Patents

Literature

39results about How to "Reduce activation costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing geopolymers by taking stone coal vanadium extraction tailings as main raw materials

ActiveCN103482890AFavorable strength developmentHigh compressive strengthCement productionSlagMetakaolin

The invention relates to a method for preparing geopolymers by taking stone coal vanadium extraction tailings as main raw materials. The technical scheme is as follows: the method adopts the following raw materials in percentage by weight: 55-76% of stone coal vanadium extraction tailings, 1-5% of hydrated lime, 0.3-2% of anhydrous sodium sulfate, 10-16% of metakaolin, 6-10% of sodium hydroxide and 6-13% of silica fume. The preparation method disclosed by the invention comprises the steps of firstly, uniformly mixing the stone coal vanadium extraction tailings and an activating agent, standing, calcining, and performing mechanical vibration milling to obtain activated slag; then, adding metakaolin and sand, and stirring; finally, adding a liquid alkali activator prepared from sodium hydroxide, silica fume and water, stirring, forming, aging and curing to prepare the stone coal vanadium extraction tailing geopolymers. The method disclosed by the invention is simple in process, low in cost, relatively small in energy consumption, high in tailing utilization ratio and environment-friendly; the prepared geopolymers are relatively high in compression strength, strong in dry shrinkage resistance, good in permeability resistance and high in durability, and have a good curing effect on heavy metal ions.

Owner:WUHAN UNIV OF TECH

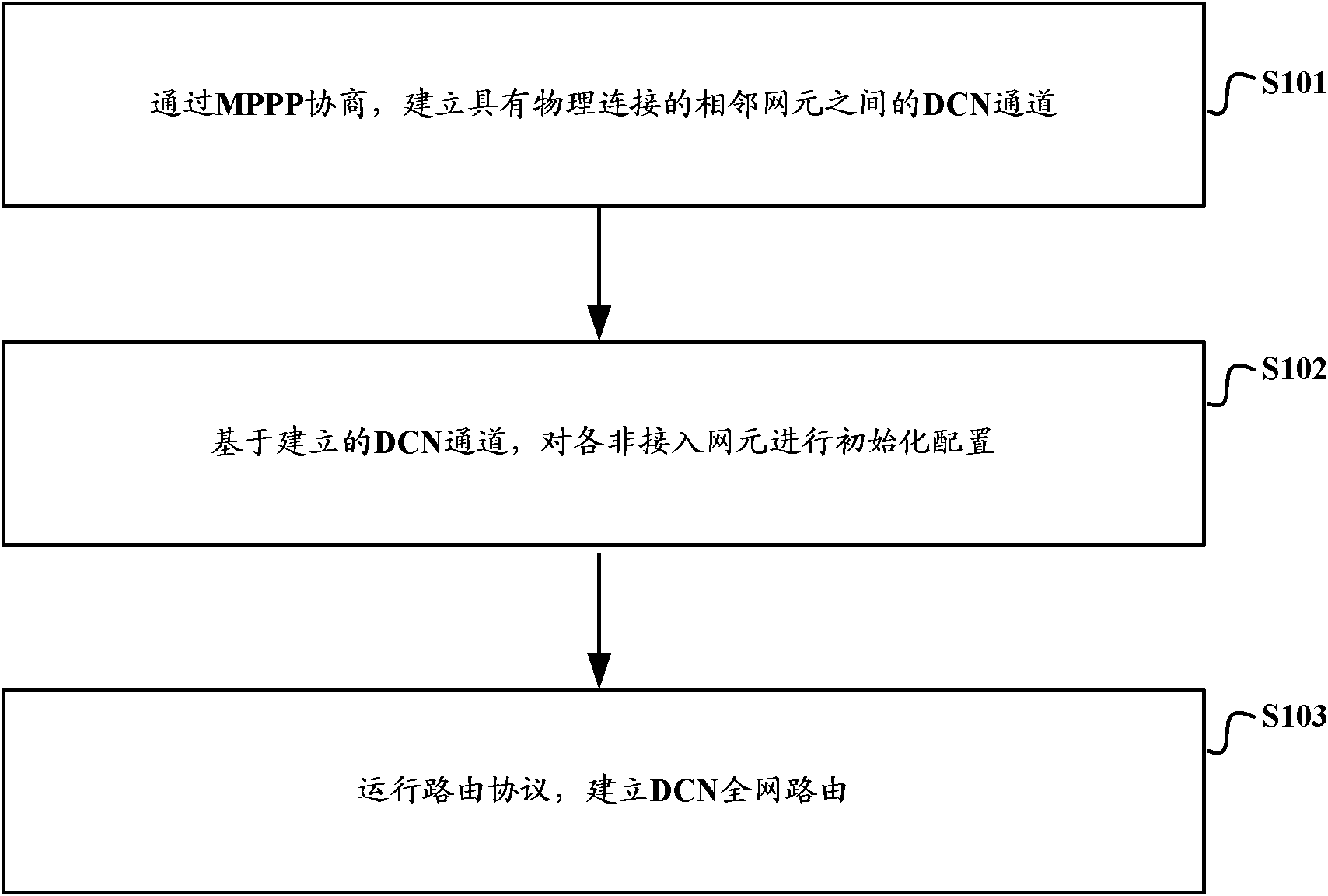

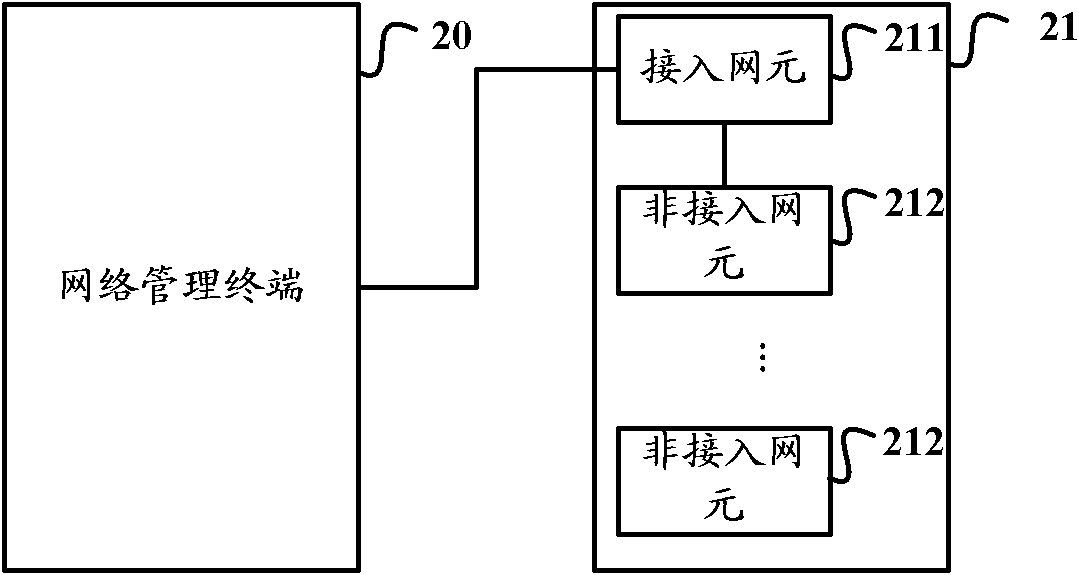

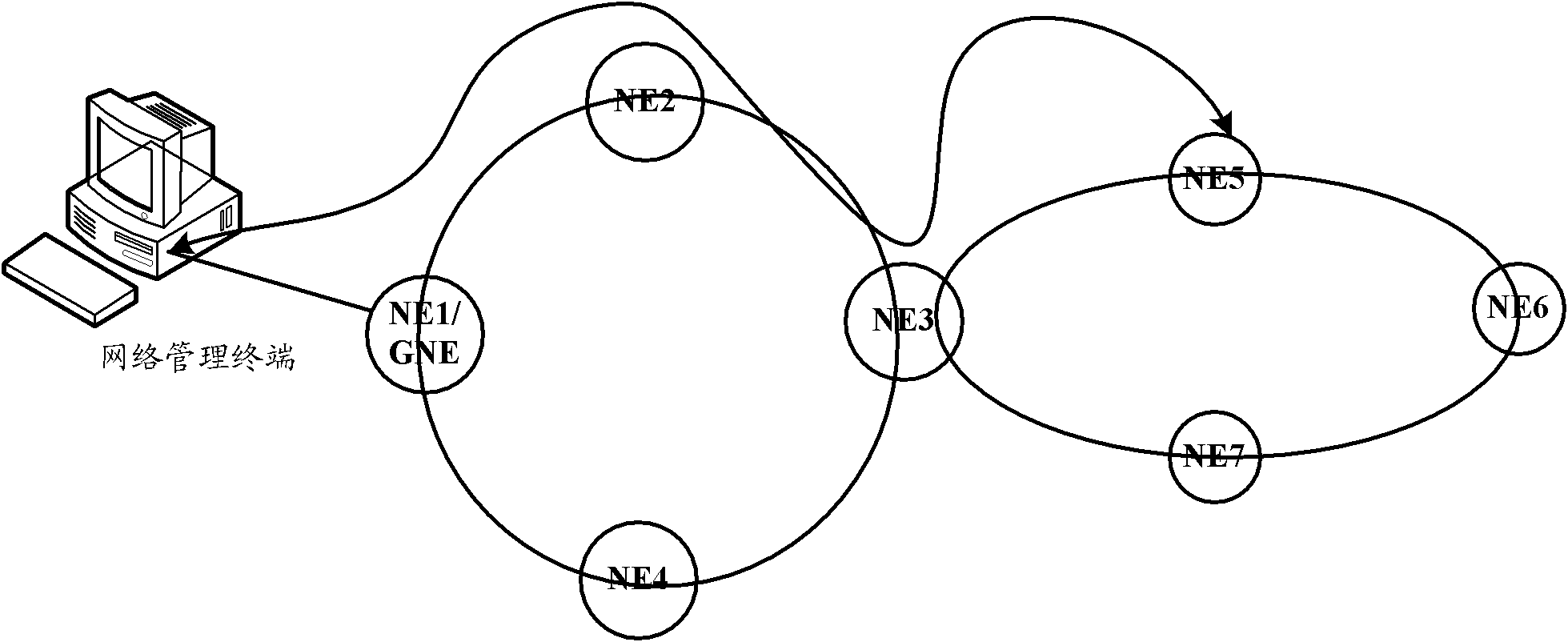

Method and system for opening data communication network

InactiveCN101984581AOpen to achieveSimplify the activation processData switching networksComputer hardwareAccess network

The invention discloses a method and system for opening a data communication network (DCN), which is used for simplifying the DCN opening procedure, improving the DNC opening efficiency and reducing the DNC opening cost. The opening method comprises the following steps: establishing a DCN channel between adjacent physically connected network elements by multilink point-to-point (MPPP) negotiation; carrying out initialization configuration on non-access network elements based on the established DCN channel; and operating a routing protocol and establishing a DCN total network route.

Owner:ZTE CORP

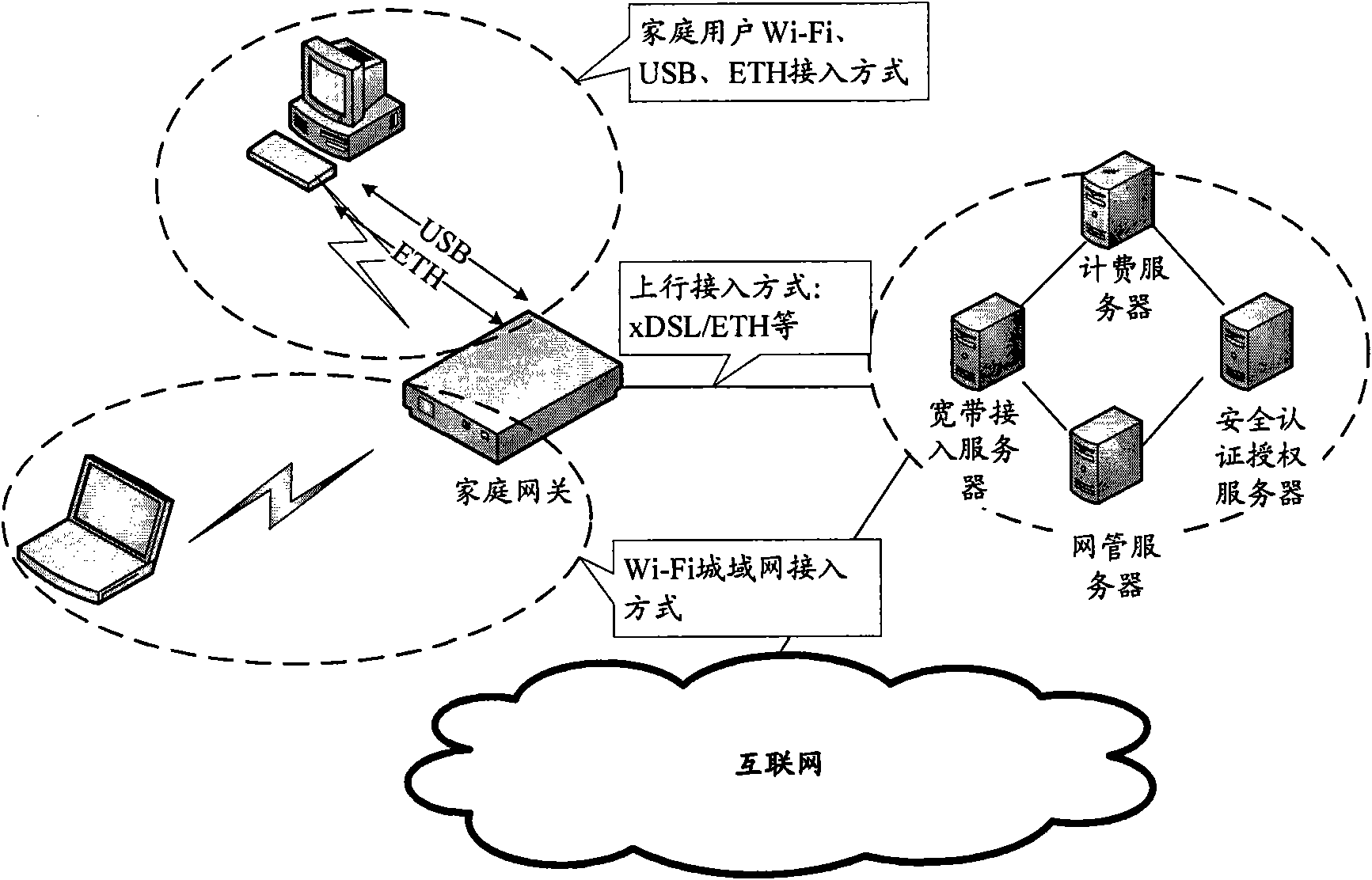

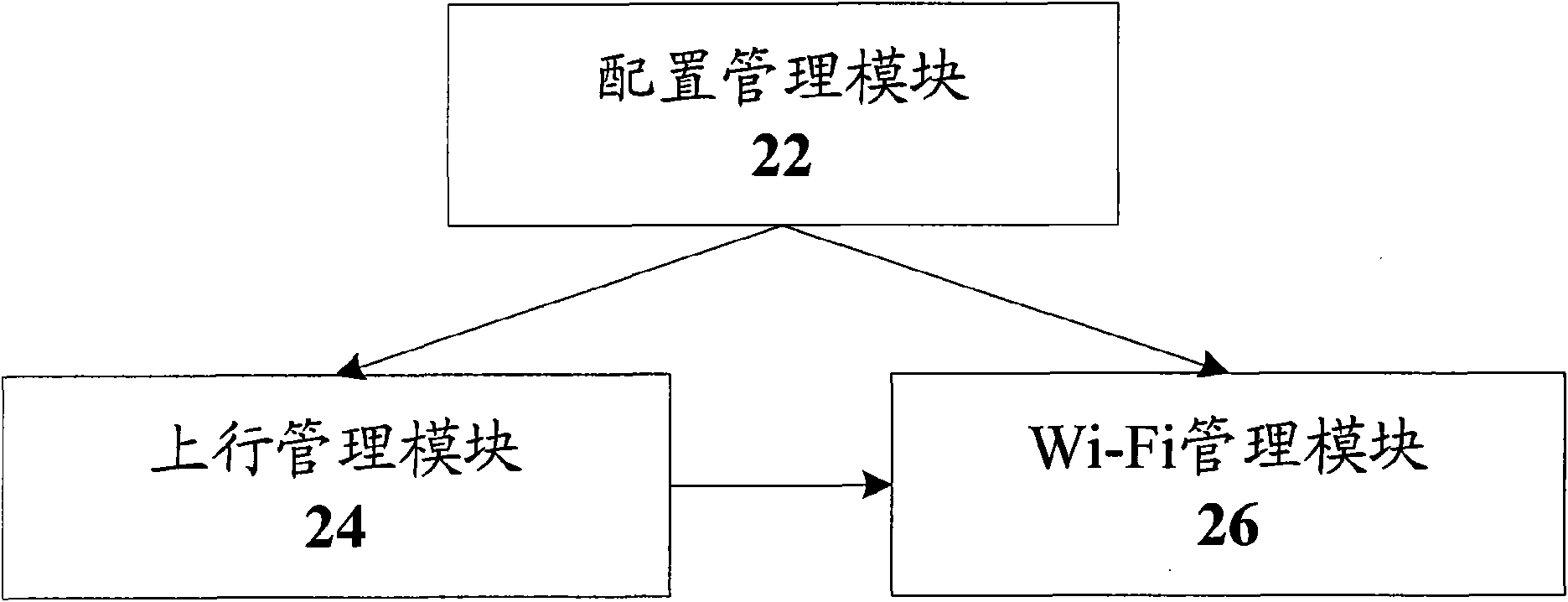

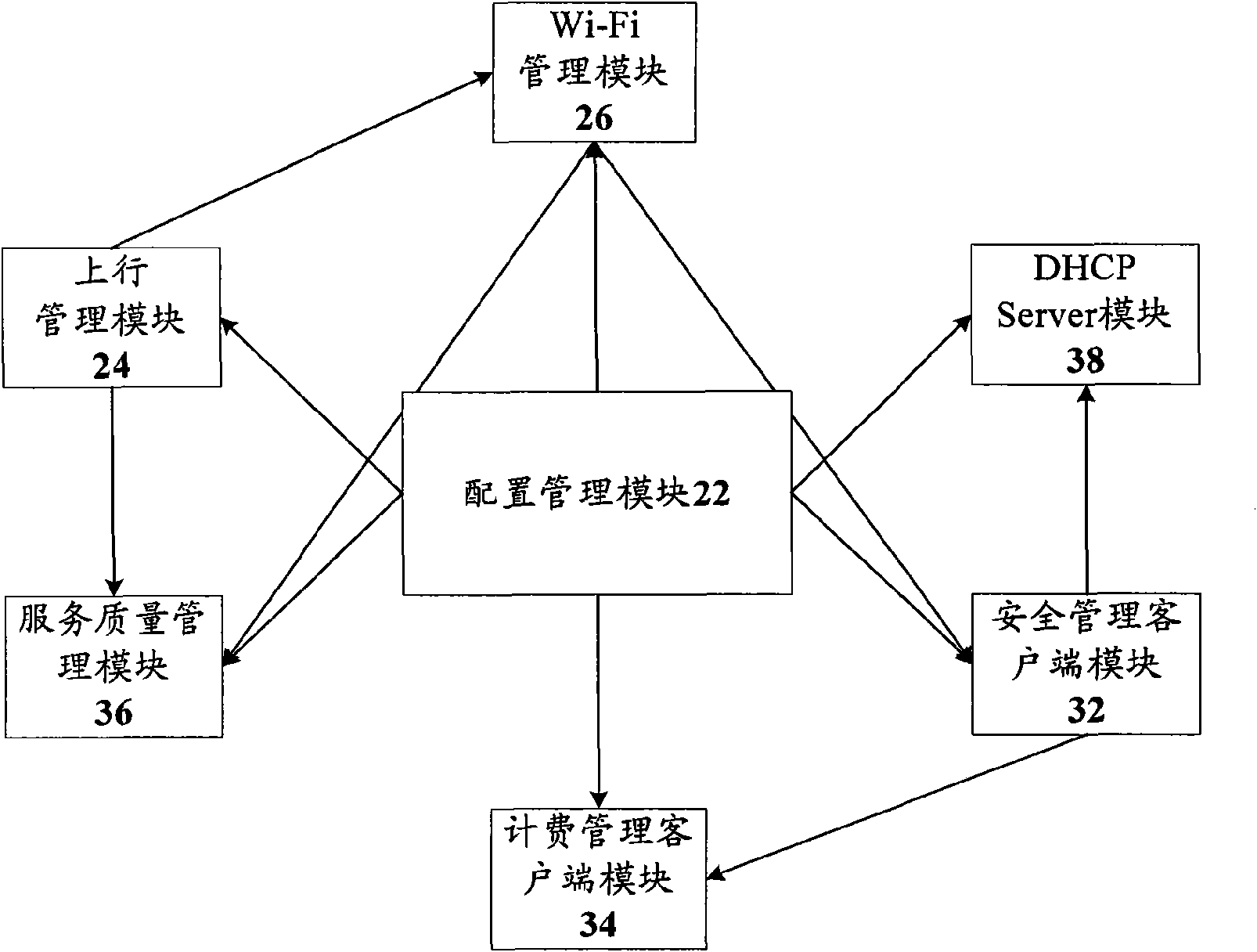

Realization method of Wi-Fi metropolitan area network and home gateway

ActiveCN101656964AAvoid wastingLow input costNetwork topologiesConnection managementWi-FiDistributed computing

The invention discloses a realization method of a Wi-Fi metropolitan area network and a home gateway. The home gateway comprises a configuration management module, an uplink management module and a Wi-Fi management module, wherein configuration management module is used for configuring and managing the home gateway; the uplink management module is used for configuring a safe uplink passage and theWi-Fi management module is used for maintaining and managing the Wi-Fi metropolitan area network SSID and establishing the connection with the metropolitan area network by the safe uplink passage. The invention is convenient for managing, charging and maintaining Wi-Fi metropolitan area network business and has low opening cost.

Owner:ZTE CORP

Method for activating electroless copper-plated textile with nickel salt

InactiveCN103805971AStrong chelating abilityLow raw material costLiquid/solution decomposition chemical coatingCopper platingNickel salt

The invention relates to a method for activating electroless copper-plated textile with a nickel salt. The method comprises the steps of soaking the textile into a 10-30g / L coarsening liquid, heating to 60 DEG C and preserving heat for 30min, next, heating to 90 DEG C and preserving heat for 60min, and then washing and drying; soaking the textile into a chitosan solution, soaking twice and rolling twice, and air-drying; soaking the textile in a nickel sulfate solution at the normal temperature, and then soaking into a sodium borohydride solution, cleaning and air-drying to obtain the activated textile, and finally, soaking in an electroless copper plating liquid for plating, and finally washing with water and drying. A macromolecule adsorption nickel salt activating fluid developed in the method is friendly to the environment and capable of either improving the binding force of a coating and the substrate textile or activating a palladium salt with a nickel salt, and therefore, the activation cost is low and the pollution caused by noble metals is reduced, and the method is high in operability.

Owner:JINAN YUMO SCI & TRADE CO LTD

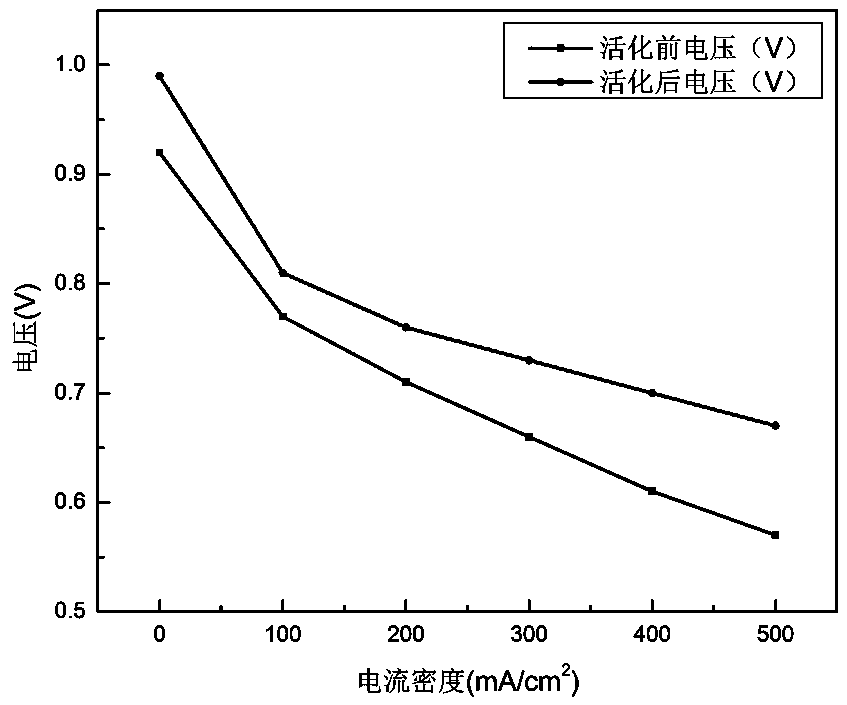

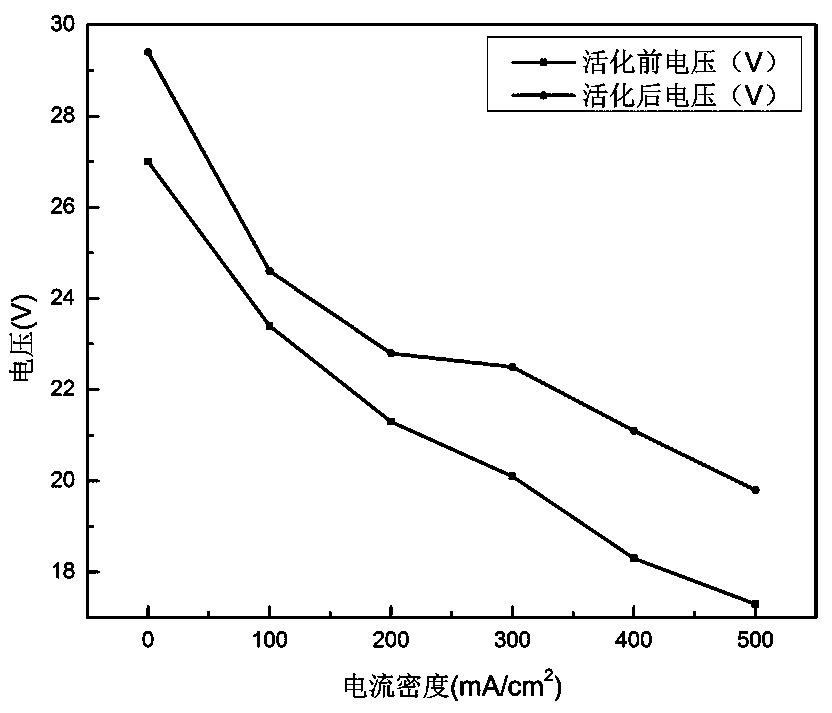

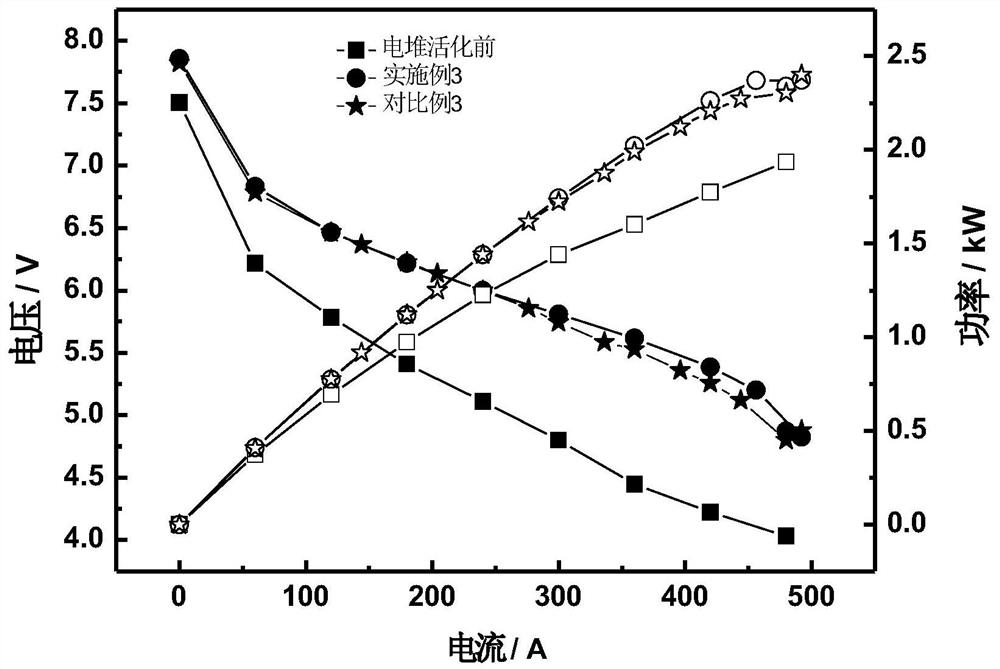

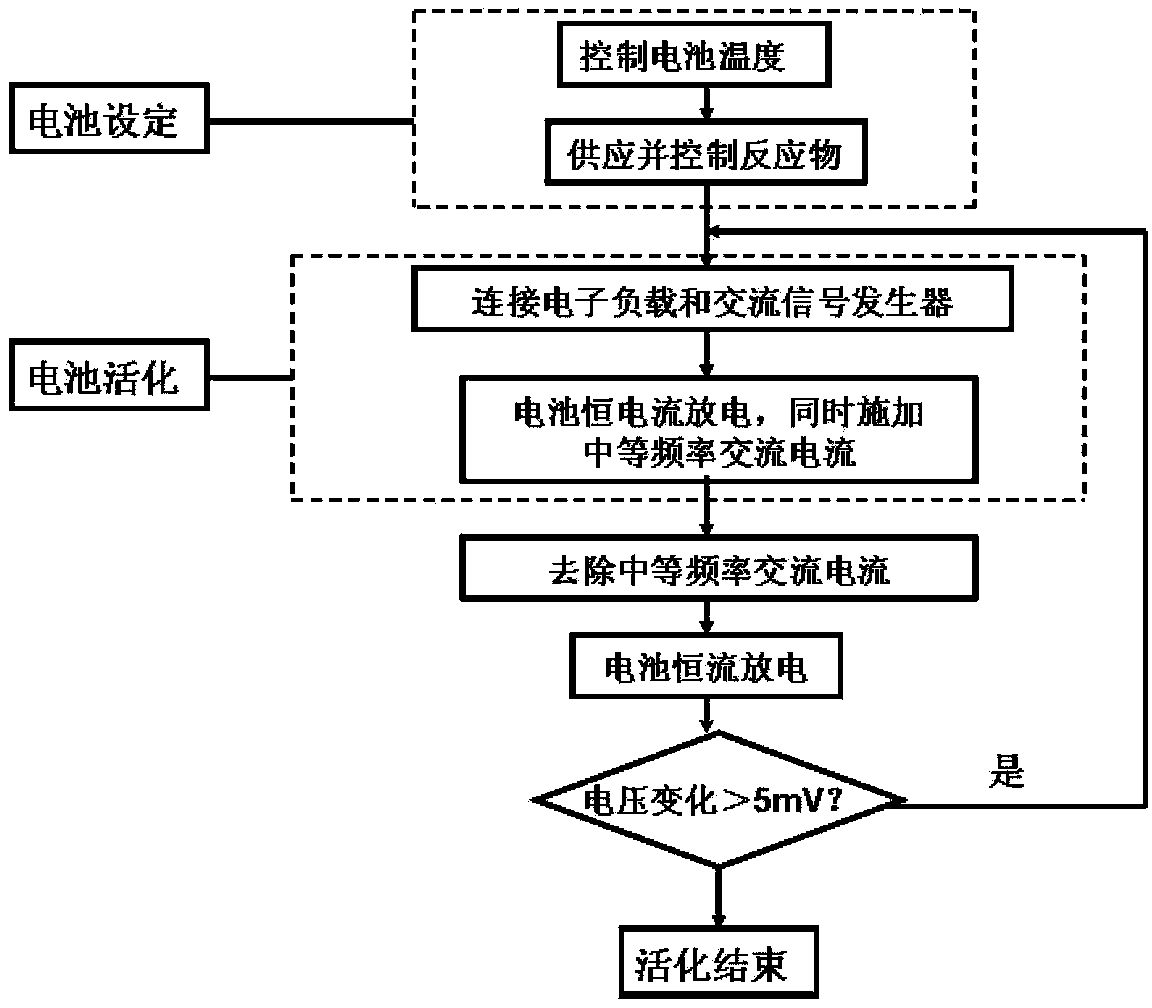

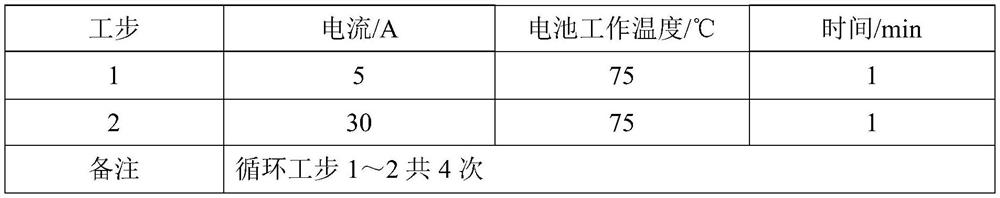

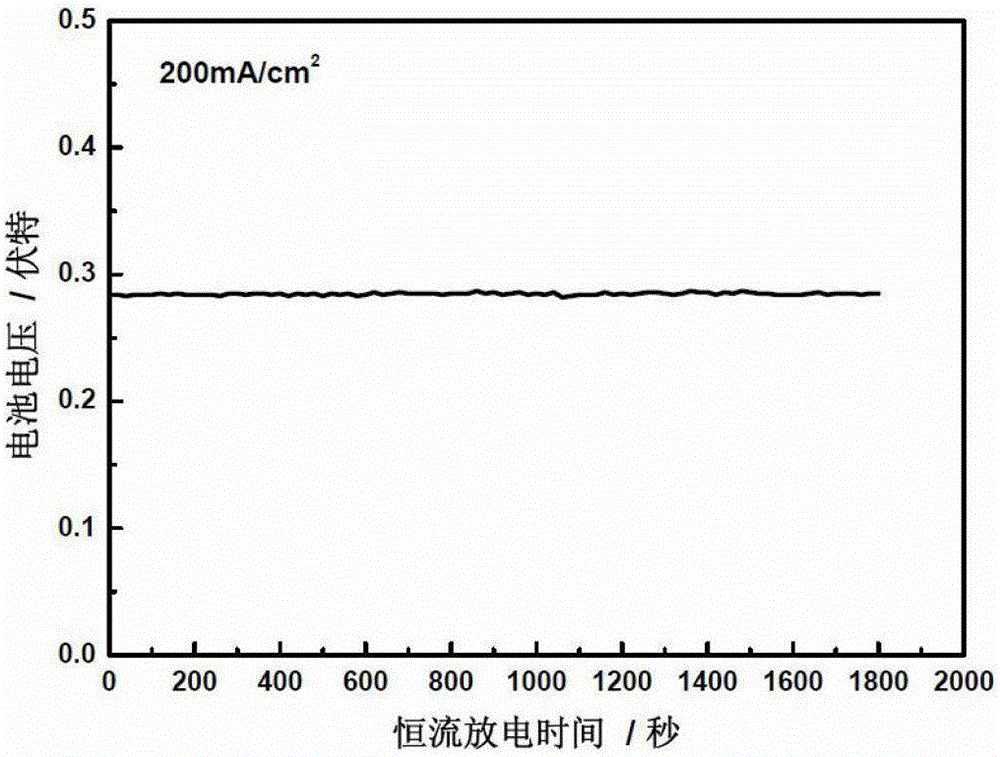

Proton exchange membrane fuel cell stack activation method

InactiveCN110911714AFinish quicklyReduce consumptionFuel cellsEngineeringProton exchange membrane fuel cell

The invention discloses an activation method of a proton exchange membrane fuel cell stack. The activation method comprises the following steps: step 1, checking the air tightness of the proton exchange membrane fuel cell stack; step 2, introducing hydrogen into the anode of the proton exchange membrane fuel cell stack, introducing air into the cathode of the proton exchange membrane fuel cell stack, gradually reducing the voltage of the proton exchange membrane fuel cell stack in a constant-voltage mode, and keeping the voltage for 5-10 minutes; 3, cooling the proton exchange membrane fuel cell stack; step 4, repeating the step 2 and the step 3 for 3-5 times, and then stopping air intake of the anode; and 5, introducing hot water into the anode of the proton exchange membrane fuel cell stack until the performance of the proton exchange membrane fuel cell stack is stable. According to the activation method of the proton exchange membrane fuel cell stack provided by the invention, the activation cost is remarkably reduced, and the whole activation process can be completed within about 1 hour.

Owner:浙江高成绿能科技有限公司

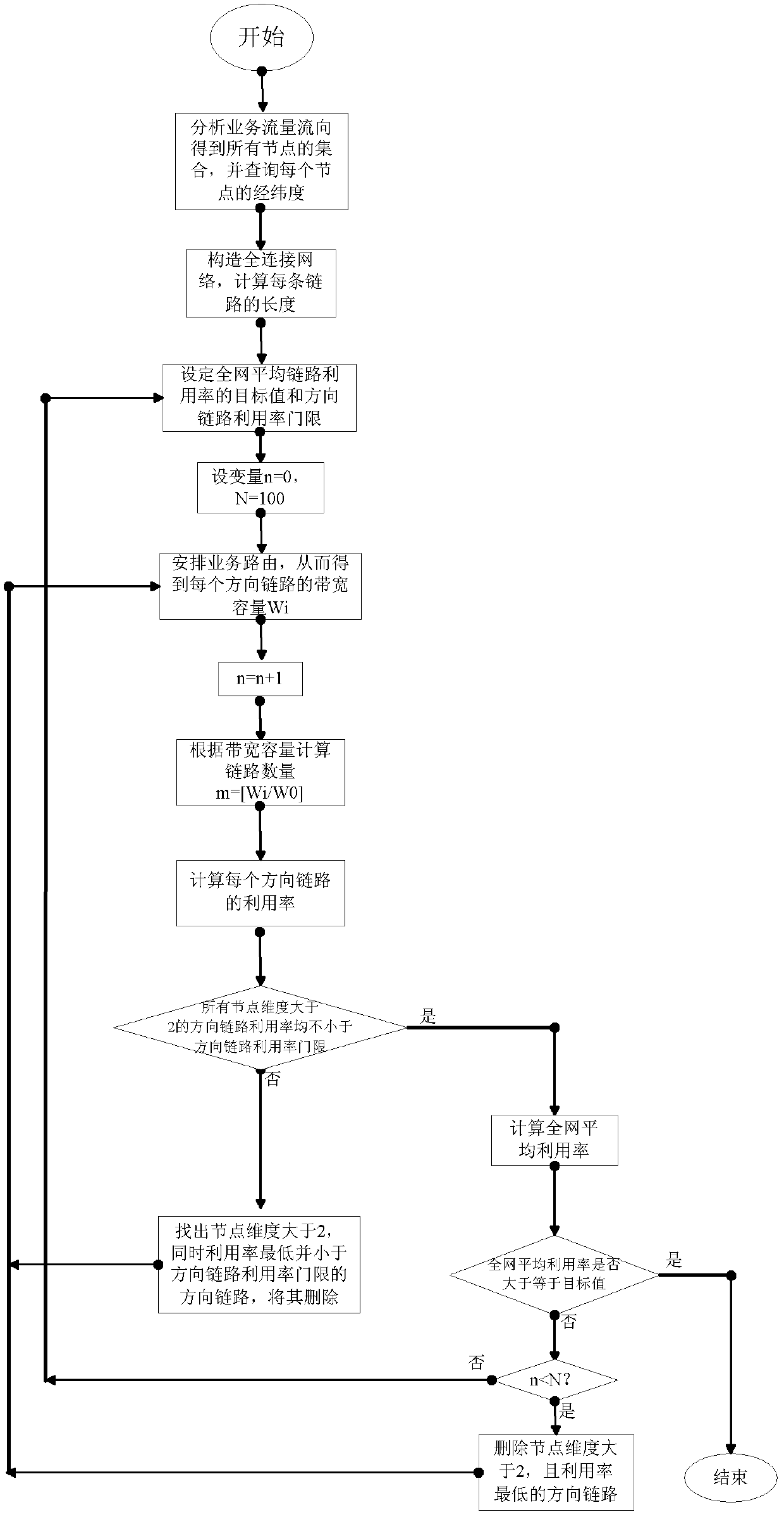

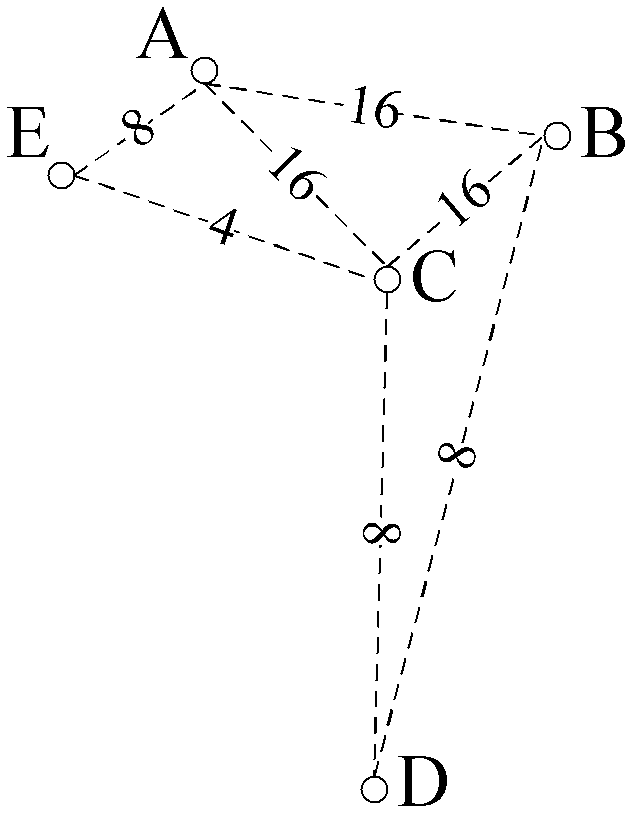

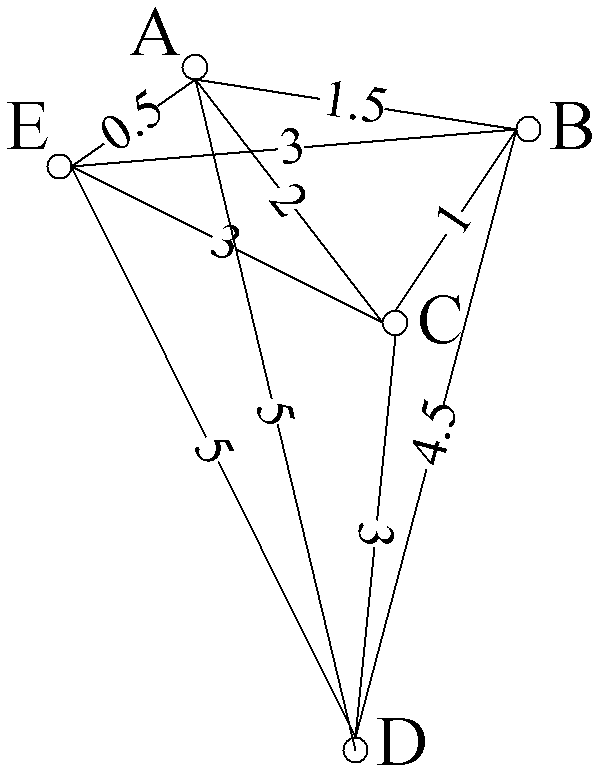

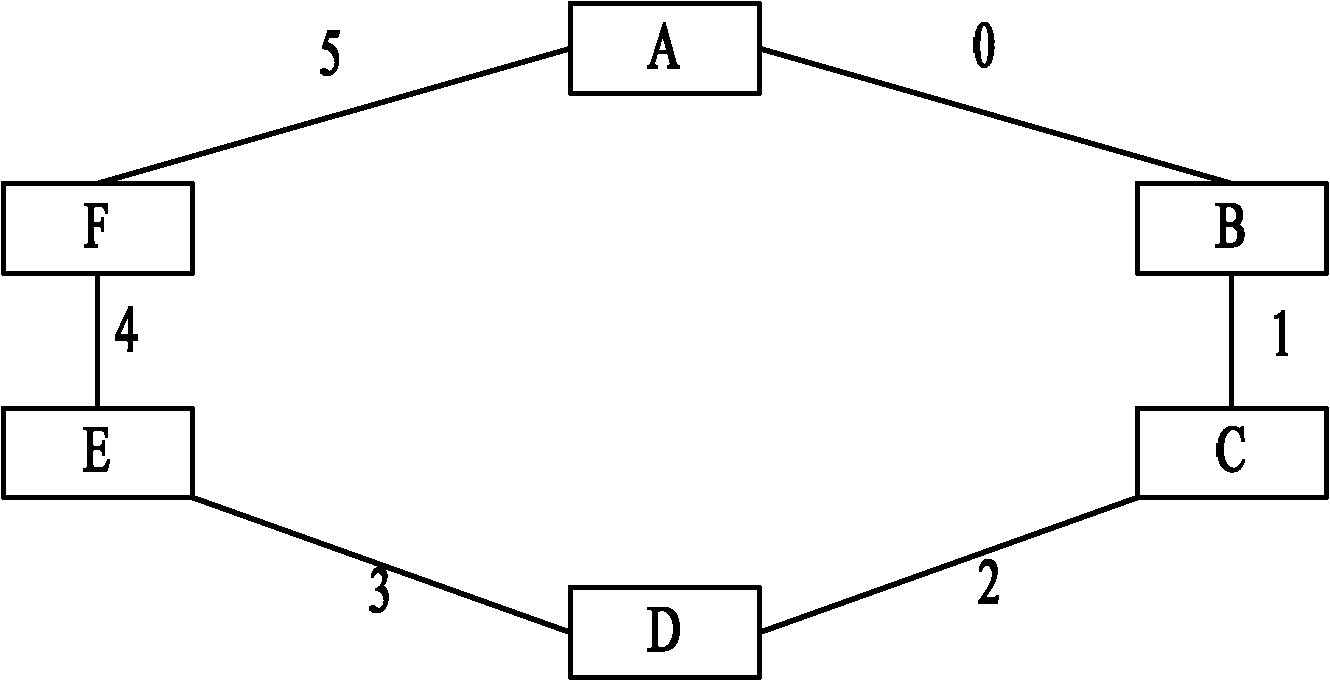

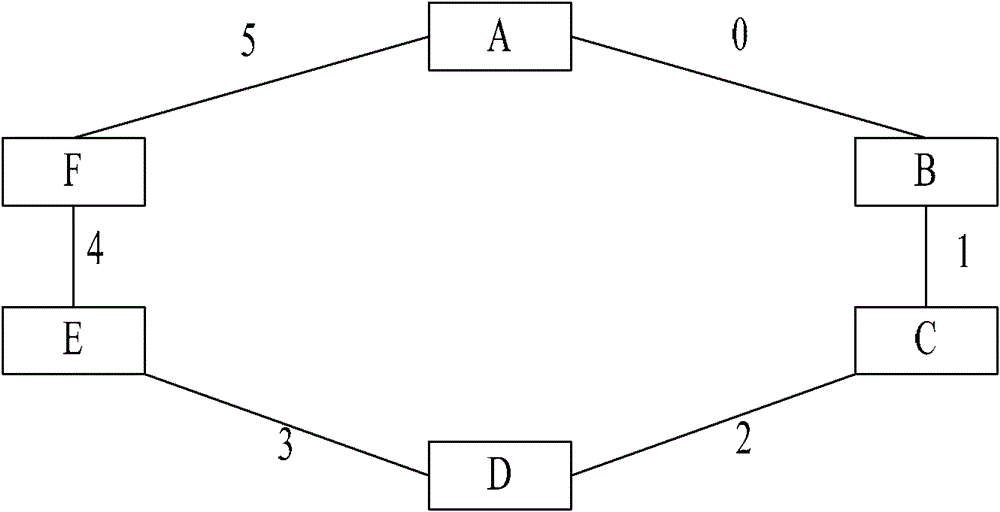

Method for automatically designing topology of business-driven transmission network

InactiveCN102710431AReduce activation costsOpening cost solutionData switching networksResource utilizationNetwork link

The invention discloses a method for automatically designing topology of a business-driven transmission network. The method includes firstly, building a fully connected network according to a business flow direction; secondly, setting a target value sigma of an average link utilization rate of the total network and a direction link utilization rate threshold sigma 0; thirdly, setting a variable n and setting the maximum planning frequency N; fourthly, obtaining bandwidth capacity Wi of each network link; fifthly, computing the quantity m of the links in each direction; sixthly, computing utilization rates of the links in various directions; seventhly, analyzing the utilization rates of all the links in topology G(V, L); eighthly, further deleting links in relevant directions if judgment for a result obtained in the seventh step is negative; and ninthly, computing an average utilization rate eta of the total network if the judgment for the result obtained in the seventh step is positive. By the aid of the method, the problem that topology of a network difficultly matches with a business flow direction in the prior art can be effectively solved, pertinence of network building and resource utilization rate are improved, provision and scheduling of later business are facilitated, and engineering investment is protected.

Owner:HUAXIN CONSULTATING CO LTD

Activation method before chemical plating based on photocuring technique

InactiveCN107119459AFast activationIncrease productivityVegetal fibresAnimal fibresActivation methodChemical plating

The invention relates to an activation method before chemical plating based on a photocuring technique. The activation method comprises the following steps: (1) preparing an aqueous photocuring activation liquid; (2) settling the aqueous photocuring activation liquid on a fabric, drying, and performing ultraviolet photocuring. In the activation process, a photocuring technique is adopted to anchor precious metal ions on the surface of the fabric, the operation is simple, green and environment-friendly, the binding fastness of an activated layer and base cloth is improved, meanwhile the amount of the precious metal salts is reduced, and the production cost of the activation process is reduced. The activation method can be applied to activiation treatment before chemical plating of various fabrics and is wide in application range, excellent in activation effect and easy in industrial production.

Owner:SAINTYEAR HLDG GROUP +1

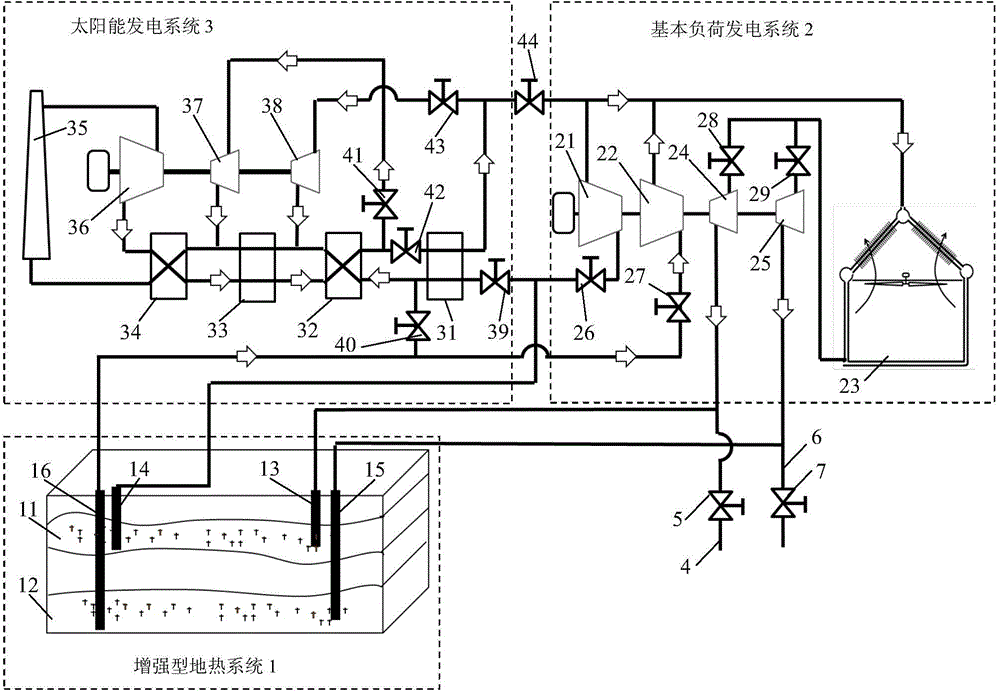

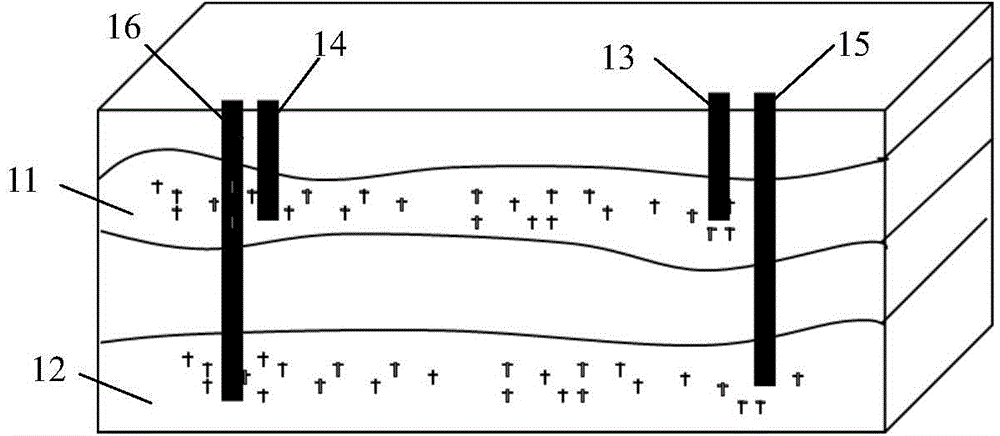

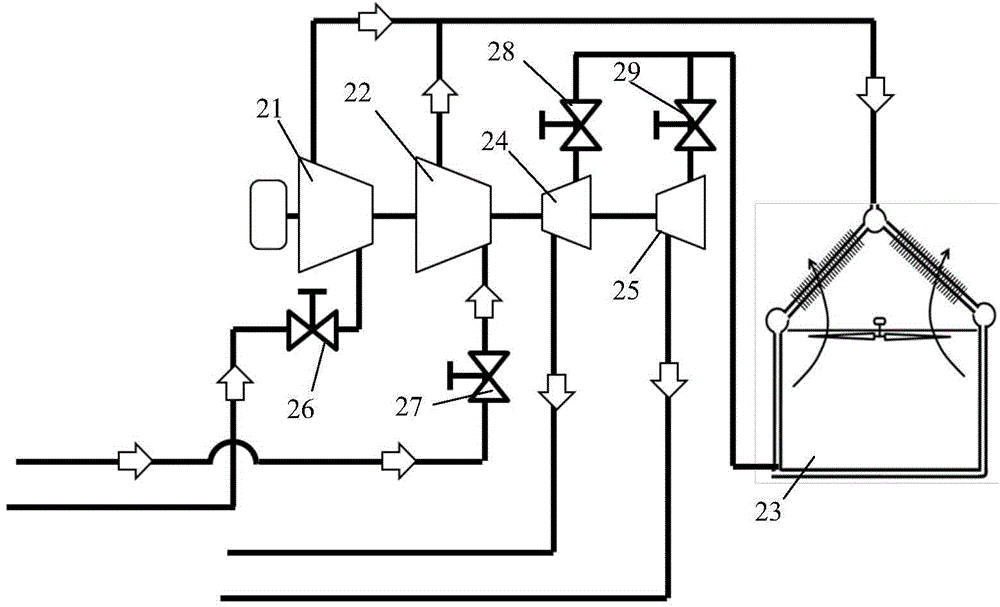

Enhanced geothermal and solar combined power generation method and system

ActiveCN104481824AEfficient conversionReduce activation costsFrom solar energyMachines/enginesElectric energyPower station

The invention relates to an enhanced geothermal and solar combined power generation method and an enhanced geothermal and solar combined power generation system. The method comprises the steps that CO2 serving as a working medium absorbs heat in an enhanced geothermal system, so that the temperature is raised; the enhanced geothermal system outputs supercritical CO2 with different temperatures and certain pressure; part of the supercritical CO2 enters a basic load generation system, and the basic load generation system converts part of the heat absorbed by the supercritical CO2 from the enhanced geothermal system into electric energy serving as a basic load of a power station; the other part of the supercritical CO2 enters a solar generation system, and the solar generation system continuously heats the supercritical CO2 to certain temperature by utilizing solar energy through an energy grade matching method, a heat regeneration series optimization method, an air exhaust compression series optimization method and a heat regenerator flow adjusting method, and then efficiently converts the heat into the electric energy.

Owner:TSINGHUA UNIV

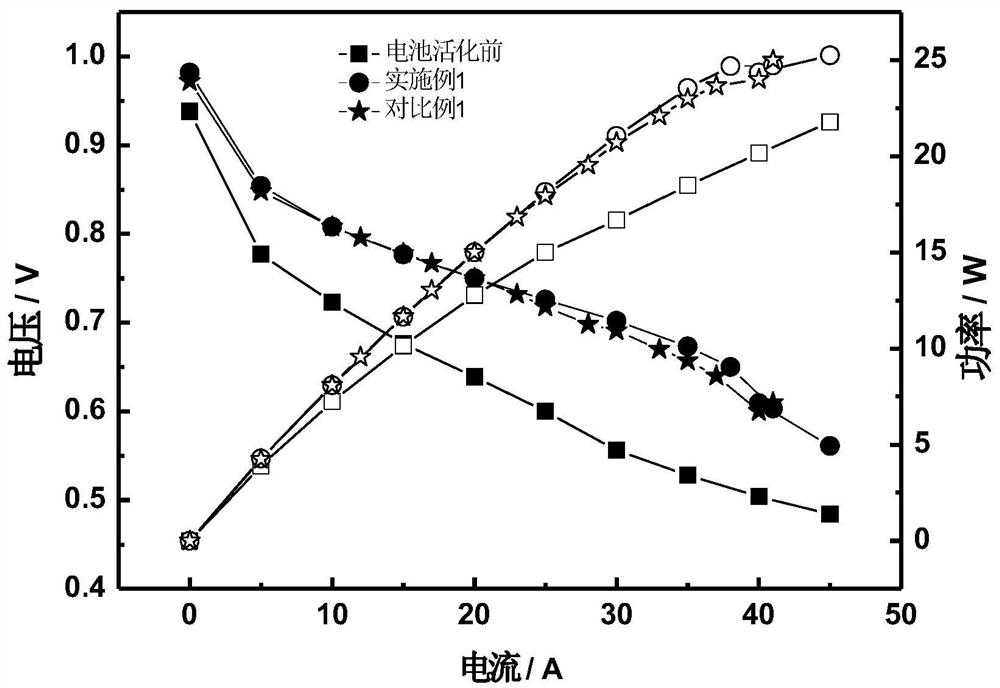

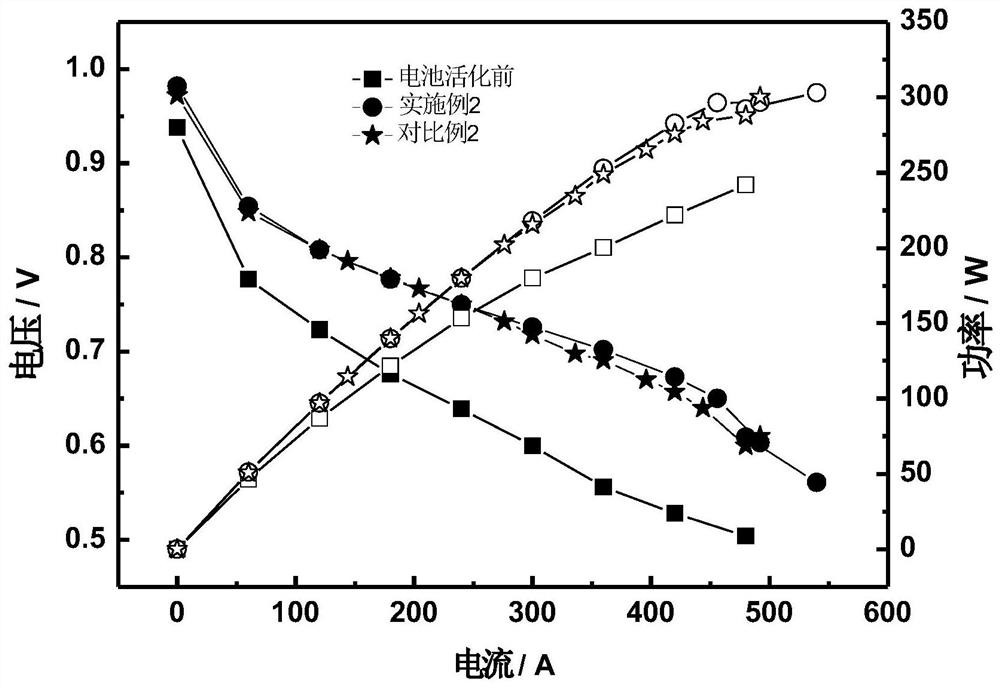

Rapid low-cost activation method for membrane electrode of proton exchange membrane fuel cell

The invention belongs to the technical field of fuel cells, and particularly relates to a rapid low-cost activation method for a membrane electrode of a proton exchange membrane fuel cell. The activation method comprises the following steps: introducing dry nitrogen into two poles of a single cell or an electric pile for safe purging and removing air and impurities in the fuel cell; heating the single cell or electric pile; introducing humidified hydrogen into an anode and a cathode of the cell respectively, keeping the hydrogen in the cell, and carrying out discharge-free wet hydrogen treatment on the single cell or the electric pile of the fuel cell; and stopping hydrogen supply, discharging residual gas and the like. The non-discharge wet hydrogen activation method is adopted, so that the catalyst activity of the proton exchange membrane fuel cell can be improved, the activation time can be greatly shortened, the gas fuel consumption is reduced, and the activation cost is greatly reduced. According to the activation method, MEA can be rapidly activated without using an electronic load and consuming a large amount of hydrogen, the energy is saved, the cost is reduced, and the defects of a pre-activation (non-discharge) method and a discharge activation method are overcome.

Owner:WUXI WEIFU HIGH TECH CO LTD

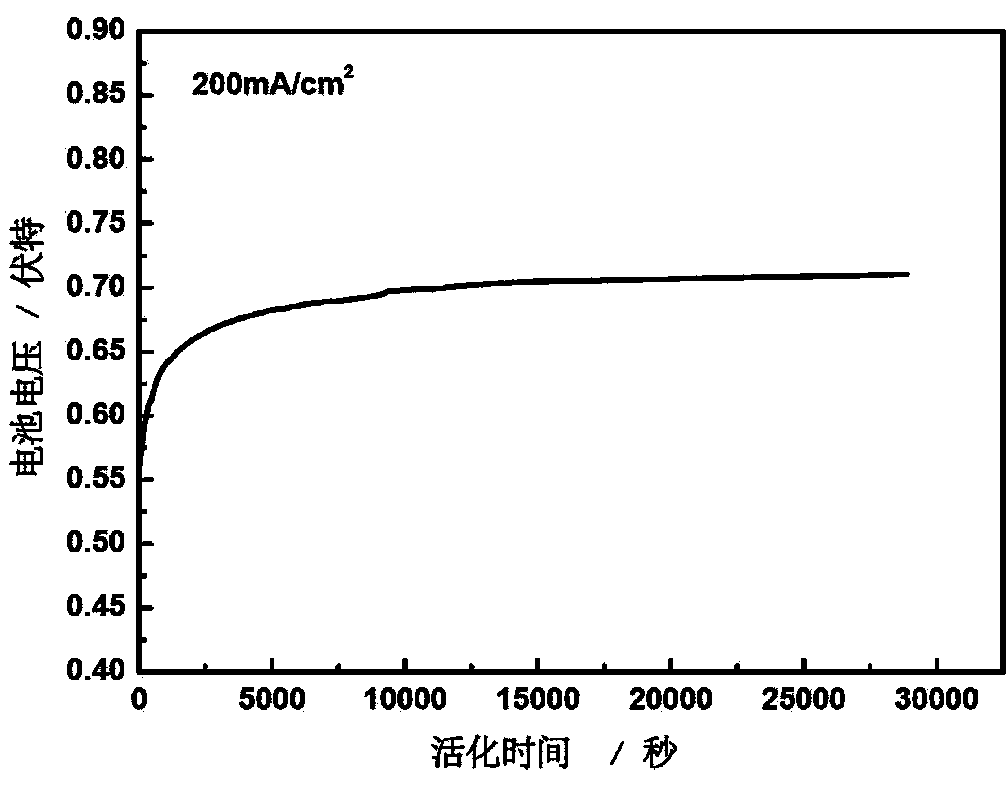

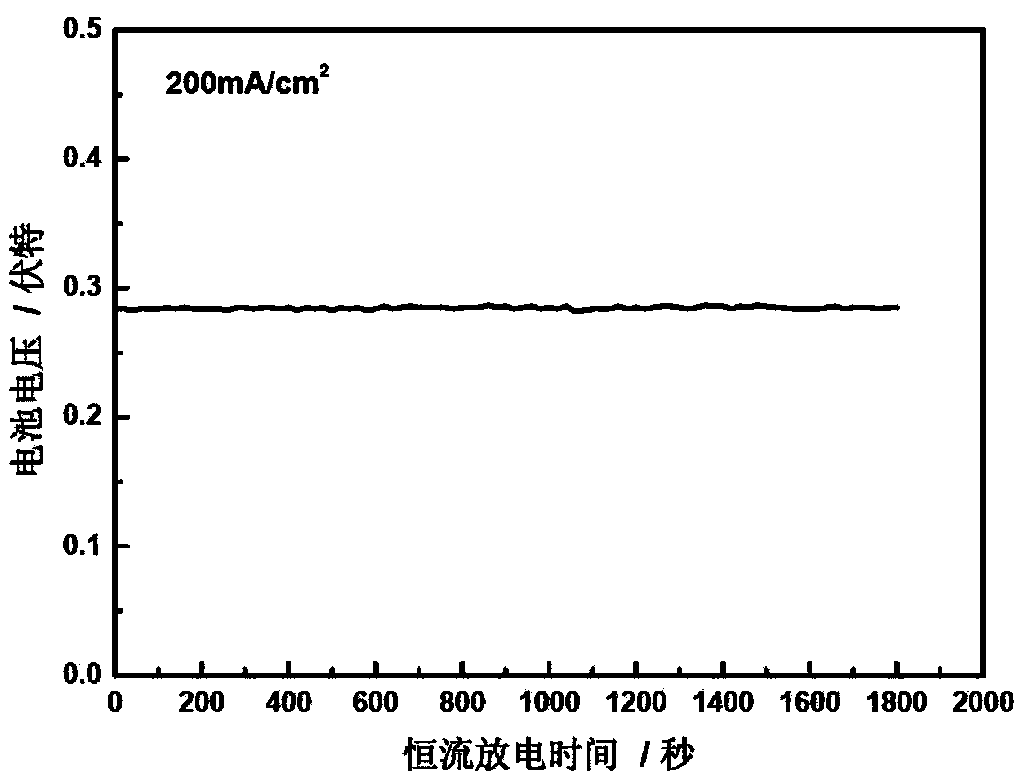

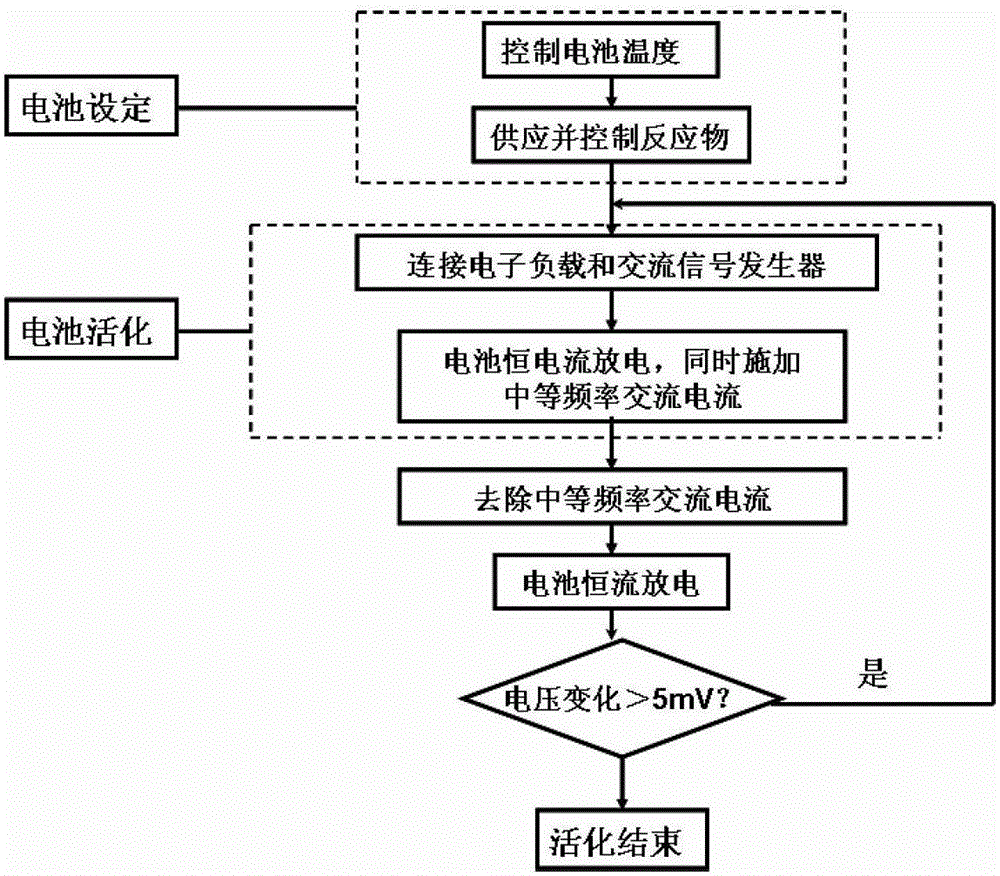

Single-cell activation method for direct borohydride fuel cell

ActiveCN103840184ASimple systemEliminate dependenciesFuel cell controlAqueous electrolyte fuel cellsElectrochemical responseEngineering

The present invention provides a single-cell activation method for a direct borohydride fuel cell (DBFC). The single-cell activation method is characterized by comprising three steps such as initial stage activation, electrochemical alternating current accelerated activation and cell performance testing, has characteristics of rapid electrochemical reaction interface expansion, short activation time, fuel saving, simple system and the like, and is especially suitable for activation of the DBFC with characteristics of low catalyst activity and long activation time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

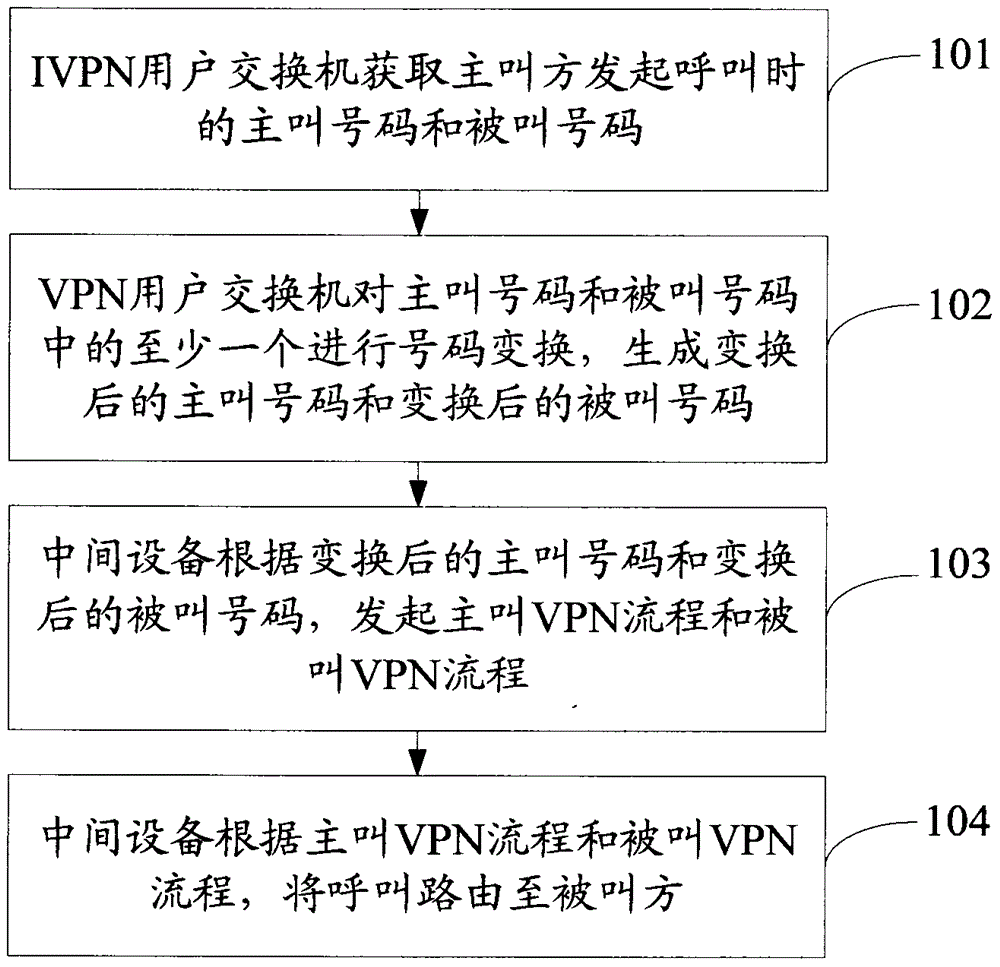

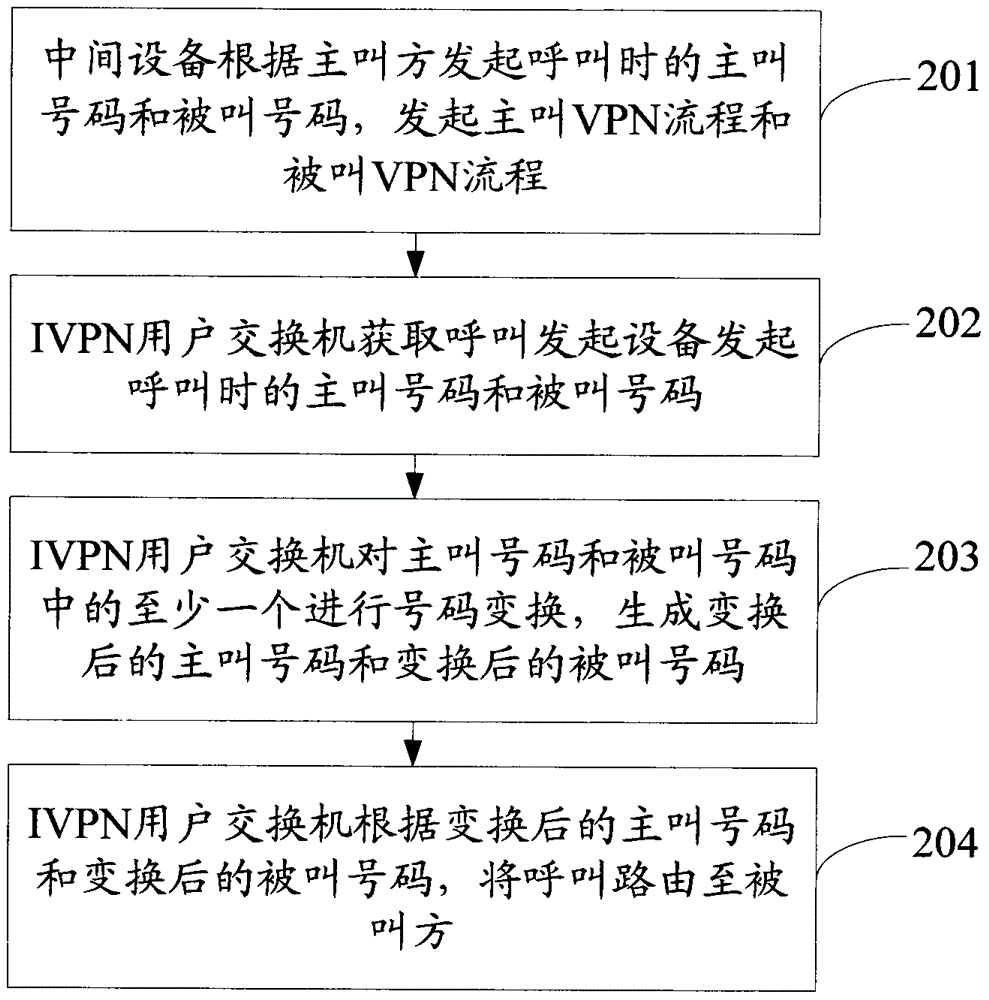

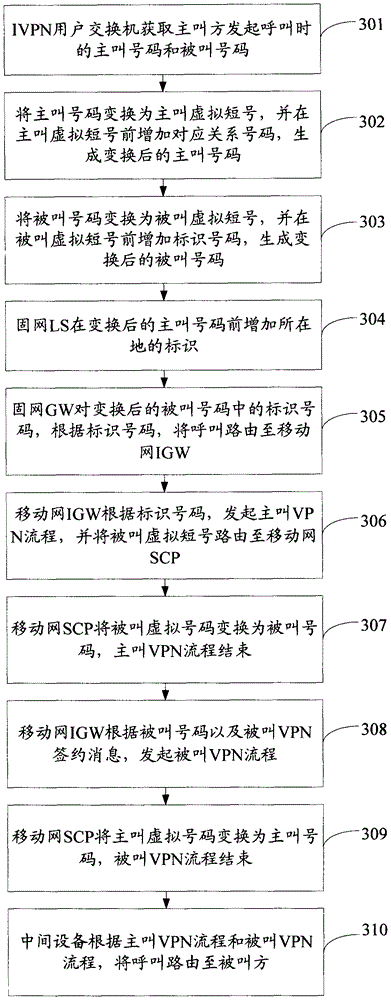

Communication network fusion method and communication network fusion system

InactiveCN105979105AReduce activation costsExpand the groupSpecial service for subscribersNetworks interconnectionTelecommunicationsService user

The invention discloses a communication network fusion method and a communication network fusion system, and belongs to the field of communication. The method comprises the following steps: an IVPN user switch acquires a calling number and a called number when a calling party initiates a call; the IVPN user switch transforms at least one of the calling number and the called number to generate a transformed calling number and a transformed called number; intermediate equipment initiates a calling VPN process and a called VPN process according to the transformed calling number and the transformed called number; and the intermediate equipment routes the call to a called party according to the calling VPN process and the called VPN process. IVPN service user groups are expanded, the support ability of the background is greatly improved, and the service opening cost is reduced greatly.

Owner:李琪

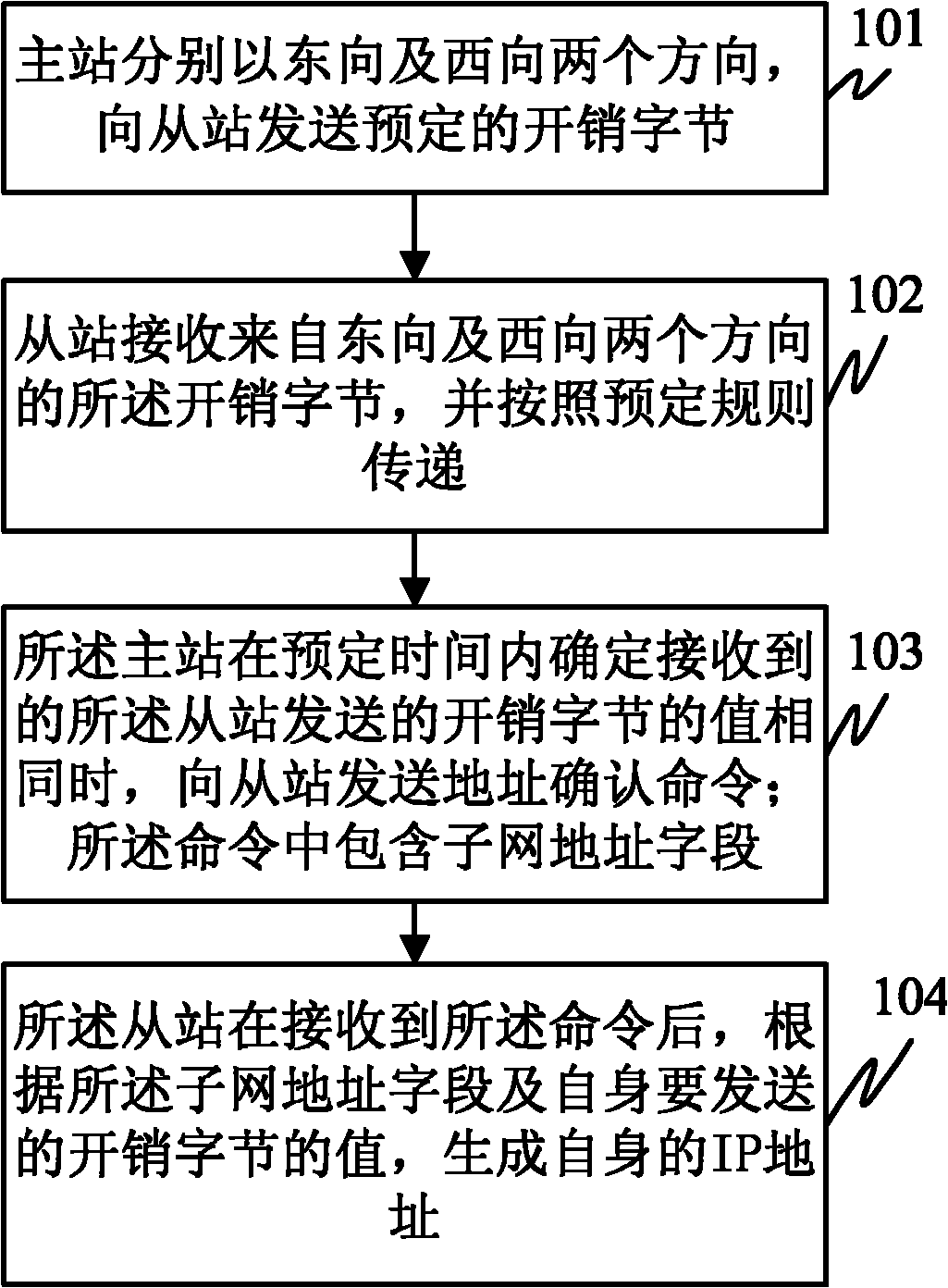

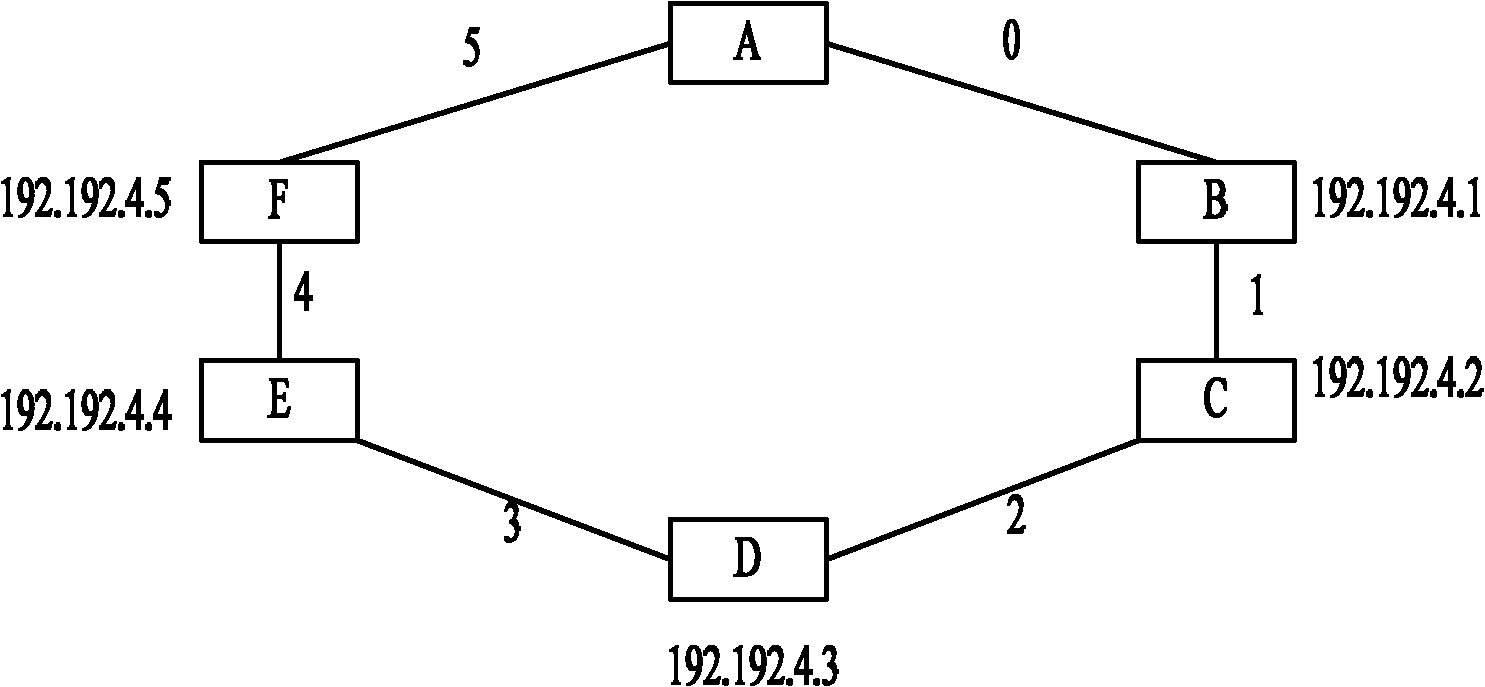

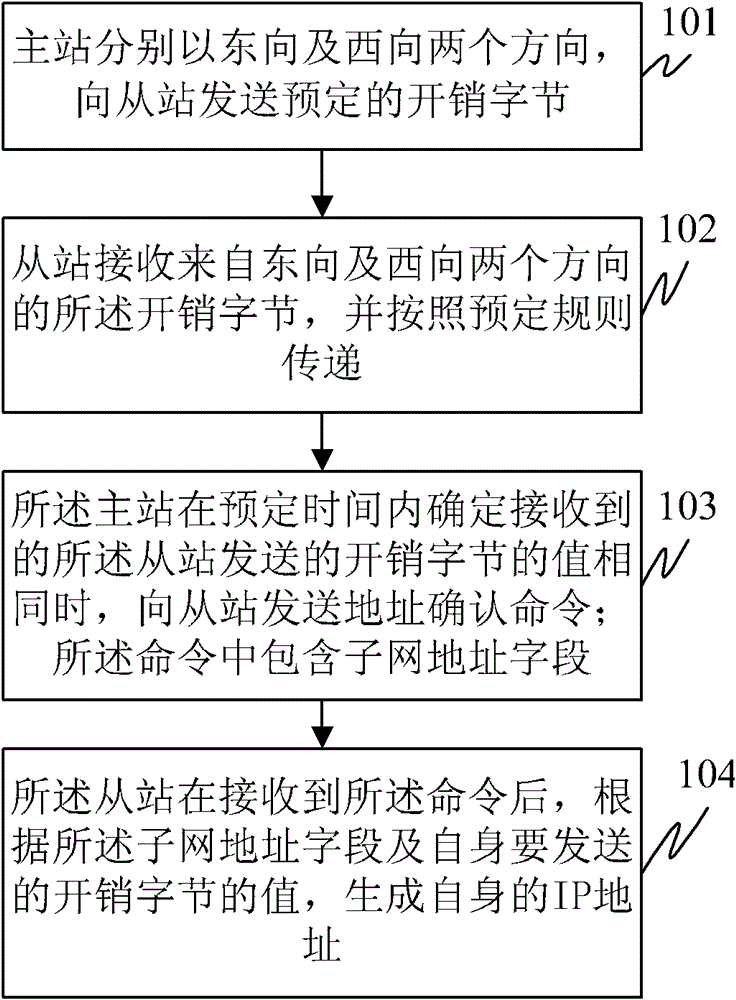

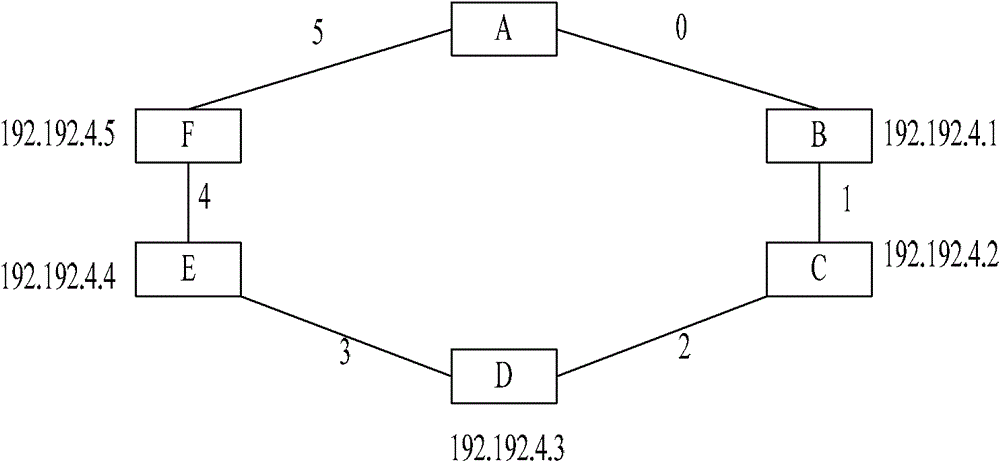

Synchronous digital hierarchy ring network topology discovery method

ActiveCN102075350AReduce occupancyReduce activation costsTime-division multiplexLoop networksIp addressRing network

The invention discloses a synchronous digital hierarchy (SDH) topology discovery method. The method is characterized by comprising the following steps that: a master station sends predetermined overhead bytes to a slave station in east and west directions; the slave station receives the overhead bytes from the east and west directions and transfers the overhead bytes according to a predetermined rule; the master station sends an address confirmation command to the slave station when determining that the received overhead bytes sent by the slave station are the same in preset time, wherein the command comprises a subnet address field; and the slave station generates an internet protocol (IP) address of the slave station according to the subnet address field and the values of the overhead bytes to be sent by the slave station after receiving the command. The invention also provides a topology discovery method for a chain network. By adopting the technical scheme provided by the invention, the network can be accessed under the condition that an IP address is not required to be allocated to a network element in advance, so that the operation cost is reduced.

Owner:BEIJING HUAHUAN ELECTRONICS

Method for chemically plating nickel at textile surface without using palladium

InactiveCN103114437BImprove adsorption capacityImprove bonding fastnessFibre treatmentCross-linkNickel salt

The invention relates to a method for chemically plating nickel at textile surface without using palladium; the method comprises the following steps of: (1), carrying out roughening treatment on the textile surface; (2), adding acetic acid solution drop by drop into chitosan liquid, at the end of the dripping process, stirring, de-foaming by ultrasonic wave, dripping glutaraldehyde solution, stirring, reacting, obtaining cross linking modified chitosan CCTS, and keeping on stirring; (3), immersing the textile into CCTS solution, taking out the textile, roll compacting, and baking to obtain the pretreated textile; and (4), immersing the textile into nickel salt solution, activating, drying, immersing into boron hydride salt solution, reducing, drying, and then carrying out chemical nickel plating in a chemical nickel system, finally the product is obtained. By adopting the method, the raw material cost of the chemical metal plating at the textile surface is reduced, the noble metal pollution is reduced, the using property of the textile is improved, and the shielding effectiveness of the prepared textile is 50-70dB within the range from 300KHz to 3000MHz, and therefore the method has an excellent practical prospect.

Owner:DONGHUA UNIV

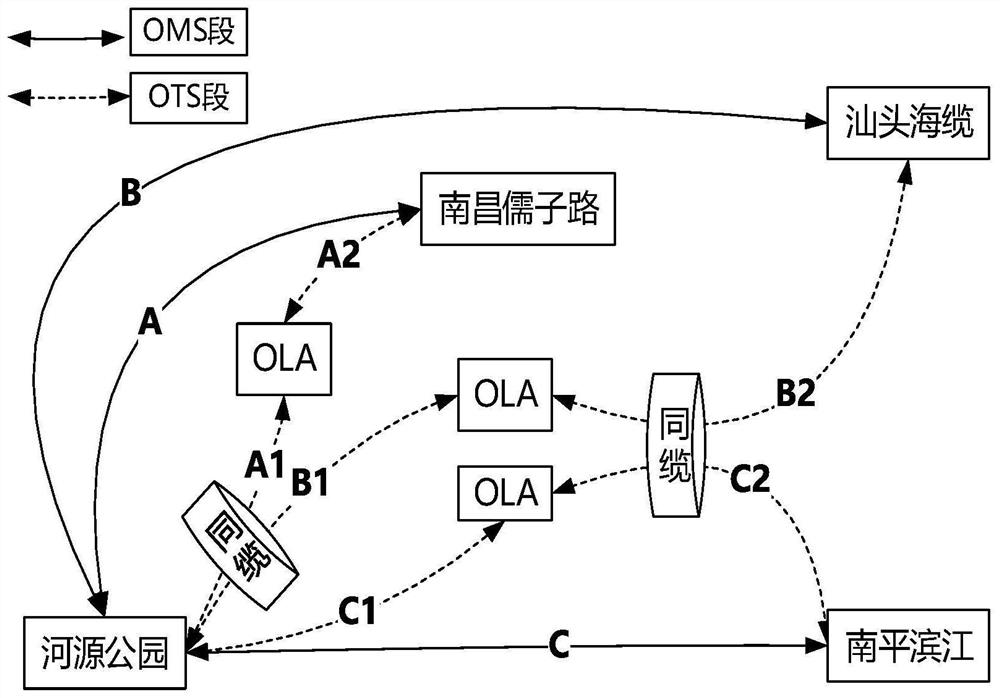

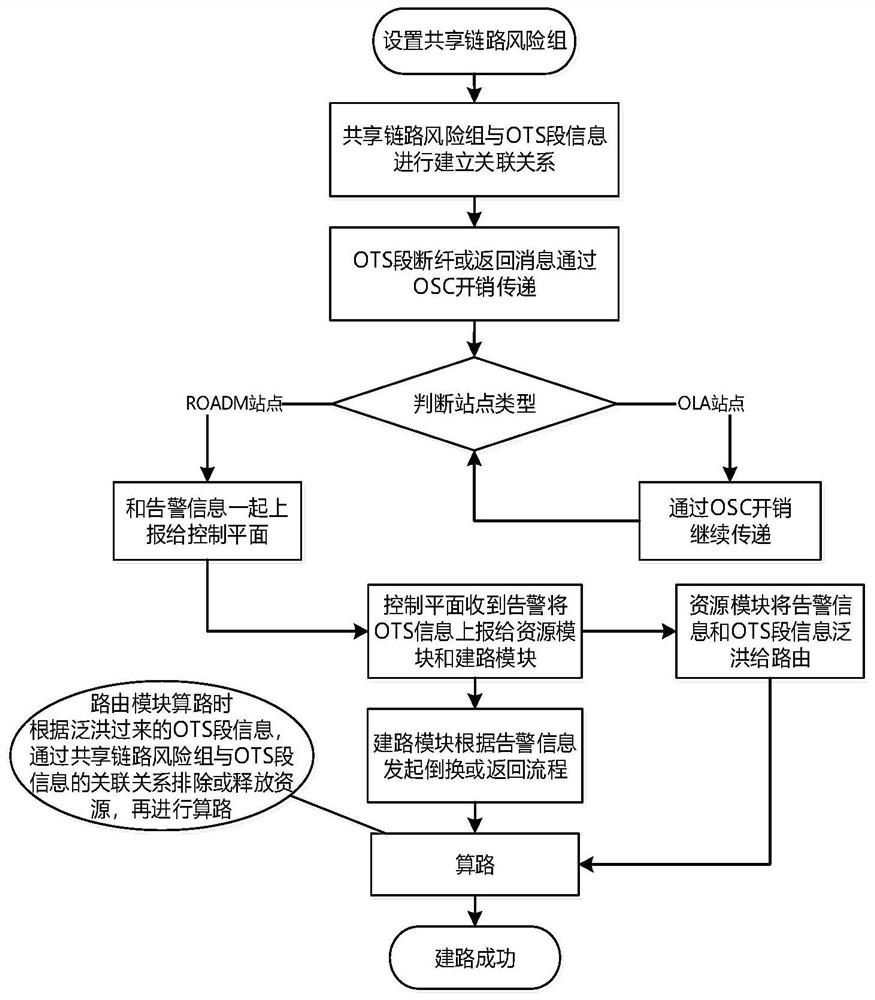

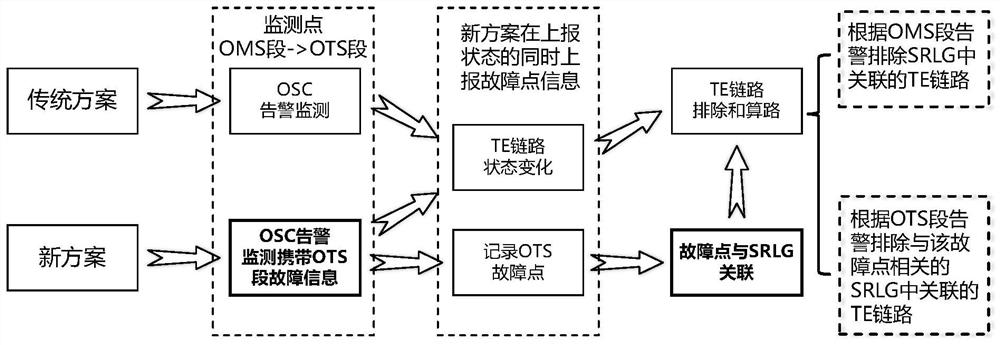

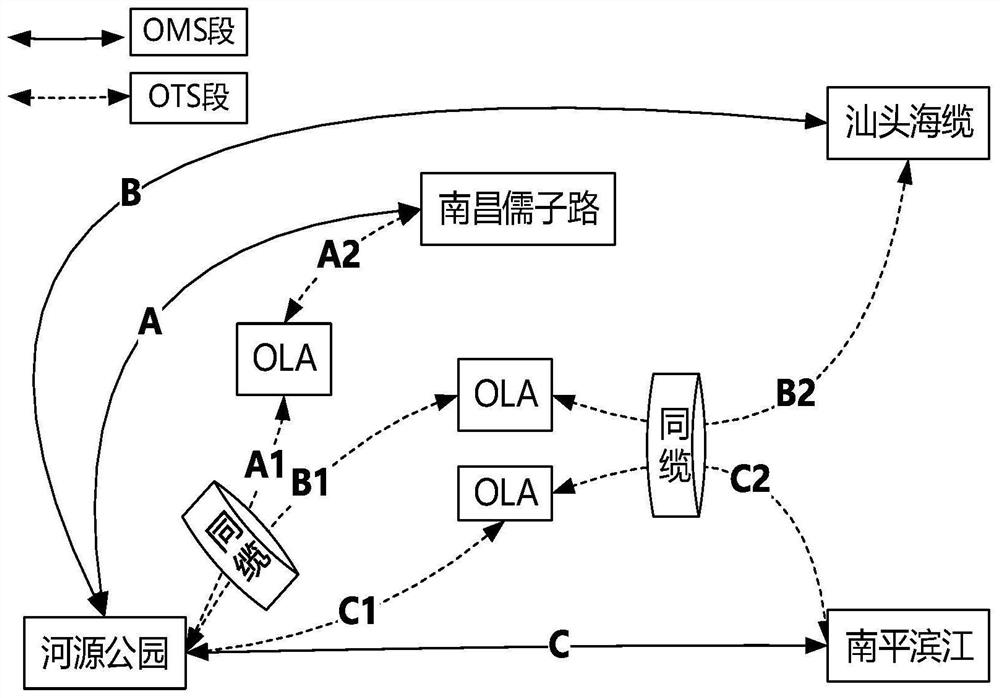

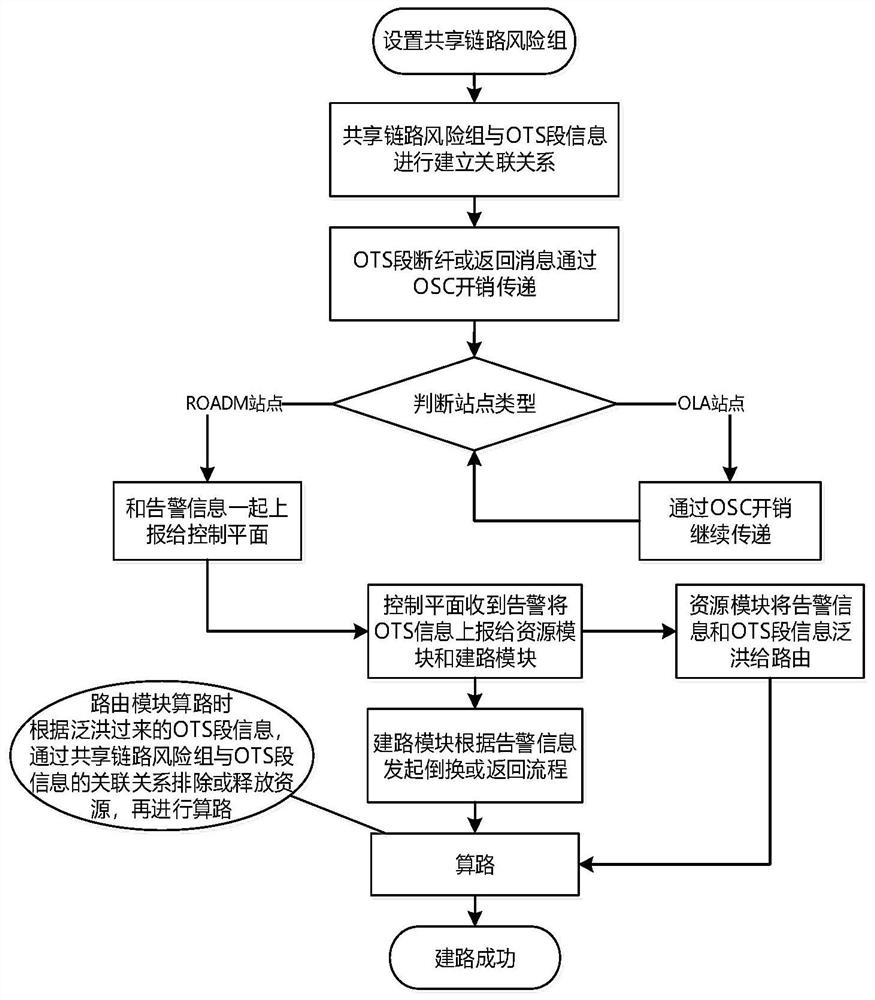

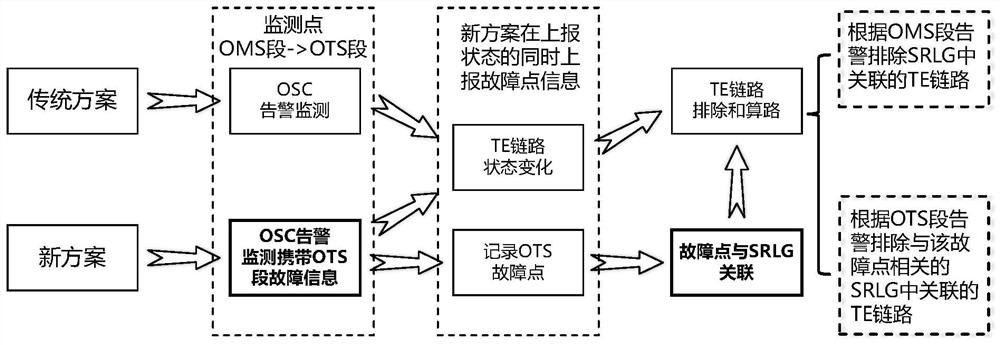

Resource optimization method based on shared link risk group and electronic equipment

ActiveCN112804096AImprove resource utilizationIncreased switching success rateElectromagnetic transmissionData switching networksMonitoring siteComputer network

The invention discloses a resource optimization method based on a shared link risk group, and the method comprises the steps: (1) refining a link fault monitoring point, marking an OTS segment, and enabling the link monitoring point to be refined from an OMS segment to the OTS segment in the OMS segment; (2) associating an OTS segment link monitoring point with a shared link risk group, wherein the OMS segment refers to a link between the ROADM sites, and the OTS segment refers to a link between the ROADM sites and the OLA sites or between two OLA sites. The method provided by the invention can improve the resource utilization rate, improve the switching success rate and reduce the project opening cost. The invention further provides the corresponding electronic equipment.

Owner:FENGHUO COMM SCI & TECH CO LTD

Gasoline-containing activated carbon for exhaust gas adsorption

InactiveCN107570112AImprove adsorption capacityImprove adsorption efficiencyOther chemical processesDispersed particle separationPhosphoric acidSilicon dioxide

The invention discloses gasoline-containing activated carbon for exhaust gas adsorption. The gasoline-containing activated carbon comprises a carbonized material and an impregnating solution impregnated inside the carbonized material, wherein the impregnating solution comprises the following components: phosphoric acid, magnesium oxide, zinc chloride, polystyrene microspheres, gypsum powder, silica, magnesium silicate, polyacrylamide and polyisobutylene succinimide. In the invention, the impregnation solution with an adsorption effect on gasoline vapor is impregnated into the carbonized material to form the gasoline-containing activated carbon for exhaust gas adsorption with a gasoline vapor adsorption amount higher than that of the conventional common activated carbon.

Owner:成都漆彩之星环保科技有限公司

Method for preparing geopolymers by taking stone coal vanadium extraction tailings as main raw materials

ActiveCN103482890BFavorable strength developmentHigh compressive strengthCement productionSlagMetakaolin

Owner:WUHAN UNIV OF TECH

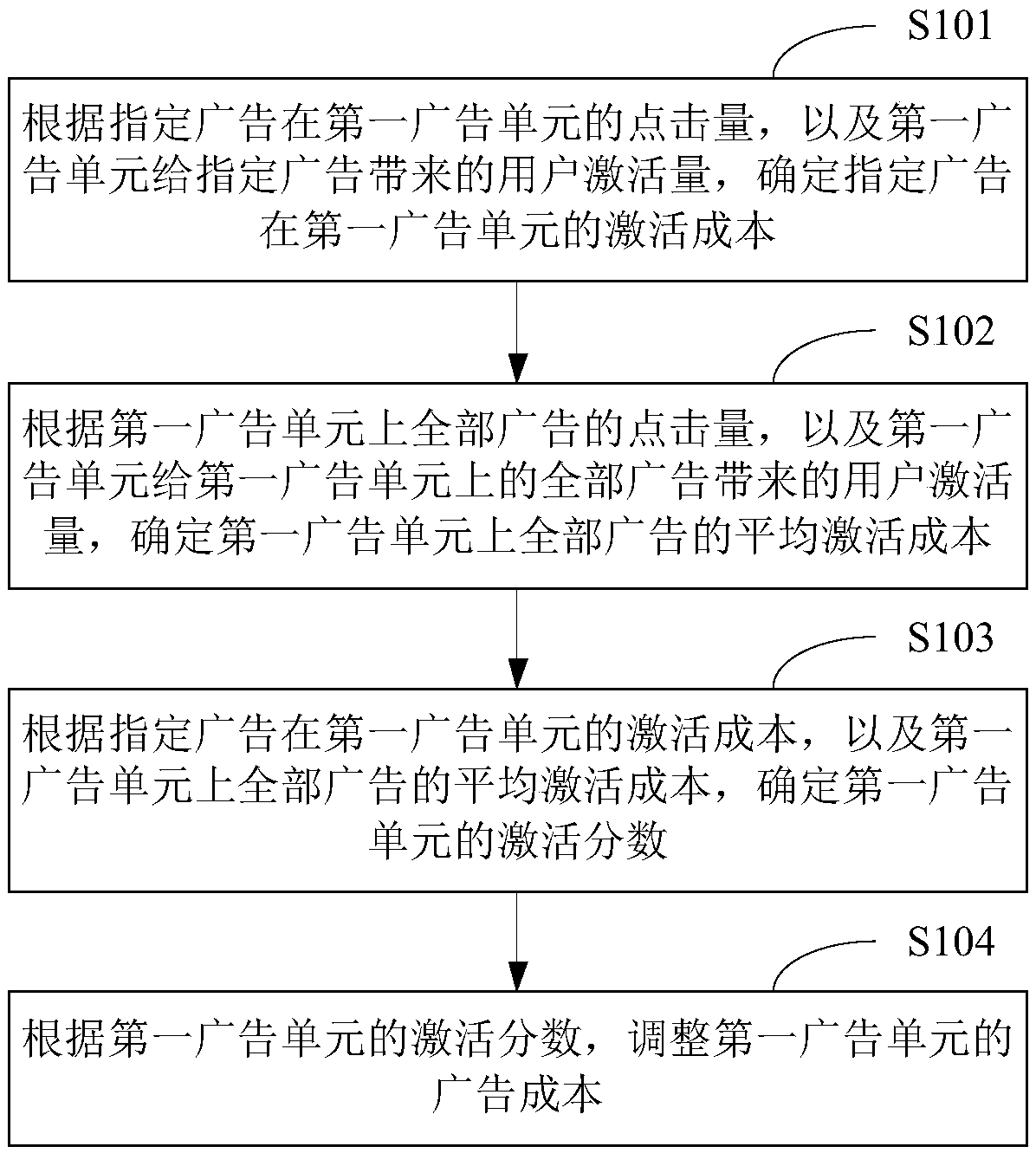

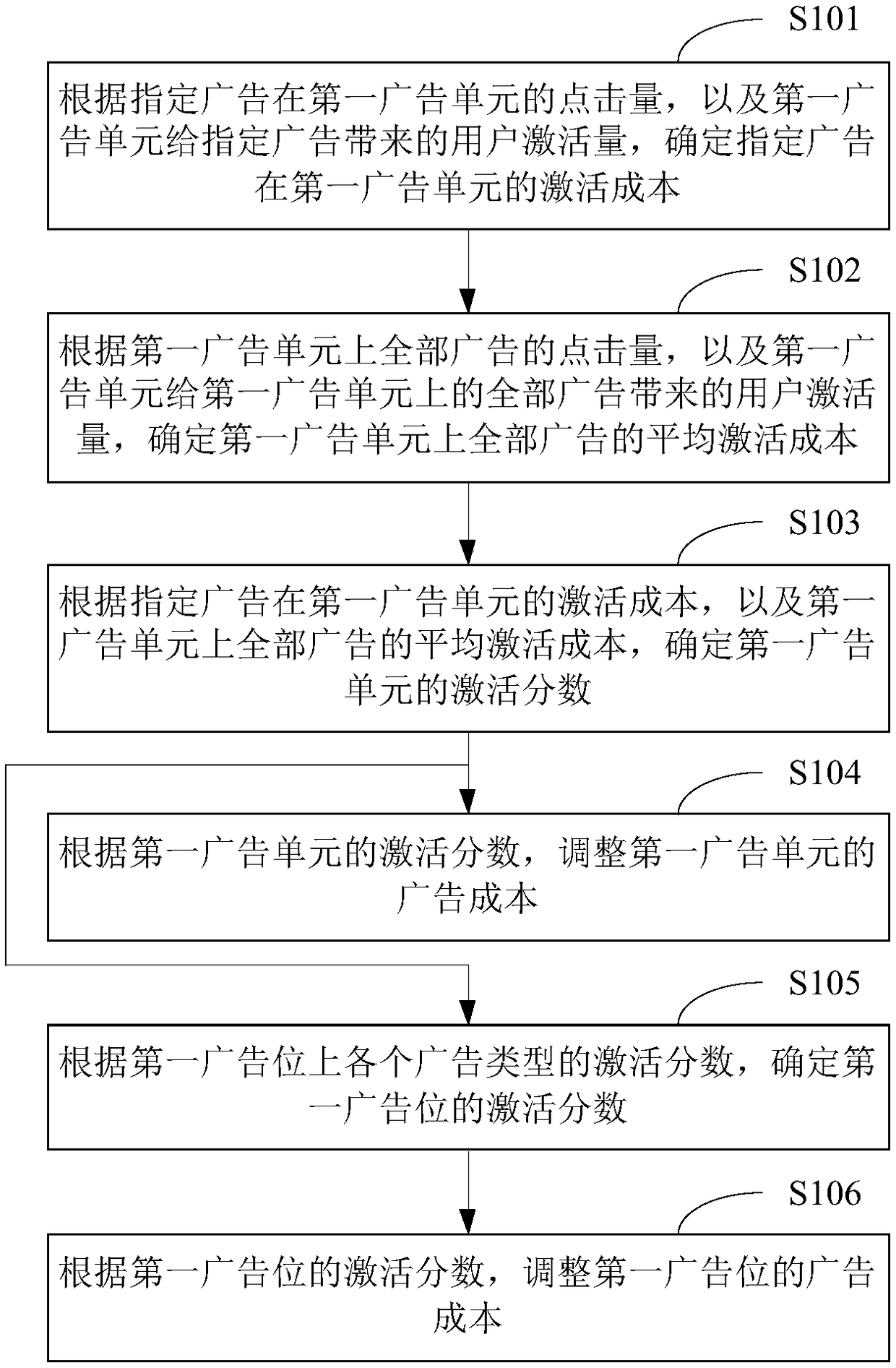

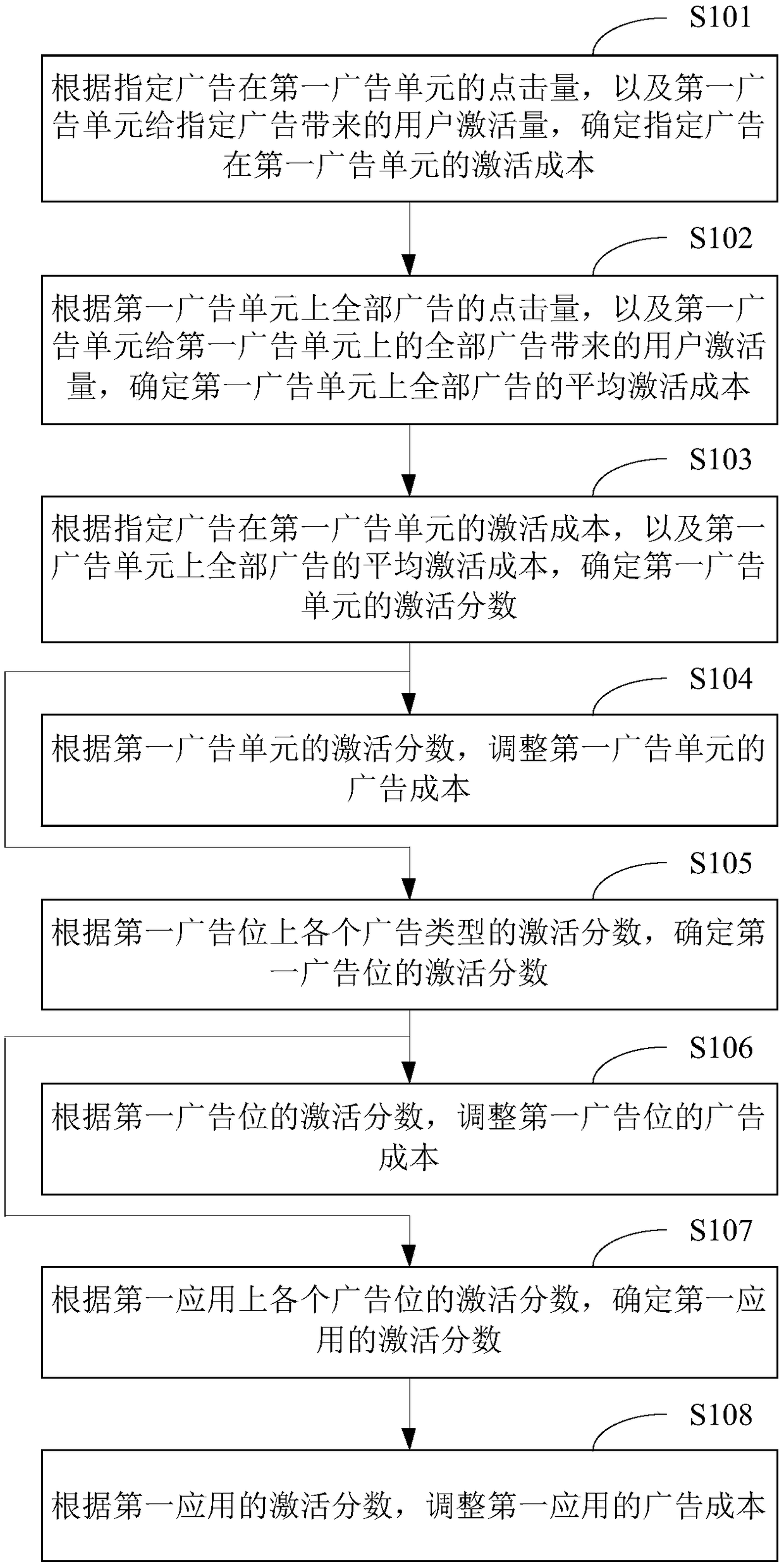

Advertisement delivery monitoring method and apparatus

InactiveCN108734517AControl the cost of advertisingActivation cost flexible adjustmentMarketingDelivery costWorld Wide Web

The invention relates to an advertisement delivery monitoring method and apparatus. The method comprises the following steps: determining an activation cost of specified advertisement on a first advertisement unit according to a click amount of the specified advertisement in the first advertisement unit, and a user activation amount brought by the first advertisement unit to the specified advertisement; determining an average activation cost of all advertisement on the first advertisement unit according to the click amounts of all advertisement on the first advertisement unit and the user activation amounts brought by the first advertisement unit to all advertisement on the first advertisement unit; determining an activation score of the first advertisement unit according to the activationcost of the specified advertisement on the first advertisement unit and the average activation cost of all advertisement on the first advertisement unit; and adjusting the advertisement cost of the first advertisement unit according to the activation score of the first advertisement unit. By adoption of the advertisement delivery monitoring method and apparatus provided by the invention, the advertisement cost of the first advertisement unit can be flexibly adjusted according to the user activation amount corresponding to the advertisement, so that the advertisement delivery cost of an advertiser can be effectively controlled.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

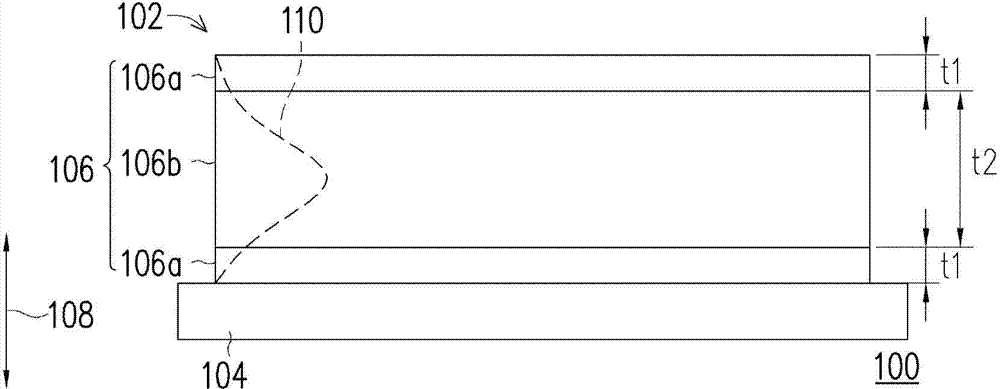

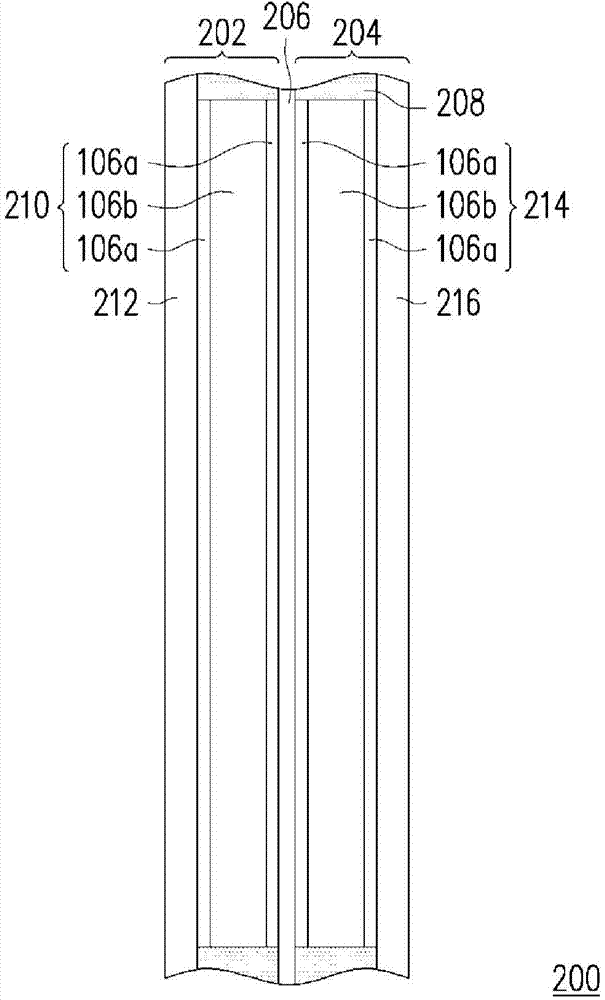

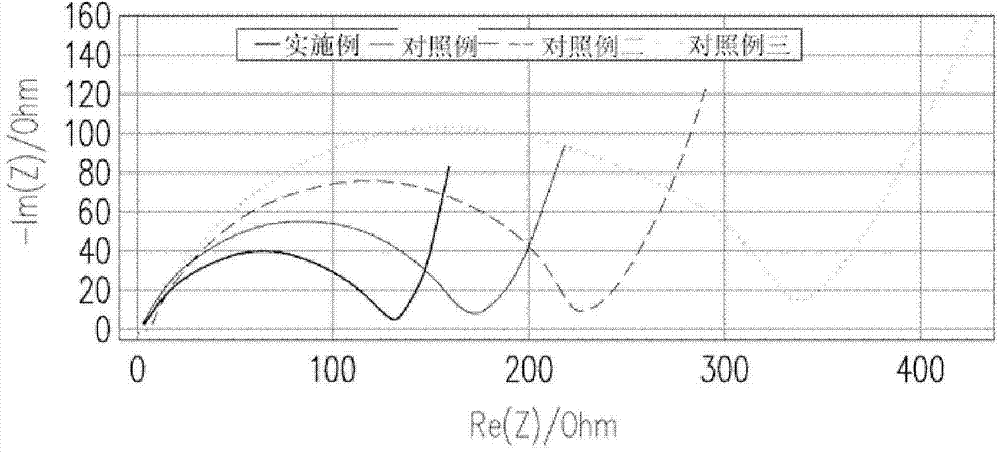

Power storage device and super capacitor device

ActiveCN104715931AInhibition of self-discharge behaviorReduce lossLead-acid accumulatorsHybrid capacitor electrodesOxidation reductionPower storage

A power storage device includes a positive electrode and a negative electrode disposed opposite to the positive electrode. The positive electrode and the negative electrode are respectively disposed on at least one surface of a current collector foil. The positive electrode and the negative electrode respectively include an active material, a conductive auxiliary and an adhesive, wherein the active material includes a porous material, an oxidation-reduction electrode material, or combination thereof. At least one of the positive electrode and the negative electrode has a multilayer structure containing three or more layers. The concentration of the oxidation-reduction electrode material in the outmost layer of the multilayer structure is the lowest.

Owner:IND TECH RES INST

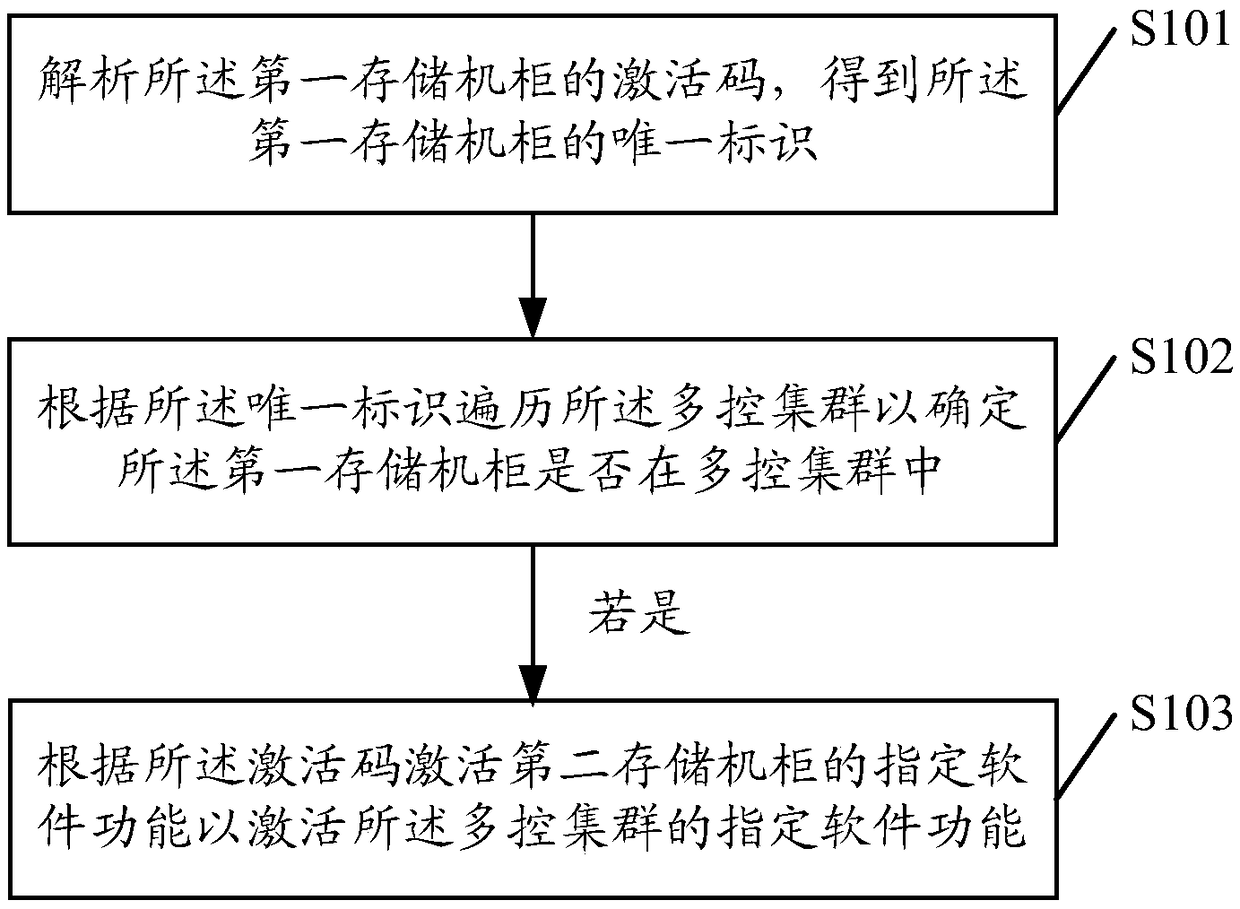

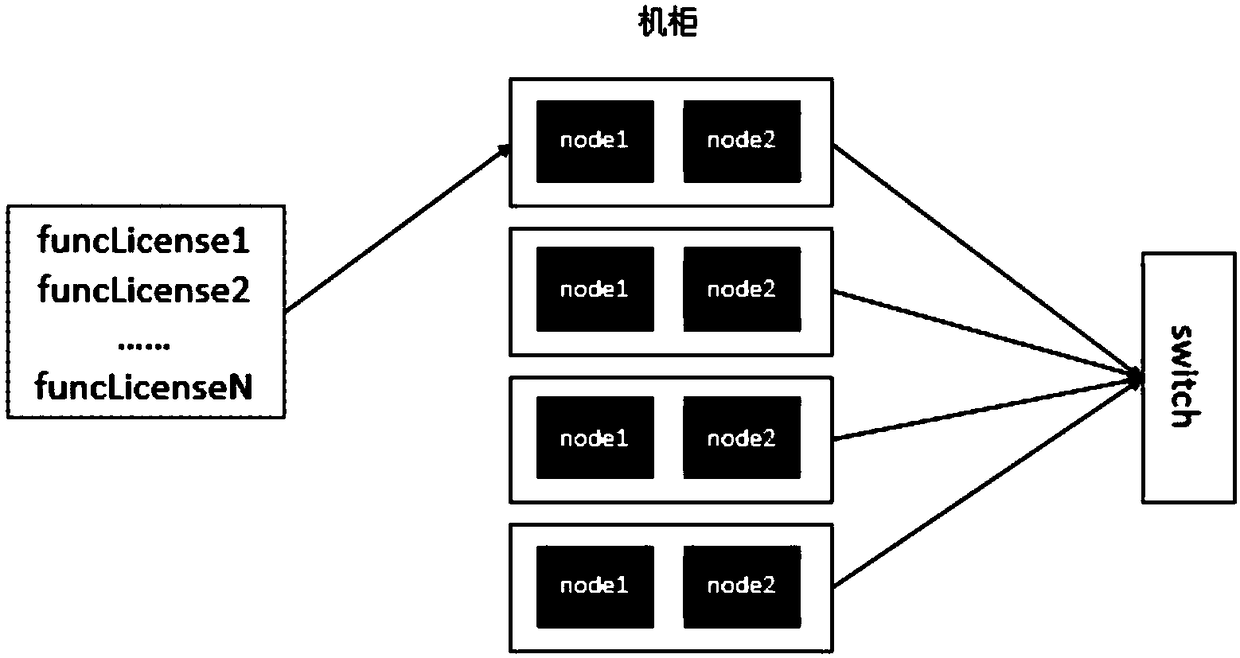

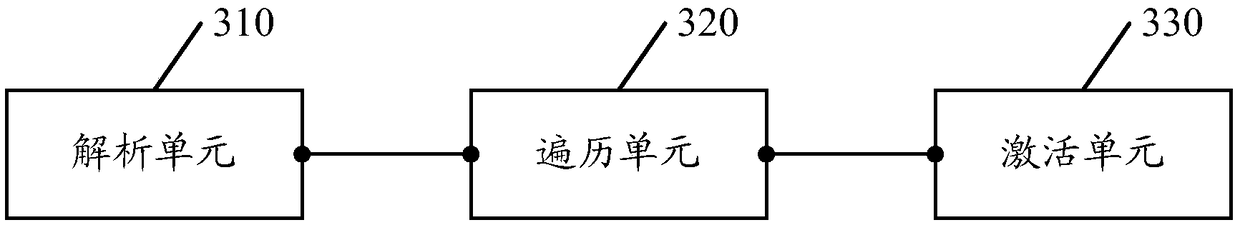

Activation method and device

ActiveCN109344573AEasy to activateReduce activation costsProgram/content distribution protectionActivation methodUnique identifier

The invention discloses an activation method, which comprises the following steps: the activation code of the first storage cabinet is analyzed to obtain the unique identification of the first storagecabinet; Traversing the multi-control cluster according to the unique identifier to determine whether the first storage cabinet is in the multi-control cluster; If yes, activating the designated software function of the second storage cabinet according to the activation code to activate the designated software function of the multi-control cluster; Wherein the second storage cabinet is a storagecabinet other than the first storage cabinet in the multi-control cluster. The method realizes that the whole multi-control cluster shares an activation code, reduces the activation cost and the activation workload, and makes the activation of the multi-control cluster more convenient. An activating device is also disclosed.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

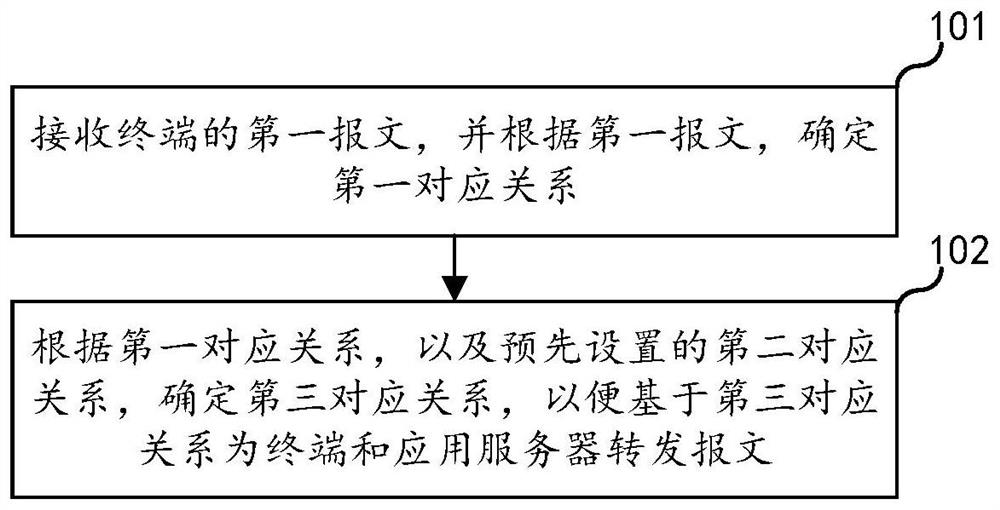

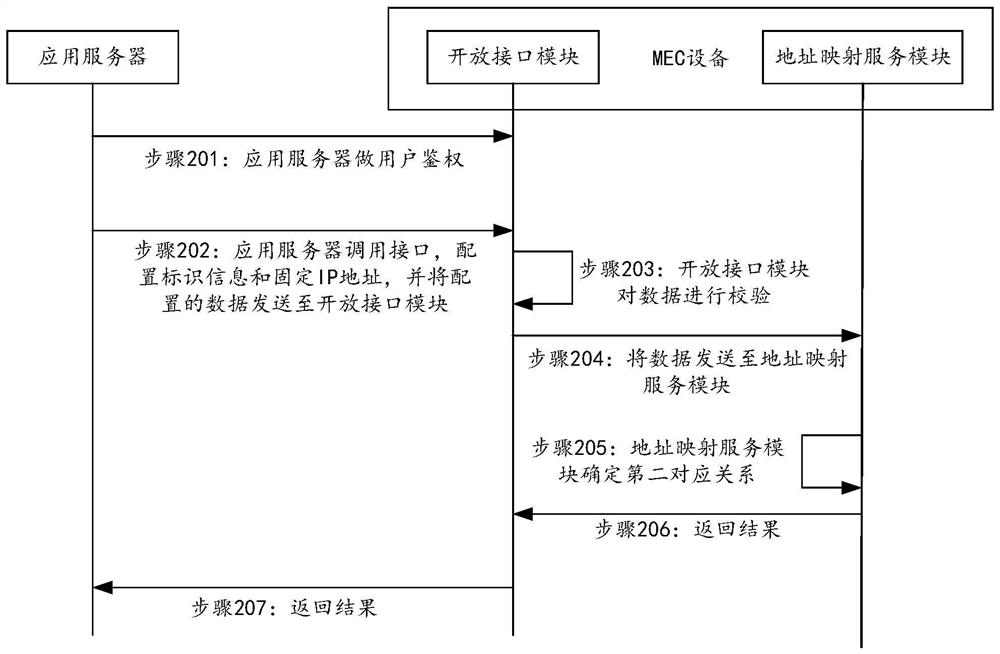

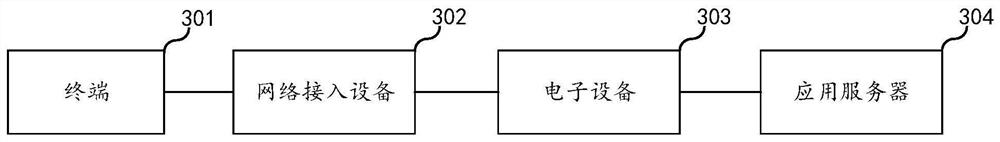

Network access method, electronic equipment and storage medium

PendingCN113810900ASave IP resourcesReduce activation costsAssess restrictionTransmissionApplication serverIp address

The embodiment of the invention relates to the technical field of communication, and discloses a network access method, electronic equipment and a storage medium. In some embodiments of the invention, the network access method is used for accessing a terminal to a network to which an application server belongs, and comprises the following steps: receiving a first message of the terminal, and determining a first corresponding relationship according to the first message, wherein the first corresponding relation at least indicates the corresponding relation between the identification information of the terminal and the actual internet protocol IP address of the terminal; according to the first corresponding relation and a preset second corresponding relation, determining a third corresponding relation so as to forward the message for the terminal and the application server based on the third corresponding relation; wherein the second corresponding relation at least indicates the corresponding relation between the identification information of the terminal and the fixed IP address of the terminal, and the third corresponding relation at least indicates the corresponding relation between the actual IP address of the terminal and the fixed IP address of the terminal. According to the embodiment, IP resources are saved, and the opening cost and the maintenance cost are saved.

Owner:ZTE CORP

A kind of method of nickel salt activation electroless copper plating textile

InactiveCN103805971BStrong chelating abilityLow raw material costLiquid/solution decomposition chemical coatingEnvironmental resistanceCopper plating

The invention relates to a method for activating electroless copper-plated textile with a nickel salt. The method comprises the steps of soaking the textile into a 10-30g / L coarsening liquid, heating to 60 DEG C and preserving heat for 30min, next, heating to 90 DEG C and preserving heat for 60min, and then washing and drying; soaking the textile into a chitosan solution, soaking twice and rolling twice, and air-drying; soaking the textile in a nickel sulfate solution at the normal temperature, and then soaking into a sodium borohydride solution, cleaning and air-drying to obtain the activated textile, and finally, soaking in an electroless copper plating liquid for plating, and finally washing with water and drying. A macromolecule adsorption nickel salt activating fluid developed in the method is friendly to the environment and capable of either improving the binding force of a coating and the substrate textile or activating a palladium salt with a nickel salt, and therefore, the activation cost is low and the pollution caused by noble metals is reduced, and the method is high in operability.

Owner:JINAN YUMO SCI & TRADE CO LTD

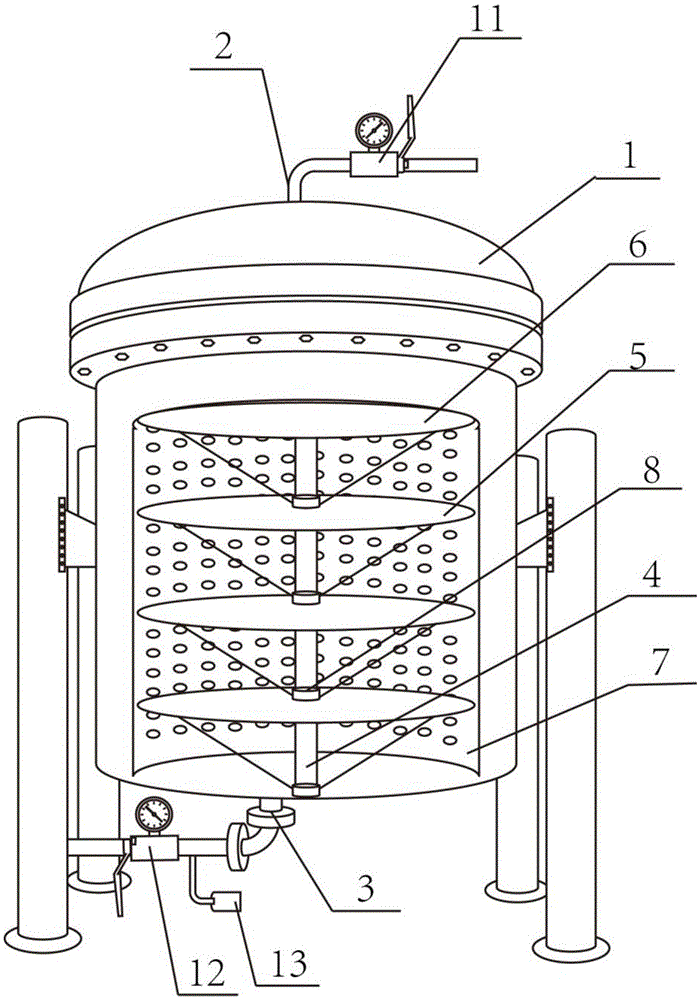

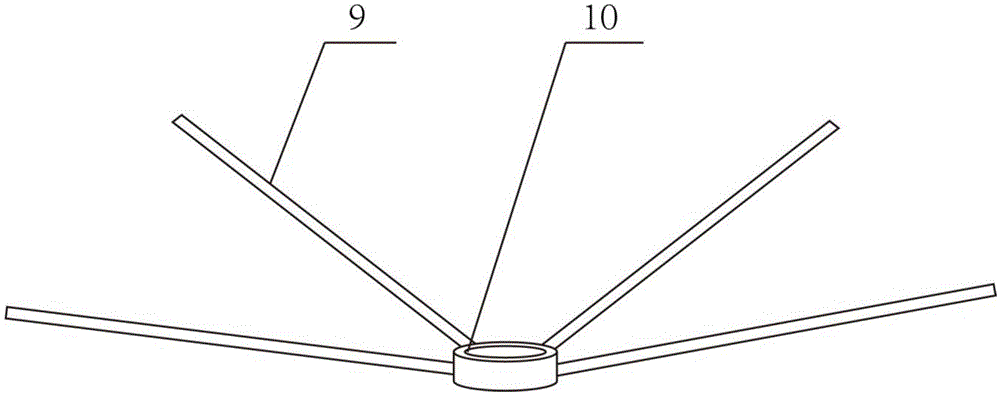

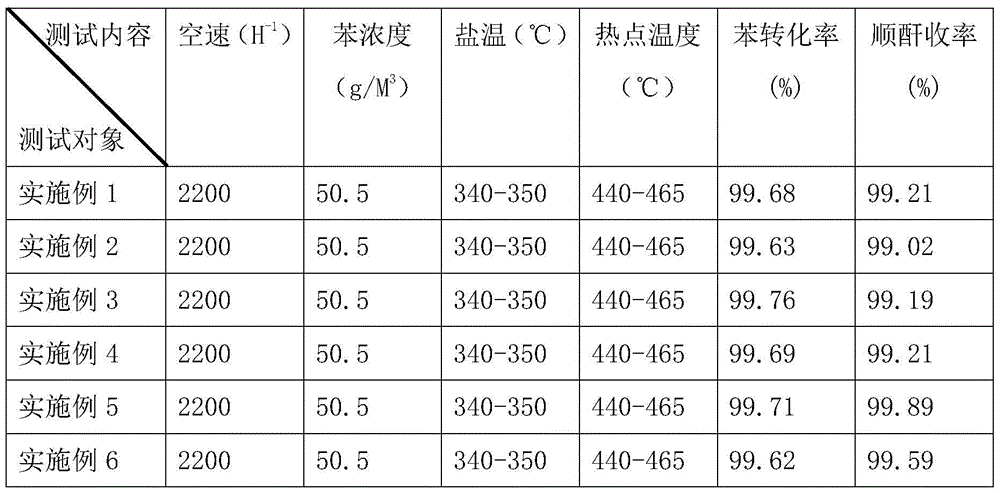

Method for activating benzene-method maleic anhydride catalyst outside reactor

InactiveCN105457686AReduce manufacturing costSave energyOrganic chemistryCatalyst regeneration/reactivationBenzeneRoom temperature

The invention discloses a method for activating a benzene-method maleic anhydride catalyst outside a reactor. The method comprises the following steps: 1, placing the benzene-method maleic anhydride catalyst in the activation reactor; 2, introducing air into the activation reactor, so that the interior of the activation reactor is filled with air; 3, raising the temperature of the benzene-method maleic anhydride catalyst, wherein the temperature-raising gradient is 60-100 DEG C / h, after the temperature is raised to 300 DEG C, changing the temperature-raising gradient to 0-80 DEG C / h, and raising the temperature to 440-460 DEG C; 4, after the temperature is preserved for 3-5 hours, lowering the temperature to 420-440 DEG C, introducing ammonia gas, when the volume ratio of ammonia gas to air in the activation reactor reaches 1 / 25 to 1 / 15, stopping gas introduction, and continuing preserving the temperature for 2-4 hours, then lowering the temperature to the room temperature, wherein the temperature lowering time is one hour, so that the benzene-method maleic anhydride catalyst activated outside the reactor is obtained. According to the method, air and a gas mixture of ammonia gas and air are adopted as activation atmosphere in sequence, activation cost is lowered, stability of catalyst activity is guaranteed, and stability of the benzene conversion rate is greatly improved.

Owner:TIANJIN TIANHUAN FINE INST OF CHEM ENG

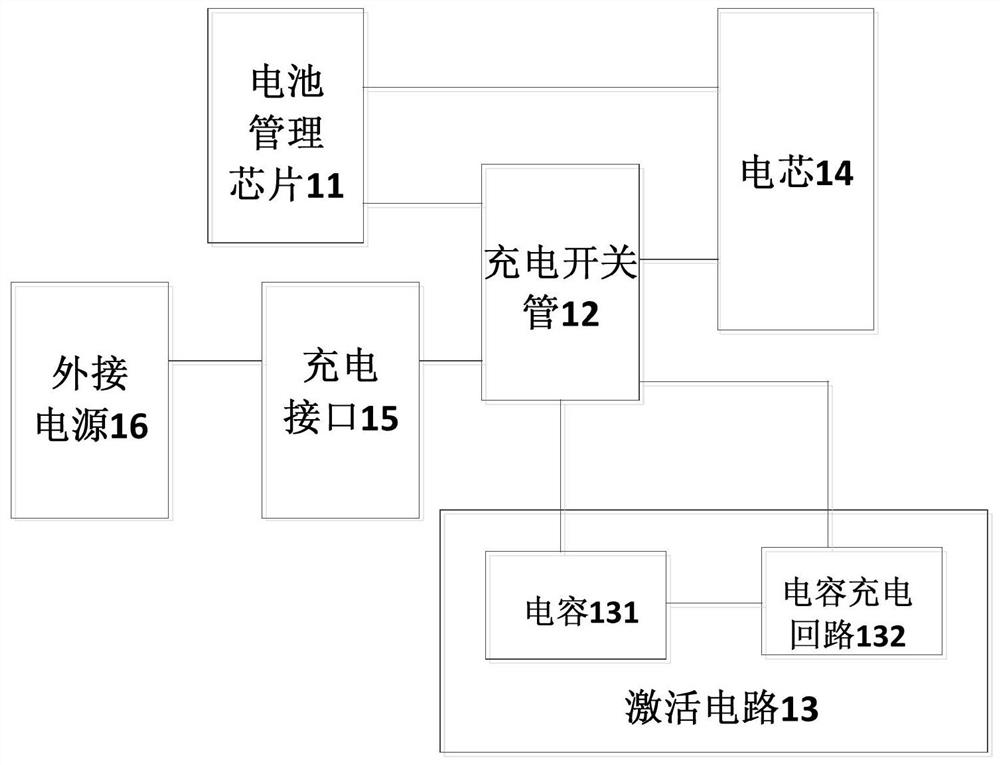

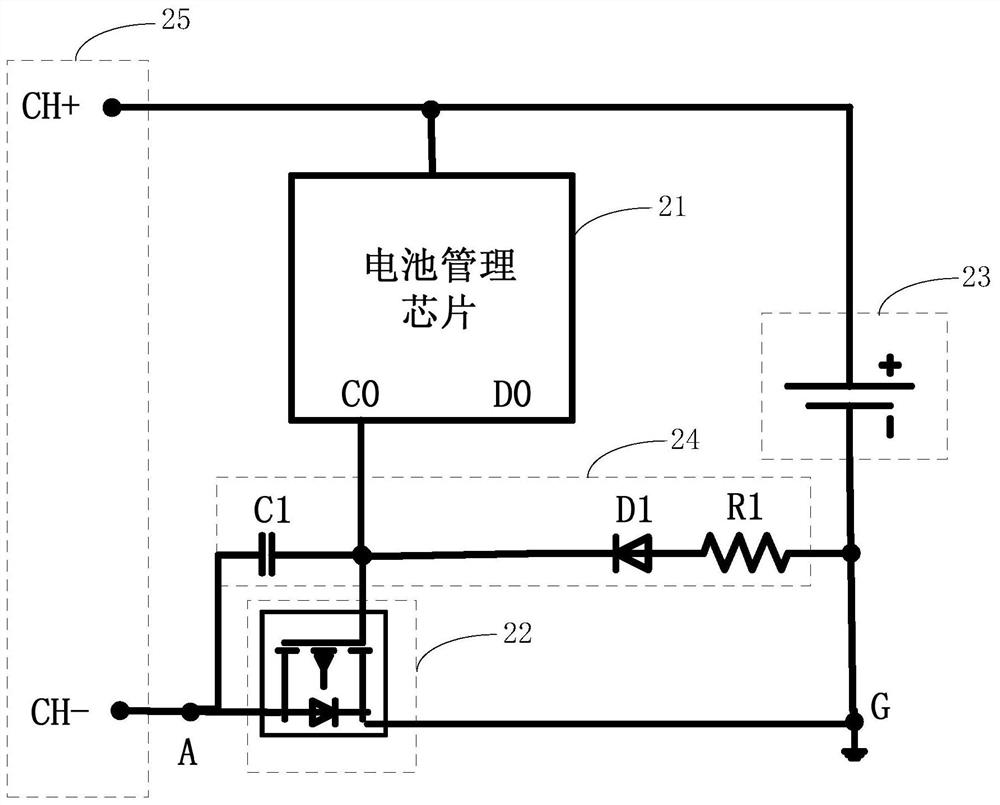

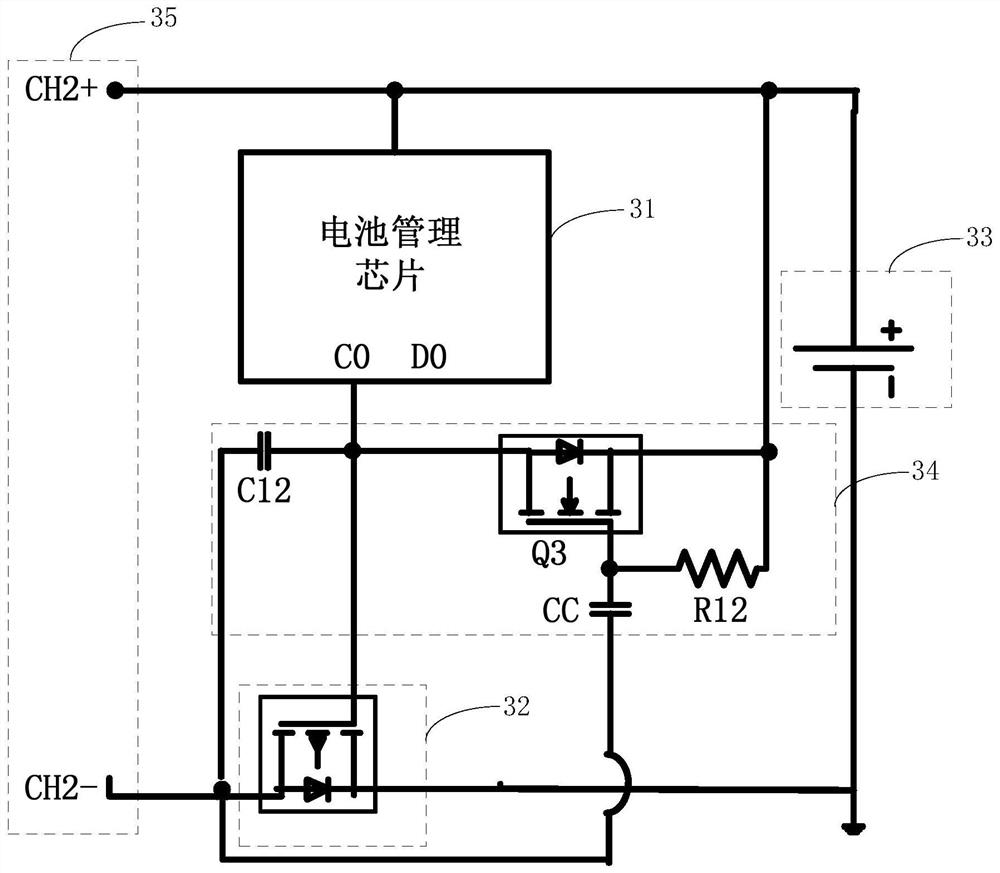

Activation circuit and activation method thereof, battery protection circuit, battery

ActiveCN108365276BAchieve activationShort activation timeBatteries circuit arrangementsSecondary cells charging/dischargingElectrical batteryElectric capacity

Owner:HYTERA COMM CORP

Synchronous digital hierarchy ring network topology discovery method

ActiveCN102075350BReduce occupancyReduce activation costsTime-division multiplexLoop networksIp addressRing network

The invention discloses a synchronous digital hierarchy (SDH) topology discovery method. The method is characterized by comprising the following steps that: a master station sends predetermined overhead bytes to a slave station in east and west directions; the slave station receives the overhead bytes from the east and west directions and transfers the overhead bytes according to a predetermined rule; the master station sends an address confirmation command to the slave station when determining that the received overhead bytes sent by the slave station are the same in preset time, wherein thecommand comprises a subnet address field; and the slave station generates an internet protocol (IP) address of the slave station according to the subnet address field and the values of the overhead bytes to be sent by the slave station after receiving the command. The invention also provides a topology discovery method for a chain network. By adopting the technical scheme provided by the invention, the network can be accessed under the condition that an IP address is not required to be allocated to a network element in advance, so that the operation cost is reduced.

Owner:BEIJING HUAHUAN ELECTRONICS

Activated carbon fiber ball and preparation method thereof

InactiveCN103566885BLow costImprove activation efficiencyCarbon compoundsOther chemical processesFiberPorosity

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

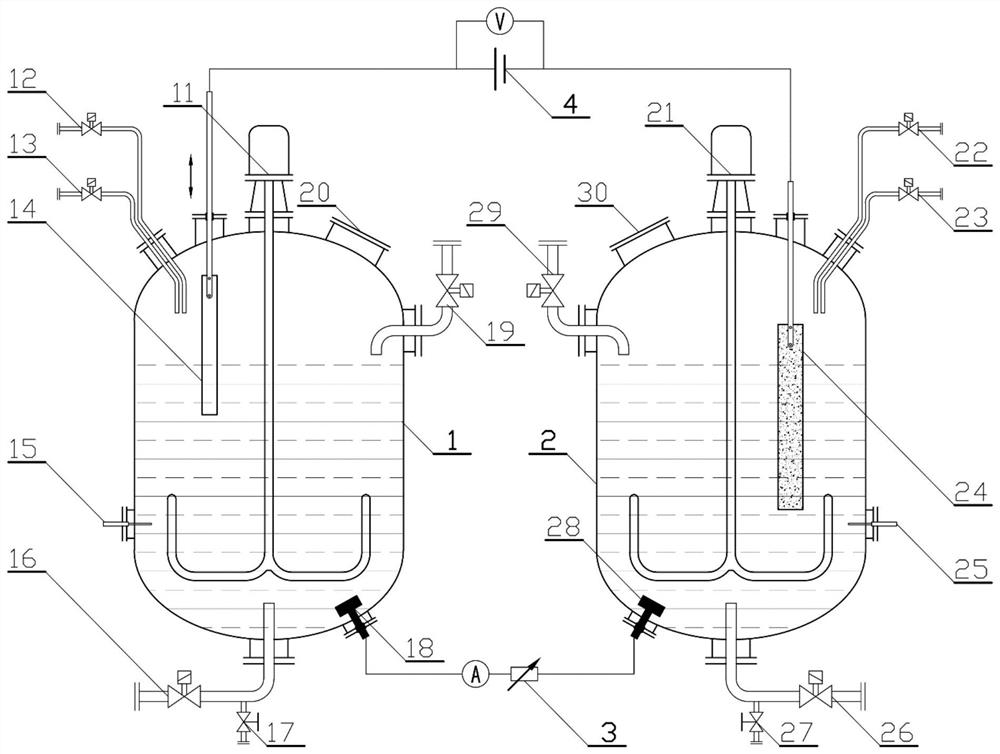

Process and equipment based on electric persulfate activation technology

ActiveCN113264583AControl speedQuality improvementWater treatment parameter controlEnergy based wastewater treatmentEngineeringCathode reaction

The invention discloses a process and equipment based on an electric persulfate activation technology. The equipment comprises an anode reaction kettle, a cathode reaction kettle, an adjustable direct-current power supply and a high-precision variable resistor; an anode electrode capable of moving up and down is arranged on the anode reaction kettle; a cathode electrode is arranged on the cathode reaction kettle; the anode electrode and the cathode electrode are electrically connected with the positive electrode and the negative electrode of the adjustable direct-current power supply respectively; the positions, close to the bottoms, of the side walls of the anode reaction kettle and the cathode reaction kettle are each provided with a bottom inert electrode, the two bottom inert electrodes are electrically connected through a wire, and the high-precision variable resistor is connected between the wires in series. By accurately controlling the depth of the anode electrode in the medicament, the voltage of the adjustable direct-current power supply and the resistance of the high-precision variable resistor, the electric activation current can be effectively controlled, the speed and quality of the electric activation of the persulfate are further controlled, and the method is easy to operate and has wide engineering and market prospects.

Owner:JIANGSU DDBS ENVIRONMENT REMEDIATION

A resource optimization method and electronic equipment based on shared link risk group

ActiveCN112804096BImprove resource utilizationImprove the success rate of switchingElectromagnetic transmissionMonitoring siteComputer network

Owner:FENGHUO COMM SCI & TECH CO LTD

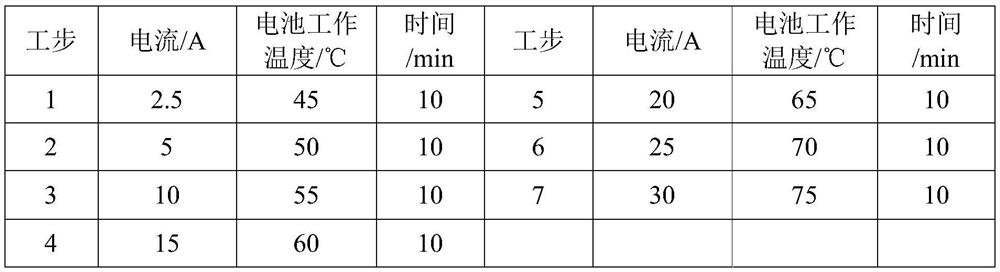

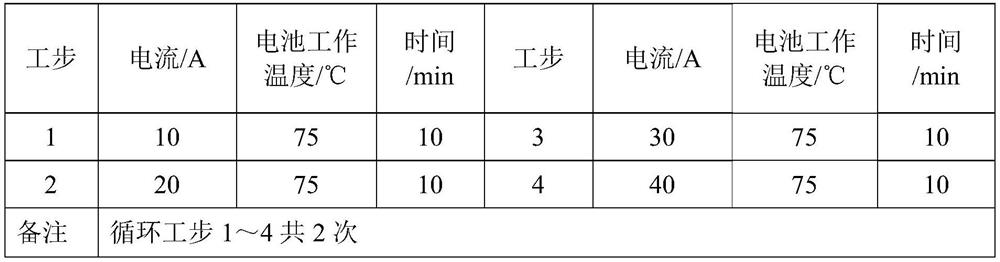

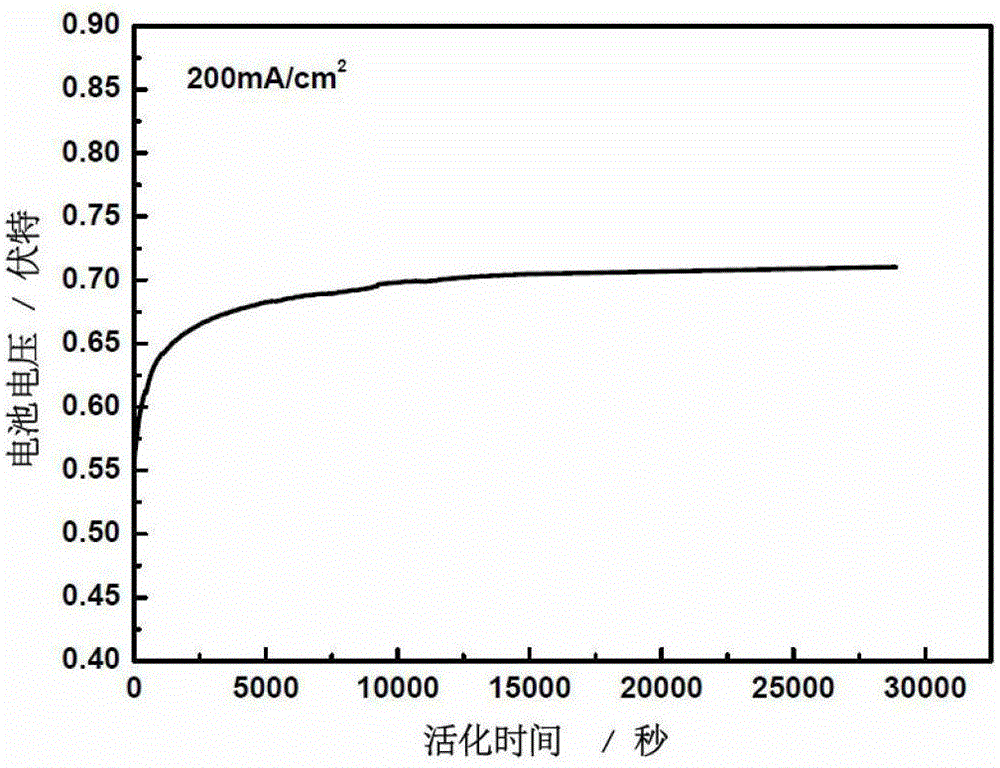

Rapid activation method of proton exchange membrane fuel cell

ActiveCN110649291BPromote wettingIncrease roughnessCell electrodesFinal product manufactureVoltage dropEngineering

The invention provides a rapid activation method for a proton exchange membrane fuel cell. The newly prepared CCM membrane is subjected to plasma surface treatment, and then it is made into a proton exchange membrane fuel cell, and the activation is carried out according to the following steps: Gradually increase and forcefully increase the output current in stages until the battery operating temperature reaches 70 to 80°C and the output voltage drops to 0.4 to 0.5V; (b) Fix the battery operating temperature at 70 to 80°C, and gradually force it in stages Increase the output current until the output voltage drops to 0.4~0.5V, and cycle 1~4 times; (c) Fix the working temperature of the battery at 70~80℃, first press 50~200mA / cm 2 the smaller output current, then press 800~1200mA / cm 2 The larger output current, cycle 2 to 8 times. The method of the invention is simple in process, can shorten the activation time of the battery, and improve the production efficiency.

Owner:先进储能材料国家工程研究中心有限责任公司

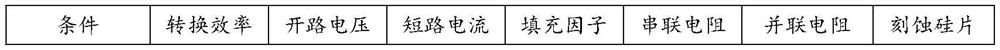

Etching liquid activating agent as well as preparation method and application thereof

PendingCN114188216APromote activationImprove wettabilityFinal product manufactureSemiconductor/solid-state device manufacturingPtru catalystActive agent

The invention discloses an etchant activator and a preparation method and application thereof, the etchant activator is used for manufacturing crystalline silicon solar cells, the etchant activator comprises silicon powder and a mixed solution, and the mixed solution comprises a surfactant, a catalyst, a dispersant and water. When the activating agent is used, the activating agent is added into the etching liquid for the crystalline silicon solar cell, so that the etching liquid can be quickly activated, the activation time is shortened to 15-20 minutes, the productivity of equipment is favorably improved, the consumption of silicon powder is far less than that of a damaged or poor-quality silicon wafer, the cost of the silicon powder is far lower than that of the damaged or poor-quality silicon wafer, and the service life of the silicon powder is prolonged. And the activation cost is reduced.

Owner:JA SOLAR

A kind of direct borohydride fuel cell cell activation method

ActiveCN103840184BPromote activationQuick buildFuel cell controlAqueous electrolyte fuel cellsElectrochemical responseCell activation

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com