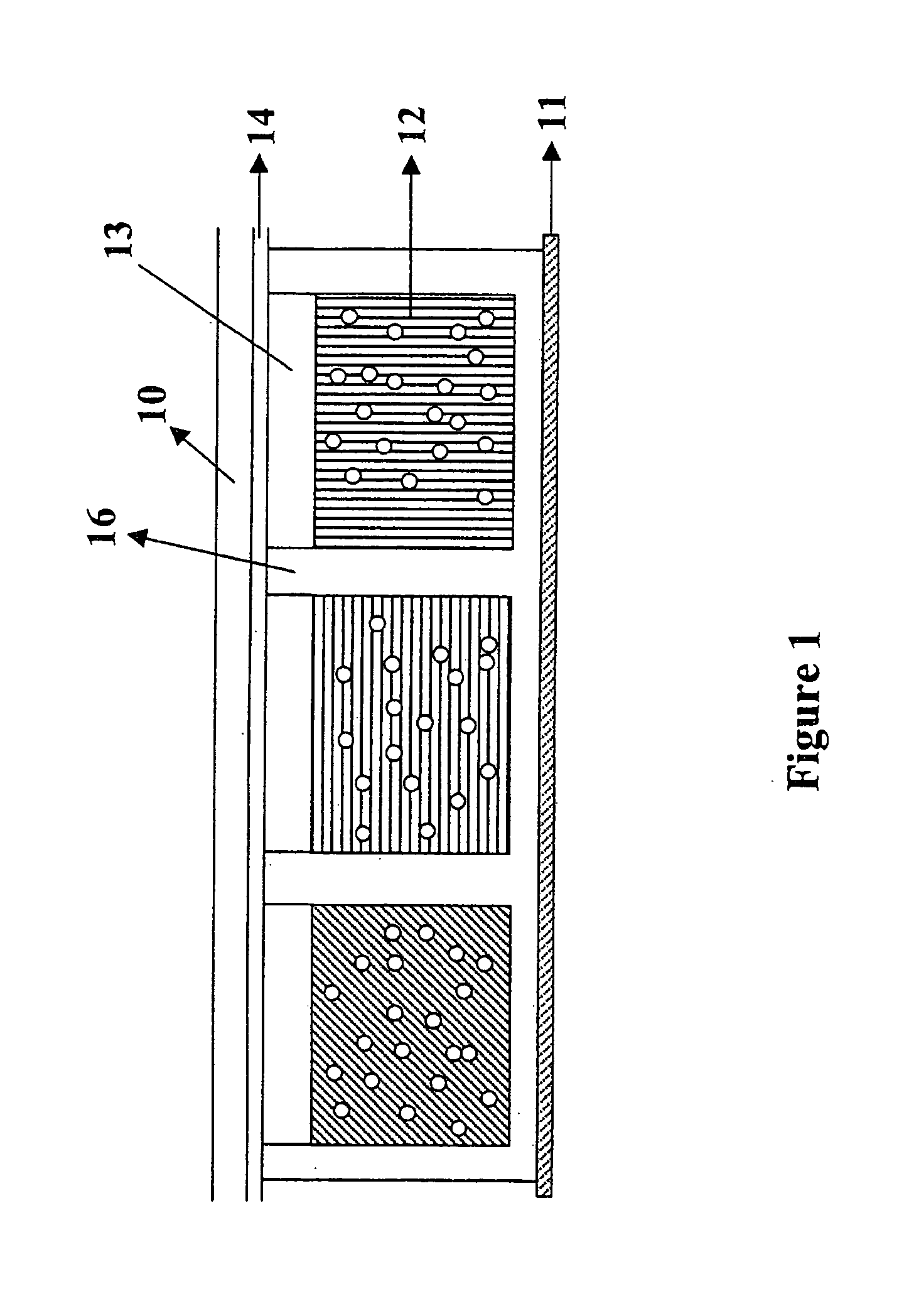

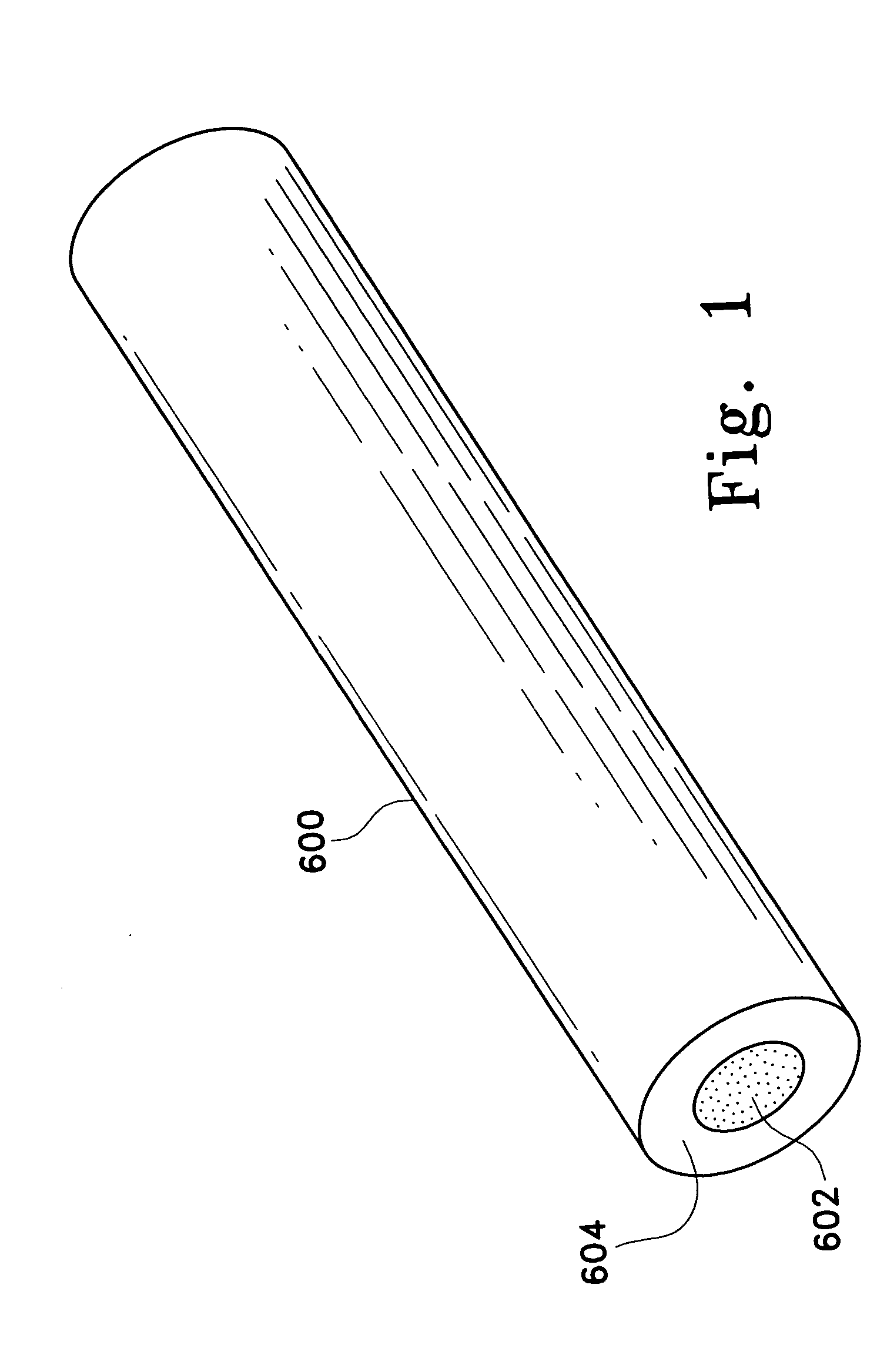

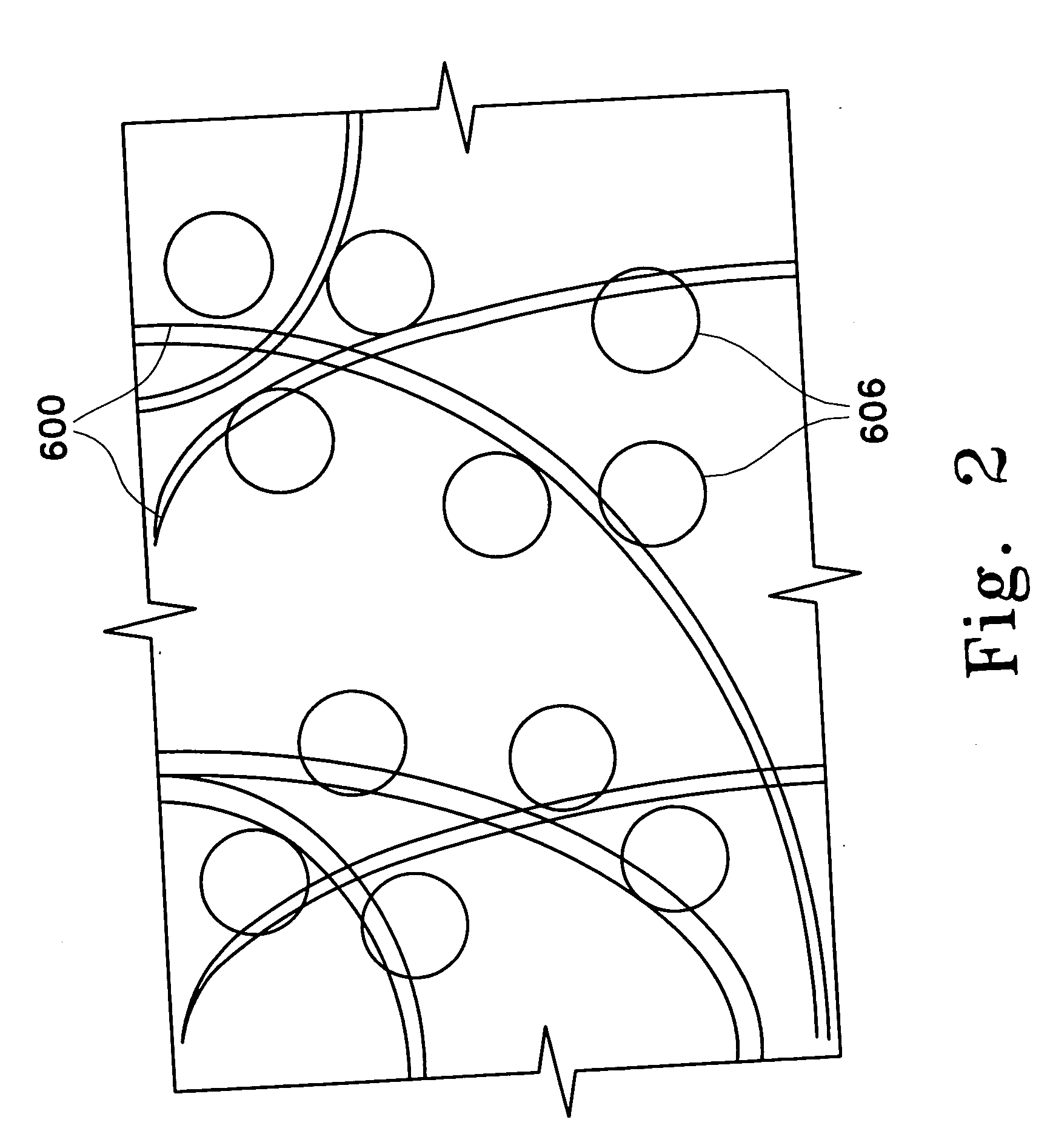

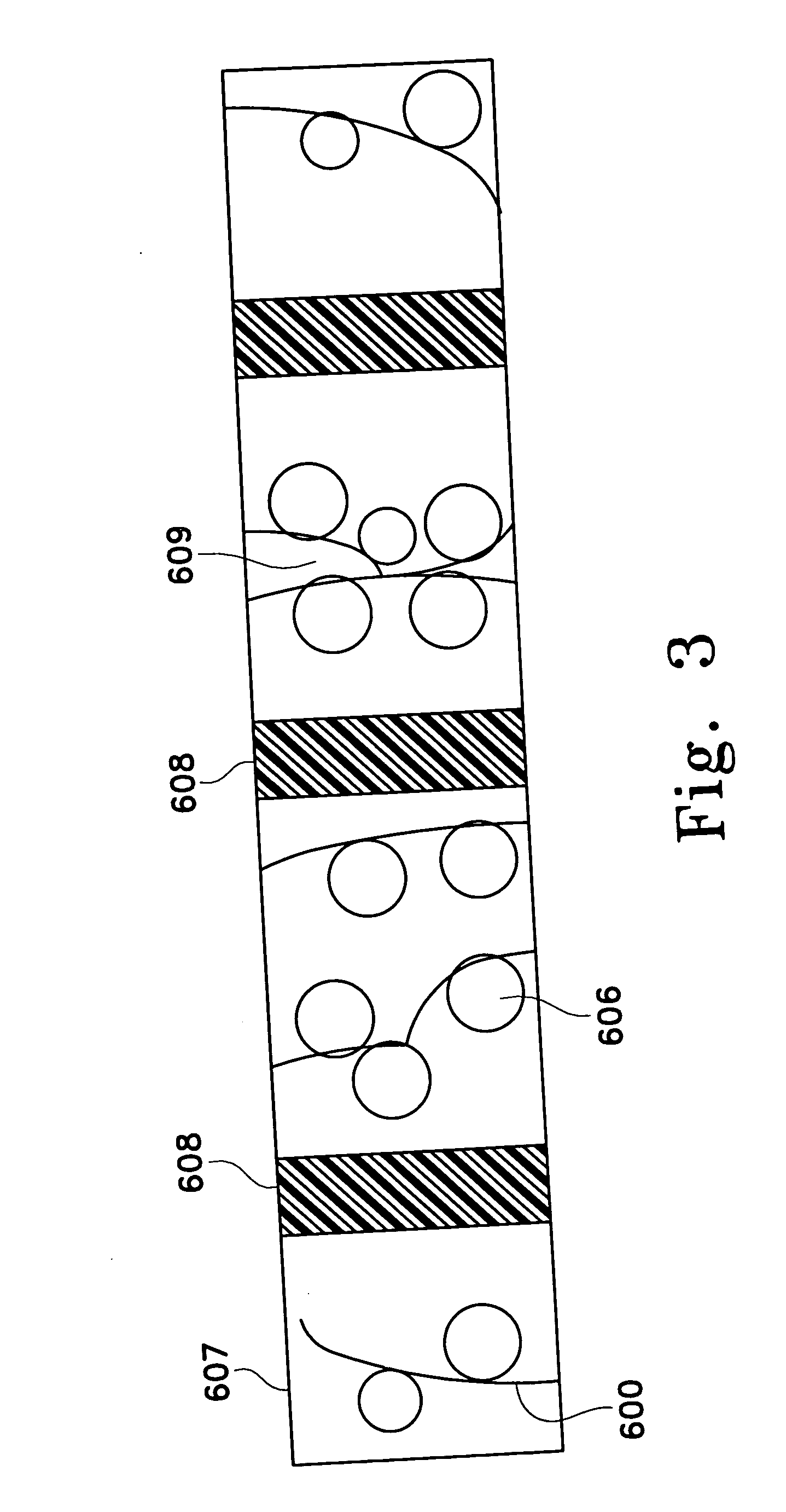

Absorbing pathogen-inactivating compounds with porous particles immobilized in a matrix

InactiveUS20050142542A1Reduce risk of leakageEasy to manufactureImmobilised enzymesOther blood circulation devicesWhole blood productSorbent

Methods and devices are provided for reducing the concentration of low molecular weight compounds in a biological composition, while substantially maintaining a desired biological activity of the biological composition. The device comprises highly porous adsorbent particles, and the adsorbent particles are immobilized by an inert matrix. The matrix containing the particles is contained in a housing, and the particles range in diameter from about 1 μm to about 200 μm. The matrix can be fibrous, and the particles can have a surface area greater than 750 m2 / g and a pore diameter between about 25 and 800 Å. The device can be used to adsorb and remove a pathogen-inactivating compound that is a nucleic acid-binding compound such as psoralen, an acridine derivative or a dye from a biological composition such as a blood product.

Owner:CERUS CORP

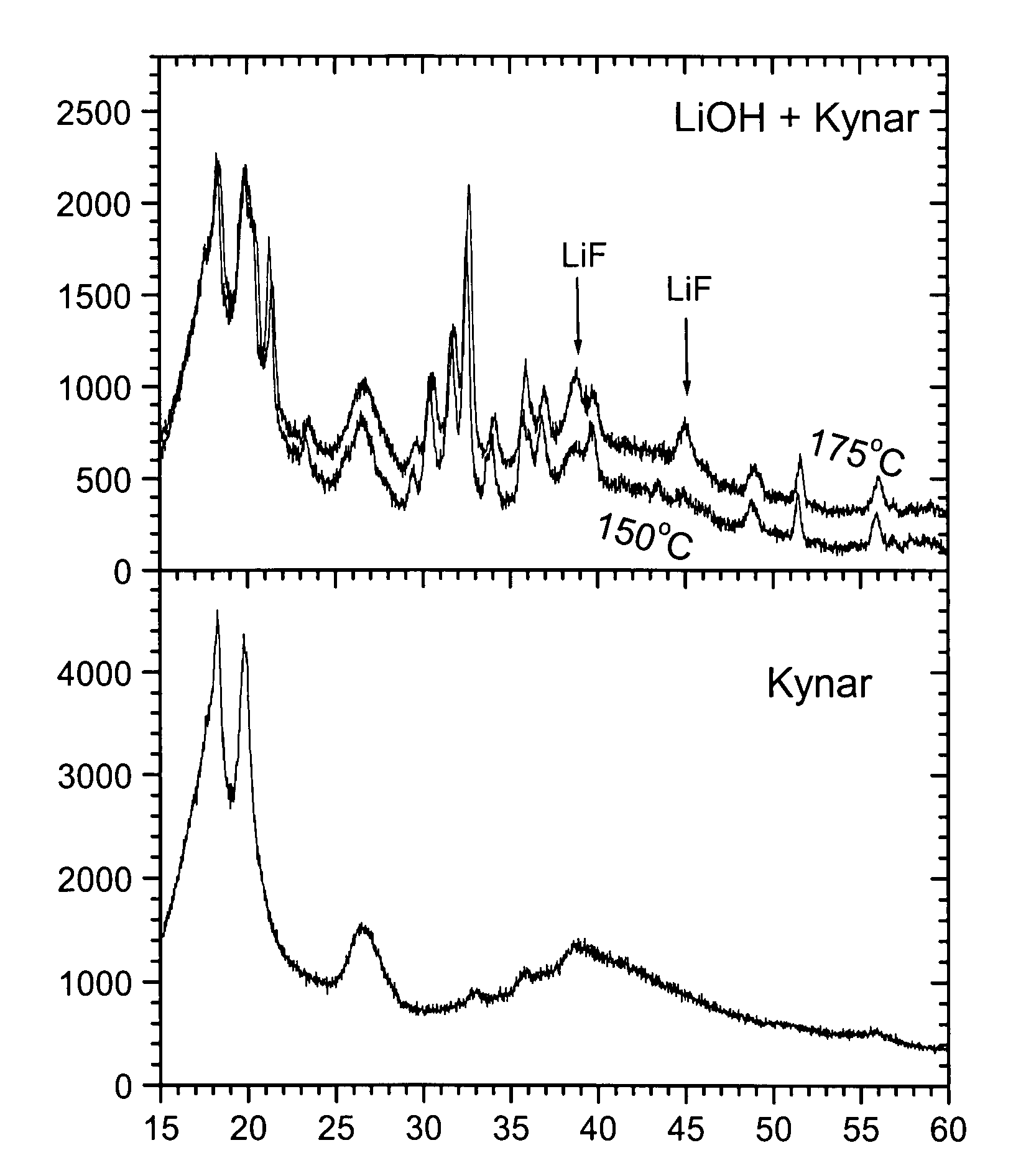

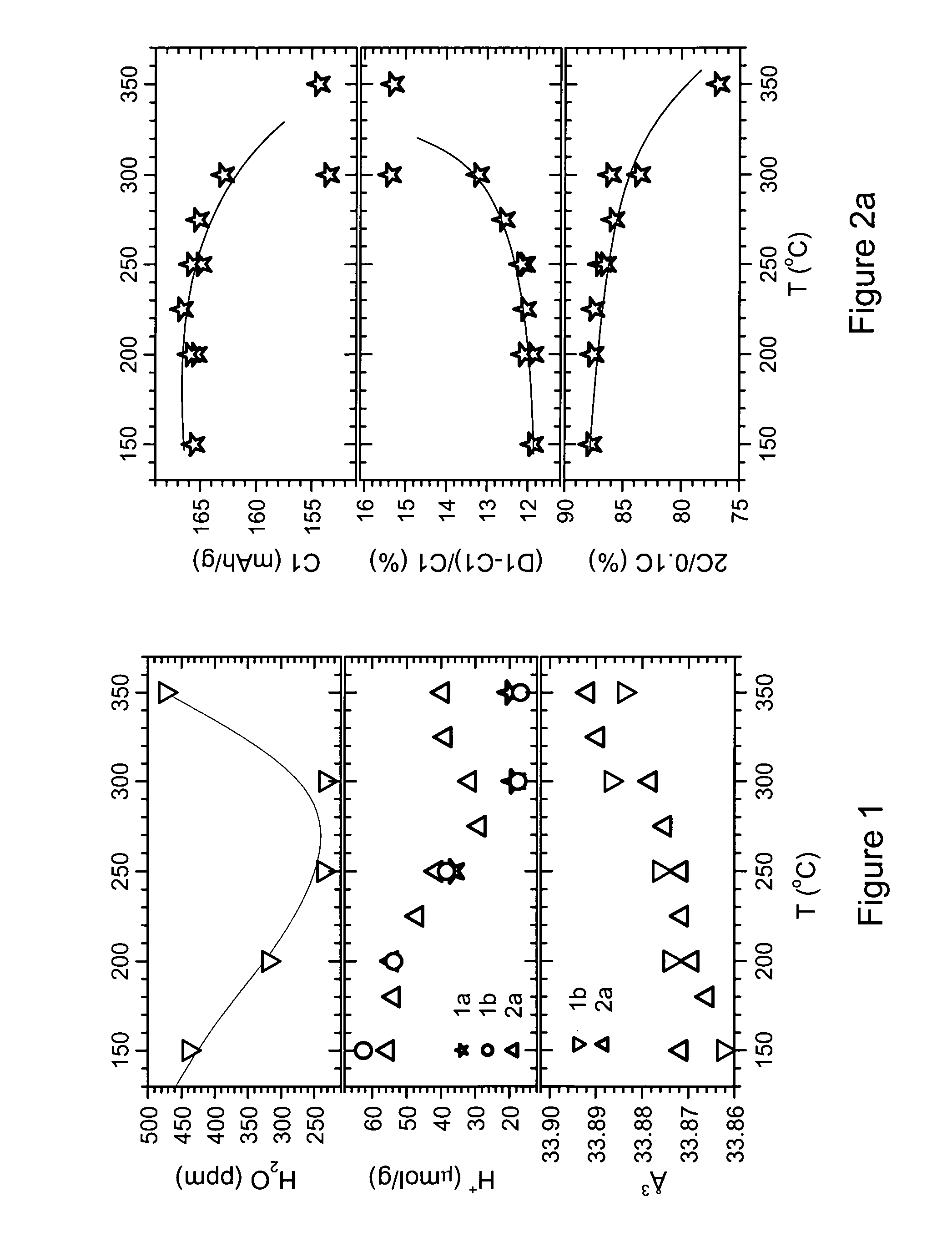

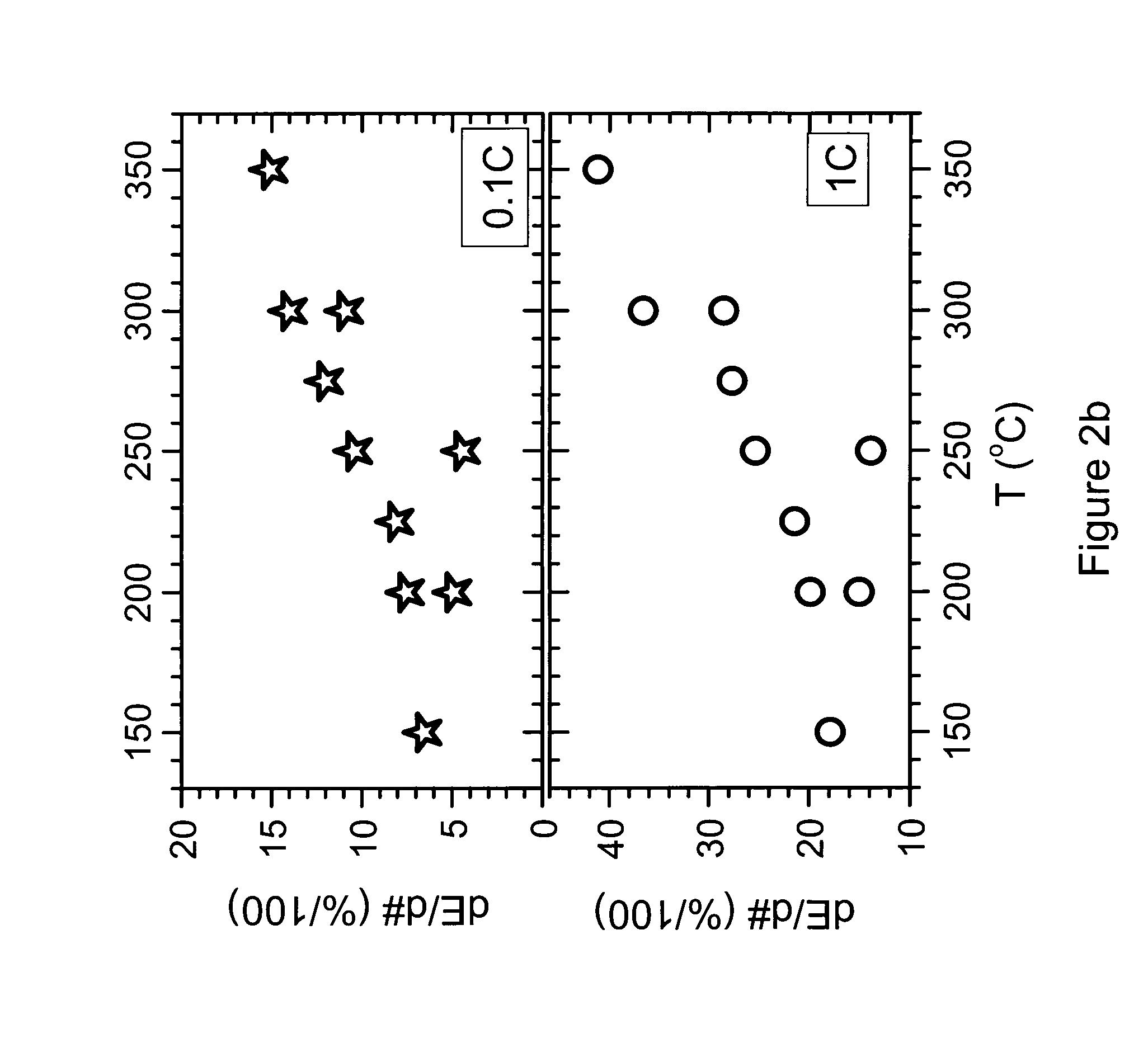

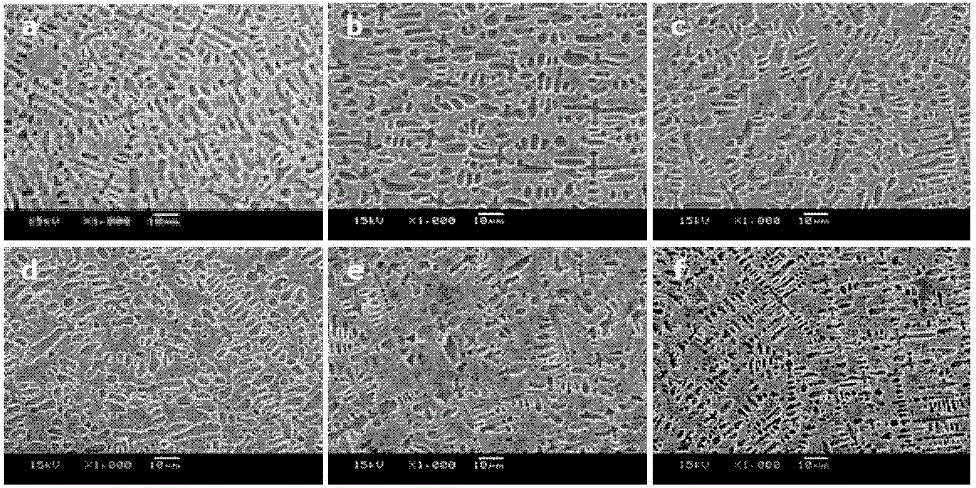

Double-Shell Core Lithium Nickel Manganese Cobalt Oxides

ActiveUS20120270104A1Good wetting propertiesNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithiumManganese

A lithium transition metal oxide powder for use in a rechargeable battery is disclosed, where the surface of the primary particles of said powder is coated with a first inner and a second outer layer, the second outer layer comprising a fluorine-containing polymer, and the first inner layer consisting of a reaction product of the fluorine-containing polymer and the primary particle surface. An example of this reaction product is LiF, where the lithium originates from the primary particles surface. Also as an example, the fluorine-containing polymer is either one of PVDF, PVDF-HFP or PTFE. Examples of the lithium transition metal oxide are either one of —LiCOdMeO2, wherein M is either one or both of Mg and Ti, with e<0.02 and d+e=1; —Li+aM′1−aO2±bM1kSm with −0.03≦a≦0.06, b<0.02, M′ being a transition metal compound, consisting of at least 95% of either one or more elements of the group Ni, Mn, Co, Mg and Ti; M1 consisting of either one or more elements of the group Ca, Sr, Y, La, Ce and Zr, with 0≦k≦0.1 in wt %; and 0≦m≦0.6, m being expressed in mol %; and —LiaNixCOyM″O2+eAf, with 0.9<a′<1.1, 03.5≦x≦0.9, 0<y≦0.4, 0<z≦0.35, e<0.02, 0≦f≦0.05 and 0.9<(x+y+z+f)<1.1; M″ consisting of either one or more elements from the group Al, Mg, and Ti; A consisting 1000 of either one or both of S and C. For making the coated powder, an example process comprises the steps of:—providing a bare lithium transition metal oxide powder, mixing this powder with a fluorine-containing polymer, and heating the obtained powder-polymer mixture at a temperature between at least 50° C. and at most 140° C. above the melting temperature of the fluorine-containing polymer.

Owner:UMICORE AG & CO KG +1

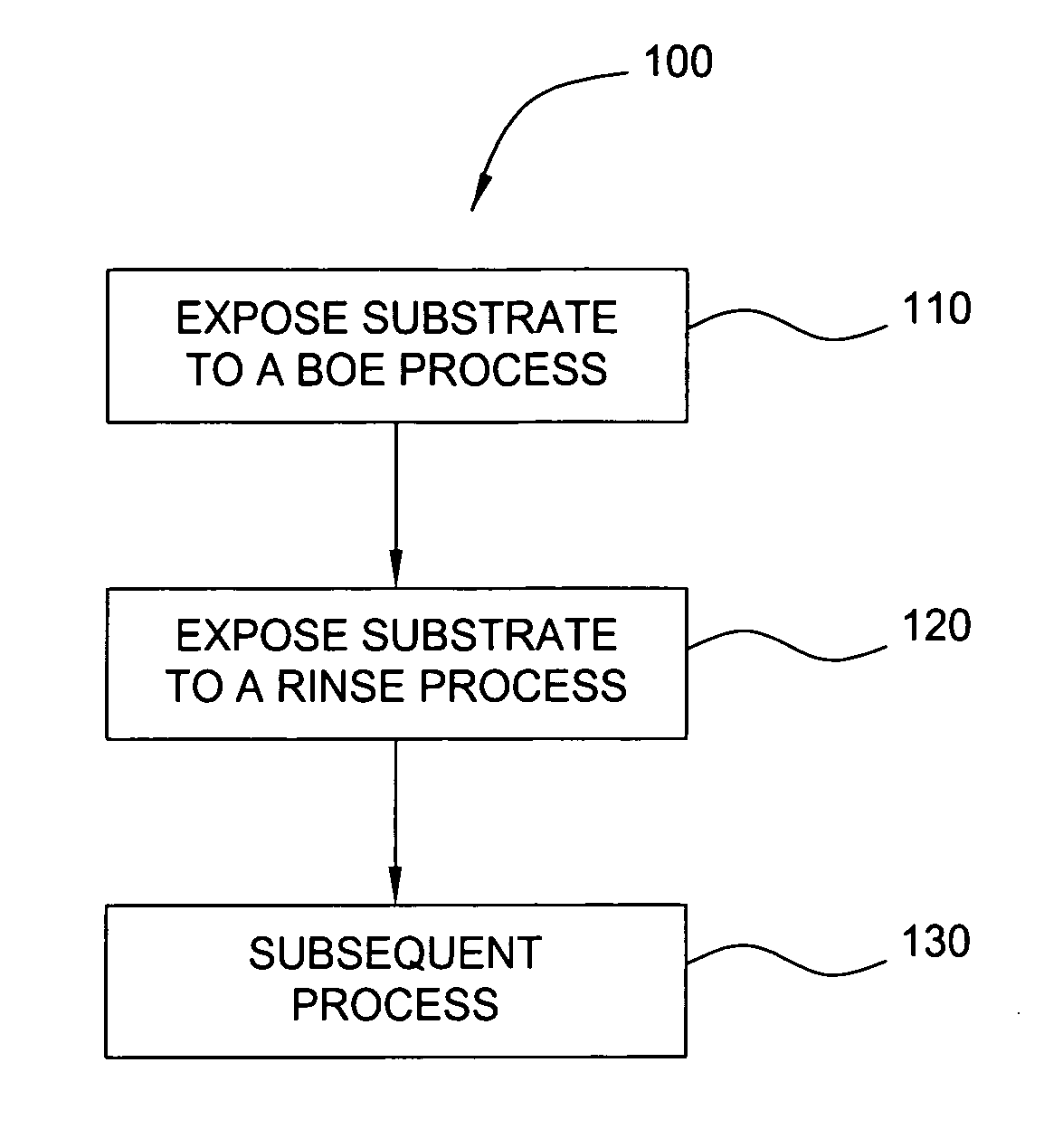

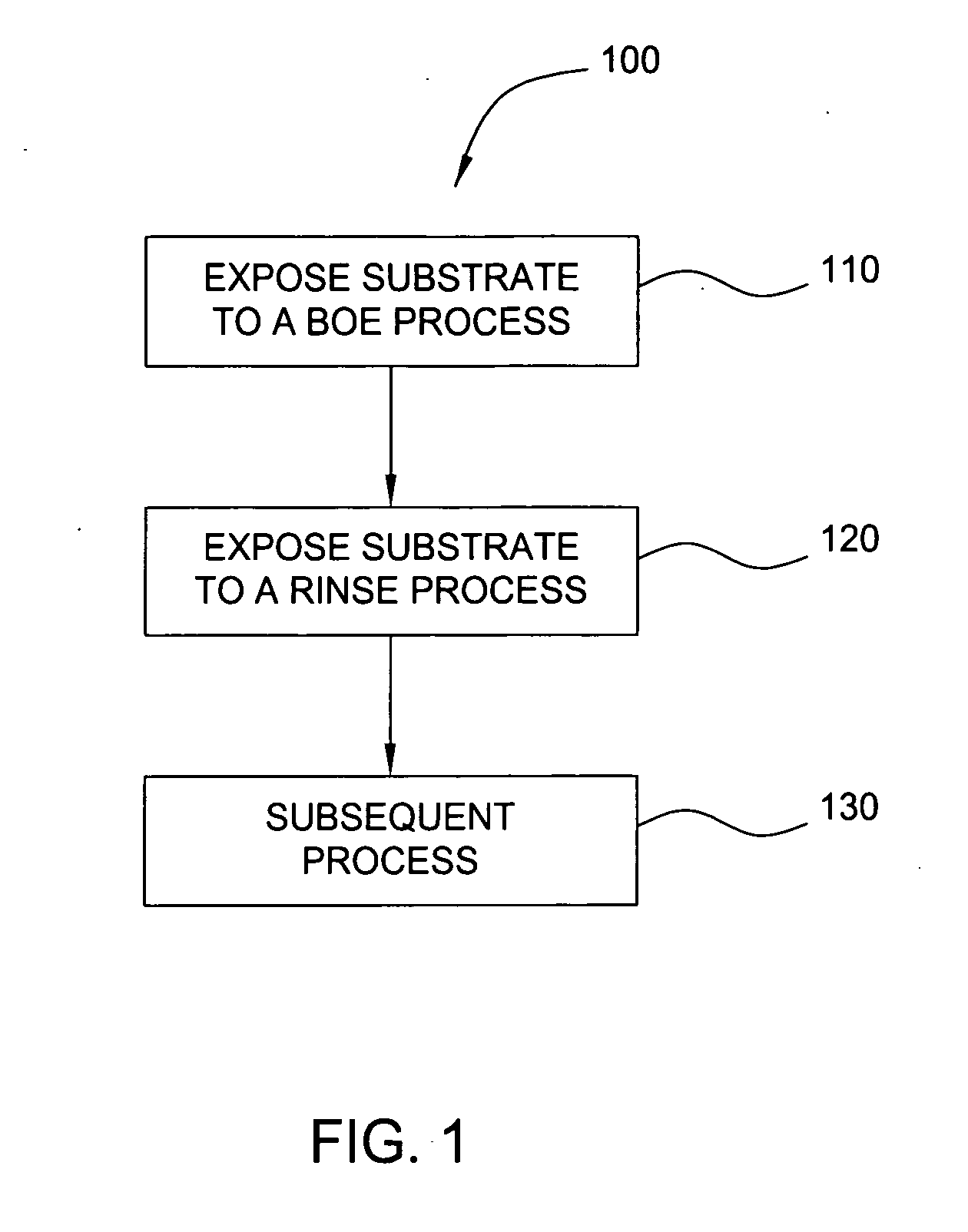

Composition and method for selectively removing native oxide from silicon-containing surfaces

InactiveUS20070099806A1Good wetting propertiesDetergent mixture composition preparationSemiconductor/solid-state device manufacturingChemistryAlkanolamine

Embodiments of the invention are provided which include compositions of buffered oxide etch (BOE) solutions and methods that use the BOE solutions during a process to selectively remove a native oxide layer from a substrate surface containing thermal oxide layers. The BOE solutions generally contain HF and alkanolamine compounds. The viscosity of the BOE solution may be adjusted by varying a concentration ratio of at least two alkanolamine compounds. In one example, a BOE solution is provided which includes, by weight, a first alkanolamine concentration within a range from about 0.5% to about 10%, a second alkanolamine concentration within a range from about 0.5% to about 10%, a HF concentration within a range from about 0.5% to about 10%, a water concentration within a range from about 80% to about 98%, a pH value within a range from about 3.5 to about 5, and a viscosity within a range from about 10 cP to about 30 cP.

Owner:STEWART MICHAEL P +1

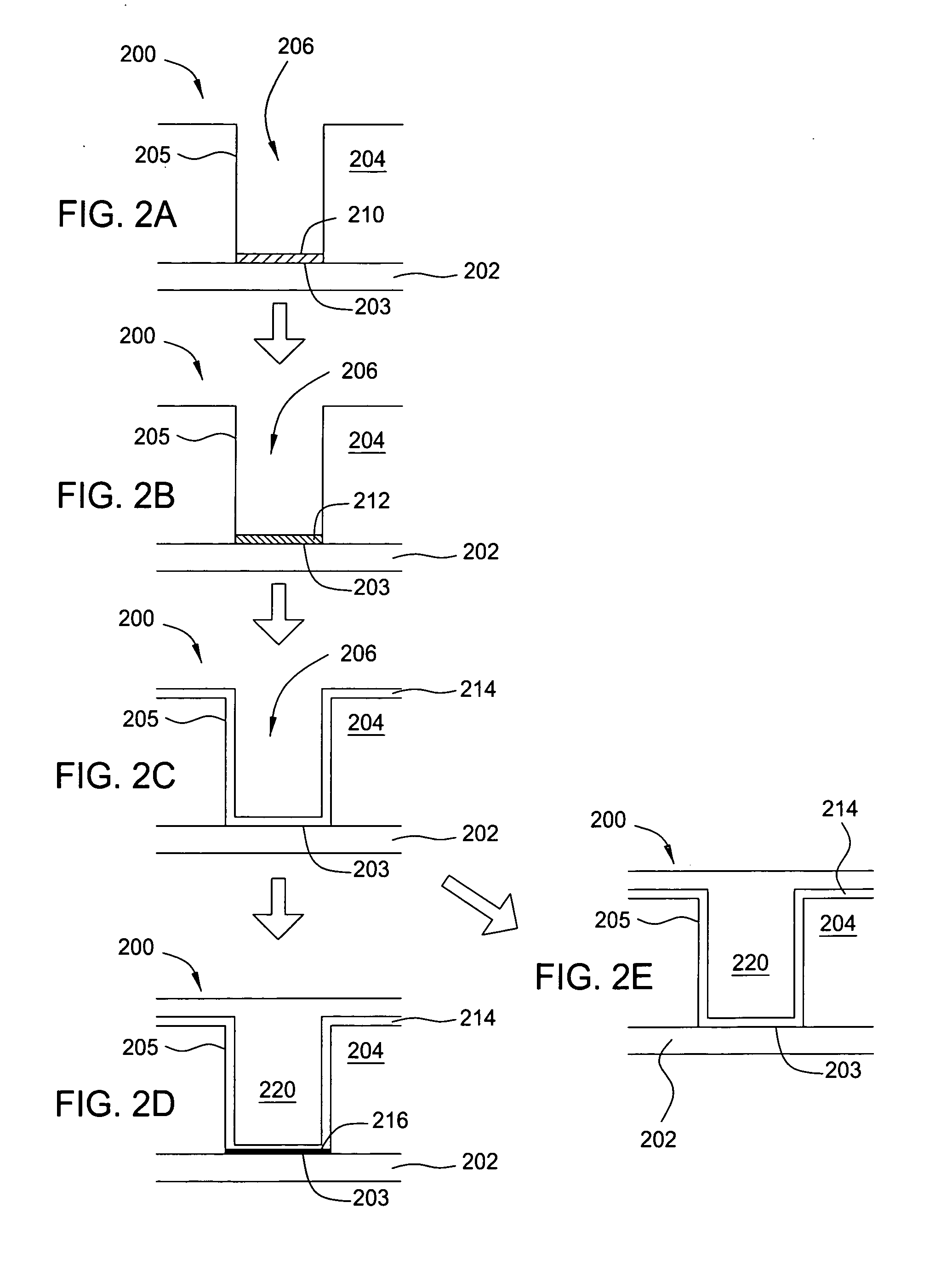

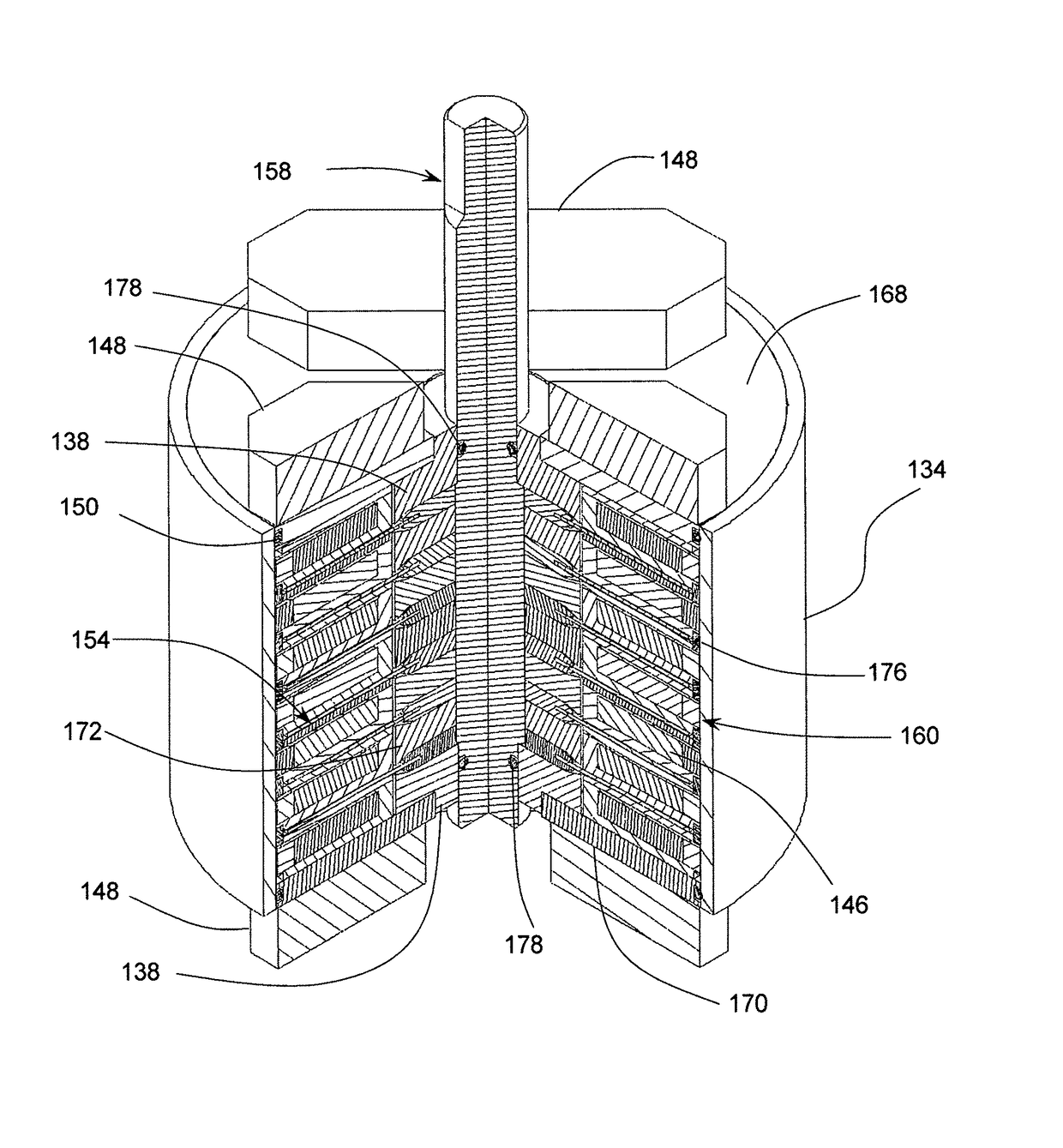

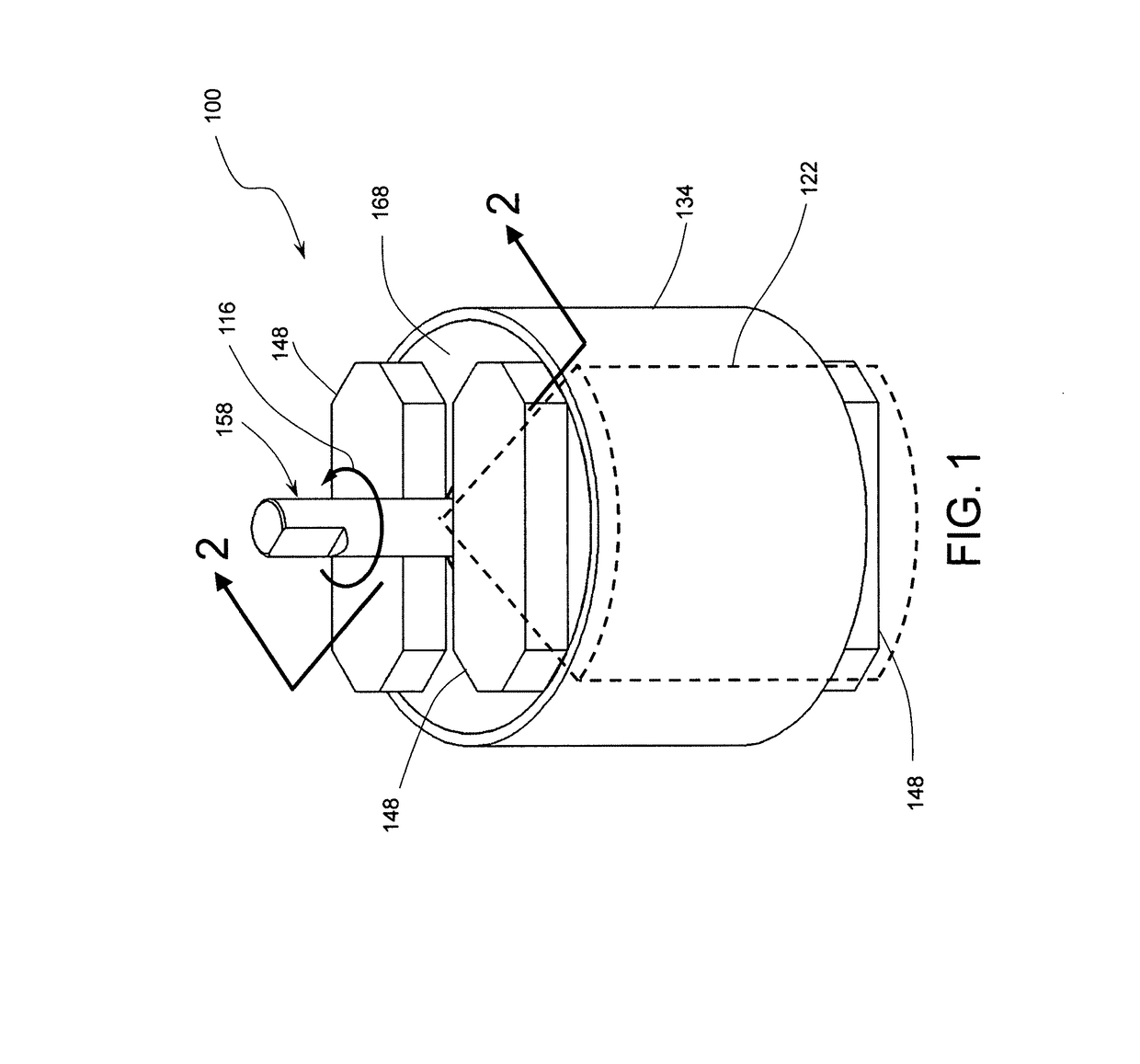

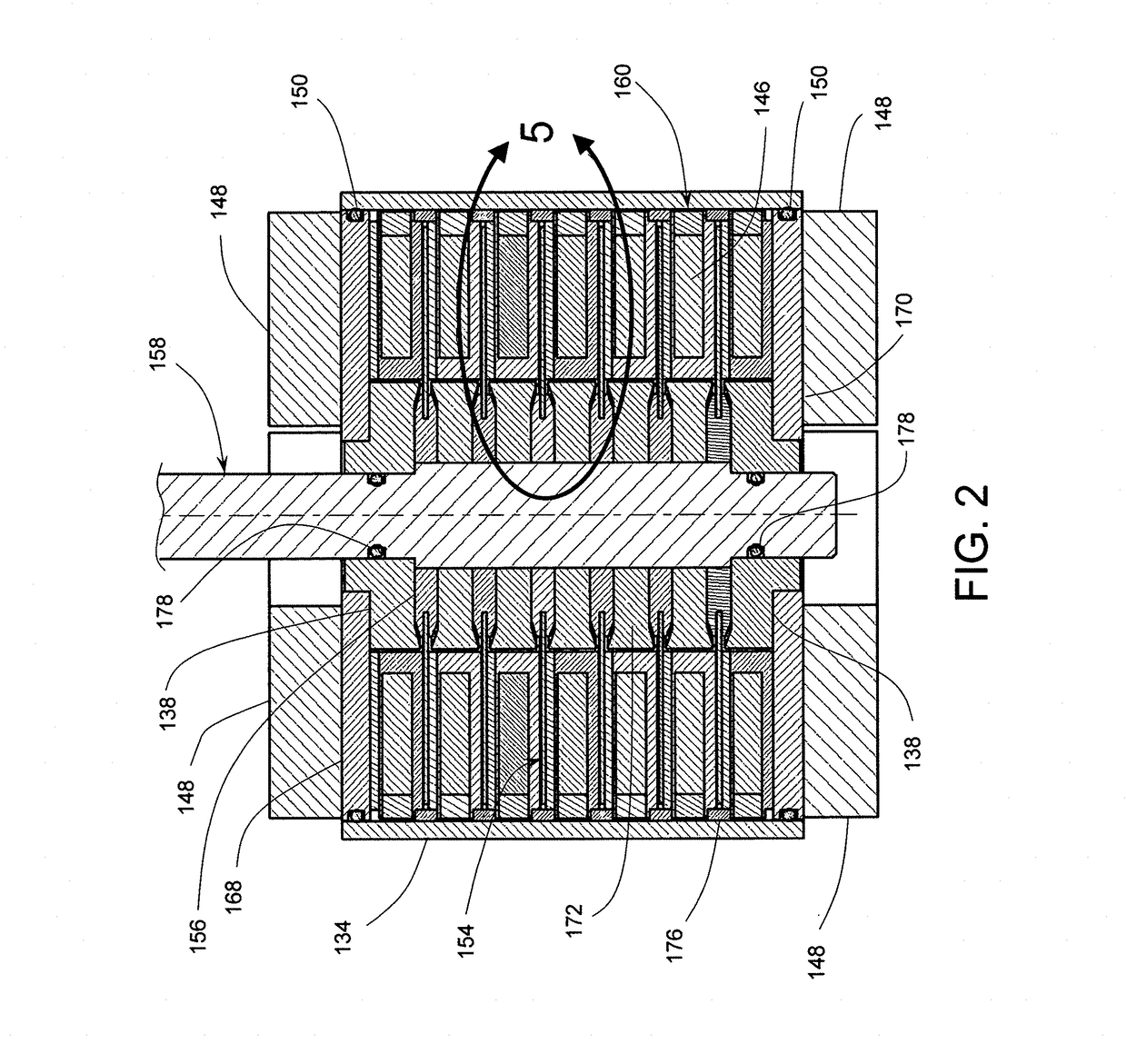

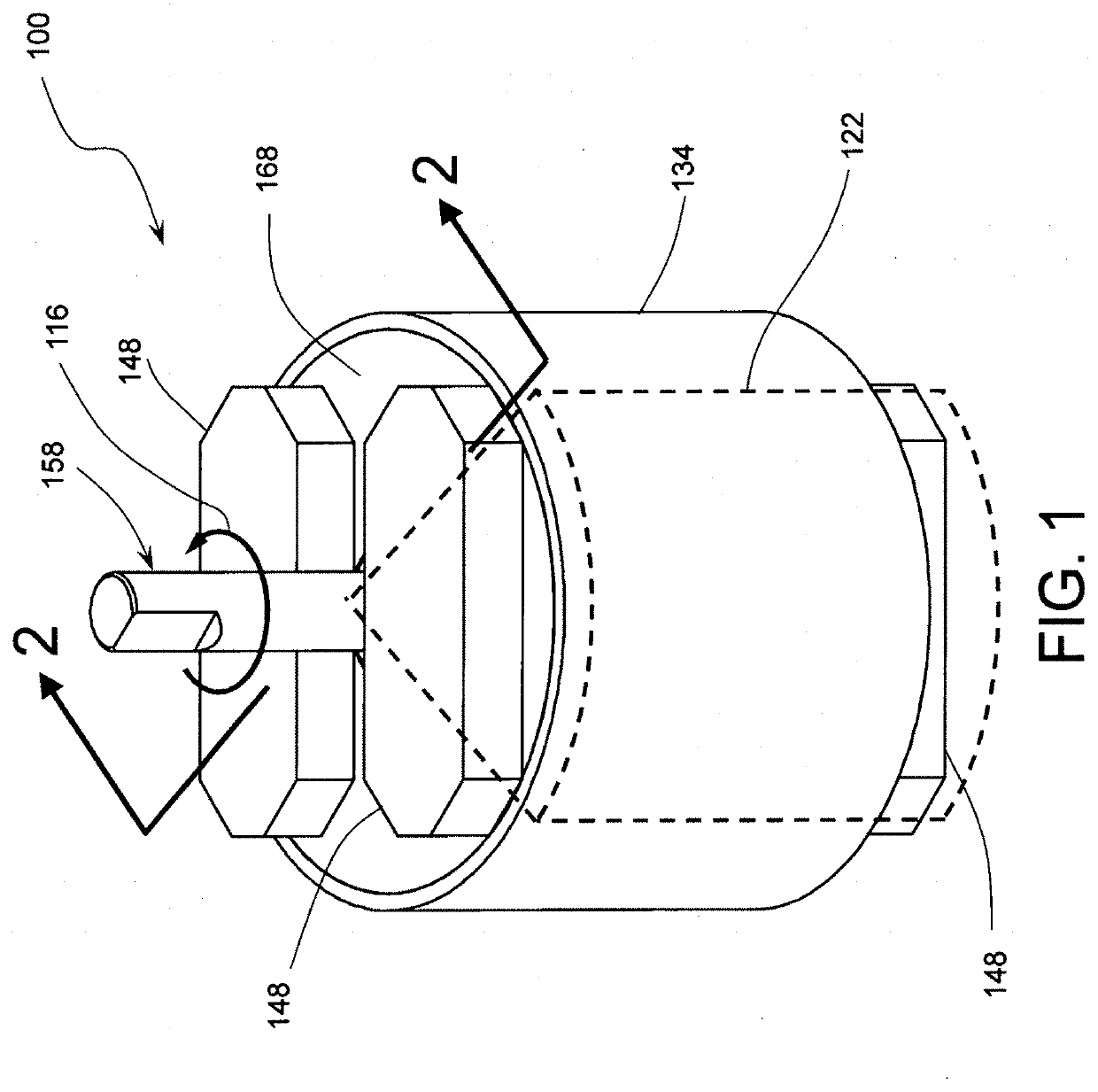

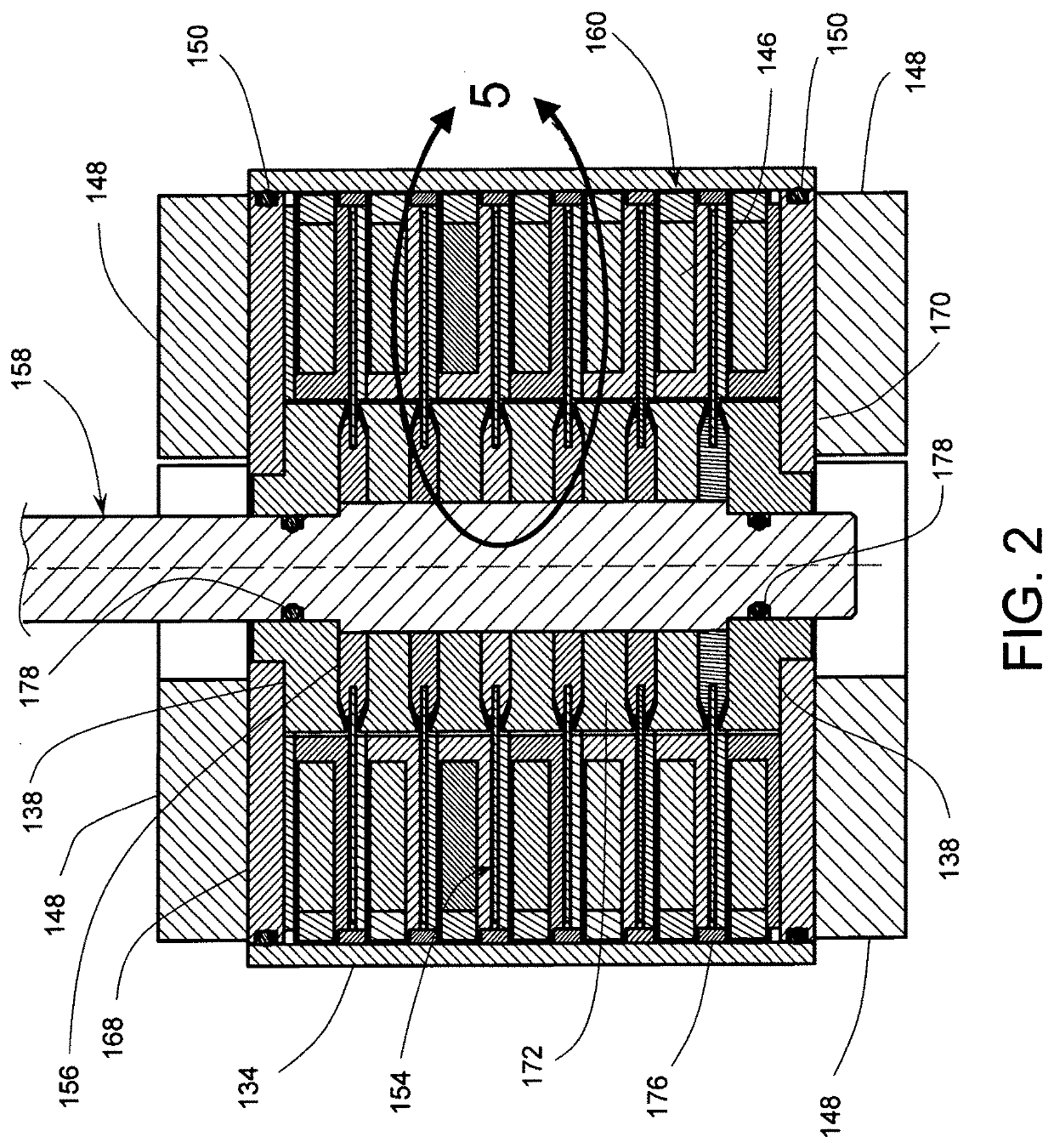

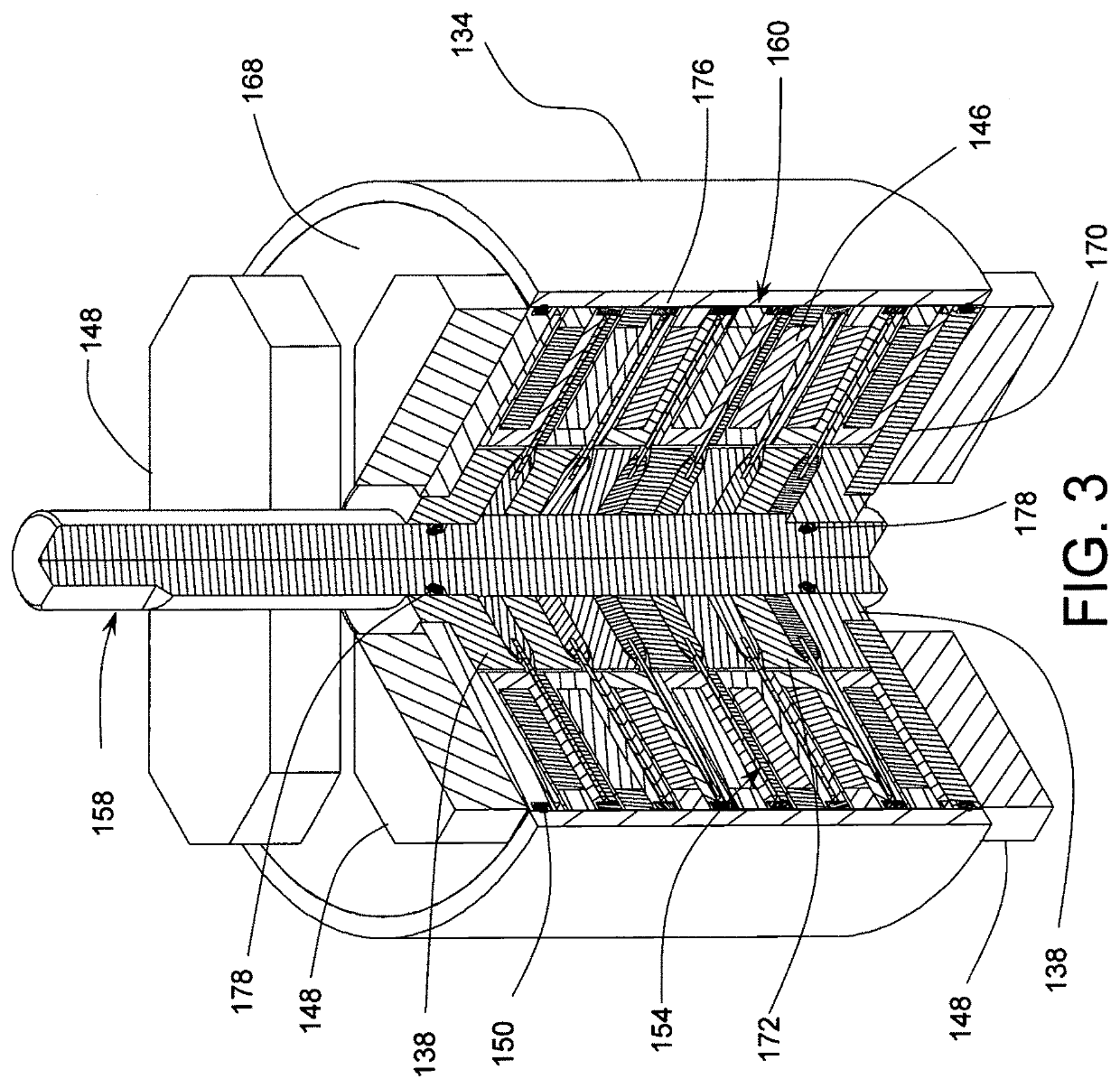

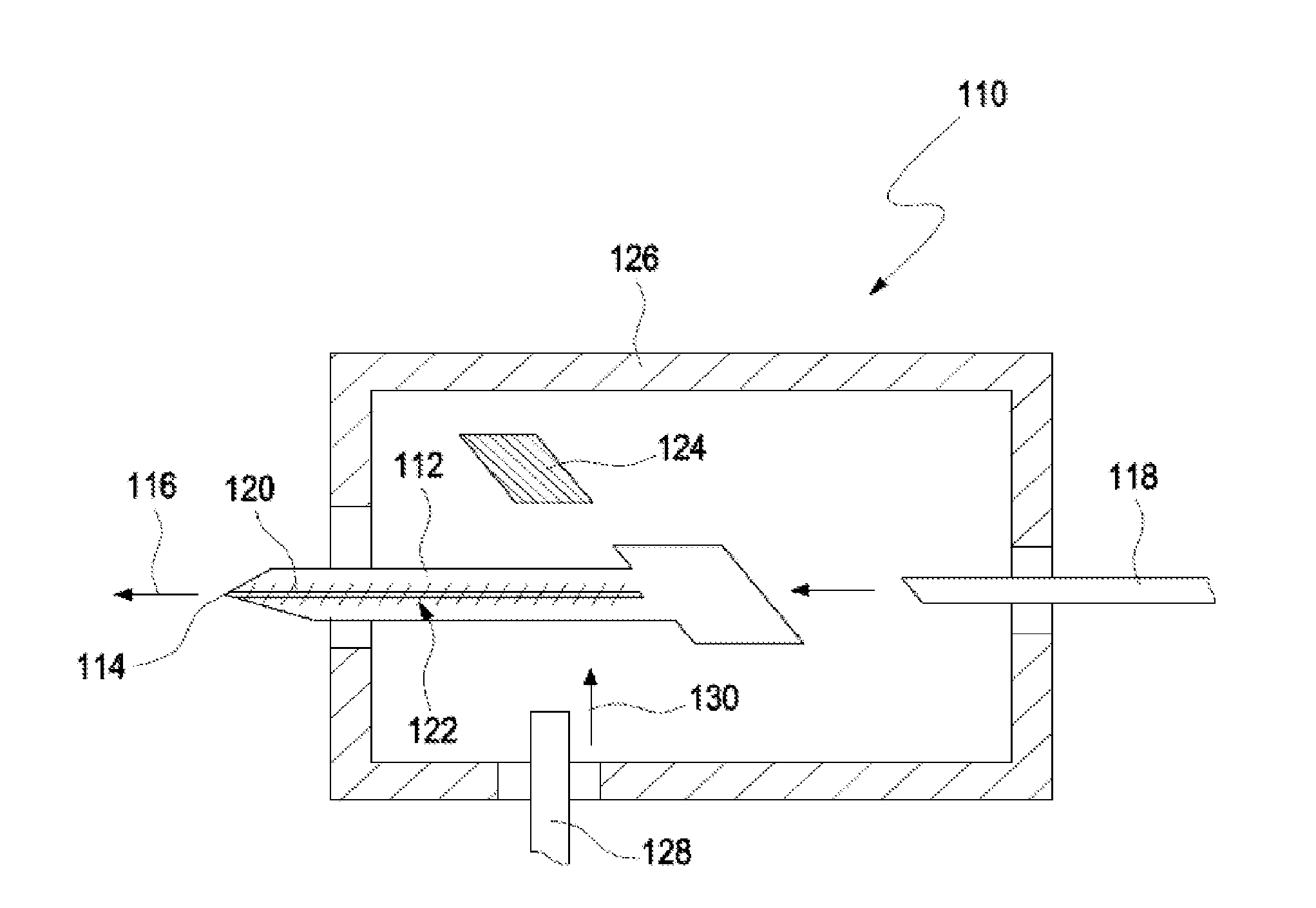

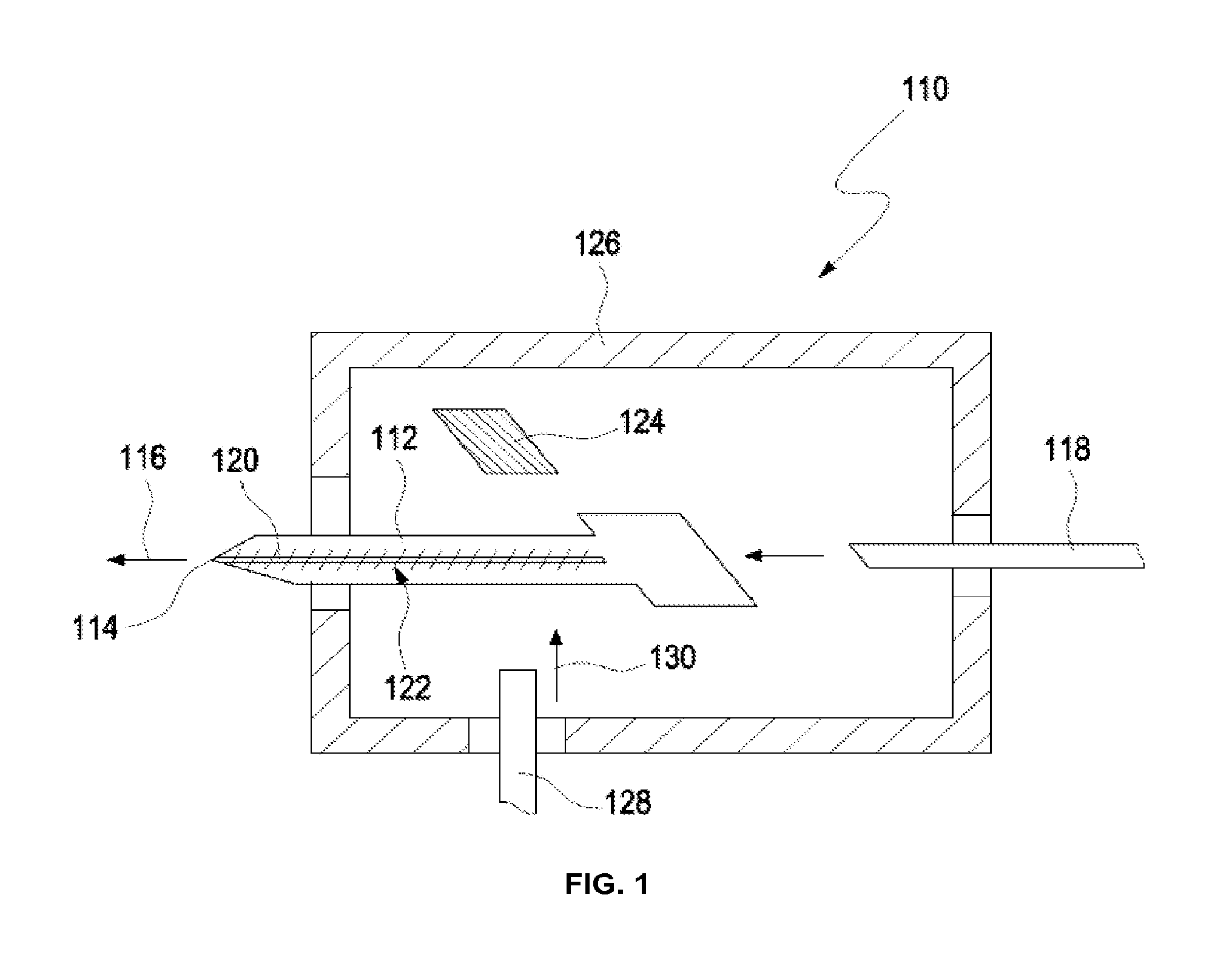

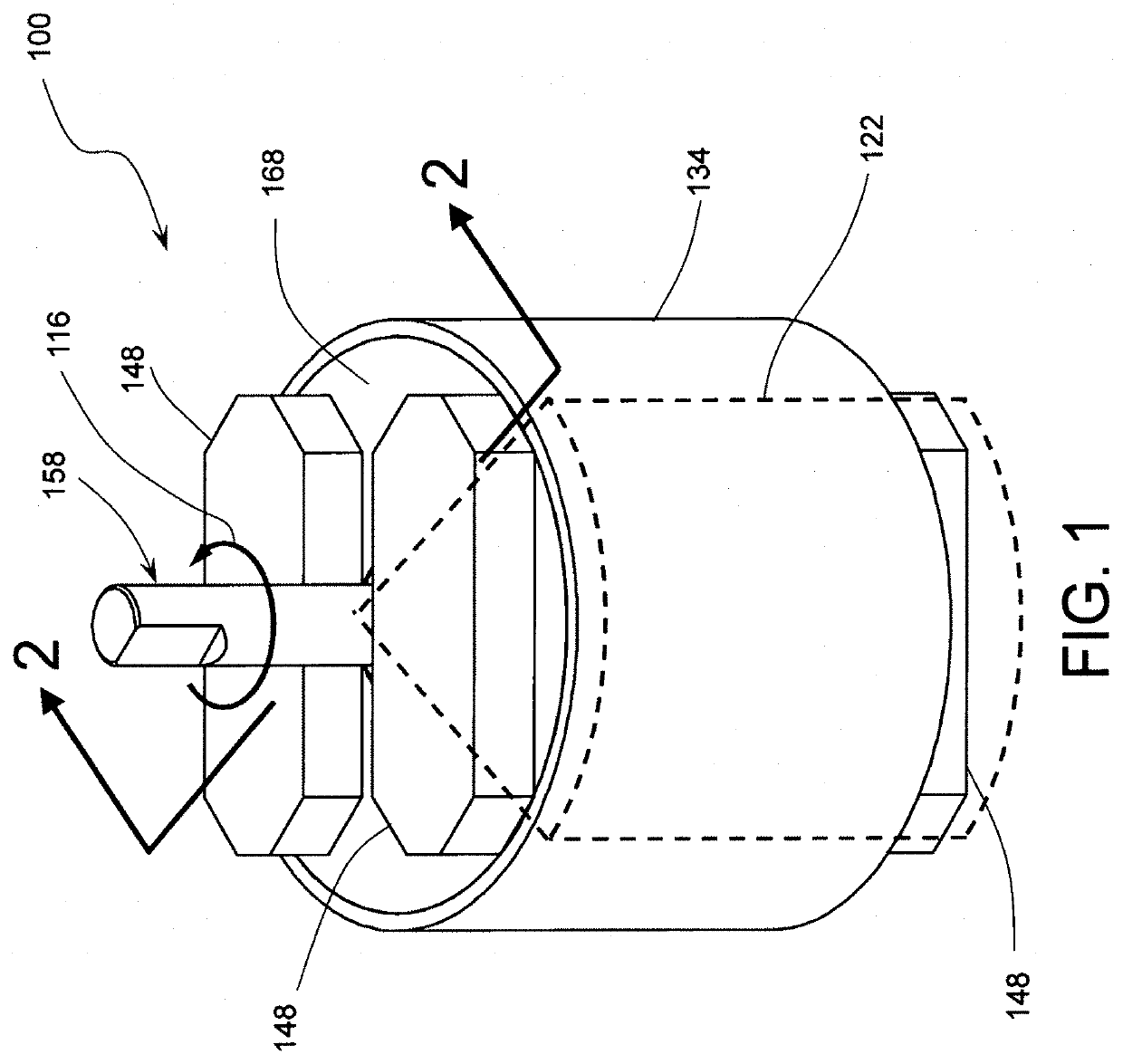

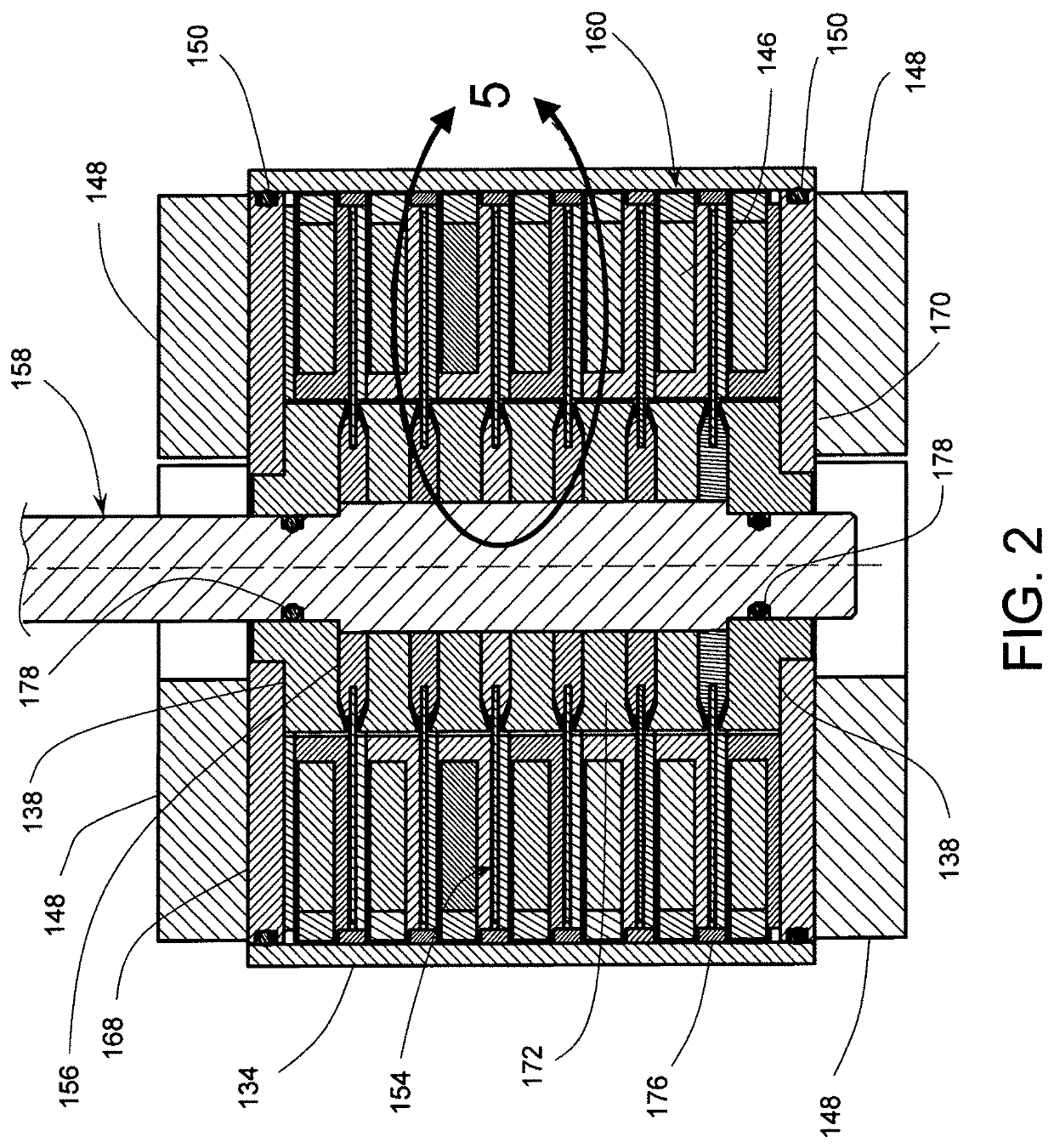

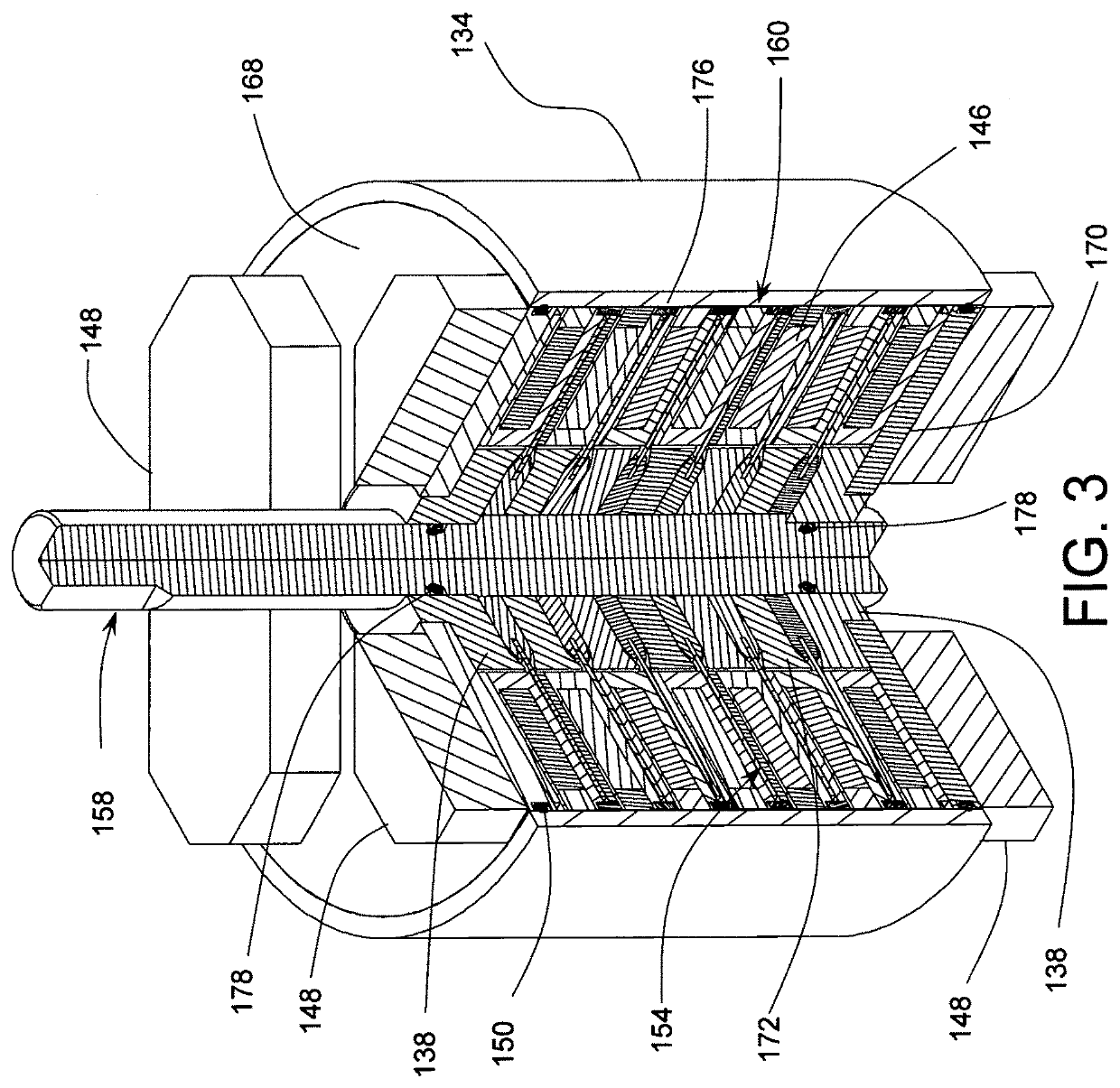

Magnetocaloric Refrigerator

ActiveUS20180045437A1Conducive to efficient heat transferImprove rendering capabilitiesIndirect heat exchangersMachines using electric/magnetic effectsCompression deviceMechanical energy

The invention is for an apparatus and method for a refrigerator and a heat pump based on the magnetocaloric effect (MCE) offering a simpler, lighter, robust, more compact, environmentally compatible, and energy efficient alternative to traditional vapor-compression devices. The subject magnetocaloric apparatus alternately exposes a magnetocaloric material to strong and weak magnetic field while switching heat to and from the material. Action of the heat switches is coordinated with the magnetic field strength to move heat up the thermal gradient. The invention may be practiced with multiple magnetocaloric stages to attain large differences in temperature. Key applications include thermal management of electronics, as well as industrial and home refrigeration, heating, and air conditioning. The invention offers a simpler, lighter, compact, and robust apparatus compared to magnetocaloric devices of prior art. Furthermore, the invention may be run in reverse as a thermodynamic engine, receiving low-level heat and producing mechanical energy.

Owner:VETROVEC JAN

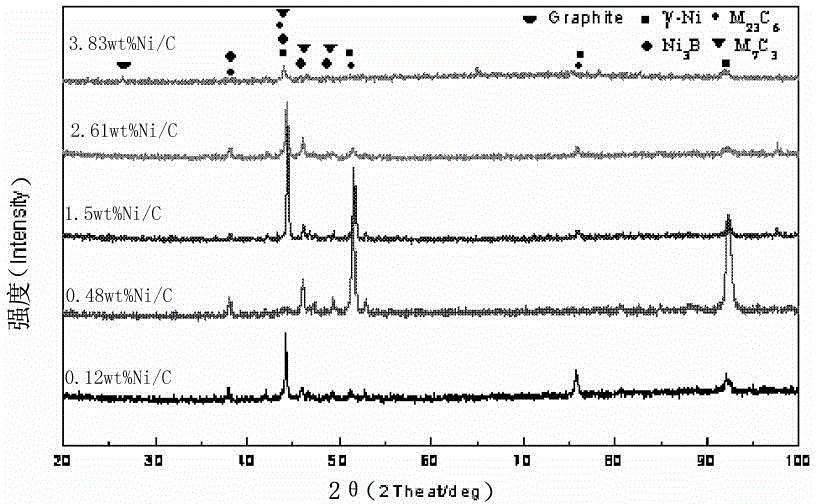

Nickel-coated graphite self-lubricating composite material and application thereof

ActiveCN103060614AGood wear resistanceGood wetting propertiesMetallic material coating processesCarbon steelGrinding

The invention relates to a nickel-coated graphite self-lubricating composite material and an application thereof. An employed technical scheme is that the nickel-coated graphite self-lubricating composite material is composed of, by weight percent: 95.0-99.9 % of self-melting alloy powder and 0.1-5.0 % of nickel-coated graphite. A laser cladding coating process comprises taking the self-melting alloy powder and the nickel-coated graphite, uniformly mixing by a ball milling method or a grinding method, using a preset method or a powder feeding method, and using a continuous CO2 laser device for laser cladding on a substrate. A content of the nickel-coated graphite varies widely. The nickel-coated graphite is uniform and dense in coating structure, excellent in wear resistance and antifriction performances, and good in metallurgy combination with substrates, can meet requirements of carbon steel and alloy steel for friction and wear performance in different working conditions. A coating preparation process is high in scale and automation degree, and thus the nickel-coated graphite self-lubricating composite material can be widely applied in fields of aerospace, machinery, automobile, military industry, etc.

Owner:SHENYANG AIRCRAFT CORP

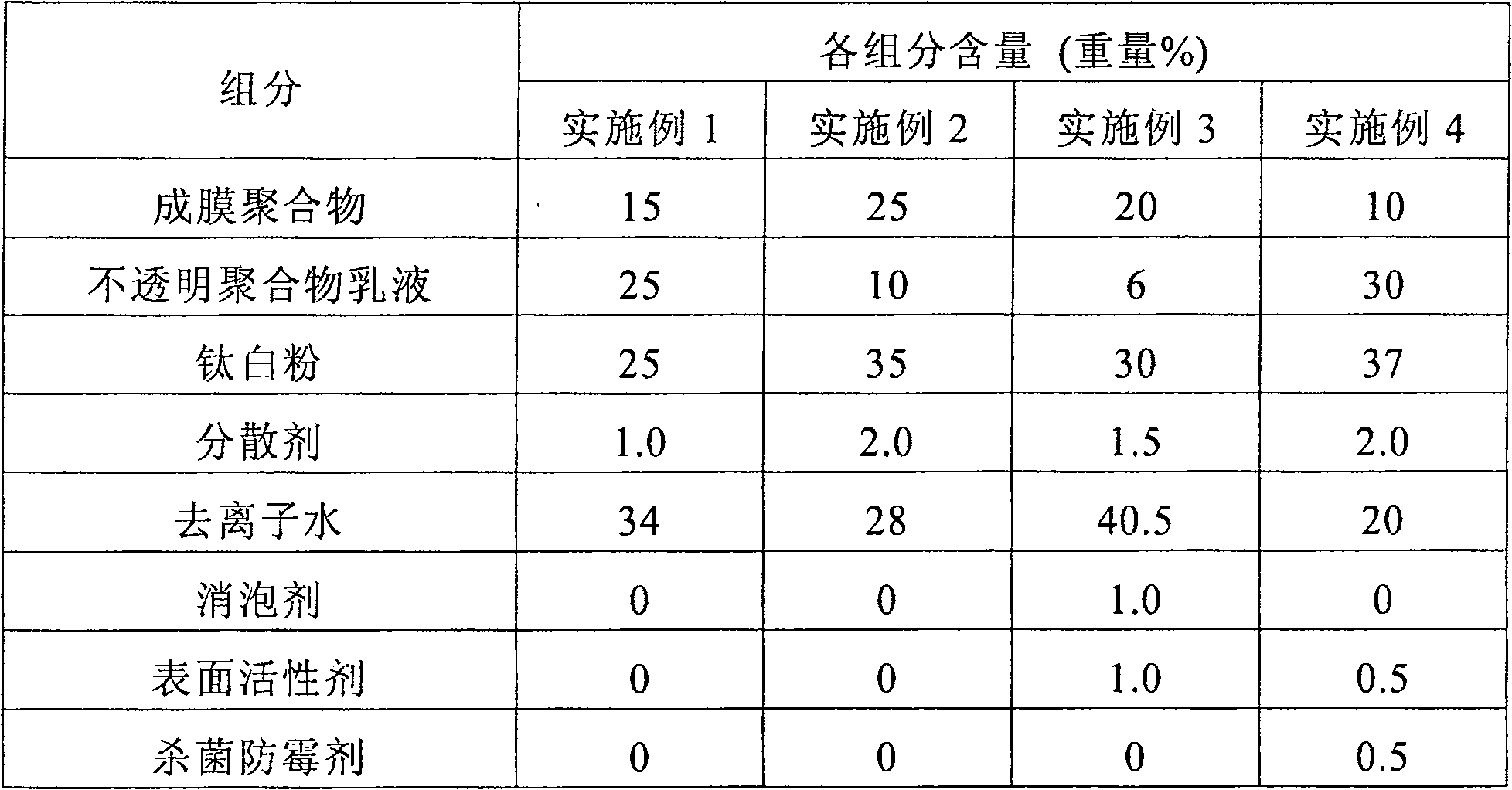

Water-base correction fluid composite and preparation method thereof

This invention relates to a water-base tippex combination, according to weight it composed by 10 to 30% film-forming polymer, 5 to 30% opacity polymer emulsion, 20 to 50% white pigment, 0.5 to 2% dispersant and 10 to 50% water. The opacity polymer emulsion is styrene - acroleic acid copolymer latices, and styrene - acroleic acid copolymer exist by particle form of monodisperse sphericity. This tippex takes opacity polymer emulsion to substitute titanium pigment, greatly reduce material cost, and has favorable wetting property,, easy applying, the rewritten time is less than 60 seconds.

Owner:上海乐美文具有限公司

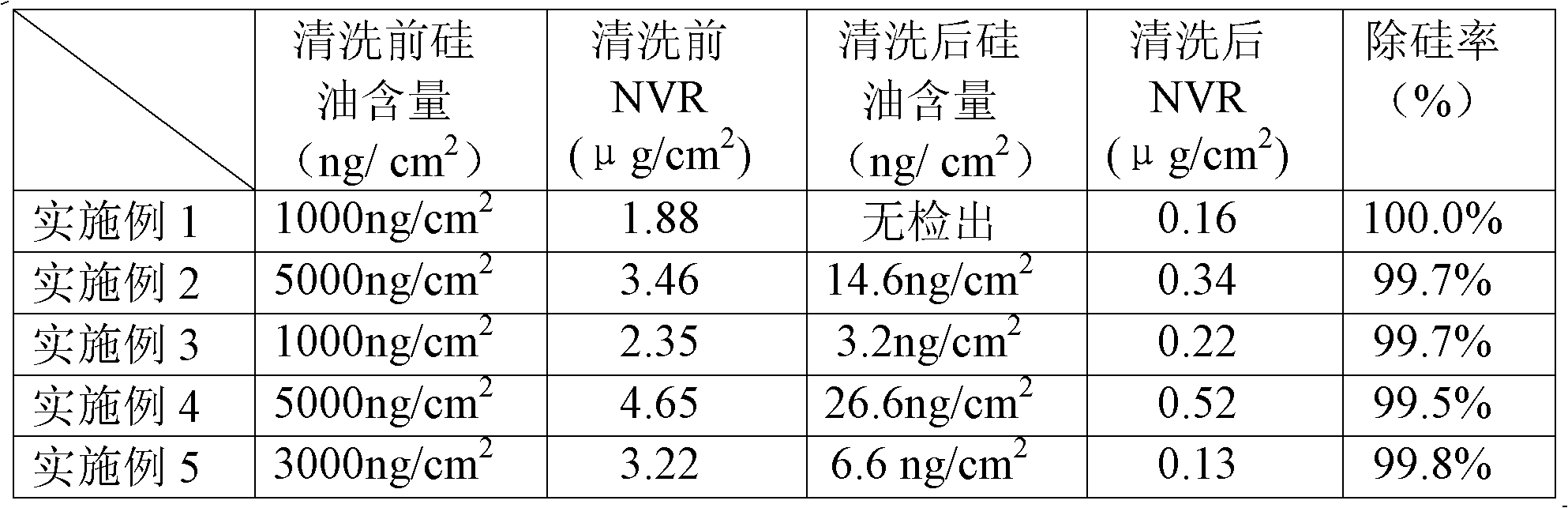

Silicone oil removing water base detergent

ActiveCN102358873AEasily biodegradableEfficient removalOrganic detergent compounding agentsSurface-active detergent compositionsWater basedPoly(ethylene glycol) dimethyl ether

The invention discloses a silicone oil removing water base detergent, comprising a mixed liquor of water and polyoxyethylene octylphenol ether, sorbide ester, glycol monoether and polyethylene glycol dimethyl ether, wherein the polyoxyethylene octylphenol ether accounts for 0.01-0.5wt% of the mixed liquor, and the sorbide ester accounts for 0.005-0.1wt% of the mixed liquor, and the glycol monoether accounts for 0.1-1.0wt% of the mixed liquor, and the polyethylene glycol dimethyl ether accounts for 0.01-0.5wt% of the mixed liquor. Aiming at problems that dust free chamber consumptions have standard exceeded silicone oil content and are not easily cleaned, and exisiting silicone oil removing detergent is not suitable for processing of dust free chamber consumptions, the invention provides a water base detergent, which is suitable for cleaning dust free chamber consumptions, and has simple formula, low costs, good silicone oil removing effect and good biodegradability.

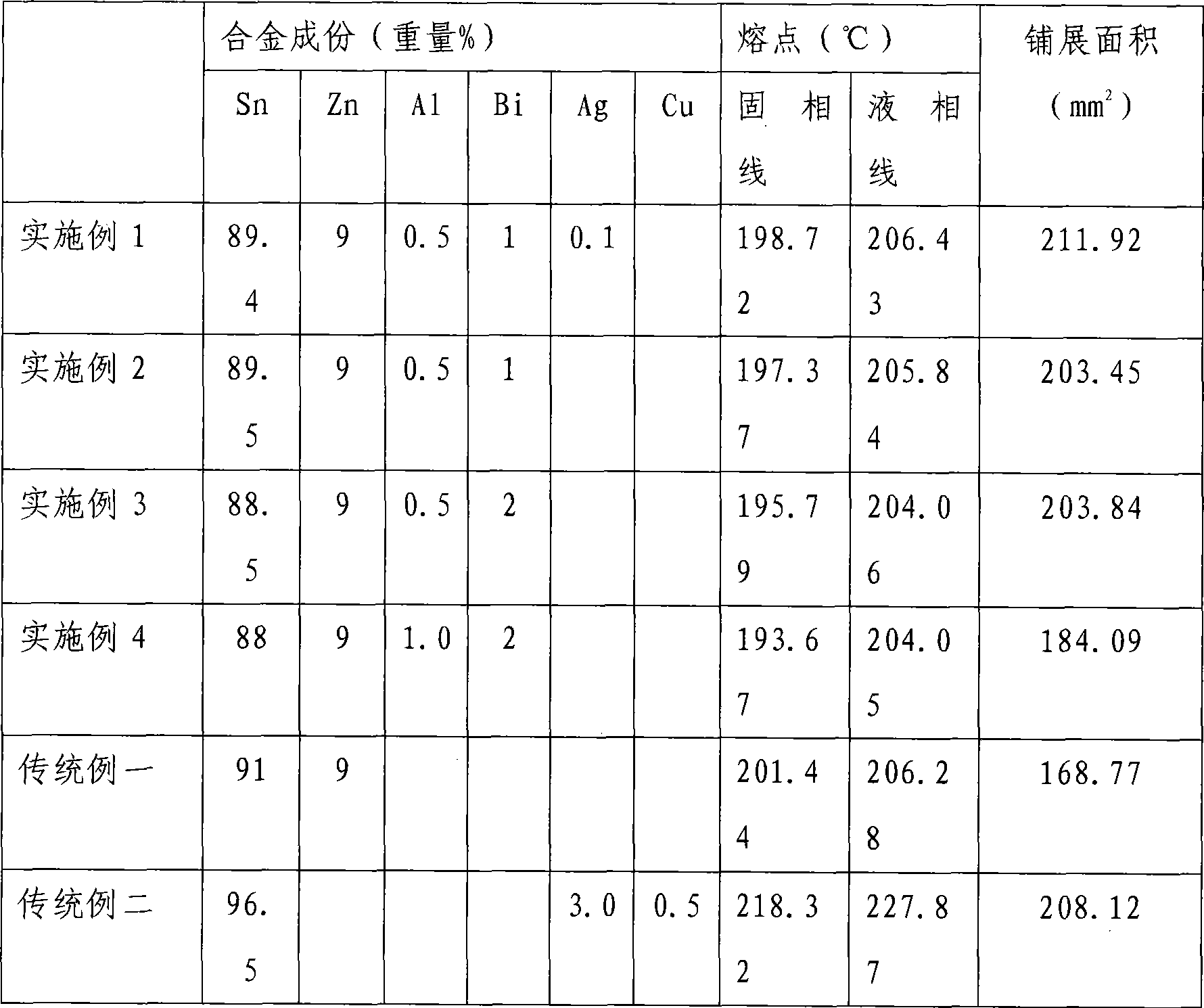

Lead-free solder for aluminum soft soldering

InactiveCN101486133AStrong antioxidantGood wetting propertiesWelding/cutting media/materialsSoldering mediaZincChemical composition

The invention discloses low-temperature brazing solder for aluminum substrate materials. The solder is leadless solder; and not only the solidified structure is improved compared with needle zinc-phase tin-zinc eutectic alloy and the wettability is improved but also the solder can form joints with higher strength with aluminum substrates. The low-temperature brazing solder for the aluminum substrate materials comprises the following chemical compositions in percentage by weight: 9 to 15 percent of zinc, 0.01 to 2 percent of aluminum, 0.01 to 2 percent of silver, 1 to 3 percent of bismuth, and the balance being tin. The leadless solder alloy obtained by the proposal does not use toxic lead, has stronger antioxidation and better wettability compared with the prior Sn-Zn alloy, and is more suitable for aluminum soft soldering compared with the prior Sn-Ag-Cu solder alloy; and the joints have better performance and lower cost.

Owner:YIK SHING TAT INDUSTRIALCO LTD +2

Bone cement and methods of use thereof

ActiveUS9642932B2High viscosityGood wetting propertiesImpression capsSurgical adhesivesPolymer scienceBone cement

A bone cement comprising an acrylic polymer mixture which is formulated to have a relatively high viscosity for a relatively long window, due to distributions of molecular weights and / or sizes of acrylic beads.

Owner:DEPUY SYNTHES PROD INC

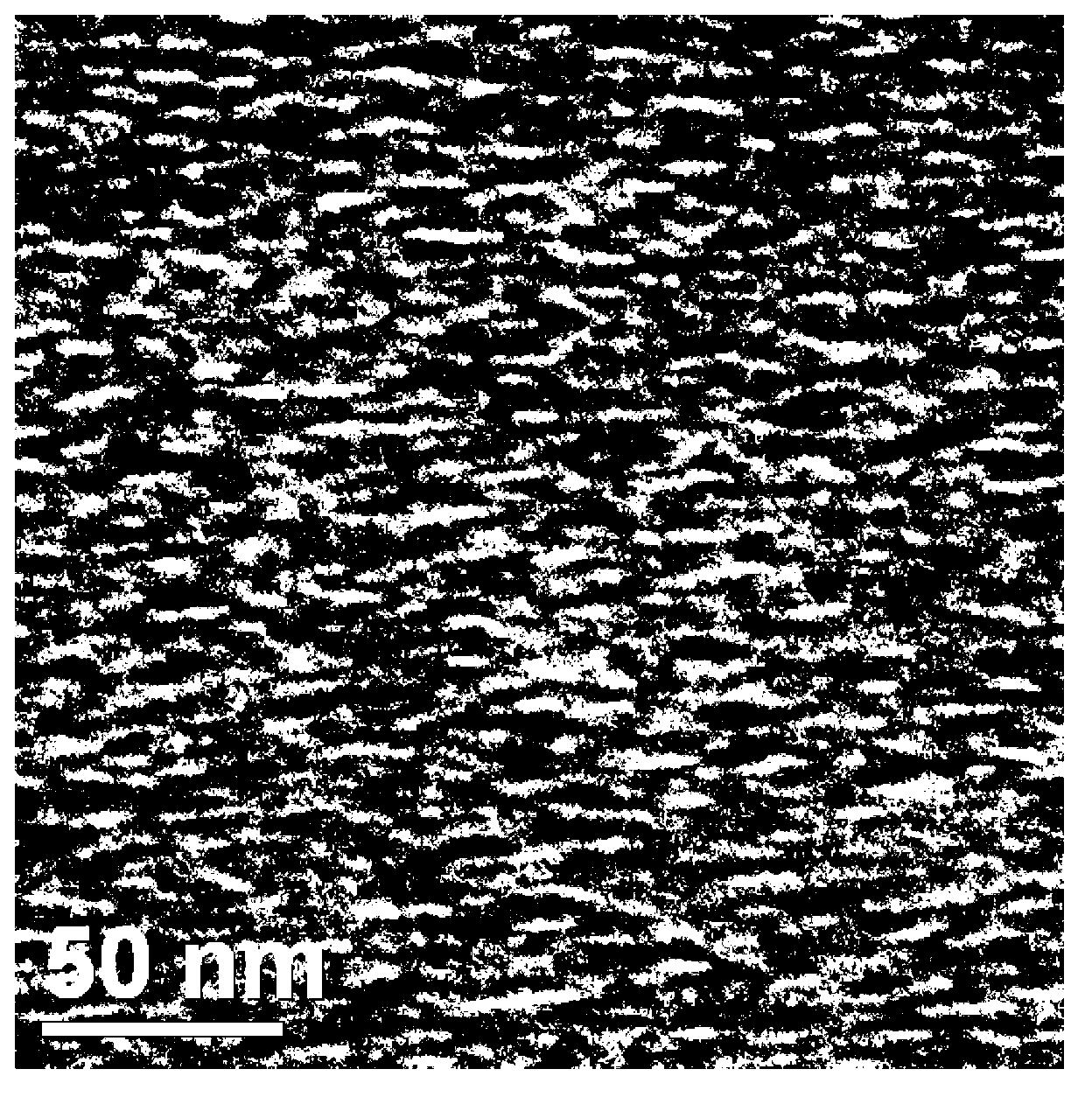

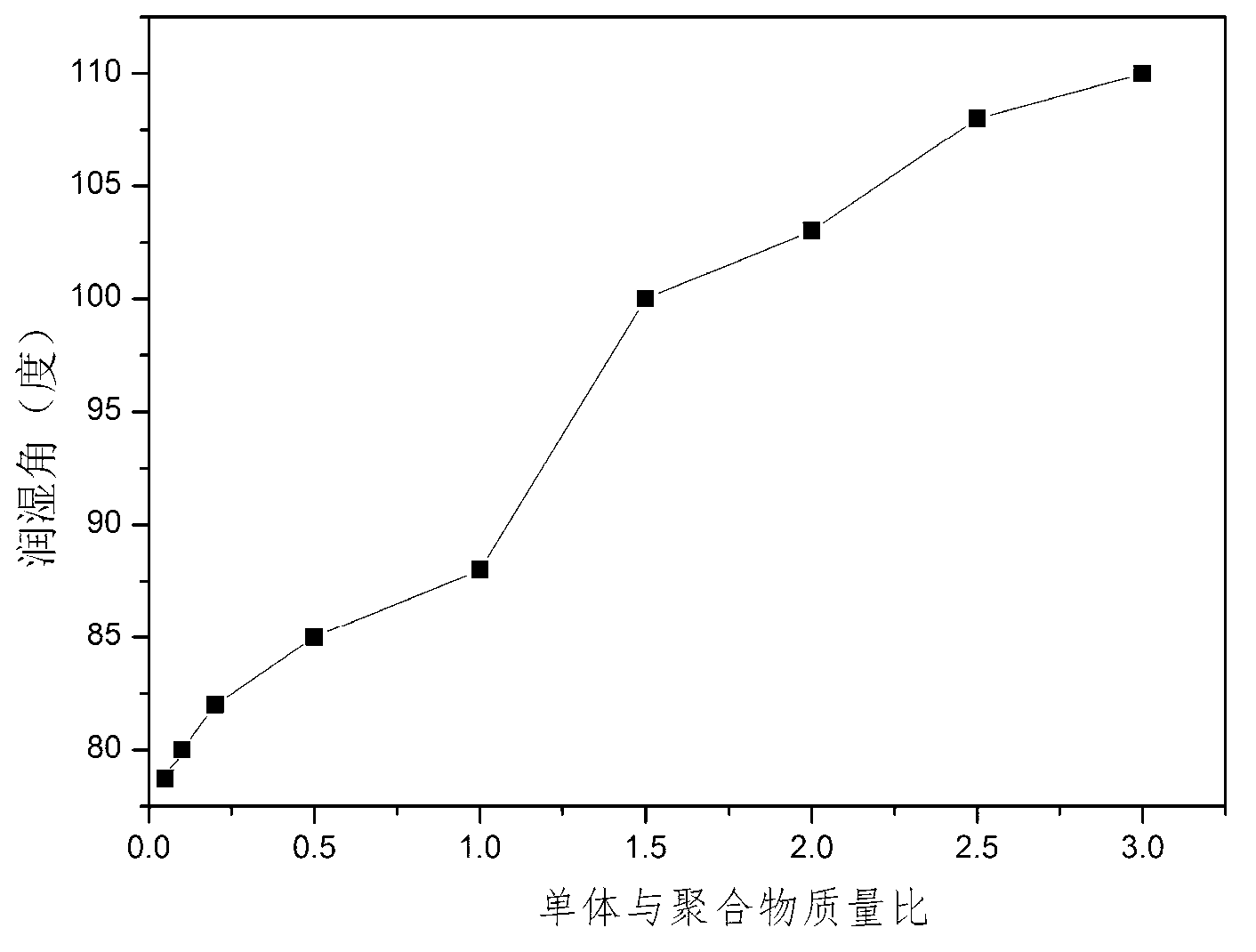

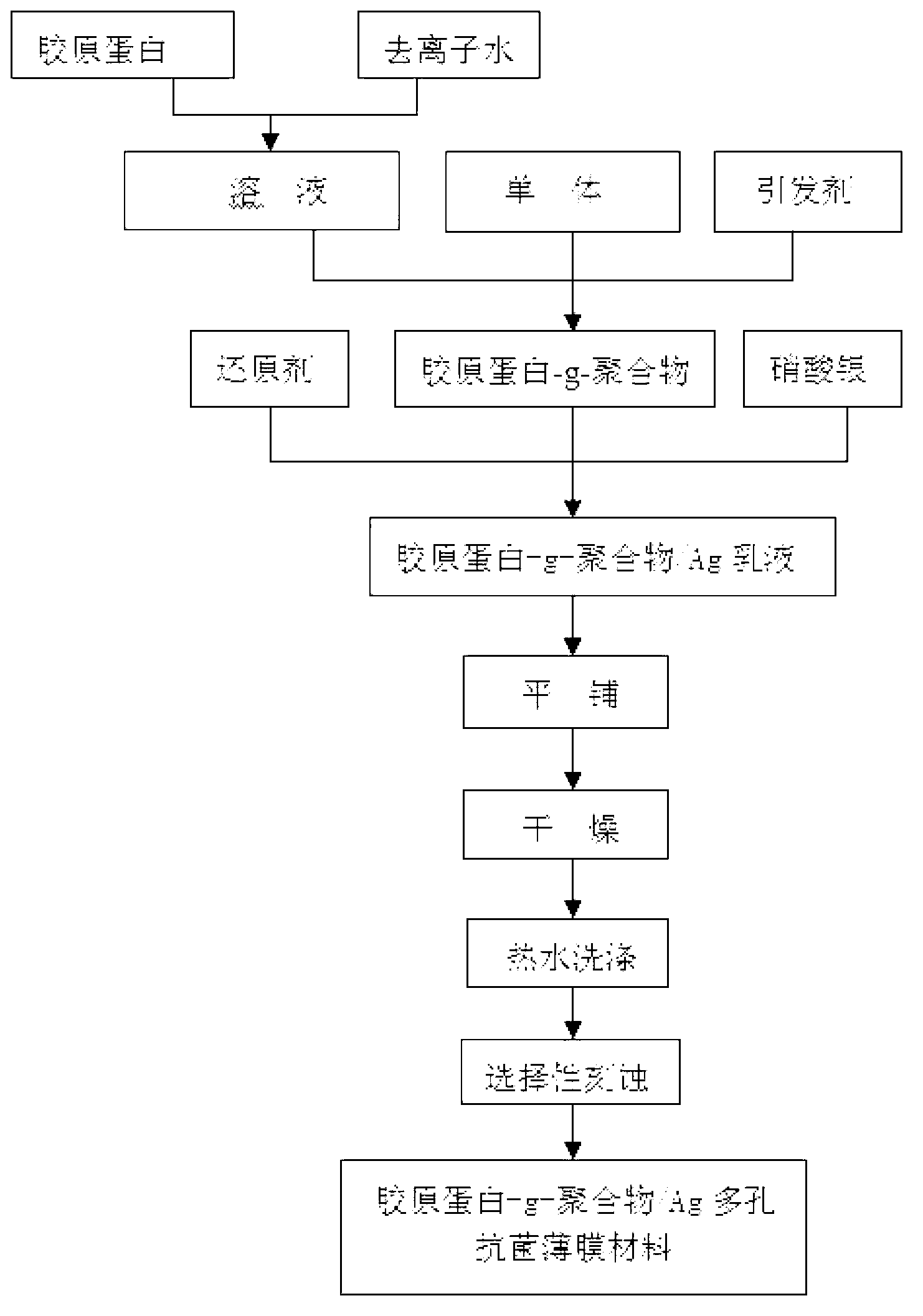

Collagen-g-polymer/Ag multi-hole nano antibacterial film material and preparation method thereof

InactiveCN102936390AGood wetting propertiesOpen up new application fieldsBiocideDisinfectantsActive agentFilm material

The invention discloses a collagen-g-polymer / Ag multi-hole nano antibacterial film material and a preparation method thereof. The mass ratio of the monomer and the collagen of the material is 0.05-1, the mass concentration of Ag nano particles in a collagen solution is in a range from 15mg / g to 30mg / g, the monomer is one of styrene, vinyl acetate, vinyl chloride or methyl acrylate, sizes of Ag nano particles are in a range from 3nm to 6nm, the hole diameter of the material is in a range from 3nm to 10nm, and the grafting ratio of the collagen is in a range from 4% to 42%. Accordingly, the number of the monomer is changed, a surface active agent which has good compatibility with the collagen is added, and quality factors such as the hole size and the uniformity of a film can be adjusted and controlled. The material has advantages of natural materials and synthetic polymer materials and is worthy of popularization in the field of biological materials.

Owner:NANJING UNIV OF SCI & TECH

Lead-free low-temperature solder and preparation method thereof

InactiveCN107877031AImprove liquidityImprove wettabilityWelding/cutting media/materialsSoldering mediaIndiumSlag

The invention belongs to the technical field of solder, and particularly relates to a lead-free low-temperature solder. The solder comprises, by mass, 0.001-58.0% of bismuth, 0.001-1.0% of silver, 0.001-2.0% antimony, 0.001-0.1% of indium, 0.001-0.15% of phosphorus, 0.001-0.08% of germanium, 0.001-0.015% of beryllium, 0.001-0.015% of cerium and the balance tin. Compared with the prior art, when welding is carried out at the temperature of 139DEG C to 200DEG C, little oxidation slag is generated, the surface of a tin furnace can be kept bright basically without oxidation at the temperature, thesolder can not be oxidized within 50 seconds at 200-260 DEG C, so that the welding efficiency is greatly improved, and the damage to electronic components of a PCBA board is reduced; the low-temperature solder is good in oxidation resistance; and in the welding process, compared with a common Sn-Ag-Cu system, the solder has fewer welding defects, the surfaces of welding spots are very light-bright, the welding spots are full, continuous welding does not occur, so that the welding quality is effectively improved, and the solder and the method are environment-friendly and safe.

Owner:THOUSAND ISLAND METAL FOIL

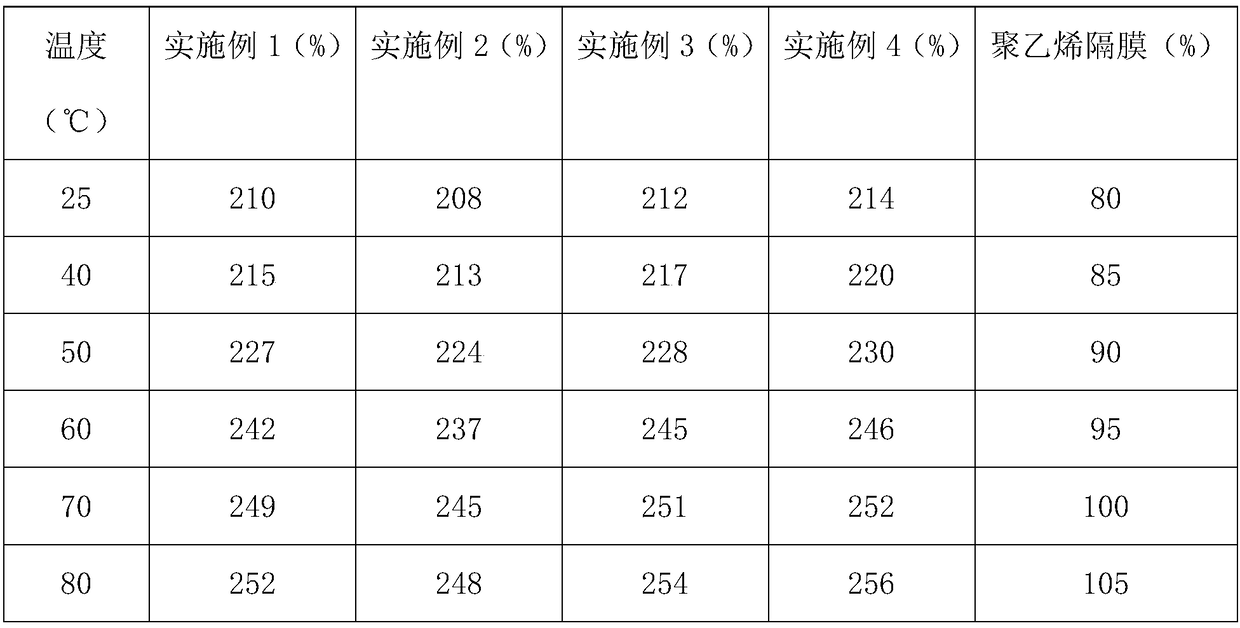

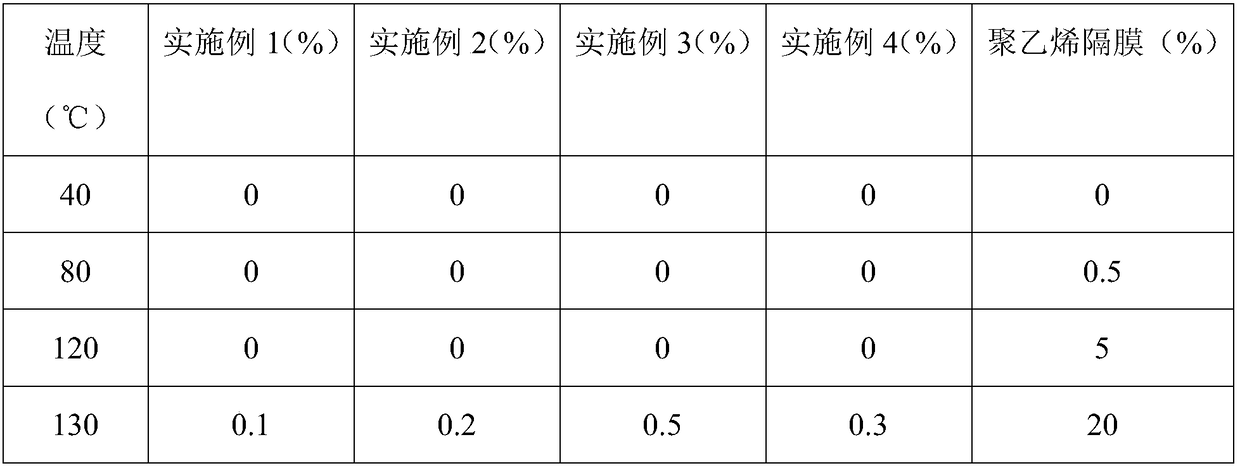

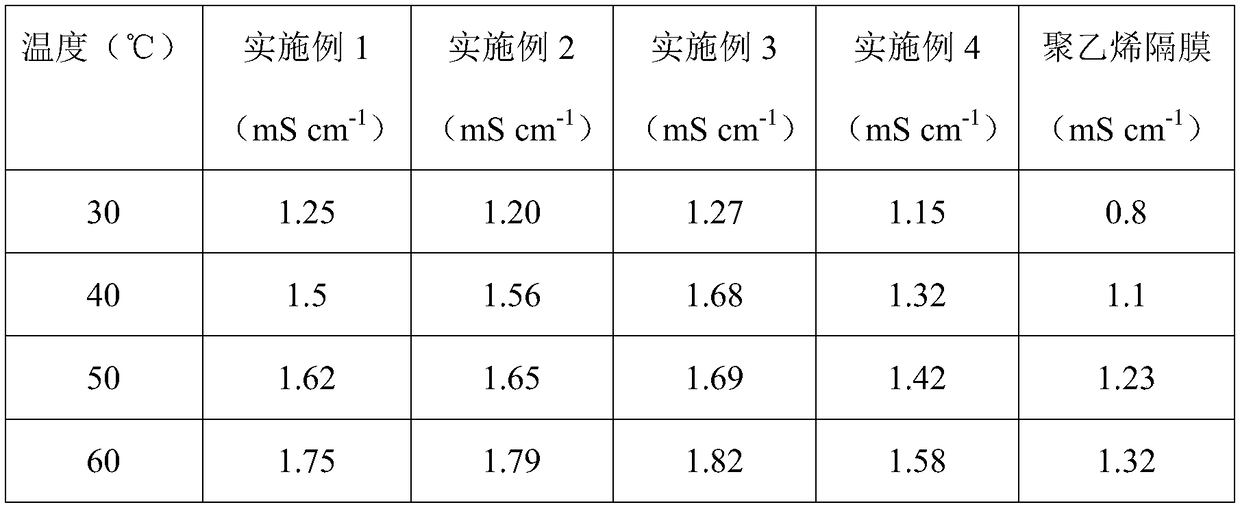

High temperature resistant battery diaphragm containing cellulose fiber substrate and preparation method thereof

InactiveCN107591512AGood wetting propertiesGood liquid absorption and liquid retention capacitySecondary cellsCell component detailsIonEmulsion

The invention discloses a high temperature resistant battery diaphragm containing a cellulose fiber substrate and a preparation method thereof. The high temperature resistant battery diaphragm has a thickness of 20-40micrometer, a porosity of 40-60%, and air permeability of 15-30sec / 100cc. The diaphragm includes a cellulose fiber substrate, a porous adhesive layer and an inorganic coating. The preparation method includes: subjecting an aqueous polyurethane emulsion to mechanical foaming, conveying a foam glue to a foam bath device, immersing the cellulose fiber substrate by traction into foambath for gluing, and letting the foam glue form the porous adhesive layer on the substrate surface; coating the cellulose fiber substrate and the porous adhesive layer with an inorganic paint, conducting compounding to form an inorganic coating; and performing drying. The high temperature resistant battery diaphragm provided by the invention has the advantages of good imbibition and liquid retention ability, no shrinkage, longitudinal and horizontal hot shrinkage both below 2%, high ion penetrability, low resistance, excellent mechanical properties, and stable electrochemical properties, and can prevent battery short circuit and dendrite piercing.

Owner:TIANJIN YISEN MATERIAL TECH CO LTD

Zinc-based soft solder suitable for hot-drip galvanizing repair

ActiveCN104439752AGood antioxidant propertiesGood wetting propertiesWelding/cutting media/materialsSoldering mediaRare-earth elementHot-dip galvanization

The invention relates to a zinc-based soft solder suitable for hot-drip galvanizing repair. Solder alloy comprises, by weight, 50-60 parts of zinc, 0.5-1.5 parts of aluminum, 0.1-0.5 part of rare earth and 38-49 parts of tin. The rare earth is misch metal. After the aluminum and the rare earth are added to the solder, the solder has good oxidation resistance and wetting property, and repair of galvanized steel can be well achieved. The zinc-based soft solder has oxidation resistance and high corrosion resistance, the comprehensive performance of the alloy can be effectively changed by adding the rare earth, a trace of active rare earth can be easily gathered on the interface and the surface of the alloy solder in a liquid state, so that the surface of the alloy is remarkably lowered, the rare earth cooperates with the aluminum to improve the wetting property with the surface of a repair layer (steel), the mechanical property of the solder is improved, and the malleability and the shear strength of the solder are improved.

Owner:STATE GRID CORP OF CHINA +1

Preparation method of lithium-ion battery diaphragm

InactiveCN108899459AHigh porosityImprove mechanical propertiesSecondary cellsCell component detailsCellulosePolyether ether ketone

The invention discloses a preparation method of a lithium-ion battery diaphragm. The preparation method comprises the following steps: adding cellulose into a mixed solution of dimethylformamide and 1,2-dichloromethane, smashing, and mixing, so as to obtain uniform dispersion liquid; adding polyethylene and chloromethylated polyether-ether-ketone into the dispersion liquid, uniformly stirring andmixing, adding a proper amount of a pore-forming agent, putting the liquid on a constant-temperature working table, and carrying out constant-temperature stirring, so as to obtain a uniform solution;preparing a film from the solution through the spinning of electrostatic spinning equipment; and carrying out roll pressing on the film, putting the film into a drying oven, and drying, so as to obtain the lithium-ion battery diaphragm. According to the preparation method, by utilizing cellulose and chloromethylated polyether-ether-ketone, the thermal stability and electrochemical stability of theprepared lithium-ion battery diaphragm are improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Magnetocaloric refrigerator

ActiveUS20200182517A1Reduce mechanical vibrationSmall sizeMachines using electric/magnetic effectsSustainable buildingsHeat managementHeat flow

The invention is for an apparatus and method for a refrigerator and a heat pump based on the magnetocaloric effect (MCE) offering a simpler, lighter, robust, more compact, environmentally compatible, and energy efficient alternative to traditional vapor-compression devices. The subject magnetocaloric apparatus alternately exposes portions of an MCE material to strong and weak magnetic field while coordinating the heat flow between the exposed portions by heat bridges to move the heat up the thermal gradient. The invention may be practiced with multiple MCE material portions or segments to attain large differences in temperature. Key applications include thermal management of electronics, as well as industrial and home refrigeration, heating, and air conditioning. The invention offers a simpler, lighter, compact, and robust apparatus compared to magnetocaloric devices of prior art. Furthermore, the invention may be run in reverse as a thermodynamic engine, receiving low-level heat and producing mechanical energy.

Owner:VETROVEC JAN

Preparation process of environment-friendly water-based ink

The invention discloses a preparation process of environment-friendly water-based ink. The preparation process comprises the following steps: step 1, weighing raw materials; step 2, adding deionized water into a dispersion cylinder, then adding a pigment, carrying out ultrasonic treatment at normal temperature for 10 minutes to prepare an aqueous dispersion liquid of the pigment, then adding a wetting agent and half of a dispersing agent, and carrying out high-speed dispersion and grinding to obtain color paste; and step 3, mixing the color paste with the polyacrylate emulsion, and adding a modified filler, a dispersing agent and a defoaming agent to obtain the environment-friendly water-based ink. According to the invention, the water-based polyacrylate emulsion is used as a film-formingsubstance of the ink; the emulsion has high film-forming property and adhesive force; by adding the modified filler, the phenomenon of ink aging caused by ultraviolet rays can be effectively prevented, the damage caused by the ultraviolet rays to an organic resin base material is reduced, and the water-based ink has water resistance and ultraviolet-resistant stability at the same time; the raw materials are green and environment-friendly, and the water-based ink which is environment-friendly, excellent in comprehensive performance and capable of effectively defending ultraviolet rays is obtained.

Owner:郑梦平

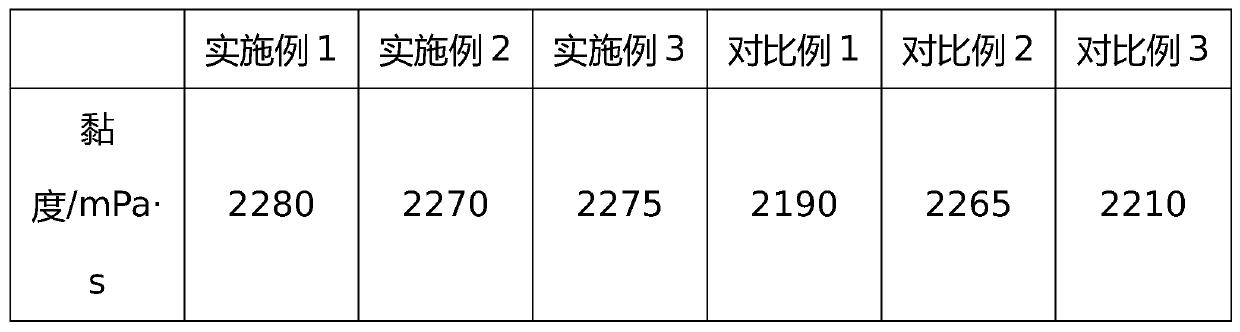

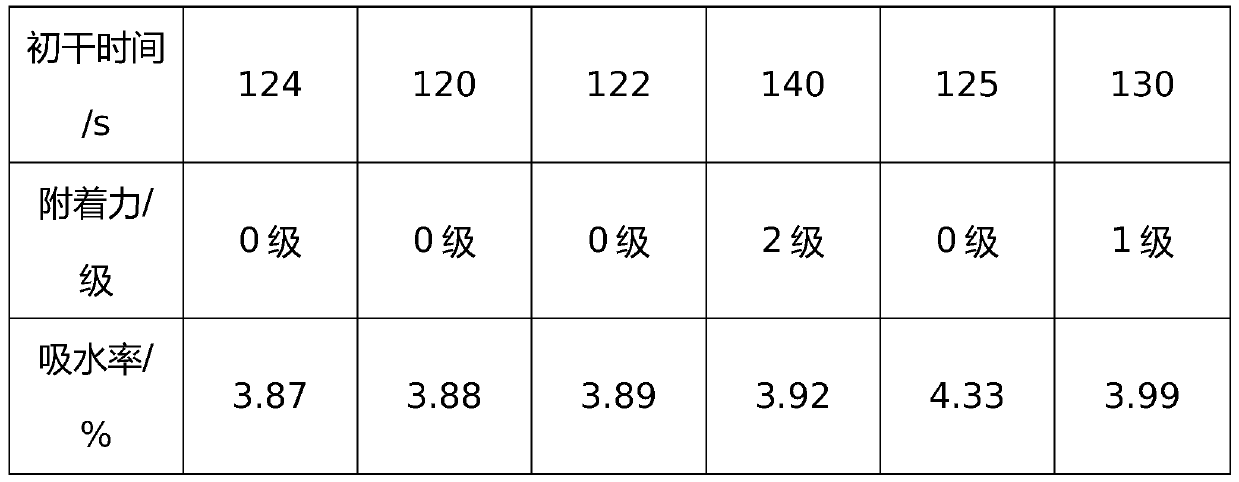

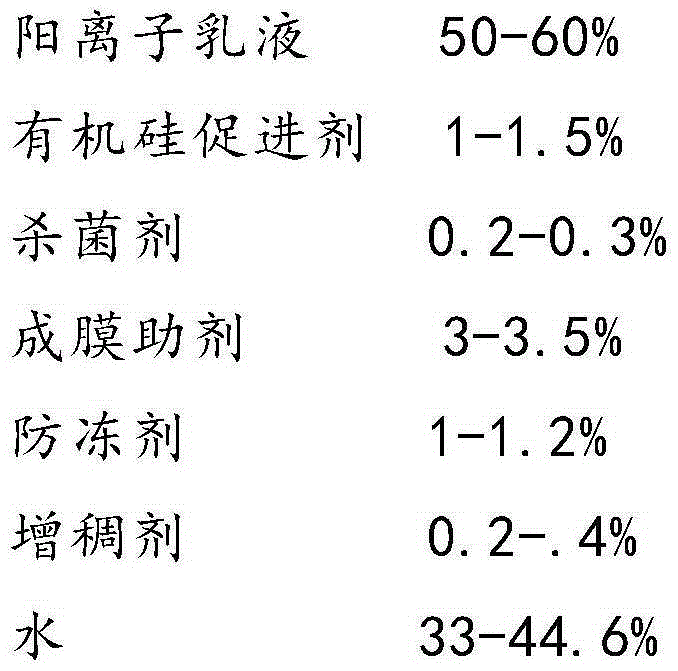

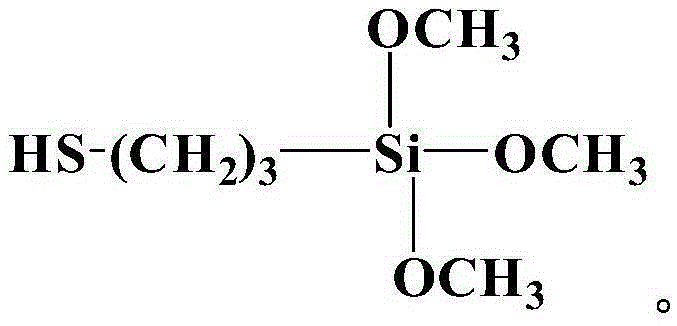

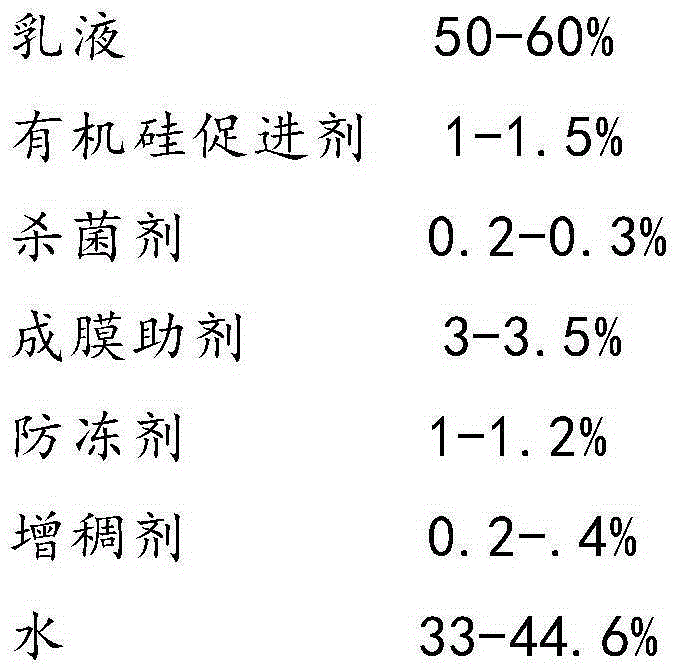

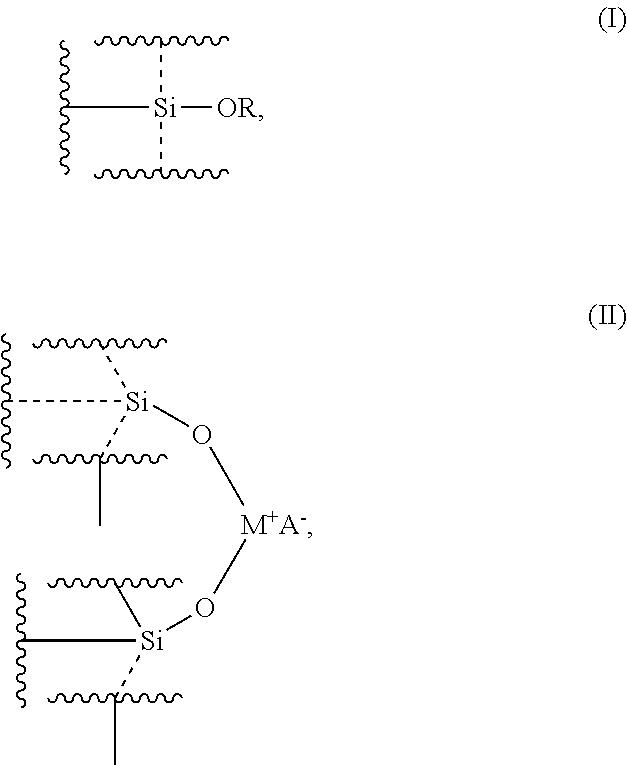

Transparent priming paint for construction and preparation method thereof

The invention provides a transparent priming paint for construction and a preparation method thereof. The transparent priming paint for the construction is prepared from the following components in mass percent: 50 percent to 60 percent of cationic emulsion, 1 percent to 1.5 percent of an organic silicon accelerant, 0.2 percent to 0.3 percent of a sterilizing agent, 3 percent to 3.5 percent of a film forming auxiliary agent, 1 percent to 1.2 percent of an anti-freezing agent, 0.2 percent to 0.4 percent of a thickening agent and 33 percent to 44.6 percent of water, wherein the organic silicon accelerant is a surface active auxiliary agent with a molecular structural formula shown by the description and capable of reducing the surface tension of the system. The transparent priming paint for the construction, provided by the invention, has excellent permeability and film forming performance, excellent waterproof and alkali-resisting performances, simple and easy construction performance, high adhesion property and broad-spectrum substrate adaptive performance.

Owner:ASIA PAINT SHANGHAI

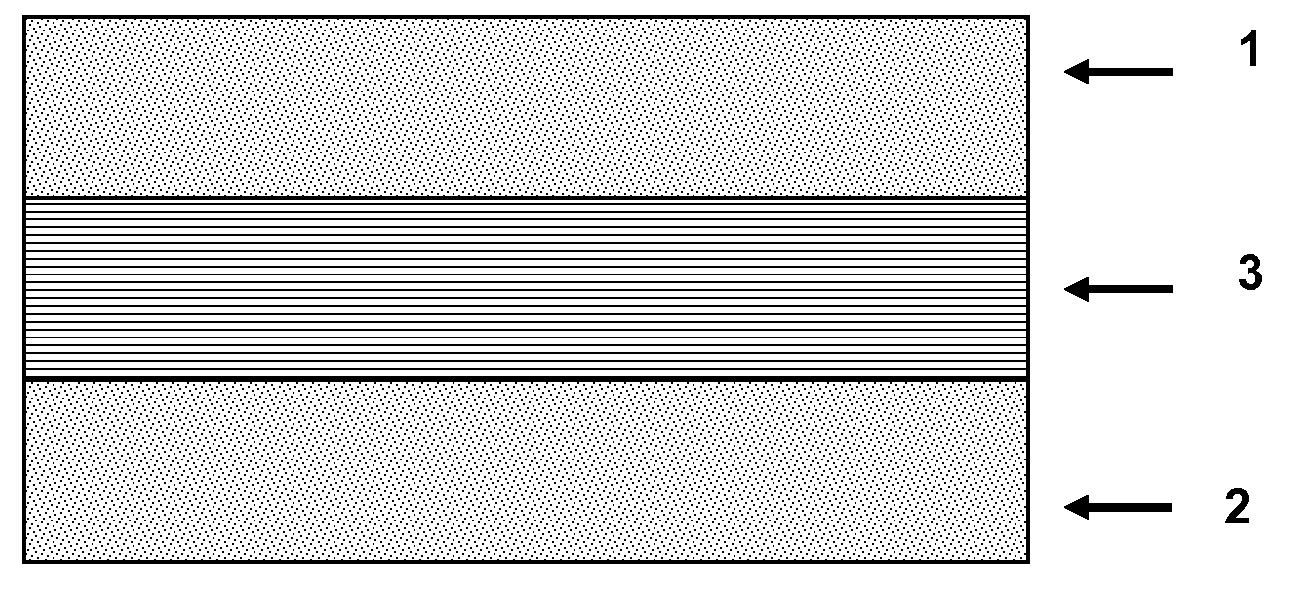

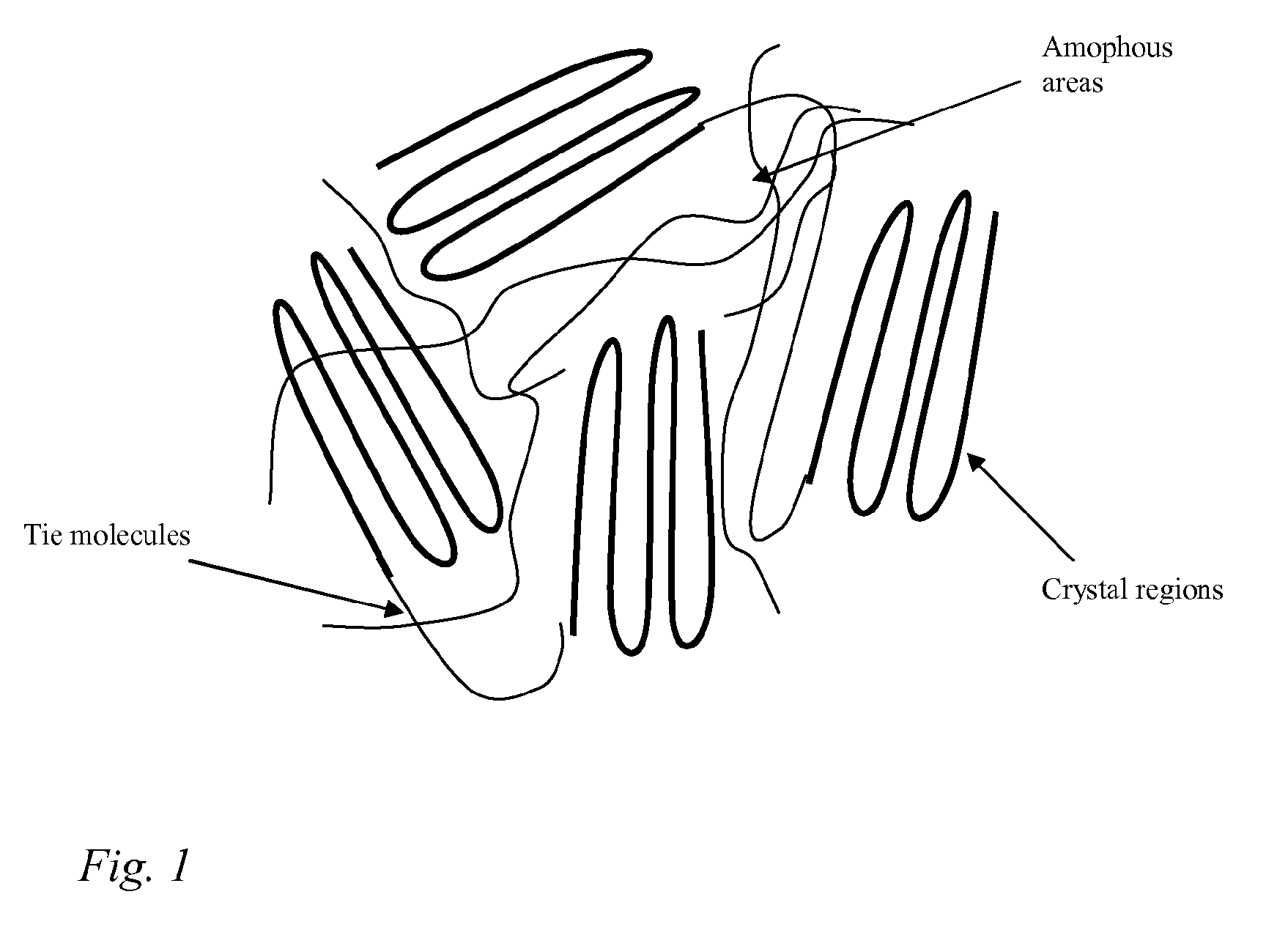

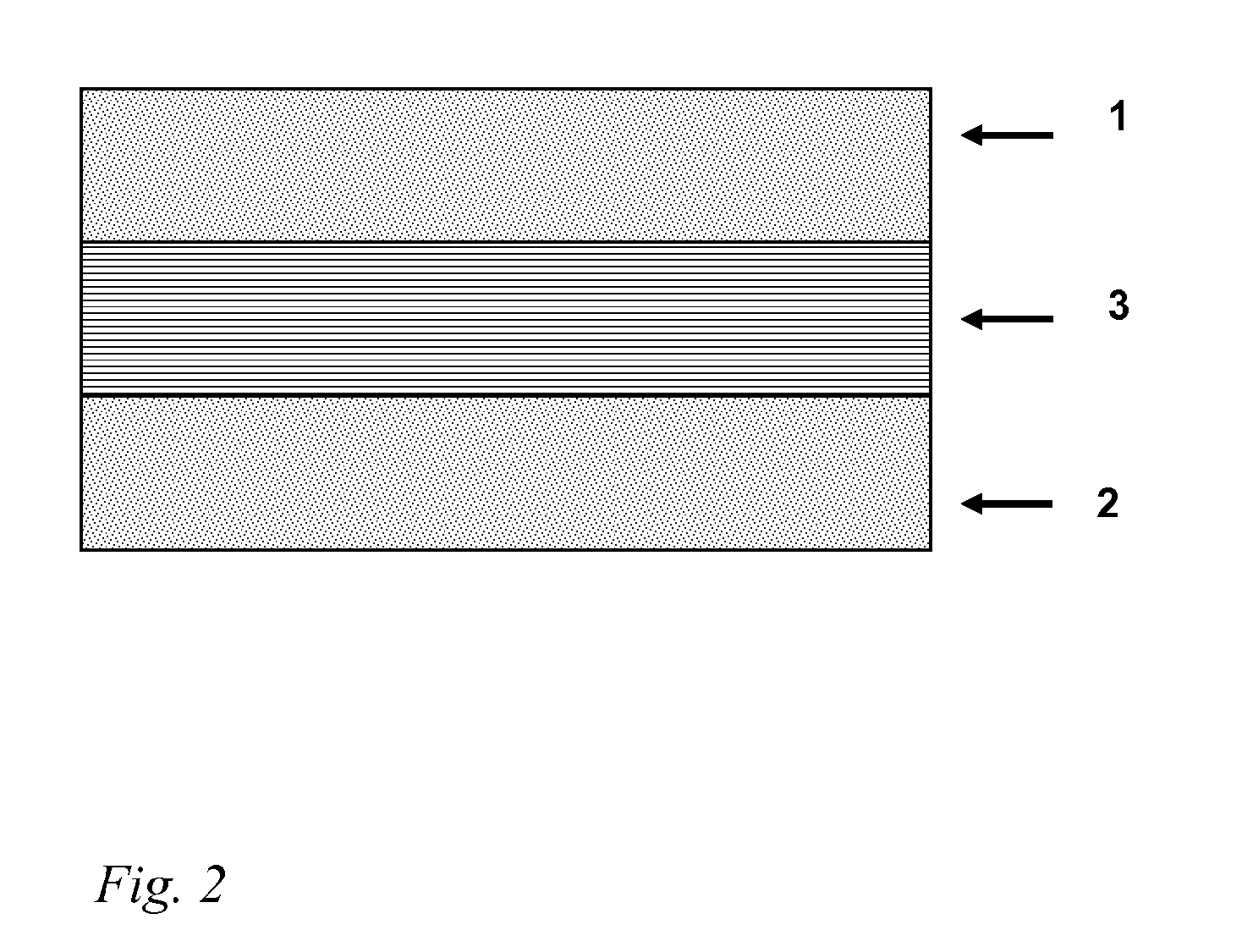

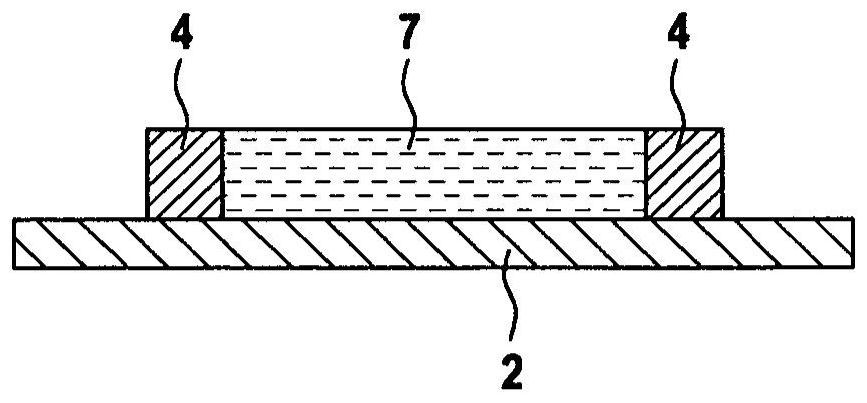

Coated wood board

InactiveUS20110045308A1Increase frictionGood wetting propertiesFireproof paintsSynthetic resin layered productsCross-linkPolyolefin

The invention relates to a coated wood board, in which the wood board is coated with a coating material. In accordance with the invention, the coating material is formed of polyolefin film, and polyolefin film is at least partially cross-linked so that the percentage of cross-linking is 10-60% bigger than the polyolefin amorphous percentage for pinning two phases, crystalline and amorphous, together for forming a wear and heat resistant coating.

Owner:UPM KYMMENE WOOD

Analytical aids with hydrophilic coating containing nanoparticles with silica structure and methods of producing and using the same

InactiveUS20160192870A1Good wetting propertiesImprove stabilityPretreated surfacesCatheterHydrophilic coatingNanoparti cles

Disclosed herein are analytical aids having a surface coated at least partially with a hydrophilic coating, where the hydrophilic coating includes nanoparticles with silica structure and an average particle size in a range from about 1 nm to about 500 nm. Also disclosed are methods of producing the analytical aids, as well as using the analytical aids in, for example, a sampling device containing the at least partially coated analytical aid.

Owner:ROCHE DIABETES CARE INC

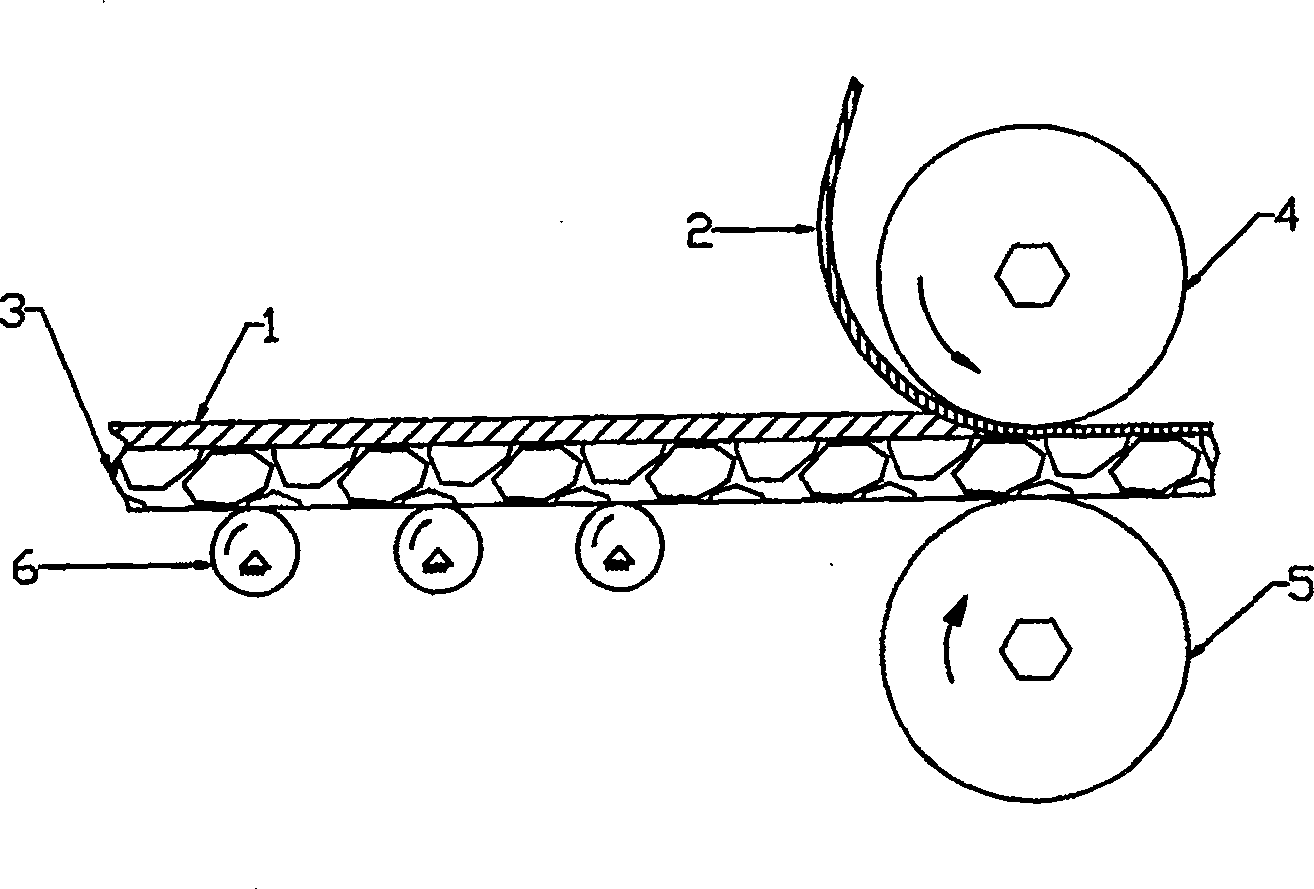

Method of welding foamed aluminium sandwich composite board

InactiveCN100463753CStable melting conditionsGood wetting propertiesWelding/cutting media/materialsWelding/soldering/cutting articlesAlloyComposite plate

The invention pertains to the field of aluminum foam welding, and discloses a preparation method to produce a composite plate with aluminum foam filler by weld-forming technique. The preparation steps are that: cleaned and dried foamed aluminum boards and aluminum boards are treated, solder is put on the treated foamed aluminum boards, and then the aluminum boards are put on the solder to be sent into a pair of roll wheel pairs to be roll compacted; the foamed aluminum boards and the aluminum boards can be roll compacted by the roll wheel pairs with the motion of a roll wheel. The solder is low melting point aluminum base alloy and the diameter of the roll wheel is more than or equal to 200mm. Oxyacetylene or lpg frame is adopted to heat the aluminum foam at the front edge of the roll wheel roll compacting and the solder layer between the aluminum boards. When the solder is melted and spread, the roll wheel pair is started, the rotational speed of the roll wheel pair is adjusted to be in accordance with the speed of heating and melting the solder and the foamed aluminum boards and aluminum boards are lightly roll compacted to ensure the two adhere tightly; after cooling, the integral body of the foamed aluminum boards and aluminum boards are turned, solder is put on the other surface of the foamed aluminum boards, aluminum boards are put on the solder and the steps are repeated to obtain the weld-formed composite plate with aluminum foam filler.

Owner:SOUTHEAST UNIV

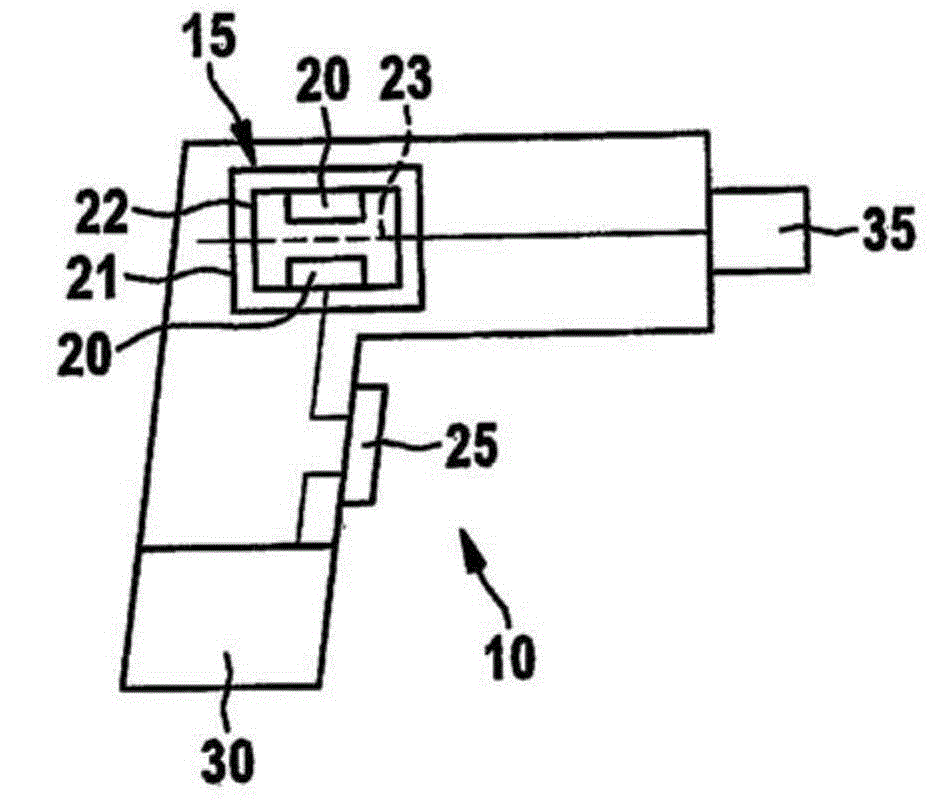

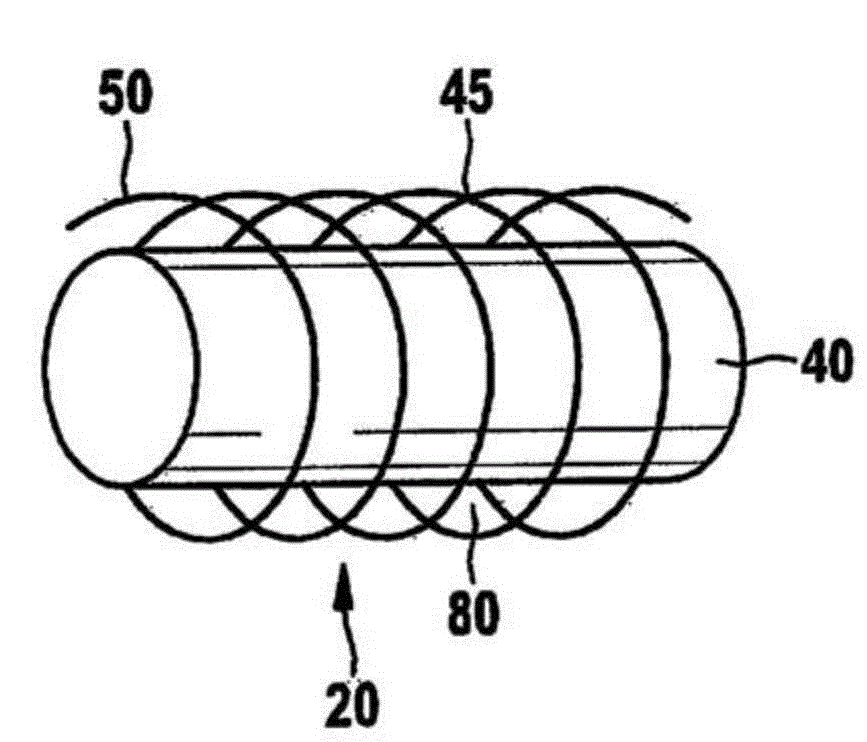

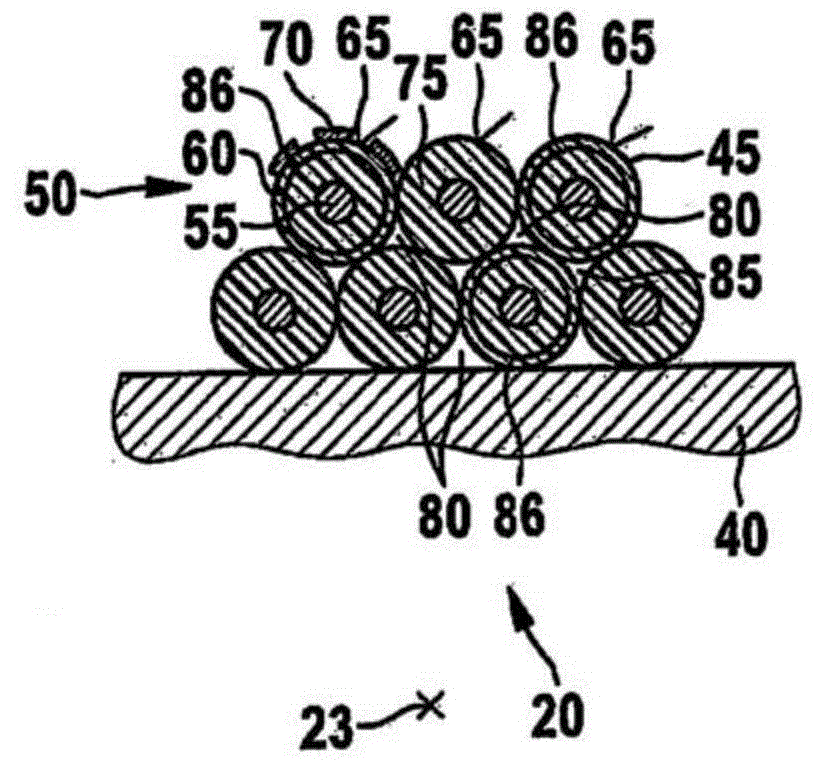

Method for activating winding wire of motor and coil with winding wire

InactiveCN104104196AReduce activation costsCheap manufacturingTransformers/inductances coils/windings/connectionsManufacturing dynamo-electric machinesElectrical conductorEngineering

The invention relates to a method for activating the winding wire (50) of a motor (15) and a coil (20) with the winding wire (50). The winding wire (50) is provided with an electrical conductor (55) wrapped by an insulator (60). The electrical conductor (55) is electrically insulated through the insulator (60). The insulator (60) is activated. During activation, the composition of the insulator (60) in the edge layer (86) of the insulator (60) is changed, and / or the surface property, especially the surface tension, of the outer circumferential surface (65) of the insulator (60) is changed.

Owner:ROBERT BOSCH GMBH

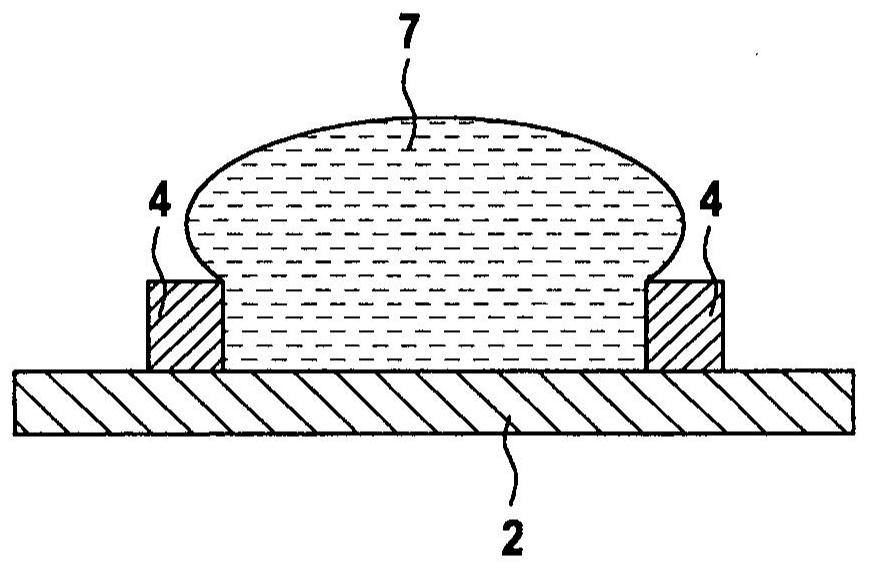

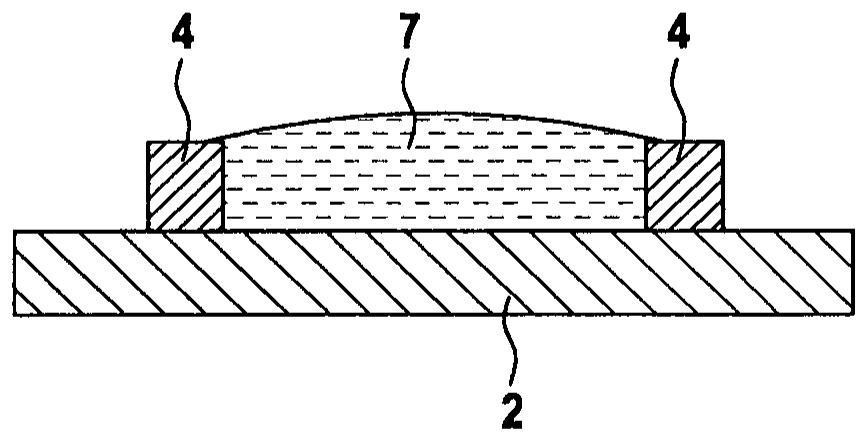

Patterned bank structures on substrates and methods of formation

ActiveCN107850843BGood wetting propertiesRisk of spillage is minimizedSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusCarbamateActive agent

Owner:MERCK PATENT GMBH

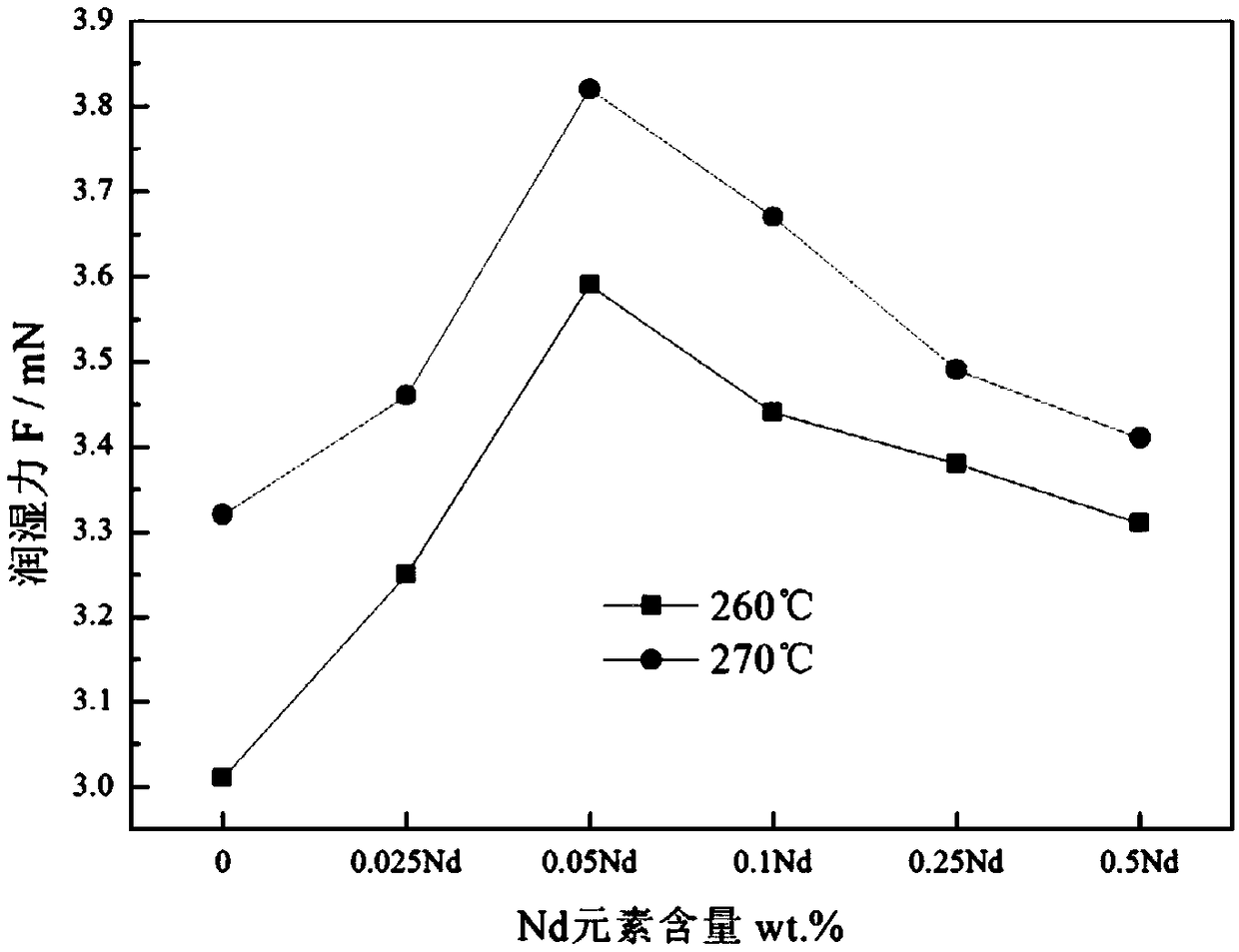

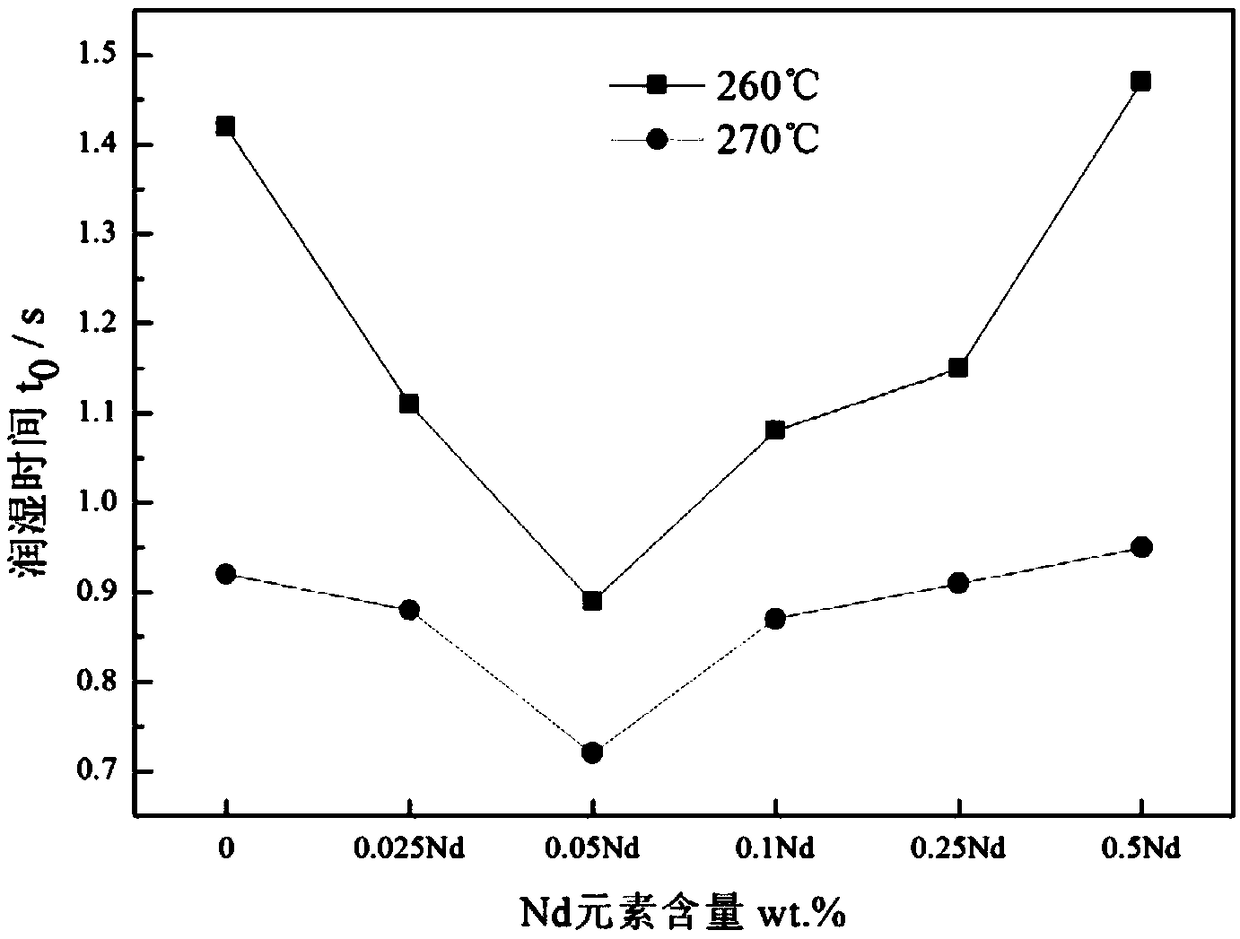

Sn-Cu-Ni lead-free solder containing Ga and Nd

ActiveCN109048114AGood wetting propertiesGood mechanical propertiesWelding/cutting media/materialsSoldering mediaReflow solderingWetting

The invention discloses a Sn-Cu-Ni lead-free solder containing Ga and Nd, and belongs to the field of soldering materials of metal materials. The Sn-Cu-Ni lead-free solder comprises, by mass, 0.45-1.1% of Cu, 0.05-0.5% of Ni, 0.003-0.008% of As, 0.014-0.020% of Sb, 0.4-0.6% of Ga, 0.04-0.06% of Nd, and the balance Sn, wherein the mass ratio of Ga to Nd is 10:1. The solder has good wetting performance, growth of tin whiskers of a soldering joint can be effectively inhibited, the reliability of the soldering joint is greatly improved, and the Sn-Cu-Ni lead-free solder can be used for wave soldering and reflow soldering of components in the electronic industry.

Owner:NANJING UNIV OF SCI & TECH

Magnetocaloric refrigerator

ActiveUS11333414B2Conducive to efficient heat transferImprove rendering capabilitiesMachines using electric/magnetic effectsSustainable buildingsHeat managementHeat flow

The invention is for an apparatus and method for a refrigerator and a heat pump based on the magnetocaloric effect (MCE) offering a simpler, lighter, robust, more compact, environmentally compatible, and energy efficient alternative to traditional vapor-compression devices. The subject magnetocaloric apparatus alternately exposes portions of an MCE material to strong and weak magnetic field while coordinating the heat flow between the exposed portions by heat bridges to move the heat up the thermal gradient. The invention may be practiced with multiple MCE material portions or segments to attain large differences in temperature. Key applications include thermal management of electronics, as well as industrial and home refrigeration, heating, and air conditioning. The invention offers a simpler, lighter, compact, and robust apparatus compared to magnetocaloric devices of prior art. Furthermore, the invention may be run in reverse as a thermodynamic engine, receiving low-level heat and producing mechanical energy.

Owner:VETROVEC JAN

Water-base correction fluid composition and preparation method thereof

This invention relates to a water-base tippex combination, according to weight it composed by 10 to 30% film-forming polymer, 5 to 30% opacity polymer emulsion, 20 to 50% white pigment, 0.5 to 2% dispersant and 10 to 50% water. The opacity polymer emulsion is styrene - acroleic acid copolymer latices, and styrene - acroleic acid copolymer exist by particle form of monodisperse sphericity. This tippex takes opacity polymer emulsion to substitute titanium pigment, greatly reduce material cost, and has favorable wetting property,, easy applying, the rewritten time is less than 60 seconds.

Owner:上海乐美文具有限公司

Welding shaping method for foamed aluminium board

InactiveCN100491040CAchieve metallurgical bondingGood wetting propertiesWelding/cutting media/materialsSoldering mediaAlloyForming processes

Owner:SOUTHEAST UNIV

Anti-pollution coating composition

InactiveCN1445314AGood wetting propertiesAntifouling/underwater paintsPaints with biocidesAlcohol sugarsWater soluble

The present invention relates to an aqueous antifouling coating composition comprising a water-soluble salt, a surfactant, and a sugar alcohol, and articles having an antifouling coating formed using the composition.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

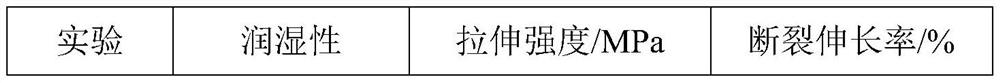

Sealant with good wettability for electronic equipment and preparation method of the sealant

ActiveCN112662319AGood wetting propertiesGood sealing performanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer chemistrySealant

The invention belongs to the technical field of sealants, and particularly relates to a sealant with good wettability for electronic equipment and a preparation method of the sealant. A sealant with good wettability for electronic equipment is prepared from the following raw materials in parts by weight: 80-120 parts of polymer resin, 1-10 parts of filler and 1-10 parts of auxiliaries. The sealant with good wettability for the electronic equipment, prepared by the invention, has good wettability, and can show more excellent sealing performance on the electronic equipment. According to the sealant with good wettability for the electronic equipment, the system viscosity is effectively controlled in the synthesis process, so that the problem that coating is difficult due to too high viscosity is solved.

Owner:湖南梵鑫科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com