Preparation process of environment-friendly water-based ink

A technology of water-based ink and preparation process, which is applied in the direction of ink, application, household utensils, etc., which can solve the problems of limited ink application, inability to effectively protect against ultraviolet rays, and low adhesion of substrate materials, so as to achieve improved adhesion, improved thermal stability, The effect of good film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation technology of environment-friendly water-based printing ink, comprises the steps:

[0028] The first step, according to the following parts by weight: 60-70 parts of polyacrylate emulsion, 6-7 parts of modified filler, 4-5 parts of pigment, 0.5-0.7 part of wetting agent, 0.8-1 part of dispersant, defoamer 0.5-0.7 parts, 10-12 parts of deionized water, weigh raw materials;

[0029] Specifically, the wetting agent is wetting agent 101A, Dalian Institute of Light Industry; the dispersing agent is polyethylene glycol; the defoaming agent is a silicone defoaming agent;

[0030] The second step, the preparation of color paste:

[0031]Add deionized water to the dispersing tank, then add the pigment, and ultrasonicate at room temperature for 10 minutes to prepare a water dispersion of the pigment, then add a wetting agent and half of the dispersant, disperse in a high-speed disperser at 6000r / min for 60 minutes, and then Put it into a sand mill and grin...

Embodiment 1

[0047] A kind of preparation technology of environment-friendly water-based printing ink, comprises the steps:

[0048] The first step, according to the following parts by weight: 60 parts of polyacrylate emulsion, 6 parts of modified filler, 4-5 parts of pigment, 0.5 part of wetting agent, 0.8 part of dispersant, 0.5 part of defoamer, 10 parts of deionized water Weigh raw materials;

[0049] The second step, the preparation of color paste:

[0050] Add deionized water to the dispersing tank, then add the pigment, and ultrasonicate at room temperature for 10 minutes to prepare a water dispersion of the pigment, then add a wetting agent and half of the dispersant, disperse in a high-speed disperser at 6000r / min for 60 minutes, and then Put it into a sand mill and grind until the particle size is less than 10 μm to obtain a color paste;

[0051] The third step is to mix the color paste with the polyacrylate emulsion, add modified fillers and the remaining half of the dispersan...

Embodiment 2

[0053] A kind of preparation technology of environment-friendly water-based printing ink, comprises the steps:

[0054] The first step, according to the following parts by weight: 65 parts of polyacrylate emulsion, 6.5 parts of modified filler, 4.5 parts of pigment, 0.6 part of wetting agent, 0.9 part of dispersant, 0.6 part of defoaming agent, and 11 parts of deionized water raw material;

[0055] The second step, the preparation of color paste:

[0056] Add deionized water to the dispersing tank, then add the pigment, and ultrasonicate at room temperature for 10 minutes to prepare a water dispersion of the pigment, then add a wetting agent and half of the dispersant, disperse in a high-speed disperser at 6000r / min for 60 minutes, and then Put it into a sand mill and grind until the particle size is less than 10 μm to obtain a color paste;

[0057] The third step is to mix the color paste with the polyacrylate emulsion, add modified fillers and the remaining half of the dis...

PUM

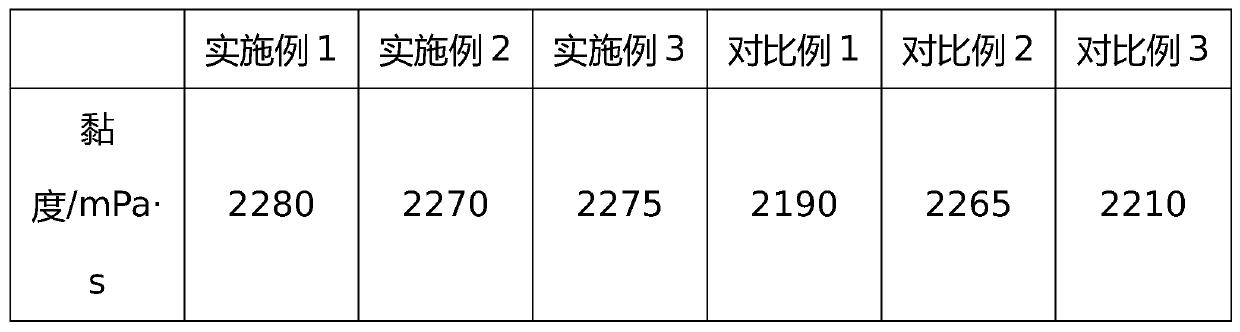

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com