Method of welding foamed aluminium sandwich composite board

A sandwich composite board and foamed aluminum board technology, applied in the field of aluminum board welding, can solve the problems of complex process, low preparation efficiency and high cost, and achieve the effect of high bonding strength, good mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

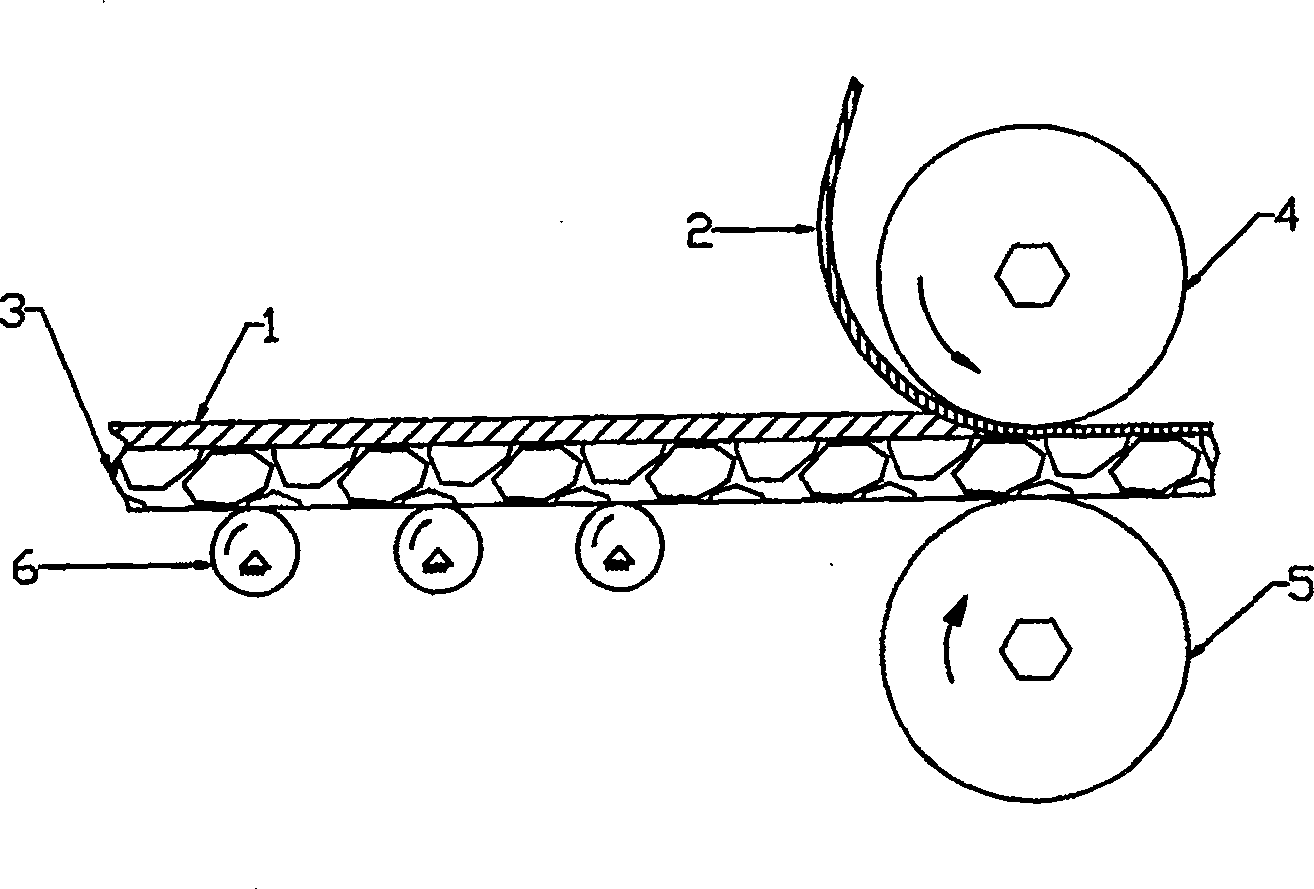

Image

Examples

Embodiment 1

[0025] The first step: use wire cutting to process the aluminum foam board 3 of any thickness into a flat plate with a length of ≥500mm and a width of ≥100mm, and then clean and dry the aluminum foam board 3 and the aluminum board 2 with detergent with a volume concentration of 2% to 5%. Dry. Cut to the same size. Wash and dry the cuboid aluminum foam board 3 of the same size and the aluminum board 2 with a thickness ≥ 1 mm, and clean the surface with acid and lye to remove rust and oil. The mass concentration of 60 ° C is 8% NaOH solution, and then washed with water and then the mass concentration is 35% HNO 3 solution, then rinse with clean water, dry and then rinse with acetone, and finally dry for later use. The concentration of NaOH solution can be 5%, 6%, 8%, HNO 3 The concentration of the solution can be 30%, 33%, 40%.

[0026] The second step: ZnCl at room temperature 2 Make a saturated solution with water, and apply it evenly on the surface of the treated foam al...

Embodiment 2

[0031] The first step: use wire cutting to process the foamed aluminum plate with a thickness of 15mm and a porosity of 75% into a flat plate with a width of 1120mm and a width of 600mm, and then clean the foamed aluminum plate and the aluminum plate with a volume concentration of 2% detergent, drying. Cut to the same size. Wash and dry the cuboid aluminum foam board and the aluminum board with a thickness of 2mm, and clean the surface with acid and lye to remove rust and oil. Wash with 5% NaOH solution, then wash with water and then use a mass concentration of 30% HNO 3 solution, then rinse with clean water, dry and then rinse with acetone, and finally dry for later use.

[0032] The second step: ZnCl at room temperature 2 Make a saturated solution with water, and apply it evenly on the treated foam aluminum board and the surface of the aluminum board;

[0033] Step 3: Put the solder on the treated foam aluminum plate and roll the treated aluminum plate into a pair of rol...

Embodiment 3

[0037]The first step: use wire cutting to process the foamed aluminum plate with a thickness of 20mm and a porosity of 90% into a flat plate with a width of 1120mm and 2100mm, and then clean the foamed aluminum plate and the aluminum plate with a volume concentration of 5% detergent, drying. Cut to the same size. Wash and dry the cuboid aluminum foam board and the aluminum board with a thickness of 1.5mm of the same size, and clean the surface with acid and lye to remove rust and oil. The concentration is 8% NaOH solution to clean, then wash with water and then use the mass concentration of 40% HNO 3 solution, then rinse with clean water, dry and then rinse with acetone, and finally dry for later use.

[0038] The second step: ZnCl at room temperature 2 Make a saturated solution with water, and apply it evenly on the treated foam aluminum board and the surface of the aluminum board;

[0039] Step 3: Put the solder on the processed aluminum foam plate and cover it to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com