Method for activating benzene-method maleic anhydride catalyst outside reactor

A benzene-method maleic anhydride and catalyst technology is applied in the field of external activation of benzene-method maleic anhydride catalysts, which can solve the problems of large variation range of benzene conversion rate, unstable catalyst activity, affecting unified use and the like, saving energy and time. , The effect of stable activity and reduction of activation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

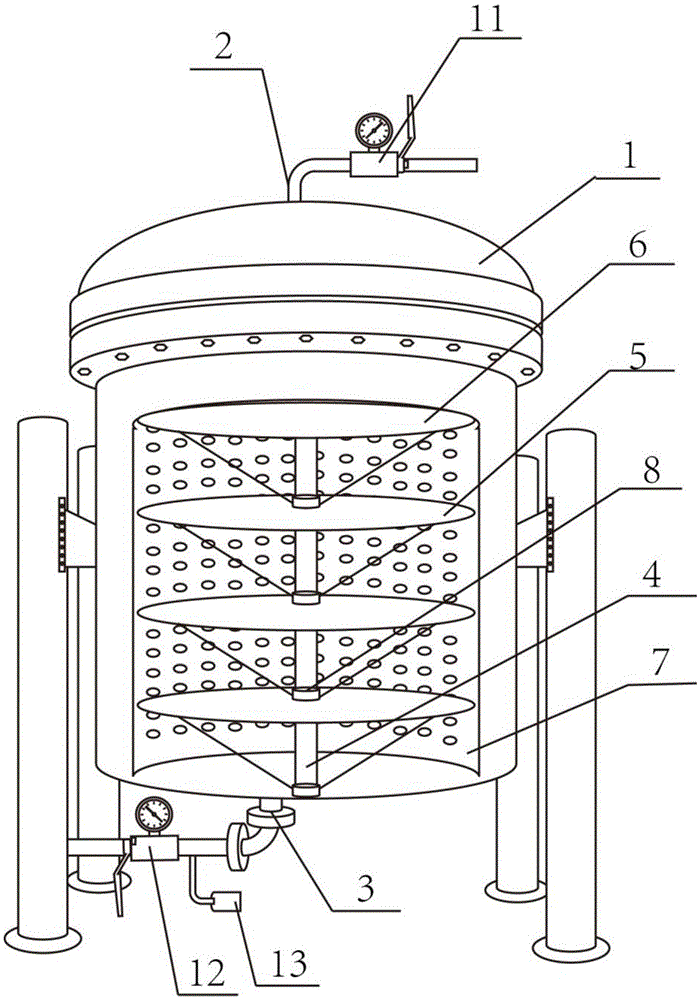

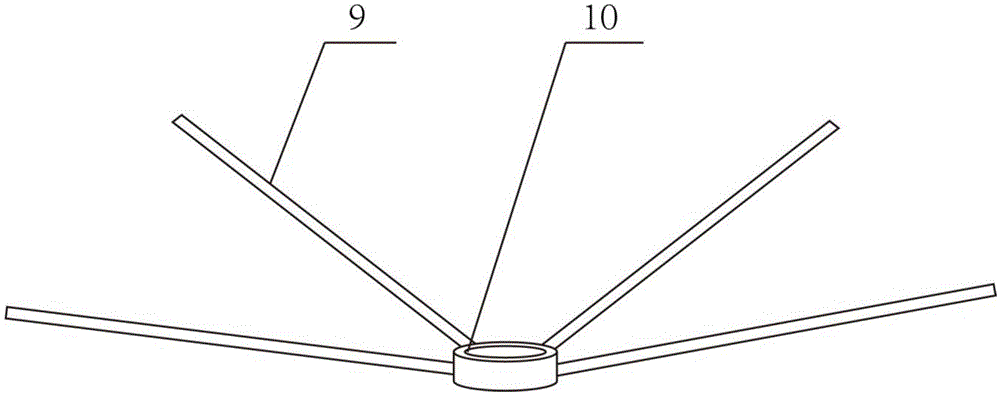

Method used

Image

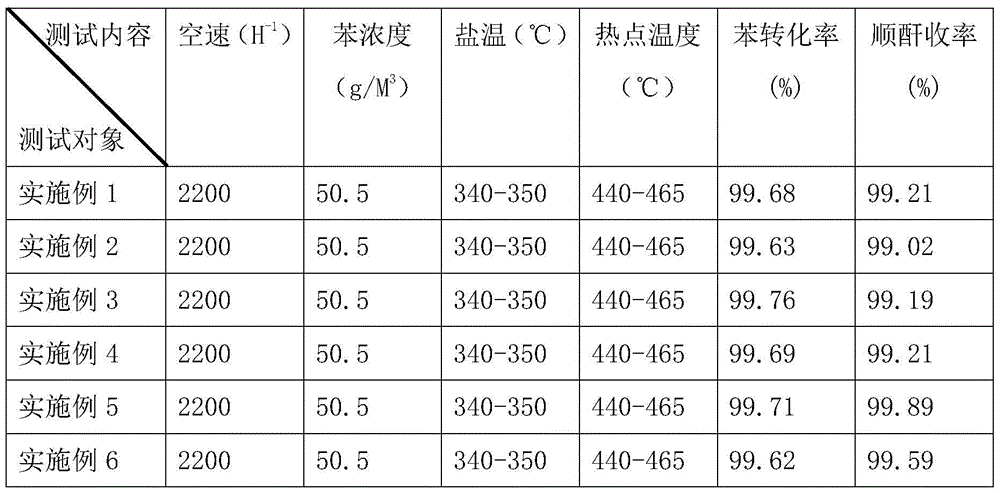

Examples

Embodiment 1

[0038] Take 300mL of benzene-based maleic anhydride catalyst, put it into the active reactor, cover the end cap, close the air inlet, raise the temperature to 300°C, the temperature gradient is 60°C / hour, and then continue to heat up to 440°C, the temperature gradient is 50°C / hour, keep warm for 5 hours and cool down to 420°C, fill the reactor with ammonia gas, monitor the ratio of ammonia / air inside through the gas detection device on the gas outlet, stop the ammonia flow when the volume ratio reaches 1 / 15 Air, close the air inlet, keep warm for 2 hours, cool down to room temperature, and the cooling is completed within one hour. The activated catalyst is then removed.

Embodiment 2

[0040] Take 300mL of benzene maleic anhydride catalyst, put it into the active reactor, cover the end cap, close the air inlet, raise the temperature to 300°C with a temperature gradient of 80°C / hour, then continue to heat up to 450°C with a temperature gradient of 70°C / hour, keep warm for 5 hours and cool down to 430°C, fill the reactor with ammonia gas, monitor the ratio of ammonia / air inside through the gas detection device on the gas outlet, stop the ammonia flow when the volume ratio reaches 1 / 20 Air, close the air inlet, keep warm for 2 hours, cool down to room temperature, and the cooling is completed within one hour. The activated catalyst is then removed.

Embodiment 3

[0042] Take 300mL of benzene maleic anhydride catalyst, put it into the active reactor, cover the end cap, close the air inlet, raise the temperature to 300°C with a temperature gradient of 100°C / hour, then continue to heat up to 460°C with a temperature gradient of 80°C / hour, keep warm for 5 hours and cool down to 440°C, fill the reactor with ammonia gas, monitor the ratio of ammonia / air inside through the gas detection device on the gas outlet, stop the ammonia flow when the volume ratio reaches 1 / 20 Air, close the air inlet, keep warm for 2 hours, cool down to room temperature, and the cooling is completed within one hour. The activated catalyst is then removed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com